Ckp HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 370 of 2189

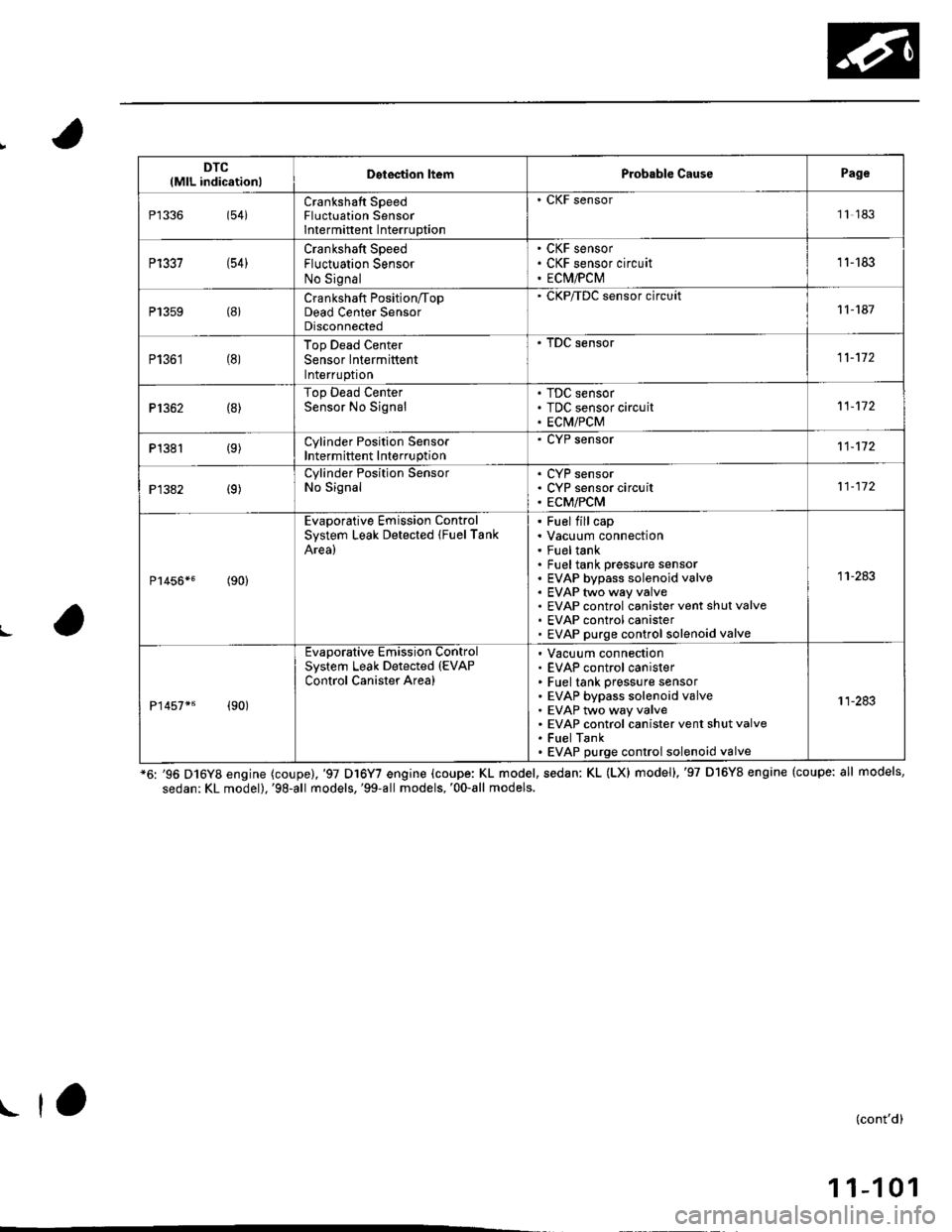

DTC(MlL indicationlDetection ltemProbable CausePage

P1336(54iCrankshaft SpeedFluctuation SensorIntermittent Interruption

. CKF sensor11 183

P1337 (54)Crankshaft SpeedFluctuation SensorNo Signal

CKF sensorCKF sensor circuitECM,PCM

11-'183

P13s9 (8)Crankshaft Position/TopDead Center SensorDisconnected

' CKP/TDC sensor circuit11-187

P1361 (8)Top Dead CenterSensor IntermittentInterruptron

. tuL sensor

11-172

P1362 (8)Top Dead CenterSensor No SignalTDC sensorTDC sensor circuitECIV/PCM

11-172

P1381 {9)Cylinder Position SensorIntermittent Interruption

. CYP sensor11-172

P1382 (9)Cylinder Position SensorNo SignalCYP sensorCYP sensor circuitECM/PCM

11-112

P1456*5(90)

Evaporative Emission ControlSystem Leak Detected {FuelTankArea)

FuelfillcapVacuum connectionFu€ltankFuel tank pressure sensorEVAP bypass solenoid valveEVAP two way valveEVAP control canister vent shut valveEVAP control canisterEVAP purge control solenoid valve

11-283

P1457*6 (90)

Evaporative Emission ControlSystem Leak Detected (EVAP

Control Canister Area)

Vacuum connectionEVAP control canisterFuel tank pressure sensorEVAP bypass solenoid valveEVAP two way valveEVAP control canister vent shut valveFuel TankEVAP purge control solenoid valve

11-283

L

*6: '96 D16Y8 engine (coupe),'97 Dl6Y7 engine (coupe: KL model, sedan: KL (LXl model),'97 D16Y8 engine (coupe: all models,

sedan: KL model),'98-all models,'99-all models,'00-all models.

(cont'd)

