Top HONDA CIVIC 2000 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 177 of 2189

Removal

Engine removal is not required for this procedure.

!@@ Make sure jacks and safety stands are placed

properly and hoist brackels are attached to correst posi-

tion on the engine,

CAUTION:

o Use fender covers to avoid damaging painted sur-

faces.

To avoid damage, unplug the wiling connectors

carelully while holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F {38'Cl

before loosening the retaining bolt.

NOTE:

. Unspecified items are common.

. Mark all wiring and hoses to avoid misconnection.

AIso, be sure that they do not contact other wiring or

hoses or interfere with other parts.

o Inspect the timing belt before removing the cylinder

n eao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (see page 6-64).

1. Disconnect the negative terminal from the battery.

Drain the engine coolant {see page 10-7).

. Remove the radiator cap to speed draining.

Remove the strut brace (see page 5-2).

Remove the intake air duct and air cleaner housing

(see page 5-3).

Remove the adjusting bolt and mounting bolt, then

remove the power steering (P/S) pump belt and pump

(see page 5 5).

2.

3.

4.

\

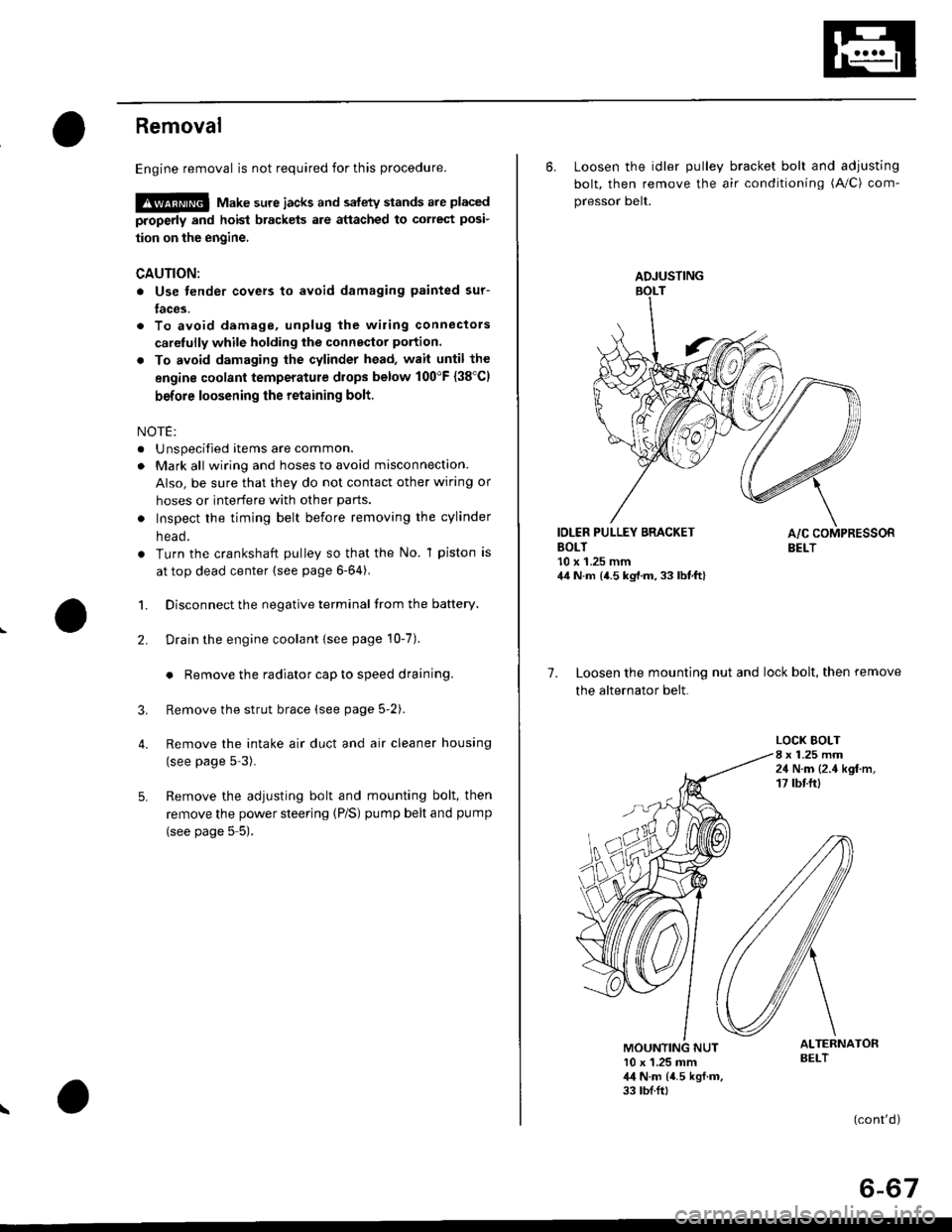

ADJUSTING

6. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A/C) com-

pressor belt.

IDLER PULLEY BRACKETBOLT10 x 1.25 mm44 N.m {4.5 kg,l.m, 33 lbt.ft}

7. Loosen the mounting nut and lock bolt, then remove

the alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgf.m,17 tbtftl

ALTERNATORBELT10 x 1.25 mm,l,l N.m {4.5 kgf.m,33 tbf.ft,

(cont'd)

6-67

Page 203 of 2189

lllustrated Index

(cont'd)

