stop start HONDA CIVIC 2000 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CIVIC, Model: HONDA CIVIC 2000 6.GPages: 2189, PDF Size: 69.39 MB

Page 372 of 2189

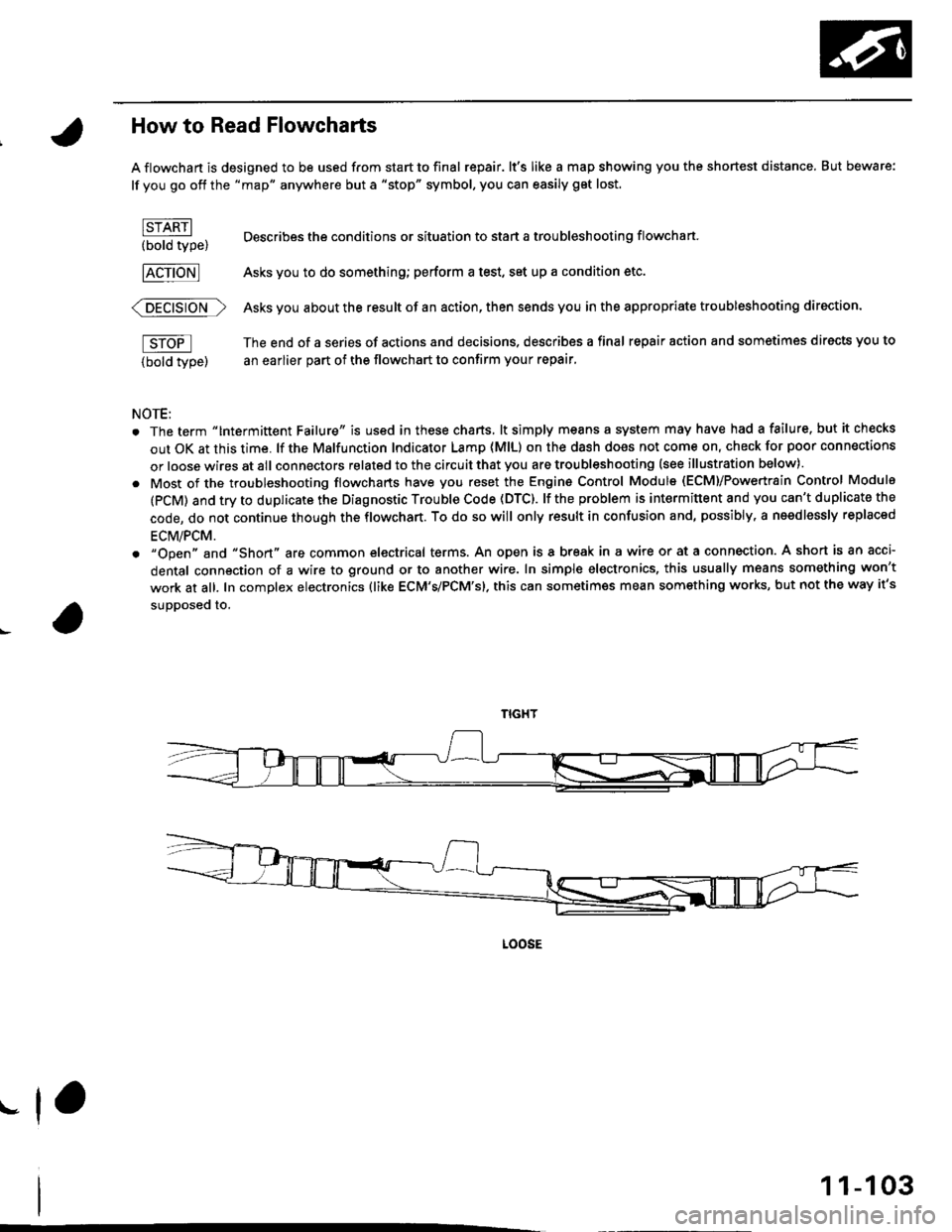

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. lt's like a map showing you the shortest distance. But beware:

lf you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

tSrARTl(bold type)

FanoNl

@

tsroP I

{bold type)

Describes the conditions or situation to start a troubleshooting flowchart.

