belt HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 121 of 2189

VTEC Rocker Arms

Inspection Using Special Tools (D16Y8 enginel

CAUTION:

o Before using the Valve Inspection Tool. mak6 surethat the air pressure gauge on the air comprsssor

indicates ovor 400 kPa {4 kgf/cm,, 57 psil.

. Inspect th6 valve clearanco before rockar arm inspec-

tion.

. Cov€r th€ timing belt with a shop towel to protect

the bolt.

. Check tho intake prima.y rockff arm of each cylindel

at TDC.

1.Remove the cylinder head cover.

NOTE: Refer to page 6-46 when installing the cylinder

neao cover,

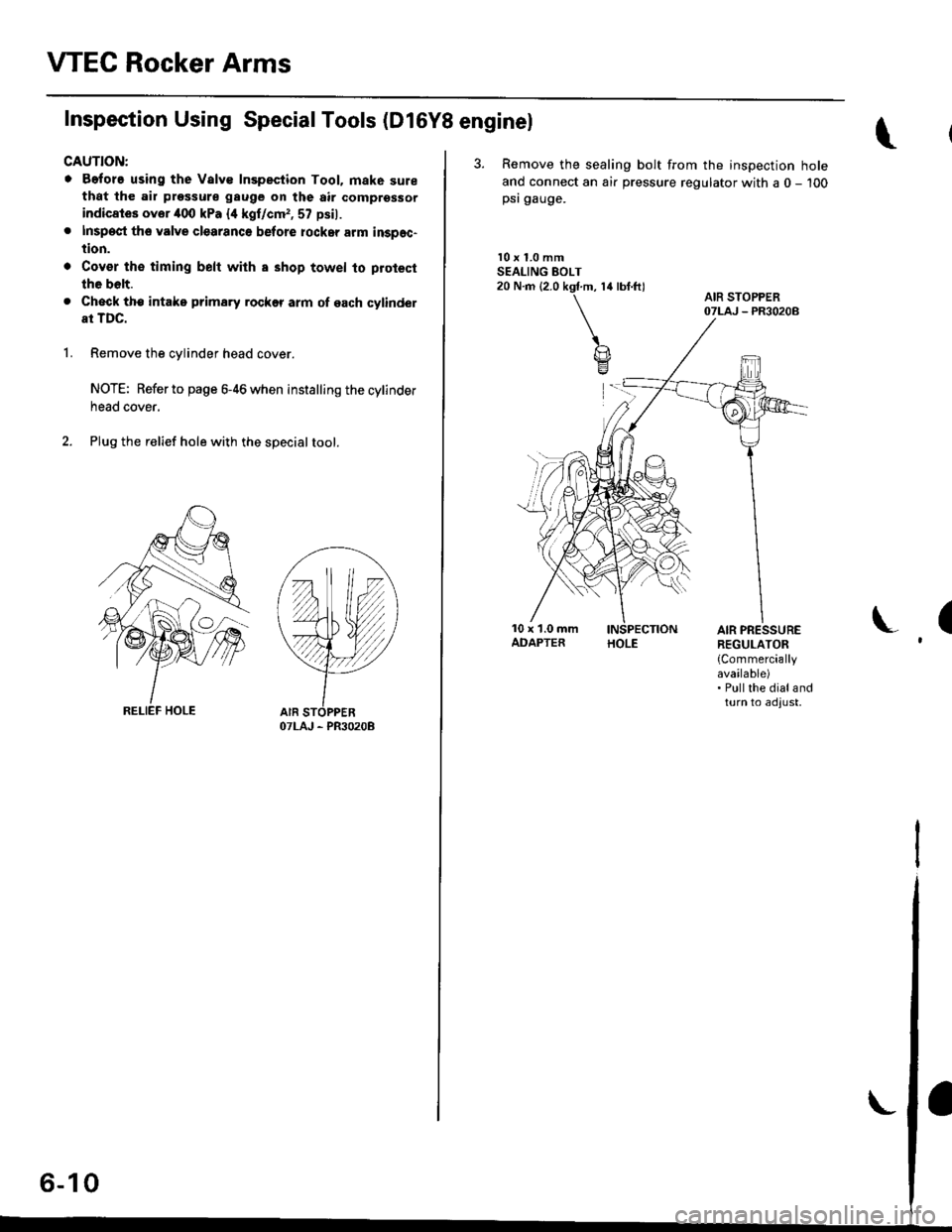

Plug the relief hole with the specialtool.

OTLAJ - PR3O2OB

I,^ A IAo- tu

3. Remove the sealing bolt from the inspection hole

ancl connect an air pressure regulator with a 0 - 100psi gauge.

l0 x 1.0 mmSEALING EOLT20 N.m (2.0 kgf.m, 14 lbf.ft)

