brake HONDA CIVIC 2000 6.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 972 of 2189

t.

rl,

fl,

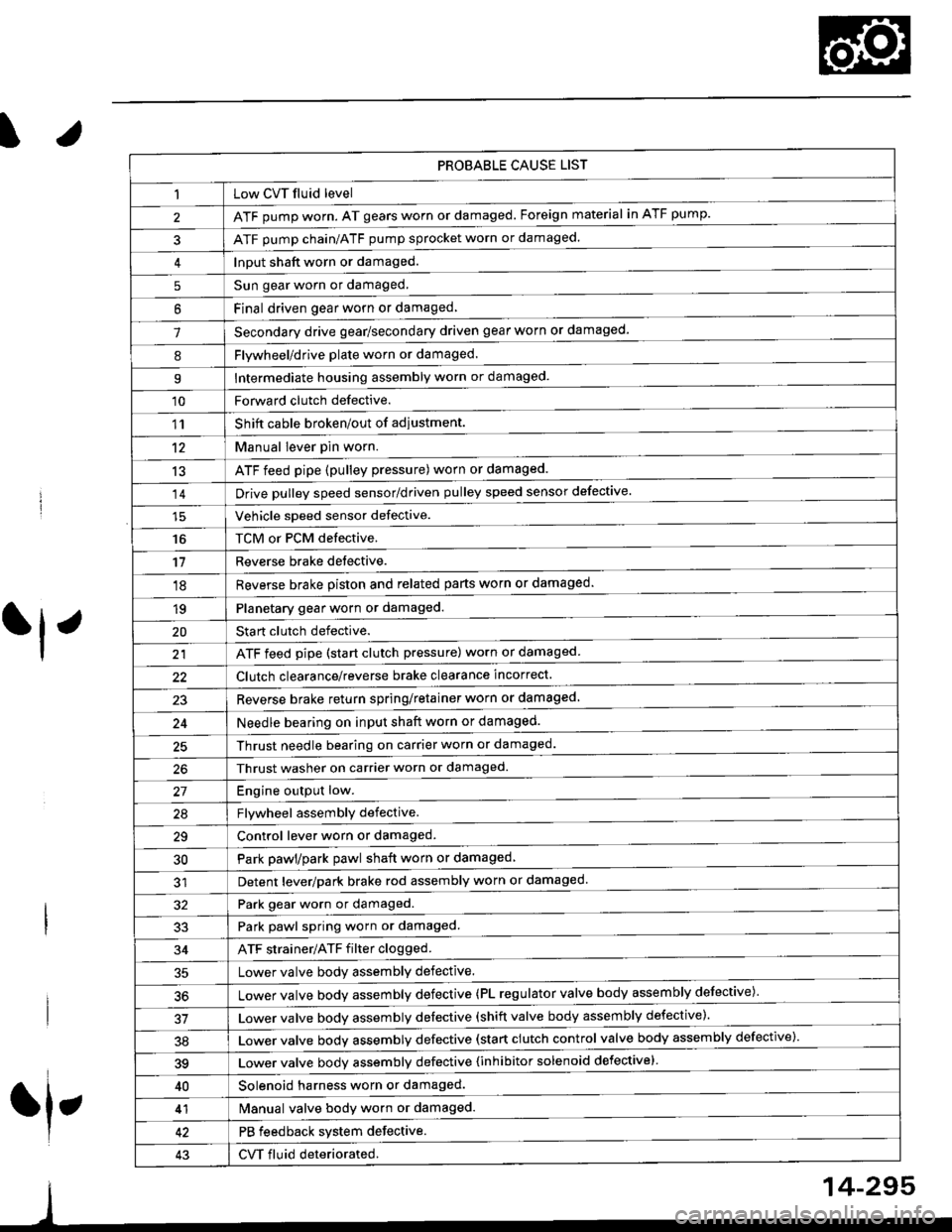

PROBABLE CAUSE LIST

Low CVT fluid level

ATF pump worn. AT gears worn or damaged. Foreign material in ATF pump.

ATF pump chain/ATF pump sprocket worn or damaged.

Input shaft worn or damaged.

Sun gear worn or damaged.

Final driven oear worn or damaqed,

Secondary drive gear/secondary driven gear worn or damaged-

5

6

1

8Flywheel/drive plate worn or damaged.

Intermediate housing assembly worn or damaged.9

'10Forward clutch defective.

Shift cable broken/out of adiustment.

M"nu"t t"uffi

ATF feed pipe (pulley pressure) worn or damaged.

Vchiclc speed sensor defective.

TCM or PCM defective.

Reverse brake detective.

1'�r

't2

13

14

16

'11

'18

1qPlanetary gear worn or damaged.

Sta rt clutch defective.

ATF feed pipe (start clutch pressure) worn or damaged

20

t't

Clutch clearance/reverse brake clearance incorrect.

23Reverse brake return spring/retainer worn or damaged

24Needle bearing on input shaft worn or damaged.

25Thrust needle bearing on carrier worn or damaged.

Thrust washer on carrier worn or damaged.

Enoine outout low.------------------------

Flvwhcel assemblv defective.

Control lever worn or damaged.

Park pawl/park pawl shaft worn or damaged

Detent lever/park brake rod assembly worn or damaged

27

29

30

32Park gear worn or damaged.

Park pawl spring worn or damaged.

ATF strainer/ATF filter clogged.

Lower valve body assembly defective.

Lower valve bodv assemblv defective (PL regulator valve body assembly defective)'

33

34

50

Lower valve bodv assembly defective (shift valve body assembly defective).

Lower valve bodv assemblv defective (start clutch control valve body assembly defective)'

39Lower valve bodv assemblv defective {inhibitor solenoid defective}

40Solenoid harness worn or damaged.

Manual valve body worn or damaged.

PB feedback system defective.

CVT fluid deteriorated.

