engine assembly HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 62 of 2189

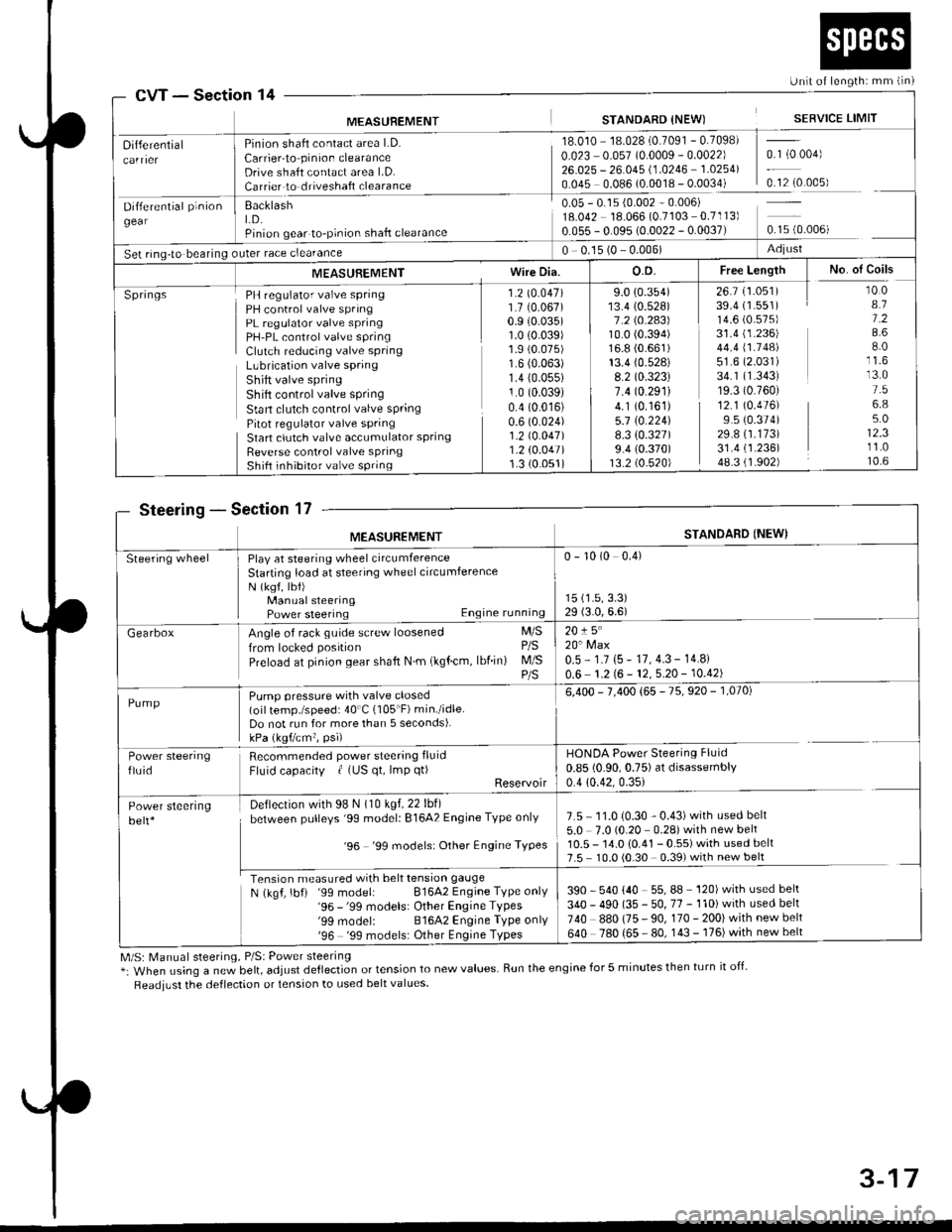

Unit of length: mm lin)

STANDARD {NEW) SERVICE LIMITMEASUREMENT

Differential

Dtri"*"t"|p'.b"gear

S"t rrg-t" b""il"s

Pinion shaft contact area LD.

Carrier-to pinion clearanceDrive shaft contact area l.D.Carrier to driveshaft clearance

BacklashLD.Pinion gear to-pinion shafl clearance

)uter race clearance

18.010 18.028'0.7091 - 0.7098)

0.023 0.057 (0.0009 - 0.0022) 0.1 (0 004)

26.025 - 26.045 (.0246 1 0254\0.045 0.086 (0.0018 - 0.0034) 0.12(0.005)

0 05 - 0.15 i0 002 0.006)18 042 18.066 {0.7103 0.7" l3)

0.055 - 0.095 (0.0022 - 0.0037) 0.15 {0.006)

0 0.15 (0 - 0.006) Adjlrst

MEASUBEMENT Wire DiaO.D. Free Length I No. of Coils

SpringsPH regulator valve spring 1 2 (0 047)

PH control valve spring 1 7 {0.067)PL regulator valve spring 0 9 (0.035)

PH'PL control valve spring 1 0 (0 039)

crutlh reduc'ns vdrve spnns ] :19 9]:lLLbrication valve spring I b (u ubJr

Shitt valve spring 1 4 (0.055)

Shift control valve spring 1 0 (0.039)

Stan clutch control valve spring 0.4 (0 016)

Pitot regulator valve spring 0.6 (0 024)

Start clutch valve accumulator spring 1 2 \0 O47)

Reverse control valve spring 1 2 (0.047)

Shift inhibitor valve spring 1 3 (0 051)

9.0 {0.354)13.4 (0.528)

1.2lO.2A3\10.0 (0.394)

16.8 (0.661)

13.4 (0.528)

8.2 (0.323)

1 .4 t0.29114.1 (0.161)

5.7 t0.224)8.3 {0.327)9.4 (0.370)

13.2 (0.520)

26.7 (1.051)

39.4 (1.551)

14.6 (0.575)

31.4 (1.236)

44.4 \1.14al51.6 (2.031)

34.1 (1.343)

19.3 (0.760)

12.1 (0.476)

9.5 (0.374)

29.8 (1.173)

31.4 (1.236)

48.3 (1.902)

r0.08.11.28.68.0

13.01.56.85.012.311.010.6

Section 14

SteeringSection 17

M/S: [,4anual steering, P/Sl Power steering*: When using a ne; bett, adjust dellection or tension to new values. Run the engine for 5 minutes then turn it off-

Readjust the deflection or tension to used belt values.

cw

MEASUREMENTSTANDARD {NEWI

Steering wheelPlay at steering wheel circumferenceStarting load at steering wheelcircumferenceN (ksf, lbf)Manual steeringPower steering Engine running

0 - 10 (0 0.4)

15 (1.5,3.3)

29 (3.0,6.6)

GearboxAngle of rack guide screw loosened M/S

from locked position P/S

Preload at pinion gear shaft N m (kglcm, lbfin) M/S

20!5"20'Max0.5 - 1.7 (5 - 17,4.3 - 14.8i

0.6 1.2 (6 - 12, 5.20 - 10.42)