(AIR PRESSUREREGULATOR

{Commerciallyavailable). Pullthe dialandturn to adjust,

Page 127 of 2189

Crankshaft Pulley and Pulley Bolt

Replacement

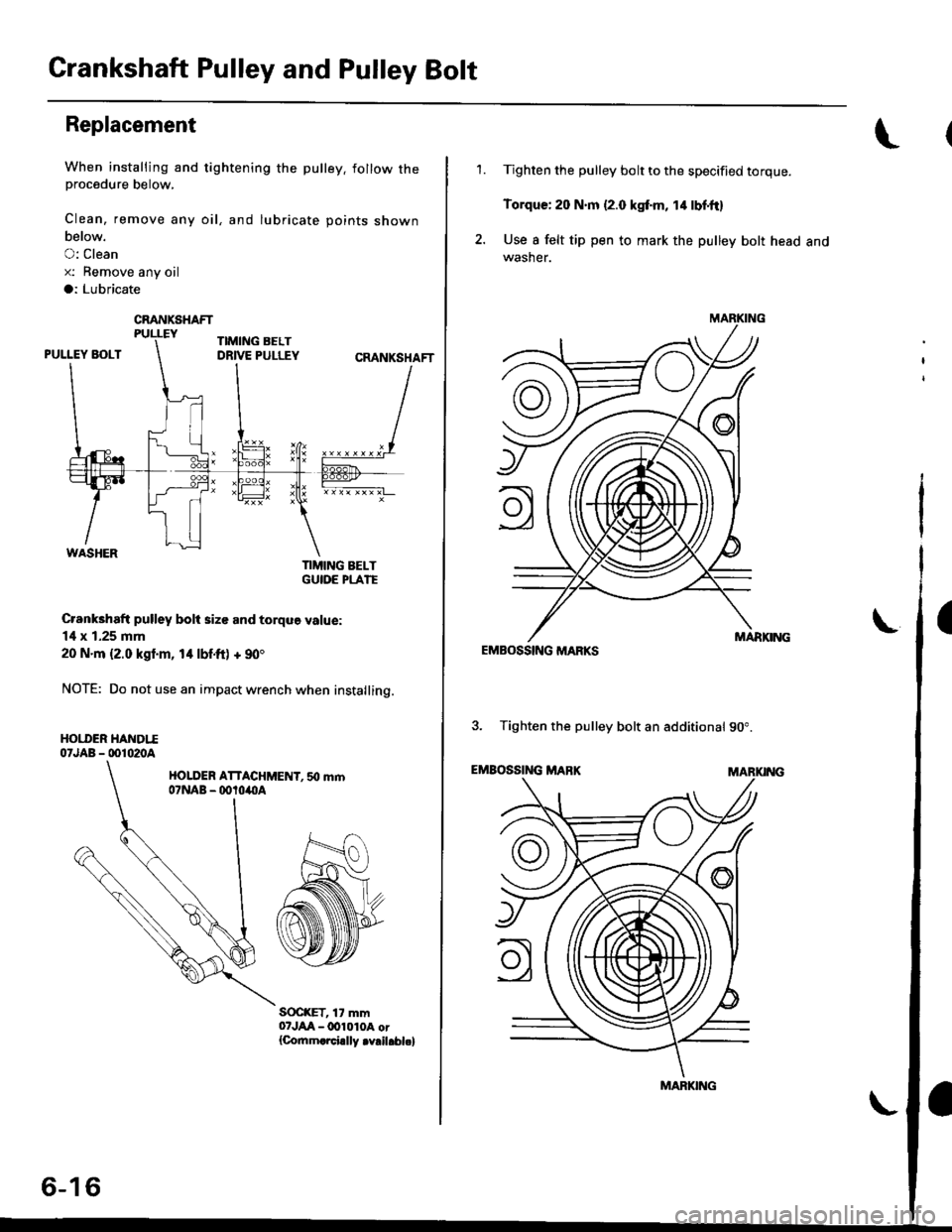

When installing and tightening the pulley. follow theprocedure below,

Clean, remove any oil, and lubricate points shown

below.

O: Clean

x: Bemove any oil

a: Lubricate

TIMING BELTGUIOE PLATE

Crankhaft pulley bolt size and torque value:

14 x 1.25 mm

20 N.m {2.0 kgl.m, 14 lbf.ft) + 90'

NOTE: Do not use an impact wrench when installing.

HOI.I'ER HANDTI07JAB - 001020A

HOLDER ATTACHMENT. 50 mm07NAB - ootoilllA

S(rc(ET, 17 mm07JAA-lxtl010A or{Co.nm.rci.lly .v.il.bl.}

CRANKSHAFT

6-16

'1.Tighten the pulley bolt to the specified torque.

Torque: 20 N.m {2.0 kgf.m, 14 lbf'ft}

Use I felt tip pen to mark the pulley bolt head andwasher.

EMBOSSING MARKS

3. Tighten the pulley bolt an additional 90".

EMBOSSING MABKMARKING

\

MARKING

MARKING

I

Page 128 of 2189

Timing Belt

Illustrated lndex

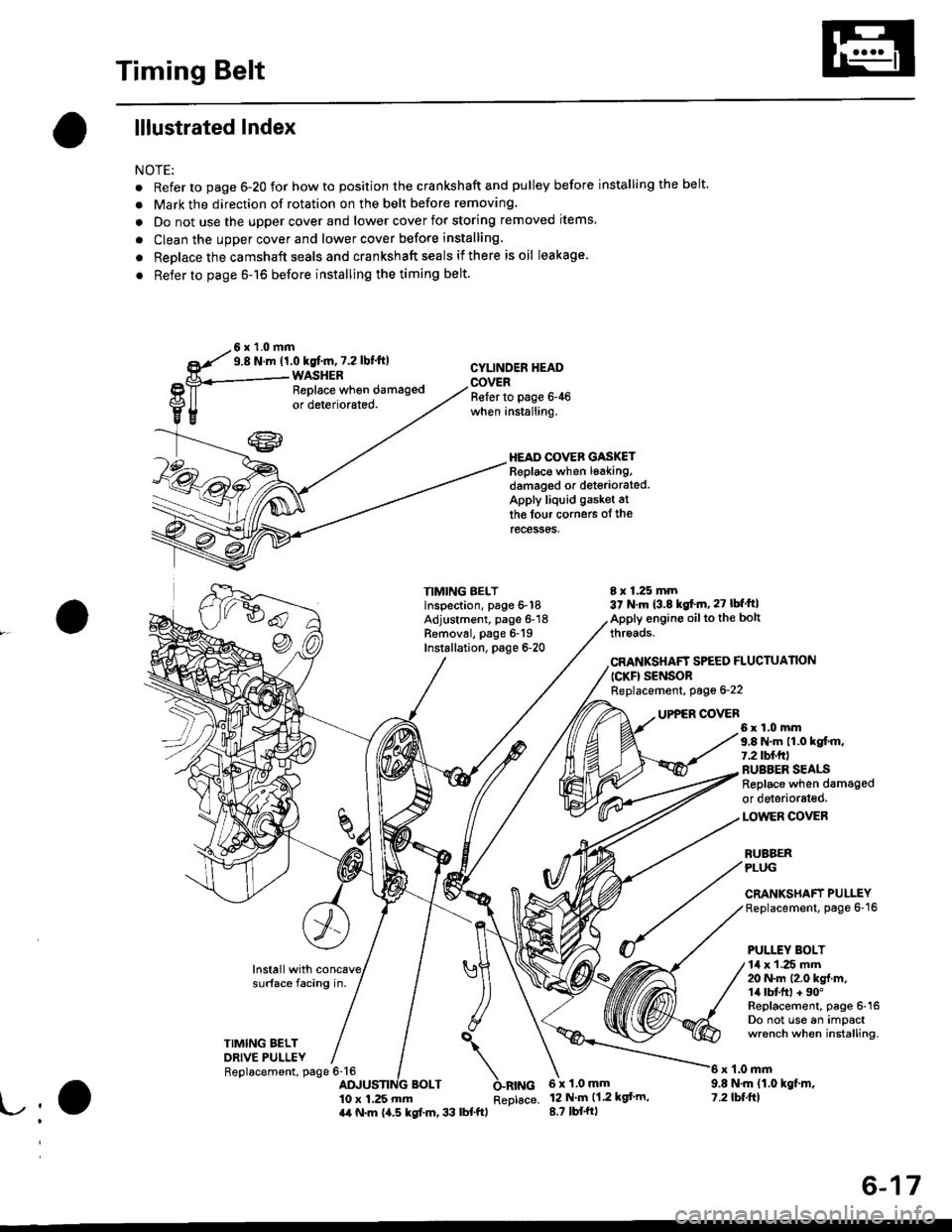

NOTE:

. Refer to page 6-20 for how to position the crankshaft and pulley before installing the belt.

. Mark the direction of rotation on the belt before removing.

a Do not use the upper cover and lower cover for storing removed items,

. Clean the upper cover and lower cover before installing.

. Replace the ca mshaft seals and cra n kshaft sea ls if there is oil leakage.

. Refer to page 6-16 before installing the timing belt.

CYLINDER HEADCOVERReler to page 6-46when installing.

HEAD COVEB GASKETReplaco when l6akin9,domaged or deteriorated.Apply liquid gasket at

th€ lour corners of thetecessos.

d

@

TIMING BELTInspection, page 6-18Adjustment, page 6-18Removal, page 6-19Installation. page 6-20

I x 1.25 mm3t N.m {3.8 kgf'm, 27 lbfftl

Apply engine oilto the bolt

thleads.

CRANKSHAFT SPEED FI.UCTUATION

lcr(Fl sENsoRReplacement, Page 6-22

UPPER COVEB

lnstallwithsurface facing in.

TIMING BELTDRIVE PULLEYReplacement, page 6_16

6x1.0mm9.8 N'm 11.0 kgt m,7.2 tbf.ft)NUBBER SEALSReplace when damagedor deledorated.

LOWER COVER

FUBBERPLUG

CRANKSHAFT PULLEYReplacement, page 6'16

PULLEY BOLTlil x 1.25 mm20 N.m 12.0 kgt.m,14 lbt'ft) + 90"Replacement, page 6'16Do not us6 an impactwrench when installing.

x 1.0 mmBOLT o-RING10 x 1,25 mm Reolace.14 N.m {,1.5 kgt m, 33 lbt ftl

6x1.0mmt2 N.m 11.2 kgf'm,8.7 tbt f0

9.E N'm (1.0 kgt.m,?.2 tbf.ftl\.-,o

6-17

Page 129 of 2189

Timing Belt

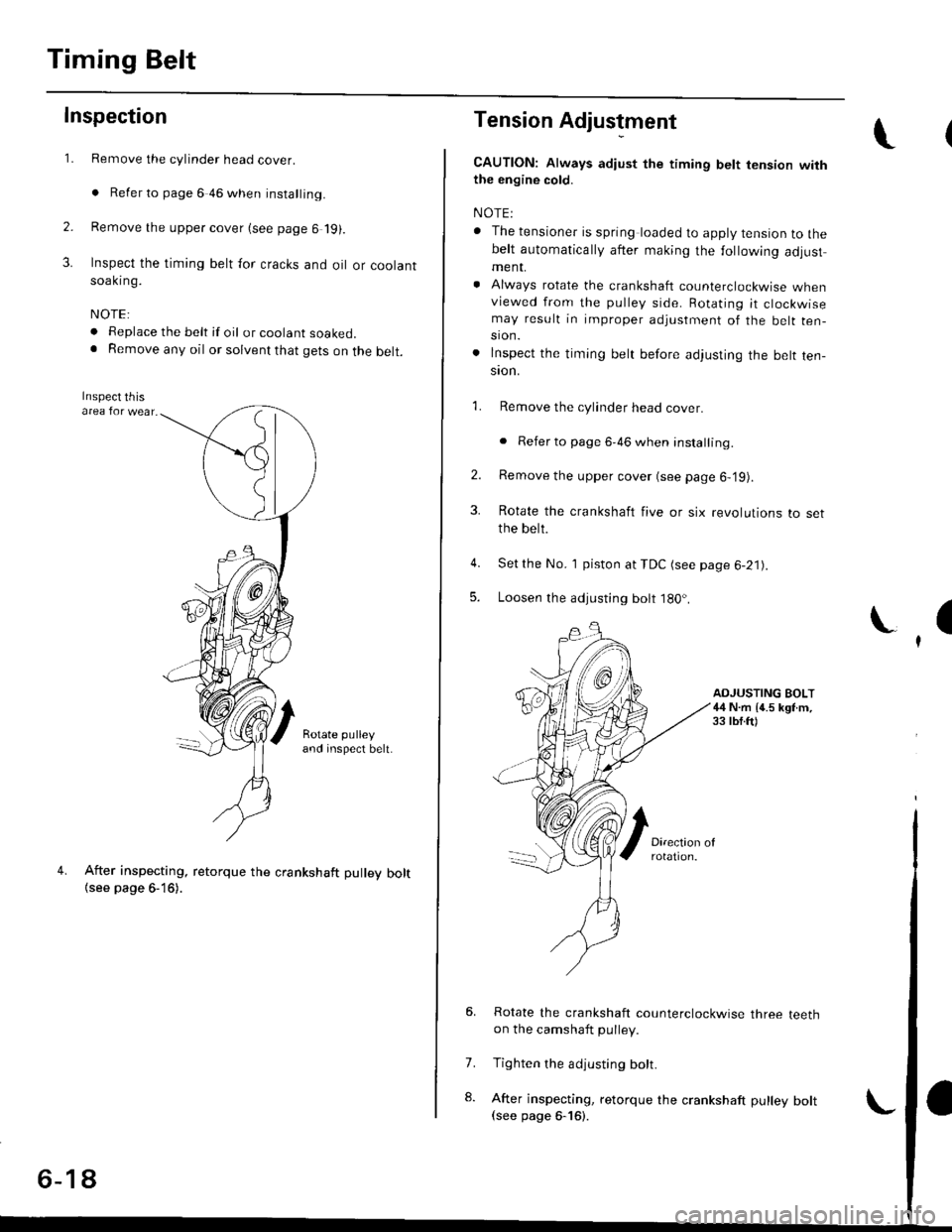

Inspection

1.