41

43

14-295

Page 973 of 2189

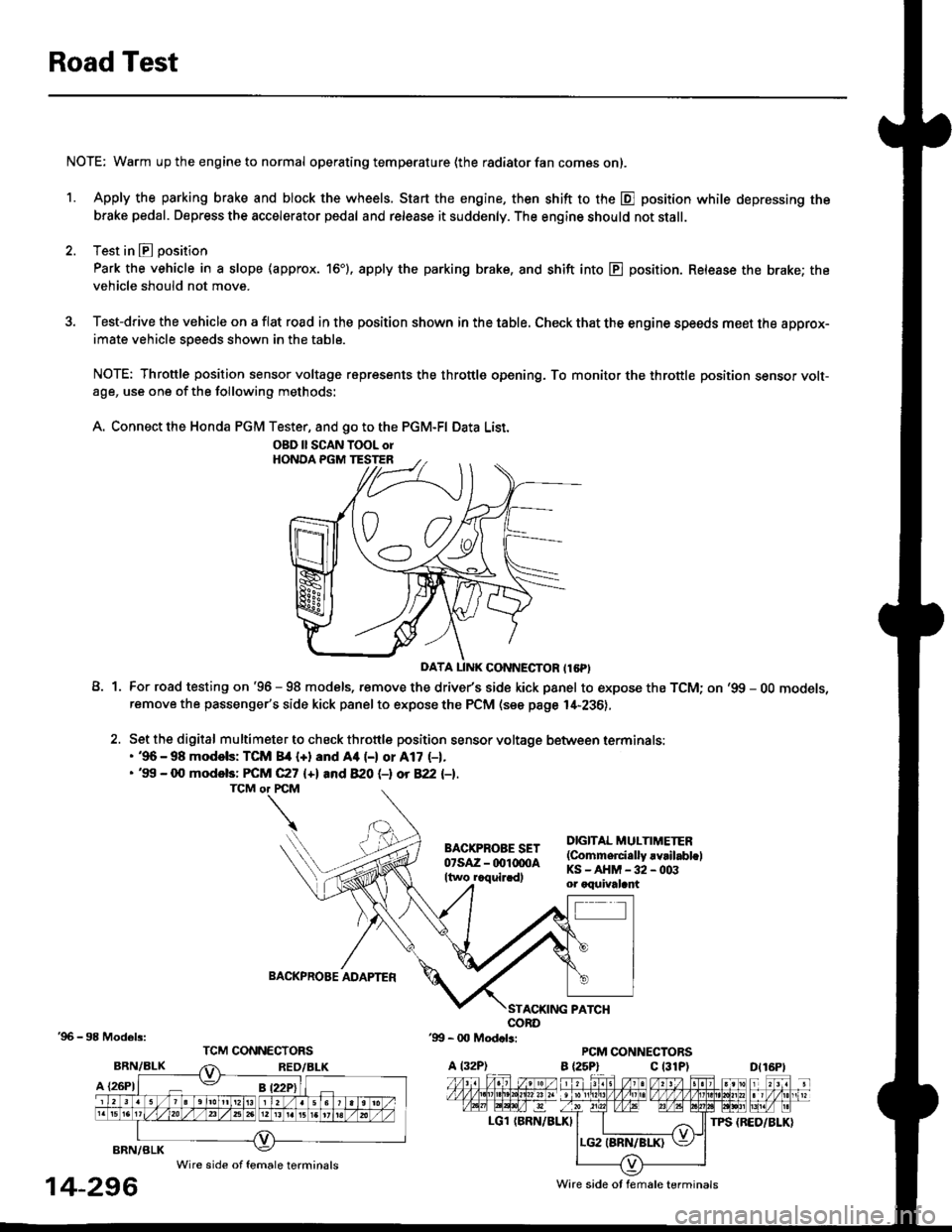

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator fan com6s on).

1. Apply the parking brake and block the wheels. Start the engine, then shift to the E position while depressing the

brake pedal. Depress the accelerator pedal and release it suddenly. The engine should not stall.

2. Test in E position

Park the vehicle in a slope (approx. 16'). apply the parking brake, and shift into E position. Release the brake; the

vehicle should not move.

3. Test-drive the vehicle on a flat road in the position shown in the table. Check that the engine speeds meet the approx-imate vehicle speeds shown in the table.

NOTE: Throttle position sensor voltage represents the throttle opening. To monitor the throttle position sensor volt-age, use one of the following methods:

A. Connect the Honda PGM Tester, and go to the PGM-FI Data List.

A1For road testing on '96 - 98 models, remove the drive/s side kick panel to expose the TCM; on '99 - OO models,remove the passenger's side kick panel to expose the PCM (see page l,[-236),

Set the digital multimeter to check throttle position sensor voltage between terminals:. '96 - 98 modols: TCM 84 {+} and Aa (-) or A17 (-1.. '99 - 0O models: FCM C27 {+l and 820 (-l ot 822 l-1.

DIGITAL MULTIMETER(Commerci.lly rvrilabl.lKS-AHM-32-003or oquivalant

BACKPROBE ADAPTER

BRN/BLK

A {26P1

TPS {BED/BLK}

'96 - 98 Models:

BRN/BLK

14-296

OBD ll SCAN TOOL orHONOA PGM TESTER

D{16Pt

Ware side ot female terminals

Wire side of female terminals

Page 975 of 2189

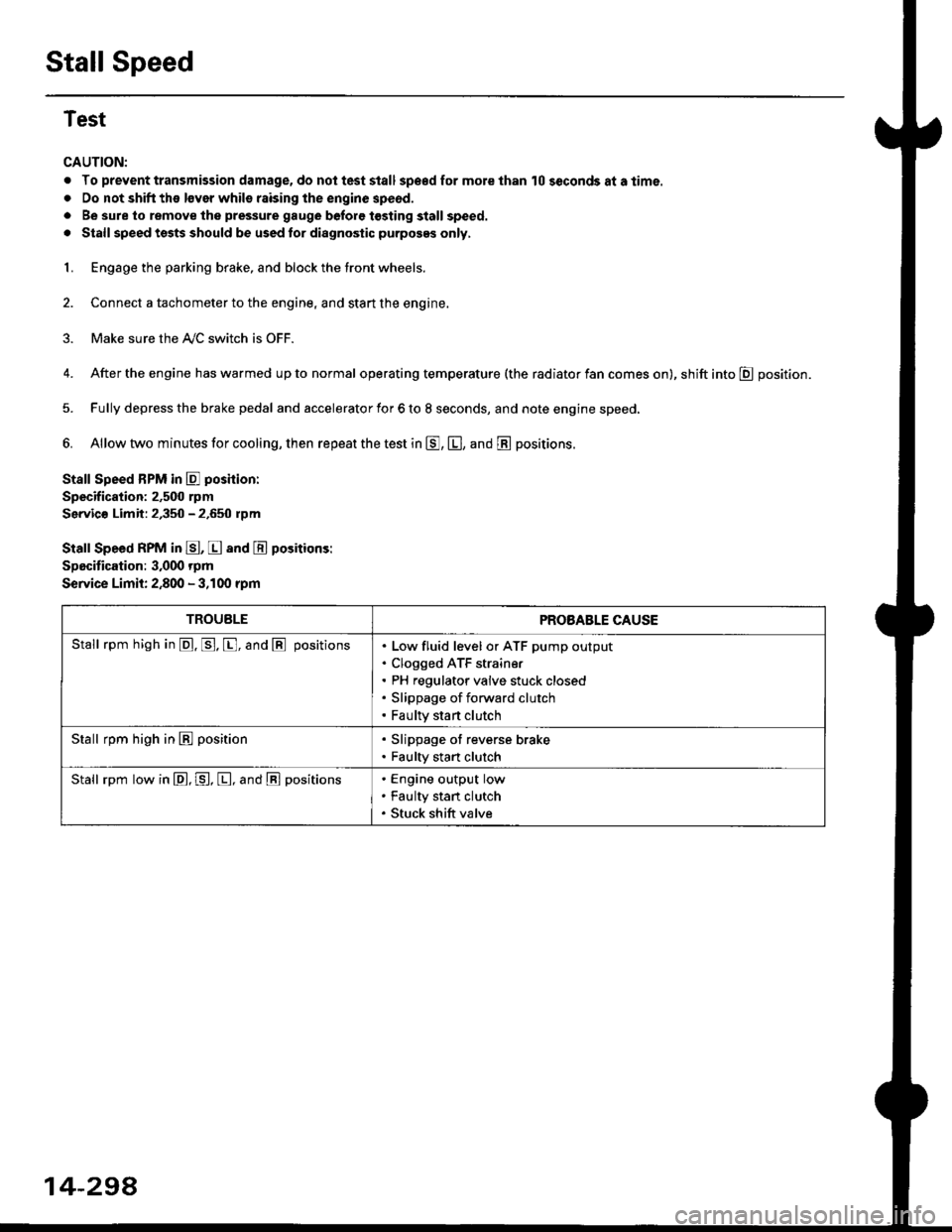

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not test stall sp€€d for mole than 10 seconds at a time.

