Acc HONDA CIVIC 2000 6.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 436 of 2189

I

Misfire Detected in One Cylinder

P0301 | The scan tool indicates Diagnostic Trouble Code (DTC) P0301: Cylinder 1 misfire detected.

[F03O2l 16"""untool indicates Diagnostic Trouble code (DTc) P0302: Cylinder2 misfire detected.

[FO3Ofl 16" ".un toot indicates Diagnostic Troubte Code (DTC) P0303; Cylinder 3 misfire detected.

I P0304 I ths..rr tool indicates Diagnostic Trouble Code (DTC) PO3O4: Cylinder 4 misfire detected.

D€scription

lMisfire detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluctuation (CKF) sensor

which is attached to the crankshaft,

lf misfiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence, and DTC

PO3O1, P0302, PO3O3 or P0304 will be stored. Then, after the misfire has ceased, the MIL will come on.

lf misfiring that increases emissions is detected during two consecutive driving cyclss, the MIL will come on, and DTC

P0301, P0302, P0303 or P0304 will be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as a misfire DTC, troubleshoot those DTCS first, then

recheck for the misfire DTC.

PO106*1, P0107, P0108. P1128*3'*5, P1129*3'*5: MAP sensor

P0131, P0132: HO2S

P0171, P0172iFuel suppiy system

P0335, P0336: CKF sensor

P0401. P1491, P1498: EGR system

P0441: EVAP system Insufficient purge flow*6

Pl359. P1361. Pl362: TDC sensor

P1381. Pl382: CYP sensor*o: '96 models*6: '96 D16Y5 engine,'96 D16Y/ engine,'96 D16Y8 engine {sedan),'97 D16Y5 engine,'97 D16\4, engine (coupe: KA,

KC models, sedan KA. KC, KL (DX) models, hatchback:all models),'97 D16Y8 engine (sedan: KA, KC models)

Possible Cause

. Fuel injector clogging, fuel leakage, air leakage

. Fuel injector circuit open or shorted

. Spark plug carbon deposits, fouling, malfunction

. lgnition wires open. leaking

. Distributor malfunction

. ComDression low

. Valve clearance out of spec

. VTEC system malfunction (D16Y5, D16Y8. 81642 engine)

. HO2S

. HO2S circuit

(cont'd)

11-167

r'a

Page 447 of 2189

PGM-FI System

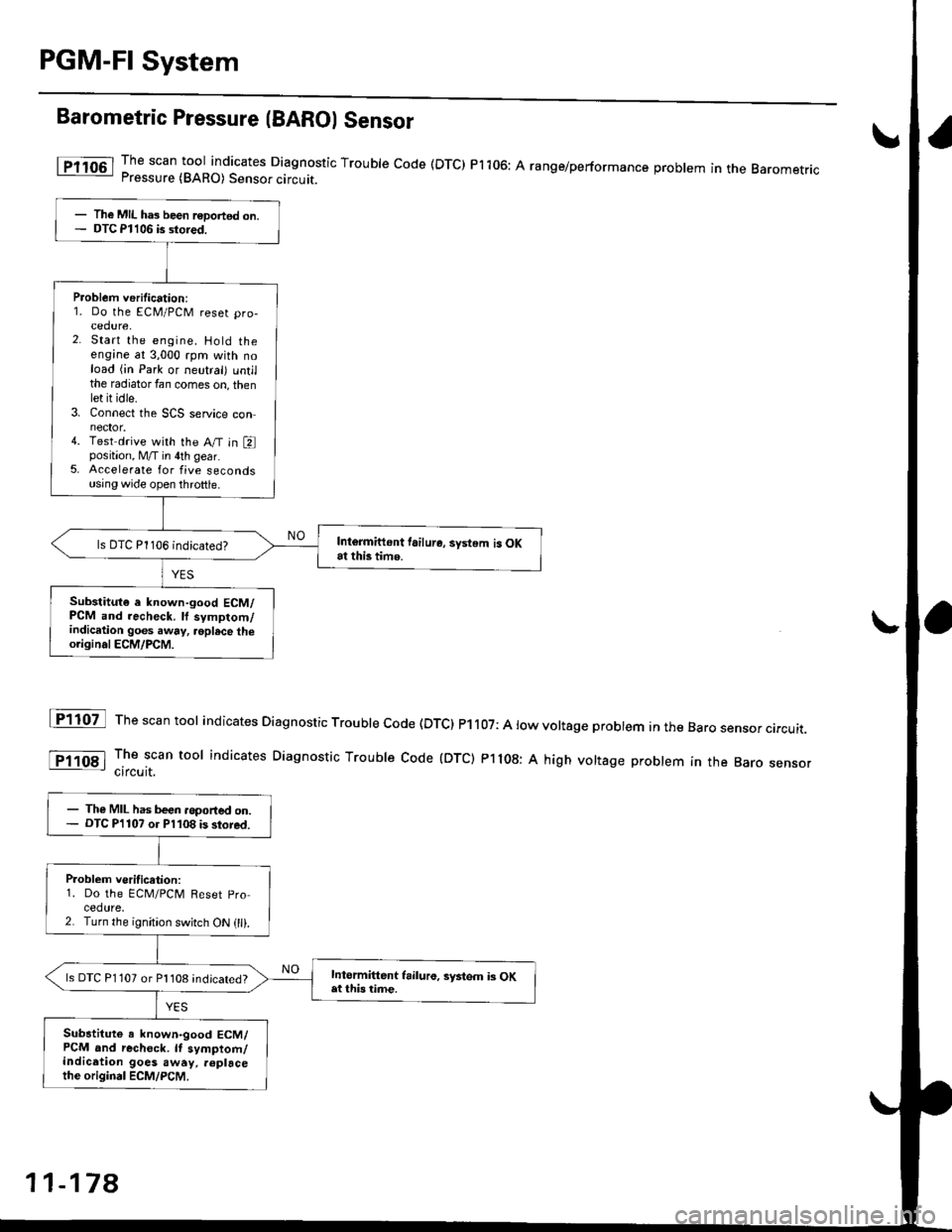

Barometric Pressure (BAROI Sensor

The scan tool indicates Diagnostic Trouble code (DTC) Pi106: A range/performance problem in the BaromerrrcPressure (BARO) Sensor circuit.

