headlights HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

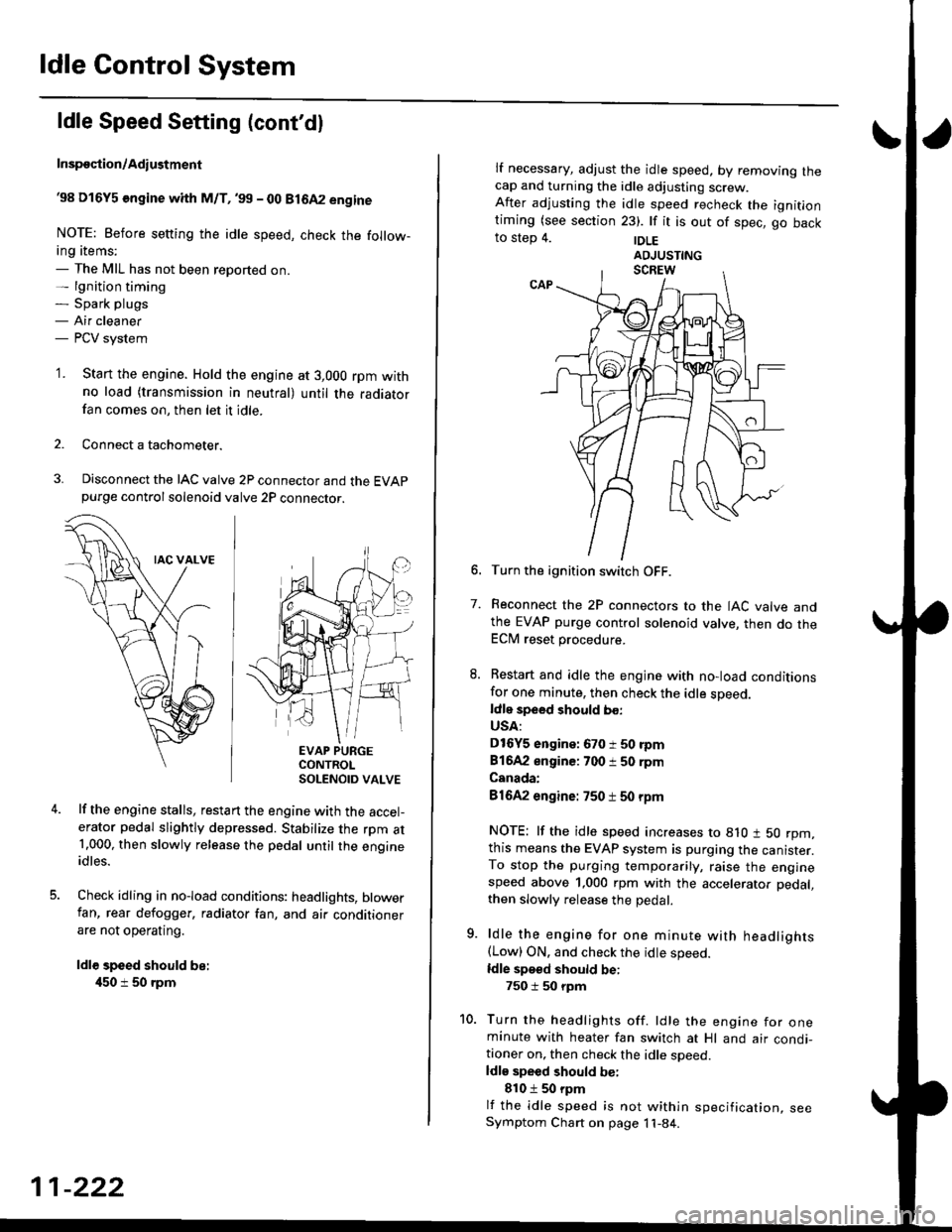

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 521 of 2189

Emission Gontrol System

System Description

The emission control system includes a Three Way Cata-lytic Convener (TWC), Exhaust Gas Recirculation (EGR)

system,. Positive Crankcase Ventilation (pCV) system andEvaporative Emission (EVAP) Control system. The emis-sion control system is designed to meet federal and stateemission standards.*: D16Y5 engine

Tailpipe Emission

Inspestion

@@ Do not smoke during ihis procedure. Keepany open flame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm withno load (in Park or neutral) until the radiator fancomes on. then let it idle.

2. Connect a tachometer.

Check and, if necessary, adjust the idle speed (see

page 11-220 - 223).

Warm up and calibrate the CO meter according to themeter manufacturer's instructions.

Check idle CO with the headlights, heater blower,rear window defogger, cooling fan, and air condition-er off.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

CO mete. should indicate 0.1% maximum.

NOTE: '98 Dl6Y5 engine - lf the idle speed incress-es to 8101 50 rpm, this means the EVAp system ispurging the canister. To stop the purging temporari-ly. raise the engine speed above 1,000 rpm with theaccelerator pedal, then slowly release the pedal.