Pump pressure with valve closed(oil temp./speed: 40'C (105"F) min./idleDo not run for more than 5 seconds).kPa (kgtcm?, psi)

6,400 - 7,400 {65 - 75, 920 - 1,070)

Power steeringfluidRecommended power steering fluid

Fluid capacity | {US qt, lmp q0Reservoir

HONDA Power Steering Fluid

0.85 (0.90,0.75) at disassembly0.4 {0.42.0.35}

7.5 11.0 {0.30 - 0.43)with used belt

5.0 7.0 (0.20 0.28) with new belt10.5 - 14.0 10.41 - 0.55) with used belt7.5 10.010.30 0.39) with new belt

390 540 {40 55,88 '120) wrth used bek

340 - 490 (35 - 50, 77 - 110) with used belt

740 880 (75 - 90, 170 - 200) with new belt

640 780 (65 - 80, 143-176)with newbelt

Power steeringbelt*

Deflection with 98 N (10 kgf,22 lbf)

between pulleys '99 modell 81642 Engine Type only

'96 '99 models: Other Engine TYPes

ron.ionffiN (kgf, lbf) '99 model: 81642 Engine Tvpe only'96 -'99 models: Other Engine TYPes'99 modelr 81642 Engine TYPe onlY'96 '99 models: Other Engine TYPes

3-17

Page 72 of 2189

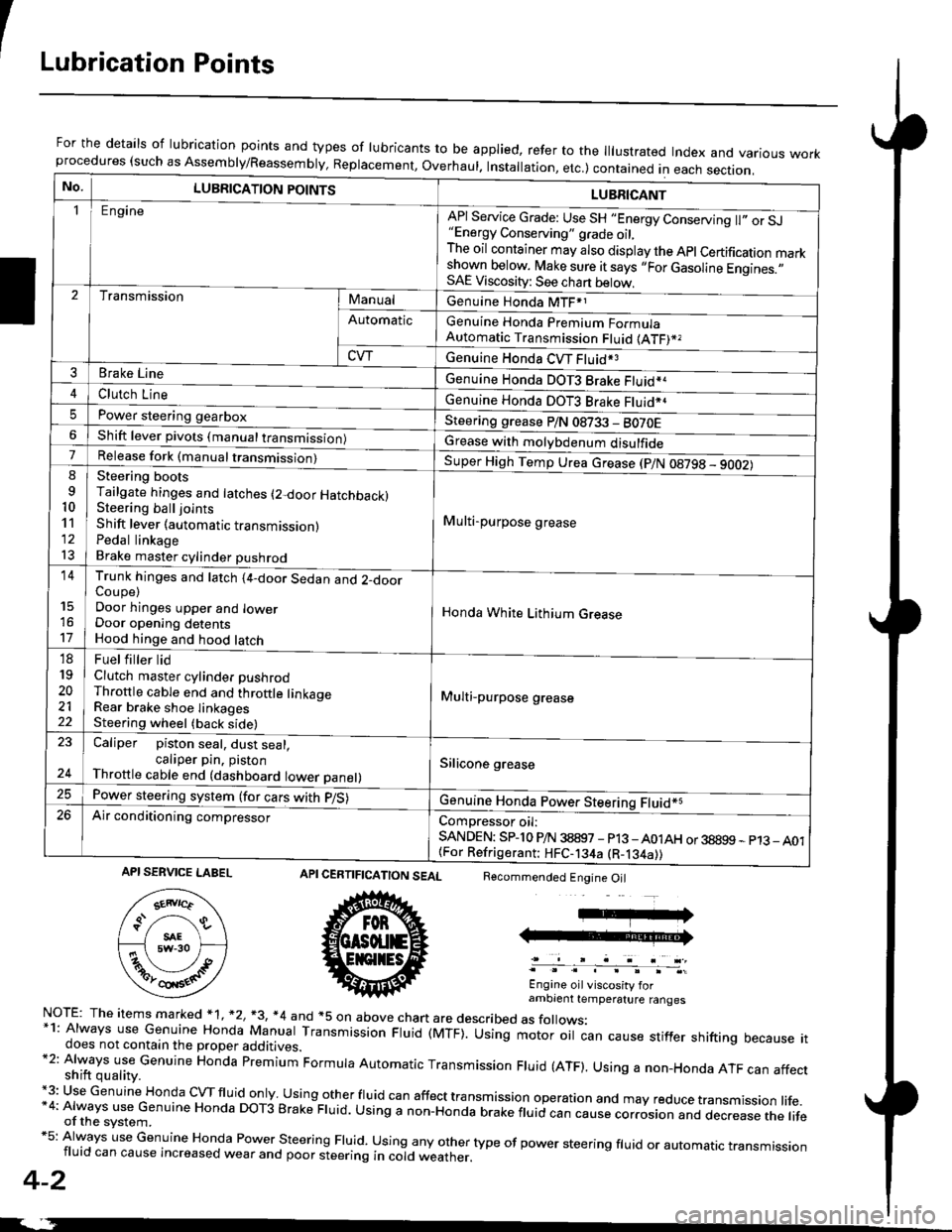

ILubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the lllustrated Index and various workprocedures (such as Assembly/Reassembly, Replacement, Overhaul. Installation, etc.) contained in each section.

No.LUBRICATION POINTS

Engine

LUBRICANT

"Energy Conserving" grade oil,The oil container may also display the Apl Certification markshown below. Make sure it says ,,For Gasoline Engines.,,SAE Viscosity: See chart below,

I

TransmissionManualGenuine Honda MTF*1

Genuine Honda Premium FormulaAutomatic Transmission Fluid (ATF)*,

Genuine Honda CVT Fluid*3

Genuine Honda DOT3 Brake Fluid*a

Automatic

CVT

3Brake Line

ClL,tci t""e4

I

Genuine Honda DOT3 Brake Fluid*aPower steering gearboxSteering grease P/N 08733 - BO70EShift lever pivots (manual transmission)Grease with molybdenum disulfide7-:ti

9

10'l'l

l3

14

't7

18

19

20

2122

Release fork (manual trancmi

Shift lever (automatic transmission)Pedal linkageBrake master cylinder pushrod

Super High Temp Urea crease (p/N 08798 - 9OO2)

i Multi-purpose grease

I

I

Honda White Lithium Grease

Multi-purpose grease

Silicone grease

@

Trunk hinges and latch (4-door Sedan and 2-doorCoupe)Door hinges upper and lowerDoor opening detentsHood hinge and hood latch-FUet T ter ttd

Clutch master cylinder pushrodThrottle cable end and throttle linkageRear brake shoe linkagesSteering wheel (back side)

23

E-

Caliper piston seal, dust seal,caliper pin. pistonThrottle cable end (dashboard lower panel)

Power steering system (for cars with p/S)

Air conditioning compressorComDressor oil:SANDEN: SPlo P/N 38897 - p13 -A01AH or 38899 - p13_ A01{For Refrigerant: HFC-134a (R-134a))

CERTIFICATION SEAL

ffi

NorE: The items m arked * 1, *2, +3, *4 and +5 on above chan are described as folows:*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because itdoes not contain the proper additives.*2: Always use Genuine Honda premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affectshift quality.+3: Use Genuine Honda cVTfluid only usingotherfluid can affect tra nsmission operation and may reduce transmission life.*4: Always use Genuine Honda DoT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and dec.ease the lifeof the svstem.*5: Always use Genuine Honda Power steering Fluid. using any other type of power steering fluid or automatrc transmissionfluid can cause increased wear and poor steering in cold weather.