The scan tool indicates Diagnostic Trouble code (DTc) P1107: A low voltage probtem in the Baro sensor circurr.

The scan tool indicates Diagnostic Troubre code {DTC) p1108: A high vortage probrem in the Baro sensorcircuit.

fF1lot

tPlloal

The MIL ha3 been r€Dortsd on.DTC Pl106 is stored.

Problem verification:1. Do the ECM/PCM reset pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.3. Connect the SCS service connector.4. Test drive with the A/T in Eposition, M/T in 4th gear.5. Accelerate for five secondsusing wide open throttle.

Intormittont tailure, system is OKat this time.ls DTC P1106 indicated?

Substitut€ e known-good ECM/PCM and recheck. ll symptom/indication goes .way, .oplsce theo.iginal ECM/PCM.

The MIL has been .oported on.DTC P'l107 o. Pl108 is stored.

P.oblem veritication:1. Do the ECM/PClvl Reset pro

cedure,2. Turn the ignition switch ON (ll).

Intormittent frilure, syitem i3 OKat this time.ls DTC P1 107 or Pl108 indicated?

Substitute a known-good ECM/PCM and rechock. It symptom/indication goes away, .6placethe original ECM/PCM.

11-178

Page 473 of 2189

ldle Gontrol System

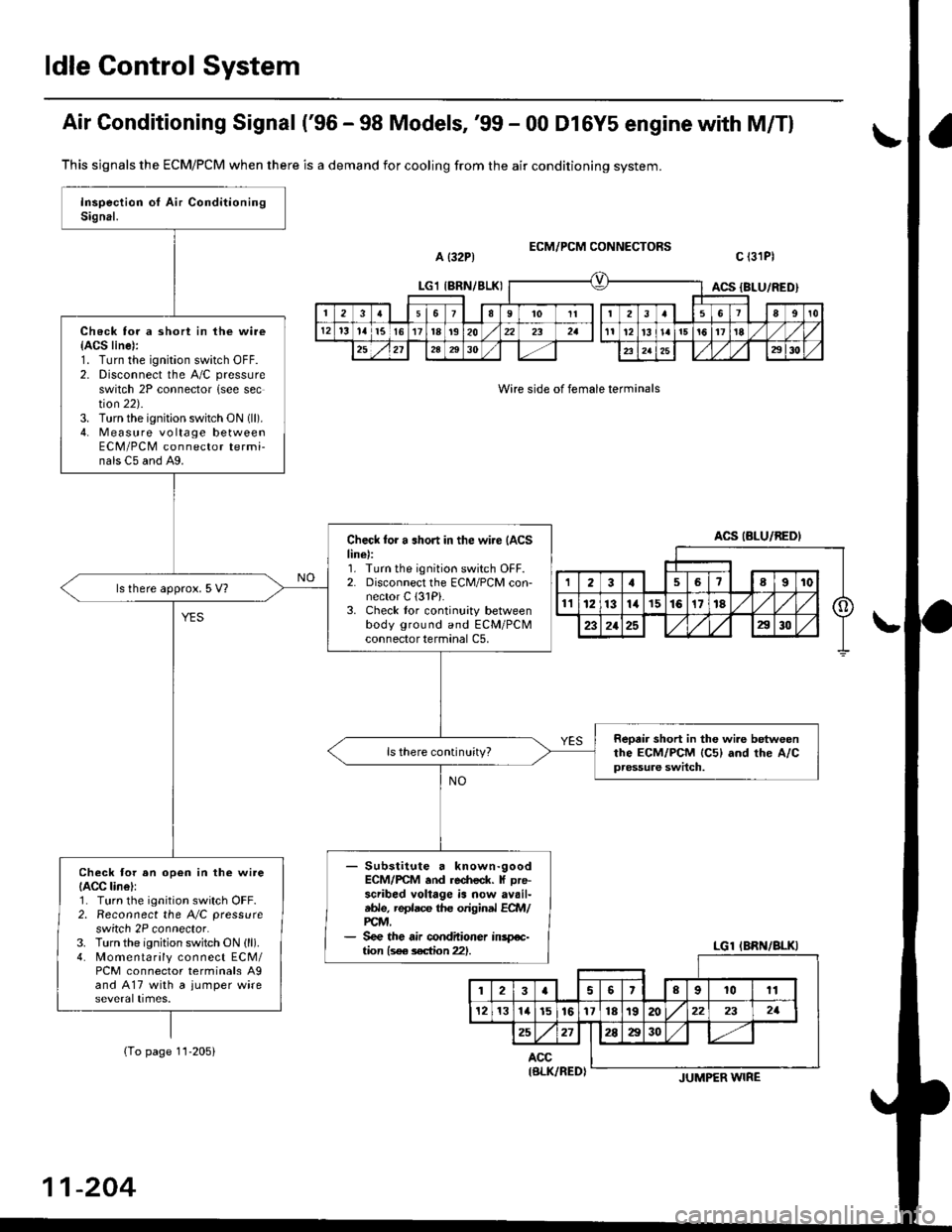

Air Gonditioning Signal ('96 - 98 Models, '99 - 00 Dl6Y5 engine with M/Tl

a {32P1ECM/PCM CONNECTORS

Wire side of female terminals

c l3lPl

This sjgnals the ECM/PCM when there is a demand for cooling from the air conditioning system.

(To page 11-205)

Check for a short in the wire{ACS line):1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch 2P connector {see section 22).3. Turn the ignition switch ON (ll).