. Do not shift the lsver whils raising the engine speod.

. Be sure lo remove the pressure gauge before tosting stall speed.

. Stall speed tssts should be used tor diagnostic purposes only,

1. Engage the parking brake, and block the tront wheels.

2. Connect a tachometer to the engine, and stan the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed,

6. Allow two minutes for cooling, then repeat the test in E, E, and E positions.

Stall Speed BPM in E poshion:

Specification: 2,500 rpm

Servic€ Limit: 2,350 - 2.650 rpm

Stall Speed RPM in E, E and E positions:

Specitication: 3,000 rpm

Service Limit: 2,800 - 3,100 rpm

TROUBLEPROBABLE CAUSE

Stall rpm high in @. p. [, and @ positionsLow fluid level or ATF pump output

Clogged ATF strain€r

PH regulator valve stuck closed

Slippage of forward clutch

Faulty start clutch

Stall rpm high in E position. Slippage of reverse brake. Faulty start clutch

Stall rpm low in E, P, [, and @ positionsEngine output low

Faulty stan clutch

Stuck shift valve

14-294

Page 977 of 2189

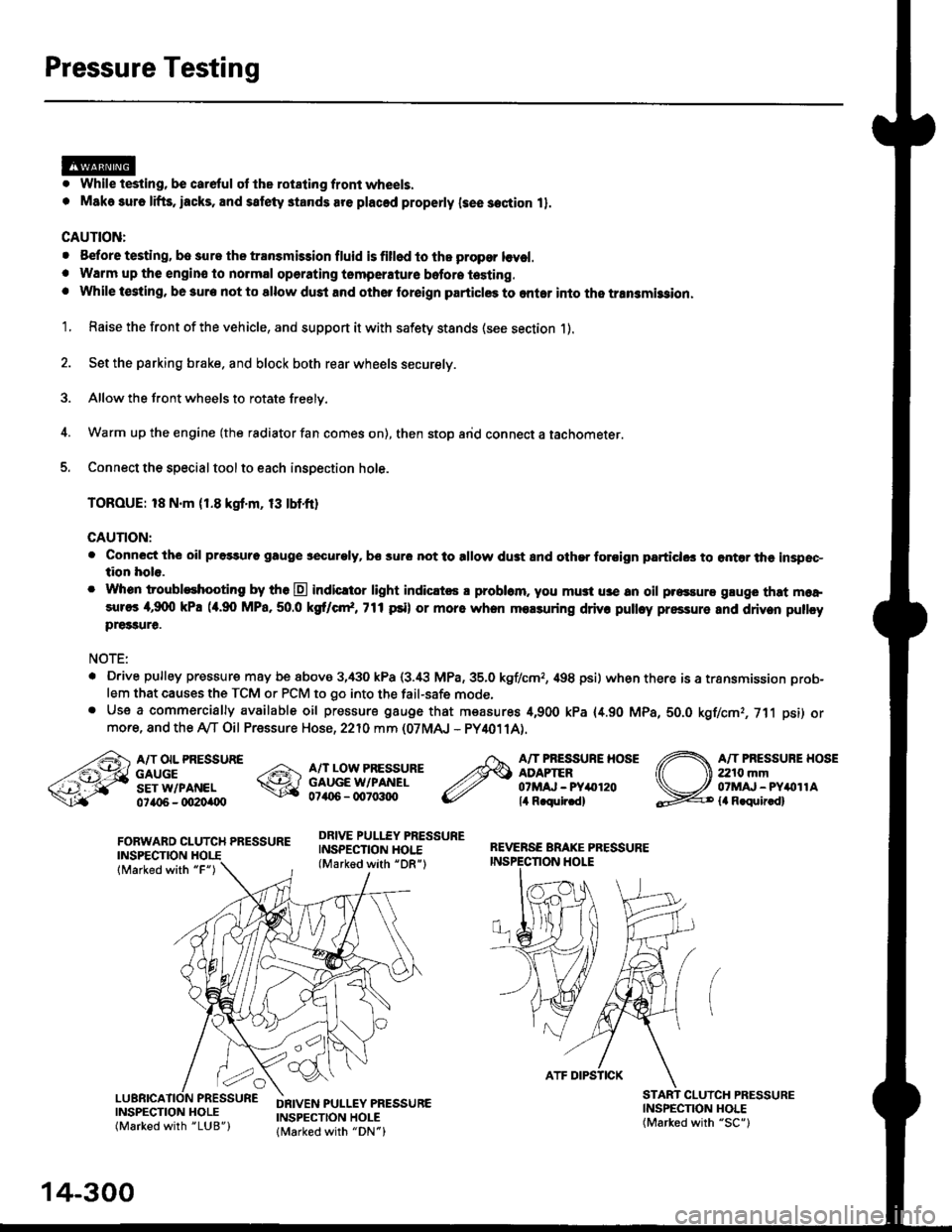

Pressure Testing

. While testing, be careful of the rot8ling front wheels.

. M8k6 suro lifts, iacks, and satety stands are placed properly lsee section 11.

CAUTION:

. Before testing, be sur. the transmb3ion fluid is fillod to the propor lcvel.. Warm up the engin€ to nolmal operating tsmperature bofore testing. While t€sting, be 3ure not to allow dust and other loreign particles to onler into the transmi$ion.

1. Raise the front of the vehicle, and support it with safety stands (see section 1).

2. Set the parking brake. and block both rear wheels securely.

3. Allow the front wheels to rotate freely.

4. Warm up the engine (the radiator fan comes on), then stop arid connect a tachometer.

5. Connect the special tool to each inspection hole.

TOROUE: 18 N.m (1.8 kgt'm, 13 tbtfr)

GAUTION:

. Connect the oil pressuro gauge !!€curoly, bs sur6 not to allow dust and other foroign particlG3 to ontar the inspsc-tion hole.

. Whon troubleshooting by tho E indicltor light indic.t6 a problam. you mu3t u3e an oil p.essure gluge that moa,sures 4,9(X) kPa (a.90 MPa,50.0 kS cr*,771psi) or more when molsuring driv. pulley pressure and driven pullcypre33ure.

NOTE:

. D.ive pulley pressure may be above 3,430 kPa (3.i8 MPa,35.0 kgf/cmr, 498 psi) wh€n there is a transmission prob-

lem that causes the TCM or PCM to go into the fail-safe mode,. Use a commercially available oil pressure gauge that measures 4,900 kPa {4.90 MPa, 5O.O kgf/cmr, 711 psi) ormore, and the Ay'T Oil Pressure Hose, 2210 mm (07MAJ - PY4011A).