4-2

Recommended Engine Oil

Engine oil viscosity forambrent temperature ranges

API SERVICE LABEL

Page 100 of 2189

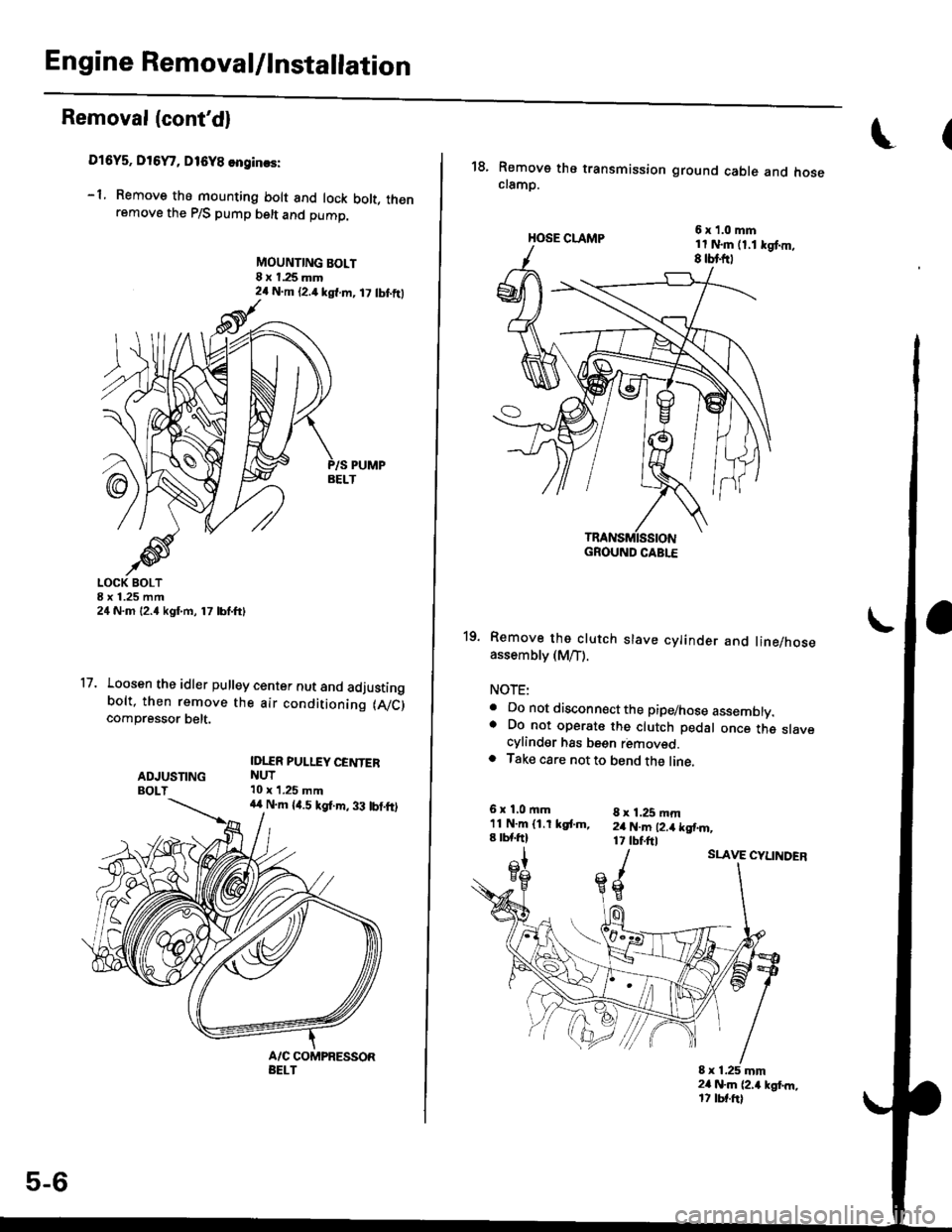

Engine Removal/lnstailation

Removal (cont'dl

Dl6Y5. DrGYr, D16Y8 enginas:

-1. Remove the mounting bolt and lock bolt, thenremove the P/S pump belt and pump.

MOUNTING BOLT8 x 1.25 mm24 N.m {2.4 kgl.m, 17 tbf.ftl

LOCK BOLT8 x 1.25 mm24 N.m 12.4 kgf.m, 17 lbf.ftl

17. Loosen the idler pulley center nut and adjustingbolt, then remove the air conditioning (A[/C)compressor belt.

IDI.IR PULLEY CENTERNUT10 x 1.25 mma,l N.m {,1.5 kgt.m, 33 lbf.ft)

5-6

(

'18. Remove the ransmission ground cable and hosect8mo.

HOSE CLAMP6 x '1.0 mm

19. Remove the clutch slave cylinder and line/hoseassembty (M/T).

NOTE:

. Do not disconnectthe pipe/hose assembly.. Do not operate the clutch pedal once the slavecylind€r has been removed.o Take care not to bend the line.

