width HONDA CIVIC 2000 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 152 of 2189

Valve Guides

7.

VALVESEAT

PFUSSIAN BTUE COMPOUNO

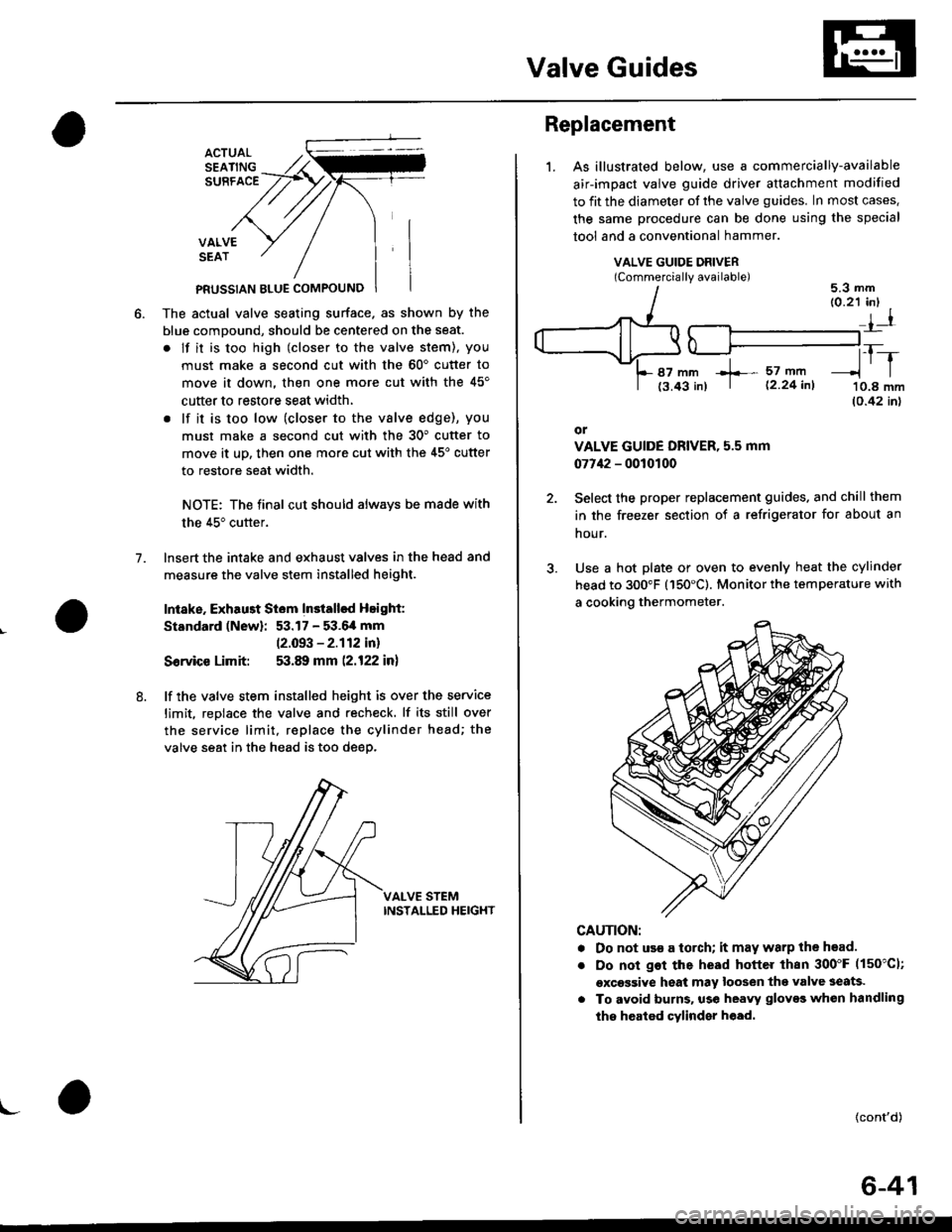

The actual valve seating surface. as shown by the

blue comDound, should be centered on the seat.

. lf it is too high (closer to the valve stem), you

must make a second cut with the 60'cutter to

move it down, then one more cut with the 45'

cutter to restore seat width,

. lf it is too low (closer to the vslve edge), you

must make a second cut with the 30" cutter to

move it uD, then one more cut with the 45'cutter

to restore seat width.

NOTE: The final cut should always be made with

the 45" cutter.

lnsert the intake and exhaust valves in the head and

measure the valve stem installed height.

Intake. Exhau3t Siem Installsd Height:

Standard (New): 53.17 - 53.6,4 mm

12.093 - 2.112 in)

Sorvice Limit: 53.89 mm (2.122 in)

lf the valve stem installed height is over the service

limit. reDlace the valve and recheck. lf its still over

the service limit, replace the cylinder head; the

valve seat in the head is too deep.

VALVE STEMINSTALLED HEIGHT

8.

\-

Replacement

1.As illustrated below, use a commercially-available

air-impact valve guide driver attachment modified

to fit the diameter of the valve guides. In most cases.

the same procedure can be done using the special

tool and a conventional hammer.

VALVE GUIDE DRIVERlCommerciallv available)5.3 mm

87 mm +- 57 mft

t3.43 in) | 12 24 inl

tr-r'10.8 mm(0.42 inl

or

VALVE GUIDE DRIVER, 5.5 mm

07742 - 0010100

Select the proper replacement guides. and chill them

in the freezer section of a refrigerator for about an

nour.

Use a hot plate or oven to evenly heat the cylinder

head to 300"F (150'C). Monitor the temperature with

a cooking thermometer.

CAUTION:

. Do not use a torch; it may warp the head.

Do not got the head hottel than 300"F (150"C1;

excessive heat may loosen thg valve seats.

To avoid burns. use heayy gloves whon handling

the heated cylinder h€ad.

{cont'd)

6-41

Page 188 of 2189

Valve Seats

Reconditioning

1. Renew the valve seats in the cylinder

valve seat cutter.