11-252

eFORWARD -

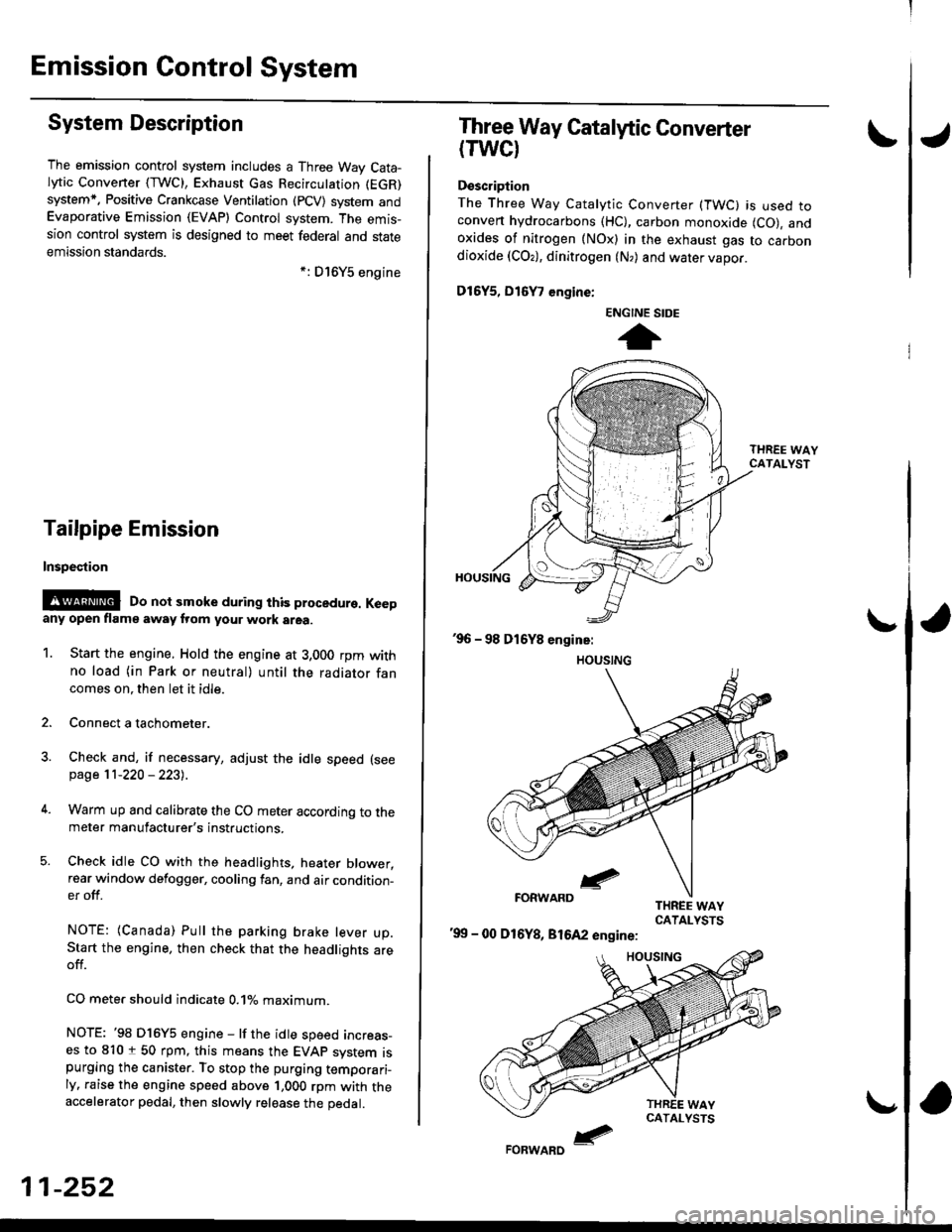

Three Way Catalytic Converter

(TWCI

Doscription

The Three Way Catalytic Converter (TWC) is used toconven hydrocarbons (HC), carbon monoxide (CO), andoxides of nitrogen (NOx) in the exhaust gas to carbondioxide (COr), dinitrogen (N,) and water vapor.

D15Y5, D16

, engine:

'99 - 00 D16Y8, 81642 engine:

ENGINE SIDE

t

Page 1575 of 2189

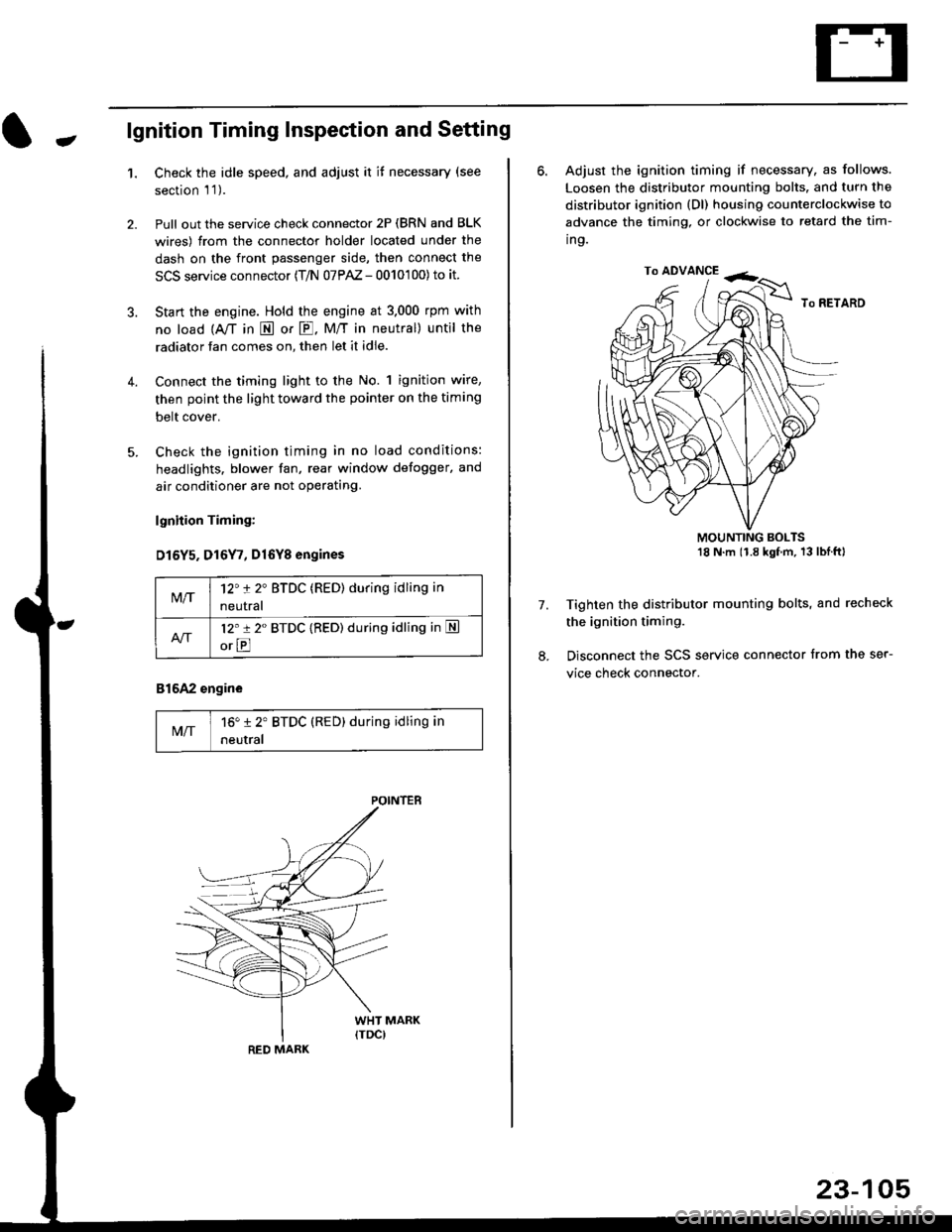

-lgnition Timing Inspection and Setting

1.Check the idle speed, and adjust it it necessary (see

section 'l '1 ).

