Air con HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 116 of 2189

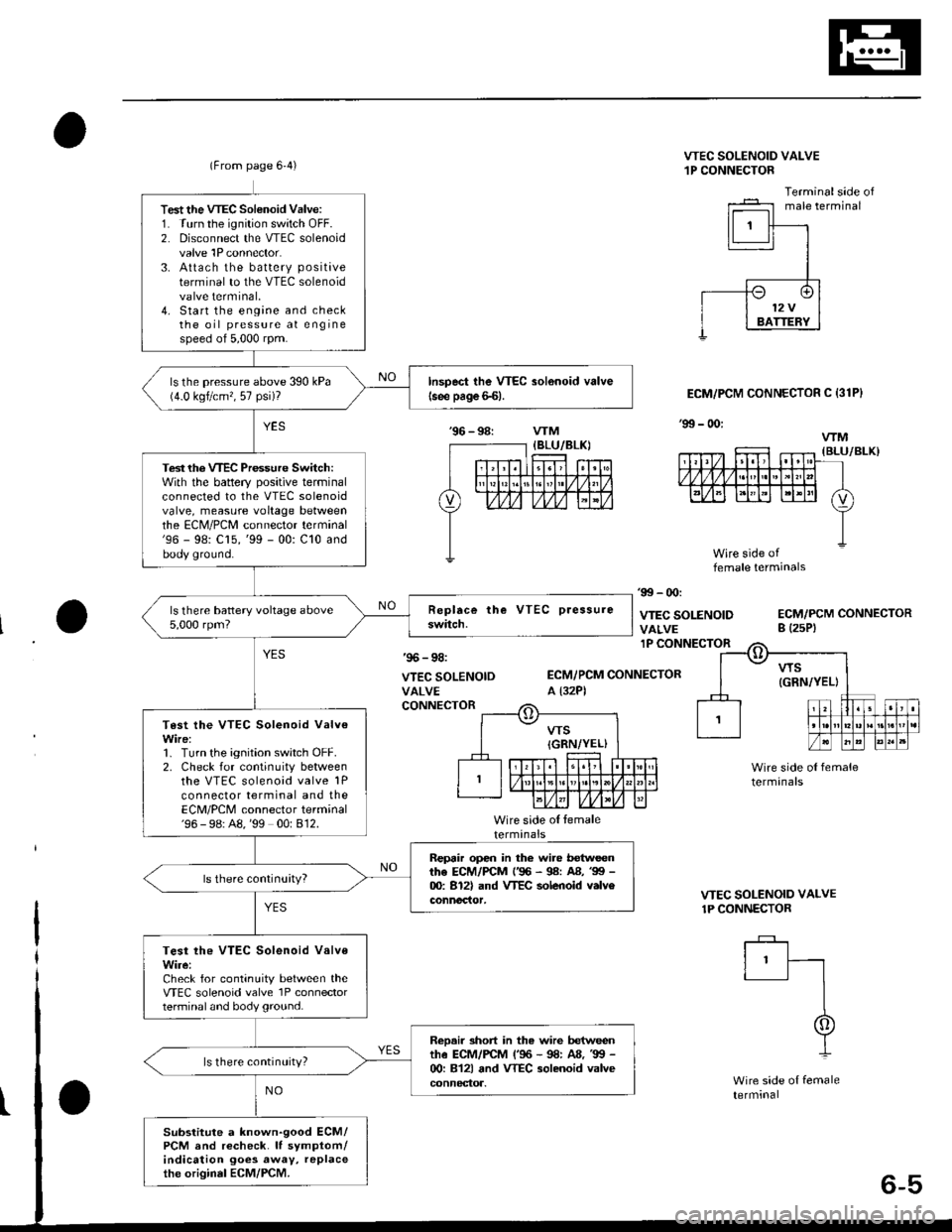

(From page 6'4)

Test the VTEC Solenoid Valve:1. Turn the ignition switch OFF.2. Disconnect the wEC solenoidvalve 1P connector.3. Attach the battery positave

terminal to the VTEC solenoidvalve terminal.4. Start the engine and checkthe oil pressure at enginespeed of 5,000 rpm.

Inspect lhe VTEC solonoid valve

lsee p6ge m).ls the pressure above 390 kPa(4.0 kgtcm'�,57 psi)?

Test the VTEC Pressure Switch:With the battery positive terminalconnected to the VTEC solenoidvalve, measure voltage betweenthe ECM/PCM connector terminal'96 - 98: Cl5,'99 - 00: C10 andbody ground.

ls there battery voltage above5,000 rpm?

T6st the VTEC Solenoid Valvewire:1. Turn the ignition switch OFF.2. Check for continuity betweenthe VTEC solenoid valve 1Pconnector terminal and theECM/PCM connector terminal'96 - 98: A8, '99 00r B'12.

Repair open in the wire betweenthe ECM/PCM ('96 - 98: A8, '99 -

0o: 8l2l and VTEC solenoid v.lv6connoc{or.

Test the VTEC Solenoid Valve

Check for continuity between theVTEC solenoid valve 1P connectorterminal €nd body ground.

ReDair 3hort in the wire betweenthe ECM/FCM ('96 - 98: A.8, '99 -

0O: Bl2l and VTEC aolenoid valveconnectot,

ls there continuity?

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away, replacethe original ECM/PCM.

VTEC SOLENOID VALVE1P CONNECTOR

Terminalside ofmale terminal

ECM/PCM CONNECTOR C {31P}

'99 - 00:'96 - 98:

CONNECTOR

'99 - 00:

VTEC SOLENOIDVALVE

ECM/PCM CONNECTORB {25Pt1P CONNECTOR'96 - 98:

VTEC SOLENOIDVALVE

ECM/PCM CONNECTOR

A {32P1

VTS{GRN/YEL)

wire side o{ femaleterminals

wire side oI temaleterminals

VTM

Page 119 of 2189

VTEC Rocker Arms

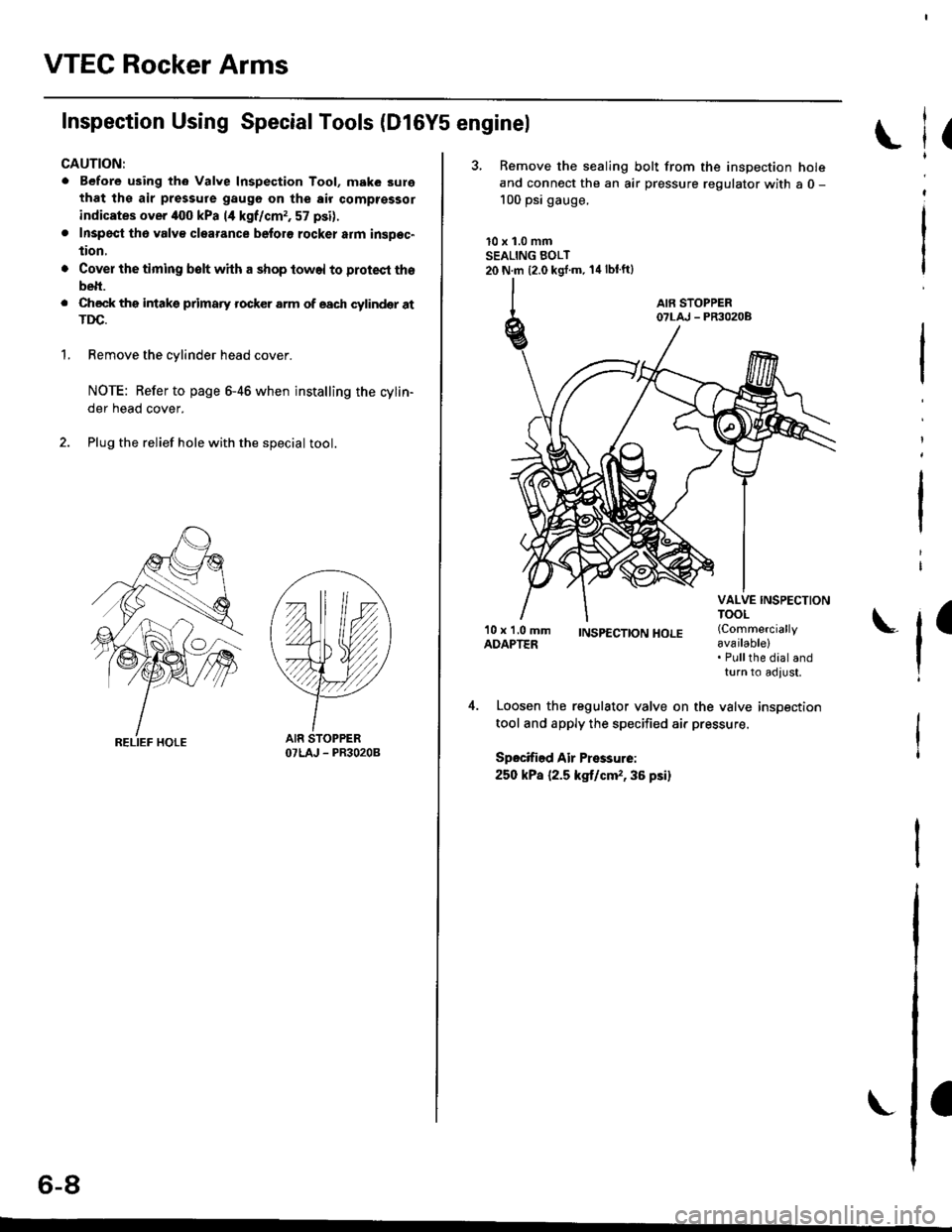

Inspection Using SpecialTools (Dl6Y5 enginel

CAUTION:

. Before using th6 Valve Inspection Tool, make 3ure

that ths air pressure gaugo on the air comptsssor

indicates over iloo kPa 14 kgf/cmr, 57 psi).

. Inspecl th6 valv€ clearance beforo rocker atm insDec"

tion,

'1.

Cover the timing belt with a shop towel to protect tho

belt.

Check ths intakg primaty rocker arm of each cylindqr atTDC.

Remove the cylinder head cover.

NOTE: Refer to page 6-46 when installing the cylin-

der head cover.

Plug the relief hole with the special tool.

YY

OTLAJ - PR3O2OB

(

3, Remove the sealing bolt from the inspection holeand connect the an air pressure regulator with a 0 -

100 psi gauge.

10 x 1.0 mmSEALING BOLT20 N.m {2.0 kgj'm. 14lblft}

l

I

'10 x 1.0 mmADAPTER;NSp€CTTONHOLE (Commercially

available)

l'Pullthe dial andturn to adlust,

Loosen the regulator valve on the valve inspection

tool and apply the specified air pressure.

