o ring HONDA CIVIC 2000 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 67 of 2189

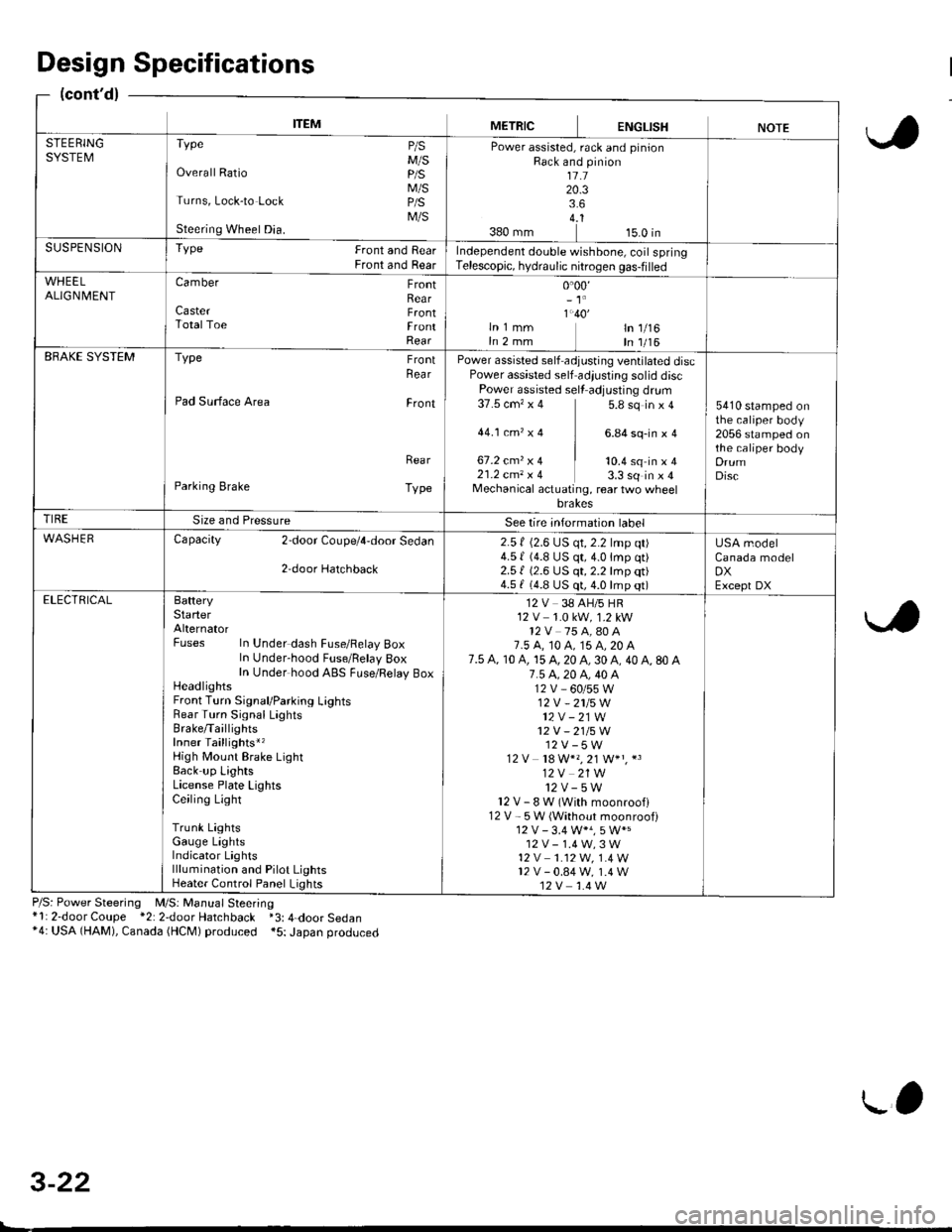

ITEMMETRICENGLISHNOTESTEERINGSYSTEMTvpe P/sM/SOverall Ratio p/S

M/STurns, Lock-to Lock p/S

M/SSteering Wheel Dia.

Power assisted, rack and pinionRack and pinion1l.120.33.64..1380 mm 15.0 inSUSPENSIONTYPe Front and RearFront and RearIndependent double wishbone, coil springTelescopic, hydraulic nitrogen gas-filled

WHEELALIGN| 4ENTCamber FrontRearCaster F.ontTotalToe FrontRear

0.00,- 't'

1.40'ln 1 mm ln 1/16In 2 mm In 1/16EBAKE SYSTEMType FrontRea r

Pad Surface Area Front

Rea r

Parking Brake Type

Power assisted self adjusting ventilated discPower assisted self adiustjng solid discPower assisted sell adjusting dr!m37.5 cm'�x 4 5.8 sq in x 4

44.1ctn,x4 ] 6.84sq-inxa

67.2 cmz x 4 | to.+ sq in ' I21.2 cm, x 4 3.3 sq in x 4Mechanical actuating, rear two wheelbrakes

5410 stamped onthe caliper body2056 stamped onthe caliper bodyDrumDisc

TIRESize and PressureSee lire intormation label

WASHERCapacity 2door Coupe/4,door Sedan

2,door Hatchback

2.5 f (2.6 LJS qt, 2.2 lmp qt)4.5 | (4.8 US qt,4.0lmp qt)2.51 (2.6 US qt, 2.2 lmp qt)4.5 f (4.8 US qt, 4.0 lmp qt)

USA modelCanada modelDXExcept DXELECTRICALBafteryStarterAlternatorFuses In Under dash Fuse/Felay BoxIn Under-hood Fuse/Belay 8oxIn Under hood ABS FLrse/Relay BoxHeadlightsFront Turn Signal/Parking LightsRear Turn Signal LaghtsBrake/TaillightsInner Taillights*,High Mount Brake LightBack up LightsLicense Plate LightsCeiling Light

Trunk LightsGauge LightsIndicator Lightslllumination and Pilot LightsHeater Control Panel Lights

12 V 38 AH/5 HR12 V 1.0 kW, 1.2 kW12V 75 A,80 A7.5 A, t0 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A, 80 A7.5 4.20 A, 40 A12V_60/55W12V -2115W

12V - 21W12V - 21/5W12V-5W12 V 18 W*" 21 W+" *3

12V 21W12v-5wl2V-8W(Withmoonroofl12 V - 5W (Without moonroof)

