brake light HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 724 of 2189

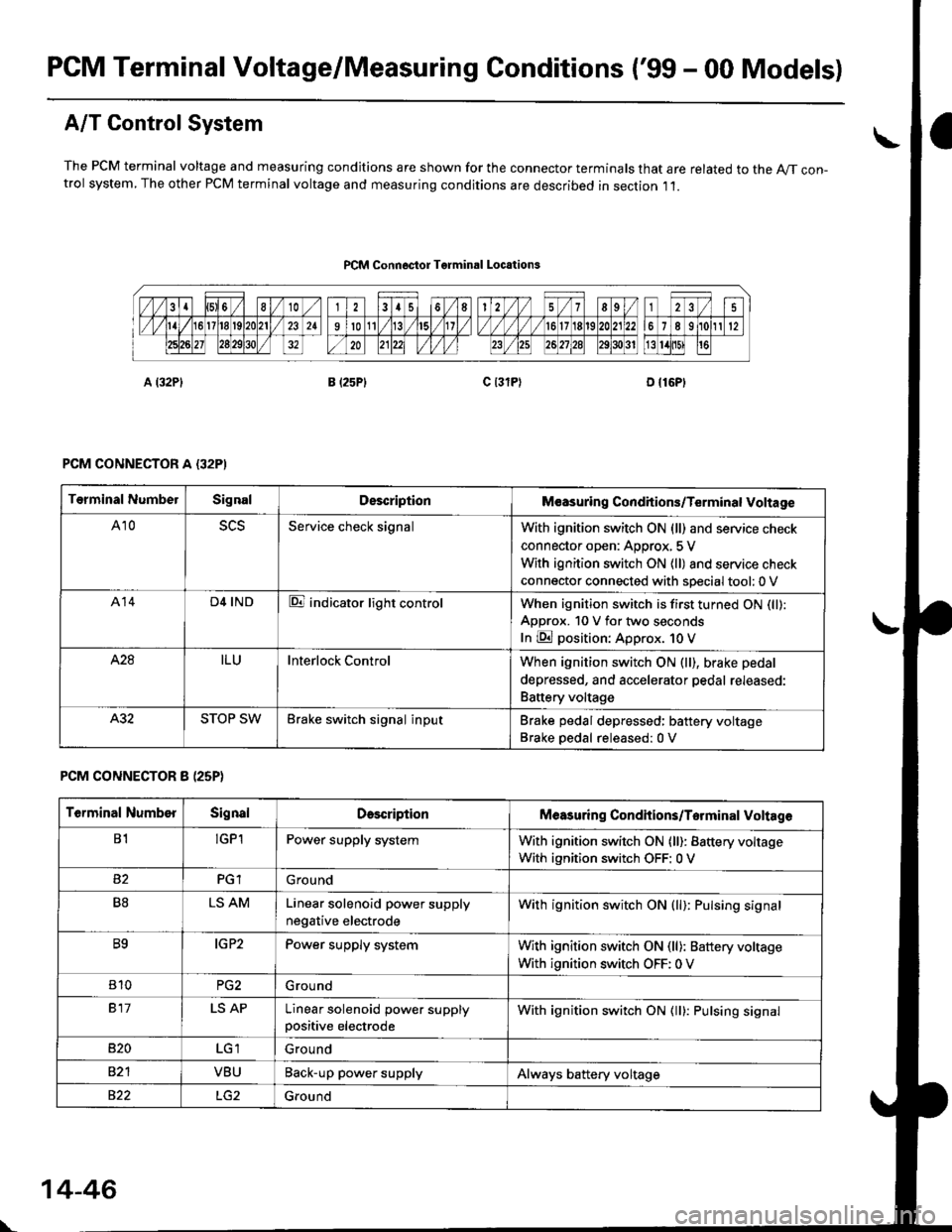

PCM Terminal Voltage/Measuring Conditions ('99 - 00 Models)

A/T Control System

The PCM terminal voltage and measuring condjtions are shown for the connector terminals that are related to the A//T con-trol system, The other PCM terminal voltage and measuring conditions are described in section ,11.

PCM Connoctor Tgrminrl Locations

PCM CONNECTOR A {32PI

PCM CONNECTOR 8 (25P}

Terminal NumbelSignalDescriptionM€asuring Conditions/Terminal Voltage

A105L5Service check signalWith ignition switch ON (ll) and service check

connector open: Approx, 5 V

With ignition switch ON (ll) and service check

connector connected with sDecial tool: 0 V

A14D4 INDE indicator light controlWhen ignition switch is first turned ON (ll):

ApDrox. 10 V for two seconds

In E position: Approx. 1O V

428ILUInterlock ControlWhen ignition switch ON (ll), brake pedal

depressed, and accelerator pedal rereaseo:

Battery voltage

A.32STOP SWBrake switch signal inputBrake pedal depressed: battery voltage

Brake oedal released:0 V

Terminal NumberSignalDescdptionMeasuring Condhions/Torminal Voltag6

B1!GP1Power supply systemWith ignition switch ON (ll): Battery voltage

With ignition switch OFF: 0 V

PGlGround

B8LS AMLinear solenoid power supply

negative electrode

With ignition switch ON (ll): Pulsing signal

B9IG P2Power supply systemWith ignition switch ON (ll): Baftery voltage

With ignition switch OFF: 0 V

810PG2G rou nd

917LS APLinear solenoid power supplypositive electrode

With ignition switch ON (ll): Pulsing signal

B�20Ground

VBUBack-up power supplyAlways battery voltage

822Ground

\

14-46

Page 731 of 2189

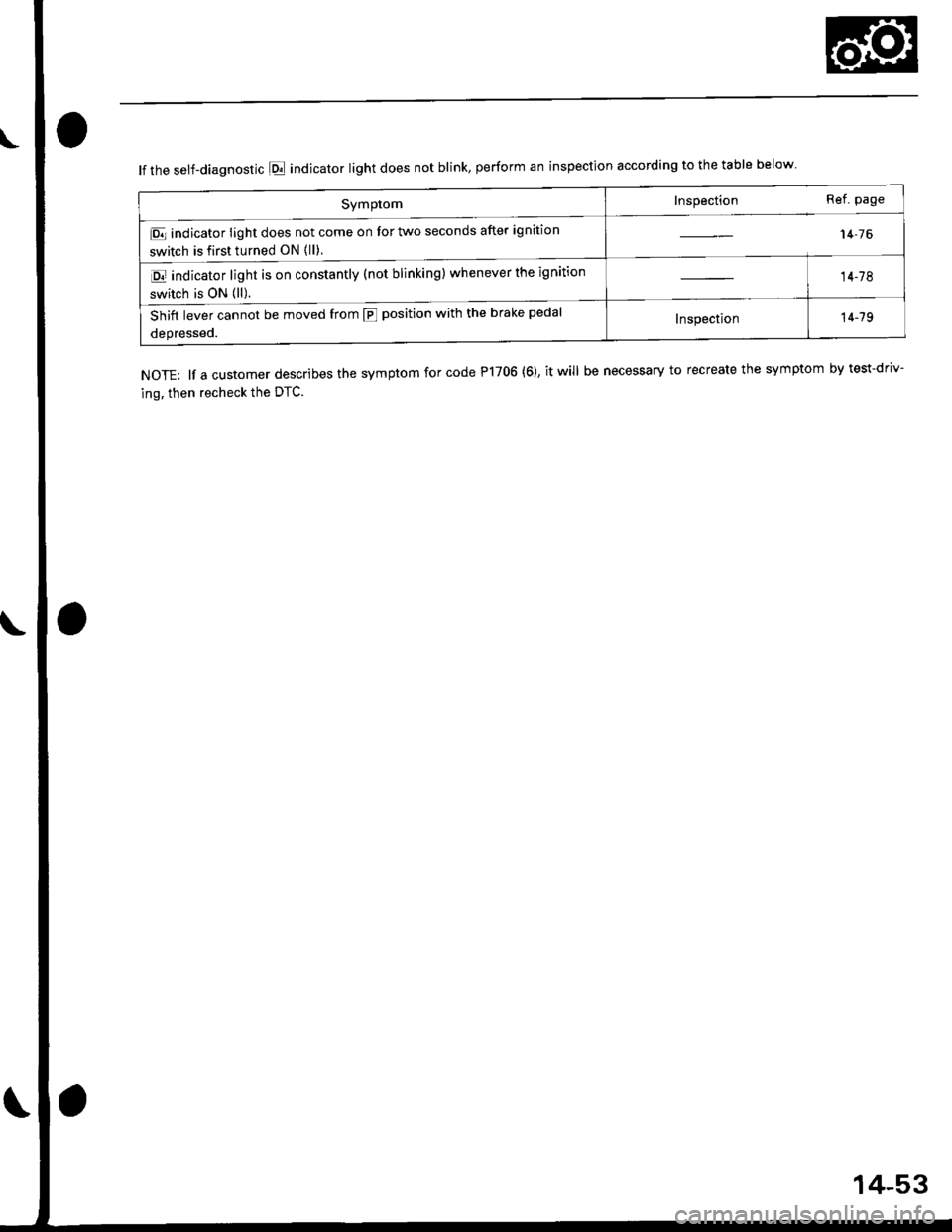

SYmPtom

E indicator light does not come on tor two seconds after ignition

switch is first turned ON {ll}.

E indicator light is on constantly (not blinking) whenever the ignition

switch is ON (ll).

Shift lever cannot be moved from @ position with the brake pedal

depressed.

Inspection Ref. Page

11-16

14-78

Inspection't4-79

lf the self-diagnostic l-d indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code Pl706 {6), it will be necessary to recreate the symptom by test-driv-

ing, then recheck the DTC.

14-53

Page 733 of 2189

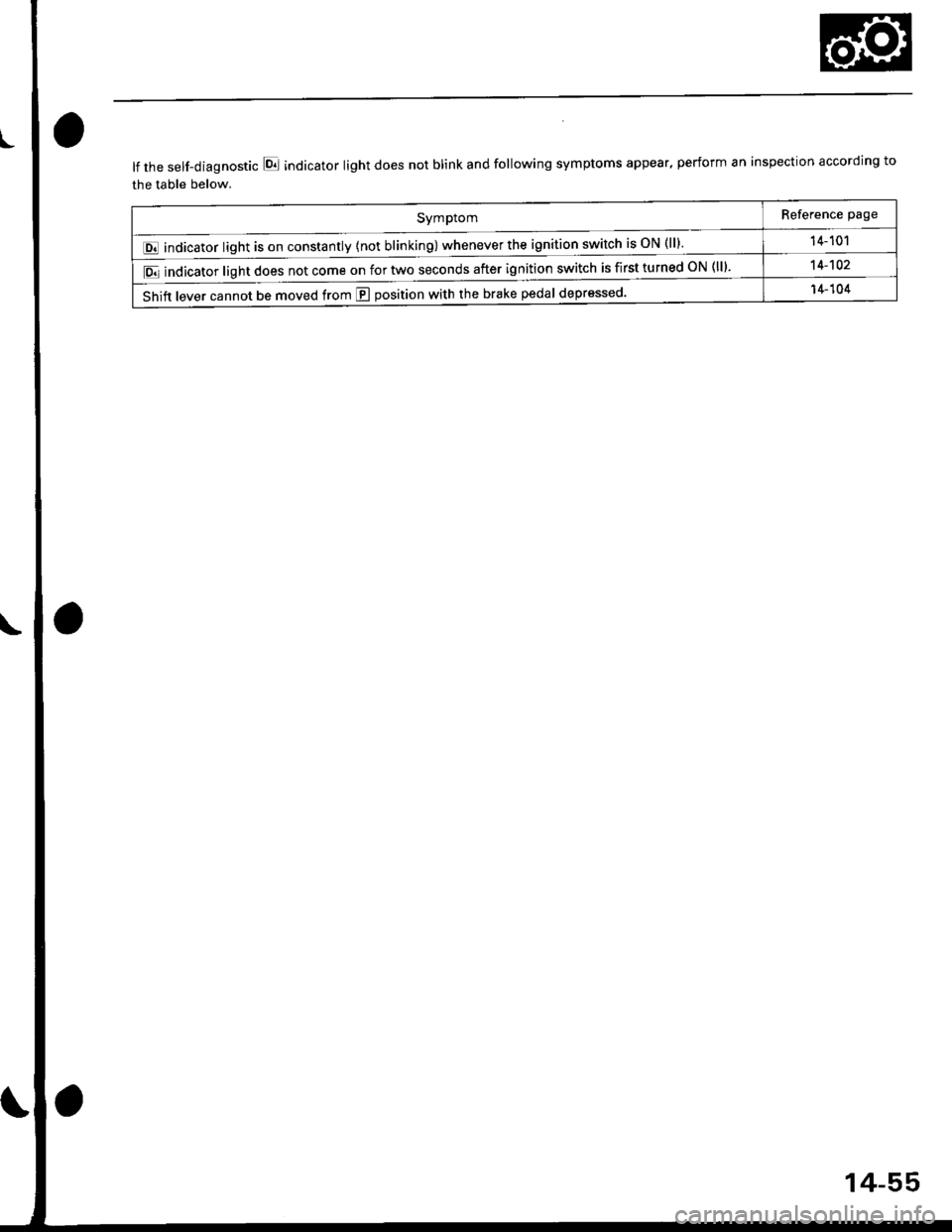

E i"dl.r." fiSh, 1."""". y{*fu

Reference page

14- 101

lE indicator light does not come on for two seconds after ignition switch is first turned oN (ll).14-102

Shift lever cannot be moved from E position with the brake pedal deprsssed'14-104

lf the self-diagnostic E indicator light does not blink and following symptoms appear, perform an inspection according to

the table below.

