specifications HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 822 of 2189

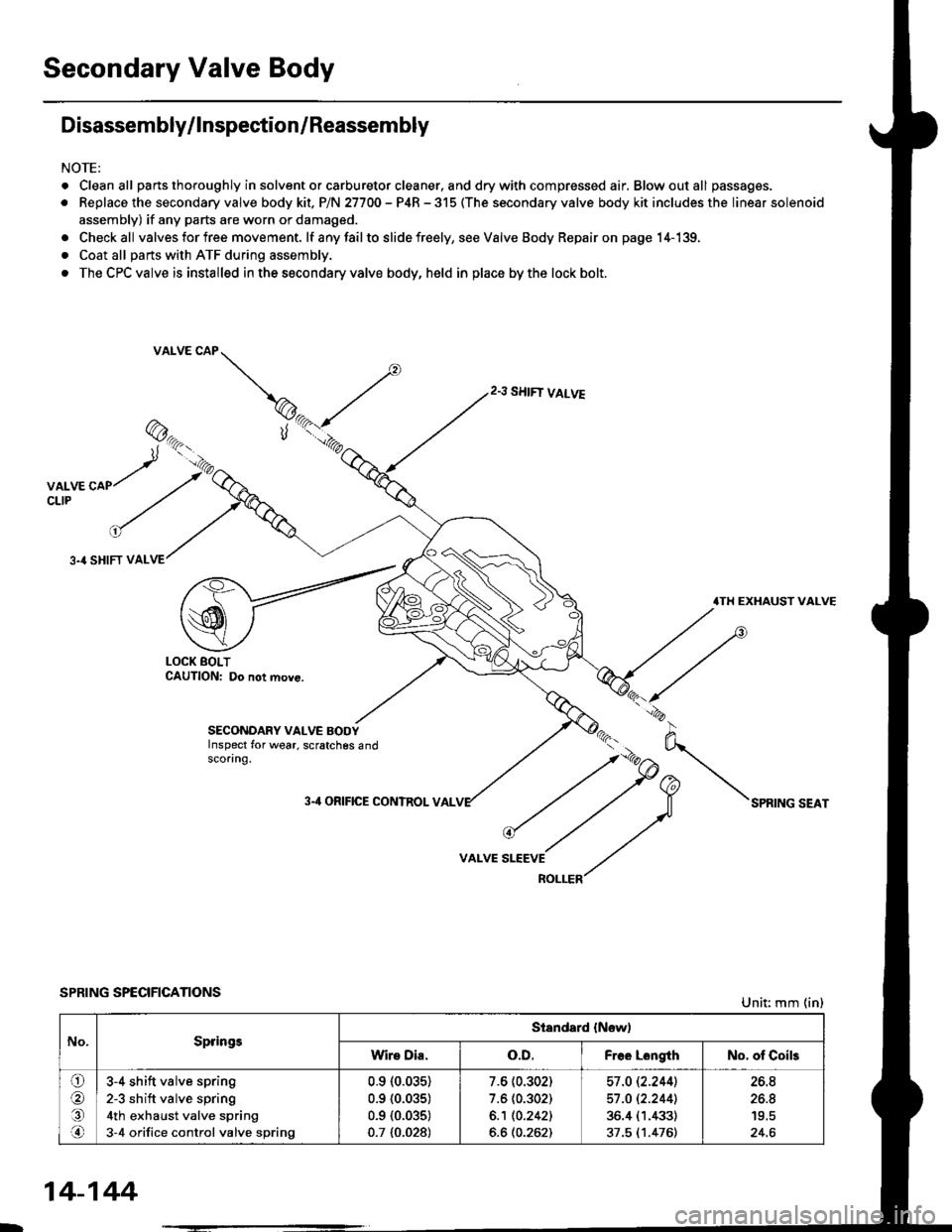

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner. and drywith compressed air, Blowoutall passages.

. Replace the secondary valve body kit. P/N 27700 - P4R - 315 (The secondary valve body kit includes the linear solenoid

assembly) if any parts are worn or damaged.

. Checkall valves for free movement. lf anyfailto slide freely, seeValveBody Repairon page 14-139,

. Coat all parts with ATF during assembly.

. The CPC valve is installed in the secondary valve body, held in place by the lock bolt.

2.3 SHIFT VALVE

3.4 SHIFT VAL

.TH EXHAUST VALVE

LOCK BOLTCAUTION: Do not move.

SECONDARY VALVE BODYInspect for wear, scratches 6ndscoring.

3-'l ORIFICE CONTROL VAL

VALVE

SPRING SPECIFICATIONSUnit: mm (in)

No.SpringsStandard {New)

Wire Dia.o.D.Free LongthNo. of Coils

ora,.n

3-4 shift valve spring

2-3 sh ift valve spring

4th exhaust valve spring

3-4 orifice control valve spring

0.910.035)

0.9 {0.035)

0.9 {0.035)

0.7 {0.028)

7.6 (0.302)

7.6 (0.302)

6.1 10.2421

6.6 (0.262)

57 .O 12.2441

57 .O 12.2441

36.4 (1.433)

37.5 (1.476)