12V-1.4W,3W't2 v 1.12W. 1.4 W12v-0.84w, 1.4 W12V 1.4 W

Design Specifications

(cont'd)

P/S: Power Steering M/S: Manual Steering*l: 2-door Coupe *2: 2door Hatchback *3: 4-door Sedan*4: USA (HAM), Canada (HCM) produced *5: Japan produced

3-22

L'

Page 72 of 2189

ILubrication Points

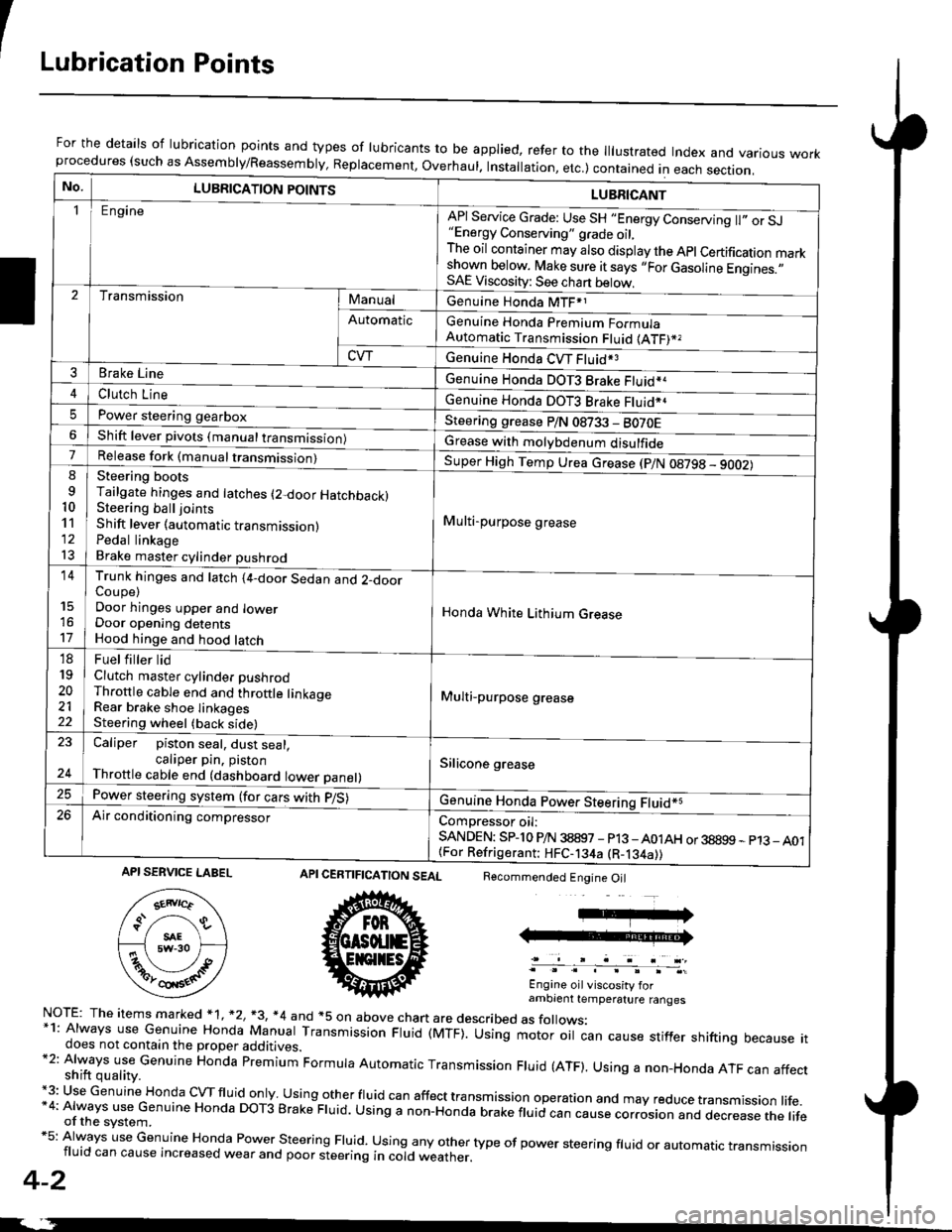

For the details of lubrication points and types of lubricants to be applied, refer to the lllustrated Index and various workprocedures (such as Assembly/Reassembly, Replacement, Overhaul. Installation, etc.) contained in each section.

No.LUBRICATION POINTS

Engine

LUBRICANT

"Energy Conserving" grade oil,The oil container may also display the Apl Certification markshown below. Make sure it says ,,For Gasoline Engines.,,SAE Viscosity: See chart below,

I

TransmissionManualGenuine Honda MTF*1

Genuine Honda Premium FormulaAutomatic Transmission Fluid (ATF)*,

Genuine Honda CVT Fluid*3

Genuine Honda DOT3 Brake Fluid*a

Automatic

CVT

3Brake Line

ClL,tci t""e4

I

Genuine Honda DOT3 Brake Fluid*aPower steering gearboxSteering grease P/N 08733 - BO70EShift lever pivots (manual transmission)Grease with molybdenum disulfide7-:ti

9

10'l'l

l3

14

't7

18

19

20

2122

Release fork (manual trancmi

Shift lever (automatic transmission)Pedal linkageBrake master cylinder pushrod

Super High Temp Urea crease (p/N 08798 - 9OO2)

i Multi-purpose grease

I

I

Honda White Lithium Grease

Multi-purpose grease

Silicone grease

@

Trunk hinges and latch (4-door Sedan and 2-doorCoupe)Door hinges upper and lowerDoor opening detentsHood hinge and hood latch-FUet T ter ttd

Clutch master cylinder pushrodThrottle cable end and throttle linkageRear brake shoe linkagesSteering wheel (back side)

23

E-

Caliper piston seal, dust seal,caliper pin. pistonThrottle cable end (dashboard lower panel)

Power steering system (for cars with p/S)

Air conditioning compressorComDressor oil:SANDEN: SPlo P/N 38897 - p13 -A01AH or 38899 - p13_ A01{For Refrigerant: HFC-134a (R-134a))

CERTIFICATION SEAL

ffi

NorE: The items m arked * 1, *2, +3, *4 and +5 on above chan are described as folows:*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because itdoes not contain the proper additives.*2: Always use Genuine Honda premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affectshift quality.+3: Use Genuine Honda cVTfluid only usingotherfluid can affect tra nsmission operation and may reduce transmission life.*4: Always use Genuine Honda DoT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and dec.ease the lifeof the svstem.*5: Always use Genuine Honda Power steering Fluid. using any other type of power steering fluid or automatrc transmissionfluid can cause increased wear and poor steering in cold weather.