1 1-1 01

I ta

Page 373 of 2189

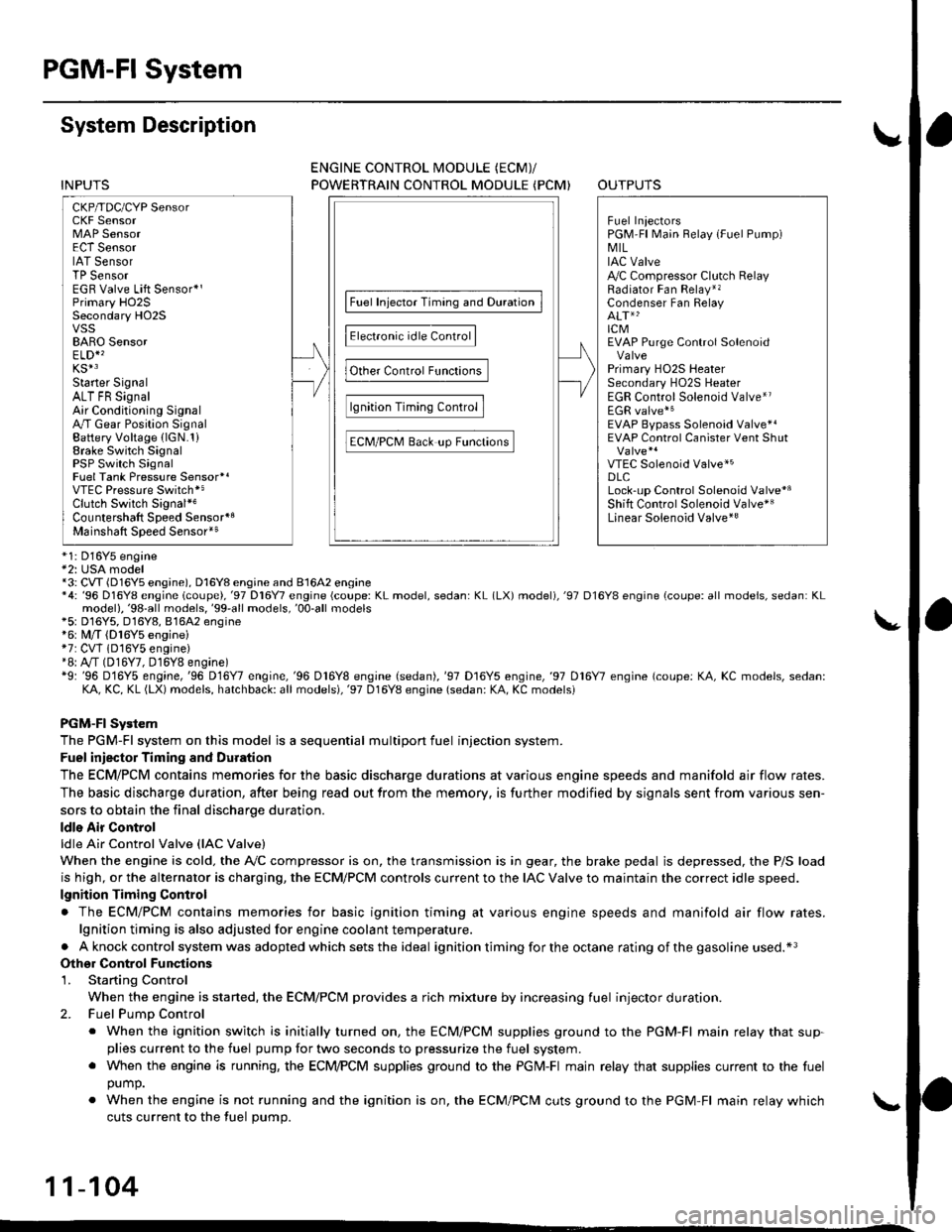

PGM-FI System

System Description

CKP/TDC/CYP Sensor

MAP Sensor

IAT SensorTP SensorEGR Valve Lift Sensor*'Primary H02SSecondary HO2SVSSBARO SensorELD*'KS€Starter SignalALT FR SignalAir Conditioning SignalA/T Gear Position SignalBattery Voltage {lGN.1}Erake Switch SignalPSP Switch SignalFuel Tank Pressure Sensor*iVTEC Pressure Switch*5Clutch Switch Signal*6Countershaft Speed SensornBMainshaft Speed Sensorrs

-\

----t /

F;ilrr j"-----fi-tri-'r.;l

Fb"t."'i" d" c;;il

F,h"'c;;tr*".io";-l

@."r.l"sc;;ll

EaM/PcM B""k-p F"""till

r\

-:/

Fuel IniectorsPGM-Fl Main Belay {Fuel Pump)MILIAC Valve!y'C Compressor Clutch RelayRadiator Fan Relay*,Condenser Fan RelayALT*'lcMEVAP Purge Control Solenoid

Primary HO2S HeaterSecondary H02S HeaterEGR Control Solenoid Valve*rEGR valve*6EVAP Bypass Solenoid Valve*'EVAP Control Canister Vent Shut

VTEC Solenoid Valve*5DLCLock-up Control Solenoid Valve*aShift Control Solenoid Valve*3Linear Solenoid Valve*3

*1: Dl6Y5 engine*2: USA model*3: CW (D16Y5 ensine), D16Y8 engine and 81642 ensine*4: '96 D16Y8 engine lcoupe),'97 Dl6Y7 engine (coupe: KL model, sedan: KL (LX) model),'97 D16Y8 engine {coupe: all models, sedan: KLmodel),'98-all models,'99'all models,'00-all models+5: D16Y5, D16Y8,816A2 engine*6: M/T (D16Y5 enginei*7: CVT 1D'l6Y5 engine)+8: A/T (D16Y7, D16Y8 engine)*9: '96 D16Y5 engine,'96 D16Y7 engine,'96 Dl6Y8 engine (sedan),'97 D16Y5 engine,'97 Dl6Y7 engine (coupe: KA, KC models, sedan:KA, KC, KL (LX) models, hatchback: all models),'97 D16Y8 engine (sedan: KA, KC modelsi

PGM-FI Sy3lem

The PGM-Fl system on this model is a sequential multipon fuel injection system.

Fuel iniector Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold air flow rates.

The basic discharge duration, after being read out from the memory. is further modified by signals sent from various sen-

sors to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve llAC Valve)

When the engine is cold. the A,/C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

. The ECM/PCM contains memories for basic ignition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. Aknockcontrol system was adopted which sets the ideal ignition timing for the octane rating ofthegasoline used.*3

Othgr Control Funqtions

1. Starting Control

When the engine is started, the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on, the ECM/PCM supplies ground to the PGM-Fl main relay that sup-plies current to the fuel pump for two seconds to pressurize the fuel system.. When the engine is running, the ECI\4PCM supplies ground to the PGM-FI majn relay that supplies current to the fuel

oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

11-104

INPUTS

ENGINE CONTROL MODULE (ECMY

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

Page 375 of 2189

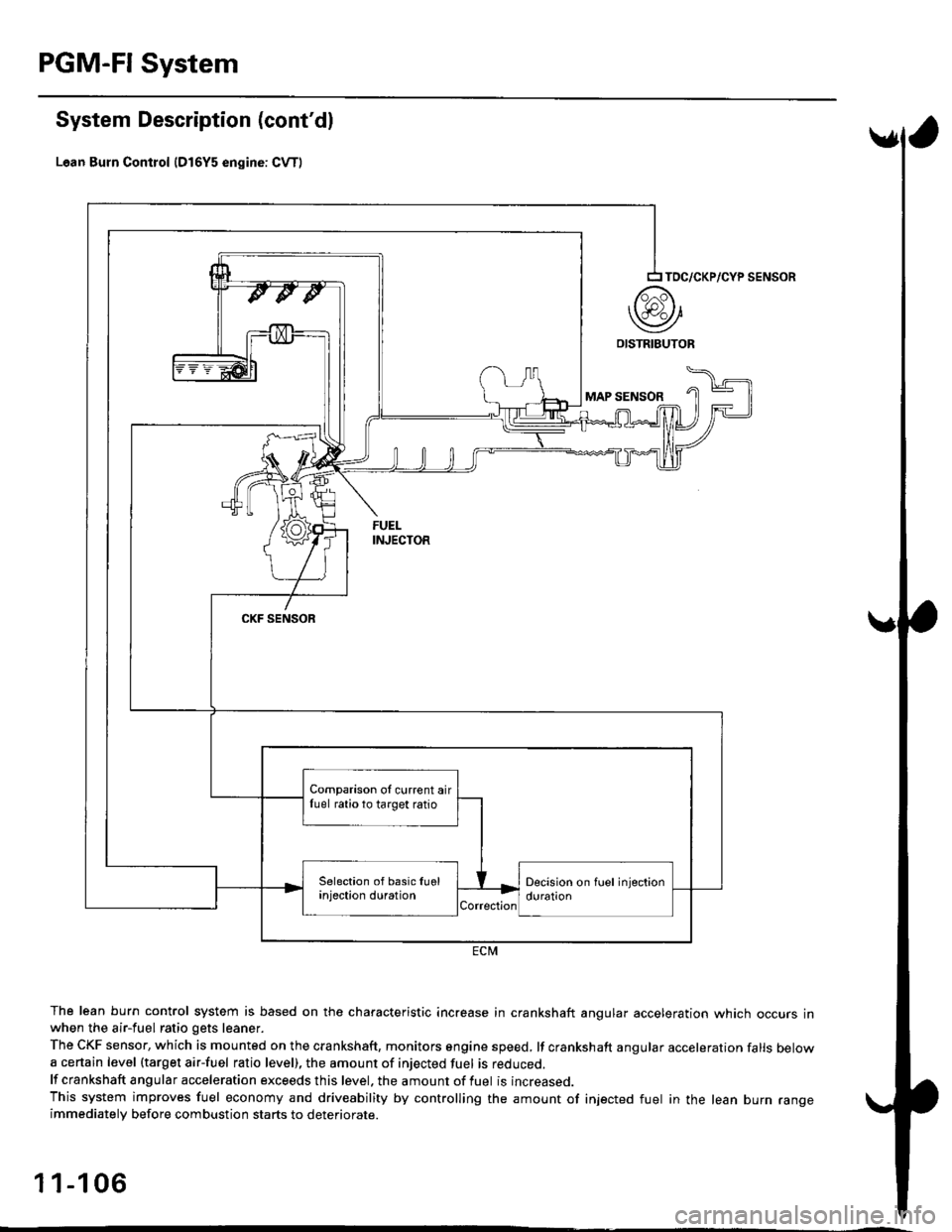

PGM-FI System

System Description (cont'dl

Lean Burn Control {D16Y5 engine: CvT)

The lean burn control system is based on the characteristic increase in crankshaft angular acceleration which occurs inwhen the air-fuel ratio gets leaner.

The CKF sensor, which is mounted on the crankshaft, monitors sngine speed, lf crankshaft angular acceleration falls belowa certain level (target air-fuel ratio level), the amount of injected fuel is reouceo.

lf crankshaft angular acceleration exceeds this level. the amount of fuel is increased.

This system improves fuel economy and driveability by controlling the amount of injected fuel in the lean burn rangeimmediatelv before combustion starts to deteriorate.

1 1-1 06

TOC/CKP/CYP SENSOR

MAP SENSOR

CKF SENSOR

ECM

Comparison oI current airfuel ratio to target ratio

Page 435 of 2189

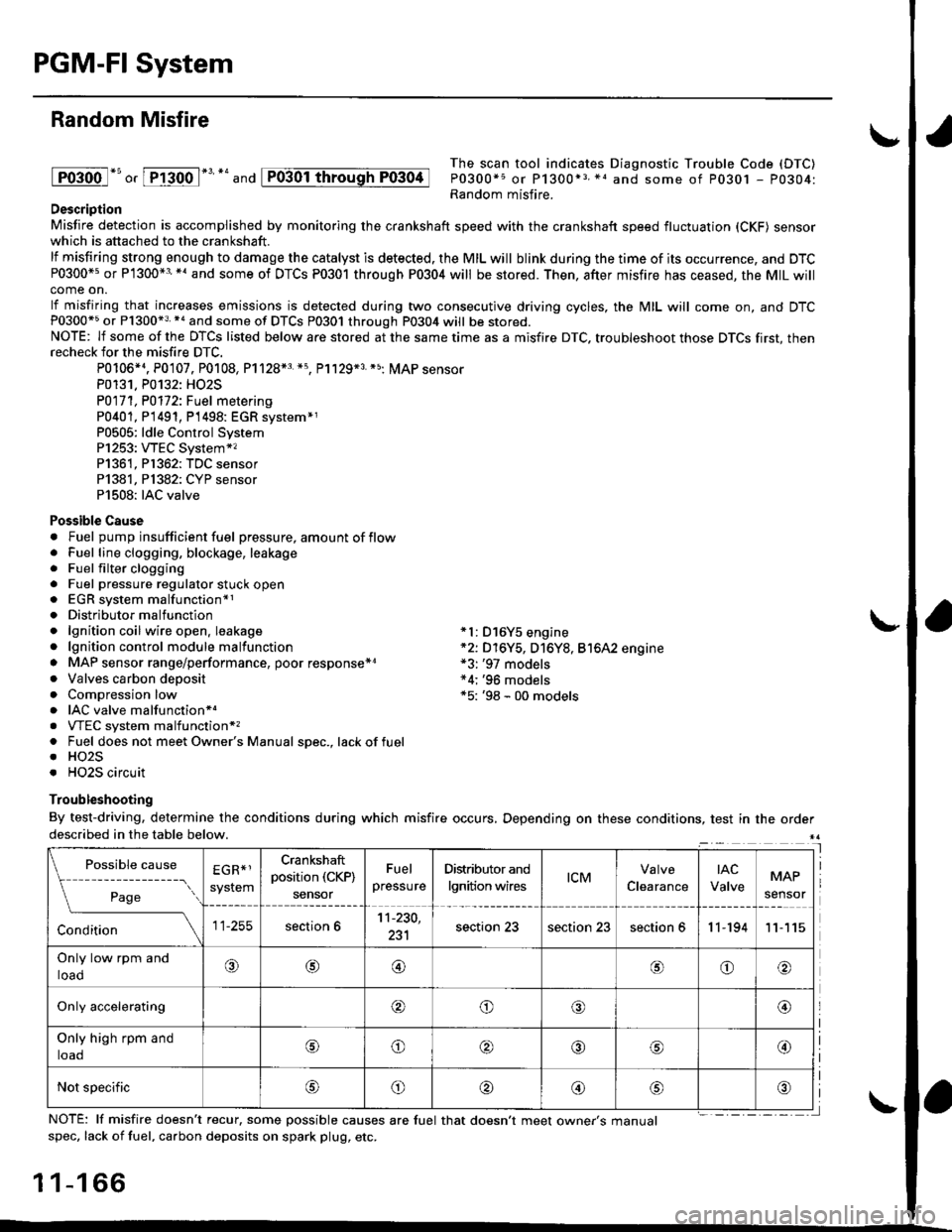

PGM-FI System

Random Misfire

lFoioo l*u o, [FTioo l*' *' and

The scan tool indicates Diagnostic Trouble Code (DTC)

P0300*5 or P1300*3 *1 and some of P0301 - P0304:Random misfire.Description

Misfire detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluctuation (CKF) sensorwhich is attached to the crankshaft.

lf misfiring strong enough to damage the catalyst is detected. the MIL will blink during the time of its occurrence, and DTCP0300*5 or P1300*3'*' and some of DTCs P0301 through P0304 will be stored. Then, after misfire has ceased, the MIL willcome on.

lf misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and DTCP0300*5 or P1300*3 *a and some of DTCS P0301 through P0304 will be stored.NOTE: lf some of the DTCS listed below are stored at the same time as a misfire DTC. troubleshoot those DTCS first, thenrecheck for the misfire DTC.