Spocified Air Pressurei

250 kPa {2.5 kg,t/cm,,36 psi}

o-at

Page 120 of 2189

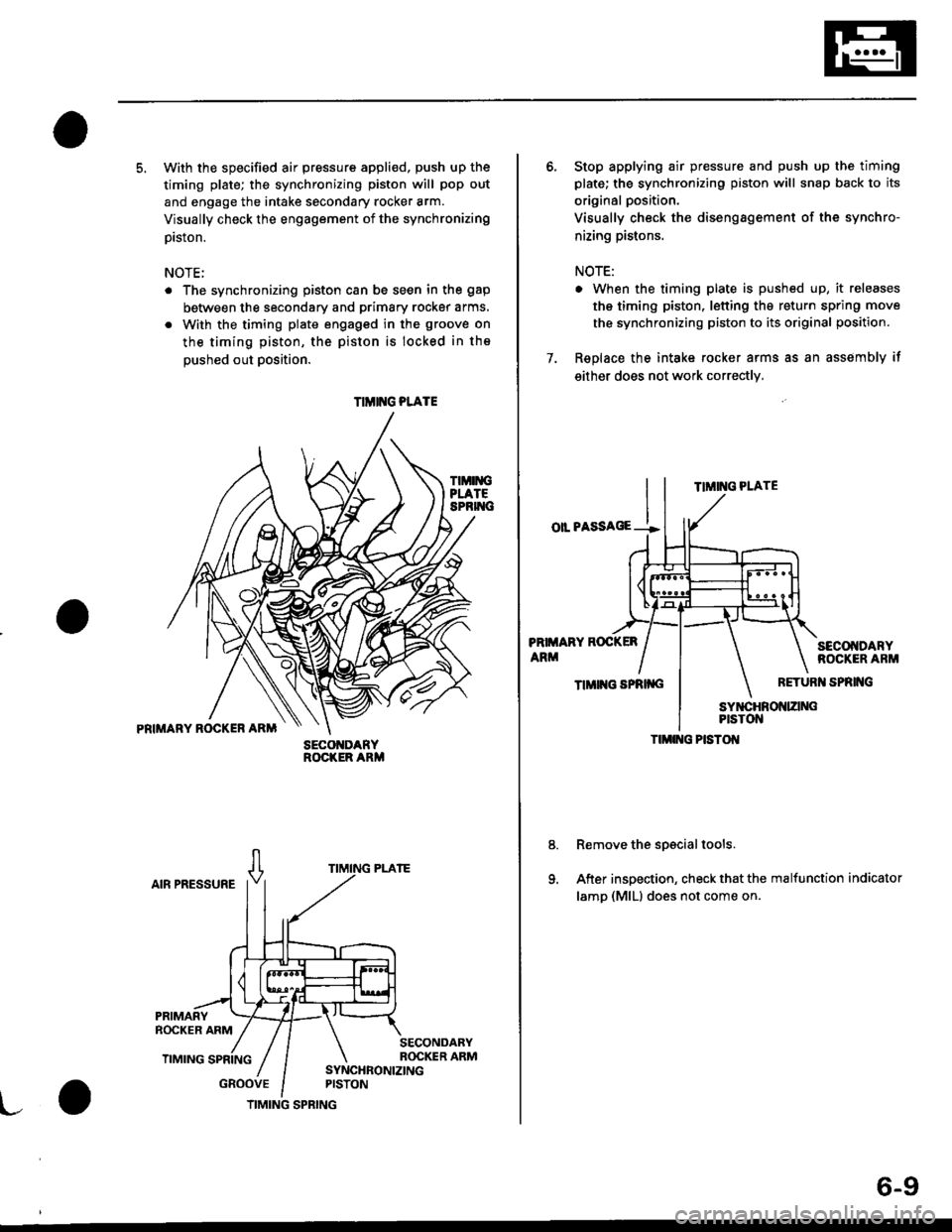

5. With the specified air pressure appli€d, push up the

timing plate; the synchronizing piston will pop out

and engage the intake secondary rocker arm.

Visually check the engagement of the synchronizing

prston.

NOTE;

The synchronizing piston can be seen in the gap

between the secondary and primary rocker arms,

With the timing plate engaged in the groove on

the timing piston, the piston is locked in the

oushed out Dosition.

TIMIiIGPLATESPRIT{C

PRIMARY ROCKER ARM

AIR PRESSURE

GROOVE

SECO DARYROCKER ARM

TIMIT{G PLATE

TIMING SPRING

6-9

6. Stop applying air pressure and push up the timing

plate; the synchronizing piston will snap back to its

original position.

Visually check the disengagement of the synchro-

nizing pistons.

NOTE:

. When the timing plate is pushed up, it releases

the timing piston, letting the return spring move

the synchronizing piston to its original position.

7. Replace the intake rocker arms as an assembly if

either does not work correctly,

TIMING PLATE

oll PASSAGE --!

PRIMARY ROCKER

ARMSECOI{DARYROCKER ARM

TIMII{G SPRII{GRETURI{ SPRING

Remove the spscial tools.

After inspection, check that the malfunction indicator

lamp (MlLl does not come on.

TIMI G PISTOI{

Page 121 of 2189

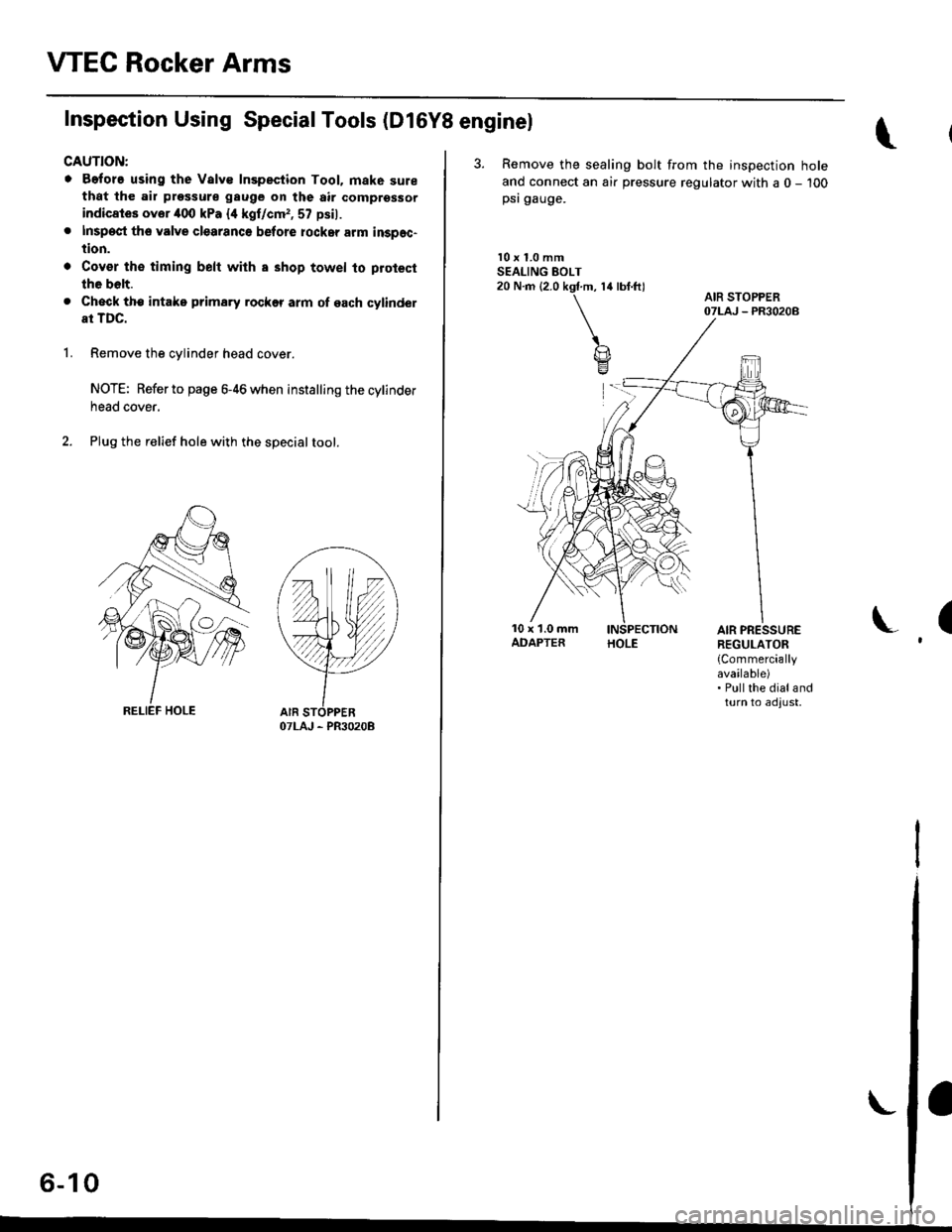

VTEC Rocker Arms

Inspection Using Special Tools (D16Y8 enginel

CAUTION:

o Before using the Valve Inspection Tool. mak6 surethat the air pressure gauge on the air comprsssor

indicates ovor 400 kPa {4 kgf/cm,, 57 psil.