FORWARD CLUTCH PRESSUREINSPECTION

lMarked with "F")

REVERSE BRAKE PRESSUREINSPECTION I.IOLE

A/T OIL PRESSUREGAUGESET W/PANEL0ta{r6 - oO2Oi|(Xt

A/T LOW PRESSUREGAUGE W/PANEL0706 - qt7o:t{ro

DRIVE PULLEY PRESSUREINSPECTION HOI.E(Marked with "DR")

A/T PRESSURE HOSEADAPTER07MAJ - PYar'120lil R.qulr.d)

A/T PRESSUBE HOSE2210 mm07MAJ - PYitollAla R.quir.d)

(

INSPECNON HOLE(Marked with "SC")

CLUICH PRESSURE

INSPECTION HOLE(Marked with "LUB")

DRIVEN PULLEY PRESSUREINSPECTION HOLElMarked with "DN")

14-300

ATF DIPSTICK

Page 978 of 2189

1.

Start the engine.

Shift to the respective shift lever positions in the table, and measure the following pressures at 1'500 rpm'

. Forward Clutch Pressure

. Reverse Brake Pressure

. Drive Pulley Pressure

. Driven Pulley Pressure

8. Shift to E posltion, and measure the lubrication pressure at 3,000 rpm'

Disconnect the special tool after pressure testlng

Install the sealing boits in the jnspection holes with new sealing washers, and tighten the bolts to the specified

toroue.

TOROUE: 18 N.m {1.8 kgf'm, 13 lbf'ft}

CAUTION: Keep all foreign particles out of the transmission'

9.

10.

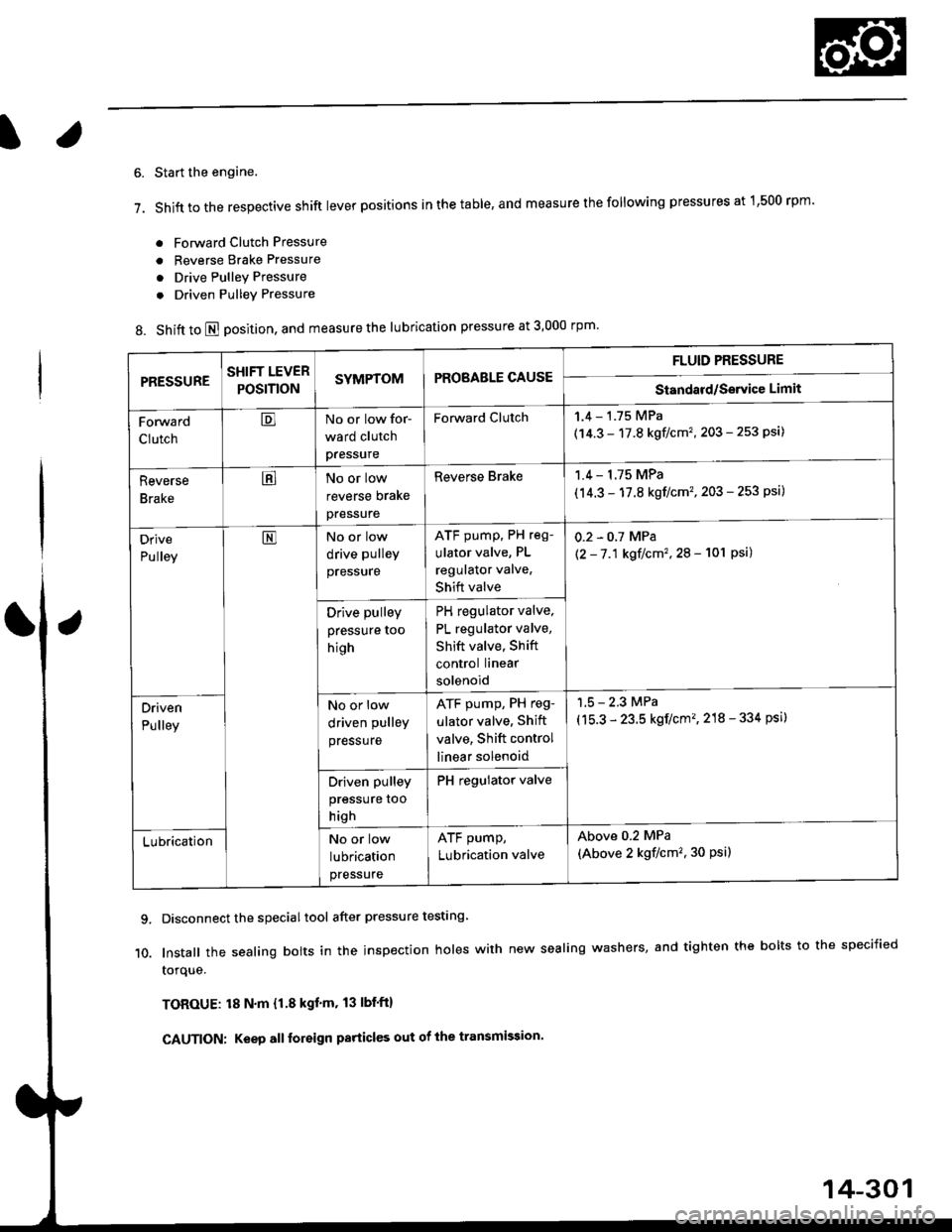

PBESSURESHIFT LEVER

POSmONSYMP{OMPROBABLE CAUSE

FLUID PRESSURE

Standard/Ssrvice Limit

Forwa rd

Clutch

ENo or low for-

ward clutch

pressure

Forward Clutch1.4 - 1.75 MPa

(14.3 - 17.8 kgtcm'�, 203 - 253 Psi)

Reverse

Brake

tsNo or low

reverse brake

pressure

Reverse Brake1.4 - 1.75 MPa

(14.3 - '17.8 kg7cm'�, 203 - 253 Psi)

Drive

Pulley

NNo or low

drive pulley

pressure

ATF pump, PH reg-

ulator valve, PL

regulator valve,

Shift valve

0.2 - 0.7 MPa

(2 - 7.1 kgflcm'�, 28 - 101 Psi)

Drive pulley

pressure roo

high

PH regulator valve,

PL regulator valve,

Shift valve. Shift

control linear

solenoid

Driven

Pulley

No or low

driven pulley

pressure

ATF pump, PH reg-

ulator valve, Shift

valve, Shift control

linear solenoid

1.5 - 2.3 MPa

(15.3 - 23.5 kg?cm'�, 218 - 334 Psi)

Driven pulley

pressure too

h igh

PH regulator valve

LubricationNo or low

lubrication

pressure

ATF pump,

Lubrication valve

Above 0.2 MPa

(Above 2 kgf/cm'�. 30 Psi)