P0106*4. P0107. P0108, P1128*3 *5, Pl129*3 *5; MAP sensorP0131. P0132: HO2S

P0171, P0112i Fuel metering

P0401, P 1491, P1498: EGR svstem*1P0505: ldle Control SystemP1253: VTEC System*,P1361, P1362: TDC sensorP1381, Pl382: CYP sensorP1508: IAC valve

Possible Cause. Fuel pump insufficient fuel pressure, amount of flow. Fuel line clogging, blockage, leakage. Fuel filter clogging. Fuel pressure regulator stuck open. EGR system malfunction*1. Distributormalfunction. lgnition coil wire open. leakage *l: D16Y5 engine. lgnition control module malfunction *2: D16Y5, D16Y8, Bt6A2 engine. MAP sensor range/performance, poor response*r *3: '97 models. Valves carbon deposit *4;'96 models. Compression low *5: '98 - 00 models. IAC valve malfunctionr.. VTEC system malfunction*,. Fuel does not meet Owner's Manual spec., lackoffuel. HO2S. HO2S circuit

Troubleshooting

By test-driving, determine the conditions during which misfire occurs, Depending on these conditions, test in the orderdescribed in the table below.

Possible

- --^ ---

rage

causeEGR*1

system

Crankshaft

position (CKP)

sensor

Fuel

pressure

Distributor and

lgnition wirestcMClearance

tAc

ValveMAP

sensor

section 611-230,

231section 23section 23section 611-19411

Only low rpm and

loado@@oo

Only accelerating@o@@

Only high rpm and

toaooo@

Not specificoo@

NOTE: lf misfire doesn't recur, some possible causes are fuel that doesn't meet owne/s manualspec, lack of fuel, carbon deposits on spark plug, etc.

1 1-1 66

I

P0304

Page 441 of 2189

PGM-FI System

tFos3sl

tFffi6l

tPr361 I

fPfi62l

fFr38il

tF13s2-l

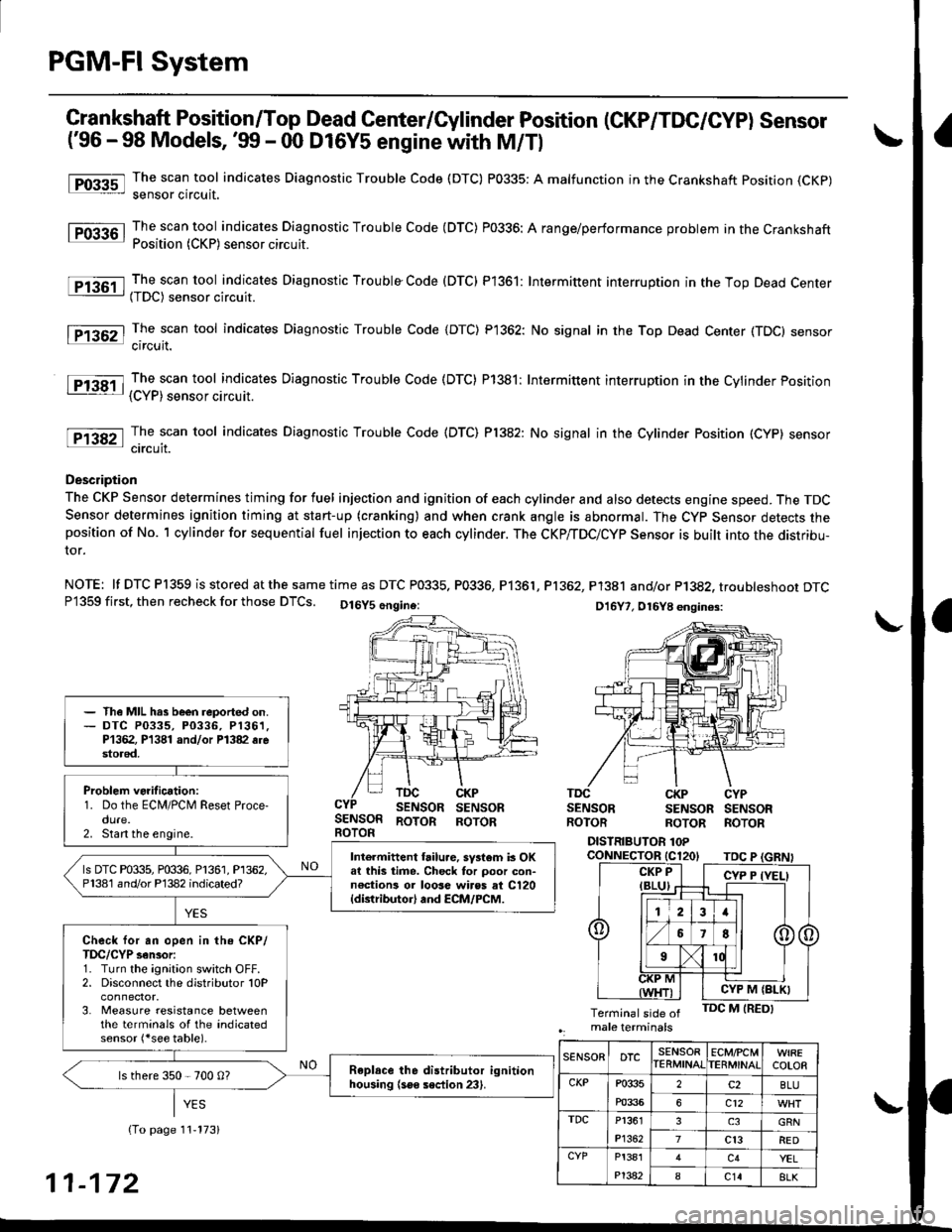

Crankshaft Position/Top Dead Genter/Gylinder Position (CKP/TDC/CYP) Sensor

('96 - 98 Models, '!n - 00 D16Y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P0335: A malfunction in the Crankshaft position (CKp)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the CrankshaftPosition (CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1361: Intermittent interruotion in the Too Dead Center(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1362: No signal in the Top Dead Center (TDC} sensorcircuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cvlinder Position{CYP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) Pl382: No signal in the Cylinder Position (CYP} sensorcircuit.

Description

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDCSensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The Cyp Sensor detects theposition of No. 1 cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-ror.