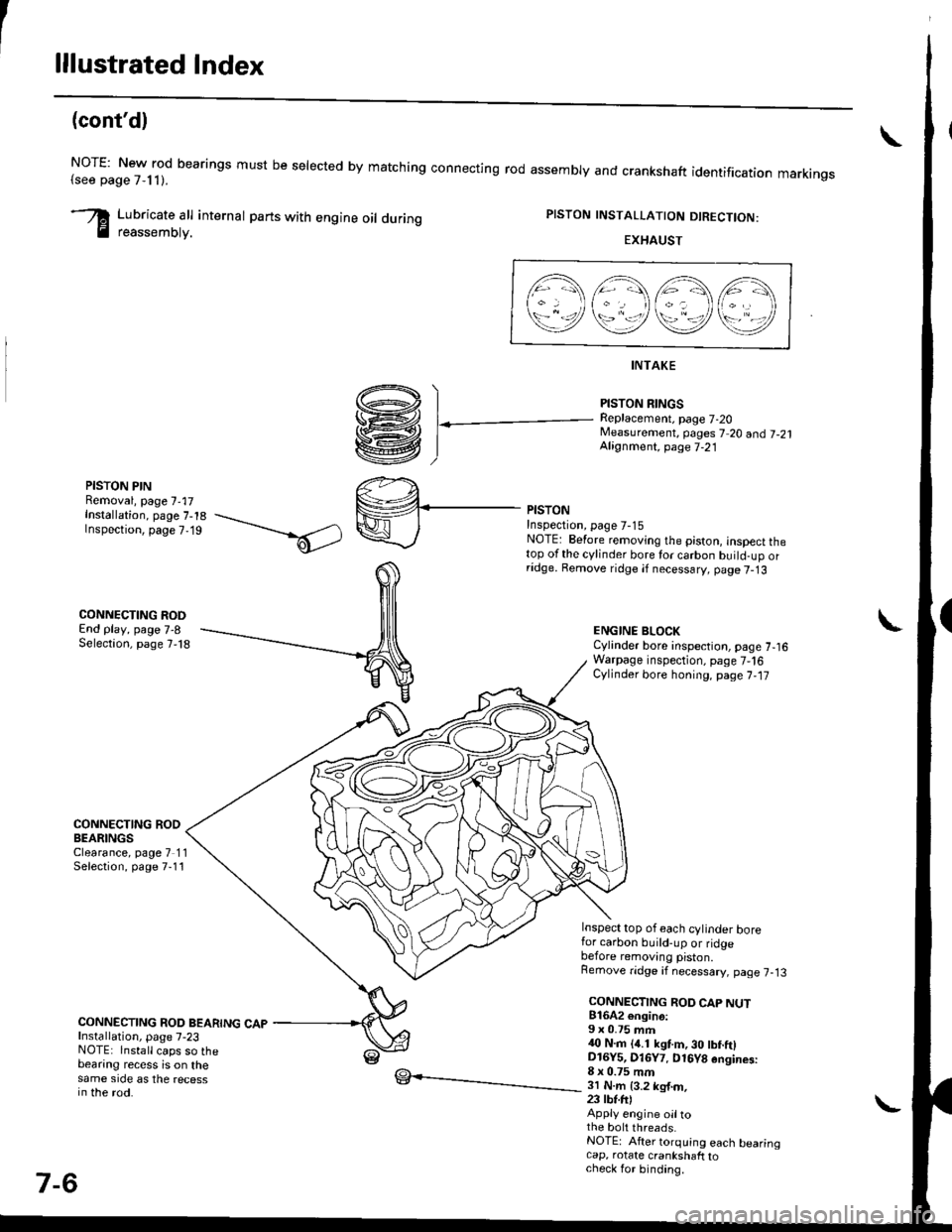

NOTE: New rod bearings must be selected by matching connecting rod assembly and crankshaft(see page 7,11).identification markings

Lubricate all internal parts with engine oil duringreassembtv.

PISTON INSTALLATION DIRECTION:

EXHAUST

4\/=\6\z\

\e/!rqrf/

INTAKE

PISTON RINGSReplacement. page 7-20Measurement, pages 7 20 andj-21Alignment, page 7-21

PISTON PINRemoval, page 7,17Installation, page 7-18Inspection, page 7,19

CONNECTING RODEnd play, page 7-8Selection, page 7,18

CONNECTING RODBEARINGSClearance, page 7 11Selection, page 7-11

CONNECTING ROD BEARING CAPInstallation, page 7-23NOTE: lnstall caps so thebearing recess is on thesame side as the recessin the rod.

PISTONInspectron, page 7-15NOTE: Betore removing the piston, inspect thetop of the cylinder bore for carbon build-up orridge. Bemove ridge if necessary, page 7-13

ENGINE BLOCKCylinder bore inspection, page 7-16Warpage inspection, page 7,'16Cylinder bore honing, page 7,17

Inspect top of each cylinder borefor carbon build-up or ridgebefore removing piston.Remove ridge if necessary, page 7-13

CONNECTING ROD CAP NUT816A2 €ngin6:9 x 0.75 mm{0 N.m (4.1 kgt m, 30 tbf.ftlD16Y5, Dl6Y7. D16Y8 engines:8 x 0.75 mm3l N.m {3.2 kg{.m,23 tbt.fr)Apply engine oiltothe bolt threads.NOTE: After torquing each bearingcap, rotate crankshaft tocheck for binding.