NOTE: lf any guides are worn (see

replace them (see page 6-80) before

valve seats,

head with a

page 6-79),

cutting the

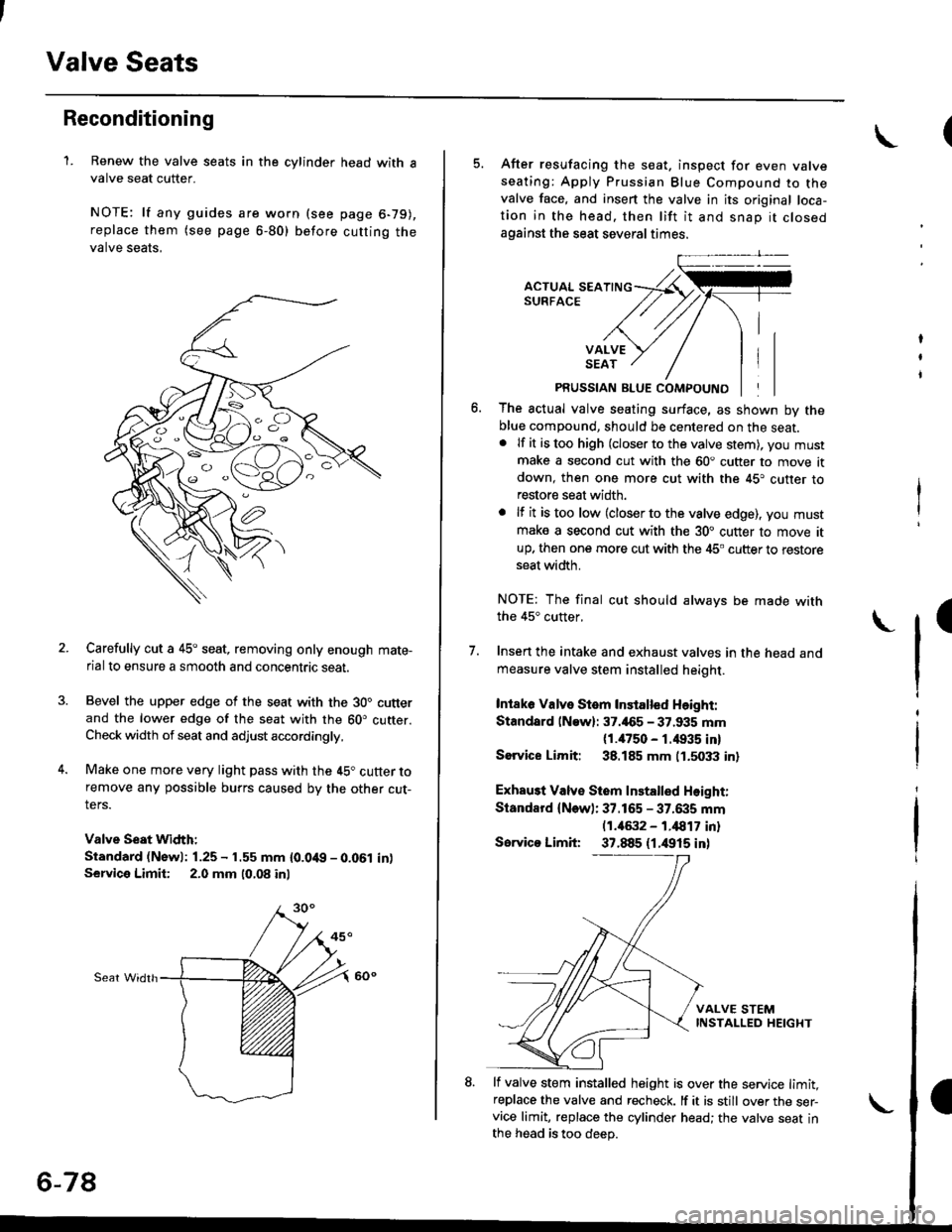

Carefully cut a 45o seat, removing only enough mate-

rial to ensure a smooth and concentric seat.

Bevel the upper edge of the seat with the 30" cutterand the lower edge of the seat with the 60. cutter.Check width of seat and adjust accordingly,

Make one more very light pass with the 45" cutter toremove any possible burrs caused bv the other cut-

ters.

Valve Seat Width:

Standard (Newl: 1.25 - 1.55 mm {0.0't9 - 0.061 in)Service Limii: 2.0 mm 10,08 inl

Sear Widrh

6-78

5. After resufacing the seat. inspect for even valveseating: Apply Prussian Blue Compound to thevalve face, and insert the valve in its original loca-tion in the head. then lift it and snap it closedagainst the seat several times.

PRUSSIAN BLUE COMPOUND

The actual valve seating surface, as shown by theblue compound, should be centered on the seat.. lf it is too high (closer to the valve stem), you mustmake a second cut with the 60. cutter to move itdown, then one more cut with the 45. cutter torestore seat width.

. lf it is too low (closer to the valve edge), you must

make a second cut with the 30. cutter to move itup. then one more cut with the 45. cutter to restoreseat width.

NOTE: The final cut should always be made withthe 45" cutter,

7. Insen the intake and exhaust valves in the head and

measure valve stem installed heioht.

Intaka Valve Stem Installed Height:

Standsrd lNaw): 37.465 - 37.935 mm(1./P50 - r.4935 inl

Sorvice Limit: 38.185 mm 0.5033 in)

Exhau3t Valv€ Stem Installed Height:

Standard (New): 37.165 - 37.6i|5 mm(1.46:t2 - 1.i1817 inl

Servico Limit 37.885 (1.4915 inl

lf valve stem installed height is over the service limit,replace the valve and recheck. lf it is still over the ser-vice limit, replace the cylinder head; the valve seat inthe h6ad is too deep.

(

Page 593 of 2189

Reverse Shift Holder

)