4-2

Recommended Engine Oil

Engine oil viscosity forambrent temperature ranges

API SERVICE LABEL

Page 96 of 2189

Engine RemovaUlnstallation

Removal

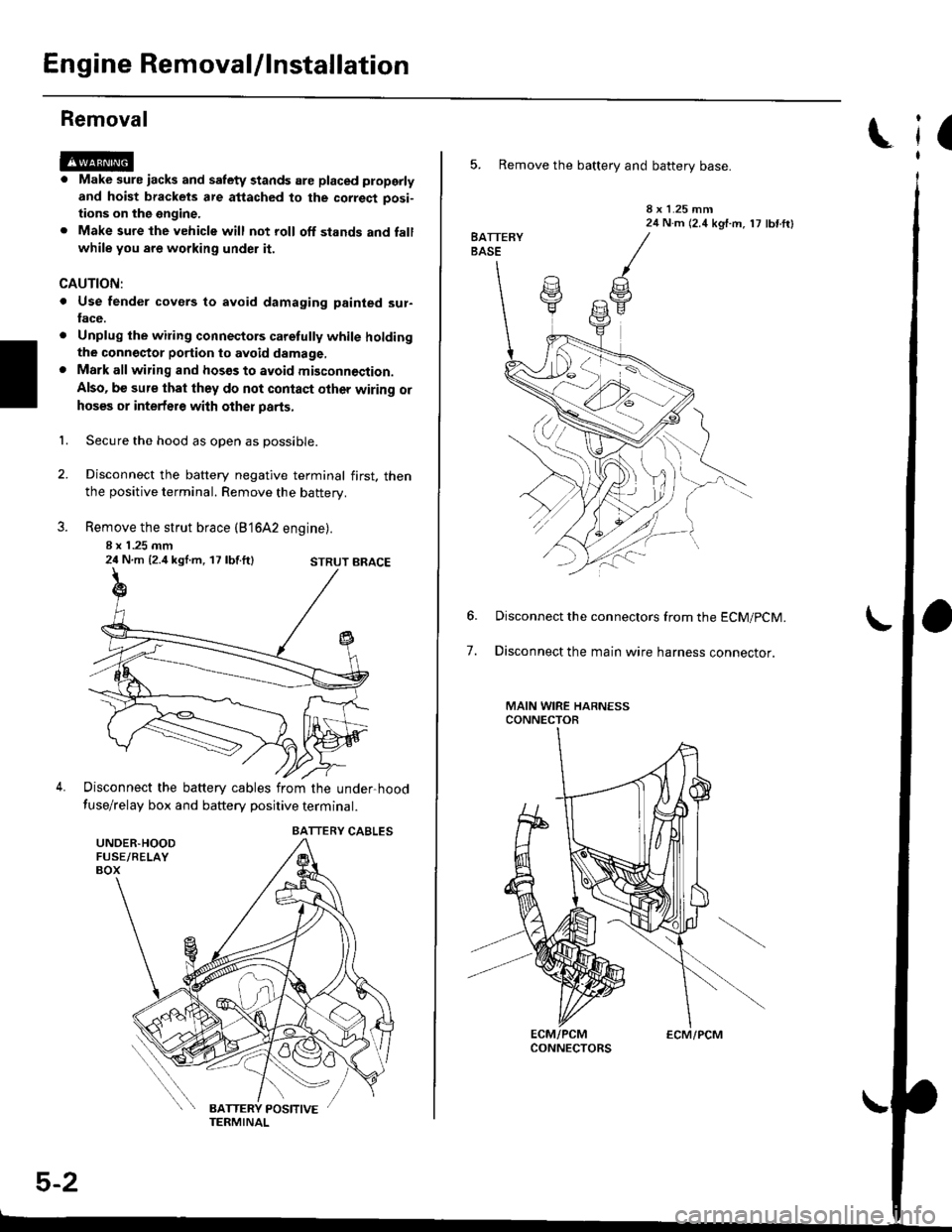

@@

1.

. Make sure iacks and salety stands are placed ploperly

and hoist brackets are attached to the correct posi-

tions on the engine.

. Make sure the vehicle will not roll off stands and fall

while you are working under it.

CAUTION:

. Use fender covers to avoid damaging painted sur-face.

. Unplug the wilin9 connectors caretully while holdingthe conngstor portion to avoid damage,. Mark all wiring and hosos to avoid misconnoction.

Also, be sure that they do not contact other wiring or

hoses or interfere with other parts,

Secure the hood as open as possible.

Disconnect the battery negative terminal first. thenthe positive terminal. Remove the battery.

Remove the strut brace (B'16A2 engine).

8 x 1 .25 mm24 N.m {2.4 kgl.m, 17 lbf.ft}

Disconnect the battery cables from the under-hood

fuse/relay box and battery positive terminal.

STRUT BRACE

UNDER.HOODFUSE/RELAYBOX

BATTERY CABLES

5-2

ECM/PCM

(

5. Remove the battery and battery base.

8 x 1.25 mm24 N.m (2.4 kgf.m, 17 lbf ftl

7.

Disconnect the connectors from the ECM/pCM.

Disconnect the main wire harness connector.