14-55

Page 757 of 2189

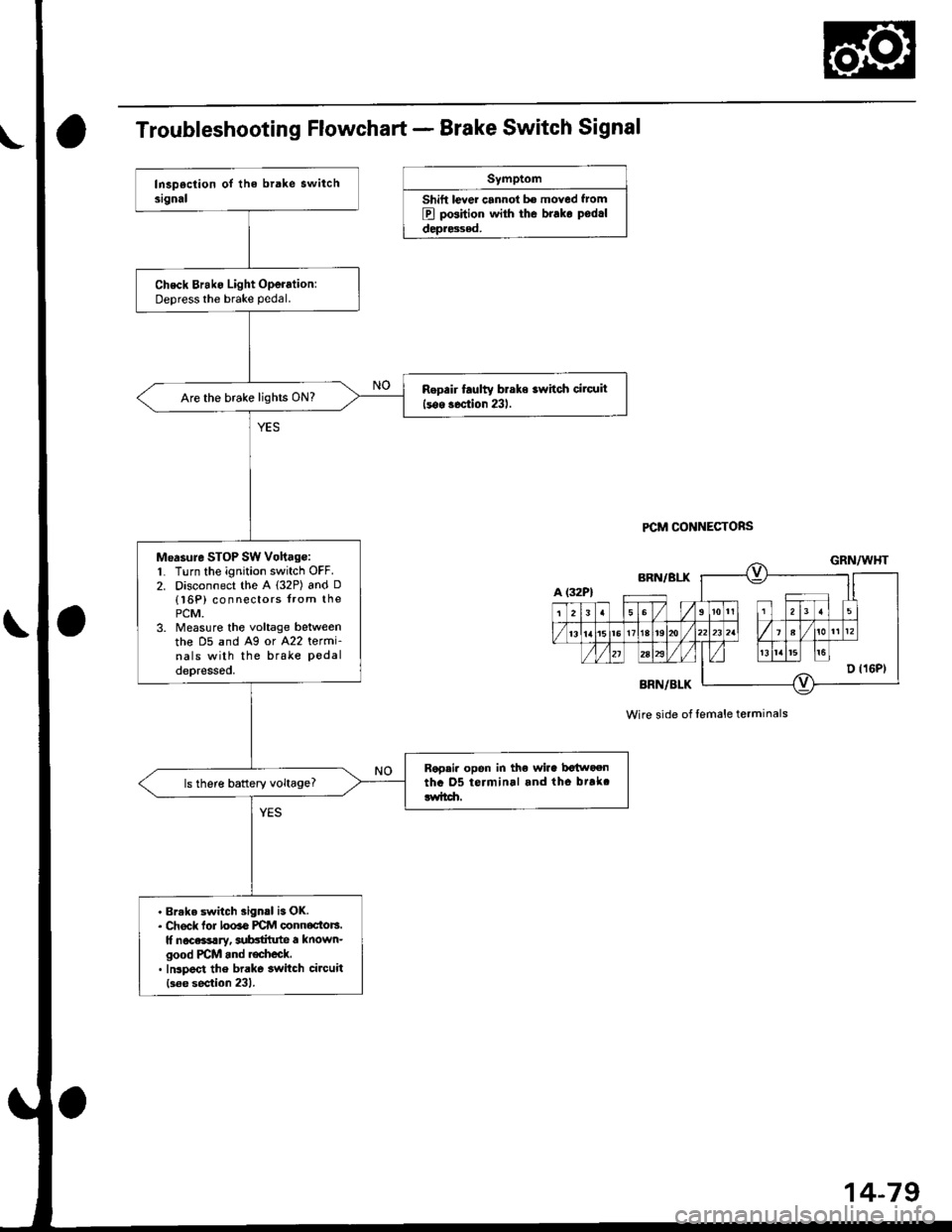

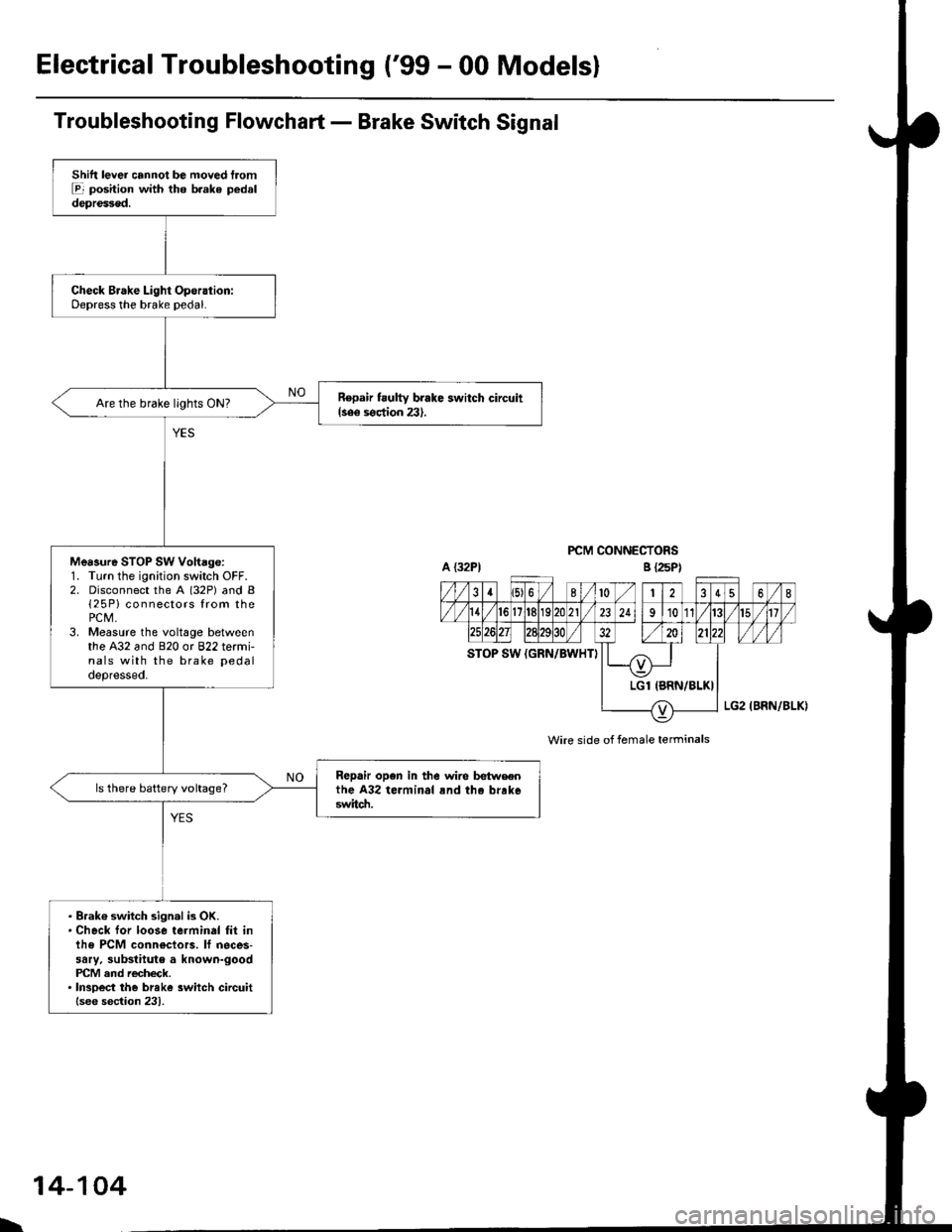

Troubleshooting Flowchart - Brake Switch Signal

Symptom

Shift lever cannol b€ moved f.om

B pGition with the brako podrl

depr8sed.

PCM CONNECTORS

Check Brako Light Operation:Deoress the brake pedal.

Rop.ir faulty braks switch cilcuit

lsos soction 231.Are the brake lights ON?

Measure SToP SW Vohag€:1. Turn the ignition switch OFF.2. Disconnect the A l32P) and D

{l6P) connectors from thoPCM.3. Measure the voltage belweenthe D5 and A9 or A22 termi-nals with the brake Pedaldepressod.

Rap.i. opon in the wira bctn oentha 05 terminal and tho btrkclwitdr.ls there battery voltage?

. Brake switch 3ign.l is OK.. Ch6ck lor looao PCM oonnoctors.It nocassary, aubctilute a known-good PCM and r€check.. Inspoct the brake switch circuit

{s6e section 231.

Wire side of lemale terminals

Page 782 of 2189

ElectricalTroubleshooting ('99 - 00 Modelsl

Troubleshooting Flowchart - Brake Switch Signal

PCM CONNECTORS

Wire side of female terminals

Shift lever cannot be moved tromE position with tho b.ake pedaldepressod.

Check Brake Light Operation:Depress the brake pedal.

Repair t ulty brake switch circuit{see s€ction 23}.Are the brake llghts ON?

Mea3ure STOP SW Vohage:1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B{25P} connectors from thePCM,3. Measure the voltage betweenthe A32 and 820 or 822 termi-nals with the brake pedal

depressed.

Repair open in the wire betwsenthe A32 terminal rnd tho brrk6switch.

ls there battery voltage?

. Brak€ switch sign.l is OK.. Check for loose terminal fil inlhe PCM conn€ctors. lf neces-sary. substitute a known-goodPICM and recheck.. InsDect the breke 3witch circuitlsee section 231.

B {25P)