26.8

26.8

24.6

14-144

Page 824 of 2189

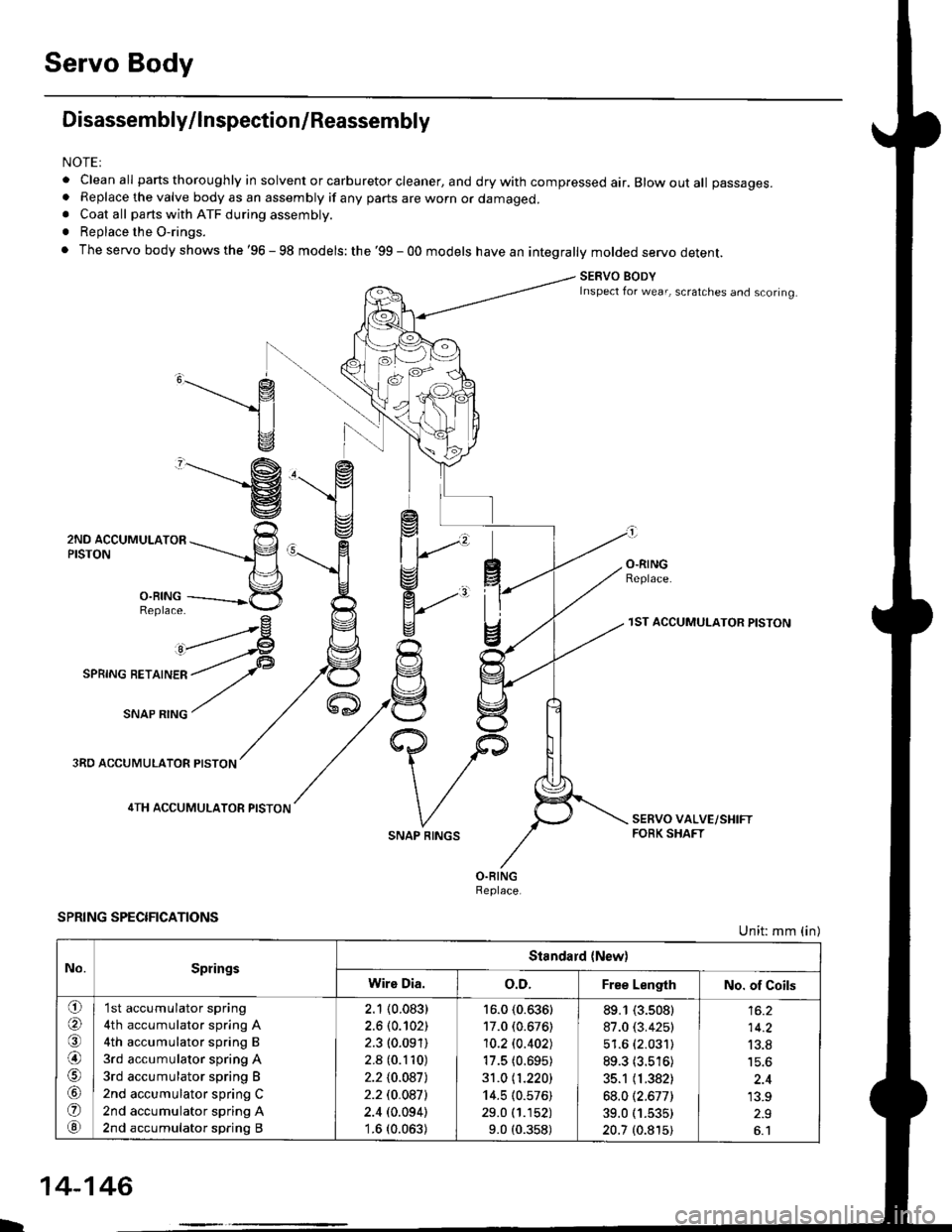

Servo Body

Disassembly/lnspection/Reassembly

NOTEI

. clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air. Blow out all passages.. Replace the valve body as an assembly if any parts are worn or damaged.. Coat all parts with ATF during assembly.

. Replace the O-rings.

. The servo body shows the '96 - 98 models: the '99 - 00 models have an integrally molded servo detent.

SERVO BODYInspect for wear, scratches and scoring.

,______.- g

1l

v

"-------'g

ZruO lCCUr,irUr-nrOn ---rrr___-p

n\='l

3,ii11---------*5

^rrr4

I

O.RINGReplace.

3RO ACCUMULATOR PISTON

4TH ACCUMULATOR PISTON

SPRING SPECIFICATIONS

SNAP RINGS

1ST ACCUMULATOR PISTON

Unit: mm (in)

No.SpringsStandard {New)

Wire Dia.o.D.Free LengthNo. of Coils

o(a

@)

o

@

'I st accumulator spring

4th accumulator spring A

4th accumulator spring B

3rd accumulator spring A

3rd accumulator spring B

2nd accumulator spring C

2nd accumulator spring A

2nd accumulator spring B

2.1 (0.083)

2.6 (0.102)

2.3 (0.091)

2.8 (0.110)

2.210.0871

2.2 t0.0a7l

2.4 (0.094)'1.6 (0.063)

16.0 (0.636)

17.0 (0.676)

10.2lo.402J

17.5 (0.695)

31.0 11.220)

14.5 (0.576)

29.0 (1.152)

9.0 (0.358)

89.1 (3.s08)

87.0 (3.425)

51.6 (2.031)

89.3 (3.516)

35.1 (1.382)

68.012.677)

39.0 (1.535)

20.7 (0.815)