. Inspect th6 valve clearanco before rockar arm inspec-

tion.

. Cov€r th€ timing belt with a shop towel to protect

the bolt.

. Check tho intake prima.y rockff arm of each cylindel

at TDC.

1.Remove the cylinder head cover.

NOTE: Refer to page 6-46 when installing the cylinder

neao cover,

Plug the relief hole with the specialtool.

OTLAJ - PR3O2OB

I,^ A IAo- tu

3. Remove the sealing bolt from the inspection hole

ancl connect an air pressure regulator with a 0 - 100psi gauge.

l0 x 1.0 mmSEALING EOLT20 N.m (2.0 kgf.m, 14 lbf.ft)

(AIR PRESSUREREGULATOR

{Commerciallyavailable). Pullthe dialandturn to adjust,

Page 122 of 2189

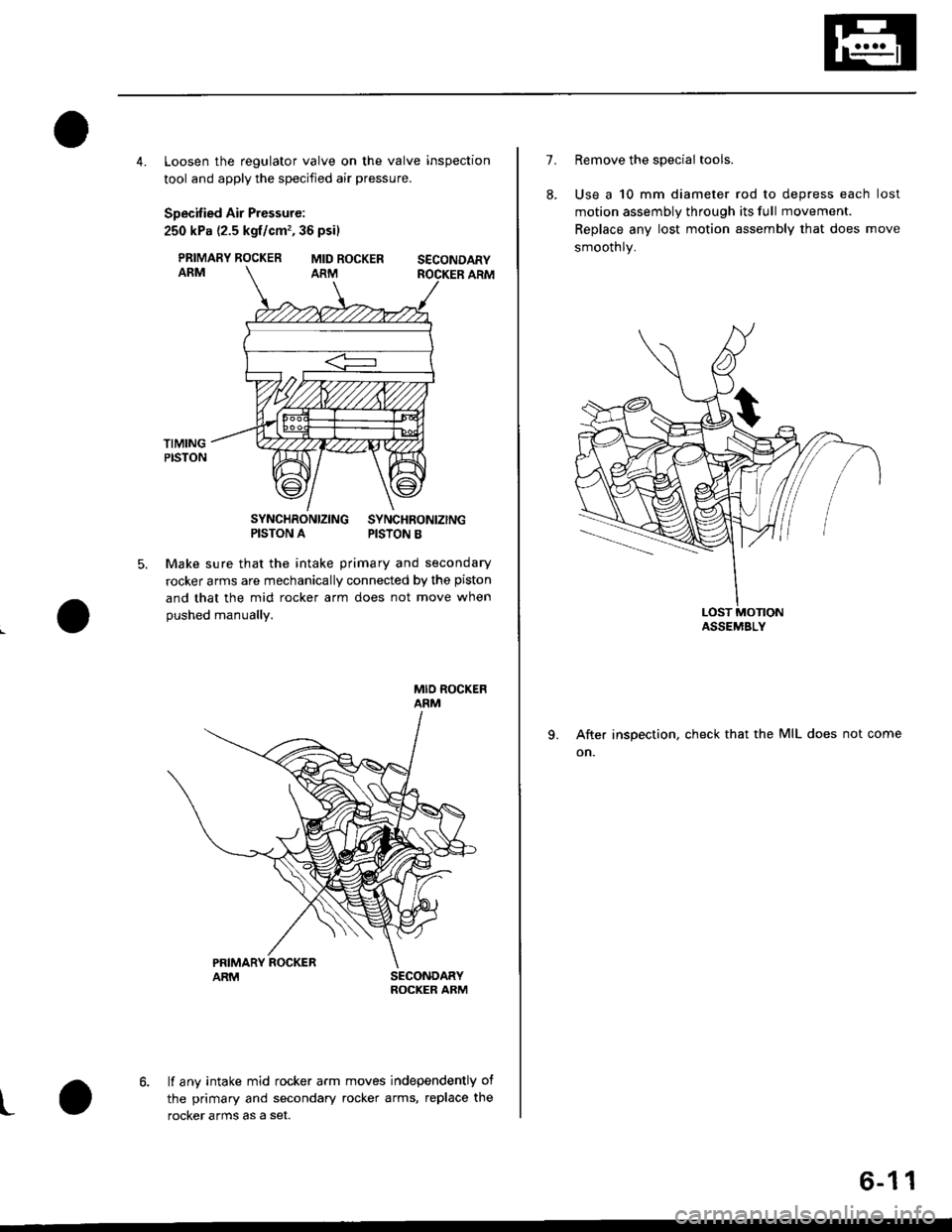

4. Loosen the regulator valve on the valve inspection

tool and apply the specified air pressure.

Specified Air Pressure:

250 kPa {2.5 kgf/cm'�, 36 psil

PRIMARY ROCKERARM

SYNCHRONIZING SYNCHRONIZINGPISTON A PISTON B

Make sure that the intake primary and secondary

rocker arms are mechanically connected by the piston

and that the mid rocker arm does not move when

oushed manuallY.

5.

MID ROCKER SECONDARYARM ROCKER ARM

SECONDARYROCKER ARM

lf any intake mid rocker arm moves independently of

the primary and secondary rocker arms, replace the

rocker arms as a set.t

1.

8.

9.

Remove the special tools.

Use a 10 mm diameter rod to depress each lost

motion assembly through its full movement.

Replace any lost motion assembly that does move

smoothly.

After inspection, check that the MIL does not come

on.