Glearance Inspection

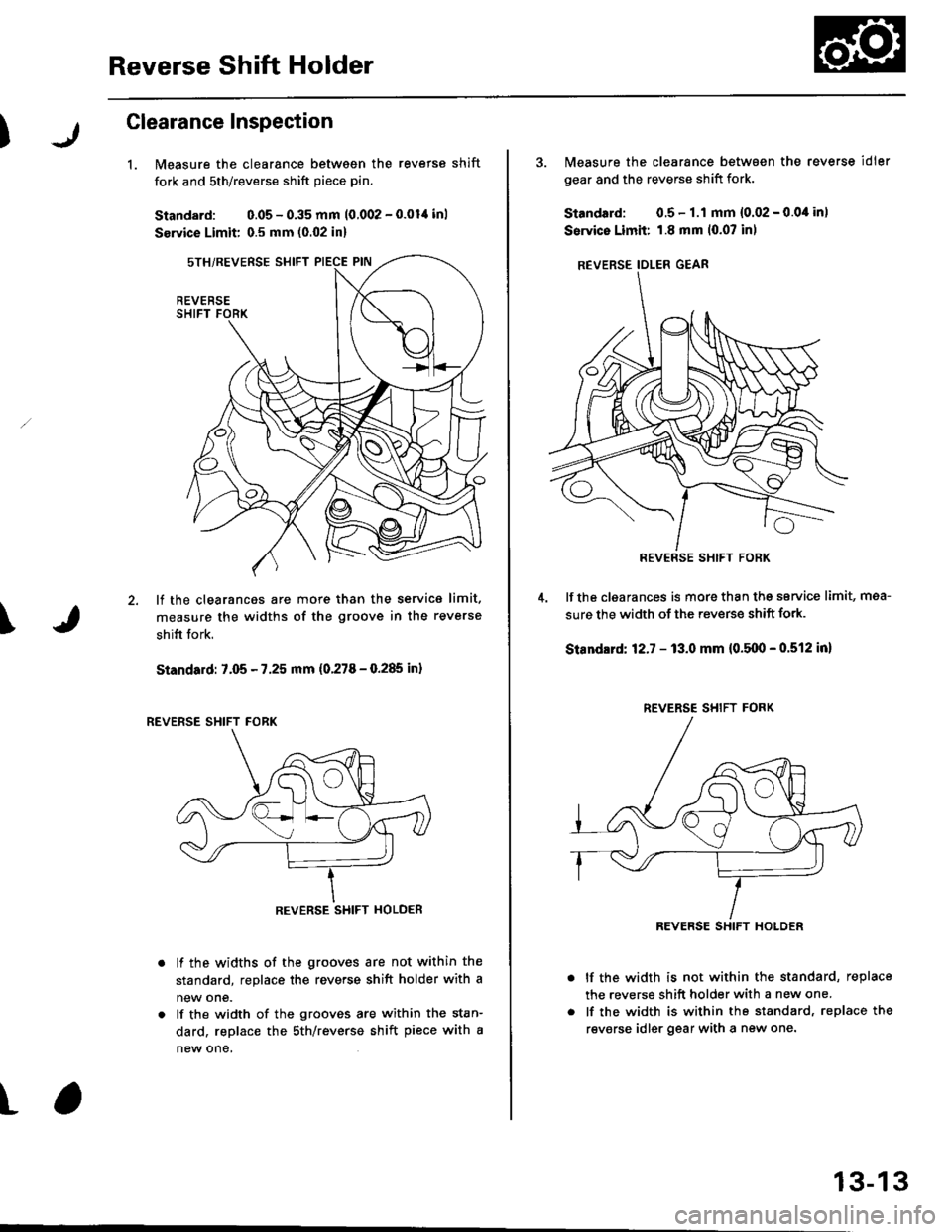

1.Measure the clearance between the reverse shift

fork and sth/reverse shift piece pin.

Standard: 0.05 - 0.35 mm 10.002 - 0.01,1 inl

Service Limit 0.5 mm (0.02 in)

lf the clearances are more than the service limit.

measure the widths of the groove in the reverse

shifi fork.

Standard: 7.05 - 7.25 mm (0.278 - 0.285 inl

lf the widths of the grooves are not within the

standard, replace the reverse shift holder with a

new one.

lf the width of the grooves are within the stan-

dard, replace the sth/reverse shift piece with a

new one,

\

t

REVERSE

REVERSE SHIFT HOLDER

3. Measure the clearance between the reverse idler

gear and the reverse shift fork.

Standard: 0.5- 1.1 mm {0.02 - 0.0,1in)

Service Limii: 1.8 mm 10.07 inl

REVERSE IDLER GEAR

lf the clgarances is more than thg service limit, mea-

sure the width of the reverse shift fork.

Standlrd: 12.7 - 13.0 mm {0.5110 - 0.512 in}

lf the width is not within the standard, replace

the reverse shift holder with a new one.

lf the width is within the standard, replace the

revsrse idler gear with a new one.