14-301

Page 979 of 2189

Lower Valve Body Assembly

Replacement

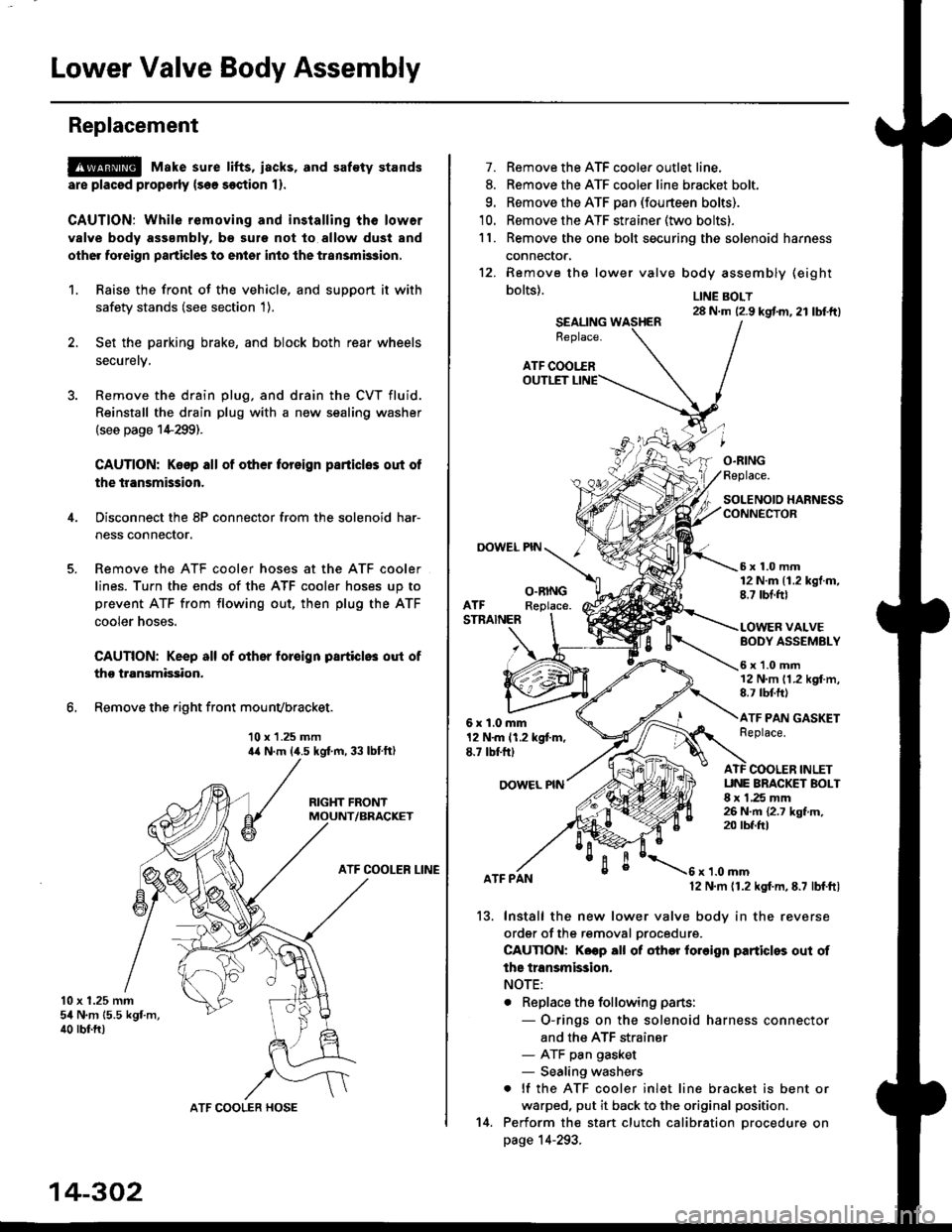

@ Make sure lifts, iacks, and saf€ty stands

are placsd prop€rly {sea section 1).

CAUTION: While removing and installing th6 lower

valve body asssmbly, b€ sule not to allow dust and

other for€ign particles to entsr inio the transmksion.

1. Raise the front of the vehicle, and support it with

safetv stands (see section 1).

2. Set the parking brake, and block both rear wheels

securetv.

4.

6.

Remove the drain plug, and drain the CVT fluid.

Reinstall the drain plug with a new sealing washer(see page 1+299).

CAUTION: Keop all of other toreign parliclos out of

the transmission.

Disconnect the 8P connector from the solenoid har-

ness connector.

Remove the ATF cooler hoses at the ATF cooler

lines. Turn the ends of the ATF cooler hoses up to

prevent ATF from flowing out, then plug the ATF

cooler noses.

CAUTION: Keep all of other foroign particlo3 out of

tho transmission.

Remove the right front mounvbracket.

10 x 1.25 mmila N.m (,1.5 kgf.m, 33 lbtft)

RIGHT FRONTMOUNT/BRACKET

ATF COOLER LINE

10 x 1.25 mmsil N.m 15.5 kgf.m,40 rbr.ft)

ATF COOLER HOSE

14-302

14.

7. Remove the ATF cooler outlet line.

8. Remove the ATF cooler line bracket bolt.

9. Remove the ATF pan (fourteen bolts).

10. Remove the ATF strainer (two bolts).

1 l. Remove the one bolt securing the solenoid harness

connector,

12. Remove the

bolts).

lower valve body assembly (eight

LINE BOLT28 N.m (2.9 kgtm,21 lbtft)SEALINGReplace.

ATF COOI.-EROUTLET

OOWEL PIN

O.RINGFeplace.

SOLENOIO HARNESSCONNECTOR

5x1.0mm12 N.m 11.2 kgt.m,8.7 tbt.ftlO.RINGReplace.ATFSTNAINER

6x1.0mm12 N.m 11.2 kgt m,E.7 tbt'ft)

OOWEL NN

BODY ASSEMBLY

6x1.0mm12 N.m 11.2 kgf.m,8.7 rbf.ft)

ATF PAN GASKETReplace.

VALVE

ATF COOLER INLETUNE BRACKET BOLT8 x 1,25 mm26 N.m {2.7 kgf.m,20 tbf.frl

13.

ATF PANx 1.0 mm12 N.m 11.2 kgf.m, E.7 lbf.ftl

Install the new lower valve bodv in the reverse

ordgr of the removal orocedure.

CAUTION: Koep all ot other fo.oign particles out of

ths transmission.

NOTE:

. Replace the following parts:

- O-rings on the solenoid harness connector

and the ATF strainer- ATF pan gasket- Sealing washers

. lf the ATF cooler inlet line bracket is bent or

warped, put it back to the original position.

Perform the start clutch calibration orocedure on

page 14-293.