Pull out the service check connector 2P (BRN and BLK

wires) from the connector holder located under the

dash on the front passenger side, then connect the

SCS service connector (T/N 07PAZ - 0010'100) to it.

Start the engine. Hold the engine at 3.000 rpm with

no load {A,/T in E or E. M/T in neutral) until the

radiator fan comes on, then let it idle.

Connect the timing light to the No. 1 ignition wire,

then point the light toward the pointer on the timing

belt cover.

Check the ignition timing in no load conditions:

headlights. blower fan, rear window defogger, and

air conditioner are not operating.

lgnhion Timing:

D15Y5. D16Y7, Dl6Yg engines

816A2 engine

MIT16" 12' BTDC (RED) during idling in

neutral

M/T12't 2" BTDC (RED) during idling in

neutral

l2'r 2" BTDC {RED) during idling in S

orE

POINTEB

RED MARK

23-105

ro ADVANCE -<;,

6. Adjust the ignition timing if necessary, as follows.

Loosen the distributor mounting bolts. and turn the

distributor ignition (Dl) housing counterclockwise to

advance the timing, or clockwise to retard the tim-

ing.

MOUNTING BOLTS18 N'm (1.8 kgfm, 13lblftl

Tighten the distributor mounting bolts, and recheck

the ignition timing.

Disconnect the SCS service connector from the ser-

vice check connector.

7.

Page 1586 of 2189

Charging System

Troubleshooting (cont'd)

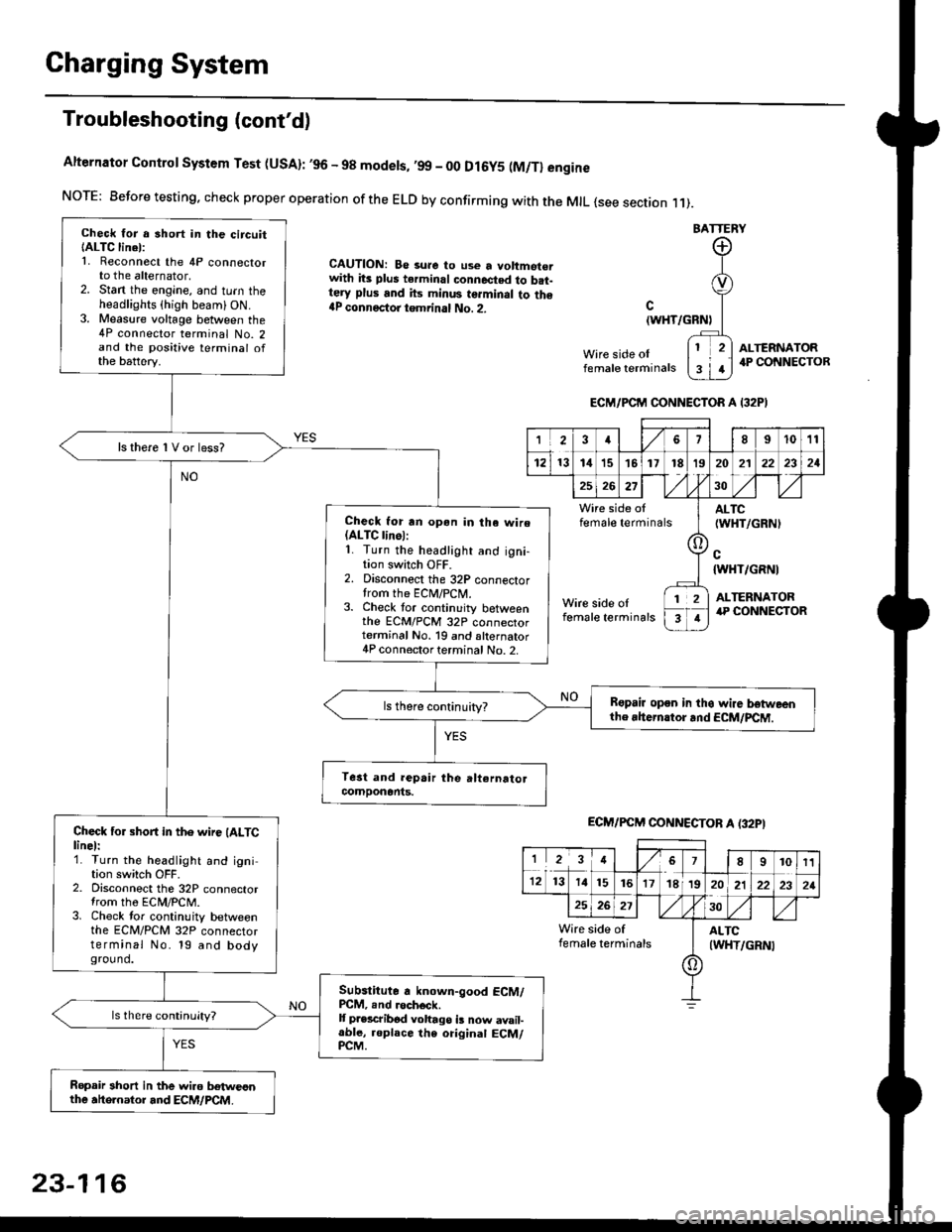

Alternator Control System Test (USA): ,96 - 98 modets, ,99 _ 00 Dl6y5 (M/Tl engine

NorE: Before testing. check proper operation of the ELD by confirming with the MrL {see section r 1).

BATTERY

CAUTION: Be 3ure to use a voltmot€.with its plus terminal connected to b.t-tery plus and its minus terminal to the{P connectoi tgmrinal No. 2.c

{WHT/GRNt

Wire side oIfemale terminals

ALTERNATOR.P CONNECTOB

Check for a 3hort in the circuitIALTC linel:1. Reconnect the 4P connectorto the alternator,2. Stan the engine, and turn theheadlights {high beam) ON.3. Measure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

ls there 1V or less?