NOTE: lf DTC P1359 is stored atthesametime as DTC P0335. P0336, P1361, Pl362, P1381 and/or P1382, troubteshoor DTCP1359 first, then recheck for those DTCS. Ot6y5 6ngine: Dt6y7, ot6y8 enqin6s:

SENSORBOTOR

TDCSENSORCKPSENSORSENSORROTORSENSORROTORSENSORROTORROTORROTOR

DISTRIBUTOR 1OPcoNNECTOR tC120tTDC P

- The MIL hrs been reported on.- DTC P0335, P0336, P1361,P1362, P1381 and/or Pl382 6restored,

Problem verification:1. Do the ECM/PCM Reset Proce-dure.2. Stan the engine.

Intermittent hilu.e, system b OKat this time. Check tor poor con-n€ctions or 10036 wiros at C120{distributor} and ECM/PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or P'l382 indicated?

Check for an open in the CKP/TDC/CYP sensor:1. Turn the ignition switch OFF.2. Disconnect the distributor 10P

3. Measure resistance betweenthe terminals of the indicatedsensor (*see table).

Replace the distributor ignitionhousing (soe section 23).ls there 350 - 700 0?

CYP M {BLK}

SENSORDTCSENSORIERMINATECMfCMTERMINATCOLOR

CKPP033s

m336

2c2BLU

6c12

TDCP1361

P1362

3GRN

7cl3RED

CYPP!381

P't382

c4YEL

8c148LK11-172

Page 442 of 2189

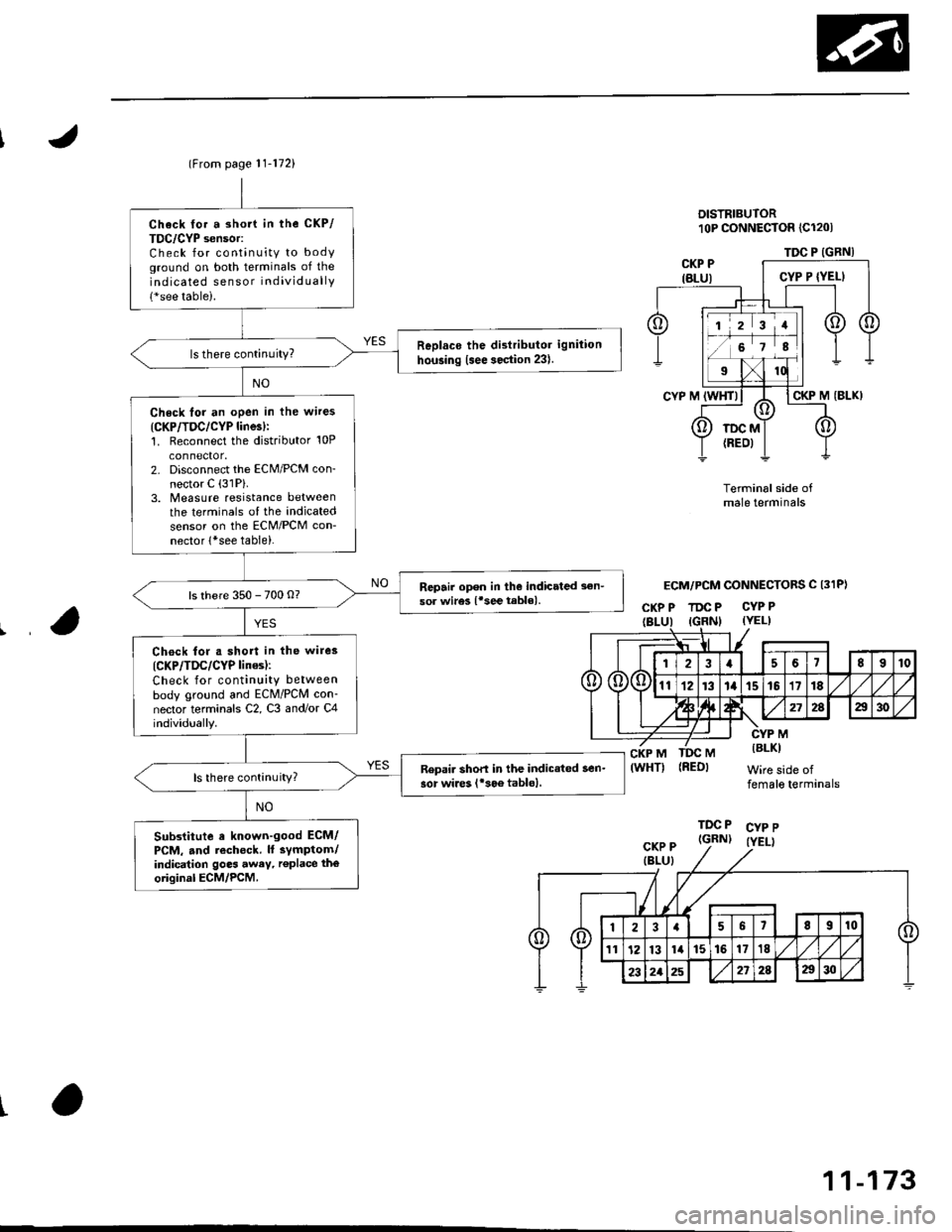

(From page | 1-172)

Check fo. a sho.t in the CKP/

TDC/CYP sensor:Check for continuity to bodYground on both terminals of the

indicated senso r individually

1*see table).

Replaco the di3tributor ignition

hoGing lsee section 23).ls there continuity?

Check for an open in the wires

ICKP/TOC/CYP line3):1. Reconnect the distributor 10P

connecaor.2. Disconnect the EcM/PCM con-

nector C {31P}.3. N4easure resistance betweenthe terminals of the indicated

sensor on the ECIM/PCM con-

nector {*see tabie}.

Repair open in the indicated sen-

sor wires lrsee tablel.ls there 350 - 700 o?

Chock lor. short in the wires

ICKP/TDC/CYP lines):

Check for continuity between

body ground and ECM/PCM con-

nector terminals C2, C3 and/or C4individually.

Repai. short in the indic.ted sen_

sor wire3 ('soe tablol,ls there continuity?

Substitute e known-good ECM/PCM, and iecheck. ll sYmptom/indication goes awev, r€Place the

original ECM/PCM.