ASSEMBLY

6-11

Page 130 of 2189

Removal

NOTE:

. Replace the timing belt at 105,000 miles (168.000 km)

according to the maintenance schedule (normal con-

ditions/severe conditions).

lf the vehicle is regularly driven in one or more of the

followlng conditions, replace the timing belt at 60.000

miles (U.S.A.) 100,000 km {Canada).

.In very high temperatures (over 110'F.43'C)

. In very low temperatures (under -20'F, -29"C)'

! Turn the crankshaft pulley so the No. 1 piston is at

top dead center (TDC) before removing the belt (see

page 6'21).

. Inspect the water pump before installing the timing

belt {see Page 10-14).

1. Remove the splash shield (see page 5-7).

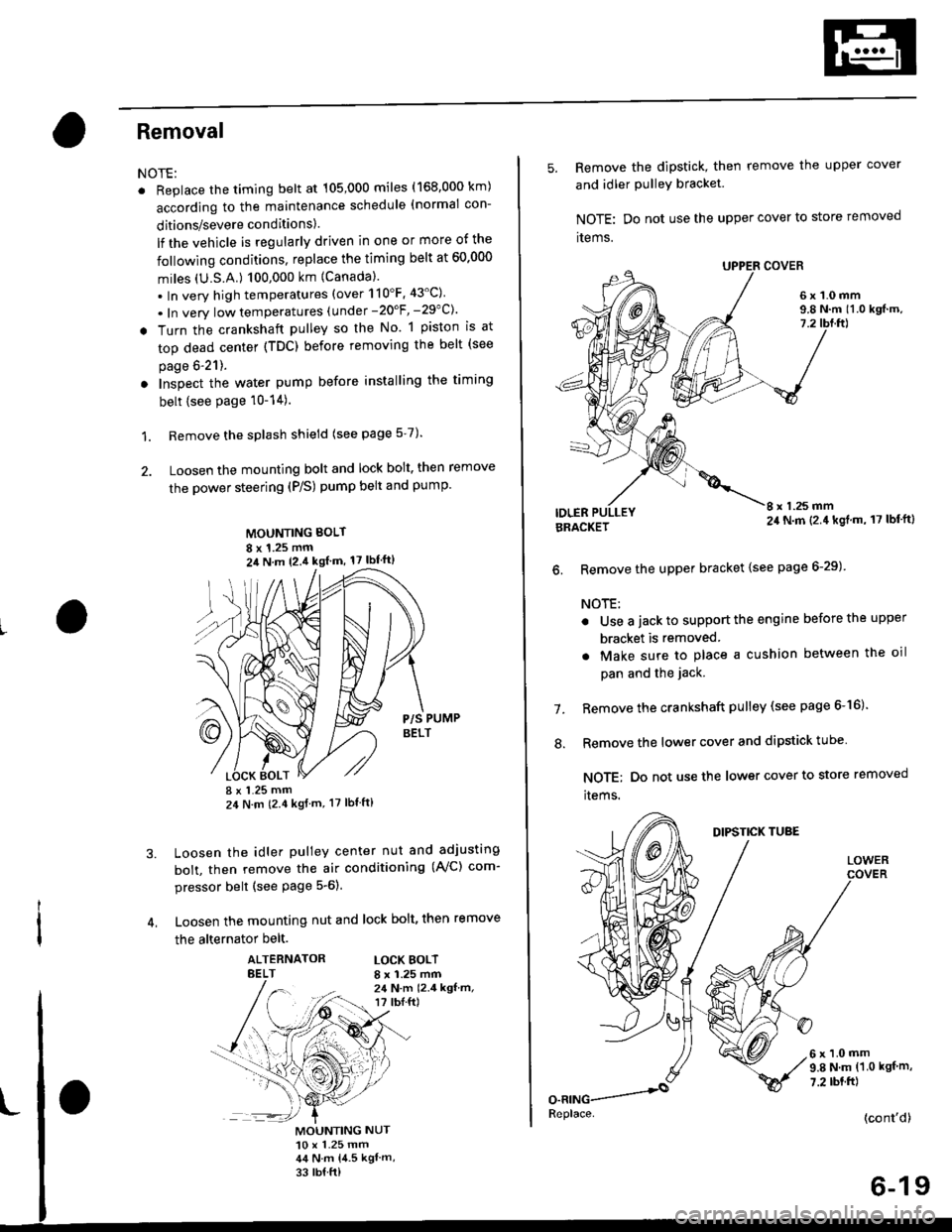

2. Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt and pump

MOUNTING BOLT

8 x 1.25 mm2il N m 12.4 kgl m, 17 lbf'ft)

P/S PUMPBELT

I x 1.25 mm24 N m (2.4 kgf m, 17 lbt ft)

Loosen the idler pulley center nut and adjusting

bolt, then remove the air conditioning (AVC) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt, then remove

the alternator belt.

ALTERNATORBELTLOCK BOLTI x 1.25 mm24 N.m 12.4 kgf.m,r? tbI.ft)

3.

MOUNTING NUT10 x 1.25 mm44 N.m 14.5 kgl m,

33 rb{ ft)

5. Remove the dipstick, then remove the upper cover

and idler PulleY bracket

NOTE: Do not use the upper cover to store removed

items.

6x1.0mm9.8 N.m 11.0 kgf.m,7.2

IDLERI x 1.25 mm24 N.m (2.4 kgl.m, 17 lbf'ft)BRACKET

6. Remove the upper bracket {see page 6-29)

NOTE:

. Use a jack to support the engine before the upper

bracket is removed

. Make sure to place a cushion between the oil

pan and the jack.

Remove the crankshaft pulley (see page 6-16).

Remove the lower cover and dipstick tube

NOTE; Do not use the lower cover to store removed

items.

1.

.'.

DIPSTICK TUBE

LOWER

6x1.0mm9.8 N.m (1.0 kgf m,

7.2 rbt.ft)

(cont'd)

6-19

Replace.