14.2

13.8

'13.9

L

14-146

Page 825 of 2189

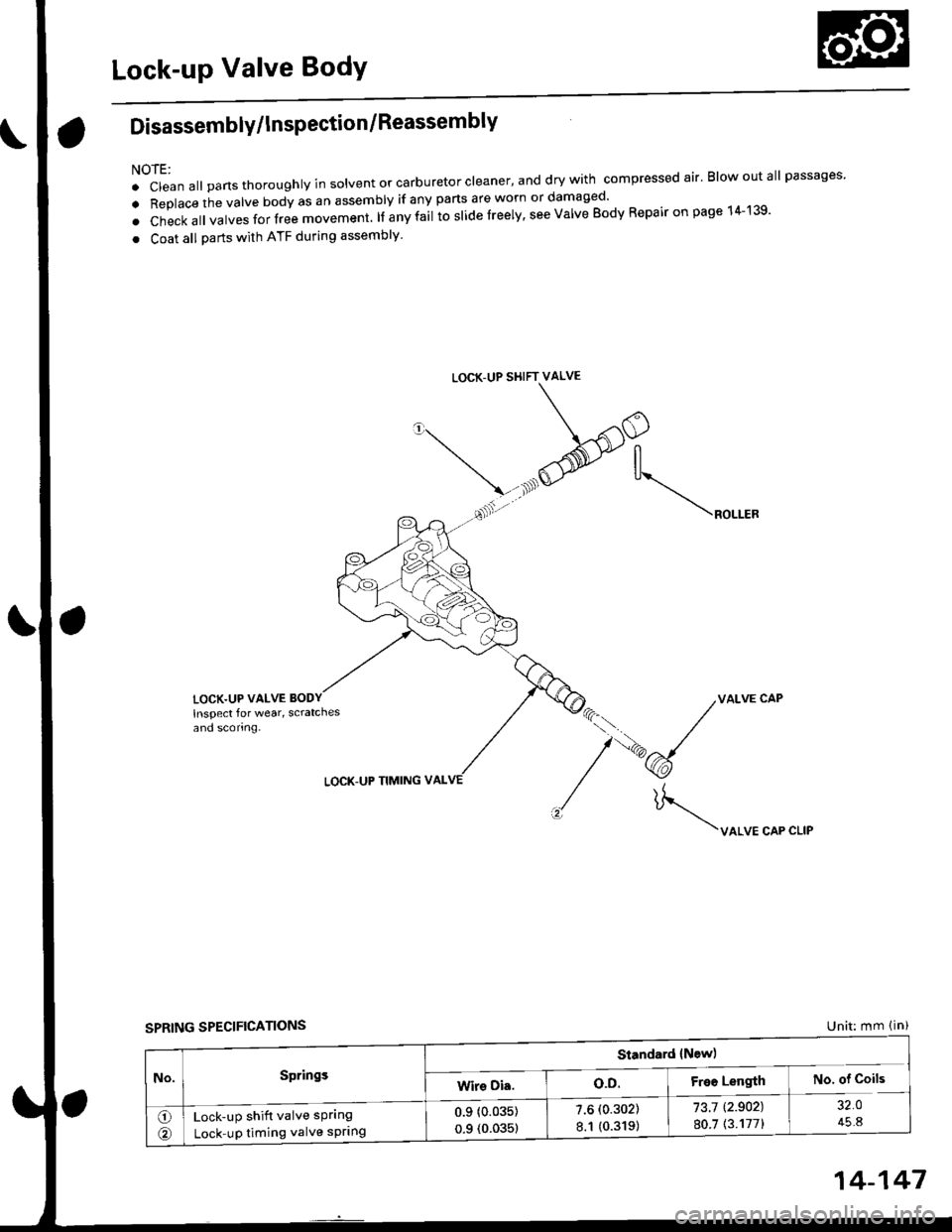

Lock-up Valve BodY

Disassembly/lnspection/Reassembly

NOTE:

. Clean all pans thoroughly in solvent or carburetor cleaner' and dry with compressed air' Blow out all passages'

a Replace the valve body as an assembly if any parts are worn or d€maged'

. Checkall valves for free movement ttanytaitio stlae freely' see Valve Body Repairon page 14-'139'

. Coat all parts with ATF during assembly

LOCK.UP VALVE BODY

Inspect for wear, scratchesand sconng.

VALVE CAP

LOCK-UP TIMING VAL

SPRING SPECIFICATIONSUnit: mm (in)

73.1 t2.902J

ao.7 13.'17717.6 (0.302)

8.1 (0.319)Lock-up shift valve sPrang

Lock-up timing valve sPrlng

14-147

Page 986 of 2189

![HONDA CIVIC 2000 6.G User Guide O ATF DIPSTICK

O o-RING Replace.

. SOLENOID HARNESS CONNECTOR

@ LOWER VALVE BODY ASSEMBLY

O DOWEL PIN

O LINE BOLT

.i ATTf COOUR IruIET LINE B8ACKET BOLT

€] lrr cooua truler LINE ASSEMBLY

O SEALING HONDA CIVIC 2000 6.G User Guide O ATF DIPSTICK

O o-RING Replace.

. SOLENOID HARNESS CONNECTOR

@ LOWER VALVE BODY ASSEMBLY

O DOWEL PIN

O LINE BOLT

.i ATTf COOUR IruIET LINE B8ACKET BOLT

€] lrr cooua truler LINE ASSEMBLY

O SEALING](/img/13/6068/w960_6068-985.png)

O ATF DIPSTICK

O o-RING Replace.

.' SOLENOID HARNESS CONNECTOR

@ LOWER VALVE BODY ASSEMBLY

O DOWEL PIN

O LINE BOLT

.i ATTf COOUR IruIET LINE B8ACKET BOLT

€] lrr cooua truler LINE ASSEMBLY

O SEALING WASHER RePIACE'

G, ATF COOLER OUTLET PIPE

6) o-RING Replace.

@ ATF FILTER

fO o-RING Replace.

@ ATF PAN(3 DOWEL PIN(D O-RING Replace.

E) ATF STRAINER

@ ATF MAGNET(9 ATF PAN GASKET RePIACE'

O ATF MAGNET

€t oRAIN PLUG

@ SEALING wAStlER Replace.