DISTRIBUTOR10P CoNNECTOR {C1201

Terminalside ofmale terminals

ECM/PCM CONNECTORS C 131P)

CI(P P TDC P CYP P(YEL)

M

CKP M(WHT)MIBLKI

Wire side offemale terminals

CYP PIYELI

(REDI

TDC P(GRN)CKP P(BLU}

t

TDC P (GRNI

11-173

Page 443 of 2189

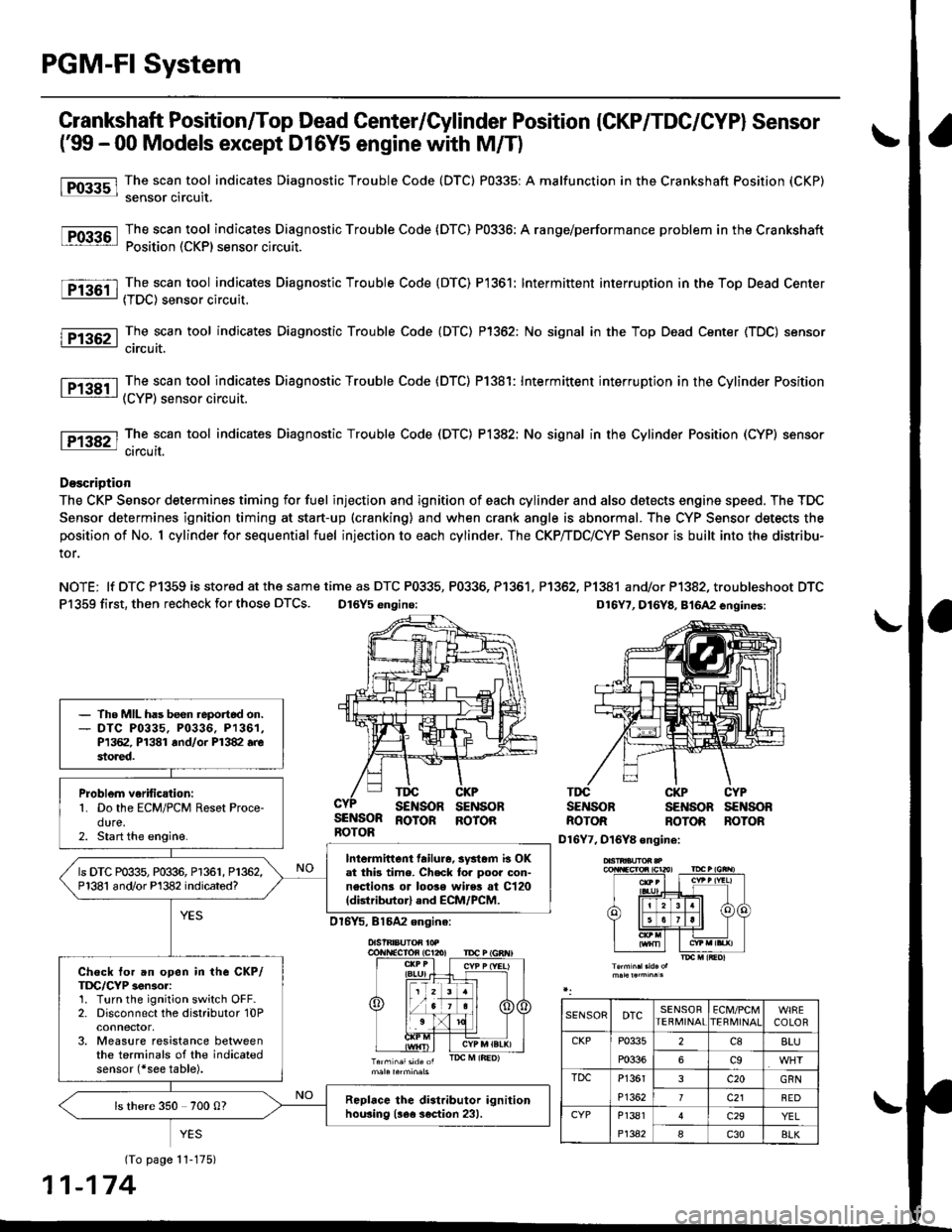

PGM-FI System

l-Fos3sl

tFos36l

tF1361 l

Fr362-1

tF13sil

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

f99 - 00 Models except D16Y5 engine with M/T)

The scan tool indicates Diagnostic Trouble Code (DTC) P0335: A malfunction in the Crankshaft Position (CKP)

sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position (CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1361: Intermittent interruption in the Top Dead Center

{TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1362: No signal in the Top Dead Center (TDC) sensor

circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position(CYP) sensor circuit.

lTiaSt The scan tool indicates Diagnostic Trouble Code (DTC) P1382; No signal in the Cylinder Position (CYP) sensor: circuil.

DoscriDtion

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up (cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 1 cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

tor.

NOTE; lf DTC P1359 is stored at the same time as DTC P0335, P0336, P1361. P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then recheck for those DTCS. D16Y5 engino:

SENSORROTOR

TDGSENSORCKPSENSOBTDCSENSOBCKPSENSOBCYPs€NsonBOTORROTORBOTONROTOR ROTOR

D16Y7, D16Y8 ongine:

(To page 11-175)

1-174

- The MIL has been reportod on.- DTC P0335, P0336. P1361,P1362, P1381 rnd/or P1382.restored.

Problem verific{tion:1. Do the ECM/PCM Reset Proce-dure.2. Start the engine.

Intormittcnt failure, systom b OKat thb time. Check to. poor con-nections or loose wires at C120(dktributorl and ECM/PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or Pl382 indicated?

Check tor an open in the CKP/TDC/CYP 3enior:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector,3. Measure resistance betweenthe terminals of the indicatedsensor (*see table).

Replrce the distributor ignitionhou3ing (!ee section 231.ls there 350 700 0?