6x1,0mm 8x1.2Smm11 N.m {1.1 kgt.m, 2a N.m t2.4 kgf.m,I tbf.ftl 17 tbf.ftl

8 x 1.25 mm2a N'm {2,4 kgt m,17 tbt.ftl

Page 112 of 2189

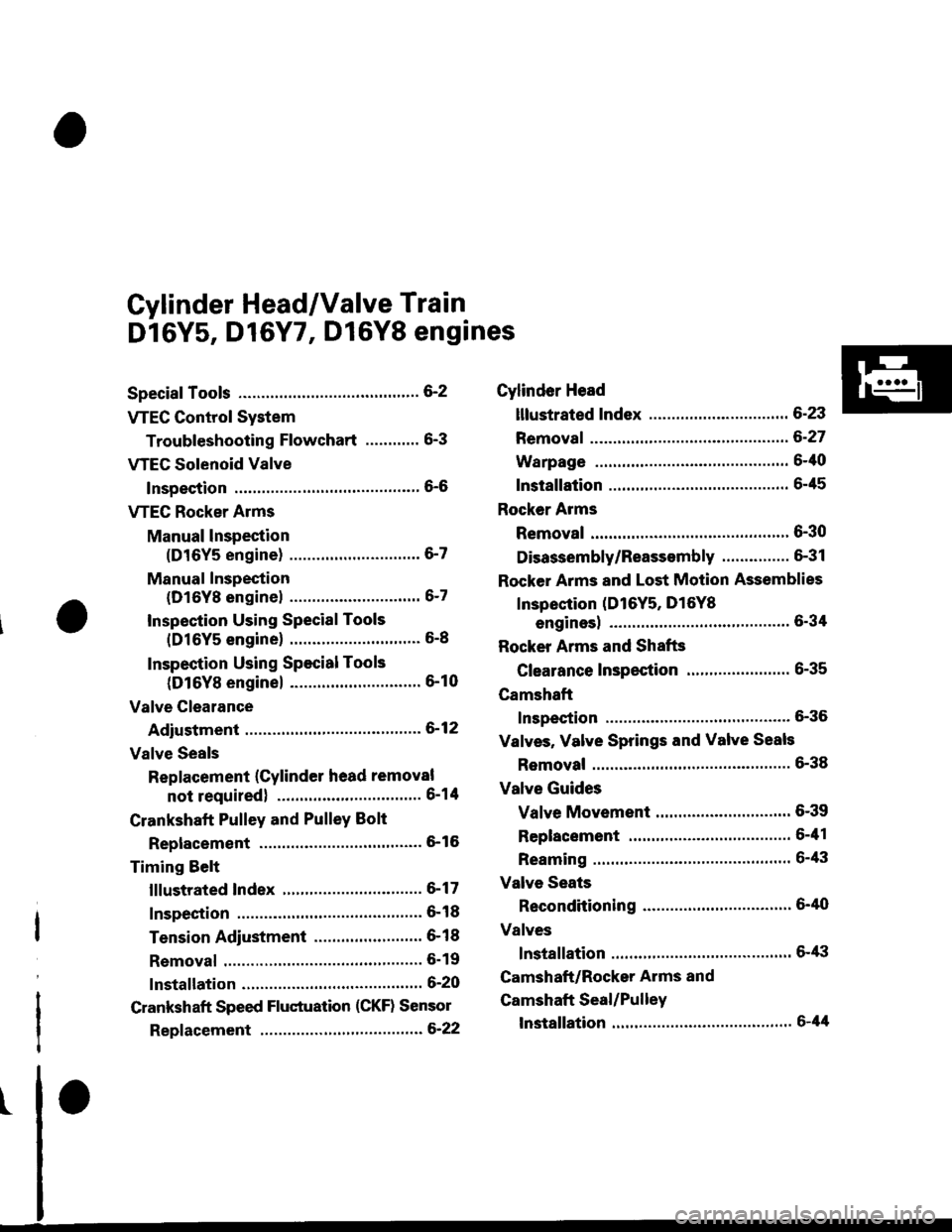

Cylinder Head/Valve Train

Dl6Y5, D16Y7, Dl6Y8 engines

Special Tools ............. G2

VTEC Control System

Troubleshooting Flowchart .........." 6-3

VTEG Solenoid Valve

Inspection ............" 6-6

VTEC Rocker Arms

Manual lnspection

(D16Y5 engine) ............................. 6-7

Manual Inspection

(D16Yg enginel ................'............ 6-7

Inspection Using Special Tools

{D16Y5 engine} .....................""'... 6-8

Inspection Using Special Tools

(D16Y8 engine) .........................'.'. 6-10

Valve Clearance

Adiustment ..."".....6-12

Valve Seals

Replacement (Cylinder head removal

not requiredl ................................ 6-1tl

Crankshaft Pulley and PulleY Bolt

Replacement ."...... &16

Timing Selt

lllustrated Index ............................... 6-17

Inspection .............. 6-18

Tension Adjustment ........................ 6- 1 I

Removal ......,,......... 6-19

lnstallation ............. 6-20

Crankshaft Speed Fluctuation (CKF) Sensor

Repf acement .........6'22

Cylinder Head

lllustrated Index ............................... 6-23

Removal ................. 6-27

Warpage ................ 6-40

lnstallation ............. 6-45

Rocker Arms

Removal ................. 6-30

Disassembly/Reassambly ............... 6-31

Rocker Arms and Lost Motion Assemblies

Inspection (D16Y5, D16Yg

enginesl "..........' 5-34

Rocker Arms and Shafts

Glearance Inspection ....................... 6-35

Camshaft

Inspection .............. 6-36

Valves, Valve Springs and Valve Seals

Removal ........""..... 6-38

Valve Guides

Valve Movement .............................. 6-39

Replacement .........6-41

Reaming .......'......'.' 6-43

Valve Seats

Reconditioning .'....6'40

Valves

lnstallation ............. 6-tt3

Camshaft/Rocker Arms and

Camshaft Seal/Pulley

lnstallation ............. 6-44

Page 117 of 2189

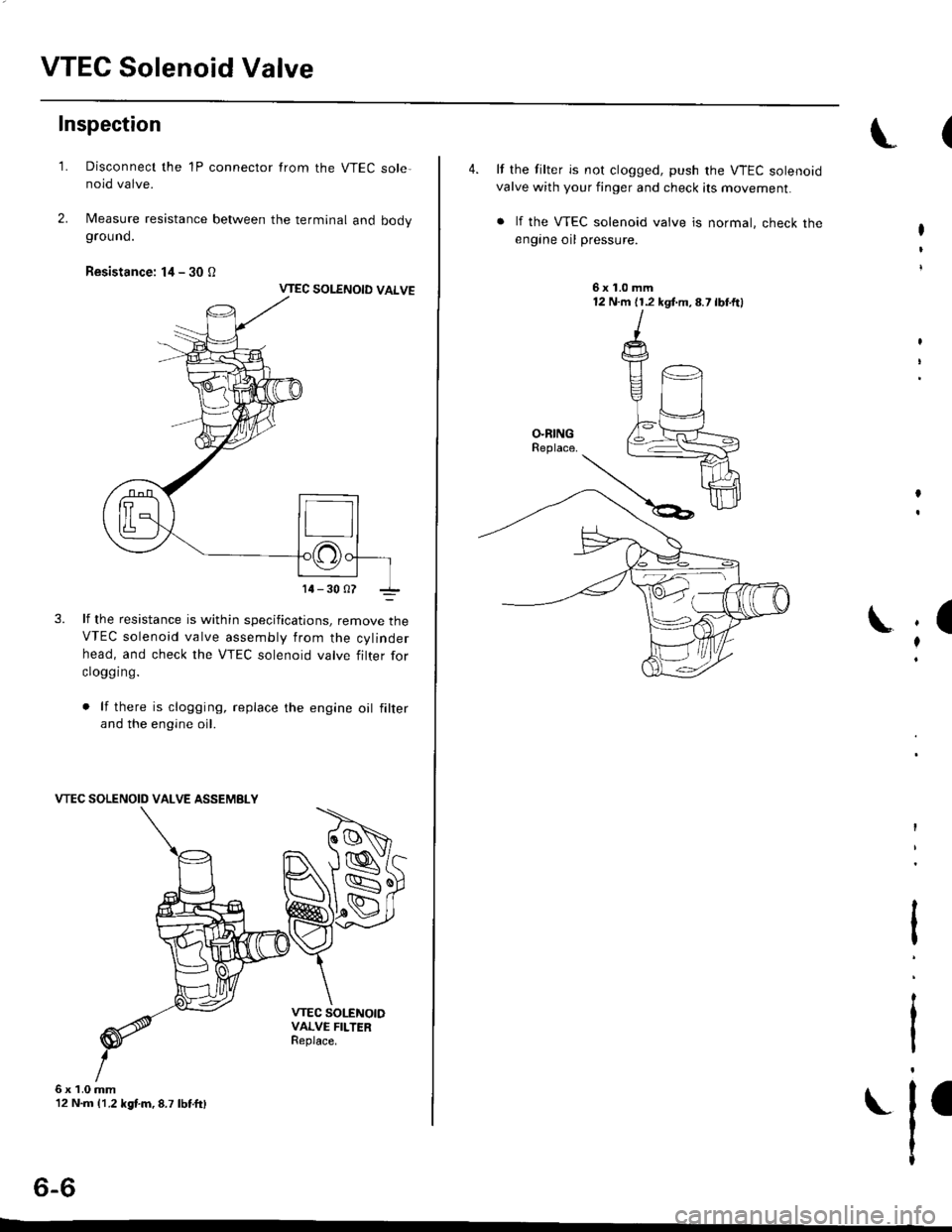

VTEC Solenoid Valve

Inspection

1.