2.

3.

Remove the cylinder head cover.

. Refer to page 6 46 when installing.

Remove the upper cover (see page 6 19).

Inspect the timing belt for cracks and oil or coolantsoakrng.

NOTE:

. Replace the belt if oil or coolant soaKeo.. Remove any oil or solvent that gets on the belt.

Rotate pulleyand inspect belt.

After inspecting, retorque the crankshaft pullev bolt{see page 6- 16).

o- I6

Tension Adjustment

CAUTION: lt*ays aa;j"t the timing bett rension withthe engine cold.

NOTE:

. The tensioner is spring loaded to apply tension to thebelt automatically after making the following adjustment.

. Always rotate the crankshaft counterclockwise whenviewed from the pulley side. Rotating it clockwisemay result in improper adjustment of the belt ten-sion.

. lnspect the timing belt before adjusting the belt ten-ston.

1.Remove the cylinder head cover.

. Refer to page 6,46 when installing.

Remove the upper cover (see page 6,'19).

Rotate the crankshaft five or six revolutions to setthe belt.

Set the No. 'l piston at TDC (see page 6-21).

Loosen the adjusting bolt 180'.

2.

3.

4.

5.

\I

ADJUSTING BOLT44 N.m {4.5 kgt m,33 rbf.ft)

7.

8.

Rotate the crankshaft counterclockwise three teethon the camshaft pulley.

Tighten the adjusting bolt.

After inspecting, retorque the crankshaft pulley bolt(see page 6-16).

Page 130 of 2189

Removal

NOTE:

. Replace the timing belt at 105,000 miles (168.000 km)

according to the maintenance schedule (normal con-

ditions/severe conditions).

lf the vehicle is regularly driven in one or more of the

followlng conditions, replace the timing belt at 60.000

miles (U.S.A.) 100,000 km {Canada).

.In very high temperatures (over 110'F.43'C)

. In very low temperatures (under -20'F, -29"C)'

! Turn the crankshaft pulley so the No. 1 piston is at

top dead center (TDC) before removing the belt (see

page 6'21).

. Inspect the water pump before installing the timing

belt {see Page 10-14).

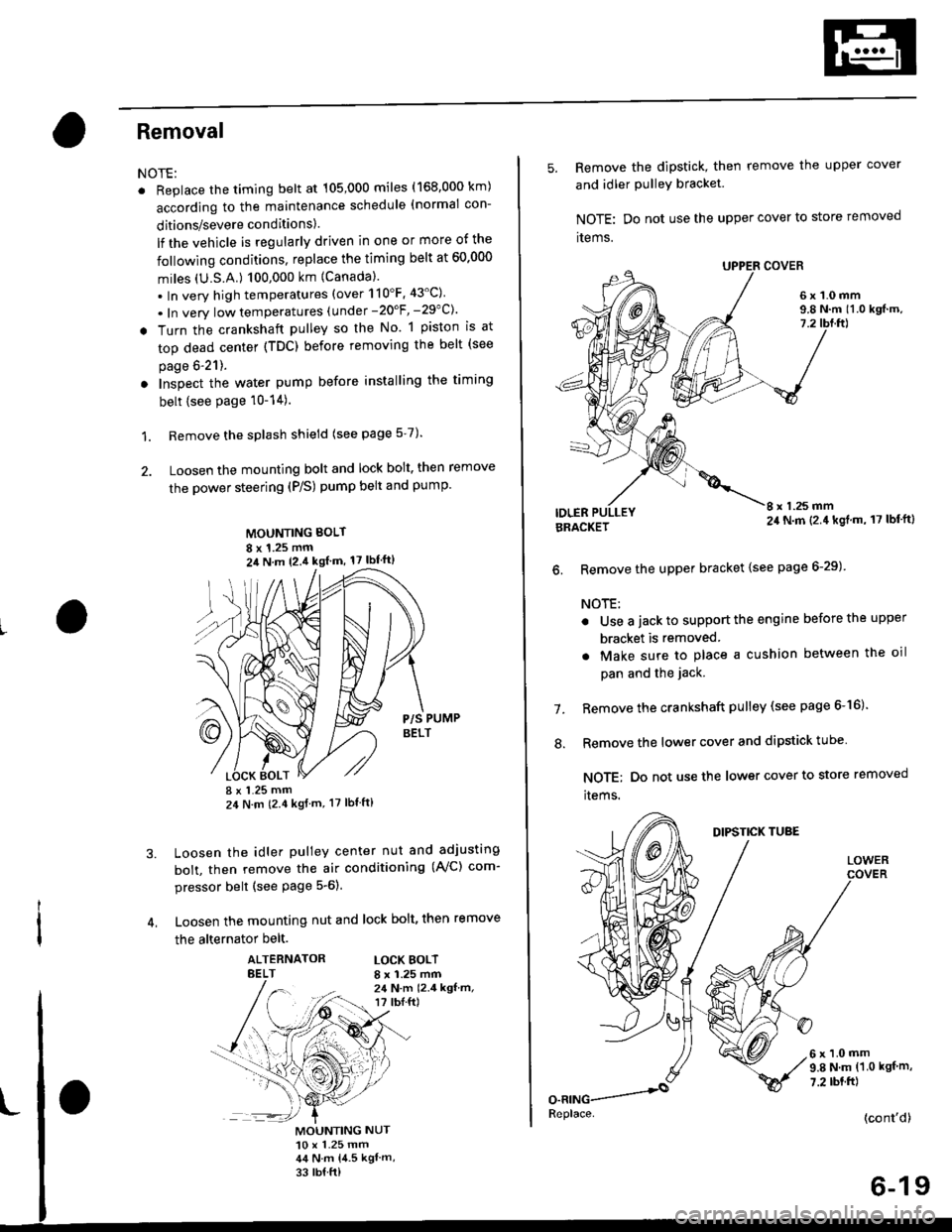

1. Remove the splash shield (see page 5-7).

2. Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt and pump

MOUNTING BOLT

8 x 1.25 mm2il N m 12.4 kgl m, 17 lbf'ft)

P/S PUMPBELT

I x 1.25 mm24 N m (2.4 kgf m, 17 lbt ft)

Loosen the idler pulley center nut and adjusting

bolt, then remove the air conditioning (AVC) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt, then remove

the alternator belt.