4. Measure vo lta ge betweenECM/PCM connector termi-nals C5 and A9.

Check for a .hort in the wi.e {ACSline):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector C (3lPi.

3. Check tor continuity betweenbody ground and ECM/PCMconnector terminal C5,

ls there approx. 5 V?

Reotir short in the wi.e betweenthe ECM/PCM lc5l and rhe A/Cpressure switch.

ls there continuity?

- Substitute a known-goodECM/rcM .nd re.fieck. f Dre-scribed voltage is now availtble, replace the original ECft4/PCM,- See the air conditioner inspe-tion ls€e s€ction 221.

Check tor an op€n in the wireIACC lin6l:1. Turn the ignition switch OFF.2. Reconnect the A/C pressure

switch 2P connector.3. Turn the ignition switch ON (ll).

4. Momentarily connect ECM/PCM connector terminals A9and A17 with a jumper wire

LGl IBRN/8LKIACS {BLU/RED)

2361I9't0Itt3a89t0

12't31al5l617t8t920232all12l3l!ai5!617'tE

252l2A2930232a252930

ACS (BLU/BEDI

LGl IBRN/BLKI

123aslslrl lolgl ro lrr I

121314l516y)nltslnl/@) zr I zr I

25271!M1 1-/r

ACC

11-204

IBLK/RED)JUMPER WIRE

Page 474 of 2189

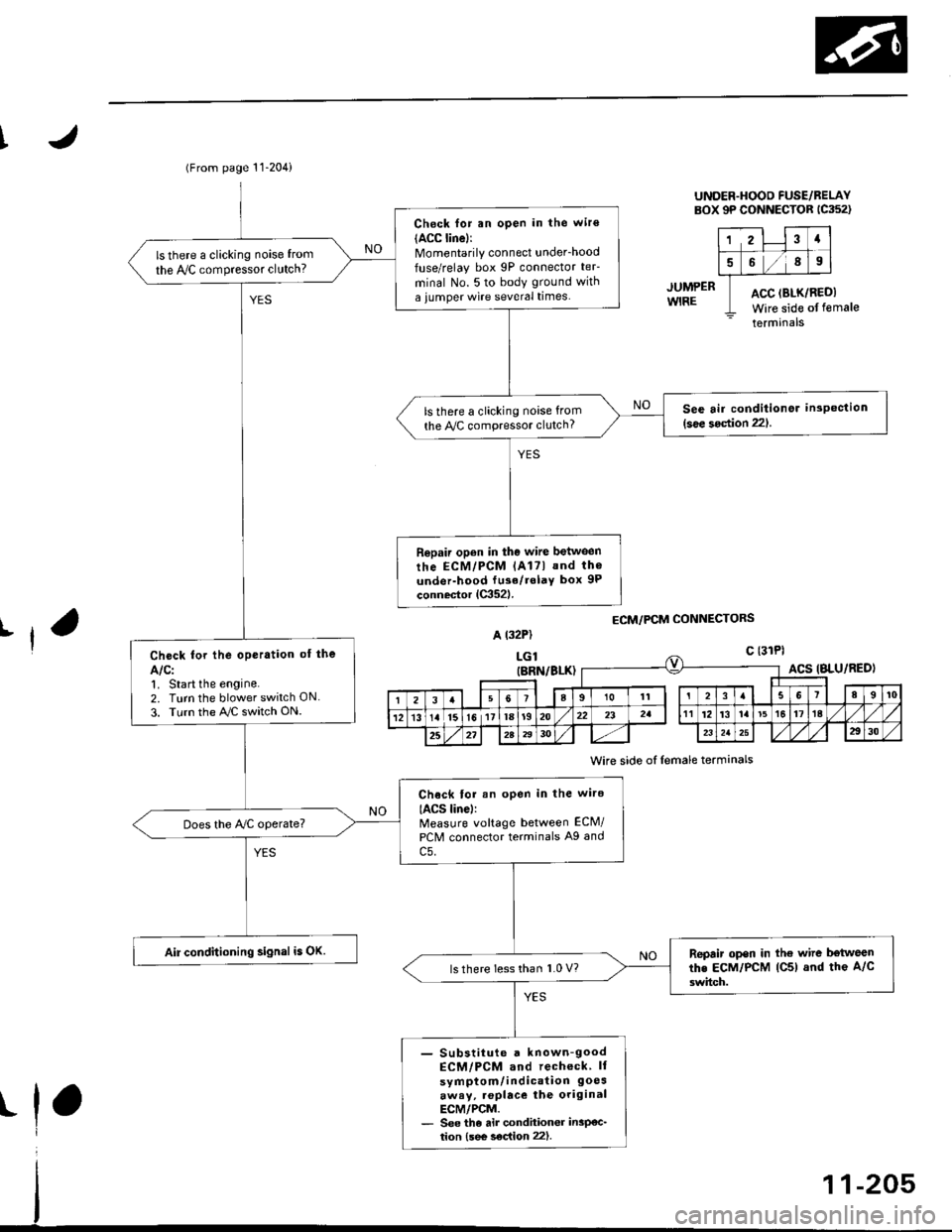

(From page 11-204)

Check for an open in the wir€(ACC linel:Momentarily connect underhood

fuse/relay box 9P connector teF

minal No. 5 to body ground with

a iumper wire several times.

ls there a clicking noise from

the IVC compressor clutch?

See air conditionor inspection(see 3oction 221.ls there a clicking noise from

the Py'C compressor clutch?

Repair open in the wire between

rhe ECM/PCM lAl7l and th6

under-hood fu3e/rolaY box 9P

connector lC352l.

Check for the oPeration of the

Alcl1. Start the engine.2. Turn the blower switch ON

3. Turn the AJC switch ON.

Chock tor an open in the wire

IACS linel:Measure voltage between ECM/

PCM connector terminals A9 and

c5.

Does the Ay'C operate?