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRemarks

8F

12J

18D

12 N.m {1.2 kgf m, 8.7 lbf'ft}

26 N.m (2.7 kgim,20 lbf'ft)

28 N.m (2.9 kgf'm,21 lbf'ft)

49 N.m (5.0 kgf'm, 36 lbf'ft)

6x1.0mm

8 x 1.25 mm

12 x 1.25 mm

18 x 1.5 mm

Line bolt

Drain plug

14-309

Page 988 of 2189

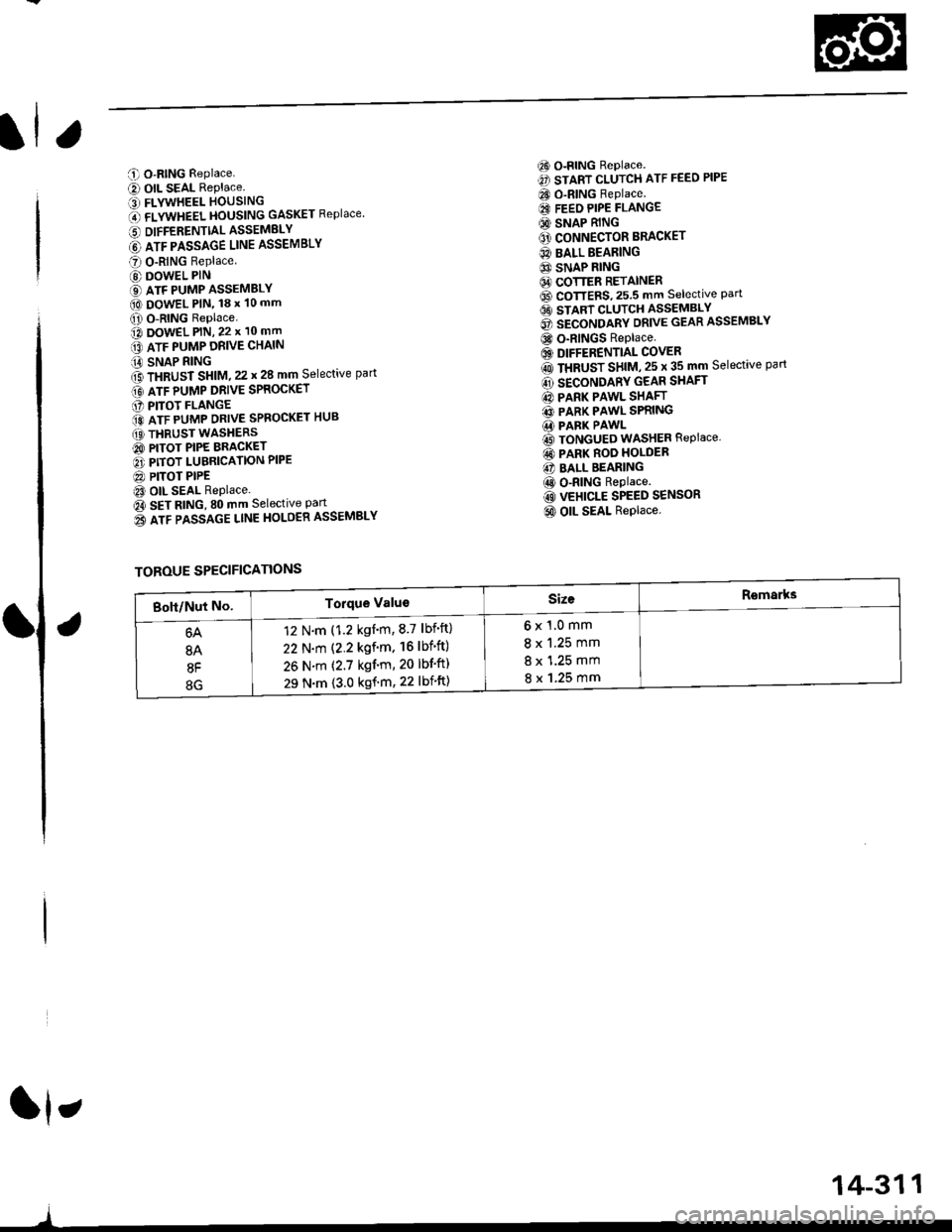

C O-RING Replace.

e) OIL SEAL RePlace.' FLYWHEEL HOUSING

O flVWneel }|OUSttttG GASKET Replace

6 DIFFERENTTALASSEMELY

@ lrr plsslce uruE ASSEMBLY

O O-RING Replace

@ DOWEL PIN

€) ATF PUMP ASSEMBLY(O DowEL PlN, 18 x 10 mm

O O-RING Replace.o DowEL PlN, 22 x 10 mm

lrr puup oRve cxltttt

iA SNAP RING

f3 fxaUst St|t|l, zz t 28 mm Selective part

Gt lrr punp ontve spaocxer

O PITOT FLANGE

ito nTF purrap ontve SPRoGKET HUB

(O THRUST WASHERS

@ PITOT PIPE BRACKET

O PITOT LUBRICATION PIPE

@ PITOT PIPEt3 OIL SEAL Replace.

Oa SEt AtitC, SO mm Selective Part

o3 lrr passlce ltnE HoLOER ASSEMBLY

6) o-RING Replace.

€) START CLUTCH ATF FEED PIPE

CO O-RING Replace.

€I FEEO PIPE FLANGE

@ SNAP RING

O' CONNECTOR BRACKET

@ BALL BEARING

6} SNAP RING64 COTTER RETAINER6D CoTTERS,25.5 mm selective Part6t stlnt cLutcH asseMsLv

@ secoruomv ontvE GEAR ASSEMBLY

@ o-RINGS Replace

6) DIFFERENTIAL COVER

rO ttaUSr SntU, zs t 35 mm Selective part

@ SECONDARY GEAR SHAFT

@ PARK PAWL SHAFT

@ PARK PAWL SPRING.1i PARK PAWL

@ TONGUED WASHER REPIACE,

@ PARK ROO HOLDER

@ BALL BEARING

@ o-RING Replace.