ALTERNATORBELTLOCK BOLTI x 1.25 mm24 N.m 12.4 kgf.m,r? tbI.ft)

3.

MOUNTING NUT10 x 1.25 mm44 N.m 14.5 kgl m,

33 rb{ ft)

5. Remove the dipstick, then remove the upper cover

and idler PulleY bracket

NOTE: Do not use the upper cover to store removed

items.

6x1.0mm9.8 N.m 11.0 kgf.m,7.2

IDLERI x 1.25 mm24 N.m (2.4 kgl.m, 17 lbf'ft)BRACKET

6. Remove the upper bracket {see page 6-29)

NOTE:

. Use a jack to support the engine before the upper

bracket is removed

. Make sure to place a cushion between the oil

pan and the jack.

Remove the crankshaft pulley (see page 6-16).

Remove the lower cover and dipstick tube

NOTE; Do not use the lower cover to store removed

items.

1.

.'.

DIPSTICK TUBE

LOWER

6x1.0mm9.8 N.m (1.0 kgf m,

7.2 rbt.ft)

(cont'd)

6-19

Replace.

Page 131 of 2189

Timing Belt

Removal (cont'd)

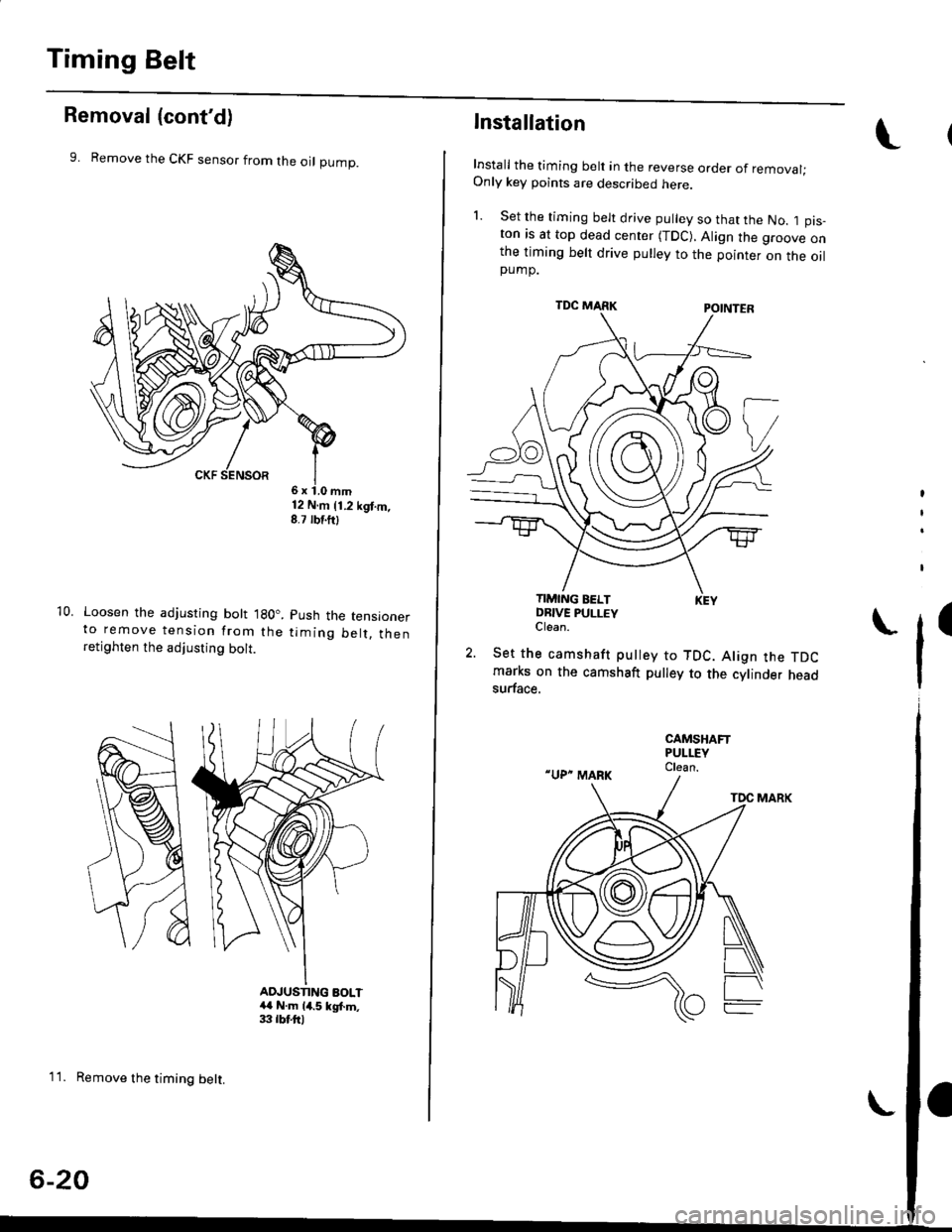

9. Remove the CKF sensor from the oI pump.

10. Loosen the adjusting bott lgO..to remove tension from theretighten the adjusting bolt.

12 N.m 11.2 kgt.m,8.7 rbf.ftl

Push the tensioner

timing be lt. then

AD.'USNNG BOLT4{ N.m 14.5 kgt m,33 tbtftl

1 1. Remove the timing belt.

6-20

lnstallation

Install the timing belt in the reverse order of removal;Only key points are described here.

l. set rhe timing belt drive pulley so that the No. 1 pis-ton as at top dead center (TDC), Align the groove onthe timing belt drive pulley to the pointer on the oilpump.