MAIN WIRE HARNESSCONNECTOR

Page 99 of 2189

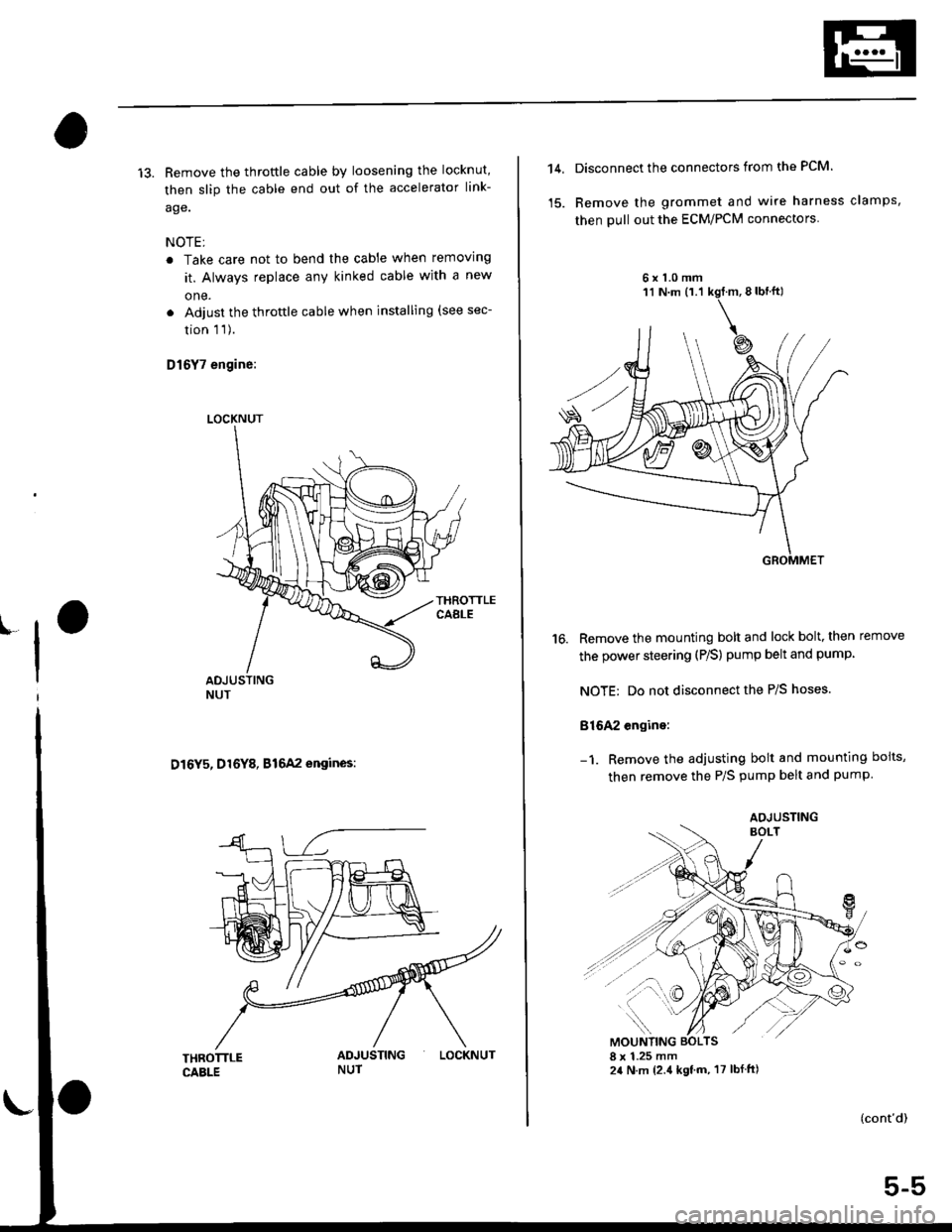

13. Remove the throftle cable by loosening the locknut,

then slip the cable end out of the accelerator link-

age.

NOTE;

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

D16Y5, D16Y8, B16A2 engines:

LOCKNUT

LOCKNUT

14,Disconnect the connectors from the PCM.

Remove the grommet and wire harness clamps,

then pull out the ECM/PCM connectors

6x1.0mm

16. Remove the mounting bolt and lock bolt, then remove

the power steering (P/S) pump belt and pump

NOTE: Do not disconnect the P/S hoses.

816A2 engine:

Remove the adjusting bolt and mounting boits,

then remove the P/S pump belt and pump

(cont'd)