Asks you to do something; perform a test, set up a condition etc.

Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

The end of a series of actions and decisions. describes a final repair action and sometimes directs you to

an earlier part of the flowchart to confirm your repair,

NOTE:

. The term "lntermittent Failure" is used in these charts, lt simply means a system may have had a failure. but it checks

out OK at this time. lf the Malfunction Indicator Lamp (MlL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below)'

. Most of the troubleshooting flowcharts have you reset the Engine Control Moduls (ECM)/Powertrain Control Module

(pCM) and try to duplicate the Diagnostic Trouble Code (DTC). lf the problem is intermittent and you can't duplicate the

code, do not continue though the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced

ECM/PCM.

. ,,Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. In simple electronics, this usually means something won't

work at all. In complex electronics (like ECM's/PCM'sl. this can sometim€s mean something works, but not the way it's

suDDosed to.

toosE

1 1-103

Page 374 of 2189

3.

5.

6.

1.

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over the following rpm:. D16Y5 engine (M/T):850 rpm. D]6Y5 engine (CVT), D'16Y8 engine (USA M/T): 920 rpm

. Dl6Y8 engine (USA A,/I), D16Y7 engine (USA A,/T);910 rpm

. D16Y8 engine (Canada M/T), D16Y7 engine (canada): 990 rpm

' D16Y8 engine (Canada M/T): 1,000 rpm

. 816A2 engine: 970 rpm

. Fuel cut-off action also takes place when engine speed exceeds 6,900 rpm (D16Y5, D16Y7 engine; D'16Y8 engine:

7,000 rpm. 816A2 engine: 8.100 rpm), regardless of the position of the throttle valve, to protect the engine from

over-rewing. With '99 Dl6Y7 engine (A,/T) and '99 D16Y8 engine (A./T), the PCM cuts the fuel at engine speeds over

5,000 rpm when the vehicle is not moving.

IVC Compressor Clutch Relay

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure smooth transition to the A,/C mode

Evaporative Emission (EVAP) Purge Control Solenoid Valve*'

When the engine coolant temperature is above 154'F (68'C). the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister.

Evaporative Emission (EVAP) Purge Control Solenoid Valve*a

When the engine coolant temperature above 154"F (68"C), intake air temperature above 32"F (0'C) and vehicle speed

above 0 mile (0 km/h) or [Ay'C compressor clutch on and intake air temperature above 160"F (41'C)], the ECM/PCM

controls the EVAP purge control solenoid valve which controls vacuum to the EVAP purge control canister.

Exhaust Gas Recirculation (EGR) Control Solenoid Valve*?

When EGR is required for control of oxides of nitrogen (NOx) emissions. the ECM controls the EGR control solenoid

valve which supplies regulated vacuum to the EGR valve

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode,

which reduces the engine load to improve the fuel economy.

ECM/PCM Fail-safe/Back-up Functions

1. Fail safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pro-

grammed value for that sensor that allows the engine to continue to run.

2. Back-uD Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self diagnosis Function lMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the lvllL and stores the DTC

in erasable memory. When the ignition is initially turned on, the ECM/PCM supplies ground for the MIL for two sec-

onds to check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S, fuel metering-related. idle control

system, ECT sensor, EGR system and EVAP control system self-diagnostic functions. When an abnormality occurs,

the ECM/PCM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and

ON 0l) again, the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is

cancelled when you jump the service check connector. The MIL will then blink immediately when an abnormality

occurs,

5. Two (or Three) Driving Cycle Detection Method

A "Driving Cycle" consists ot starting the engine. beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions is detected during two consecutive driving cycles, or TWC deterioration is detected dur-

ing three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to ease troubleshooting, this function

is cancelled when you jump the service check connector. The MIL will then blink immediately when an abnormality

occurs.