TDC MARKPOINTER

I

t

I

TIMING BELTDBIVE PULLEYClean.I

2. Set the camshaft pulley to TDC. Align the TDCmarks on the camshaft pulley to the cylinder headsurface.

Page 132 of 2189

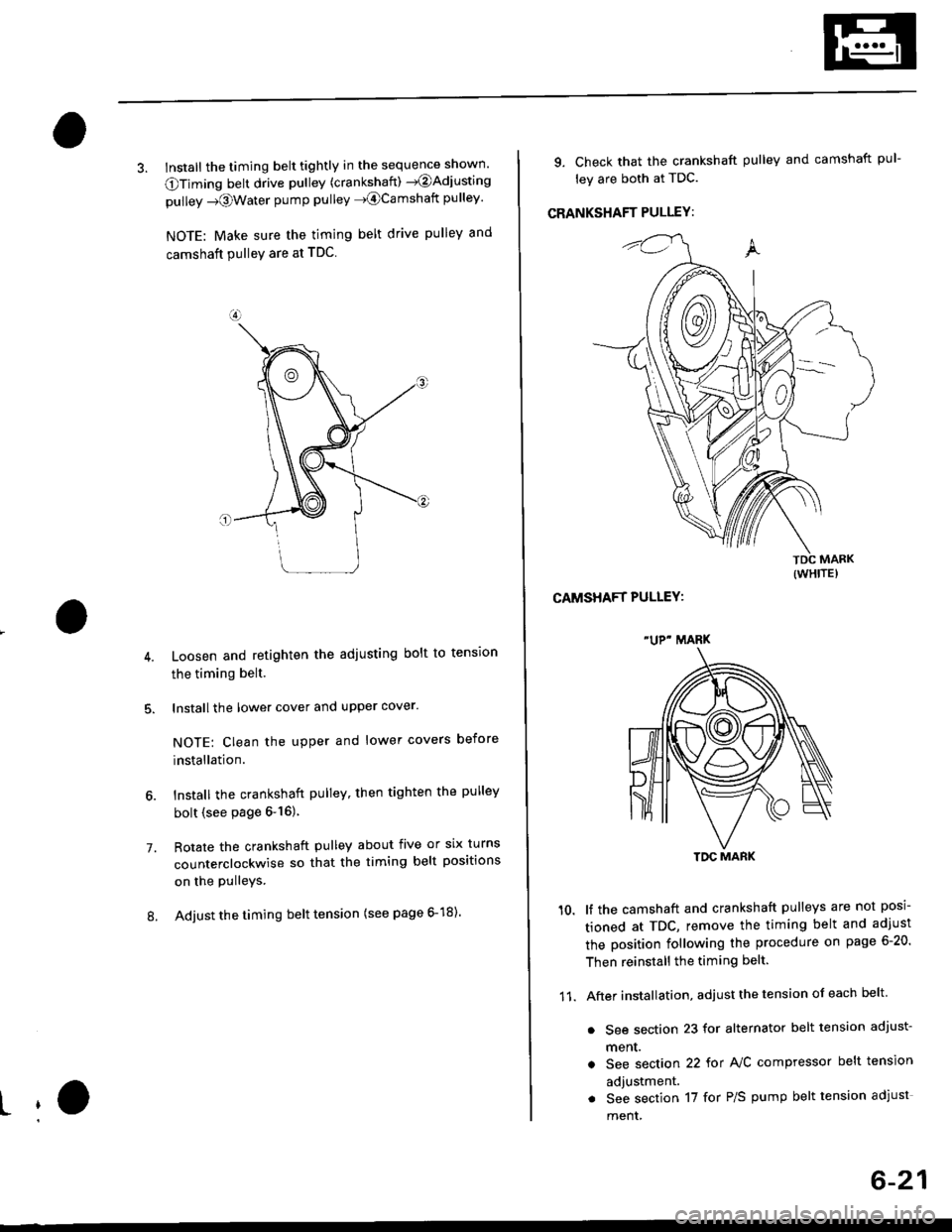

3. Install the timing belt tightly in the sequence shown'

OTiming belt drive pullev (crankshaft) )@Adjusting

pulley -towater pump pulley J@Camshatt pulley'

NOTE: Make sure the timing belt drive pulley and

camshaft PulleY are at TDC

7.

Loosen and retighten the adiusting bolt to tension

the timing belt.

lnstall the lower cover and upper cover.

NOTE: Clean the upper and lower covers before

installation.

lnstall the crankshaft pulley, then tighten the pulley

bolt (see page &16)

Rotate the crankshaft pulley about five or six turns

counterclockwise so that the timing belt positions

on the Pulleys.

Adjust the timing belt tension (see page 6-18).8.

L

9. Check that the crankshaft pulley and camshaft pul-

ley are both at TDC.

CRANKSHAFT PULLEY:

CAMSHAFT PULLEY:

lf the camshaft and crankshaft pulleys are not posi-

tioned at TDC, remove the timing belt and adjust

the position following the procedure on page 6-20'

Then reinstall the timing belt.

After installation, adjust the tension of each belt

. See section 23 for alternator belt tension adjust-

ment.

a See section 22 tot NC compressor belt tension

adjustment.

. See section 17 for P/S pump belt tension adjust

ment,

(wHrTE)

"UP" MARK

TDC MARK

11.