REV€RSE SHIFT FORK

REVERSE SHIFT FORK

REVERSE SHIFT HOLOER

13-13

Page 607 of 2189

Synchro Sleeve,

Synchro Hub

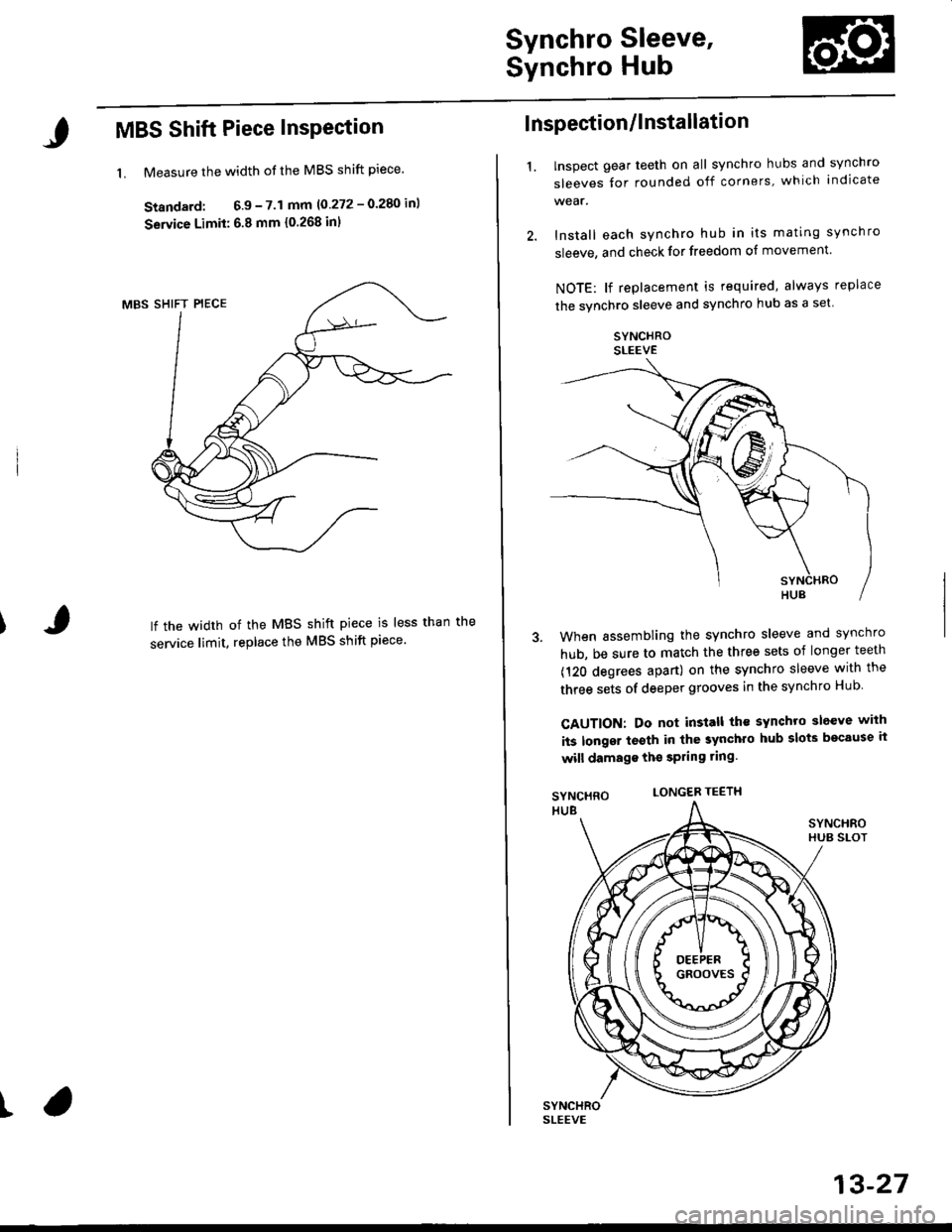

MBS Shift Piece InsPection

1. Measure the width of the MBS shift piece.

Standard; 6.9 - 7.1 mm 10 272 - 0.280 inl

Service Limit: 6.8 mm {0.268 inl

lf the width of the MBS shift piece is less than

service limit, replace the MBS shift piece'

t

I nspection/l nstallati on

'1.lnspect gear teeth on all synchro hubs and synchro

sleeves tor rounded off corners, which indicate

Install each synchro hub in its mating synchro

sleeve, and check for freedom of movement.

NOTE: lf replacement is required, always replace

the synchro sleeve and synchro hub as a set.

SYNCHROSLEEVE

When assembling the synchro sleeve and synchro

hub, be sure to match the three sets of longer teeth

(120 degrees apart) on the synchro sleeve with the

three sets of deeper grooves in the synchro Hub

CAUTION: Do not install th€ sYnchro sleeve with

its longsr t€sth in the synchro hub slots bocause ii

will damage ths spring ring.

LONGER TEETH

13-27

Page 637 of 2189

Reverse Shift Holder,

Reverse ldler Gear

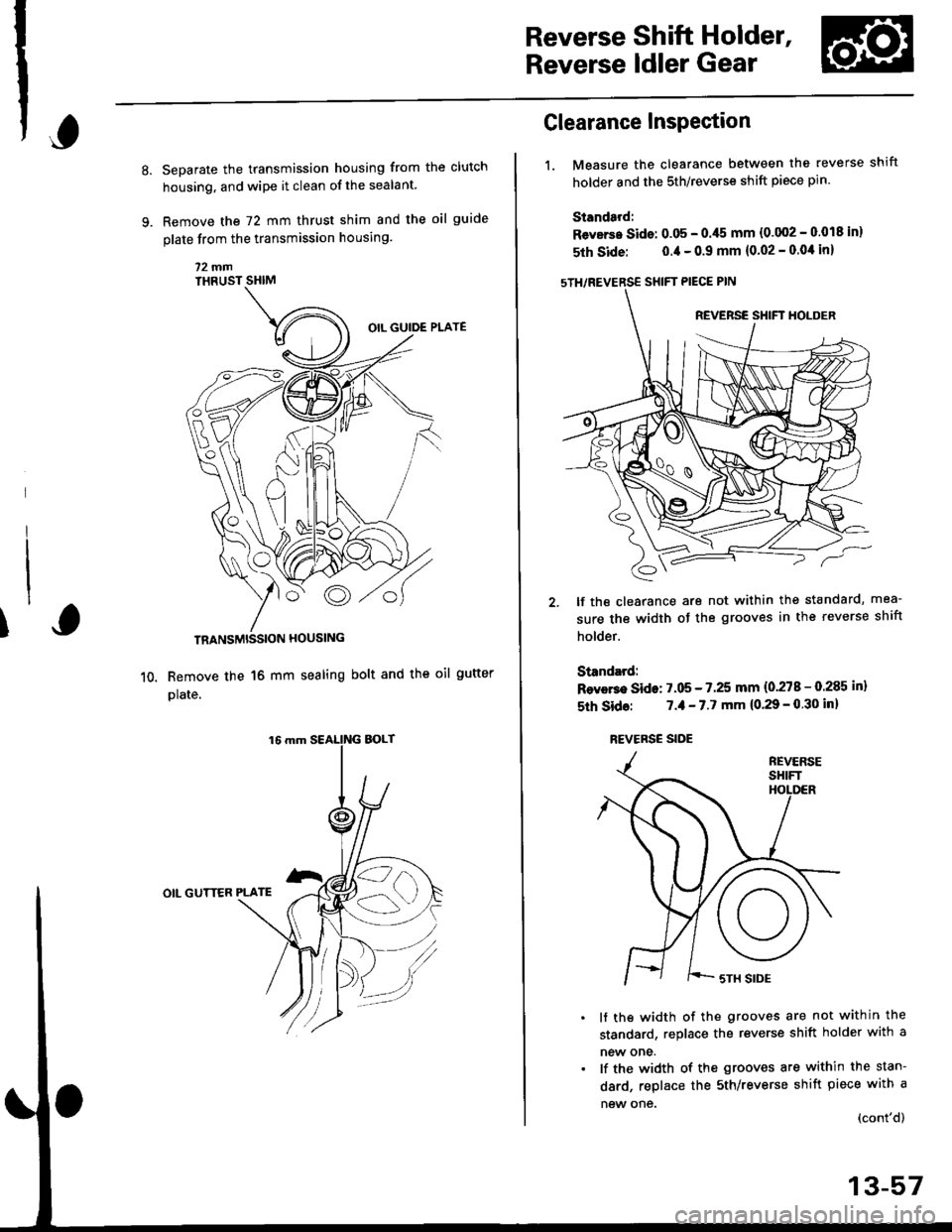

Separate the transmission housing from the clutch

housing, and wipe it clean of the sealant.