(cont'd)

1 1-1 05

.1.

Page 377 of 2189

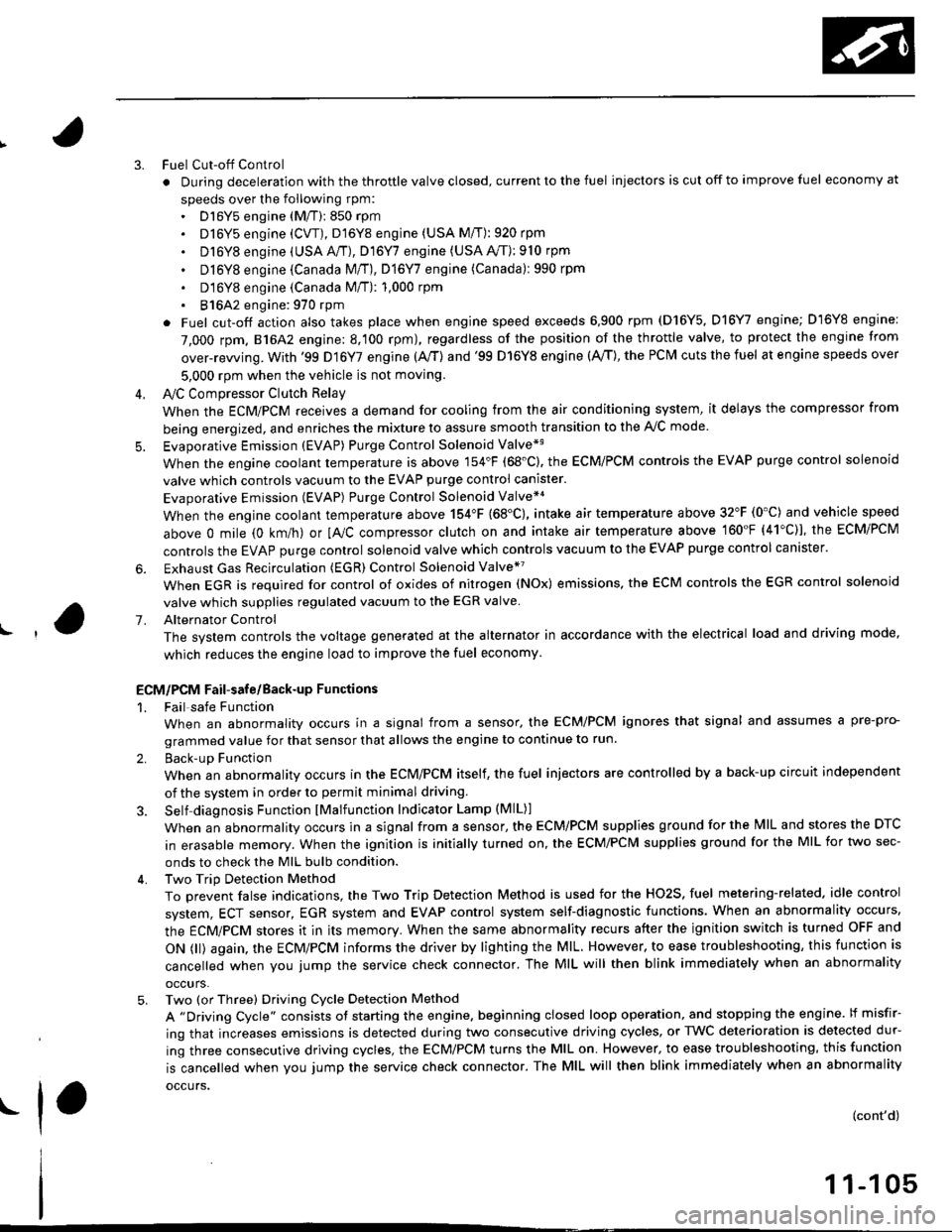

PGM-FI System

Engine Control Module/Powertrain Control Module (ECM/PCMI

('96 - 98 Models,'99 - 00 Dl6Y5 engine with M/Tl (cont'd)