6-21

Page 138 of 2189

Removal

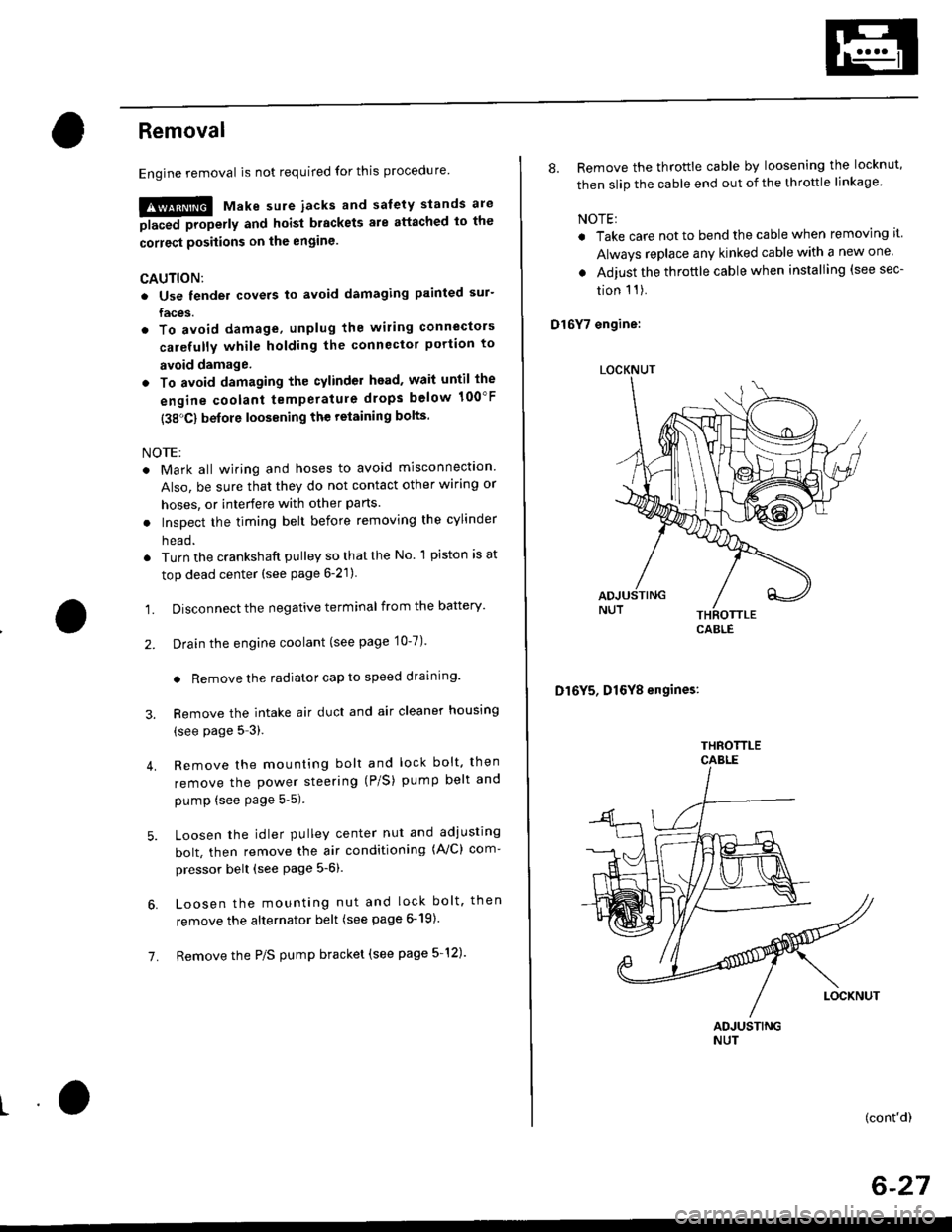

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE

Page 141 of 2189

Cylinder HeadRocker Arms

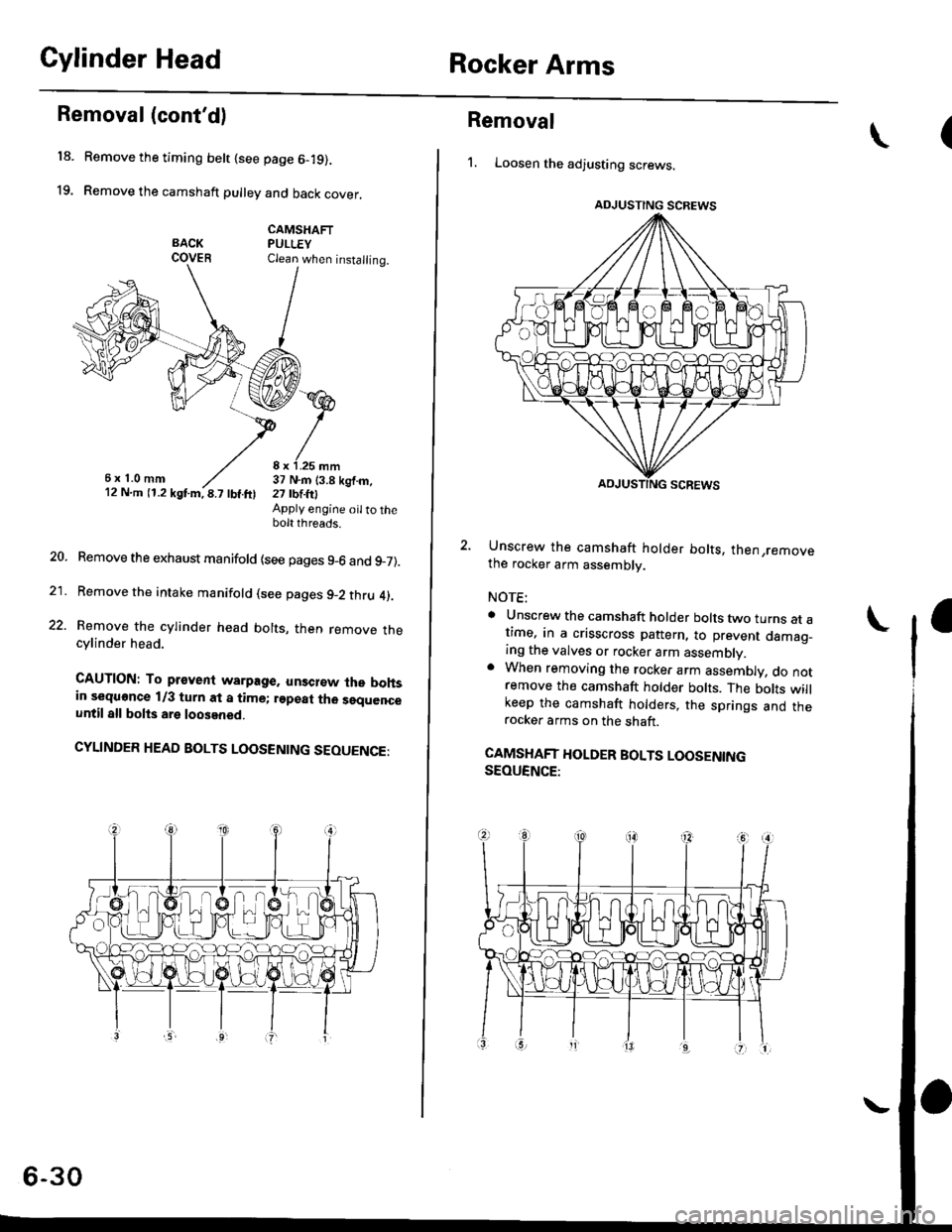

18.

19.

21.

22.

Removal (cont'd)

Remove the timing belt {see page 6-19).

Remove the camshaft pulley and back cover,

CAMSHAFTPULLEYClean when installing.

6x1.0mm8 x 1.25 mm37 N.m (3.8 kgf.m,21 tbtlrlApply engine oilto thebolt threads.