Page 980 of 2189

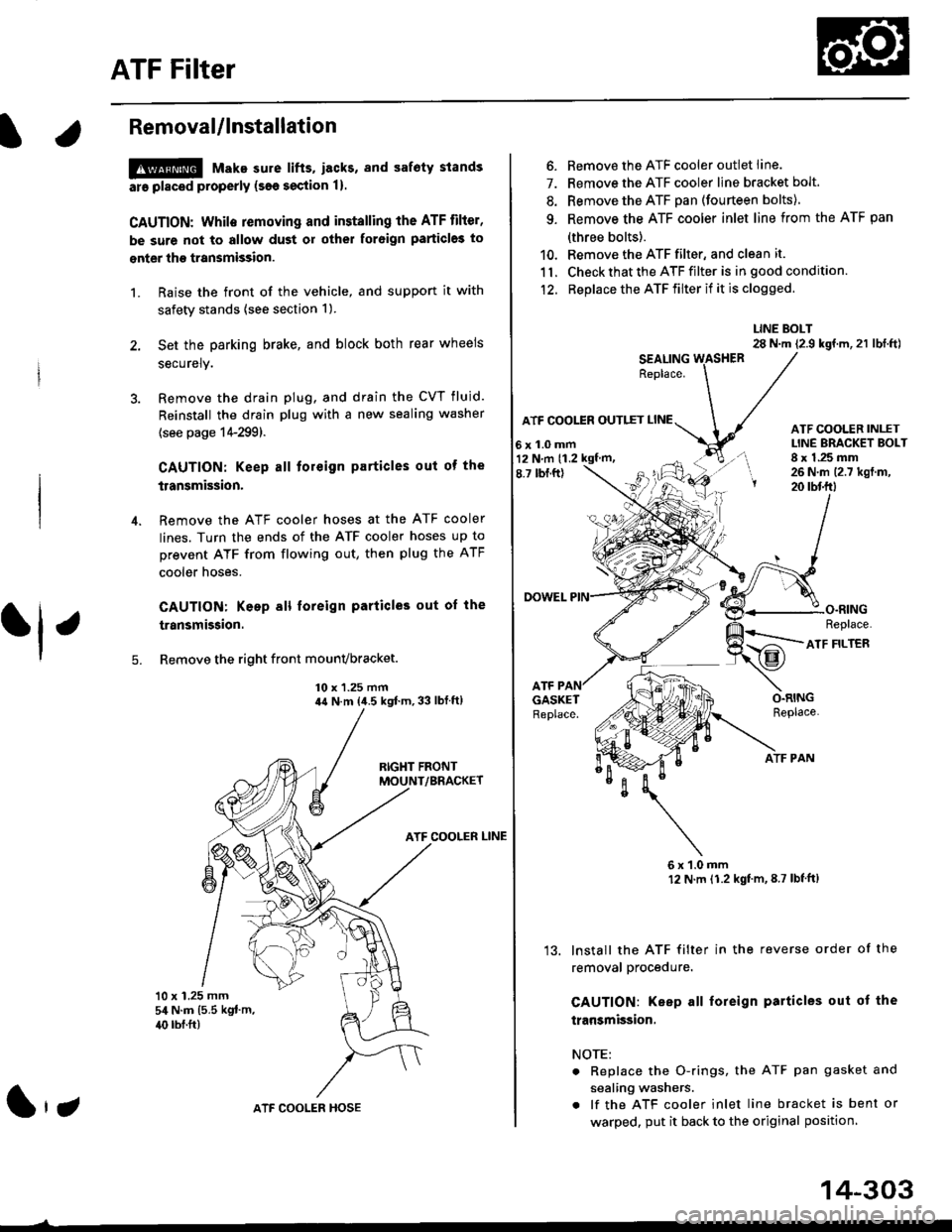

ATF Filter

l.Removal/lnstallation

!@ Make sure lifts, lEcks, snd safoty stands

ara pl8ced properly {sae section 1).

CAUTION: While removing and installing the ATF tilier,

be sure not to allow dust or other for6ign particle3 to

enter thg transmission.

1. Raise the front of the vehicle, and support it with

safety stands (see section 1).

2. Set the parking brake, and block both rear wheels

securely.

3. Remove the drain plug, and drain the CVT fluid.

Reinstall the drain plug with a new sealing washer

{see page 14-299).

fl,

5.

CAUTION: Keep all toreign particles out ot the

transmission.

Remove the ATF cooler hoses at the ATF cooler

lines. Turn the ends of the ATF cooler hoses up to

prevent ATF from flowing out, then plug the ATF

cooler noses.

CAUTION: Keep all foreign particles out of the

transmission.

Remove the right front mounvbracket.

10 x 1.25 mm4{ N.m {i1.5 kgf.m,33 lbf ft)

ATF COOLER LINE

10 x 1.25 mm54 N.m {5.5 kgt'm,

40 rbl.ft)

ATF COOLER HOSE(|'t

14-303

6. Remove the ATF cooler outlet line.

7. Remove the ATF cooler line bracket bolt.

8. Remove the ATF pan (fourteen bolts)

9. Remove the ATF cooler inlet line from the ATF pan

(three bolts).

10. Remove the ATF filter, and clean it.

11. Check that the ATF filter is in good condition.

12. Replace the ATF filter if it is clogged.

LINE BOLT28 N.m {2.9 kgf.m,21 lbt.ft)

ATF COO1TR OUTIET

6x1.0mm

ATF COOLER INI-ETLINE ERACKET BOLT8 x 1.25 mm26 N.m (2.7 kgt.m,20 rbtftt

O.RINGReplace.

ATF

ATF FILTER

ATF PAN

6x1.0mm12 N.m (1.2 kgt'm,8.7 lbl'ft)

lnstall the ATF filter in the reverse order of the

removal procedure.

GAUTION: Keep all foreign particles out ot the

transmission,

NOTE:

Replace the O-rings, the ATF pan gasket and

sealing washers.

lf the ATF cooler inlet line bracket is bent or

warped. put it back to the original position

GASKETReplace.

'13.