@ VEHICLE SPEED SENSOR

@ OIL SEAL Replace.

ft,

)

TOROUE SPECIFICATIONS

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgnm,8.7 lbf'ft)

22 N.m (2.2 kgf'm. 16lbf'ft)

26 N.m (2.7 kgf'm, 20 lbf'ft)

29 N.m {3.0 kgf'm, 22 lbift)

14-311

Page 990 of 2189

6) TRANSMISSION HOUSING GASKET Replace'

@ DOWEL PIN

@) ATF FEED PIPE

@ o-RING Replace.

60 o-RING Replace.

@) DRIVE PULLEY SPEED SENSOR

@ TRANSMISSION HANGER

@ SNAP RING

@ txaust Sxtfu, zs t 31 mm selective part

@ SALL BEARING

6J RING GEAR6D SNAP RING

@ aevense aRlxe rND PLATE Selective part

@ REVERSE BRAKE DISC

@ REVERSE BRAKE PLATE

@ DISC SPRING6} THNUST WASHER

@} finusr NeeoLr eelnNc

@ THRUST WASHER

@ GARRIER ASSEMBLY

@ THRUST WASHER

@ THRUST NEEDLE BEARING

@} SUN GEAR

@ SEALING RING REPIACE'

@ NEEDLE BEARING

@ INPUT SHAFT

@ NEEDLE BEARING

@ SEALING RING FEPIACE'

@ SEALING RING {RUBBERI Replace'

@ ATF FEED PIPE

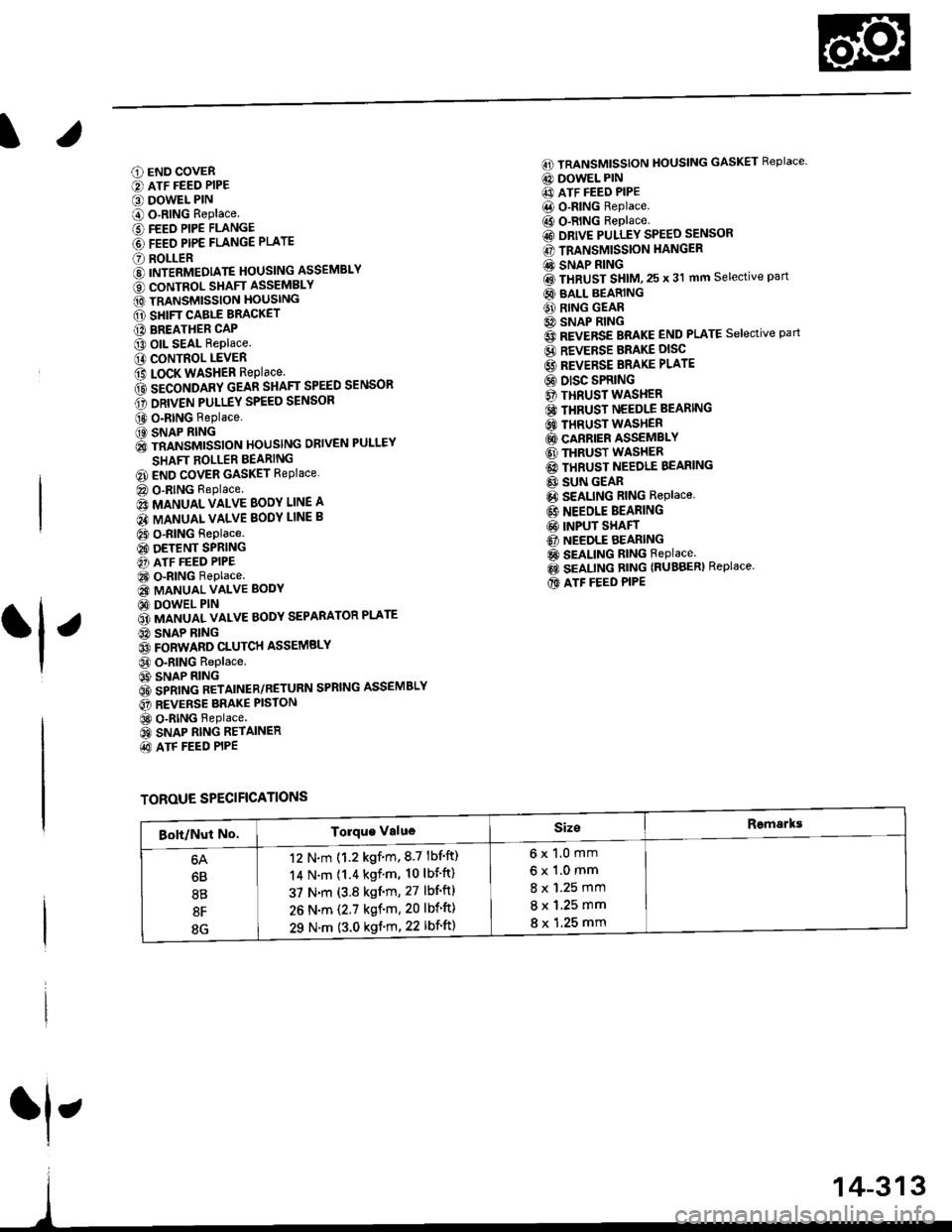

O END COVER

O ATF FEED PIPE

O DOWEL PIN

@ O-RING Replace.G) FEED PIPE FLANGE

@ reeo ppe ruruce puru

O] ROLLERO IruTENMEDNTE XOUSING ASSEMBLY

ao corutnoL sxlrr lsseugLv

@ tnlrusmtsstottt ttoustt'tc

@ SHIFT CABLE BRACKET

c) BREATHER CAP

@ oll- SEAL Replace.