Remove the exhaust manifold {see pages 9-6 and 9_7).

Remove the intake manifold (see pages 9-2 thru 4).

Remove the cylinder head bolts, then remove thecylinder head.

CAUTION: To pr€vent warpage, unsclew lhe bohsin sequonce 1/3 turn at a time; rgpeat tho sequenceuntil all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENGE:

6-30

Removal

1. Loosen the adjusting screws.

2. Unscrew the camshaft holder bolts, then,removethe rocker arm assembly.

NOTE:

a Unscrew the camshaft holder bolts two turns at at,me, in a crisscross pattern, to prevent damao_ing the valves or rocker arm assembly.. When removing the rocker arm assembly, do notremove the camshaft holder bolts. The bolts willkeep the camshaft holders, the springs and therocker arms on the shaft.

CAMSHAFT HOLDER BOLTS LOOSENINGSEOUENCE:

\(

ADJUSTING SCREWS

Page 148 of 2189

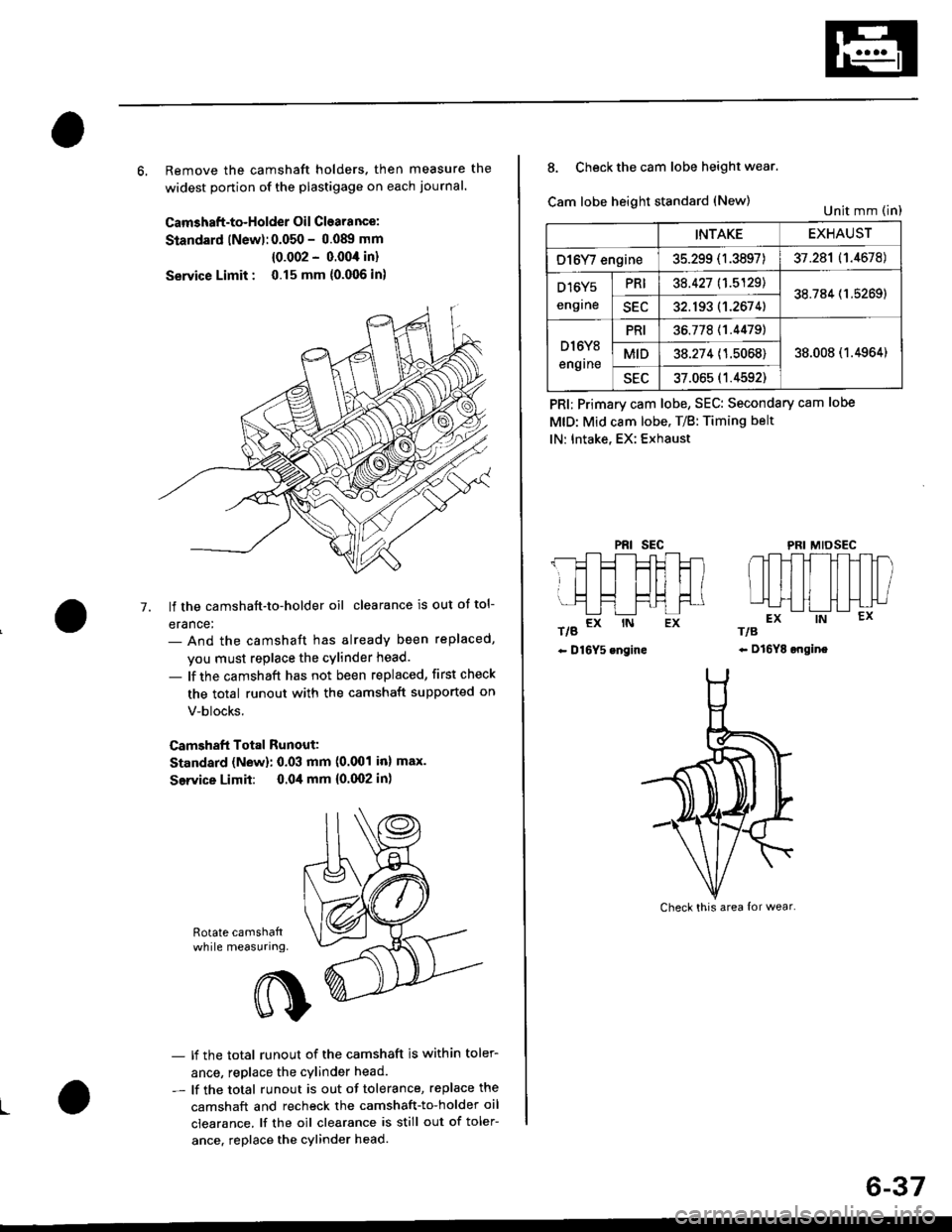

6, Remove the camshaft holders. then measure the

widest ponion of the plastigage on each journal.

Camshaft-to-Holder Oil Clearance:

Standard lNew):0.050 - 0.08!t mm

{0.002 - 0.004 in}

Service Limit : 0.15 mm {0.006 in)

lf the camshaft-to-holder oil clearance is out ot tol-

erance:- And the camshaft has already been replaced,

you must replace the cylinder head.

- lf the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Camshaft Total Runout:

Standard (New): 0.03 mm (0.001 inl max.

Service Limit: 0.04 mm {0.(X)2 in)

-7.

Rotate camshattwhile measuring.

L

- lf the total runout of the camshaft is within toler-

ance, replace the cylinder head.

- lf the total runout is out of tolerance, replace the

camshaft and recheck the camshaft-to-holder oil

clearance. lf the oil clearance is still out of toler-

ance. replace the cylinder head.

INTAKEEXHAUST

O16Y/ engine35.299 (1.3897)37.281 (1.4678)

D16Y5

engrne

PRI38.427 11.5129138.784 (1.5269)

SEC32.193 (1.2674)

D l6Y8

engrne

PRI36.77811.44791

38.008 (1.4964)MID38.274 (1.5068)

sEu37.065 (1.4592)

8. Check the cam lobe height wear.

Cam lobe height standard (New)

t/g a* rN Ex

- D16Y5 engine

PRI; Primary cam lobe, SEC: Secondary cam lobe

MtD: Mid cam lobe. T/B: Timing belt

lN: Intake, EX: Exhaust

PRIsEcMIDSEC

rts

- Dl6YE ongine

Unit mm (in)

Check this area {or wear.

6-37