Remove the 72 mm thrust shim and the oil guide

plate from the transmission housing

72fifiTHRUST SHIM

TRANSMISSION HOUSING

Remove the 16 mm sealing bolt and the oll gutter

plate.

OIL GUTTER PLATE

fi

1.

Clearance Inspection

Measure the clearance between the reverse shift

holder and the 5th/reverse shift piece pin

Standard:

Revsrs. Sids: 0.05 - 0./t5 mm {0'002 - 0.018 in}

5th Side: 0.4 - 0.9 mm (0.02 - 0.0'l in)

sTH/REVERSE SHIFT PIECE PIN

lf the clearance are not within the standard, mea-

sure the width of the grooves in the reverse shift

holder.

Standard:

Rsvers€ Side: 7.05 - 7.25 mm (0'278 - 0.285 in)

5th Sid6: 7.,1- 7.7 mm (0.29 - 0 30 inl

REVERSE SIDE

lf ths width of the grooves are not within the

standard, replace the reverse shift holder with a

new one.

lf the width of the grooves are within the stan-

dard, replace the sth/reverse shift piece with a

new one {cont'd)

13-57

Page 638 of 2189

Reverse Shift Holder, Reverse ldler Gear

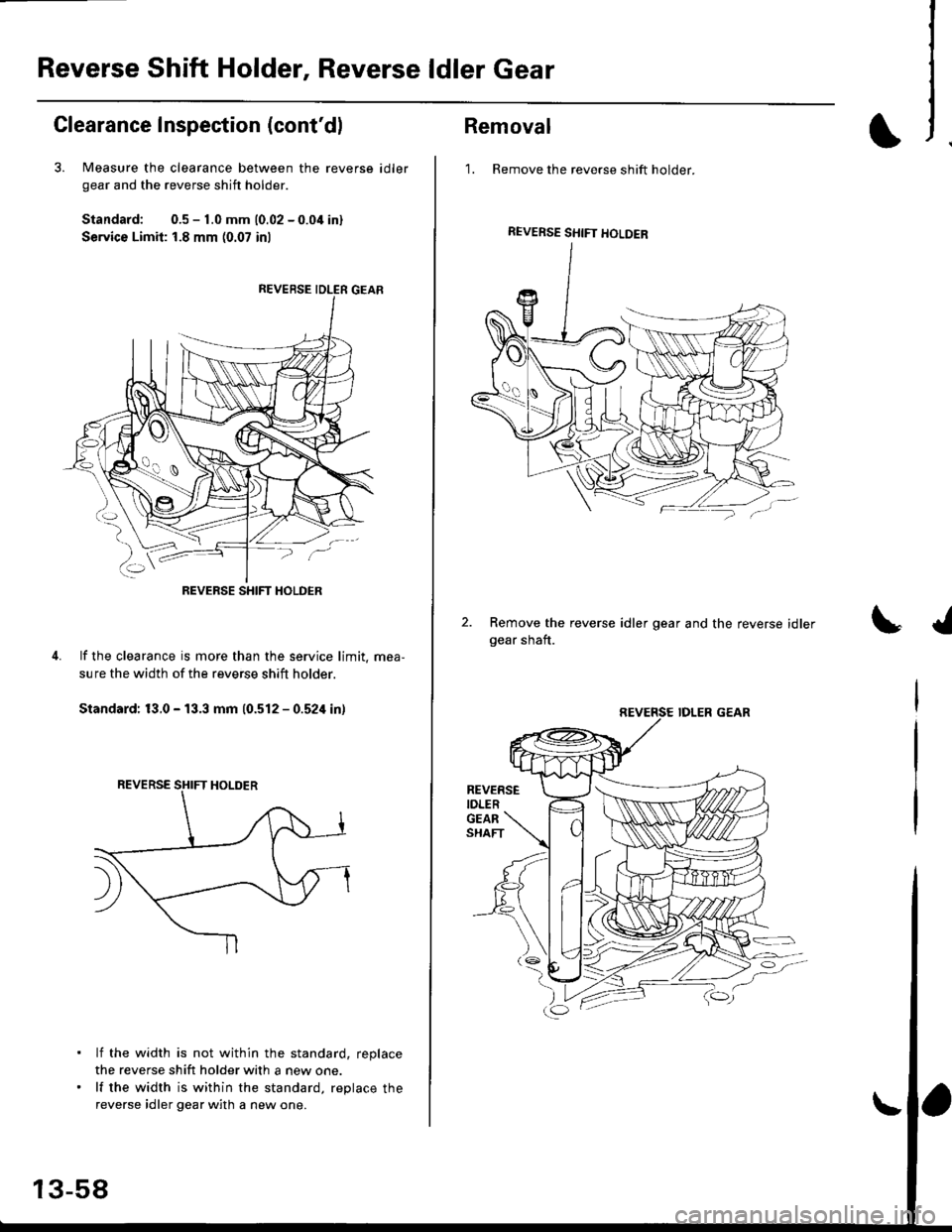

Clearance Inspection (cont'dl

3. Measure the clearance between the reverse

gear and the reverse shift holder.

Standard: 0.5 - 1.0 mm 10.02 - 0.04 inl

Service Limit: 1.8 mm (0.07 inl

id ler

lf the clearance is more than the service limit. mea,

sure the width of the reverse shift holder.

Standard: 13.0 - 13.3 mm (0.512 - 0.524 in)

lf the width is not within the standard, replace

the reverse shift holder with a new one.

lf the width is within the standard, replace the

reverse idler gear with a new one.

REVERSE SHIFT HOLDER

13-58

Removal

1. Remove the reverse shift holder.

Remove the reverse idler gear and the reverse idlergear shaft.