Air conditioning signal is OK.Repair open in the wire b€tweenthe EcM/PcM lC5) and the A/c

3witch.ls there less than 1.0 V?

- Substiiute a known-goodECM/PCM and recheck ll

symptom/indication 9oesaway, .oplace the originalECM/PCM.- See the air condhioner insP€c_tion {see s€c{ion 22).

UNDER.HOOD FUSE/BELAYBOX 9P CONNECTOR 1C352)

12Ia

589

ACC (BLK/RI

Wire side ofACC (BLK/REDI

Wire side of female

terminals

JUMPERWIRE

ECM/PCM CONNECTORSrfA t32P)

LGlc {31Pl

t

(BRN/BLK)ACS IBLU/RED)

I23a9101t3I89t0

121315l611la1920232att12't3la't5t617ta

25272A2930232a2930

Wire side of lemale terminals

Page 475 of 2189

ldle Control System

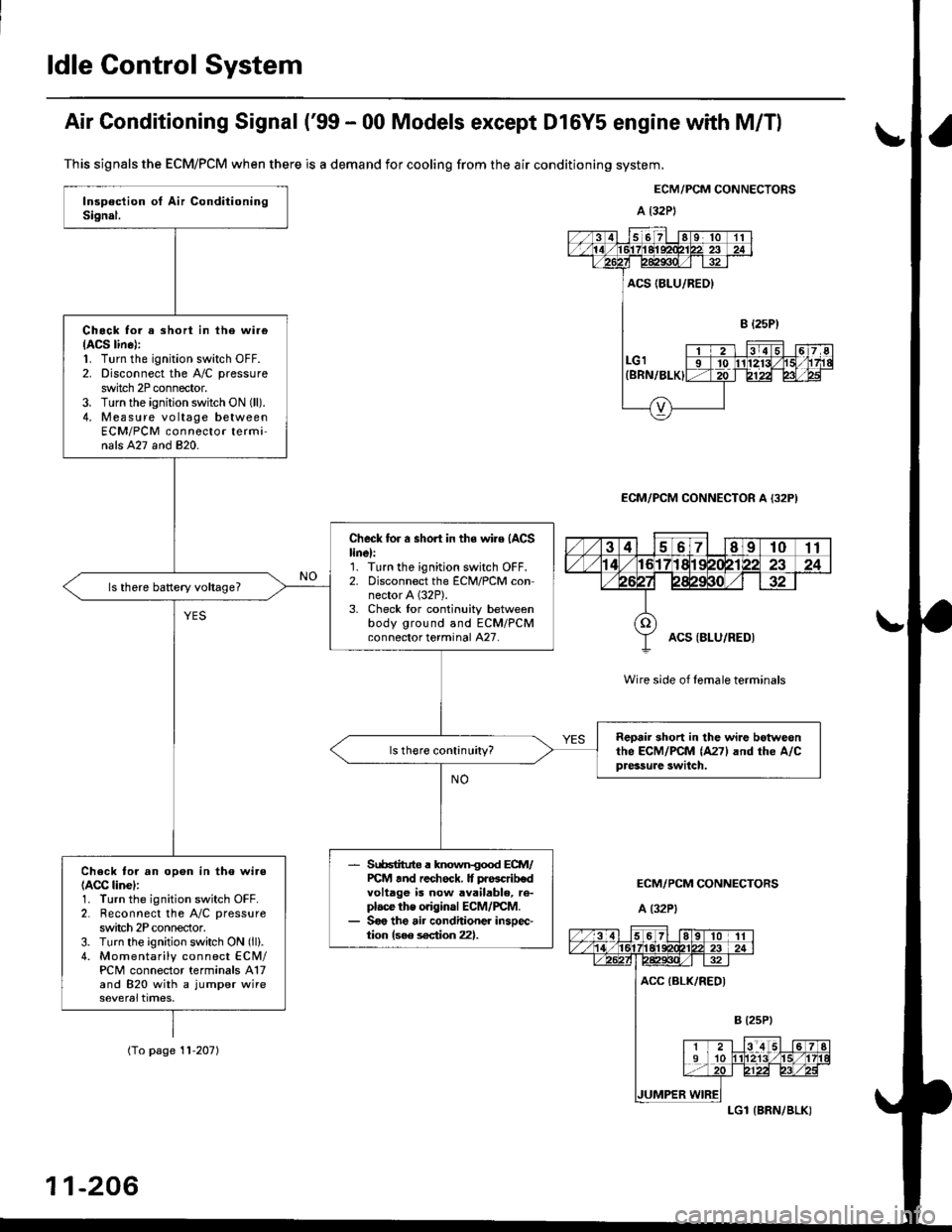

Air Conditioning Signal ('99 - 00 Models except Dl6Y5 engine with M/Tl

This signals the ECM/PCM when there is a demand for cooling from the air conditioning system.

ECM/PCM CONNECTORS

a l32P)

ECM/PCM CONNECTOR A {32P)

Wire side of female terminals

ECM/PCM CONNECTORS

A (32P1

Chock tor a short in ihe wi.e(ACS lin6):1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch 2P connector.3. Turn the ignition switch ON (ll).

4. Measure vo ltage betweenECM/PCM connector terminals A27 and 820.

Check for a short in the wire (ACS

linel:'1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM connector A (32P).

3. Check lor continuity betweenbody ground and ECM/PCMconnector terminal A27.

Reoair short in lhe wi.e botweonthe ECM/PCM (A271 and rhe A/Cpressure swilch.

Srr66tituto a known{ood ECM/PCt4 tnd rechock. It prascrib€dvoltage is now available, re-plac€ the original ECM/rcM.Soo the air conditioner insoec-tion {see s€ction 22}.

Check to. an opon in tho wi.e(ACC linel:1. Turn the ignition switch OFF.2. Reconnect the A/C pressure

switch 2P conneclor.3. Turn the ignition switch ON (ll).