\

14-104

Page 920 of 2189

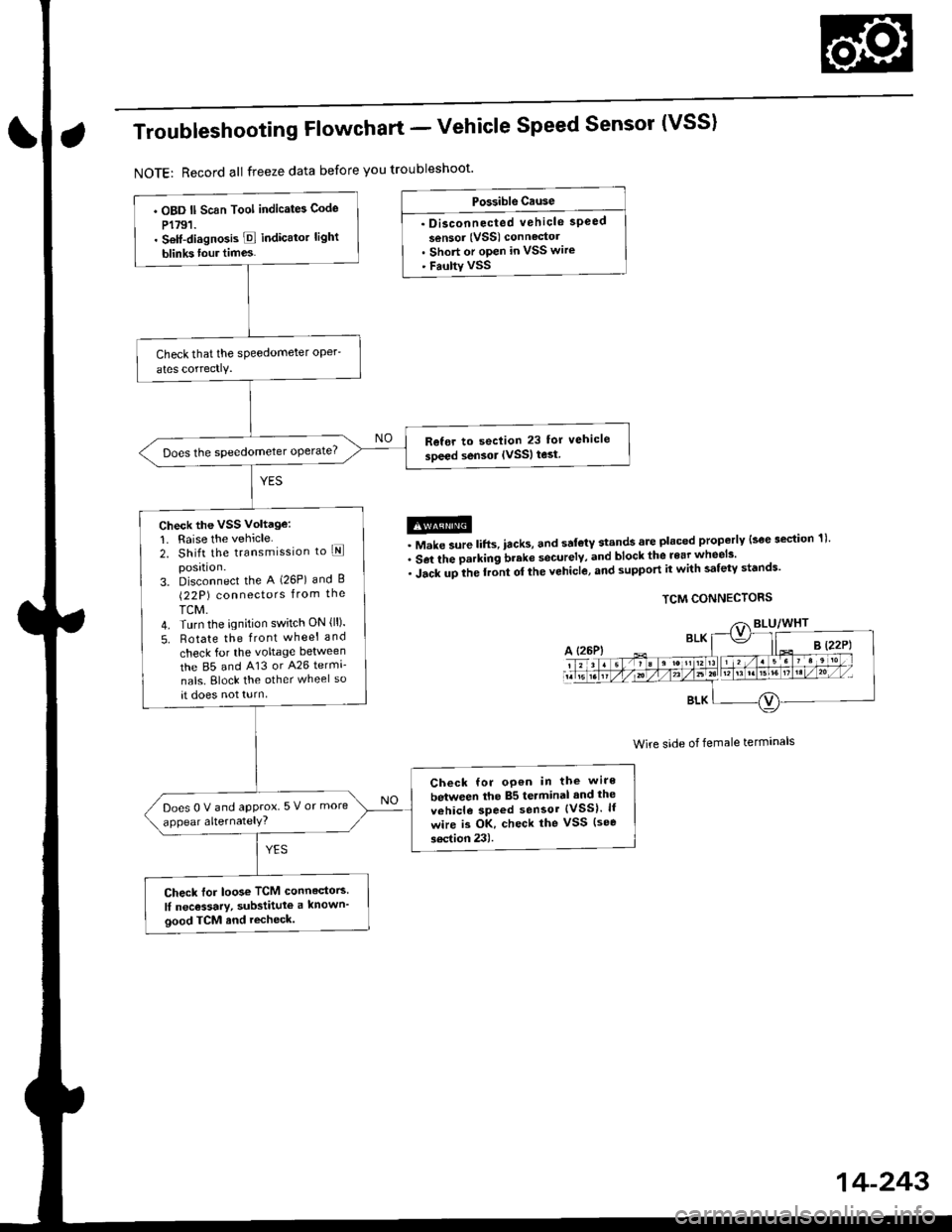

Troubleshooting Flowchart - Vehicle Speed Sensor (VSS)

NOTE: Record all freeze data before you troubleshoot'

Po$rible Ctuse

. Disconnected vehicle speed

sensor (VSS) connectol. Short or open in VSS wire' Faulty VSS

@. Make sure lifts, iacks, and sal€tY stands are placed properly lsoe section 1)'

. Set the parking brake securelv, and block the rear wheels'

. iacr upile rront or the vehicle, and support it with safety st'nds'

TCM CONNECTORS

Wire side of female terminals

. OBD ll Scan Tool indicates Code

P1791.. Setf-diagno3is E indicato. light

blinks tour times.

Refer to seclion 23 for vehicle

soeed sensor IVSSI test

Check the VSS Voltage:

1. Raise the vehicle2. Shift the transmission to lEposrtlon.3. Disconnect the A (26P) and B(22P) connectors from the

TCM.4. Turn the ignition switch ON {ll).

5. Rotate the front wheel and

check for the voltage between

the 85 and 413 or A26 termi-

nals. Block the other wheel so

at does not turn

Check for oP€n in the wire

between the 85 terminal and the

vehicle speed sensor {VSS}. lf

wire is OK, check the vSS (see

soction 23).

Does0Vandapprox 5 V or more

appear alternatelY?

Check for loos€ TCM connedors

lI nec€ssary, substitute a known'

good TCM and recheck.

14-243

Page 970 of 2189

Start Clutch Control@

T

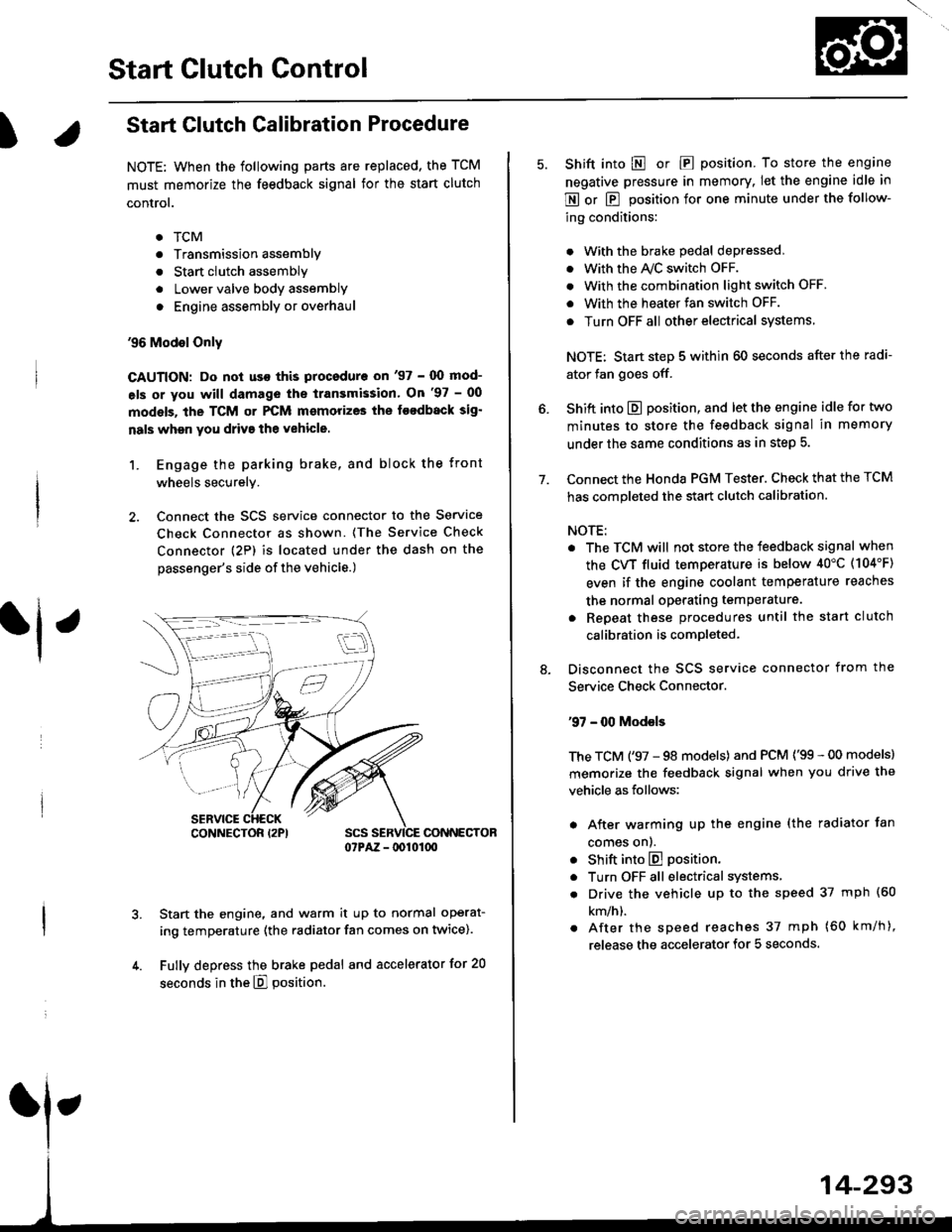

Start Clutch Calibration Procedure

NOTE: When the following parts are replaced, the TCM

must memorize the feedback signal for the start clutch

control.