@ CONTROL LEVER

G LoCK WASHER Replace.(D secololaY ceaR SHAFT SPEED sENsoR

o) onvel put-uv sPEED SENSOR

@ O-RING Replace.(O SNAP RING6 rnmrsutsstoru xouslNc oRlvEN PULLEY

SHAFT ROLLER BEARING

@ END COVER GASKET REPIACE'

@ o-RING Replace

6o mnruulL vnLVe goDY LINE A

64 MANUAL VALVE BODY LINE B

@ O-RING Replace.

@ DETENT SPRING

O ATF FEED PIPE

@ O-RING Replace.

@ MANUAL VALVE EODY

@ DOWEL PIN

@ r'rllull valve goDY SEPARAToR PLATE

6D SNAP RING

@t roRwlno cturcx ASSEMBLY

@ o-RING Replace

@ SNAP RINGo3 spnlruc aetlrupn/RETURN SPRING ASSEMBLY

@ nevense ennr eBtottt

@ o-RING Feplace.

@ SNAP RING RE'AINER

@ ATF FEED PIPE

.1,

TOROUE SPECIFICATIONS

6x1.0mm

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgf'm,8.7 lbf'ft)

14 N.m {1.4 kgf'm, 10 lbift)

37 N.m (3.8 kgf'm, 27 lbf'ft)

26 N.m (2.7 kgf'm,20 lbf'ft)

29 N.m (3.0 kgf'm, 22 lbf'ft)

6B

8B

8F

8G

14-313

rl,

Page 1080 of 2189

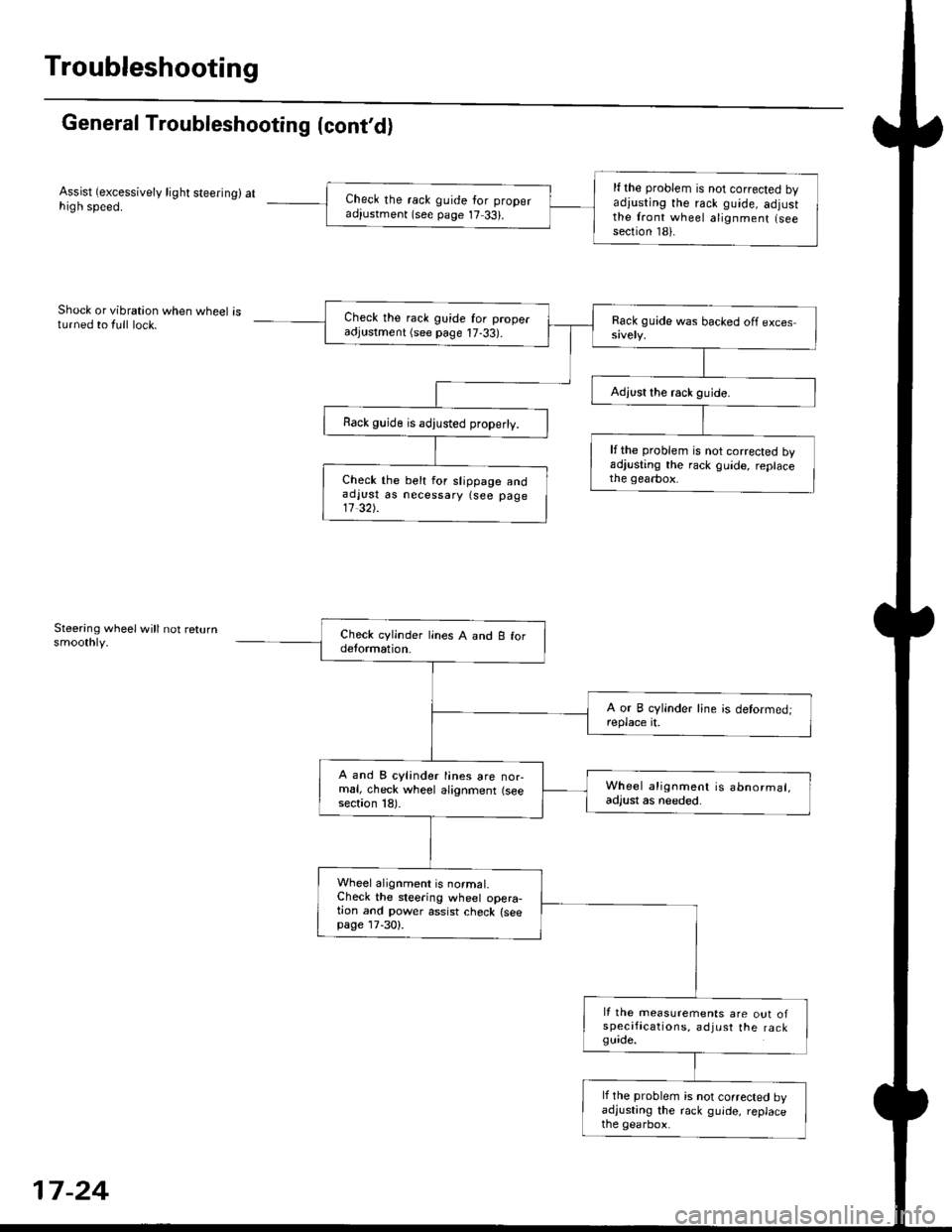

Troubleshooting

General Troubleshooting (cont'd)

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to {ull lock.

Steering wheelwill not returnsmoothly.

lf the problem is not corrected byadiusting the rack guide, adjustthe front wheel alignment lseesection 181.

Check the rack guide for properadiustment (see page 17 33).

Check the rack guide for properadjustment (see page 17-33).