REVERSE SHIFT HOLDEB

REVERSEIDLER

Page 639 of 2189

Change Holder AssemblY

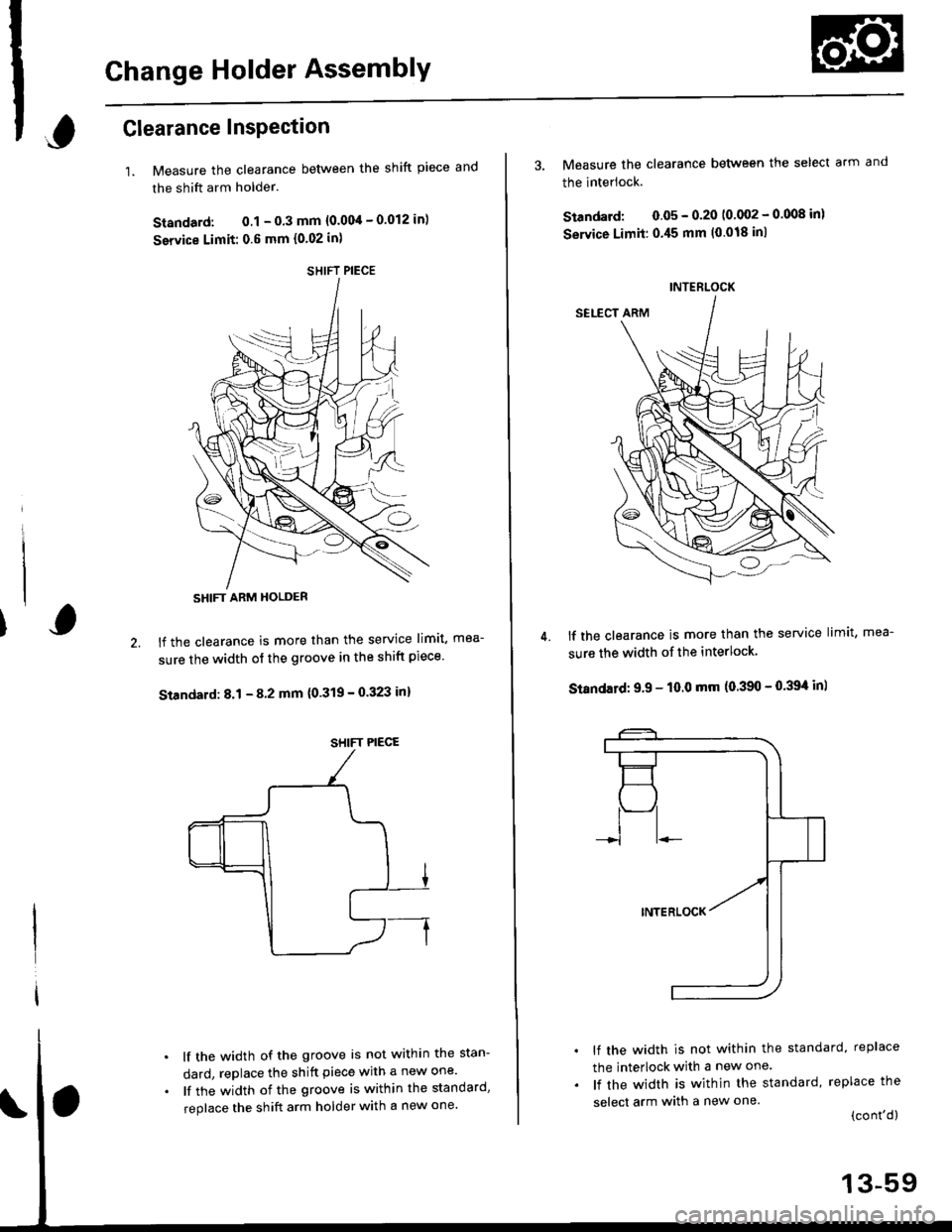

,Glearance InsPection

1.Measure the clearance between the shift piece and

the shift arm holder.

Standard: 0.1 - 0.3 mm {0.004 - 0.012 in)

service Limit: 0.6 mm {0.02 in)

lf the clearance is more than the service limit, mea-

sure the width of the groove in the shift piece'

Standard: 8.1 - 8 2 mm {0'319 - 0.323 in}

lf the width of the groove is not within the stan-

dard, replace the shift piece with a new one'

lf the width of the groove is within the standard,

replace the shift arm holder with a new one'

SHIFT PIECE

SHIFT ARM HOLDER

SHIFT PIECE

4.

3. Measure the clearance between the select arm and

the interlock.

Standard: 0.05 - 0.20 10 002 - 0.008 inl

Service Limit:0.45 mm (0.018 inl

lf the clearance is more than the service limit, mea-

sure the width of the interlock.

Standatd: 9.9 - 10.0 mm (0.390 - 0.39't in)

lf the width is not within the standard, replace

the interlock with a new one.

lf the width is within the standard, replace the

select arm with a new one.(cont'd)