5-5

AOJUSTING

Page 101 of 2189

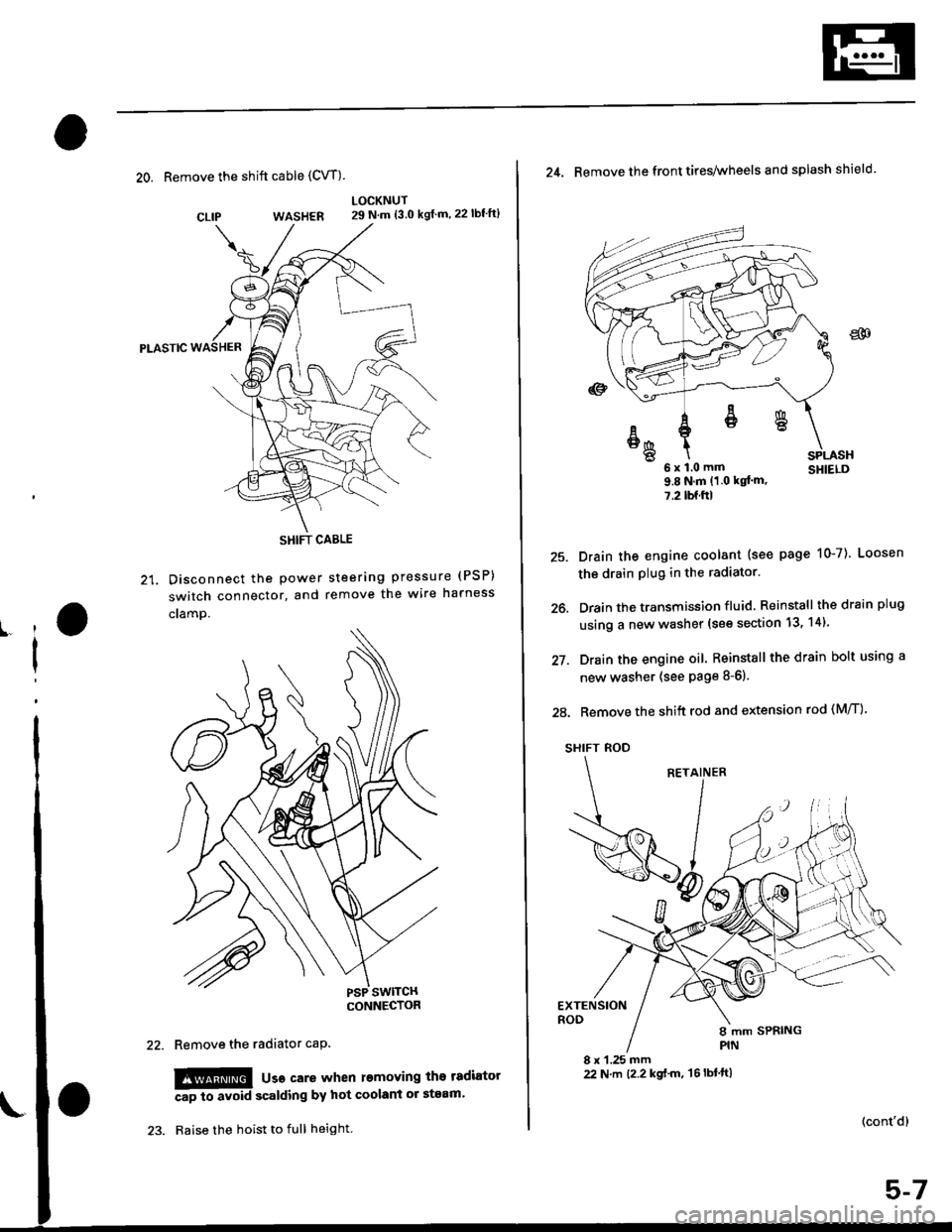

20. Remove the shift cable (CVT)

WASHER

Pt-Aslc

21. Disconnect the Power

switch connector, and

cramp.

LOCKNUT29 N.m {3.0 kgf m,22lbf'ft}

steering pressure (PSP)

remove the wire harness

CLIP

ll

I

Remove the radiator caP.

!!!@ usa care when l€moving the tadiator

Ap to avoid scalding by hot coolant or steam'

Raise the hoist to full height.

SHIFT CABLE

(cont'd)

25.

26.

27.

24. Remove the front tires/wheels and splash shield.

u x l.u mm SHIELD9.8Nm(1 0 kqt'm,

7.2lbf.ftl

Drain the engine coolant (see page 10-7). Loosen

the drain plug in the radiator.

Drain the transmission fluid Reinstall thedrainplug

using a new washer (see section 13, 14).

Drain the engine oil. Reinstall the drain bolt using a

new washer (see page 8-6).

28. Remove the shift rod and extension rod (M/T)

SHIFT ROD

EXTENSIONROD

8 x 1.25 mm22 N.m t2.2 kgf'm, 't6lbtft)

ER

6x1.0mm

Page 105 of 2189

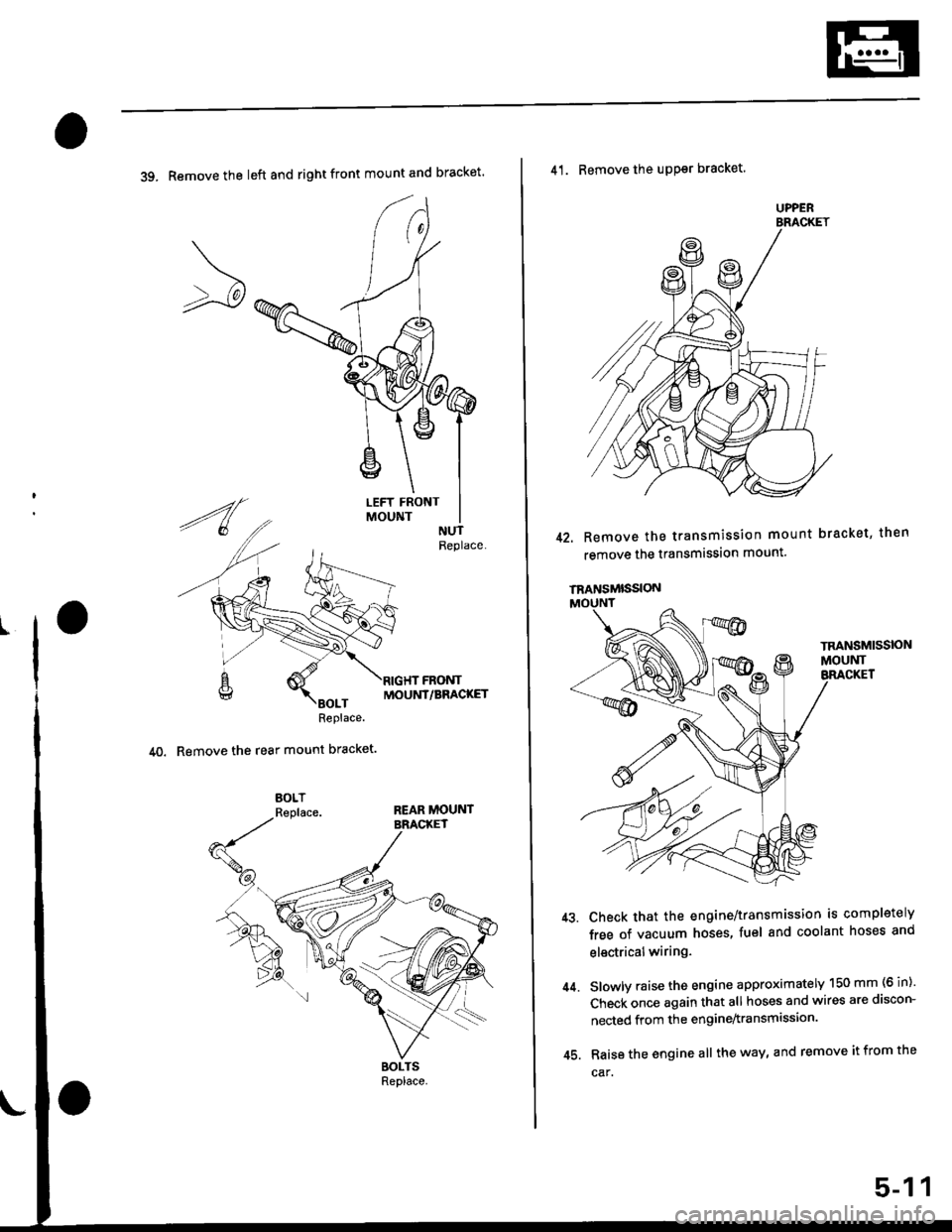

39. Remove the left and right front mount and bracket'

MOUNT/BRACKET

40. Remove the rear mount bracket.

41. Remove the uPPsr bracket.

42. Remove the transmission mount bracket, then

remove the transmission mount.

44.

Check that the engine/transmission is completely

free of vacuum hoses, fuel and coolant hoses and

electricalwiring.

Slowly raise the engine approximately 150 mm (6 in)'

Check once again that all hoses and wires are discon-

nected from the engine^ransmission

Raise the engine all the way, and remove it from the

car.

UPPER

TRANSMISSION

45.