Rack guide is adjusted properly.

lfthe problem is not corrected byadjusting the rack guide, replacethe gearbox.Check the belt for slippage andaolust as necessary {see page11 32).

A and B cylinder lines are nor-mal, check wheel alignment (seesection 18).

Wheel alignment is abnormal,adjust as needed.

Wheel alignment is normal.Check the steering wheel opera-tion and power assist check {seepage lT-30).

It the measurements are out ofspecifications, adjust the ra ckguide.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox.

17-24

Page 1130 of 2189

Wheel Alignment

Turning Angle Inspection

NOTEr Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

'1. Turn the wheel right and left while applying the

brake, and measure the turning angle of both

wneets.

Turning angle:

lnward wheel: 39'50'

Outwald wheel (ref erencel: 33'10'

2.lf the turning angle

check for bent or

nents,

is not within the specifications,

da m aged suspension compo-

18-6

Page 1155 of 2189

t

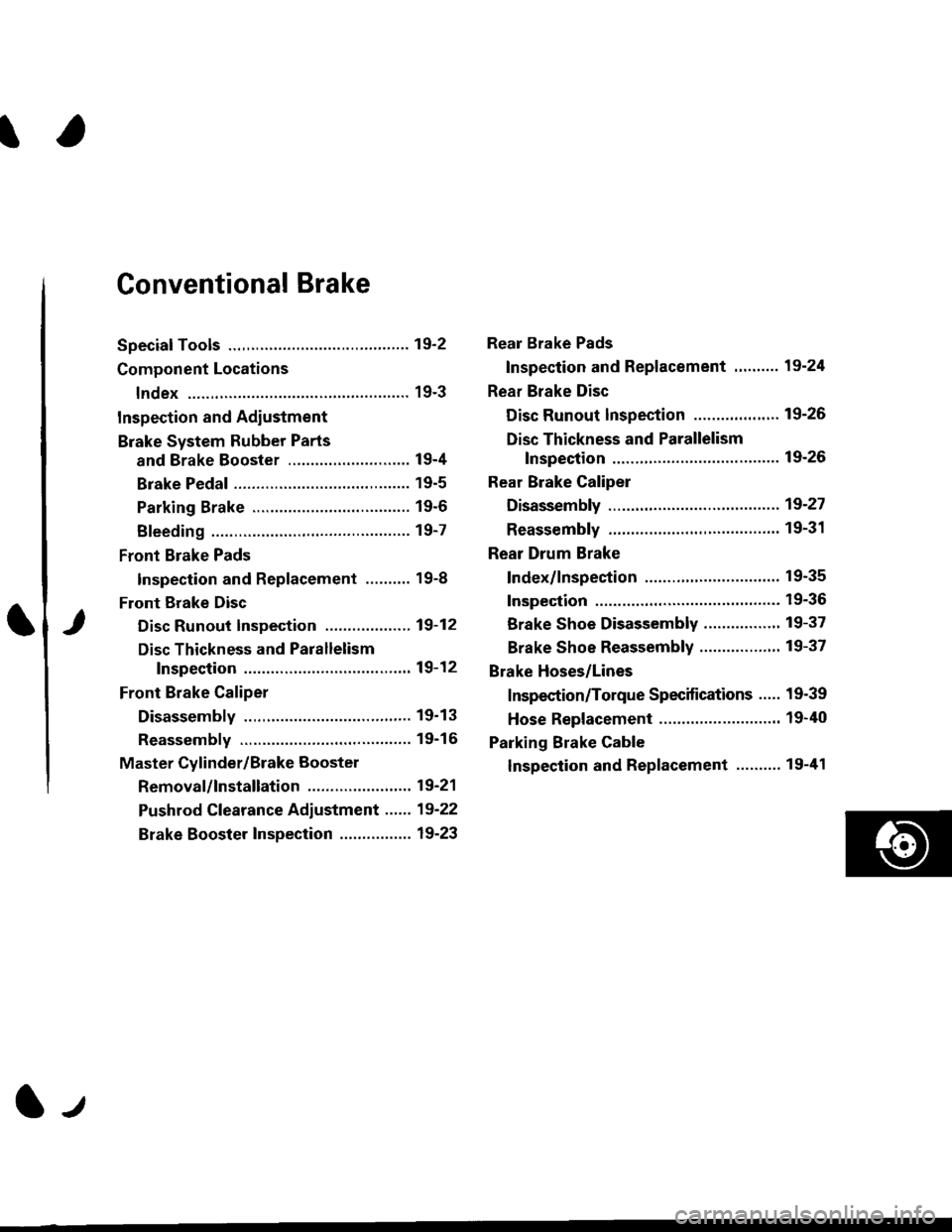

Conventional Brake

Speciaf Tools .............19'2

Component Locations

lndex ................ ...... 19-3

Inspection and Adiustment

Brake System Rubber Parts

and Brake Booster ...........,.,............. 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19-7