7-6

Page 210 of 2189

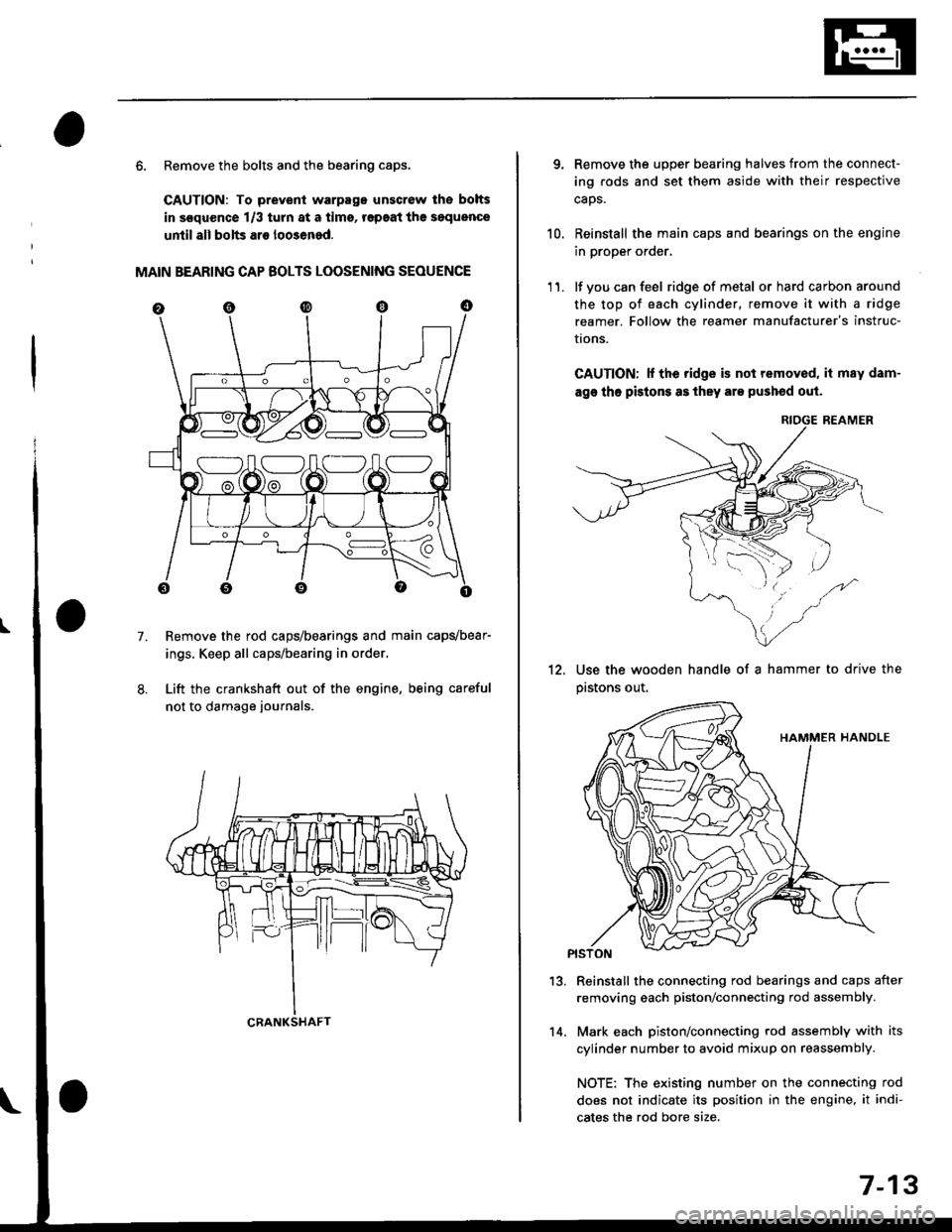

6. Remove the bolts and the bearing caps.

CAUTION: To prevenl warpago unscrow lhe bolts

in s€quence 1/3 turn at a tims, r€paat the soquence

until all bolts ar€ loo3ened.

MAIN BEARING CAP BOLTS LOOSENING SEOUENCE

Remove the rod caps/bearings and main capvbear-

ings. Keep all caps/bearing in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

7.

S:_]ILOJLOAO

CRANKSHAFT14.

7-13

qRemove the upper bearing halves from the connect-

ing rods and set them aside with their respective

caos.

Reinstall the main caps and bearings on the engine

in proper order,

lf you can feel ridge of metal or hard carbon around

the top of each cylinder, remove it with a ridge

reamer. Follow the reamer manufacturer's instruc-

I|ons.

CAUTION; lf the ridge is not removed, it may dam-

age tho pistons as they are pushod out.

RIOGE REAMER

10.

11.

12.Use the wooden handle of a hammer to drive the

pastons out.

13.Reinstall the connecting rod bearings and caps after

removing each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

Page 213 of 2189

Cylinder Block

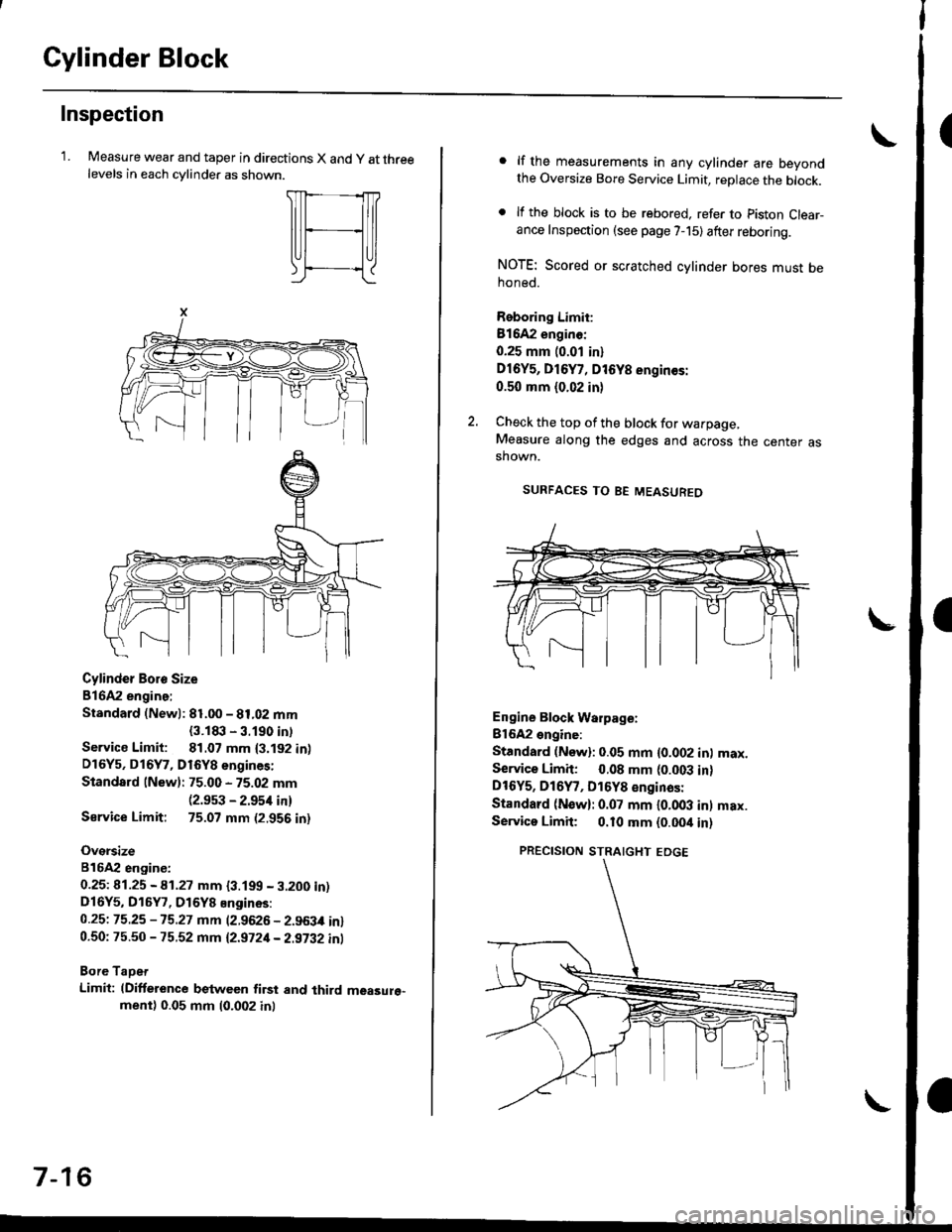

Inspection

'LMeasure wear and taper in directions X and y at threelevels in each cvlinder as shown.

Cylinder Boro Size

816A2 engine:

Standard (Newl: 81.00 - 81.02 mm

{3.1t|:l - 3.190 intService Limit: 81.07 mm {3.192 in)D16Y5, D16Y7, D16Y8 engines:

Standard lNew): 75.00 - 75.02 mm(2.9s3 - 2.954 in)

Sarvice Limit: 75.07 mm (2.956 in)

Oversize

816A2 engiDe:

0.25t 41.25 - A1.27 mm {3.199 - 3.200 in)D16Y5, D16Y7, D16Y8 Engines:

0.25t 75.25 -15.27 mm (2.9626 - 2.963,0 in)0.50: 75.50 - 75.52 mm 12.9721- 2.9i32 inl

Bore TaDet

Limit: (Difference between first and third measure"ment) 0.05 mm (0.002 inl

7-16

lf the measurements in any cylinder are beyondthe Oversize Bore Service Limit, replace the block.

lf the block is to be rebored. refer to piston Clear-ance Inspection (see page 7-15) after reboring.