Check for rn opon in tha wire(ALTC linol:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectortrom the ECM/PCN4.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and alternator4P connector terminal No. 2.

Bspair open in thg wire lrstweenthe rhern.tor .nd ECM/PCM.

Check for short in the wire (ALTClinel:1. Turn the headlight and ignition switch OFF.2. Disconnect the 32P connectortrom the ECM/PCM.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and bodyground.

Subslitute a known-good ECM/PCM, .nd .och6ck.It p.escribod vohago i! now avail-able, replace the original ECM/PCM.

Ropair 3hort in the wiro betweonthe ahe.nator and ECM/PCM.

ECM/PCM CONNECTOR A I32PI

'Ia18I1011

121314151718t9

7

202'l2221

262730

Wire side offemale terminalsALTC(WHT/GRNI

c{WHT/GRNI

ALTERNATORWire side oIfemale terminals

([l

T

12

1

ECM/PCM CONNECTOB A (32PI

I23478910t1

1213 14151617182021222321

262730

Wire side of I AITCfemate terminats

A

(WHT/GRN|

23-116

Page 1587 of 2189

-

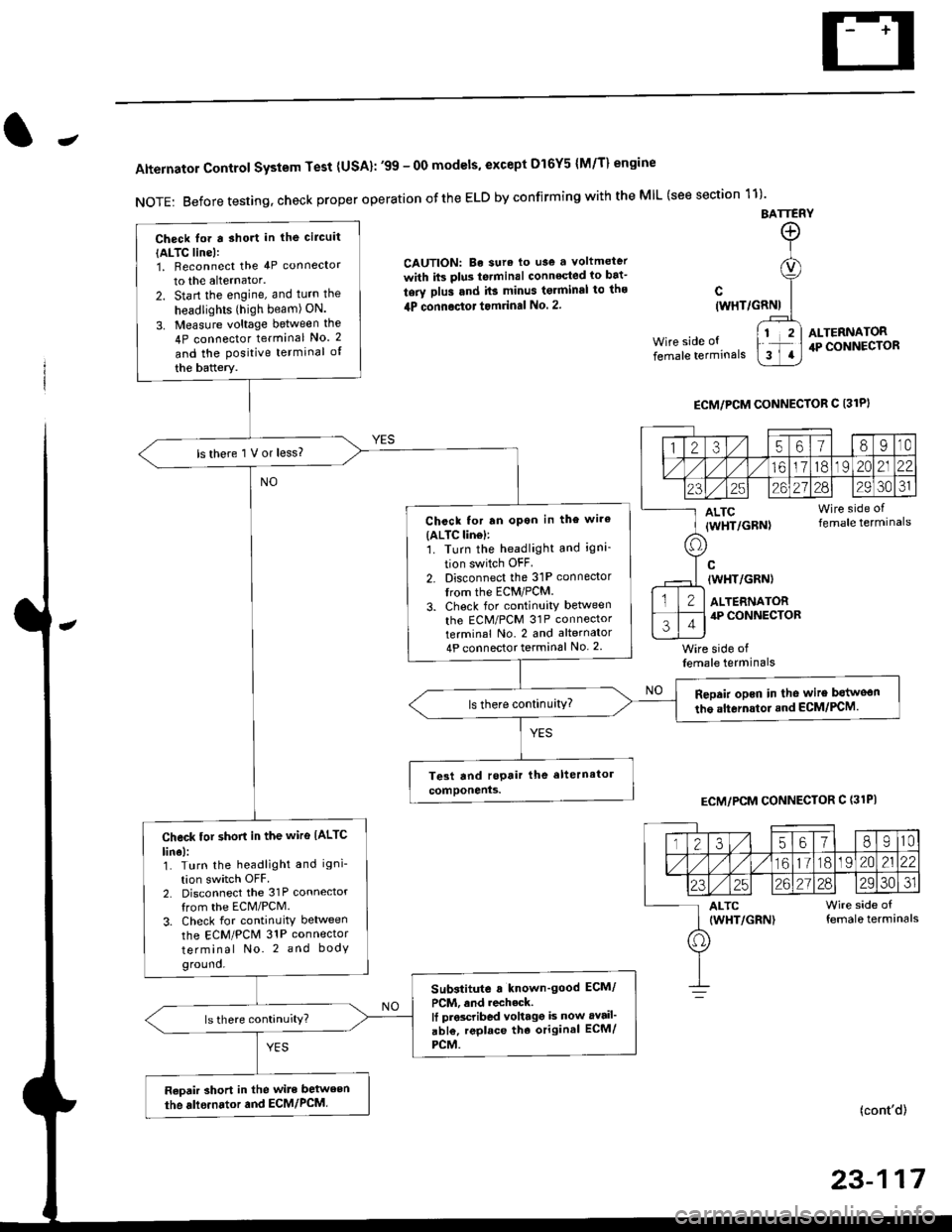

Alternator Control System Test {USA}: '99 - 0O models, except Dl6Y5 {M/T} engine

NOTE: Before testing, check proper operation ofthe ELD by confirming with the MIL (see section 11)'

BATTERY

CAUTION: Be sura lo use a voltmeter

with its plus te.minal conneqted io bat-

tery plus and it3 minus tgrminal to ths

4P connoctot tomrinal No. 2.

Wire side of

female terminals

c(WHT/GRNI

wire side offemale terminals

ALTERNATOR.P CONNECTOR

ECM/PCM CONNECTOR C 13lPI

ECM/PCM CONNECTOR C (31PI

(cont'd)

23-117

Check lor a sho.t in the circuit

{ALTC line):1, Beconnect the 4P connector

to the alternator.

2. Start the engine, and turn the

headlights (high beam) ON.

3. Measure voltage between the

4P connector terminal No. 2

and the Positive terminal of

the battery.

ls there 1 V or less?

Chcck for rn opon in the wire(ALTC lin6l:1. Turn the headlight and igni-

tion switch OFF

2. Disconnect the 31P connector

trom the ECM/PCM.

3. Check for continuity betlveen

the ECM/PCM 31P connectorterminal No. 2 and alternator

4P connector terminal No. 2

Repair opcn in the wire botweon

the alternstoi.nd ECM/PCM.ls there continuity?