4. Momentarily connect ECN4/PCM connector terminals A17and 820 with a jumper wire

(To page '! 1-207)

11-206

LGl {BRN/BLK)

Page 476 of 2189

I

JUMP€RWIRE

UNDER-HOOO FUSE/RELAYsox 9P coNNEcroR lca52l

123a

5689

ACC (8LK/REDI

Wire side ofterminals

ECM/PCM CONNECTORS

A (32P1

female

Wire side of {emale terminals

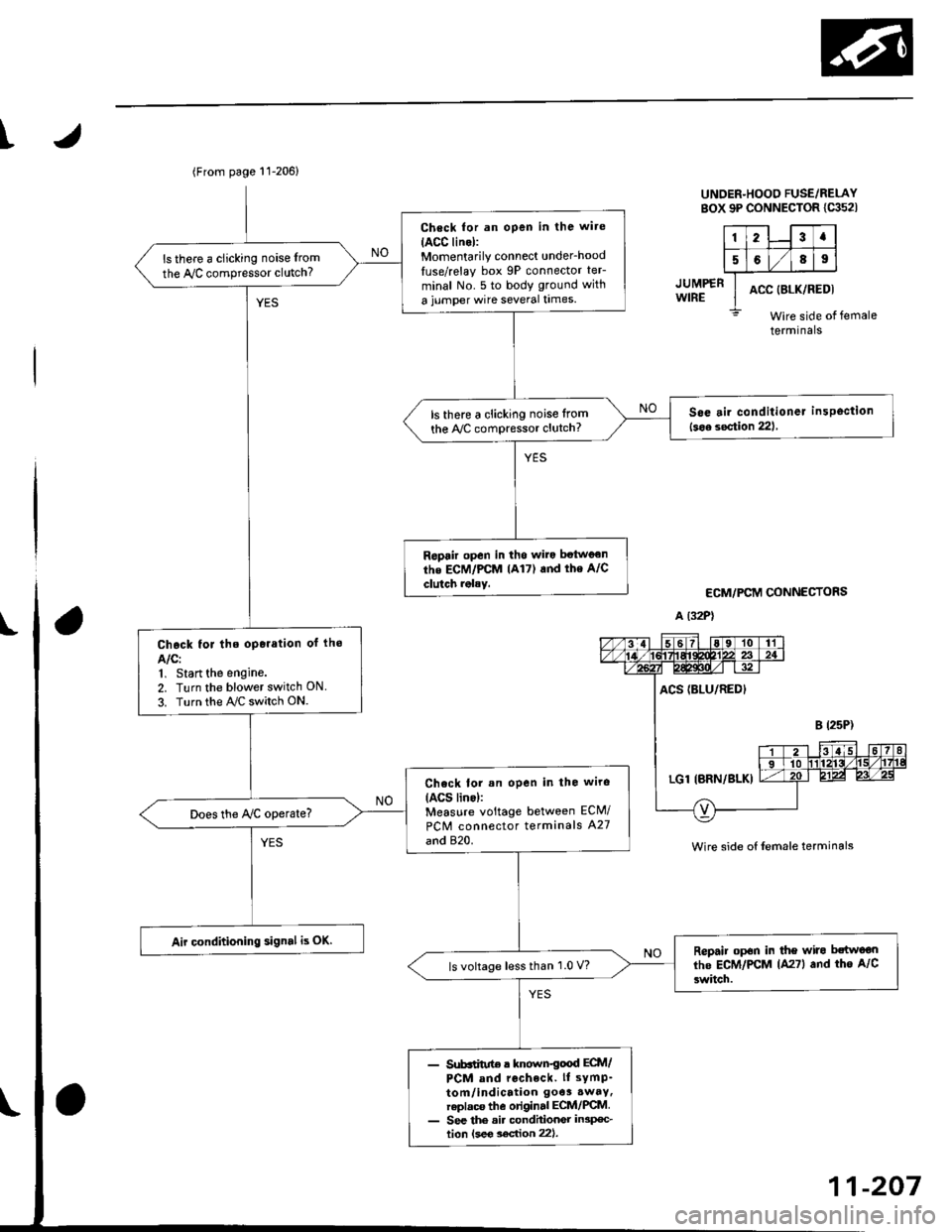

(From page 11-206)

Check for an open in the wite

IACC lino):Momentarily connect under_hood

luse/relay box 9P connector teF

minal No. 5 to body ground with

a jumper wire several times.

ls there a clicking noise from

the Iy'C compressor clutch?

S6e air conditioner insPoction

l3oa section 221ls there a clicking noise lrom

the ly'C compressor clutch?

Ropair open in tho wilo betwg€n

the ECM/PCM lA17) and the A/C

clutch rolay.

Chock for the oporation of lho

AIC:1, Start the engine.

2. Turn the blower switch ON

3. Turn the ray'C switch ON.

Check lor an open in the wiro(ACS lino):Measure voltage between ECM/

PCM connector terminals A27

and 820.

Does the Iy'C operate?

Air conditioning signal is OK.Repair op6n in the wiro bctwoon

lhe ECM/PCM lA27l and tho A/C

3witch.ls voltage lessthan 1.0 V?

- Sub6iitut€ r known€ood ECtt /PCM and rccheck. ll sYmP-

tom/indication 9oe3.waY,replaca the original ECM/PCM- See the ai. condhionGr in3p€c-tion lsee soc{ion 221.