6x1.0mm12 N.m 11.2 kgf.m,8.7 lbtft)

Disconnect the 1P connector from the VTEC sole-noid valve.

Measure resistance between the terminal and bodyground.

Resistance: l4 - 30 O

lf the resistance is within specifications, remove theVTEC solenoid valve assembly from the cylinder

head, and check the VTEC solenoid valve filter for

cloggrng.

. lf there is clogging, replace the engine oil filterand the engine oil.

VTEC SOLENOID VAI-VE ASSEMBLY

6-6

(

4. lf the filter is not clogged, push the VTEC solenoidvalve with your finger and check its movement.

. lf the VTEC solenoid valve is normal. check the

engane oil pressure.

6x1.0mm12 N.m {1.2 kgt.m,8.7lbf.ft)

I

.(

I

\

;

..l'

Page 118 of 2189

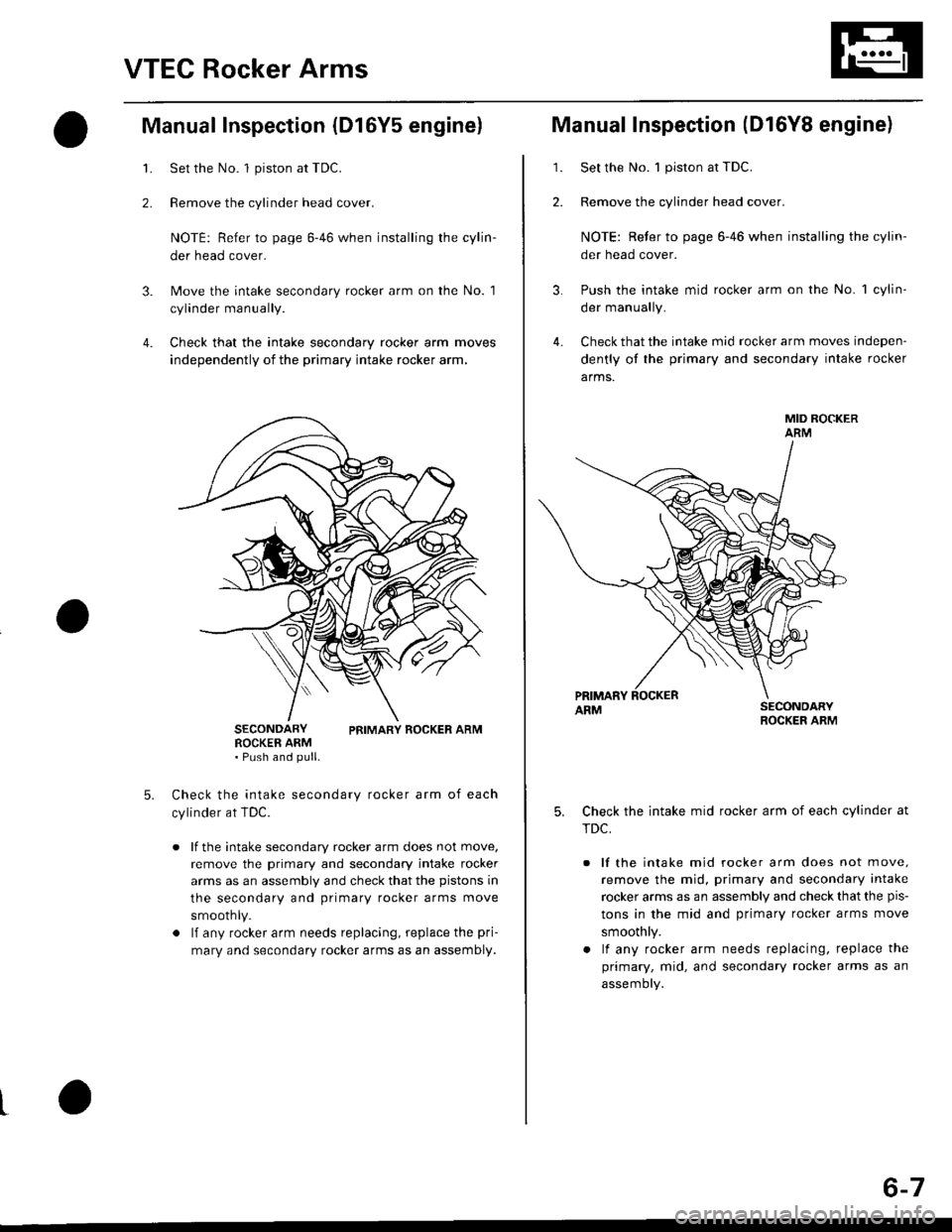

VTEC Rocker Arms

2.

Manual Inspection (D16Y5 engine)

3.

1.

4.

Set the No. 1 piston at TDC.

Remove the cylinder head cover.

NOTE: Refer to page 6-46 when installing the cylin-

der head cover.

Move the intake secondary rocker arm on the No. 'l

cylinder manually.

Check that the intake secondary rocker arm moves

independently of the primary intake rocker arm,

SECoNDARY PtROCKER ARM. Push and pull.

Check the intake secondary

cylinder at TDC.

rocker arm of each

a lf the intake secondary rocker arm does not move,

remove the primary and secondary intake rocker

arms as an assembly and check that the pistons in

the secondary and primary rocker arms move

smoothly.

a lf any rocker arm needs replacing, replace the pri-

mary and secondary rocker arms as an assembly.

PRIMARY ROCKER ARM

4.

Manual Inspection (D16YB engine)

1.Set the No. 1 piston at TDC.

Remove the cylinder head cover.

NOTE: Reter to page 6-46 when installing the cylin-

der head cover.

Push the intake mid rocker arm on the No. 1 cylin-

der manually.

Check that the intake mid rocker arm moves indepen-

dently of the primary and secondary intake rocker

arms.

MID ROCKERARM

Check the intake mid rocker arm of each cylinder at

TDC,

lf the intake mid rocker arm does not move.

remove the mid, primary and secondary intake

rocker arms as an assembly and check that the pis-

tons in the mid and primary rocker arms move

smoothly.

lf any rocker arm needs replacing, replace the

primary, mid, and secondary rocker arms as an

assemory.