12 N m (1.2 kgf m,

Page 981 of 2189

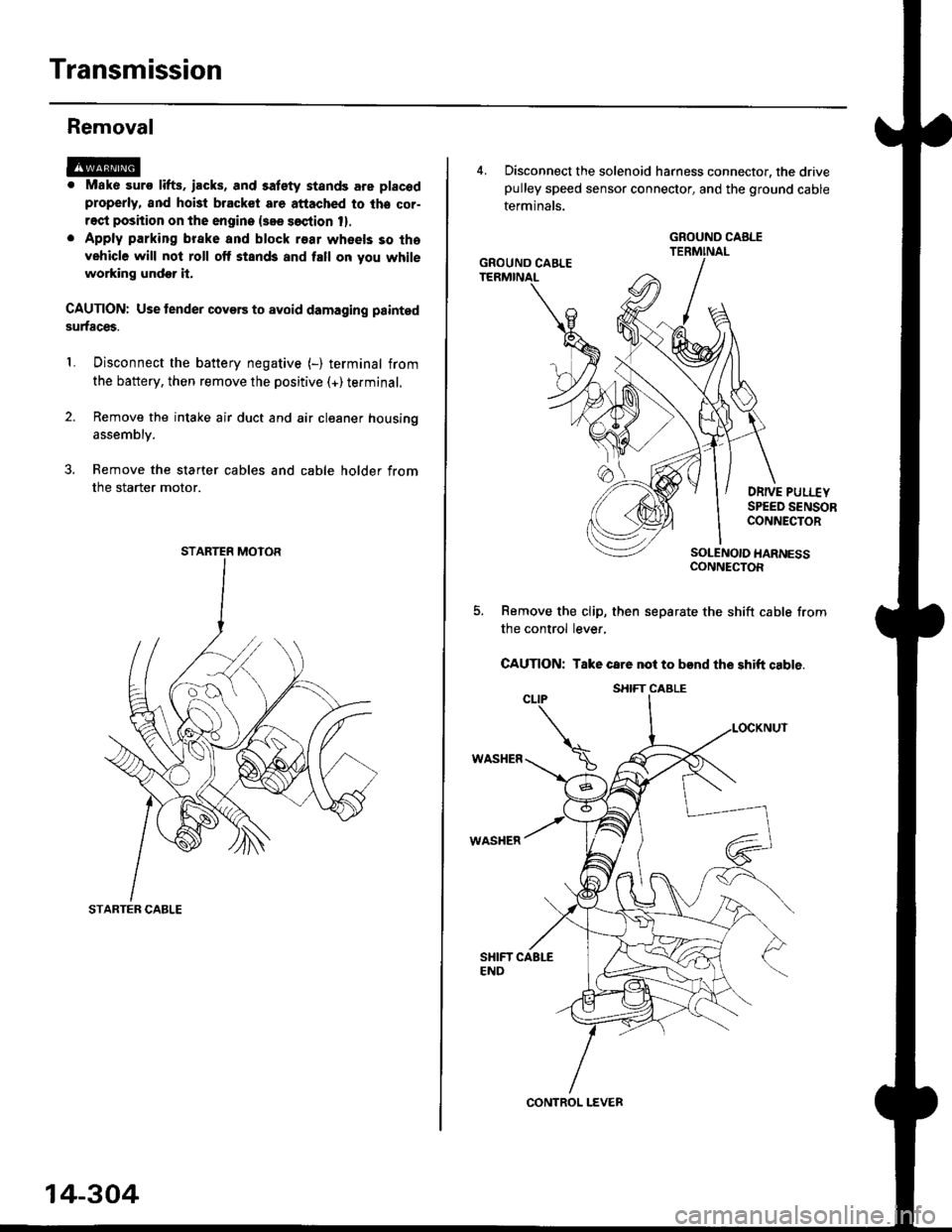

Transmission

Removal

@. Mako suro lifts. iacks, and satety stands are placod

properly, and hoi3t bracket are attached to lhe cor-

rect position on the engine {see soction 1}.

. Apply parking brake and block r€ar wheels so tha

vehicle will not roll off stands and fall on you while

working undor it.

CAUTION: Use tender covers to avoid damaging painted

surfaces.

Disconnect the battery negative (-) terminal from

the battery, then remove the positive (+)terminal.

Remove the intake air duct and air cleaner housing

1.

assembly.

3. Remove the starter cables and cable holder from

the starter motor.

STARTER CABLE

STARTER MOTOR

14-304

4, Disconnect the solenoid harness connector, the drivepulley speed sensor connector, and the ground cable

terminals.

DRIVE PULI.-EYSPEED SENSORCONNECTOR

SOLENOIO HARNESSCONNECTOR

Remove the clip, then separate the shift cable from

the control lever,

CAUTION: Take care not to bend the shift cable.

WASHER

WASHER

GROUND CABLE

GROUND CAELE

CONTROL LEVER

S}IIFT CABLE

Page 990 of 2189

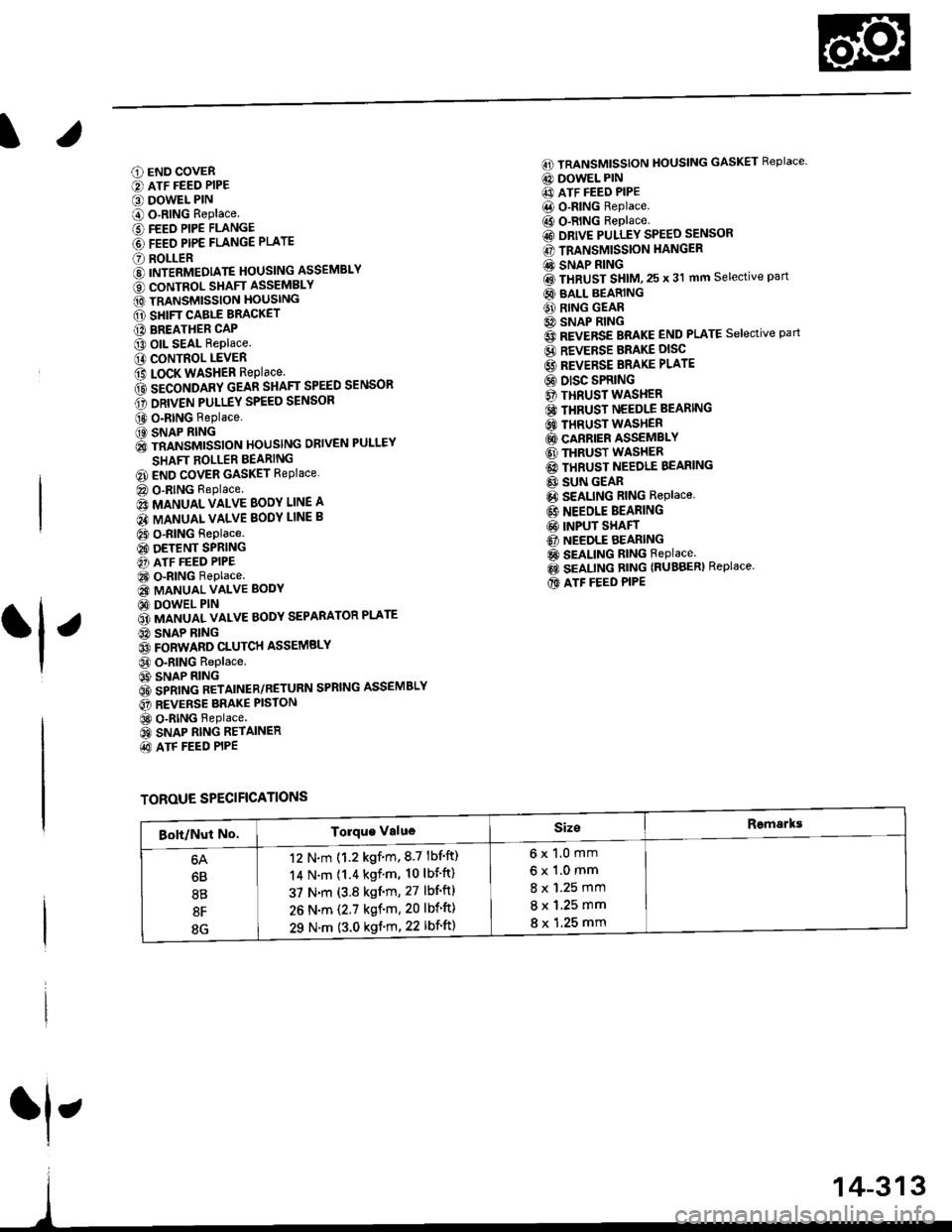

6) TRANSMISSION HOUSING GASKET Replace'

@ DOWEL PIN

@) ATF FEED PIPE

@ o-RING Replace.

60 o-RING Replace.

@) DRIVE PULLEY SPEED SENSOR

@ TRANSMISSION HANGER

@ SNAP RING

@ txaust Sxtfu, zs t 31 mm selective part

@ SALL BEARING

6J RING GEAR6D SNAP RING

@ aevense aRlxe rND PLATE Selective part

@ REVERSE BRAKE DISC

@ REVERSE BRAKE PLATE

@ DISC SPRING6} THNUST WASHER

@} finusr NeeoLr eelnNc

@ THRUST WASHER

@ GARRIER ASSEMBLY

@ THRUST WASHER

@ THRUST NEEDLE BEARING

@} SUN GEAR

@ SEALING RING REPIACE'

@ NEEDLE BEARING

@ INPUT SHAFT

@ NEEDLE BEARING

@ SEALING RING FEPIACE'

@ SEALING RING {RUBBERI Replace'

@ ATF FEED PIPE

O END COVER

O ATF FEED PIPE

O DOWEL PIN

@ O-RING Replace.G) FEED PIPE FLANGE

@ reeo ppe ruruce puru

O] ROLLERO IruTENMEDNTE XOUSING ASSEMBLY

ao corutnoL sxlrr lsseugLv

@ tnlrusmtsstottt ttoustt'tc

@ SHIFT CABLE BRACKET

c) BREATHER CAP

@ oll- SEAL Replace.