11-207

Page 489 of 2189

ldle Control System

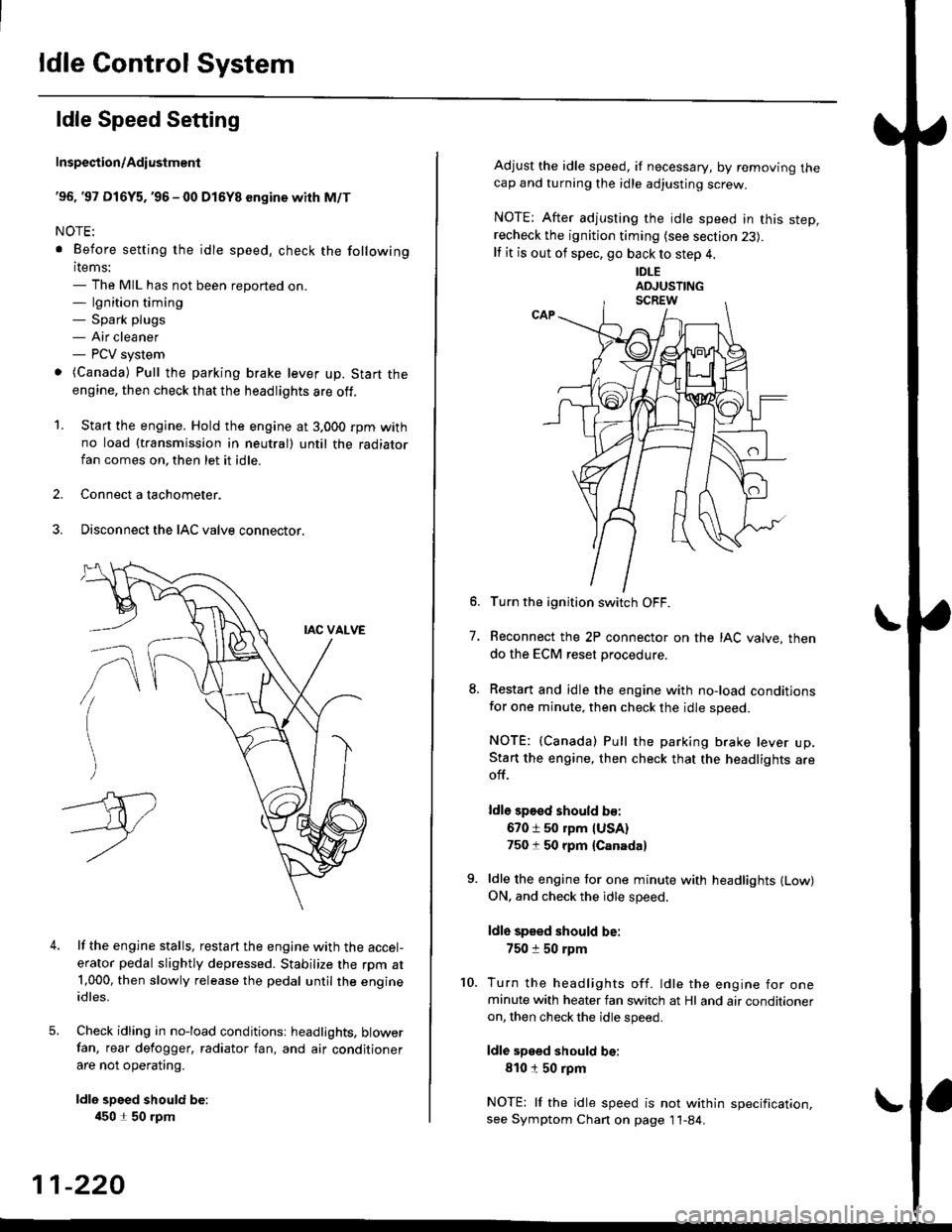

ldle Speed Setting

Inspection/Adiustmenl

'96, '97 Dl6Y5. '96 - 00 Dl5Y8 sngine with M/T

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

o (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3.000 rpm withno load (taansmission in neutral) until the radiatorfan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the IAC valve connector.

4.lf the engine stalls, restart the engine with the accel-

erator pedal slightly depressed. Stabilize the rpm at1,000, then slowly release the pedal until the engineidles.

Check idling in no-load conditionsr headlights. blowerfan. rear defogger, radiator fan, and air conditioner

are not operating.

ldle spsed should be:

450 1 50 rpm

11-220

Adjust the idle speed, if necessary, by removing thecap and turning the idle adjusting screw.

NOTE; After adjusting the idle speed in this step,recheck the ignition timing (see section 23).

lf it is out of spec, go back to step 4.

IDLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the IAC valve, then

do the ECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

ldle sp€sd should b€:

670 i 50 rpm IUSA)750 t 50 rpm {Canada}

9. ldle the engine tor one minute with headlights {Low)ON. and check the idle speed.

ldle speed should be:

750 :r 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air conditioneron, then check the idle speed.

ldle speed should be:

810150 rpm

NOTE: lf the idle speed is not within specification,see Symptom Chan on page 11-84.