. TCM

. Transmissionassembly

. Stan clutch assembly

. Lower valve bodv assembly

. Engine assembly or overhaul

'96 Model Only

CAUTION: Do not uso this procsdure on'97 - (X) mod-

els or you will damage the transmission. On '97 - 00

models, the TCM or PCM memorizes ths loodback sig'

nals when you drive the vehicle.

1. Engage the parking brake, and block the front

wheels securely.

2. Connect the SCS service connector to the Service

Check Connector as shown. (The Service Check

connector (2P) is located under the dash on the

passenger's side of the vehicle.)

CONNECTOR07PAZ - lDl01(xt

Start the engine, and warm it up to normal operat-

ing temperature (the radiator fan comes on twice).

Fully depress the brake pedal and accelerator for 20

seconds in the E] position.

rl ,

CONNECTOR I2PI

14-293

7.

Shift into E o|. E position. To store the engine

negative pressure in memory. Iet the engine idle in

E or E position for one minute under the follow-

ing conditions:

. With the brake pedal depressed,

. with the y'\/c switch oFF.

. With the combination light switch OFF.

. With the heater fan switch OFF.

. Turn OFF all other electrical systems

NOTE: Start step 5 within 60 seconds after the radi-

ator fan goes off.

Shift into E position, and let the engine idle for two

minutes to store the feedback signal in memory

under the same conditions as in step 5.

Connect the Honda PGM Tester. Check that the TCM

has completed the start clutch calibration.

NOTE:

. The TCM will not store the feedback signal when

the CVT fluid temperature is below 40"C (104'F)

even if the engine coolant temperature reaches

the normal operating temperature.

. Repeat these procedures until the start clutch

calibration is completed-

Disconnect the SCS service connector from the

Service Check Connector.

'97 - 00 Models

The TCM ('97 - 98 models) and PCM ('99 - 00 models)

memorize the feedback signal when you drive the

vehicle as follows:

. After warming up the engine (the radiator fan

comes onl.

. Shift into E position.

. Turn OFF all electrical systems,

. Drive the vehicle up to the speed 37 mph (60

km/h).

. After the speed reaches 37 mph (60 km/h),

release the accelerator for 5 seconds.

Page 977 of 2189

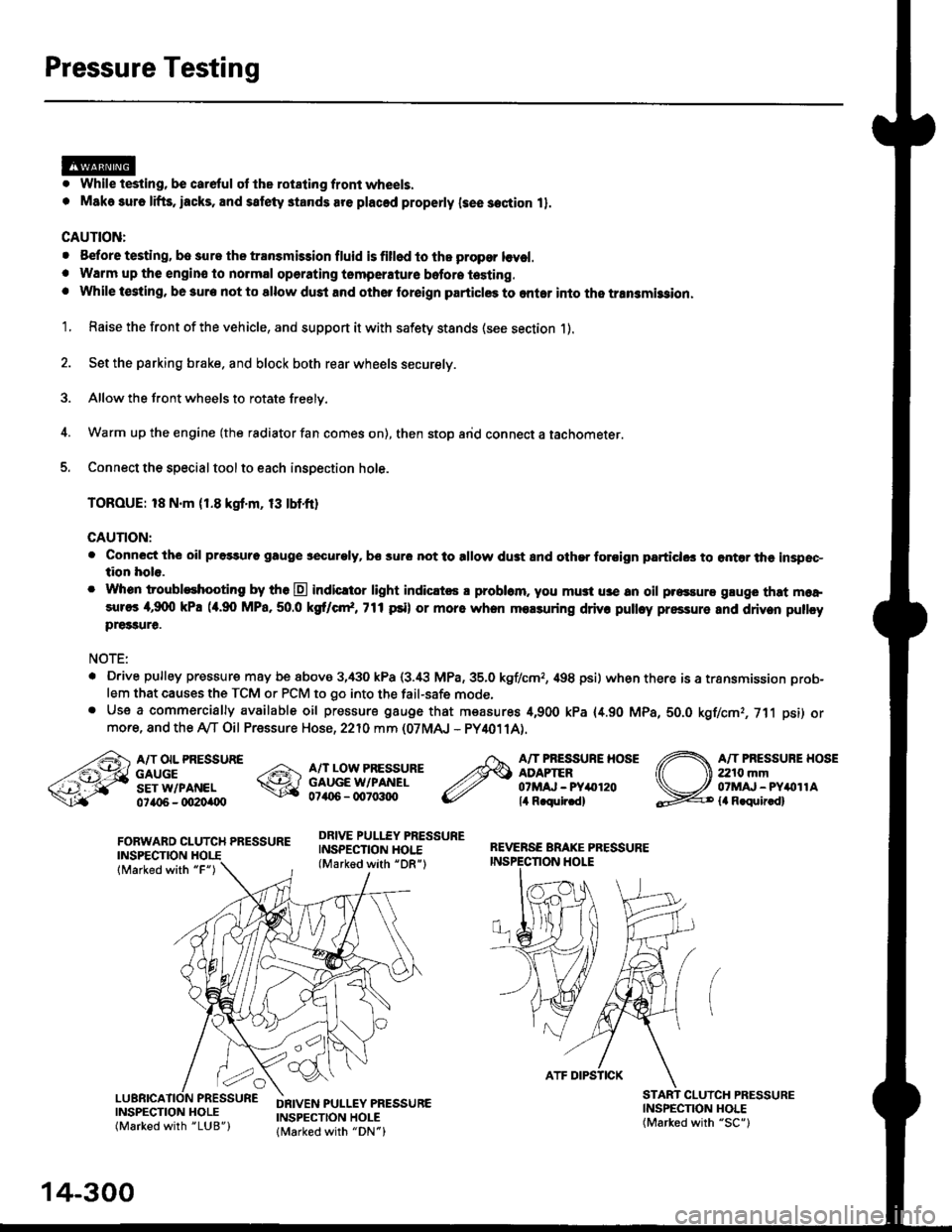

Pressure Testing

. While testing, be careful of the rot8ling front wheels.

. M8k6 suro lifts, iacks, and satety stands are placed properly lsee section 11.

CAUTION:

. Before testing, be sur. the transmb3ion fluid is fillod to the propor lcvel.. Warm up the engin€ to nolmal operating tsmperature bofore testing. While t€sting, be 3ure not to allow dust and other loreign particles to onler into the transmi$ion.

1. Raise the front of the vehicle, and support it with safety stands (see section 1).

2. Set the parking brake. and block both rear wheels securely.

3. Allow the front wheels to rotate freely.

4. Warm up the engine (the radiator fan comes on), then stop arid connect a tachometer.

5. Connect the special tool to each inspection hole.

TOROUE: 18 N.m (1.8 kgt'm, 13 tbtfr)

GAUTION:

. Connect the oil pressuro gauge !!€curoly, bs sur6 not to allow dust and other foroign particlG3 to ontar the inspsc-tion hole.