5-11

Page 110 of 2189

Engine Removal/lnstallation

Installation (cont'd)

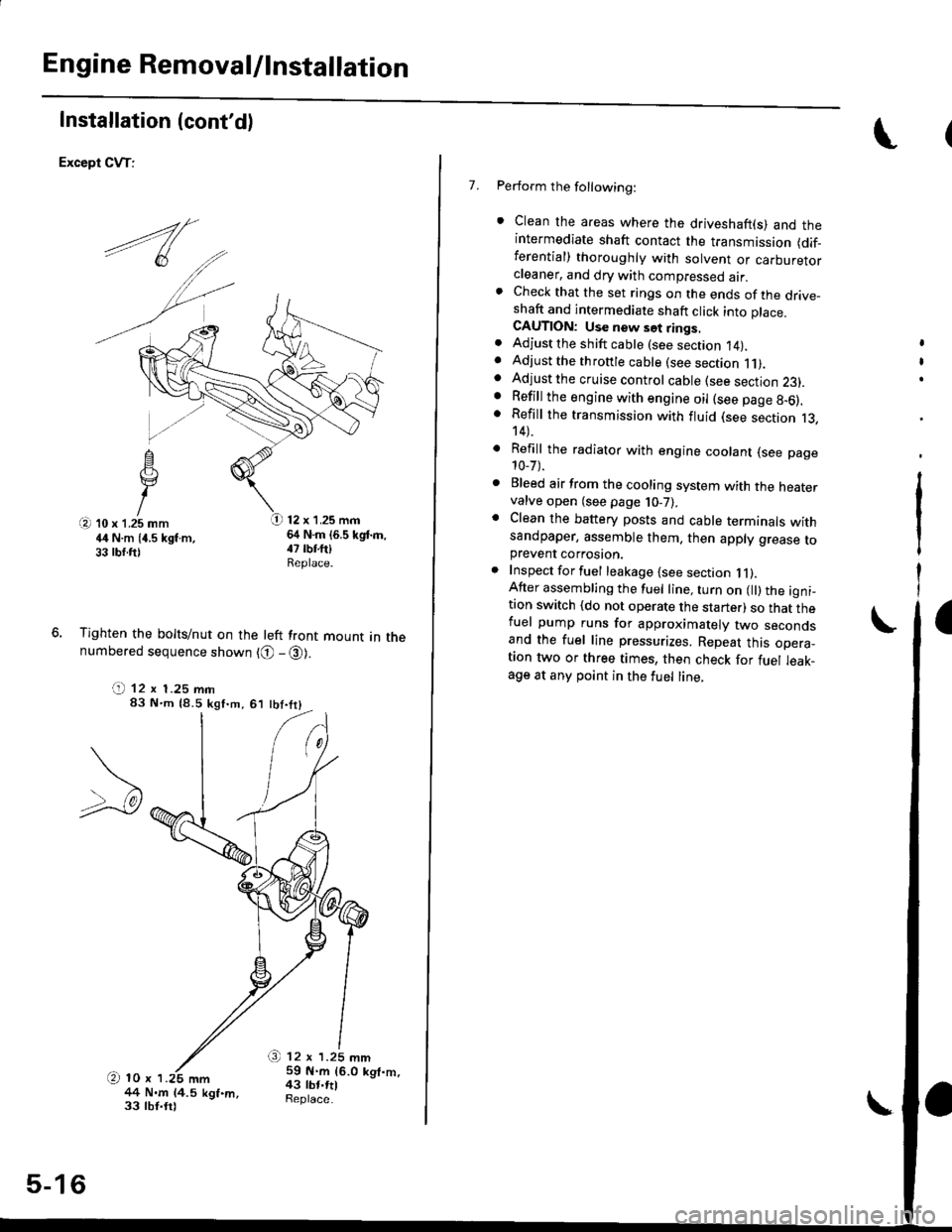

Except CVT:

12 x 1.25 mm64 N.m (6.5 kgd.m,

Tighten the bolts/nut on the left front mount in thenumbered sequence shown {O - @).

(t 12 x 1.25 mm83 N'm (8.5 kgf.m,61 tbt.trl

/+4 N.m 14.5 kgf.m,33 lbt.trl

O 12 r 1.25 mm59 N.m 16.0 kgt.m,43 tbt.rtlSeplace.

5-16

\

7. Perform the following:

. Clean the areas where the driveshaft(s) and theintermediate shaft contact the transmission (dif_ferential) thoroughly with solvent or carburetorcteaner, and dry with compressed air.. Check that the set rings on the ends of the drive_shaft and intermediate shaft click into place.CAUTION: Use new set rings,. Adjust the shift cable (see section 14).. Adjust the throttle cable (see section 11).. Adjust the cruise control cable (see section 23).. Refill the engine with engine oil (see page 8-6).. Refill the transmission with fluid (see section 13,14).

. Refill the radiator with engine coolant (see page10-7).

. Bleed air from the cooling system with the heatervalve open (see page j0-7).

. Clean the battery posts and cable terminals withsandpaper, assemble them, then apply grease toprevent corrosaon.. Inspect for fuel leakage (see section j l).After assembling the fuel line, turn on l) the igni_tion switch (do not operate the starter) so that thefuel pump runs for approximately two secondsand the fuel line pressurizes. Repeat this opera_taon two or three times, then check for fuel leak_age at any point in the fuel line,