SENSORDTCSENSORTEBMINAIECM/PCMTERI\,4INAICOLOR

CKPP0335

P0336

2c88LU

6c9

TDCP1361

P1362

3c20GRN

7c21BED

CYPP1381

P1342

c29YEL

Ic30BLK

Page 444 of 2189

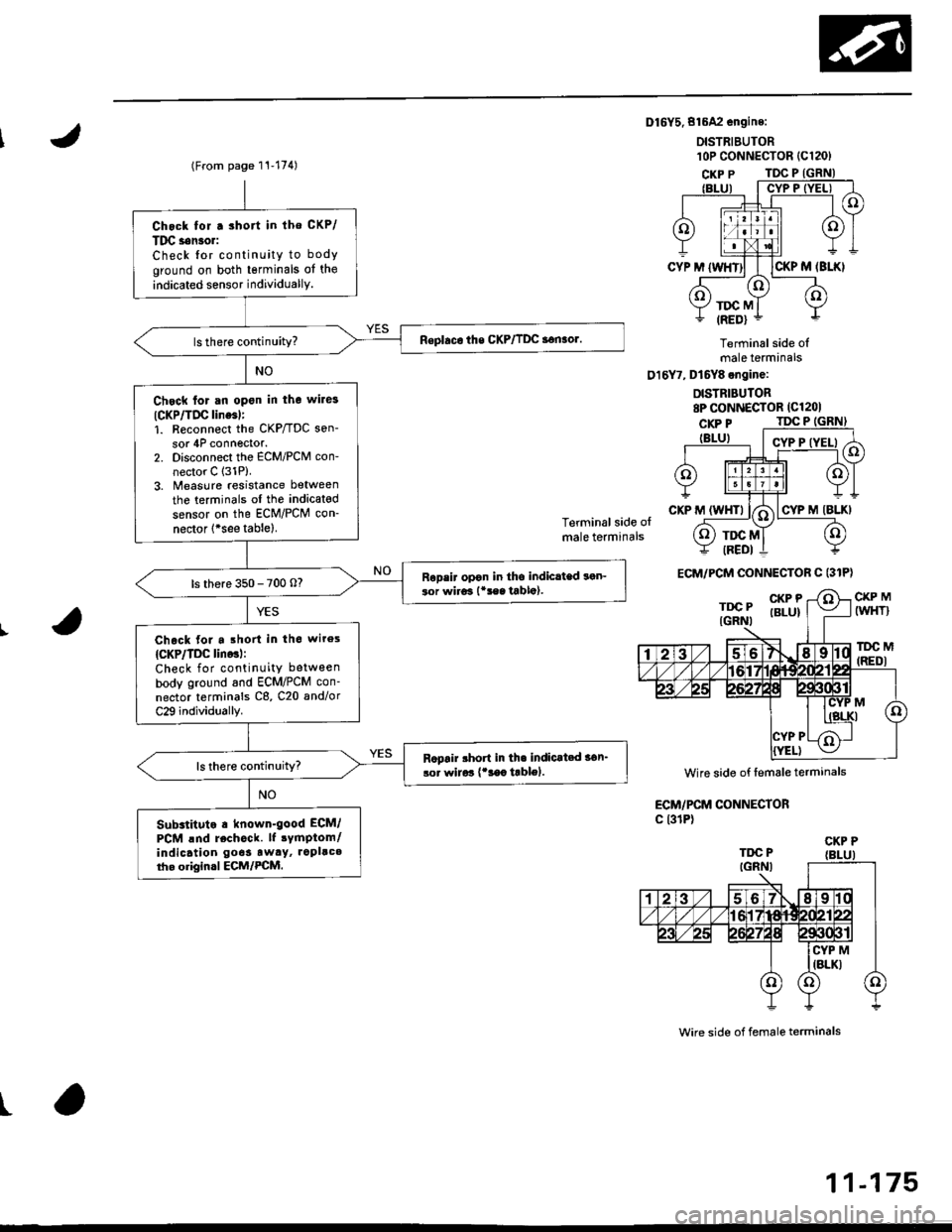

Dl6Y5.816A2 engine:

DISTRIEUTOR

Terminal side olmale terminals

016Y7, Dt6Y8 engine:

DISTRIBUTOR8P CONNECTOR (Cl201

Terminal side olmale terminals

CKP MIWHT}

lDC M(REDI

ECM/PCM CONNECTORc l31P)

wire side of female terminals

t

l0P coNNECTOR {C120)(From page 11-174)

Chock for.3hort in lho CKP/

Tlrc s6n3o.:

Check {or continuity to body

ground on both tsrminals of the

indicated sensor individuallY.

Chsck for an open in the wile3

ICKP/TIrc line6l:1. R€connect the CKP/TDC son-

sor 4P connector.2. Disconnect the ECM/PCM con-

nector C 131P).3. Measure resistance between

the terminals ol the indicated

sensor on the ECM/PCM con-

nector 1*see tablel.

Ropsir opon in tho indiclted son-ior wiro3 l*!sa tabla).ls there 350 - 700 o?

Chack for a .ho in th6 wiros

{CKP/TDC lino3l:Check for continuity between

body ground and ECM/PCM con-

nector terminals C8, C20 and/or

C29 individually.

Rcpair rhort in th. indicat.d 36n_

lor wirar {'3ac trblol.

Substituto . known-good ECM/

PCM lnd rechock. lf 3ymptom/indicatlon go6s aw.y, ropllc.tho origin.l ECM/PCM.

ECM/PCM CONNECTOR C (31P)

Wire side of femsle terminals

CKP P

11-175

Page 456 of 2189

l,a

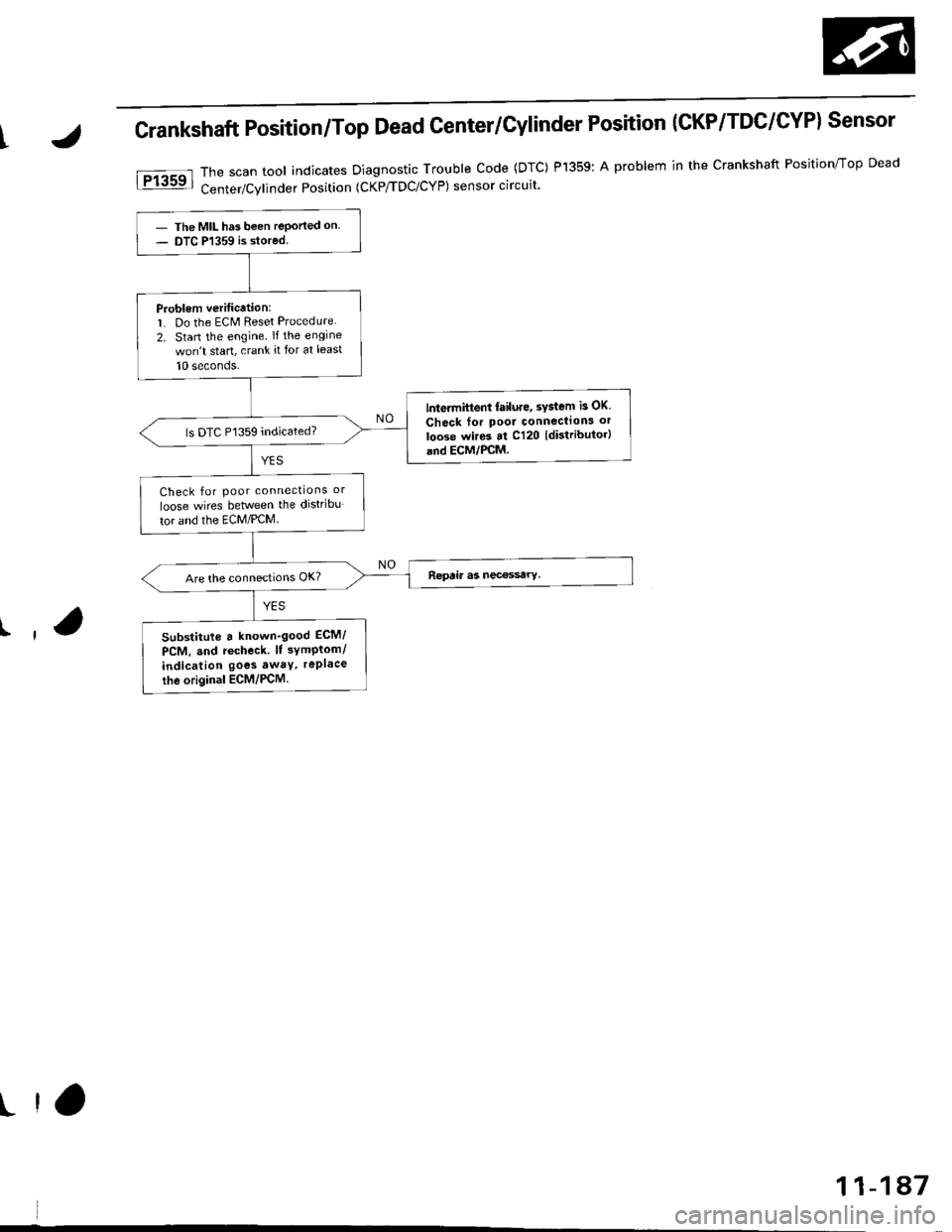

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI Sensor

Thescantoo|indicatesDiagnosticTroub|ecode(DTc)P1359:Aprob|eminthecrankshaftPosjtion/TopDead

Center/Cvlinder Position (CKP/TDC/CYP) sensor circuit'

- The MIL has been reported on- DTC P1359 is stored

Problem veritication:1. Do the ECM Reset Procedure

2. Stan the engine lftheengine

won't start, crank it for at least

10 seconds-

lntermittent failure, sYstem is OK

Check for poor connecllon3 or

loose wires at C120 {distributor}and ECM,/PCM.

ls DTC P1359 indicated?