INTERLOCK

13-59

Page 641 of 2189

UO

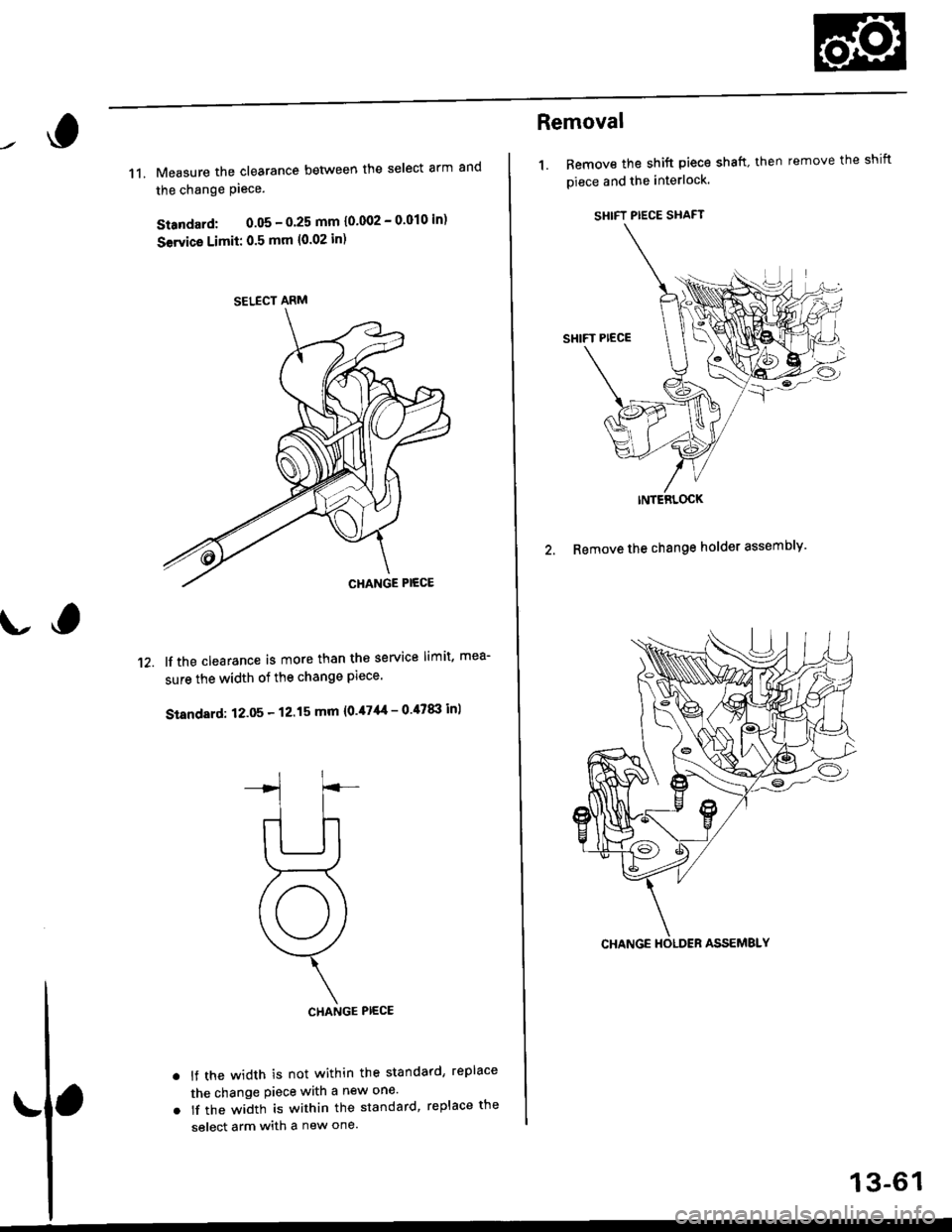

11. Measure the clearance between the select arm and

the change Piece.

Standard: 0.05 - O'25 mm 10'002 - 0'010 in)

Servica Limii: 0.5 mm {0.02 in)

lf the clearance is more than the service limit, mea-

sure the width of the change Plece.

Standard: 12.05 - 12.15 mm {0.47'|{ - 0 47tI| inl

CHANGE PIECE

lf the width is not within the standard, replace

the change Piece with a new one'

lf the width is within the standard, replace the

select arm with a new one.

't2.

a

a

SELECT ARM

Removal

1. Bemove the shift piece shaft. then remove the shift

piece and the interlock.

SHIFT PIECE SHAFT

INTERLOCK

2. Remove the change holder assembly'

13-61

Page 646 of 2189

Shift Fork Assembly

Clearance Inspection

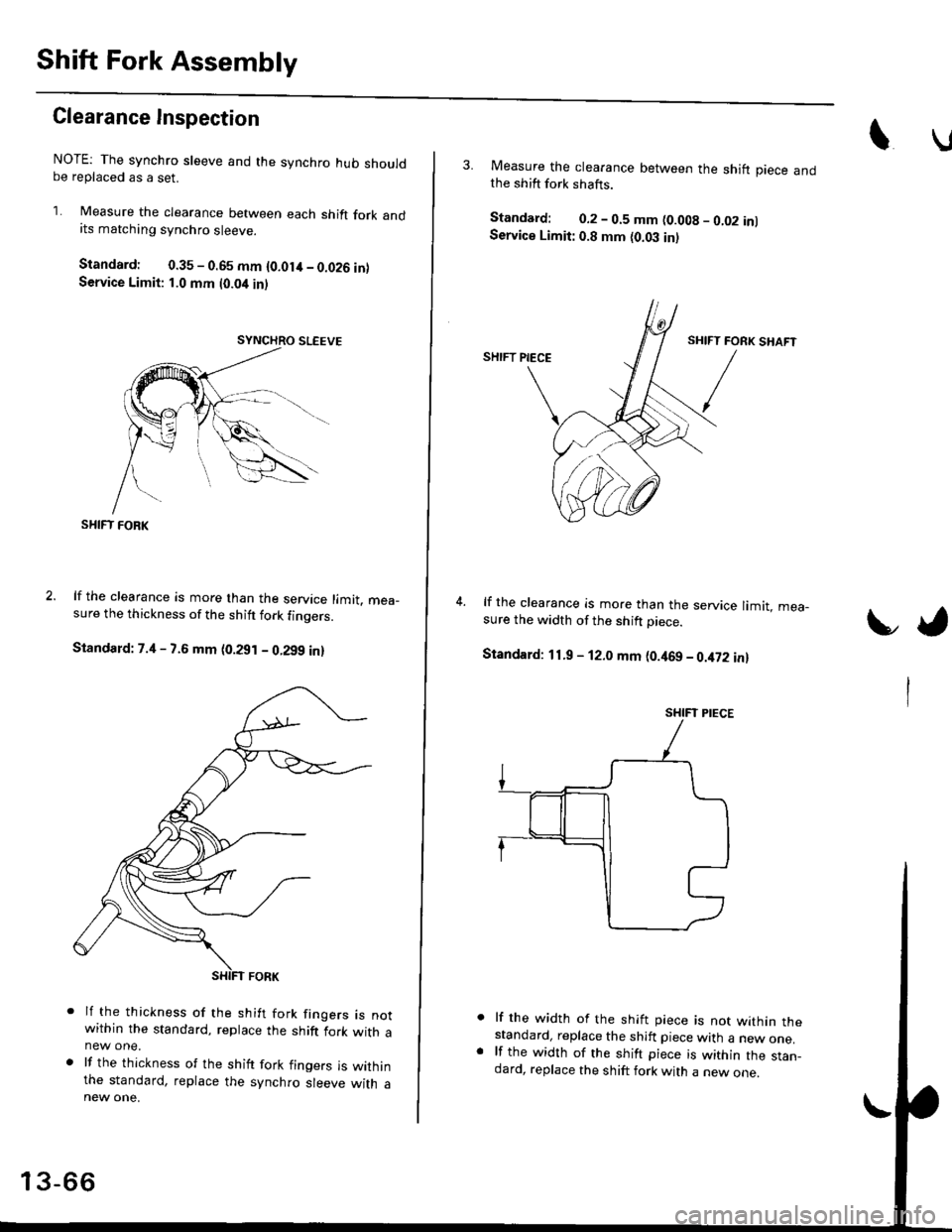

NOTE: The synchro sleeve and the synchro hub shouldbe replaced as a set.

1. Measure the clearance between each shift fork andits matching synchro sleeve.

Standard: 0.35 - 0.65 mm {O.Olit - 0.026 inlService Limit: 1.0 mm t0.04 inl

SHIFT FOBK

lf the clearance is more than the service limit. mea_sure the thickness of the shitt fork finoers.