Page 138 of 2189

Removal

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

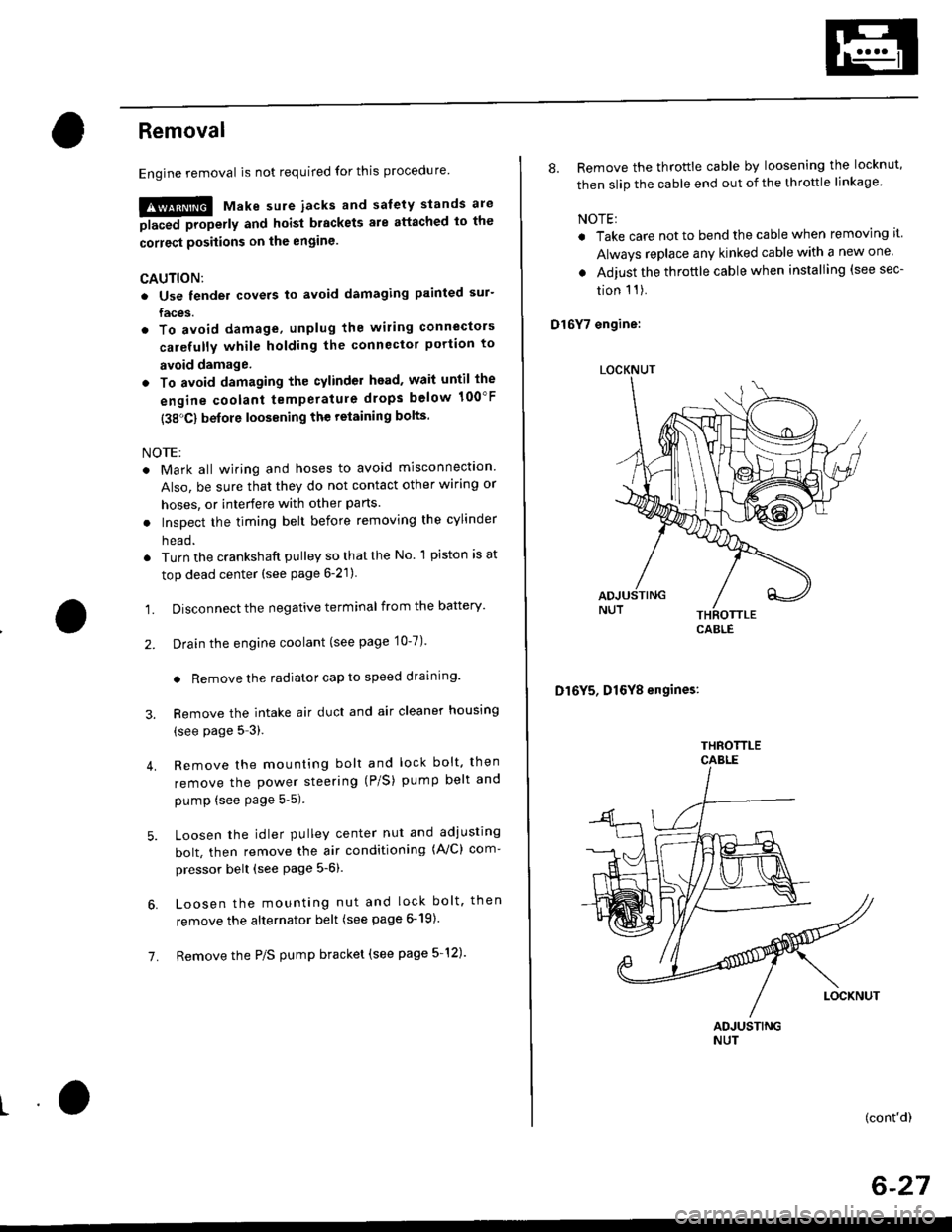

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE

Page 140 of 2189

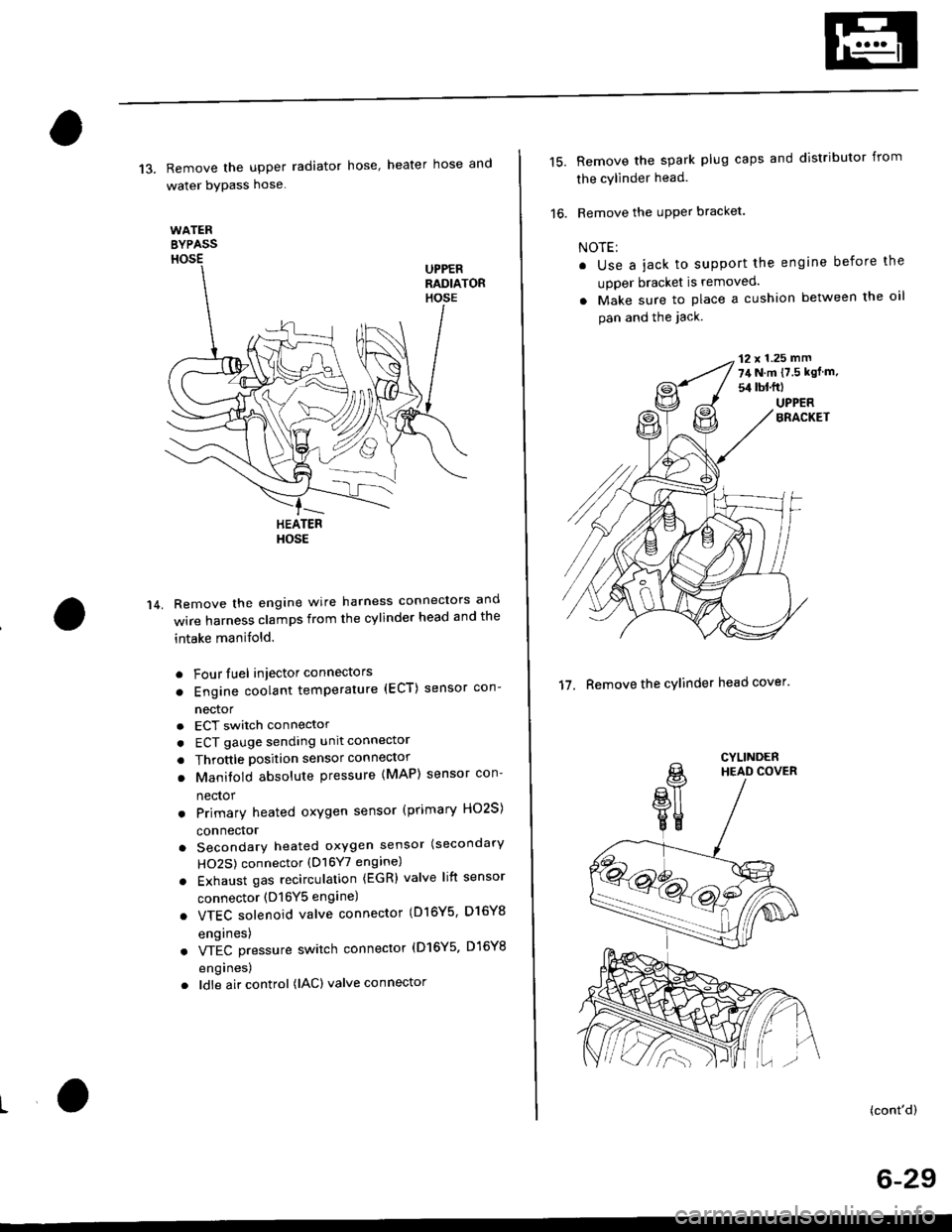

13. Remove the upper radiator hose' heater hose and

water bYPass hose

WATEREYPASSHOSEUPPERRADIATORHOSE

14.