5,

6-7

Page 135 of 2189

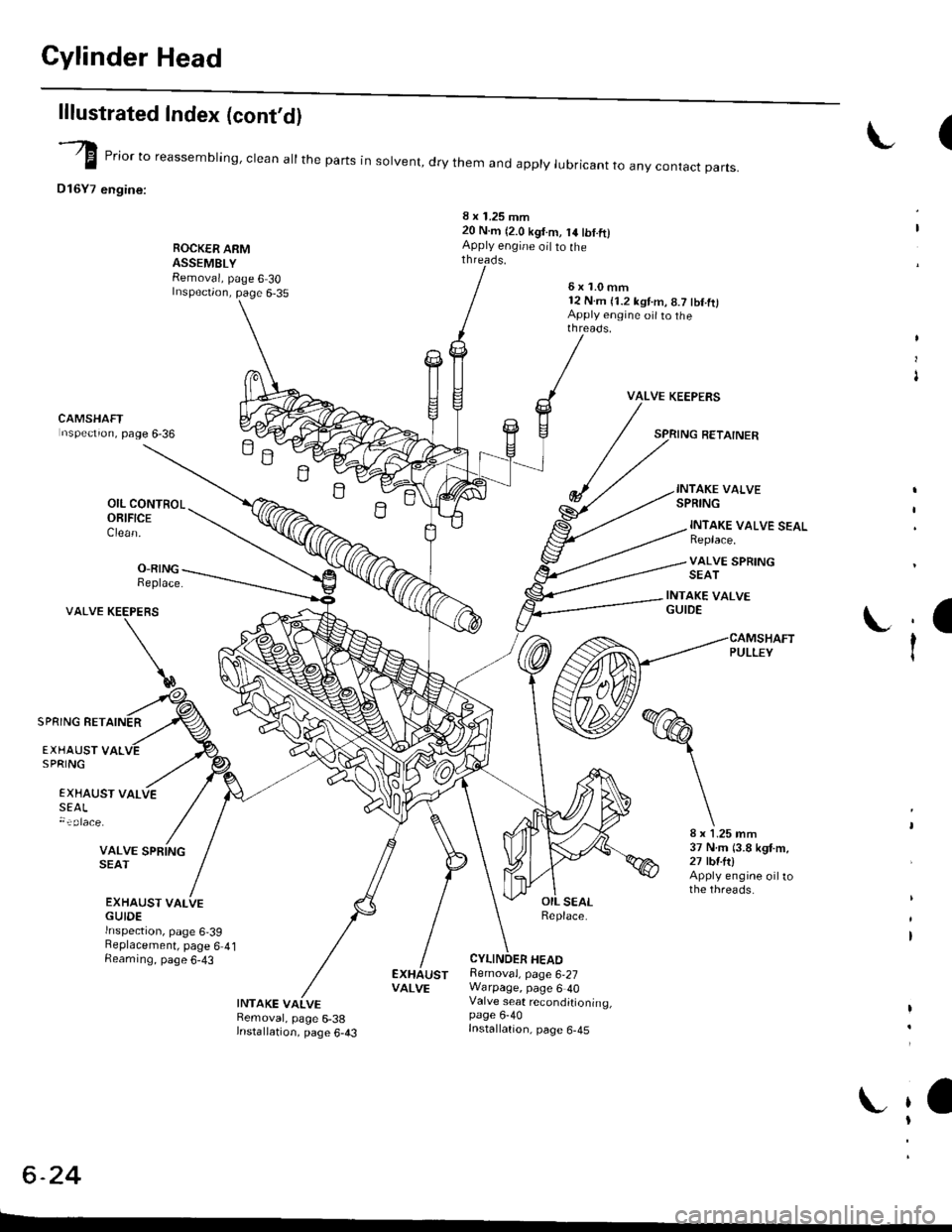

Cylinder Head

lllustrated Index (cont'dl

(-/) _.- E "or to reassembring, crean at the parts in sorvent, dry them and appry rubricant to anv contact oarts.

D16Y7 engine:

ROCK€R ARMASSEMBLYRemoval, page 6 30Inspection, page 6-35

8 x 1.25 mm20 N.m (2.0 kgt.m, 14 tbt.ftlApply engine oil to the

H

B

O-RINGReplace.

INTAKE VALVE SEALReplace.

VALVE SPRINGSEAT

INTAKE VALVEGUIDE

:a

ti

VALVE

SPRING RETAINER

EXHAUST VALVESEAL

VALVE SPRINGSEAT

EXHAUST VALVEGUIDErnspectron, page 6,39Beplacement, page 6 4lAeaming, page 6-43

8 x 1.25 mm37 N m (3.8 kgt m,27 tbtftlApply engine oiltothe threads.

INTAKE VALVERemoval, page 6-38lnstallation, page 6-43

Removal, page 6,27Warpage, page 6 40Valve seat reconditioning,page 6-40Installation, page 6-45

VALVE

t

t

t

CAMSHAFTnspectron, page 6-36

OIL CONTROLORIFICEClean.

KEEPERS

\

EXHAUST VALSPRING

c -A9-2.+

L

6x1.0mm12 N.m (1.2 kst.m, 8.7 tbf.ft)Apply engine oit to thethreads.