Page 112 of 2189

Cylinder Head/Valve Train

Dl6Y5, D16Y7, Dl6Y8 engines

Special Tools ............. G2

VTEC Control System

Troubleshooting Flowchart .........." 6-3

VTEG Solenoid Valve

Inspection ............" 6-6

VTEC Rocker Arms

Manual lnspection

(D16Y5 engine) ............................. 6-7

Manual Inspection

(D16Yg enginel ................'............ 6-7

Inspection Using Special Tools

{D16Y5 engine} .....................""'... 6-8

Inspection Using Special Tools

(D16Y8 engine) .........................'.'. 6-10

Valve Clearance

Adiustment ..."".....6-12

Valve Seals

Replacement (Cylinder head removal

not requiredl ................................ 6-1tl

Crankshaft Pulley and PulleY Bolt

Replacement ."...... &16

Timing Selt

lllustrated Index ............................... 6-17

Inspection .............. 6-18

Tension Adjustment ........................ 6- 1 I

Removal ......,,......... 6-19

lnstallation ............. 6-20

Crankshaft Speed Fluctuation (CKF) Sensor

Repf acement .........6'22

Cylinder Head

lllustrated Index ............................... 6-23

Removal ................. 6-27

Warpage ................ 6-40

lnstallation ............. 6-45

Rocker Arms

Removal ................. 6-30

Disassembly/Reassambly ............... 6-31

Rocker Arms and Lost Motion Assemblies

Inspection (D16Y5, D16Yg

enginesl "..........' 5-34

Rocker Arms and Shafts

Glearance Inspection ....................... 6-35

Camshaft

Inspection .............. 6-36

Valves, Valve Springs and Valve Seals

Removal ........""..... 6-38

Valve Guides

Valve Movement .............................. 6-39

Replacement .........6-41

Reaming .......'......'.' 6-43

Valve Seats

Reconditioning .'....6'40

Valves

lnstallation ............. 6-tt3

Camshaft/Rocker Arms and

Camshaft Seal/Pulley

lnstallation ............. 6-44

Page 114 of 2189

VTEC Control System

Troubleshooting Flowchart

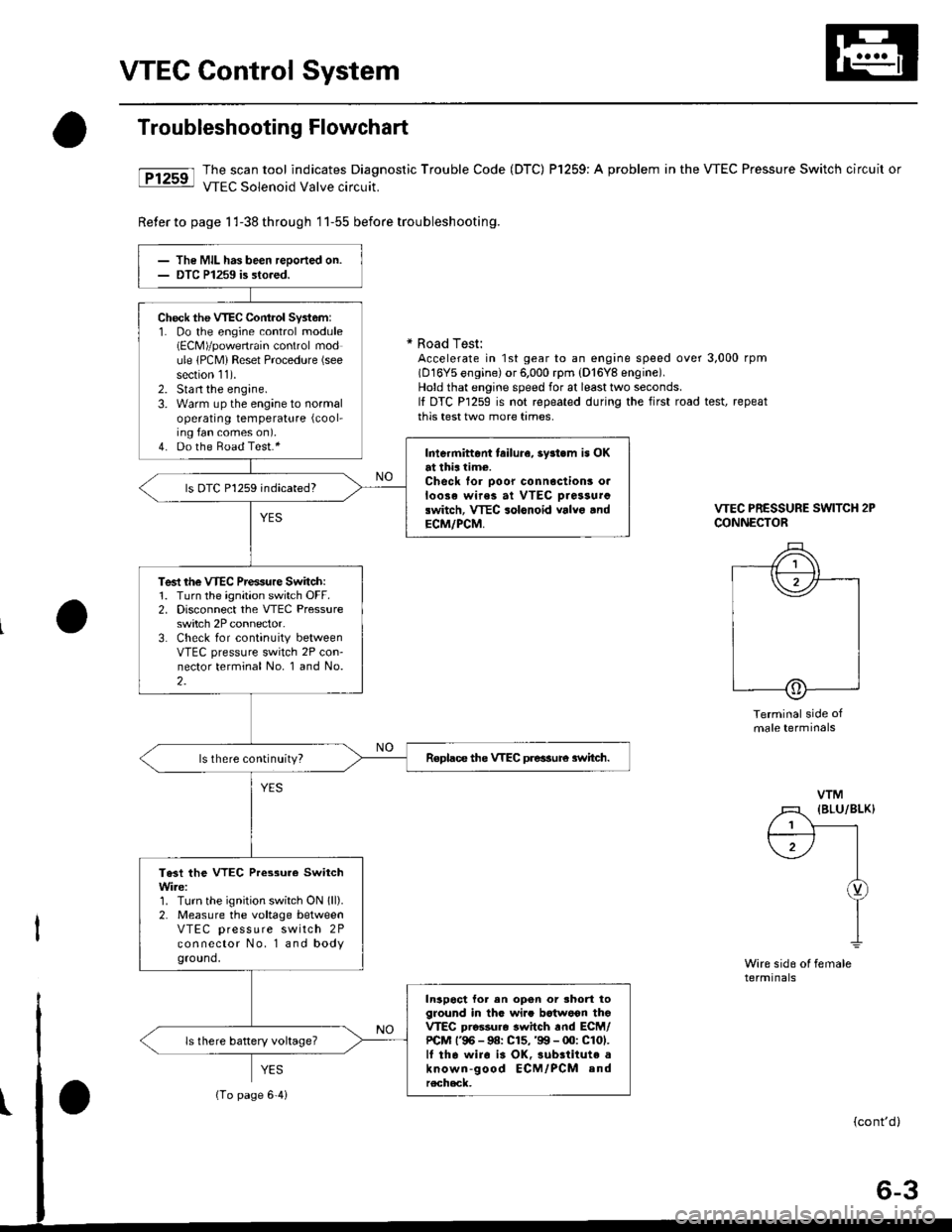

tFtrsrl #ilH:::lj1t:"J:T,?ffnostic

rrouble code (Drc) Pr25e: A probrem in the vrEc Pressure switch circuit or

Reter to page 1 l-38 th roug h 1 1-55 before trou bleshooting.

* Road Test:Accelerate in 1st gear to an engine speed over 3,000 rpm(D16Y5 engine) or 6,000 rpm (D'16Y8 engine).Hold that engine speed for at least two seconds.It DTC P1259 is not repeated during the first road test, repeatthis test two more tames.

VTEC PRESSURE SWITCH 2PCONNECTOR

Terminal side ofmale terminals

Wire sid6 ol femalerermtnats

VTM

l1 (BLu/BLK)

f;-) |I

I

Y

I

The MIL has been reoorted on.DTC P1259 is sto.ed.

Check the VTEC Cont.ol Syst6m:1. Do the engine control module(ECM)/powertrain control module lPCM) Reset Procedure (see

section 11).2. Stan the engine.3. Warm up the engine to normaloperating temperature (cool-

ing fan comes on).4. Do the Boad Test.*Intermittont tailura, 3y3t.m is OKat thia time.Check for ooor connoctionr o.loose wirea at VTEC oiassurclwitch, VTEC solonoid valvo .ndECM/PCM,

ls OTC P1259 indicated?

Test rhe VTEC Prensure Switch:1. Turn the ignition switch OFF.2. Disconnect the VTEC Pressureswitch 2P connector.3. Check for continuity betweenVTEC pressure switch 2P con-nector terminal No. 1 and No.2.

Replace the VTEC preasure 3witch.ls there continuity?