NOTE: Scored or scratched cylinder bores must behoned.

Reboring Limit:

Bl642 enginc:

0.25 mm (0.01 in)

Dl6Y5, D16Y7, D16Y8 engin€s:

0.50 mm (0.02 in)

Check the top of the block for warpage,Measure along the edges and across the center asshown.

SURFACES TO BE MEASUREO

Engine Block Warpage:

Bl6A2 engine:

Standard (Now): 0.05 mm {0.002 inl max.Service Limh: 0.08 mm (0.003 in)DtOYs, D16Y7, D16Y8 €nginas:

Standard (N€w): 0.07 mm l0.OO3 inl max.Servica Limit; 0.10 mm {0.00it in)

PRECISION STRAIGHT EDGE

Page 217 of 2189

Piston Rings

End Gap

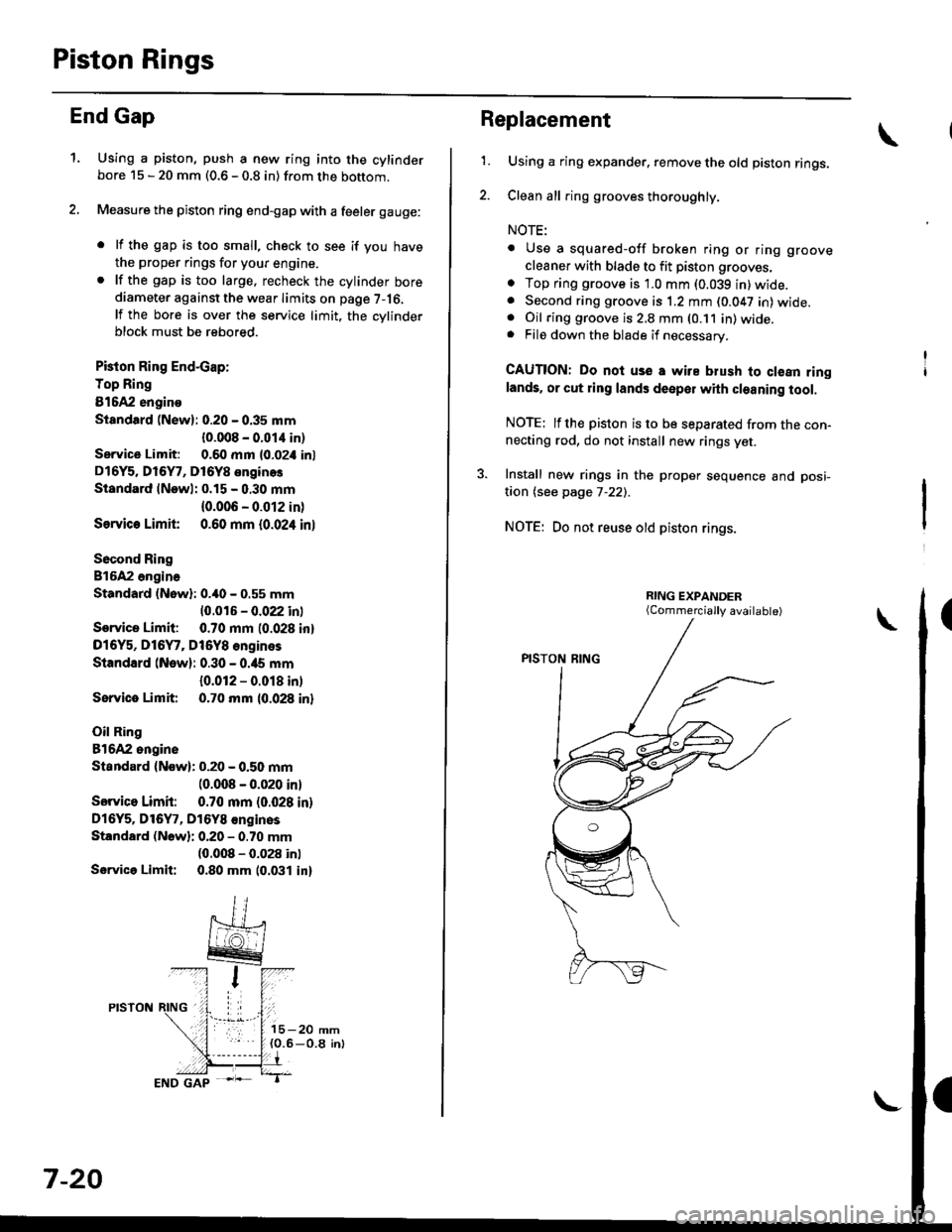

1.Using a piston, push a new ring into the cylinderbore 15 - 20 mm (0.6 - 0.8 in) from the bottom.

Measure the piston ring end-gap with a feeler gauge:

. lf the gap is too small, check to see if you have

the proper rings for your engine.. lf the gap is too large. recheck the cylinder borediameter against the wear limits on page 7-16,

lf the bore is over the service limit, the cvlinderblock must be rebored.

Pkton Ring End-cap:

Top Ring

81642 engino

Siandtrd (New): 0.20 - 0.35 mm

{0.008 - 0.01,1 in)

Service Limit: 0.60 mm l0-02i1 inl

D16Y5. Dl6Y7, D16Y8 enginos

Standard lNewl: 0.15 - 0.30 mm

{0.006 - 0.012 in)

Ssrvic€ Limit 0.60 mm {0.024 inl

Socond Ring

816A2 ongina

Standard (Nowl: 0.40 - 0.55 mm

10.016 - 0.022 inl

Service Limit: 0.70 mm (0.028 inl

D16Y5, D16Y7, Dt6Y8 engines

Standard (New): 0.30 - 0.ia5 mm

{0.012 - 0.018 in)

Sorvice Limit 0.70 mm 10.028 inl

Oil Ring

81642 ongine

Standard {Now): 0.20 - 0.50 mm(0.008 - 0.020 inl

Sorvico Limit: 0.70 mm (0.028 in)

Dl6Y5. Dl6Y7, D16Y8 €nginos

Standard (Nowli 0.20 - 0.70 mm(0.008 - 0.028 inl

Servica Limit: 0.80 mm 10.031 in)

7-20

Replacement

1.Using a ring expander. remove the old piston rings.

Clean all ring grooves thoroughly.

NOTE:

. Use a squared-off broken ring or ring groove

cleaner with blade to fit piston grooves.

o Top ring groove is 1.0 mm (0.039 in)wide.. Second ring groove is 1.2 mm (0.047 in) wide.. Oil ring groove is 2,8 mm (0.11 in) wide.. File down the blade if necessary.