. Whon troubleshooting by tho E indicltor light indic.t6 a problam. you mu3t u3e an oil p.essure gluge that moa,sures 4,9(X) kPa (a.90 MPa,50.0 kS cr*,771psi) or more when molsuring driv. pulley pressure and driven pullcypre33ure.

NOTE:

. D.ive pulley pressure may be above 3,430 kPa (3.i8 MPa,35.0 kgf/cmr, 498 psi) wh€n there is a transmission prob-

lem that causes the TCM or PCM to go into the fail-safe mode,. Use a commercially available oil pressure gauge that measures 4,900 kPa {4.90 MPa, 5O.O kgf/cmr, 711 psi) ormore, and the Ay'T Oil Pressure Hose, 2210 mm (07MAJ - PY4011A).

FORWARD CLUTCH PRESSUREINSPECTION

lMarked with "F")

REVERSE BRAKE PRESSUREINSPECTION I.IOLE

A/T OIL PRESSUREGAUGESET W/PANEL0ta{r6 - oO2Oi|(Xt

A/T LOW PRESSUREGAUGE W/PANEL0706 - qt7o:t{ro

DRIVE PULLEY PRESSUREINSPECTION HOI.E(Marked with "DR")

A/T PRESSURE HOSEADAPTER07MAJ - PYar'120lil R.qulr.d)

A/T PRESSUBE HOSE2210 mm07MAJ - PYitollAla R.quir.d)

(

INSPECNON HOLE(Marked with "SC")

CLUICH PRESSURE

INSPECTION HOLE(Marked with "LUB")

DRIVEN PULLEY PRESSUREINSPECTION HOLElMarked with "DN")

14-300

ATF DIPSTICK

Page 1135 of 2189

)

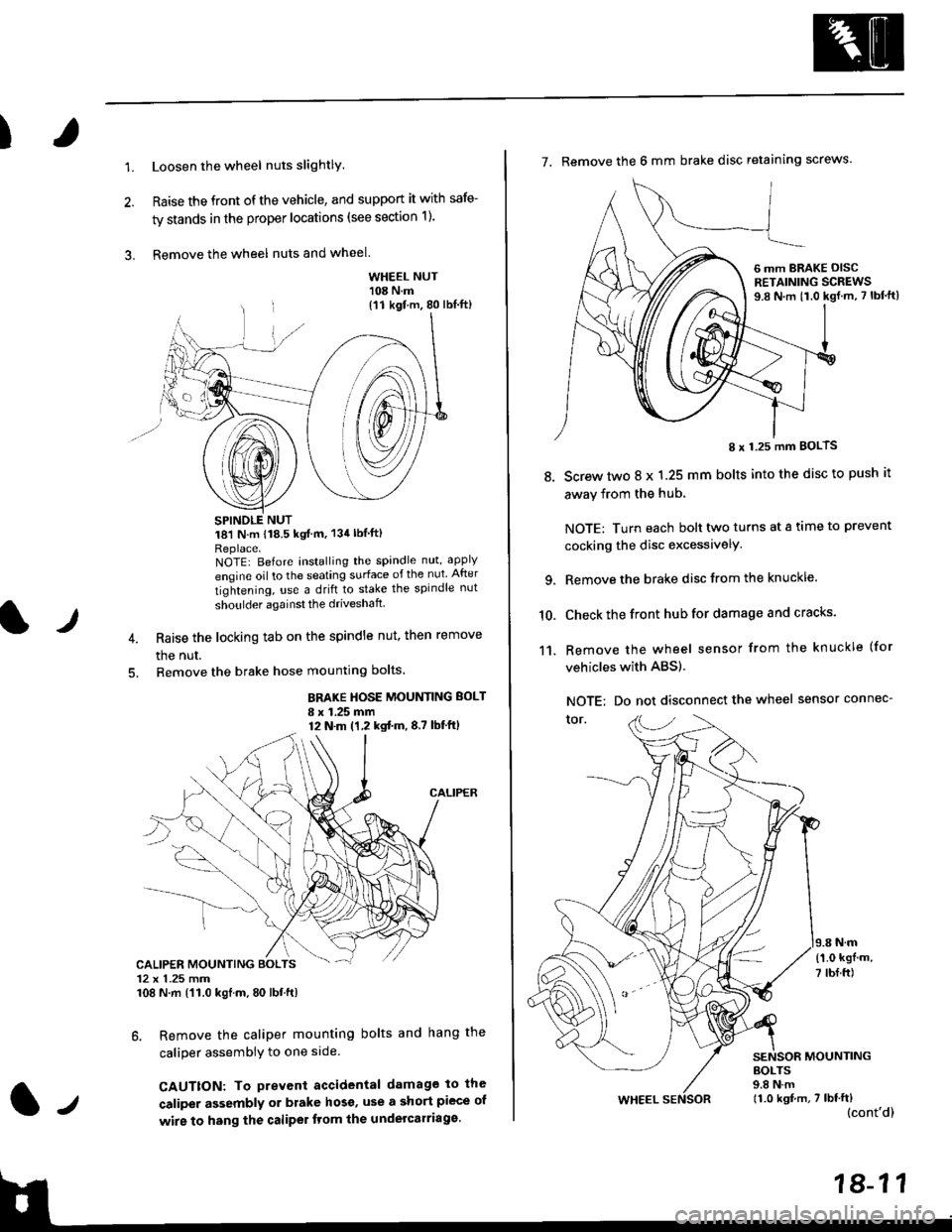

1.Loosen the wheel nuts slightlY.

Raise the front of the vehicle, and support it with safe-

ty stands in the proper locations (see section 1).

Remove the wheel nuts and wheel.3.

l)

WHEEL NUT'108 N.m

18'l N.m 118.5 kgf m, 134lblfti

Replace.NOTEI Before installing the spandle nut, apply

engine oil to the seating surface of the nut After

tightening, use a drift to stake the spindle nut

shoulder againsl the driveshaft

Raise the locking tab on the spindle nut, then remove

the nut.

Remove the brake hose mounting bolts.

BRAKE HOSE MOUNTING BOLT

I x 1.25 mm12 N.m (1,2 kgtm,8,7 lbf'ftl

6. Remove the caliper mounting bolts and hang the

caliper assembiy to one side

CAUTTON: To prevent accidental damage to the

caliper assembly or brake hoso' use a short piece of

wire to hang the caliPer tlom lhe undelcarriage.