NOTE:. When there is oo Diagnostic Trouble Code (DTC) stored, the MtL wi

stay on if the SCSservace connector is connected and the ignition switch is on,. lf this symptom is intermittent, checklor:- A loose Fl E/M 115 A) fuse in the under hood luse/relay box- A loose No. 13 FUEL PUMP fuse (15 A) in the underdash fuse/relay box- An intermittent shon in the wire between the ECM/PCM (C7) and the service cnecKconnector- An intermittent short in the wire between the ECM/PCM (A18) and the gaugeassembly- An intermittent shon in the wire between the ECM/PCM {D4) and the MAp sensorAn intermittent short in the wire between the ECM/PCM (D10), the Tp sensor, theEGR valve l:ft sensor (D16Y5 engine) and/or the Fuel tank pressure sensor (,96Dl6Y8 engine (coupe), '97 016Y7 engine (coupe: KL model, sedan: KL (LX) modeli,'97 016Y8 engine {coupe: all models, sedan: KL modeti,'98,all models}- PGM-FImain relay. See the OBD ll scan tool or Honda PGM Tester user's manuals lor specitic operatinginstructions.

ECM/PCM CONNECTOR C 13lPI

Wire side of female terminals

(To page 11 109)

(To page 11,109)

11-108

The Maltunction Indicator Lamp(MlLl stays on o. comes on eftartwo s€conds,

Check the Oiagnoslic TroubleCode {DTC}I1. Connect a scan tool or HondaPGM Tester.2. Turn the ignition switch ON (ll).

3. Read the DTC with the scantool or Honda PGM Tester.

Go to troubleshooting p.oc€dur€s(se€ pago 11{11.Are any DTC{s) indicated?

Check the DTC by MIL indication:1. Turn the ignition switch OFF.2. Connect the SCS service con,nector to the service checkconnector.3. Turn the ignition switch ON (lli.

Repair opon ol short in wirebotwoen the ECM/PCM (C8)

and Data Link Connector.Go to troublelhooting proce-dure ls6e page 11-811.

Does the MIL indicate any DTC?

Try to start the engine.

Does the engine start?

Check for a short in the wire(SCS lin€l:1. Disconnect the SCS serviceconnector.2. Stop the engine and turn theignition switch ON {lli.3. Measure voltage between theECM/PCM connector terminalC7 and body ground.

Ropair short to body Iround inthe wire betweon ECM/PCM lCTland sorvice check connector.

ls there approx. 5 V?