CAUTION: Do noi use a wire blush to clean ringlands. or cut ring lands deepol with cleaning tool.

NOTE: lfthe piston is to be separated from the con-necting rod, do not install new rings yet.

3. Install new rings in the proper sequence and posi-

taon (see page 7-22).

NOTE: Do not reuse old piston rings.

(Commercially available)

Page 218 of 2189

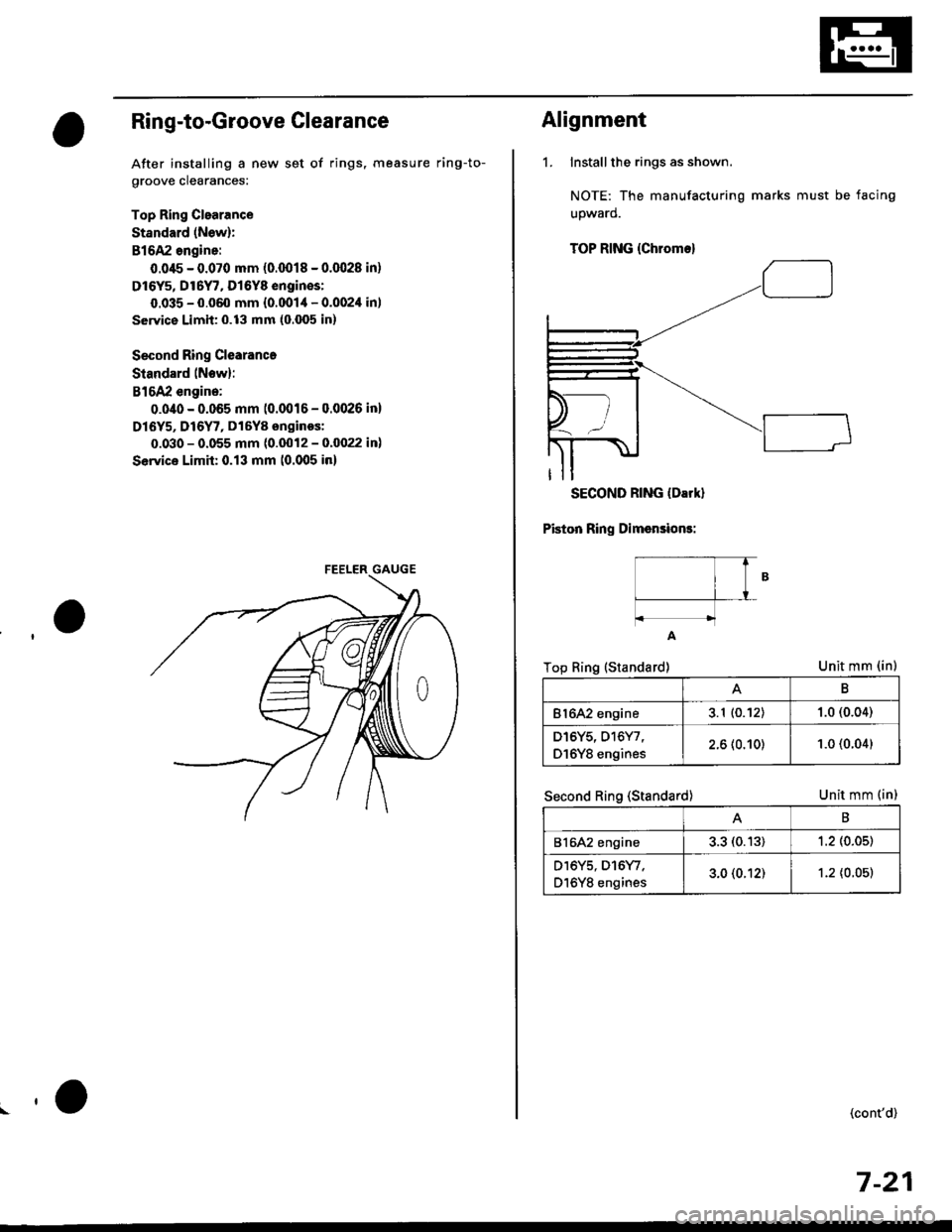

Ring-to-Groove Clearance

After installing a new set of rings, measure ring-to-

groove clearances:

Top Ring Clearance

Standard (New):

B16A2 angine:

0.045 - 0.070 mm (0.0018 - 0.(X128 in)

Dl6Y5, Dt6Y7, Dl6Y8 engin€s:

0.035 - 0.060 mm {0.0014 - 0.002'l in)

service Limit: 0.13 mm (o.fixi in)

Second Ring Clearance

Standard lNow):

B16A2 engine:

0.0/t0 - 0.065 mm (0.0016 - 0.0026 in)

Dl6Y5, D16Y7, D16Y8 onginos:

0.030 - 0.055 mm (0.(X)12 - 0.0022 in)

Sewica Limh: 0.13 mm (0.005 io)

.,o

Alignment

1. Installthe rings as shown.

NOTE: The manufacturing marks must be facing

upward.

SECOND RING (Darkl

Piston Ring Dimsnsions:

Unit mm (in)

Unit mm (in)

TOP RING (Chrome)

t----T f

lB

t---f_-L

A

Top Ring (Standard)

Second Ring (Standard)

B

Bl642 engine3.1 (0.12)1.0 (0.04)

D16Y5, D16Y7,

D16Y8 engines2.6 (0.10)1.0 (0.04)

B

816A2 engine3.3 (0.13)1.2 (0.05)

D16Y5, D16Y/.

D16Y8 engines3.0 (0.12)1.2 {0.05t

(cont'd)