VALVE KEEPERS

SPRING RETAINER

INTAKE VALVESPRING

Page 136 of 2189

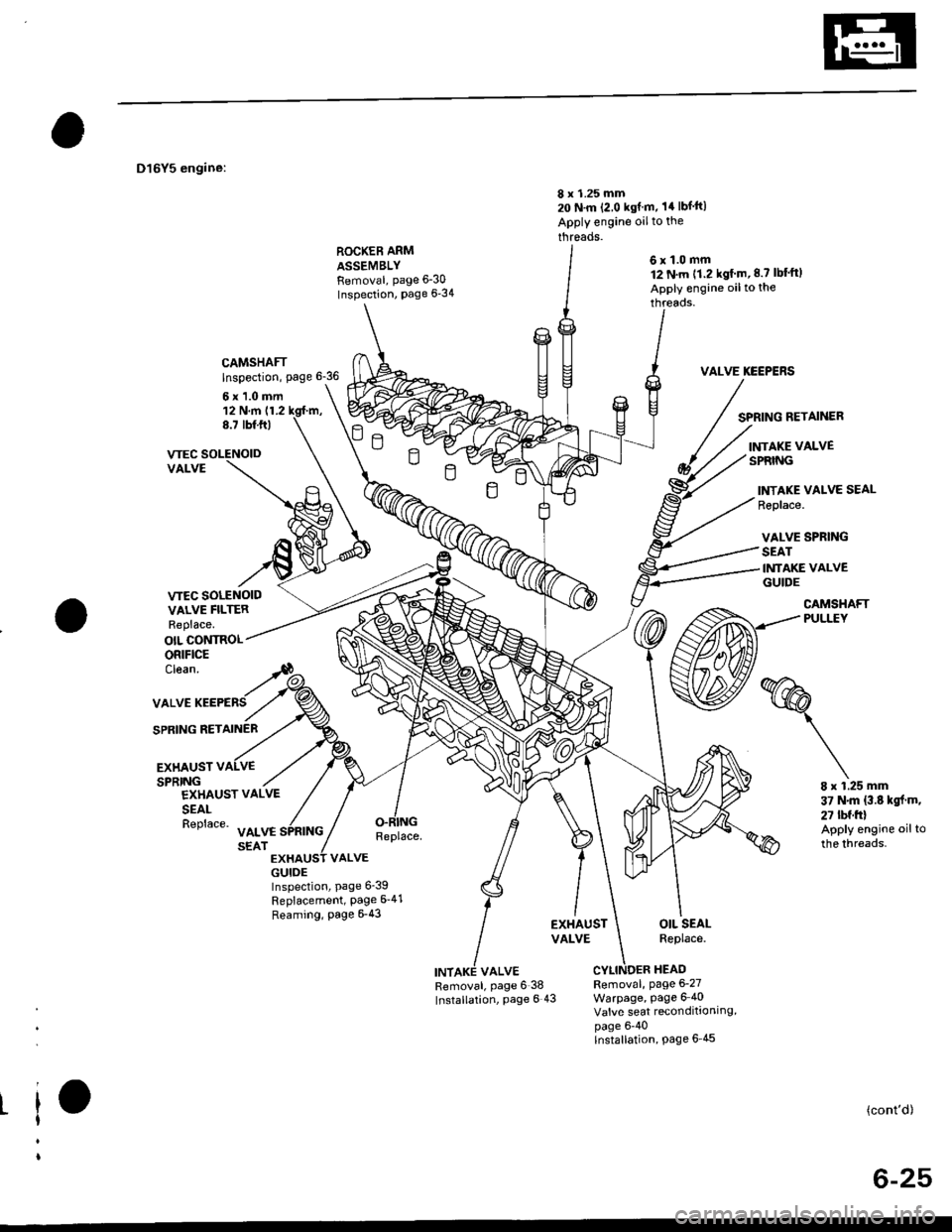

D16Y5 engine:

I x 1.25 mm20 N.m (2,0 kgf m, 14 lbf ft)

Apply engine oilto the

threads.ROCKEB ARMASSEMBLYFemoval, page 6-30

Inspection, Page 6-34

6x1.0mm12 N.m 11.2 kgf m, 8.7 lbf'ftl

Apply engine oilto the

threads.

VALVE KCEPERS

SPRING RETAINER

CAMSHAFTInspection, page 6-36

6x1.0mm12 N,m 11.28.7 tbf.ft)

WEC SOLENOIDVALVEBINTAKE VALVESPRING

INTAKE VALVE SEAL

Replace.

VALVE SPRINGSEAT

INTAKE VALVEGUIDE

CAMSHAFTPUL|'IY

VTEC SOLENOIDVALVE FILTERReplace.

OIL CONTROLORIFICEClean.

VALVE

SPRING RETAINEB

EXHAUST V

SPRING

VE

EXHAUST VALVE

SEALt"o'""".uoau,

SEATReplace.

GUIDEInspection, page 6-39Replacement, Page 6-41

Reaming, page 6-43EXHAUSTVALVEOIL SEALReplace.

HEAD

8 x 1.25 mm

37 N.m 13.8 kgf.m,

27 tbf.frlApply engine oiltothe lhreads.

(cont'd)

6-25

INTAKE VALVERemoval, page 6 38

Installalion, Page 6 43Removal, page 6-27Warpage, Page 6 40

Valve seat reconditioning'page 6-40lnstallation, page 6_45

Page 137 of 2189

Cylinder Head

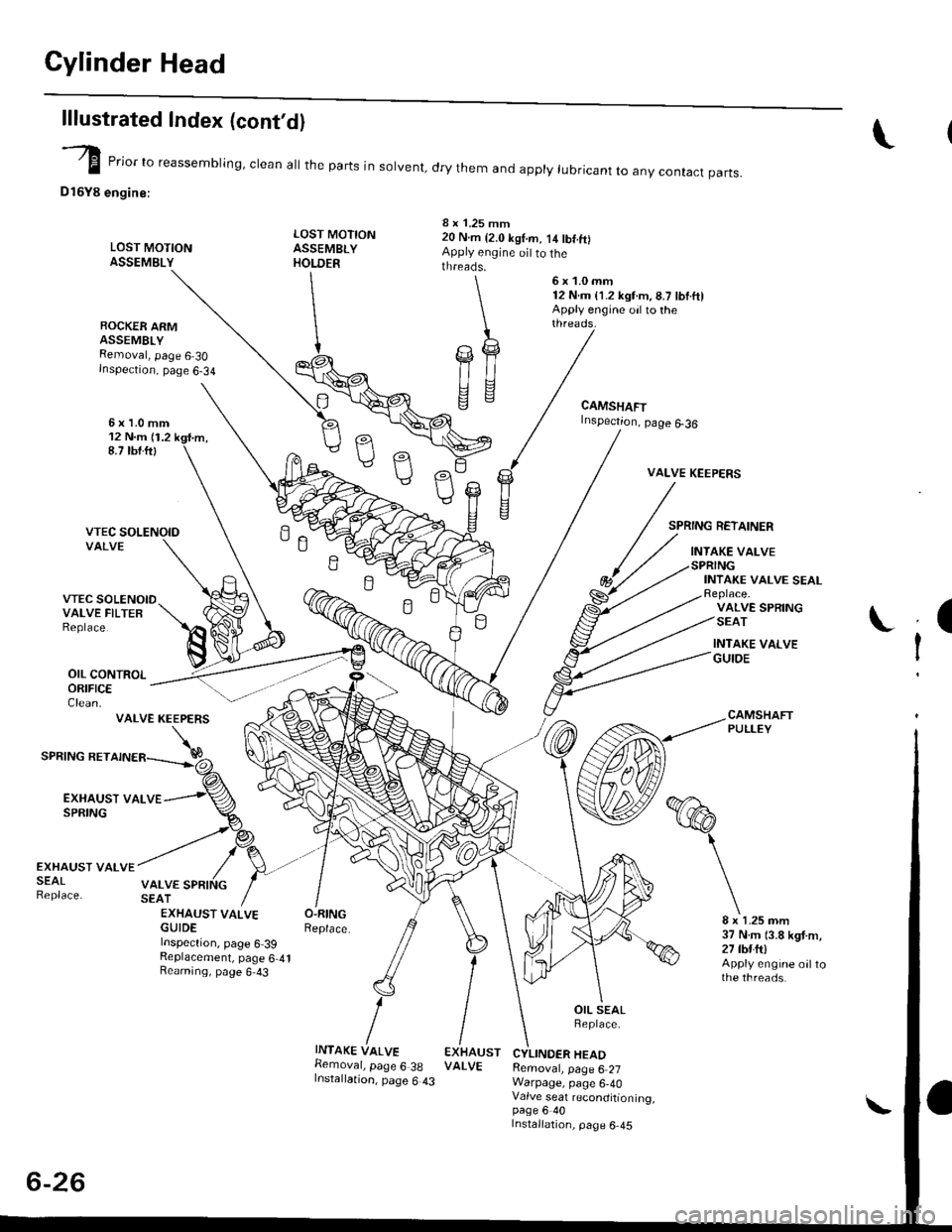

lllustrated Index (cont'dl

VALVE KEEPERS

SPRING RETAINER

INTAKE VALVE

VTEC SOLENOIDVALVE FILTEBReplace.