Check tor short in the wire IALTC

line):1. Turn the headlight and igni-

tion switch OFF2. Disconnect the 31P connector

from the ECM/PCM.

3. Check for continuity between

the ECM/PCM 31P connector

terminal No. 2 and body

ground.

Substitute a known'good ECM/

PCM, and recheck.It prscribed voltagg is now avail'

abl€, replace tho original ECM/

PCM.

Raoair short in the wite between

the alle.nator and ECM/PCM,

1235618I10

/11611lo191 zo2122

23252621?82930JI

ALTC Wire side of(WHT/GRN) female terminals

o

Page 1636 of 2189

Lighting System

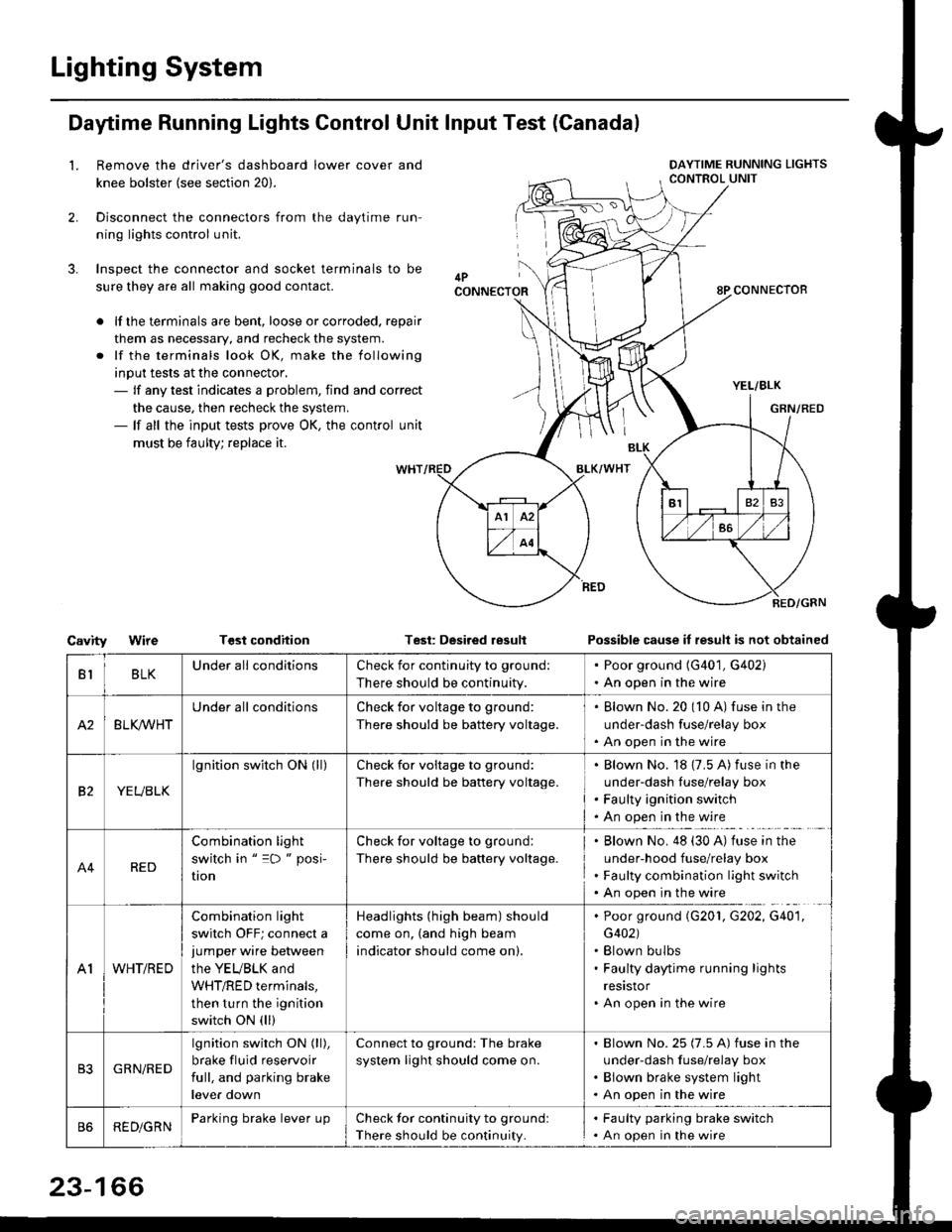

Daytime Running Lights Control Unit Input Test (Canadal

2.

3.

LRemove the driver's dashboard lower cover and

knee bolster (see section 20).

Disconnect the connectors from the daytime run-

ning lights control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

lf the terminals are bent, loose or corroded. repair

them as necessary, and recheck the system.

lf the terminals look OK, make the following

input tests at the connector,- lf any test indicates a problem, find and correct

the cause, then recheck the system.- lf all the input tests prove OK, the control unit

must be faulty; replace it.

CavityWireTGst conditionTest: Desired resultPossible cause it result is not obtained

BLKU nderall conditionsCheck for continuity to g.ound:

There should be continuity.

. Poor ground (G401, G402). An open in the wire

A2BLK /VHT

Underall conditionsCheck for voltage to ground:

There should be battery voltage.

Blown No.20 (10 A) fuse in the

under-dash fuse/relay box

An open in the wire

etYEUBLK

lgnition switch ON (ll)Check for voitage to ground:

There should be battery voltage.

Blown No. 18 {7.5 A) fuse in the

under-dash luse/relay box

Faulty ignition switch

An open in the wire

A4RED

Combination light

switch in " =D " posi-

UOn

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 (30 A) tuse in the

under-hood fuse/relay box

Faulty combination light switch

An open in the wire

A1WHT/RED

Combination light

switch OFF; connect ajumper wire between

the YEUBLK and

WHT/RED terminals,

then turn the ignition

switch ON (ll)

Headlights (high beam) should

come on, (and high beam

indicator should come on).

. Poor ground (G201, G202, G40'1,

G402). Blown bulbs. Faulty daytime running lights

resrstor. An open in the wire

GRN/RED

lgnition switch ON (ll),

brake fluid reservoir

full, and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No.25 (7.5 A) fuse in the

under-dash f use/relay box

Blown brake system light

An open in the wire

REDiGRNParking brake lever LrpCheck for continuity to groundl

There should be continuity.