7-21

Page 219 of 2189

Piston RingsCrankshaft Oil Seal

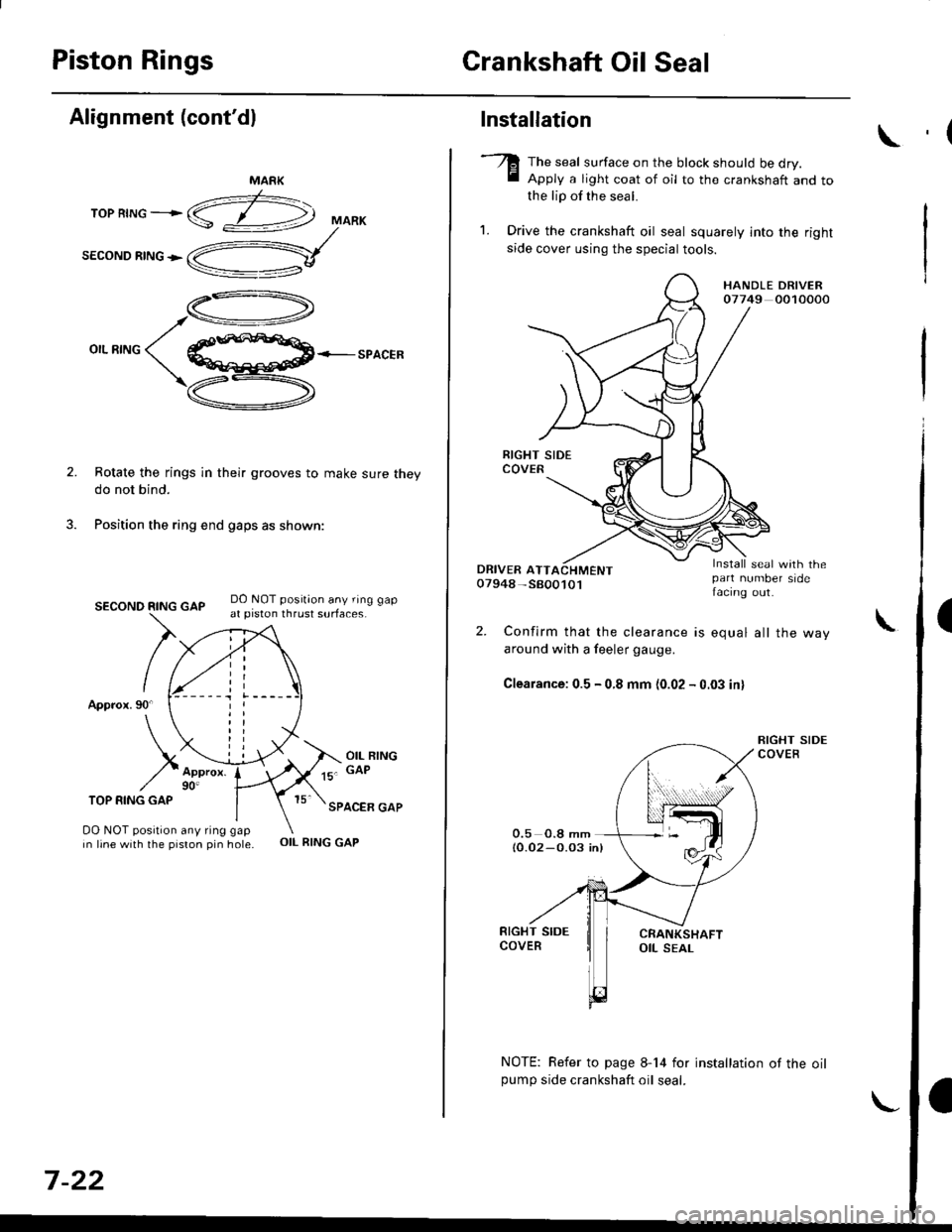

Alignment (cont'dl

TOP RING ---.>

SECOND RING >

MARK

,a-)

/\_4

o,.r^o( qffi<--sPACER

\Z-.

v

Rotate the rings in their grooves to make sure theydo not bind.

Position the ring end gaps as shown:

DO NOT position any ring gapat piston thrust surfaces.

DO NOT position any ring gapin line with the piston pin hole.OIL RING GAP

SECOND RING GAP

Approx.90

TOP RING GAP

7-22

Installation

The seal surface on the block should be dry.Apply a light coat of oil to the c.ankshaft and tothe lip of the seal.

1. Drive the crankshaft oil seal squarely into the right

side cover using the special tools.

HANDLE DRIVER07749 0010000

seal with thepan number sidefacing out.

Confirm that the clearance is equal all the way

around with a feeler gauge.

Clearance:0.5 - 0.8 mm (0.02 - 0.03 inl

NOTE: Refer to page 8-14 for installation of the oilpumo side crankshaft oil seal.

,(

\

Page 220 of 2189

PistonsGrankshaft

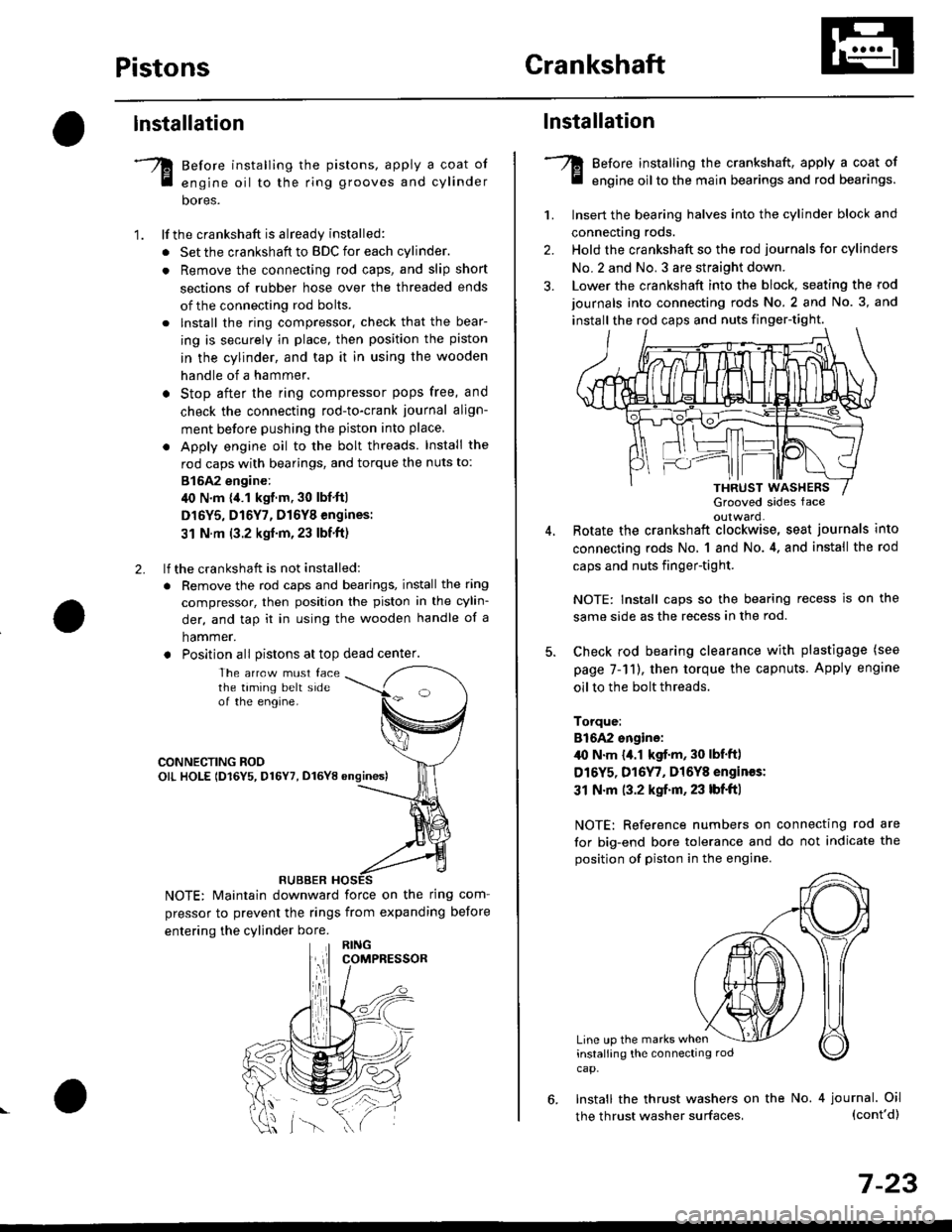

lnstallation

Before installing the pistons, apply a coat of

engine oil to the ring grooves and cylinder

bores.

lf the crankshaft is already installed:

. Set the crankshaft to BDC for each cylinder.