Page 491 of 2189

ldle Control System

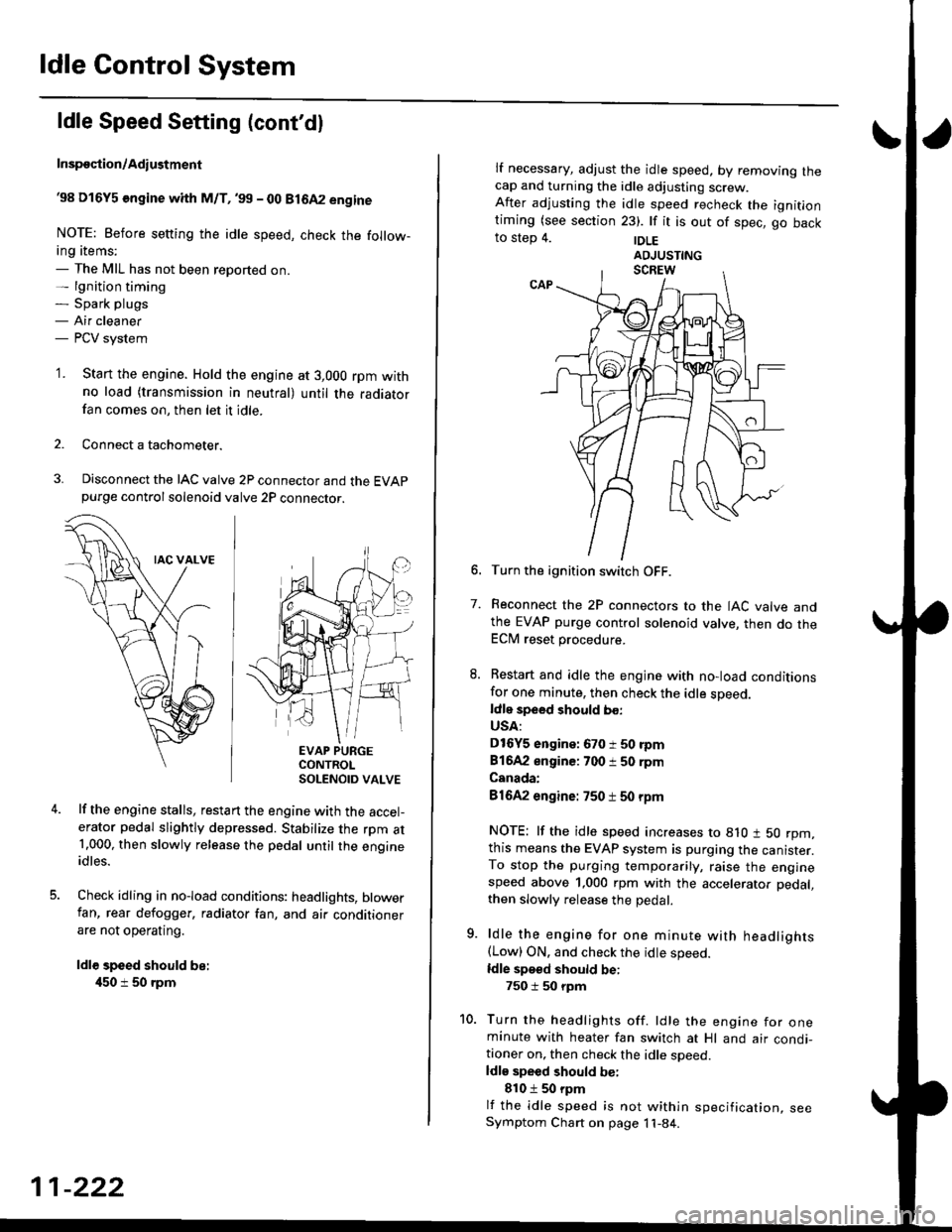

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

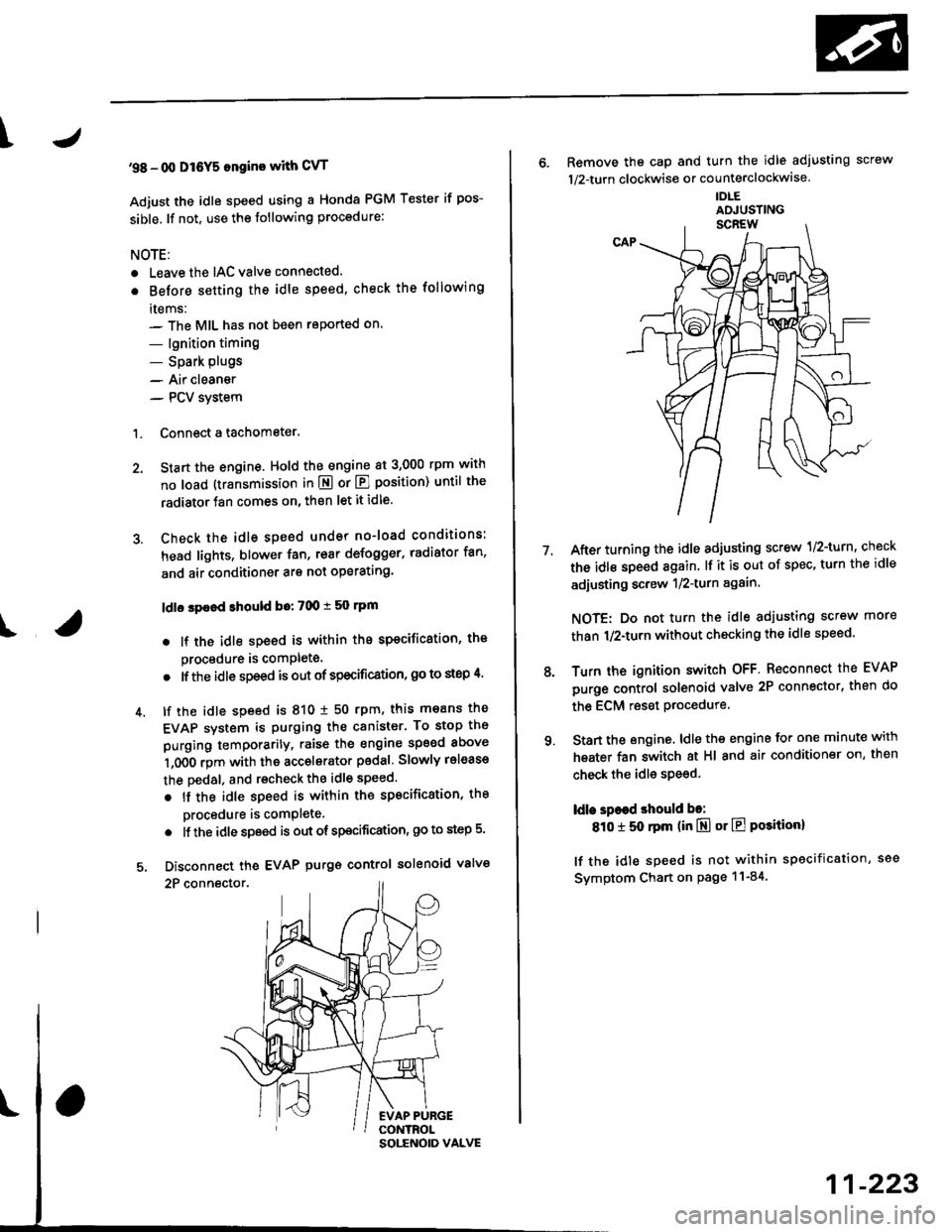

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 496 of 2189

I

Fuel Tube/Ouick-Gonnect Fittings

Precautions

!@ Do not smoke while working on the fuel

system, Keep open flames away from your work a.ea'