. Faulty parking brake switch. An open in the wire

23-166

Page 1637 of 2189

Headlights/Front Turn

Signal/Parking Lights

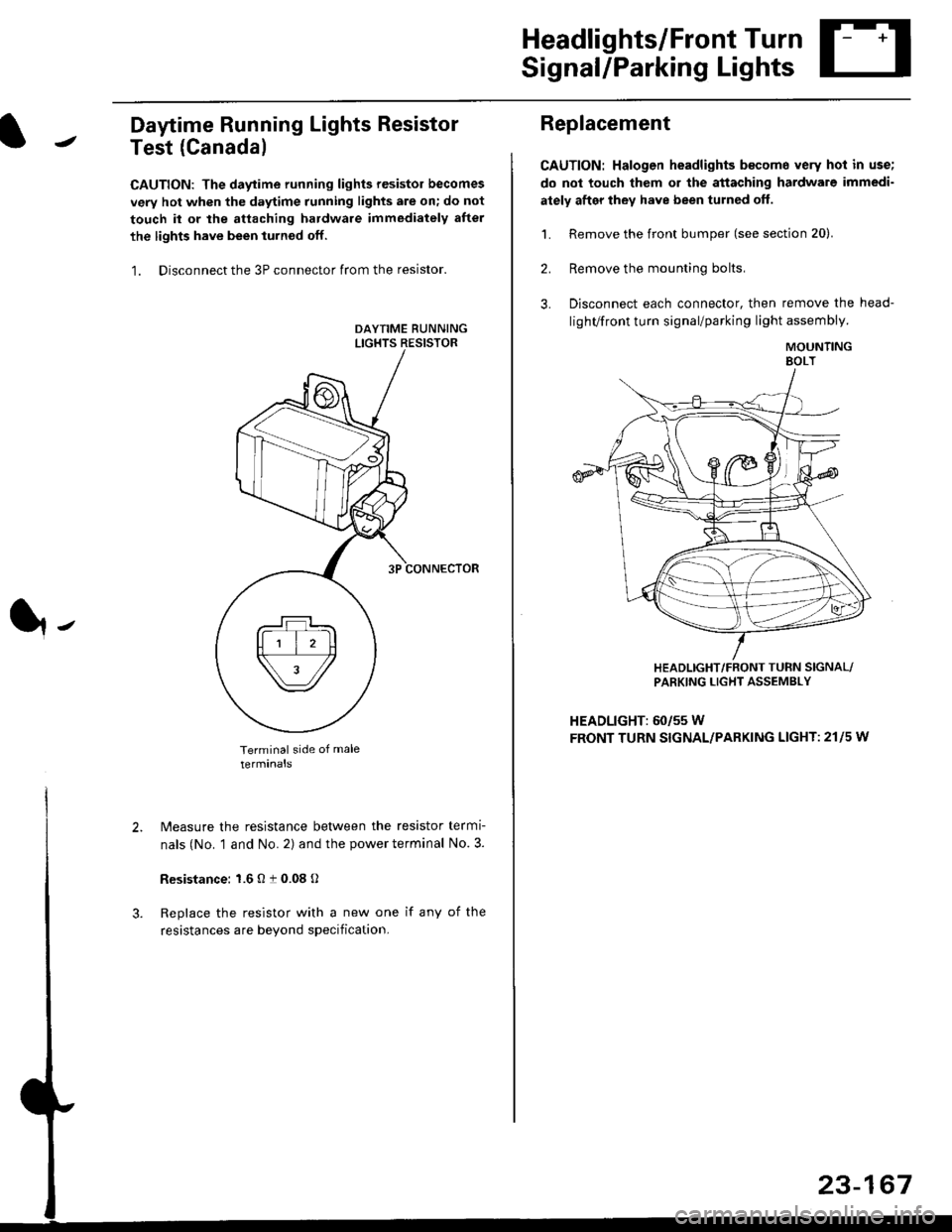

Daytime Running Lights Resistor

Test (Canada)

CAUTION: The daytime running lights resistor becomes

very hot when the daytime running lights are on; do not

touch il or the attaching hardware immediately after

the lights have been iurned off.

1. Disconnect the 3P connector from the resistor.

Terminal side of male

terminals

N4easure the resistance between the resistor termi

nals (No. 1 and No. 2) and the power terminal No. 3.

Resistance: 1.6 O t 0.08 O

Replace the resistor with a new one if any of the

resistances are beyond specification.

It-

Replacement

CAUTION: Halogen headlights b€come very hot in use;

do not touch them or the attaching hardware immedi-

ately after they have been turned off.

1. Remove the front bumper (see section 20).

2. Remove the mounting bolts,

3. Disconnect each connector, then remove the head-

lighVfront turn signal/parking light assembly.