. Remove the connecting rod caps, and slip short

sections of rubber hose over the threaded ends

of the connecting rod bolts.

. lnstall the ring compressor. check that the bear-

ing is securely in place, then position the piston

in the cylinder, and tap it in using the wooden

handle of a hammer.

o Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place

. Apply engine oil to the bolt threads. Install the

rod caps with bearings, and torque the nuts to:

815A2 engine:

40 N.m {,1.1 kgf.m, 30 lbf'ft|

D16Y5, D16Y7, D16Y8 engines:

31 N.m (3.2 kgf'm,23 lbf'ft)

lf the crankshaft is not installed:

. Remove the rod caps and bearings, install the ring

compressor, then position the piston in the cylin-

der, and tap it in using the wooden handle of a

hammer.

. Position all Distons at top dead center.

1.

2.

The arrcw must facethe taming belt sideof the engine.

CONNECTING ROOOIL HOLE lD16Y5, D16Y7, D16YB ongines)

NOTE: Maintain downward force on the ring com-

pressor to prevent the rings from expanding before

entering the cylinder bore.

RUBBER

,lll

lnstallation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bearings.

Insert the bearing halves into the cylinder block and

connecting rods.

Hold the crankshaft so the rod journals for cylinders

No.2 and No. 3 are straight down.

Lower the crankshaft into the block, seating the rod

journals into connecting rods No. 2 and No. 3, and

install the rod caps and nuts finger-tight.

1.

2.

3.

5.

Grooved sides faceoulward.Botate the crankshaft clockwise, seat journals into

connecting rods No, 1 and No.4, and install the rod

caps and nuts finger-tight.

NOTE: Install caps so the bearing recess is on the

same side as the recess in the rod.

Check rod bearing clearance with plastigage (see

page 7-11), then torque the capnuts. Apply engine

oil to the bolt threads.

Torque:

816A2 sngine:/l{, N.m {a.l kgf.m, 30 lbf'ftl

D16Y5, D16Y7, Dl6Y8 engines:

31 N.m (3.2 kgf.m, 23 lbf'ft|

NOTE: Reference numbers on connecting rod are

for big-end bore tolerance and do not indicate the

position of piston in the engine.

Line up the marks wheninstalling the connectrng rod

cap.

6. Install the thrust washers on the No. 4 journal. Oil(cont'd)

7-23

the thrust washer surfaces,

Page 221 of 2189

Crankshaft

Installation (cont'd)

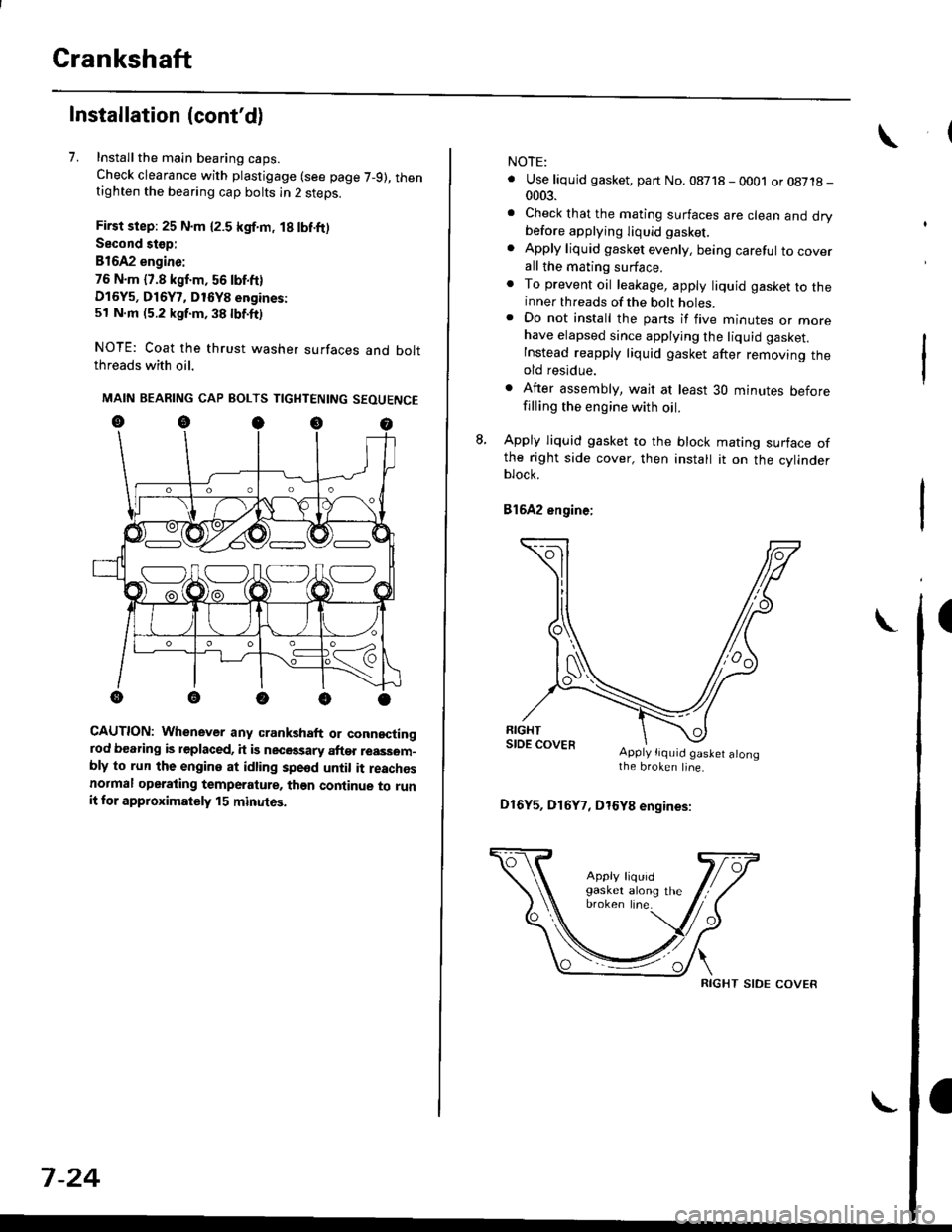

7. Installthe main bearing caps.

Check clearance with plastigage (see page 7-9), thentighten the bearing cap bolts in 2 steps.