@ CONTROL LEVER

G LoCK WASHER Replace.(D secololaY ceaR SHAFT SPEED sENsoR

o) onvel put-uv sPEED SENSOR

@ O-RING Replace.(O SNAP RING6 rnmrsutsstoru xouslNc oRlvEN PULLEY

SHAFT ROLLER BEARING

@ END COVER GASKET REPIACE'

@ o-RING Replace

6o mnruulL vnLVe goDY LINE A

64 MANUAL VALVE BODY LINE B

@ O-RING Replace.

@ DETENT SPRING

O ATF FEED PIPE

@ O-RING Replace.

@ MANUAL VALVE EODY

@ DOWEL PIN

@ r'rllull valve goDY SEPARAToR PLATE

6D SNAP RING

@t roRwlno cturcx ASSEMBLY

@ o-RING Replace

@ SNAP RINGo3 spnlruc aetlrupn/RETURN SPRING ASSEMBLY

@ nevense ennr eBtottt

@ o-RING Feplace.

@ SNAP RING RE'AINER

@ ATF FEED PIPE

.1,

TOROUE SPECIFICATIONS

6x1.0mm

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgf'm,8.7 lbf'ft)

14 N.m {1.4 kgf'm, 10 lbift)

37 N.m (3.8 kgf'm, 27 lbf'ft)

26 N.m (2.7 kgf'm,20 lbf'ft)

29 N.m (3.0 kgf'm, 22 lbf'ft)

6B

8B

8F

8G

14-313

rl,

Page 995 of 2189

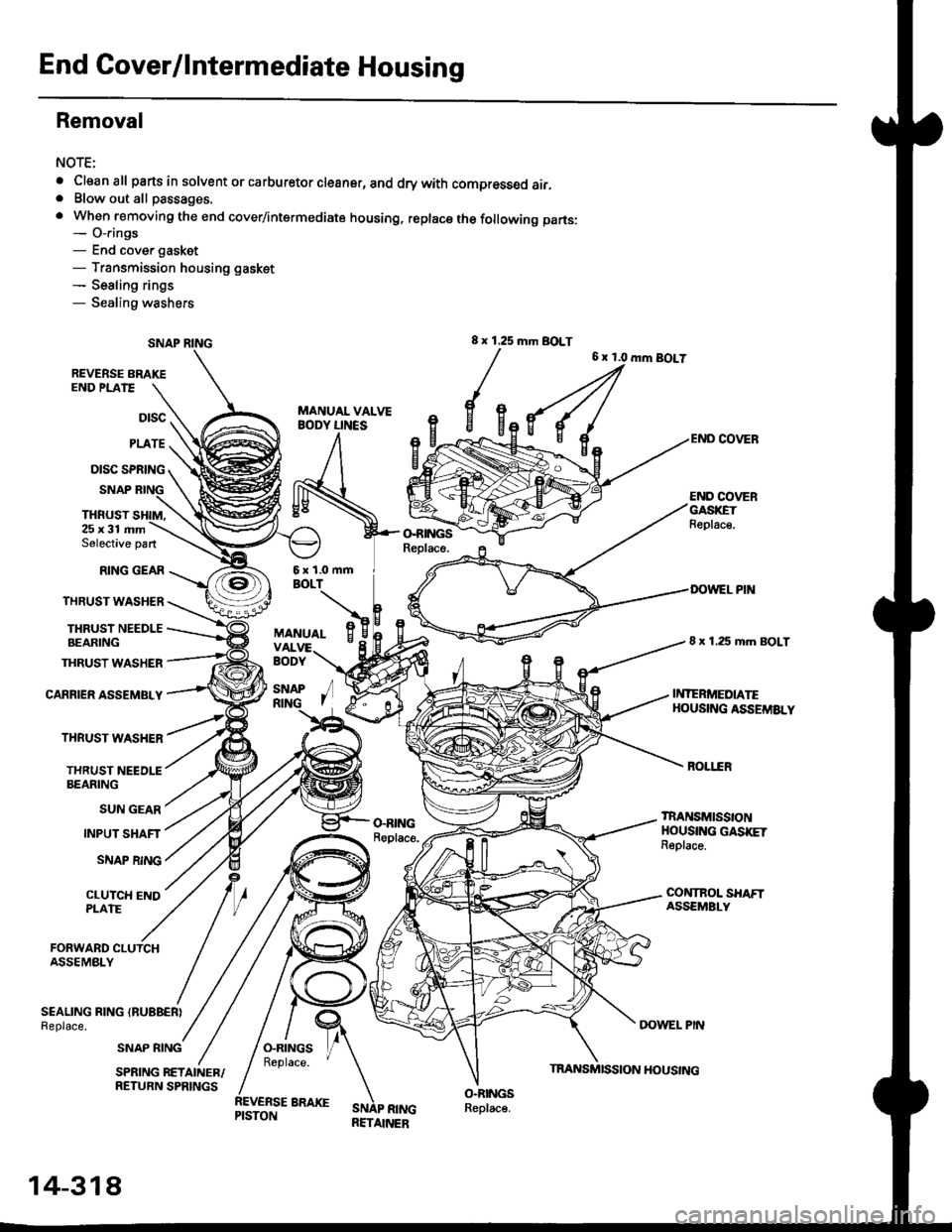

End Cover/lntermediate Housing

Removal

NOTE:

. Cleanall parts in solvent or carburetor cleansr, and drywith compressed air,. Blow out all passages.

. When removing the end cover/intermediate housing, replacs the following parts:- O-rings- End cover gasket- Transmission housing gasket- Sealing rings- Sealing washers

8 x 1 .25 mm BOLT

REVERSE BRAKE

{u

END PLATE

6 x 1.0 mm BOLT

Dtsc

PLATE

DISC SPRING

SNAP

THRUST

END COVERGASXETFeplac€.25x31 mmSelective part

RING GEAR

THRUST WASHER

THRUSI NEEDLEBEARING

THRUST WASHER

CARRIER ASSEMBLY

THRUST WASHER

THRUST NEEDLEBEARING

SUN GEAR

INPUT SHAFT

SNAP RING

CLUTCH ENDPLATE

sNAP /R|NG I

8 x 1.25 mm BOLT

TRANSMISSTONHOUSING GASKETReplace.

DOWEL PIN

INIERMEDIATEHOUSING ASSEMSLY

FORWARD CLUTCHASSEMBLY

SEALING RING (RUBBER}

Replace.

SNAP RING

o.BINGReplace.

SNAP RINGRETAINER

SPRING RETAINER/RETURN SPRINGS

14-318

HOUSING