MOUNTINGEOLT

HEADLIGHT/FRONT TUFN SIGNAL/PARKING LIGHT ASSEMBLY

HEADLIGHT: 60/55 W

FRONT TURN SIGNAL/PARKING LIGHT: 21l5 w

23-167

Page 1638 of 2189

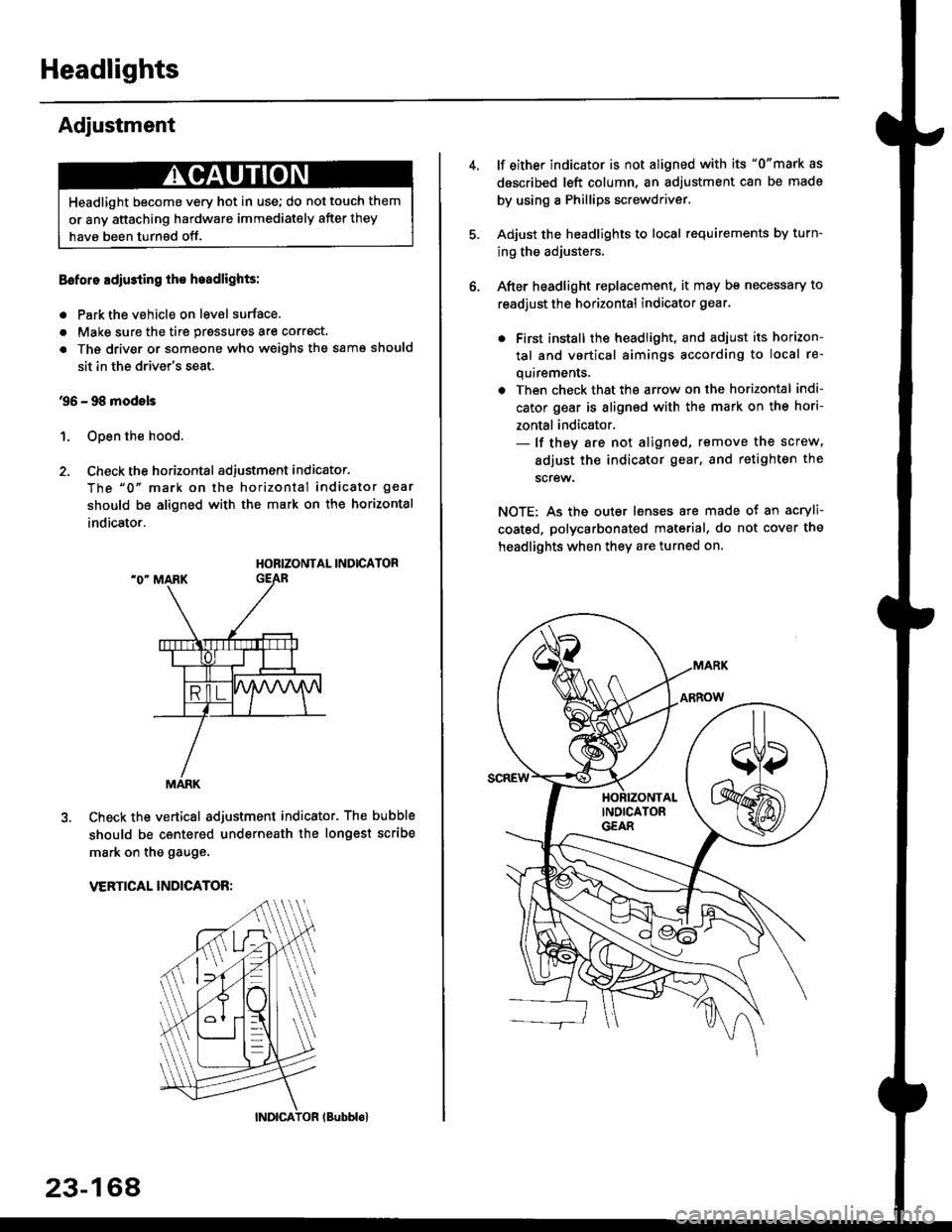

Headlights

Adjustment

Eoforo adiu3ting th€ h.adlights:

. Park the vehicle on level surface.

. Make sure the tire prgssures are correct.

a The driver or someone who weighs the same should

sit in the driver's seat.

96 - 98 modols

1. Open the hood.

2. Check the horizontal adjustment indicator.

The "0" mark on the horizontal indicator gear

should be aligned with the mark on the horizontal

indicator.

HORIZONTAL INDICATOR

Check the vertical adjustment indicator. The bubble

should be centered underneath the longest scribe

mark on the gauge.

VERTICAL INDICATOR:

Headlight become very hot in use; do not touch them

or any attaching hardware immediately after they

have been turnsd off.

MARK

23-164

(Bubblol

lf either indicator is not aligned with its "0"mark as

described left column, an adjustment can be made

by using a Phillips screwdriver.

Adjust the headlights to local requirements by turn-

ing the adjusters.

After headlight replacement, it may bs necessary to

readjust the horizontal indicator gear.

. First install the headlioht, and adjust its horizon-

tal and vertical aimings according to local re-

quirements.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator.- lf they are not aligned, remove the screw,

adiust the indicator gear, and retighten the

screw.

NOTE: As the outer lenses are made ot an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.