Te3t the VTEC Pressure SwitchWire:1. Turn the ignition switch ON lll).2. Measure the voltage betweenVTEC press u re switch 2Pconnector No. l and bodyground.

In3poct for en opon or shod toground in thG wi.. bctwoon thoVTEC pro$ur6 switch rnd ECM/PCM l'96 - 9a: C15,'99 - 00: C101.lf tha wiro i3 OK,3ubrtitute aknown-good ECM/PCM andrecheck.

ls there battery voltage?

{To page 6'4i

Page 115 of 2189

I

VTEC Control System

Troubleshooting Flowchart (cont'd)

VTEC PRESSURE SwlTCH 2PCONNECTOR

Wire side of female(€rmrnats

VTEC SOLENOID VALVE lPCONNECTOR

I r----'t I

ll ' ff---r'�-'�1

I

I

-L

Terminal side ofmale terminal

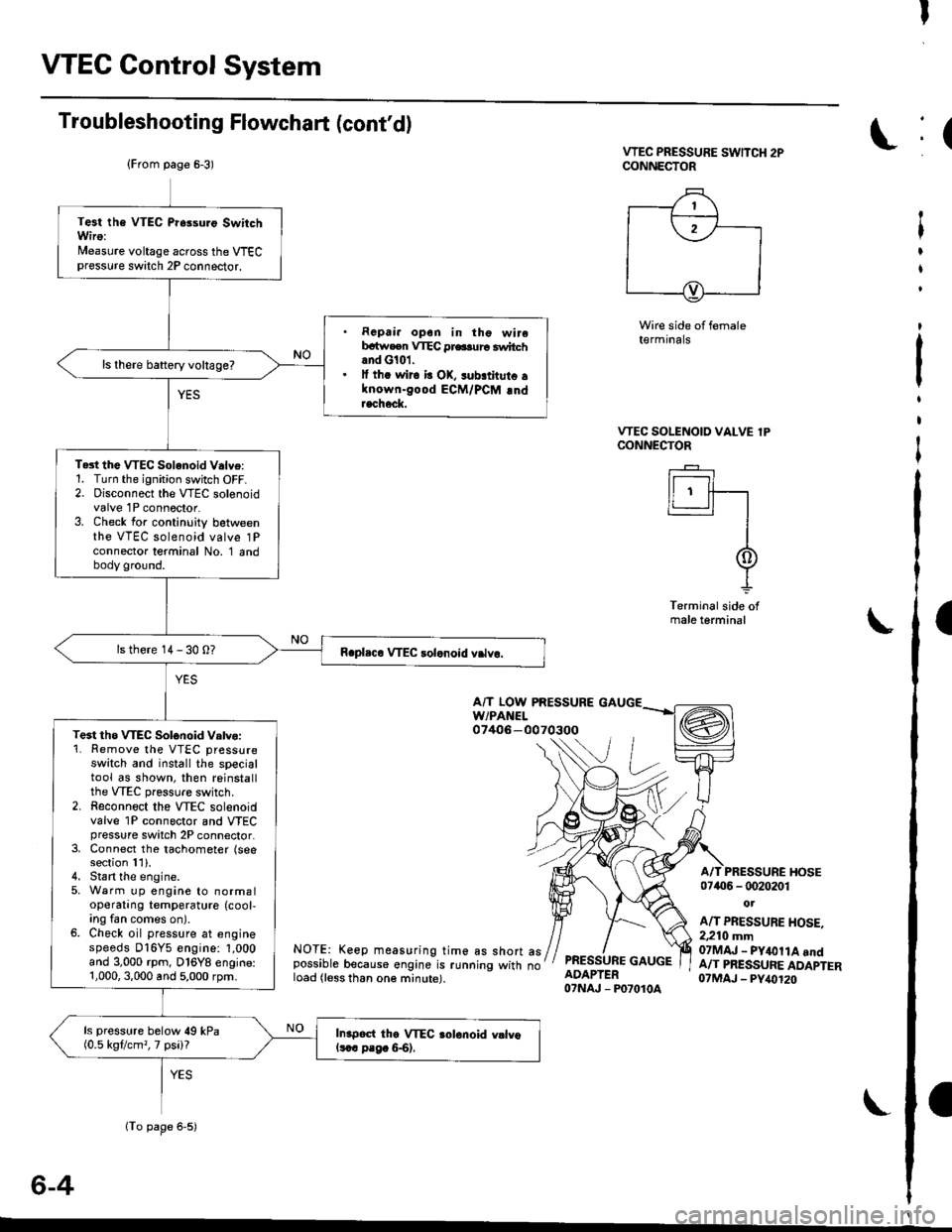

A/T LOW PRESSUREw/PAt{EL07406-0070300

NOTE: Keep measuring time as short aspossible because engine is running with noload (less than one minute).

PRESSURE GAUGEADAPTER07NAJ - P07010A

A/T PRESSURE I{OSE07406 - 0020201

ot

A/T PRESSURE HOSE.2,210 mm07MAJ - PY&llA andA/T PRESSURE ADAPTER07MAJ - PY,()120

6-4

(From page 6-3)

(To page 6-5)

Test the VTEC Pr6suro SwitchWiro:Nleasure voltage across the VTECpressure switch 2P connector.

. Rcpai. opon in tho wirebrtw.en VTEC pr6.urc switchand G101.. lf th. wir6 b OK, sub.thuto alnown-good ECM/PCM !ndracheck.

ls there baftery voltage?

Te3t the VTEC Solonoid V.lve:1. Turn the ignition switch OFF.2. Disconnect the VTEC solenoidvalve 1P connector.3. Check for continuity betweenthe VTEC solenoid valve 1Pconnector terminal No. 1 andbody ground.

ls there 14 - 30 0?

Te3t tho WEC Solonoid Vatvo:'1. Remove the VTEC pressureswatch and install the specialtool as shown, then reinstallthe VTEC pressure switch.2. Reconnoct the VTEC solenoidvalve 1P connector and VTECpressure switch 2P connector.3, Connect the tachometer (seesection 11).4. Stan the engine.5, Warm up engine to normaloperating temperature (cool,ing fan comes on).6. Check oil pressure at enginespeeds D16Y5 engine: 1,000and 3.000 rpm, D16Y8 engine:1,000,3,000 and 5,000 rpm.

ls pressure below 49 kPa(0.5 kgflcm,, 7 psi)?In.poct the VTEC aolonoid vllvols.c p.g. &6).

:(

t

I

t

:

t

I

I