First step: 25 N.m {2.5 kgf.m, 18 lbf.ft)

Second stop:

B1642 engine:

76 N.m {7.8 kgf.m, 56 lbf.ft)

D16Y5, D16Y7, D16Y8 engines:

51 N.m (5.2 kgf.m, 38 lbf.ft)

NOTE: Coat the thrust washer surfaces and boltthreads with oil.

MAIN BEARING CAP BOLTS TIGHTENING SEOUENCE

oocoo

CAUTION: Whenever any crankshaft or connectingrod bearing is replaced, it is necGssary after reassom-bly to run the engine at idling spe6d until it reachesnormal operating temperature, than continue to runit for approximately 15 minutos.

:V fr\-/.---\-/.-

7-24

NOTE:

. Use liquid gasket, part No. 08718 - 0001 or08718-0003.

. Check that the mating surfaces are clean and drybefore apptying liquid gasket.

. Apply liquid gasket evenly, being careful to coverall the mating surface.. To prevent oil leakage, apply liquid gasket to theinner threads of the bolt holes.. Do not install the parts if five minutes or morehave elapsed since applying the liquid gasket.

Instead reapply liquid gasket after removing theold residue.

. After assembly, wait at least 30 minutes beforefilling the engine with oil.

L Apply liquid gasket to the block mating surface ofthe right side cover, then install it on the cylinderblock.

Bl6A2 engine;

Apply tiquid gaslet alongthe broken line.

D16Y5, D16Y7, D16Y8 engines:

RIGHT SIDE COVER

Page 264 of 2189

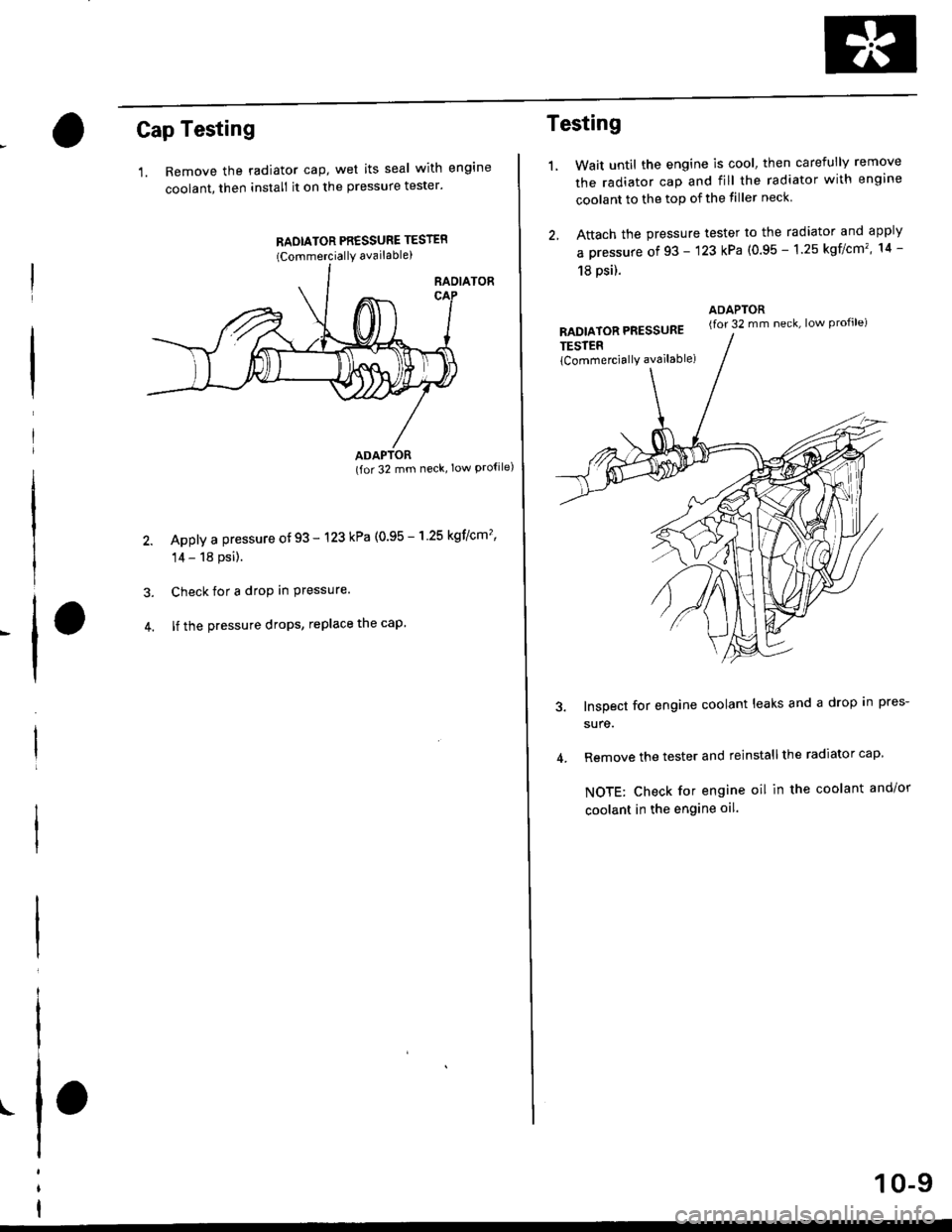

Cap Testing

1. Remove the radiator cap, wet its seal with engine

coolant, then install it on the pressure tester'

RADIATOR PR€SSURE TESTER(CommerciallY available)

RAOIATOR

(for 32 mm neck' low Pro{ile)

Apply a pressure of 93 - 123 kPa (0.95 - 'l 25 kgflcm'�'

14 - 18 psi).

Check for a drop in Pressure.

lf the pressure drops, replace the cap

I

t

ADAPTOR

Testing

LWait until the engine is cool, then carefully remove

the radiator cap and fill the radiator with engine

coolant to the top of the tiller neck

Attach the pressure tester to the radiator and apply

a pressure of 93 - '123 kPa (0.95 - 1.25 kgflcm'�, 14 -

18 psil.

RADIATOR PRESSURE

TESTER

lCommerciallY available)

ADAPTOR(for 32 mm neck, low Profile)

Inspect for engine coolant leaks and a drop In pres-

sure.

Remove the tester and reinstall the radiator cap

NOTE: Check for engine oil in the coolant and/or

coolant in the engine oil.

10-9