Page 1639 of 2189

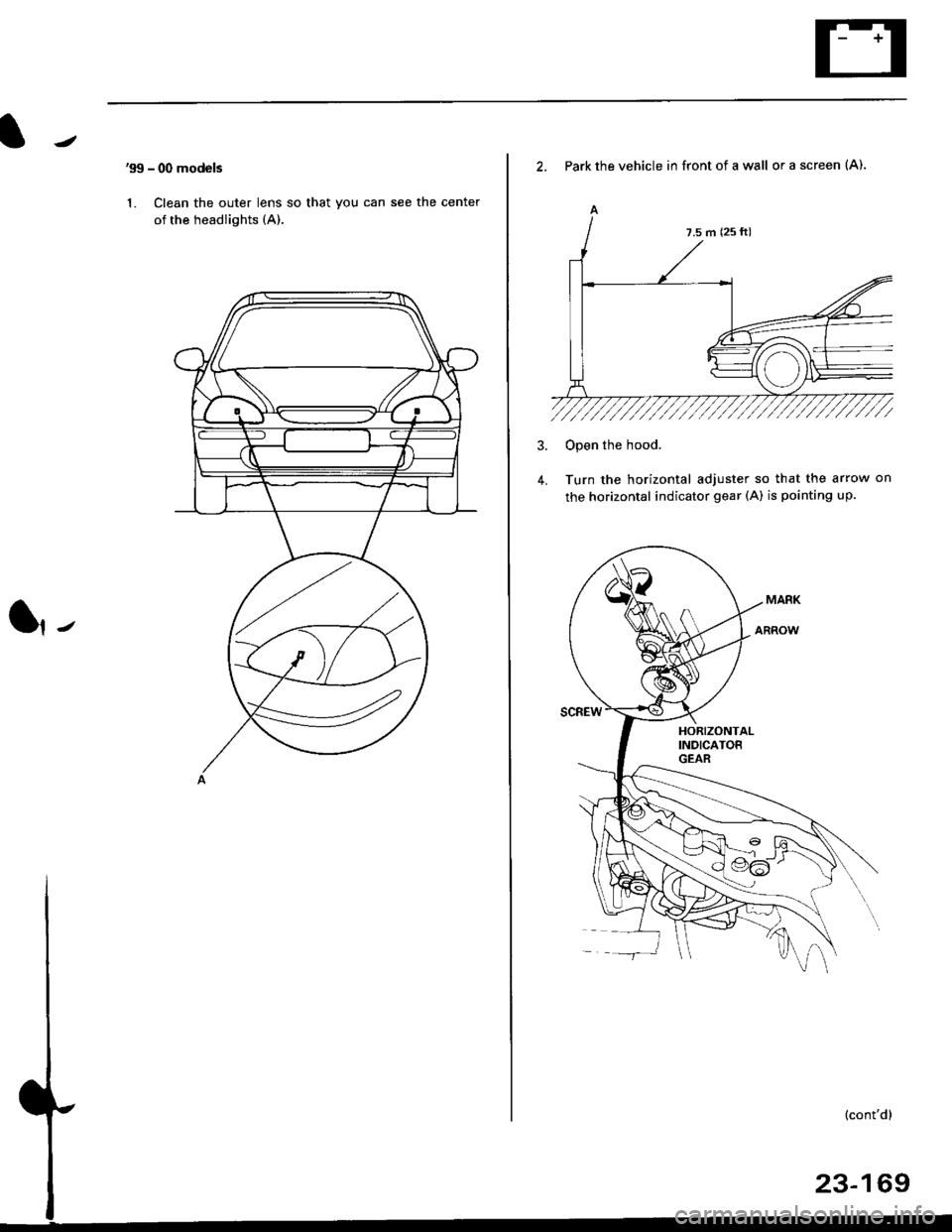

'99 - 00 models

1. Clean the outer lens so that you can see the center

of the headlights (A).

l,-

2. Park the vehicle in front of a wall or a screen (A).

A

4.

Open the hood.

Turn the horizontal adjuster so that the arrow on

the horizontal indicator gear (A) is pointing up.

7.5 m (25 ft)

Page 1640 of 2189

Headlights

Adjustment (cont'dl

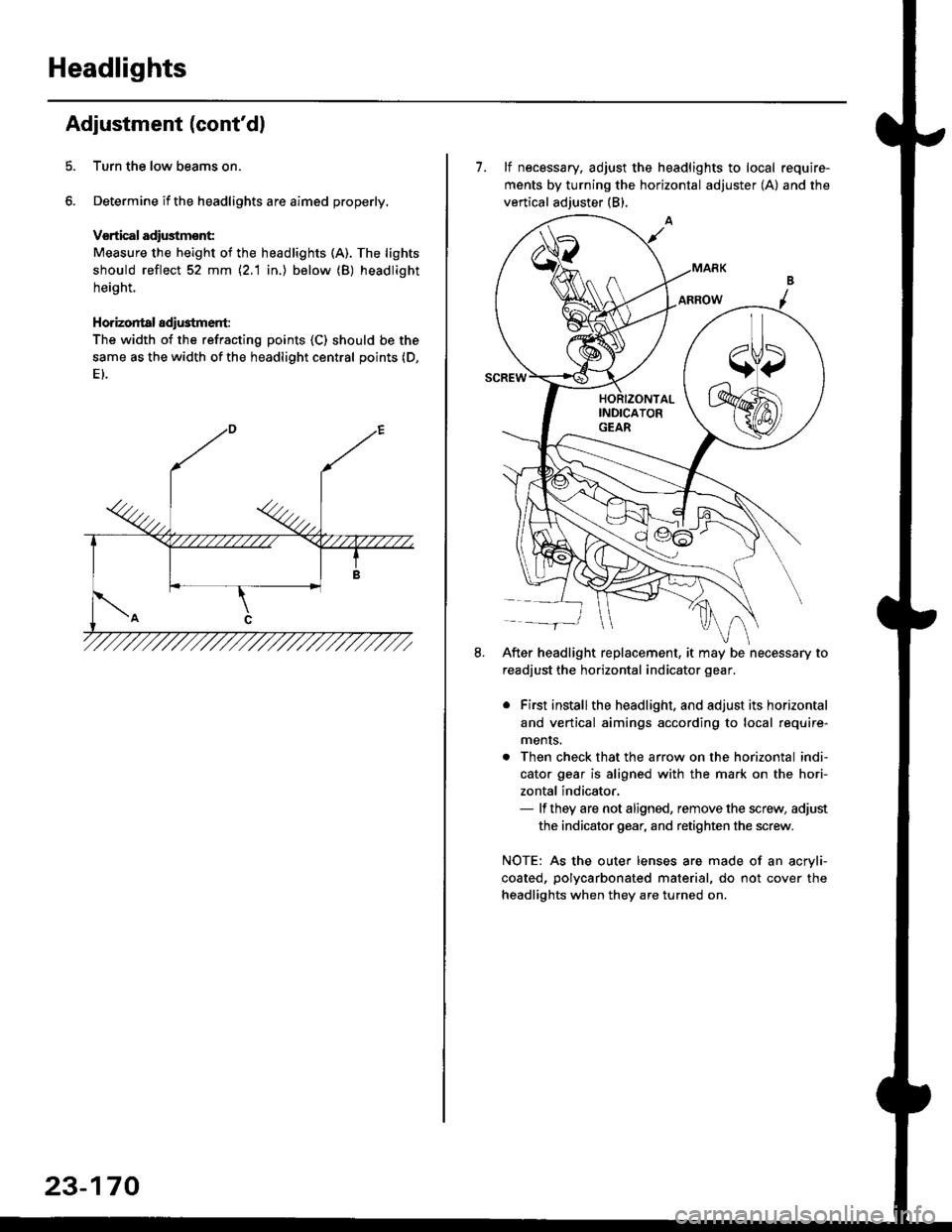

Turn the low beams on.

Determine if the headlights are aimed properly.

Vsrtical adiustmsnt:

Measure the height of the headlights (A). The lights

should reflect 52 mm \2.1 in.) below (B) headlight

height.

Horizontal adi$tment:

The width of the refracting points (C) should be the

same as the width of the headlight central points (D,

23-170

7. lf necessary, adjust the headlights to local require-

ments by turning the horizontal adjuster (A) and the

vertical adjuster (B).

After headlight replacement, it may be necessary to

readjust the horizontal indicator gear.

. First installthe headlight, and adjust its horizontal

and vertical aimings according to local require-

ments.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator,- lf they are not aligned, remove the screw, adjust

the indicator gear, and retighten the screw.

NOTE: As the outer lenses are made of an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.