Front Brake Pads

Inspection and Replacement .......... 19-8

Front Erake Disc

Disc Runout Inspection ................... 19-12

Disc Thickness and Parallelism

Inspection .......... 19-12

Front Brake Caliper

Disassembly .......... 19'13

Reassembly ........... 19-16

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-21

Pushrod Clearance Adiustment ...... 19-22

Brake Booster Inspection ................ 19-23

Rear Brake Pads

Inspection and Replacement ,,........ 19-24

Rear Brake Disc

Disc Runout lnspection ................... 19-26

Disc Thickness and Parallelism

Inspection .......... 19-26

Rear Brake Caliper

Disassembly ...........19-27

Reassembly ........." 19-31

Rear Drum Brake

Index/lnspection .............................. 19-35

Inspection ....,.,....... 19-36

Brake Shoe Disassembly ..............." 19-37

Brake Shoe Reassembly ...............'.. 19-37

Brake Hoses/Lines

Inspection/Torque Specifications ..... 19-39

Hose Replacement ........................... 19-40

Parking Brake Cable

lnspection and Replacement ........,. 19-41

l-l

Page 1193 of 2189

Brake Hoses/Lines

LJ

Inspection/Torque Specifications

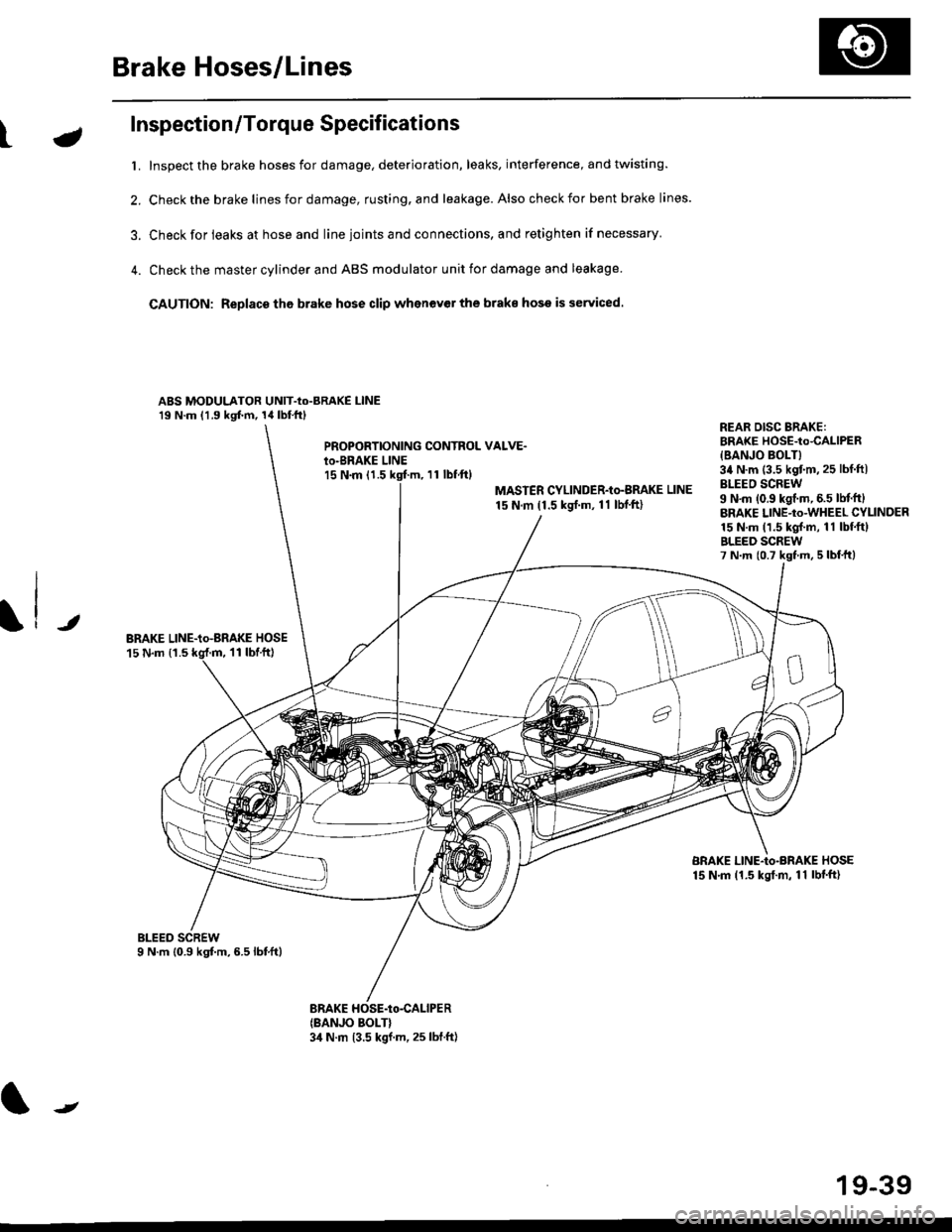

t. Inspect the brake hoses for damage, deterioration, leaks, interference, and twisting.

2. Check the brake lines for damage, rusting. and leakage. Also check for bent brake lines.

3. Check for ieaks at hose and line ioints and connections, and retighten if necessary'

4. Check the master cylinder and ABS modulator unit for damage and leakage

CAUTION: Replace tho brake hose clip whenev€r the brake hose is serviced.

ABS MODULATOR UNIT-Io-BRAKE l-lNE19 N.m (1.9 kgf.m, 14lbl.ftl

PROPOBTIONING CONTROL VALVE.io-BRAKE LINEl5 N.m (1.511 tbf.ftl

MASTER CYLINDER-Io-BMKE LINE

15 N.m (1.5 ksrf.m, 11 lbf'ft)

REAR DISG BRAKE:BRAKE HOSE-to4ALlPER

{BANJO BOLT}34 N.m (3.5 kgtm,25 lbf ftlBLEEO SCREW9 N'm (0.9 kgf.m, 6.5 lM.ftlBRAKE LINE-to-WHEEL CYLINDER15 N.m (1.5 kgl.m, 11 lbf.ftlBLEED SCREW7 N.m {0.7 kst m, 5 lbf,ttl

JBRAKE LINE-io-aRAKE HOSE15 N.m {1.511 tbtft)

BRAKE LINE-Io-BRAKE HOSE15 N.m (1.5 kgt.m, 11 lbf'ft)

(BANJO BOLT}3,1 N.m 13.5 kgf.m, 25 lbf.ft)

J

19-39