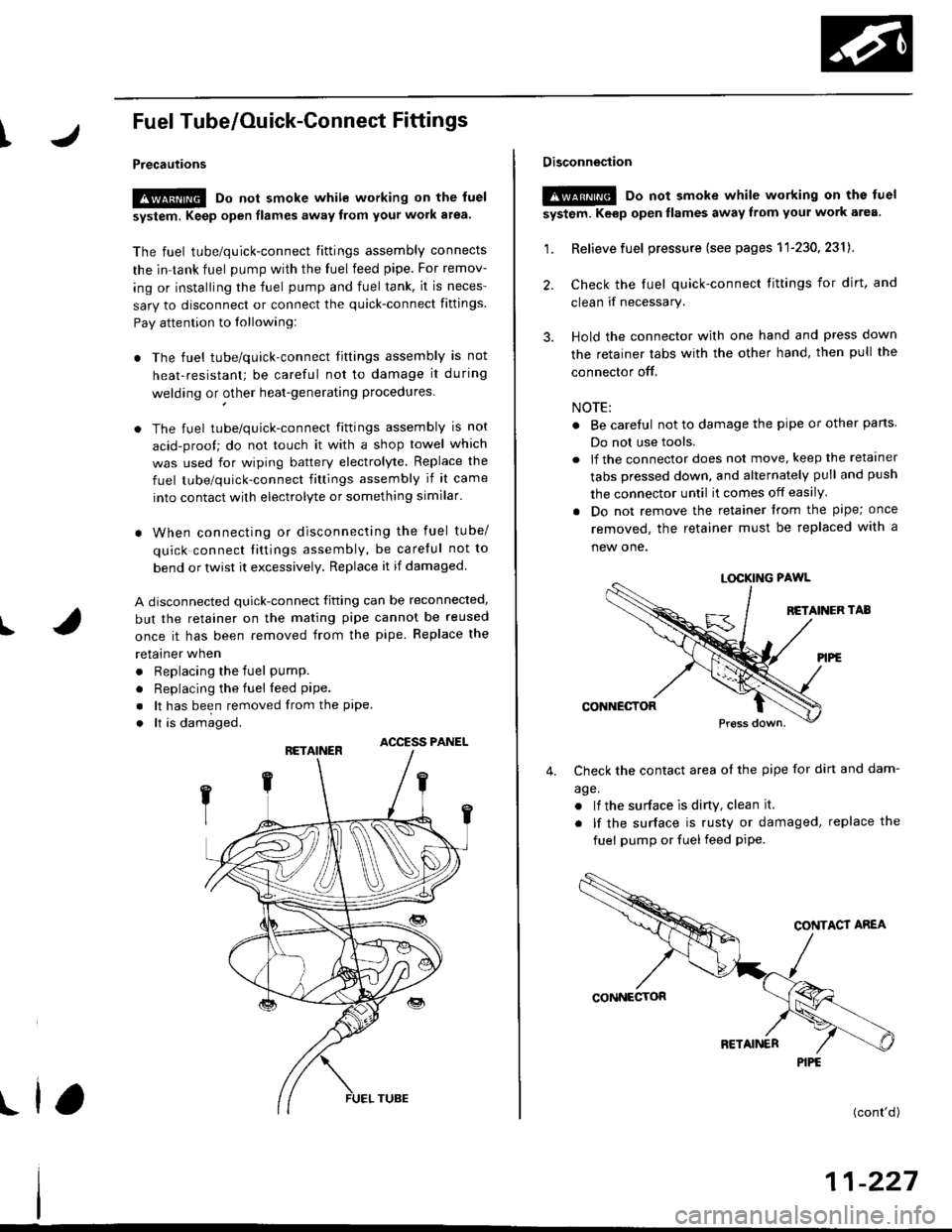

The fuel tube/quick-connect fittings assembly connects

the in tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to lollowing:

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during

welding or other heat-generating procedures

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. Replace the

fuel tube/quick-connect fitlings assembly if it came

into contact with electrolyte or something similar.

. When connecting or disconnecting the fuel tube/

quick connect liltings assembly, be careful not to

bend or twist it excessively. Replace it if damaged

A disconnected quick-connect fitting can be reconnecled,

but the retainer on the mating pipe cannot be reused

once it has been removed from the pipe. Replace the

retatner wnen

. Replacing the fuel pump.

. Replacing the fuel leed pipe.

. lt has been removed lrom the PiPe.. lt is damaged.

ACCESS PANEL

I

Disconnestion

!@ Do not smoke while working on the luel

system. Keep open llames away lrom youl work area.

1. Relieve fuel pressure (see pages 11'230,2311.

2. Check the tuel quick-connect tittings for dirt, and

clean if necessary.

3. Hold the connector with one hand and press down

the retainer tabs with the other hand, then pull the

connector off.

NOTE:

o Be carelul not to damage the pipe or other pans

Do not use tools.

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pape; once

removed, the retainer must be replaced with a

new one.

LOCKING PAWL

BETAINER TAB

CONNECTOR

Check the contact area o{ the pipe for dirt and dam-

age.

. lf the surface ls dirty, clean it.

. lf the surface is rusty or damaged, replace the

fuel pump or fuel feed piPe.

4.

(cont'd)

11-227

PIPE