HEATERHOSE

Remove the engine wire harness connectors and

wire harness clamps from the cylinder head and the

intake manifold.

o Four fuel injector connectors

. Engine coolant temperature (ECT) sensor con-

nector

a

a

a

ECT switch connector

ECT gauge sending unit connector

Throttle position sensor connector

Manitold absolute pressure (MAP) sensor con-

nector

Primary heated oxygen sensor (primary HO2S)

connector

Secondary heated oxygen sensor (secondary

HO2S) connector (D16Y7 engine)

Exhaust gas recirculation (EGR) valve lift sensor

connector (D16Y5 engine)

. VTEC solenoid valve connector (Dl6Y5, D16Y8

engrnes)

. VTEC pressure switch connector (D16Y5. D16Y8

engrnes,

. ldle air control (lAC) valve connector

15.Remove the spark plug caps and distributor from

the cylinder head.

Remove the uPPer bracket.

NOTE:

. Use a jack to support the engine before the

upper bracket is removed.

. Make sure to place a cushion between the oil

pan and the jack.

12 x 1.25 mm

74 N.m {7.5 kgf m.

sil lbl.ftl

UPPERBRACKET

'17. Remove the cylinder head cover'

CYLINDERHEAD COVER

(cont'd)

6-29

Page 145 of 2189

Rocker Arms and Lost Motion Assemblies

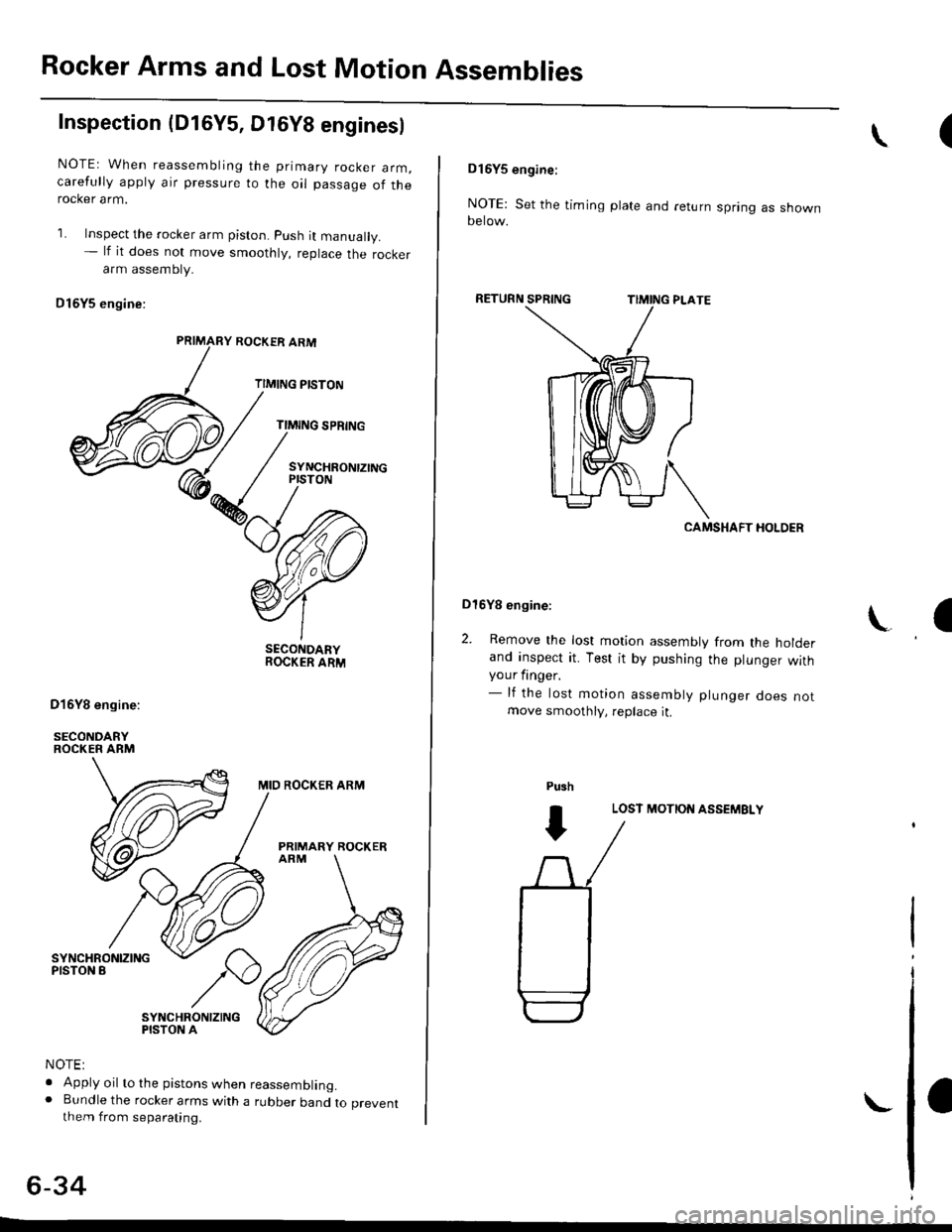

Inspection (D16Y5, Dt6Y8 enginesl

NOTEr When reassembling the primary rocker arm,carefully apply air pressure to the oil passage of therocker arm.

1. Inspect the rocker arm piston. push it manually.- lf it does not move smoothly, replace the rockerarm assembty.

Dl6Y5 engine:

ROCKER ARM

TIMING PISTON

TIMING SPRING

SYNCHRONTZINGPISTON

SECONDARYROCKER ARM

MID ROCKER ARM

PRIMARY ROCKER

SYNCHRONIZINGPISTON A

NOTE:

. Apply oil to the pistons when reassembling.o Bundle the rocker arms with a rubber band to preventthem from separating.