OIL CONTROLORIFICEClean.

INTAKE VALVE SEALReplace.VALVE SPRINGSEAT

INTAKE VAI.VEGUIOE

CAMSHAFTPULLEY

I

I

VALVE KEEPERS

SPRING RET

EXHAUST VALVESPRING

@

EXHAUST VALVESEALReplace.

8 x 1.25 mm37 N.m 13.8 kgt m,27 tbfitlApply engine oiltothe threads.

EXHAUSTVALVE

-vp

e,.io"o reassembring, crean at the parts in sorvent, dry them and appry rubricant to any contact parts.

D16Y8 engine:

LOST MOTIONASSEMgLY

ROCKER ARMASSEMBLYRemoval, page 6 30Inspection, page 6-34

5xl.0mm12 N.m {1.28.7 tbf.ft)

VALVE SPRINGSEATEXHAUSTVALVE O.RINGGUIDE Replace.Inspection, page 6 39Replacement, page 6 41Reaming, page 6 43

LOST MOTIONASSEMBLYHOLDER

INTAKE VALVEBemoval, page 6 38Installation, page 6 43

20 N.m 12.0 kgl.m, 14 tbf.ft)Apply engine oit to thethreads.

\

\

s9illl

CAMSHAFTInspection, page 6-36

OIL SEALBeplace.

CYLINDER HEADRemoval, page 6 27Warpage, page 6-40Valve seat reconditioning,page 6 40Installation, page 6-45

6x1.0mm12 N.m (1.2 kgt.m,8.7 lbf.ftlApply engine oil to thethreads,

Page 141 of 2189

Cylinder HeadRocker Arms

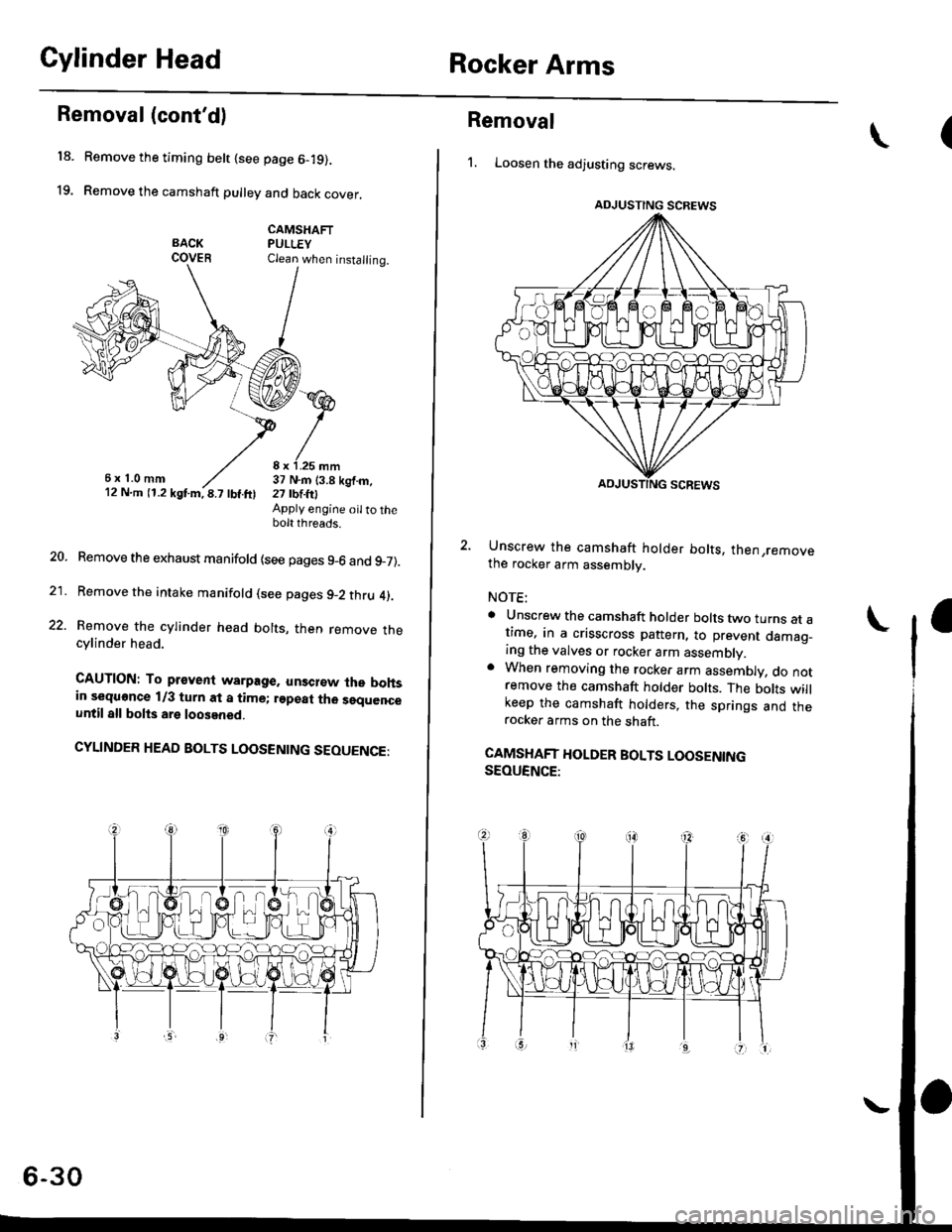

18.

19.

21.

22.

Removal (cont'd)

Remove the timing belt {see page 6-19).

Remove the camshaft pulley and back cover,

CAMSHAFTPULLEYClean when installing.

6x1.0mm8 x 1.25 mm37 N.m (3.8 kgf.m,21 tbtlrlApply engine oilto thebolt threads.

Remove the exhaust manifold {see pages 9-6 and 9_7).

Remove the intake manifold (see pages 9-2 thru 4).

Remove the cylinder head bolts, then remove thecylinder head.

CAUTION: To pr€vent warpage, unsclew lhe bohsin sequonce 1/3 turn at a time; rgpeat tho sequenceuntil all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENGE:

6-30

Removal

1. Loosen the adjusting screws.

2. Unscrew the camshaft holder bolts, then,removethe rocker arm assembly.

NOTE:

a Unscrew the camshaft holder bolts two turns at at,me, in a crisscross pattern, to prevent damao_ing the valves or rocker arm assembly.. When removing the rocker arm assembly, do notremove the camshaft holder bolts. The bolts willkeep the camshaft holders, the springs and therocker arms on the shaft.

CAMSHAFT HOLDER BOLTS LOOSENINGSEOUENCE:

\(

ADJUSTING SCREWS