{11 kgf m, 80 lbl.ft)

CALIPER MOUNTING BOLTS12 x 1.25 mm108 N.m {'11.0 kgtm, 80 lbt.ft)

7. Remove the 6 mm brake disc retaining screws.

8.

I x 1.25 mm BOLTS

Screw two 8 x 1.25 mm bolts into the disc to push it

away from the hub,

NOTE: Turn each bolt two turns at a tame to prevent

cocking the disc excessivelY.

Remove the brake disc from the knuckle.

Check the front hub for damage and cracks.

Remove the wheel sensor from the knuckle (for

vehicles with ABS).

NOTE: Do not disconnect the wheel sensor connec-

tor.

N.m

6 mm BRAKE OISCRETAINING SCREWS9.8 N.m t1.0 kgf.m, 7 lbf'ft)

{'1.0 kgf m,

7 tbf.ft)

10.

11.

MOUNTING

WHEEL

BOLTS9.8 N.m11.0 kgf,m, 7 lbf'ft)(cont'd)

Page 1148 of 2189

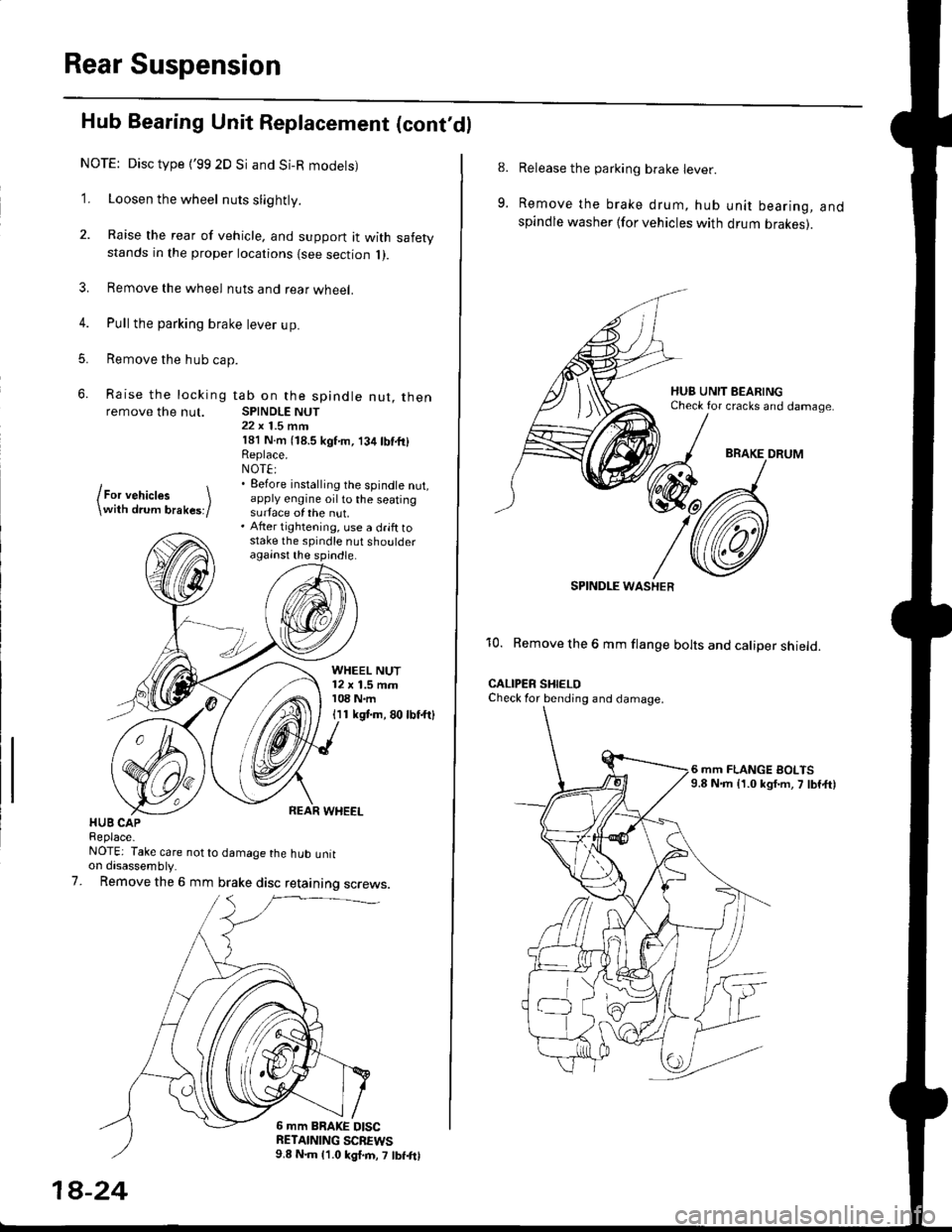

Rear Suspension

Hub Bearing Unit Replacement (cont'dl

NOTE: Disc type {'99 2D Si and Si-R modets)

1. Loosen the wheel nuts slightly.

2. Raise the rear of vehicle, and support it with safetystands in the proper locations {see section 1).

3. Remove the wheel nuts and rear wheel.

4. Pull the parking brake lever up.

5. Remove the hub cap.

6. Raise the locking tab on the spindle nut, thenremove the nut. SPINDLE NUT22 x 1.5 mrn181 N.m (18.5 kgf'm, 134lbf.fi)Replace.NOT€:. Eefore installing the spindle nut,apply engine oil to the seatingsurface of the nut.. After tightening, use a drift tostake the spindle nut shoulderagainst the spindle.

lFor vehictes \\with drum brakes;/

WHEEL NUT12 x 1.5 mm108 N.m

I I 1 kgt m, 80 lbf.ftl

HUB CAPReplace-NOTE: Take care not to damage the hub untton disassembly.

Remove the 6 mm brake disc retaining screws.7.

6 mm BRAKE DISCRETAINING SCBEWS9.8 N.m 11.0 kgl.m, 7 lbf.frl

1A-24

8.

9.

Release the parking brake lever.

Remove the brake drum, hub unit bearing, andspindle washer lfor vehicles with drum brakes).

BRAKE DRUM

SPINDI-E WASHER

10. Remove the 6 mm flange bolts and caliper shield.

CALIPER SHIELOCheck for bending and damage.

6 mm FLANGE BOLTS9.8 N.m {1.0 kgf.m, 7 lbf,ft)