6-34

(\

DI6YS engine:

NOTE: Set the timing plate and return spring as shownoerow.

RETURN

CAMSHAFT HOLDER

Dl6Yg engine:

2. Remove the lost motion assembly from the holderand inspect it. Test it by pushing the plunger withyour finger.- lf the lost motion assembly plunger does notmove smoothly, replace it.

LOST MOTION ASSEMBLY

\a

Pu3h

I

Page 152 of 2189

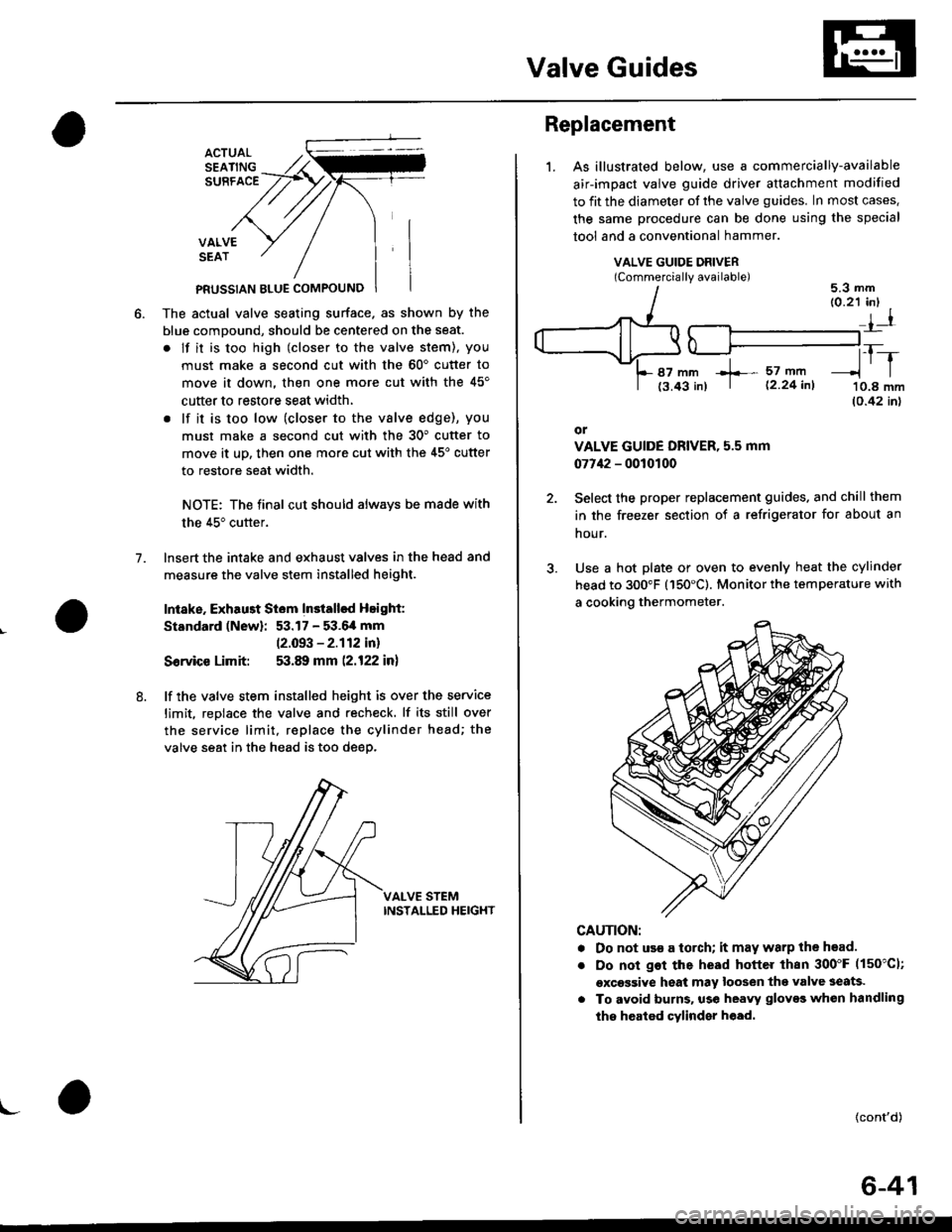

Valve Guides

7.

VALVESEAT

PFUSSIAN BTUE COMPOUNO

The actual valve seating surface. as shown by the

blue comDound, should be centered on the seat.

. lf it is too high (closer to the valve stem), you

must make a second cut with the 60'cutter to

move it down, then one more cut with the 45'

cutter to restore seat width,

. lf it is too low (closer to the vslve edge), you

must make a second cut with the 30" cutter to

move it uD, then one more cut with the 45'cutter

to restore seat width.

NOTE: The final cut should always be made with

the 45" cutter.

lnsert the intake and exhaust valves in the head and

measure the valve stem installed height.

Intake. Exhau3t Siem Installsd Height:

Standard (New): 53.17 - 53.6,4 mm

12.093 - 2.112 in)

Sorvice Limit: 53.89 mm (2.122 in)

lf the valve stem installed height is over the service

limit. reDlace the valve and recheck. lf its still over

the service limit, replace the cylinder head; the

valve seat in the head is too deep.

VALVE STEMINSTALLED HEIGHT

8.

\-

Replacement

1.As illustrated below, use a commercially-available

air-impact valve guide driver attachment modified

to fit the diameter of the valve guides. In most cases.

the same procedure can be done using the special

tool and a conventional hammer.

VALVE GUIDE DRIVERlCommerciallv available)5.3 mm

87 mm +- 57 mft

t3.43 in) | 12 24 inl

tr-r'10.8 mm(0.42 inl

or

VALVE GUIDE DRIVER, 5.5 mm

07742 - 0010100

Select the proper replacement guides. and chill them

in the freezer section of a refrigerator for about an

nour.

Use a hot plate or oven to evenly heat the cylinder

head to 300"F (150'C). Monitor the temperature with

a cooking thermometer.

CAUTION:

. Do not use a torch; it may warp the head.

Do not got the head hottel than 300"F (150"C1;

excessive heat may loosen thg valve seats.

To avoid burns. use heayy gloves whon handling

the heated cylinder h€ad.

{cont'd)

6-41