Check for poor connections or

loose wires between the distribu

tor and the ECM/PCM

Substitute a known'good ECM/

PCM, and rccheck. lt 3ymPtom/

indication goes awtY, rePlace

the original ECM/PCM.

r ta

11-1A7

Page 680 of 2189

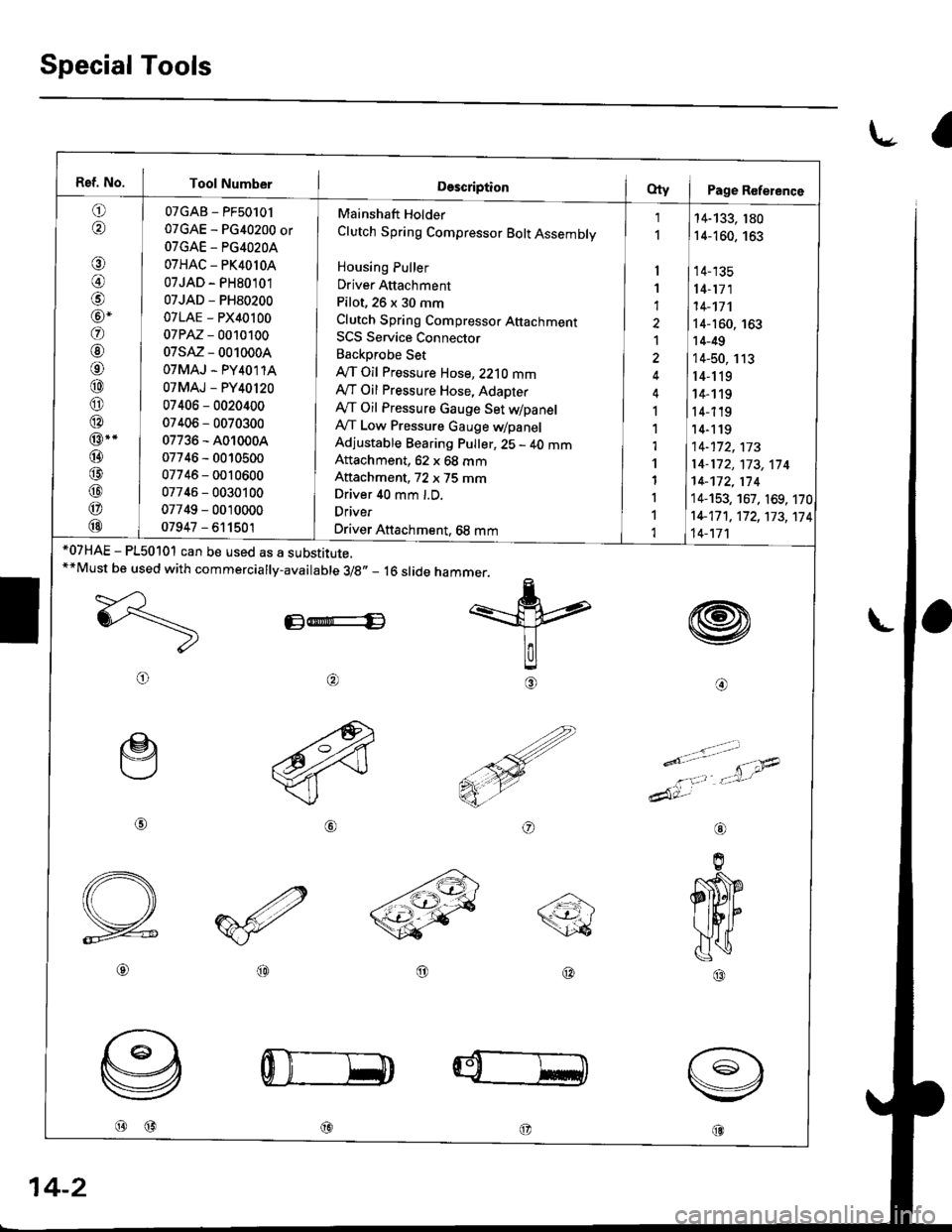

Special Tools

l.- a

Ref. No. Tool Number

o,6'\

€)

@)

@-

@

@

o

@

@

@

@..

@

@

@

@

@

07GAB - PF50101

07GAE - PG40200 or

OTGAE - PG4O2OA

07HAC - PK4010A

07JAD - PH80101

07JAD - PH80200

07LAE - PX40100

07PM - 0010100

07sM - 0010004

OTMAJ - PY4O1 1A

07MAJ - PY40120

07406 - 0020400

07406 - 0070300

07736 - A010004

07746 - 0010500

07746 - 0010600

07746 - 0030100

07749 - 0010000

07947 - 611501

Mainshaft Holder

Clutch Spring Compressor Bolt Assembly

Housing Puller

Driver Attachment

Pilot, 26 x 30 mm

Clutch Spring Compresso. Attachmenr

SCS Service Connector

Backprobe Set

IVT Oil Pressure Hose, 2210 mmAy'T Oil Pressure Hose, Adapter

Ay'T Oil Pressure Gauge Set dpanelA,/T Low Pressure Gauge WpanelAdjustable Bearing Pulter, 25 - 40 mmAftachment, 62 x 68 mm

Aftachment, 72 x 75 mmDriver 40 mm l.D.

Driver

Driver Attachment, 68 mm

I

1

1

1

I

1,l

'l

1

I

1

1

14-133, 180

14-160, 163

14-135

14-171

14-'�t7'l

14-160, 163

14-49

14-50, 113

r4-119

14- 1 19

14-119'14-1 19

14-172,173

14-172,'t73,114

14-172,174

14-153, 167. 169, 170

1+17 1 , 17 2, 173, 17

14-'t7'l

4

w

@o

*07HAE - P150101 can be used as a substitute.**Must be used with commercially-available 3/8,, _ 16 slide

E-E

@

@@

hammer.

=k

lalg

€)

ry

o

e

@

o

----a\\<-t-'- /\26

@@

@@@

aL

14-2