Standard: 7.4 - 7.6 mm (0.291 - 0.299 in)

lf the thickness of the shift fork frngers rs notwithin the standard, replace the shift fork with anew one.

lf the thickness of the shift fork fingers is withinthe standard, replace the synchro sleeve with a

13-66

3. Measure the clearance between the shift piece andthe shift fork shafts.

Standard: 0.2 - 0.5 mm (0.008 - 0.02 inlService Limit: 0.8 mm {0.03 in)

lf the clearance is more than the service limit. mea-sure the width of the shift Diece.

Standard: 11.9 - 12.0 mm (0.469 - 0.it72 in)

lf the width of the shift piece is not within thestandard, replace the shift piece with a new one.lf the width of the shift piece is within the stan_dard, replace the shift fork with a new one.

t,

SHIFT PIECE

Page 832 of 2189

Gountershaft

Inspection (cont'dl

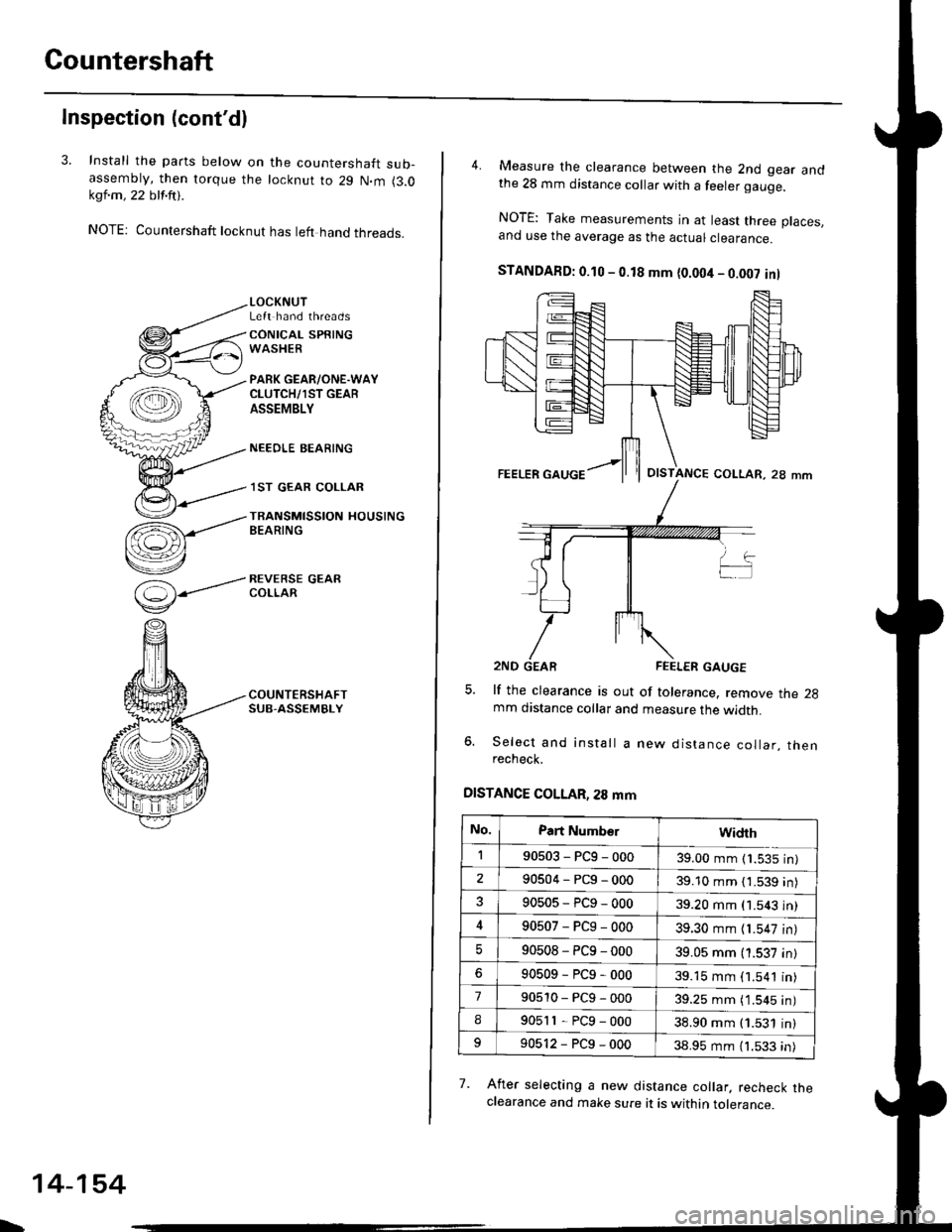

3. Install the parts below on the countershaft sub-assembty, then torque the locknut to 29 N.m (3.0kql.m , 22 blf.ftt .

NOTE: Countershaft locknut has left hand threads.

(=)-----'

v

LOCKNUTLeft hand threads

CONICAL SPRINGWASHER

PARK GEAR/ONE.WAYCLUTCH/1ST GEARASSEMBLY

NEEOLE BEARING

.I ST GEAR COLLAR

TRANSMISSION HOUSINGBEARING

REVERSE GEARCOLLAR

\

14-154

4. Measure the clearance between the 2nd gear andthe 28 mm distance collar with a feeler gauge.

NOTE: Take measurements in at least three places.and use the average as the actuar ctearance.

STANDAFD: 0.10 - 0.18 mm {0.004 - 0.002 inl

lf the clearance is out of tolerance. remove the 2gmm distance collar and measure the width.

Select and install a new distance collar, thenrecheck.

DISTANCE COLLAR, 28 mm

7. Afret selecting a new distance collar, recheck theclearance and make sure it is within tolerance.

OISTANCE COLLAR, 28 mm

No.Part Numb€rwidrh

190503-PCg-00039.00 mm (1.535 in)

290504-PCg-00039.10 mm { 1.539 in)

90505-PCg-00039.20 mm (1.543 in)

90507-PCg-00039.30 mm {1.547 in)

90508-PC9-00039.05 mm (1.537 in)

90509-PCg-00039.15 mm (1.541 in)

790510-PCg-00039.25 mm ( 1.545 in)

I90511-PCg-00038.90 mm (1.531 in)

90512-PCg-00038.95 mm (1.533 in)