scs tBRNI

Page 384 of 2189

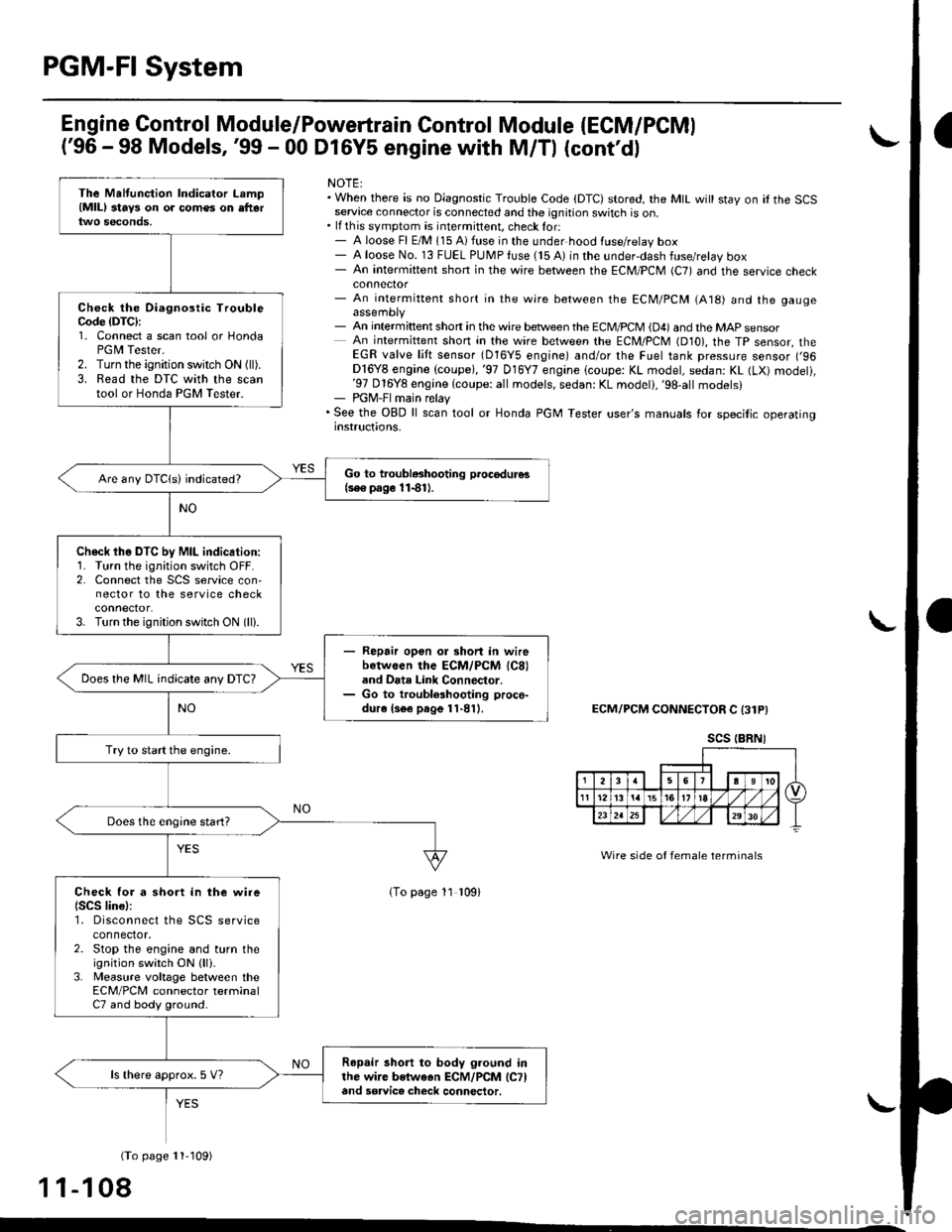

Manifold Absolute Pressure (MAP) Sensor ('96 Models)

The scan tool indicates Diagnostic Trouble Code (DTC) P0106: A mechanical problem (vacuum leak) in the

Manifold Absolute Pressure (MAP) Sensor system'

TheMAPsensorconvertsmanifoIdabsoIutepressureintoeiectricaIsigna|sandinpUtstheEcM/PcM'

OUTPUTVOLTAGE

(v13.5

3.0

2.5

2.0

1.5

1.0

0.5

0lin. Hgl GAUGE

- The MIL has been reported on- OTC P0106 is storod.- Or from Ptobable Cause Lisl.

Problom verificetion:1. Do the ECM/PCM Reset Pro-

cedure.2. Start the engine and keep

engine speed at 1,000 rpm for

one minute with the transmis'

sion in @ or I Position {Mff

in neutral).

ls DTC P0106 indicated?

Check tor vacuum leakage or

blockage between the MAP sen'

sor and throftle bodyCheck the MAP sensor outPut:

1. Turn the ignition switch OFF

2. Turn the ignition switch ON (ll).

3. Check the MAP with the scan

tool.ls there leakage or blockage?

Chock the MAP s€nsol output:

1. Stop the engane.2. Turn the ignition switch ON (ll).

3. Check the MAP with the scan

tool.

READING300(mm Hgl

(To page 11 116)

{cont'd)ll,(To page 11-116)

1 1-1 15

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

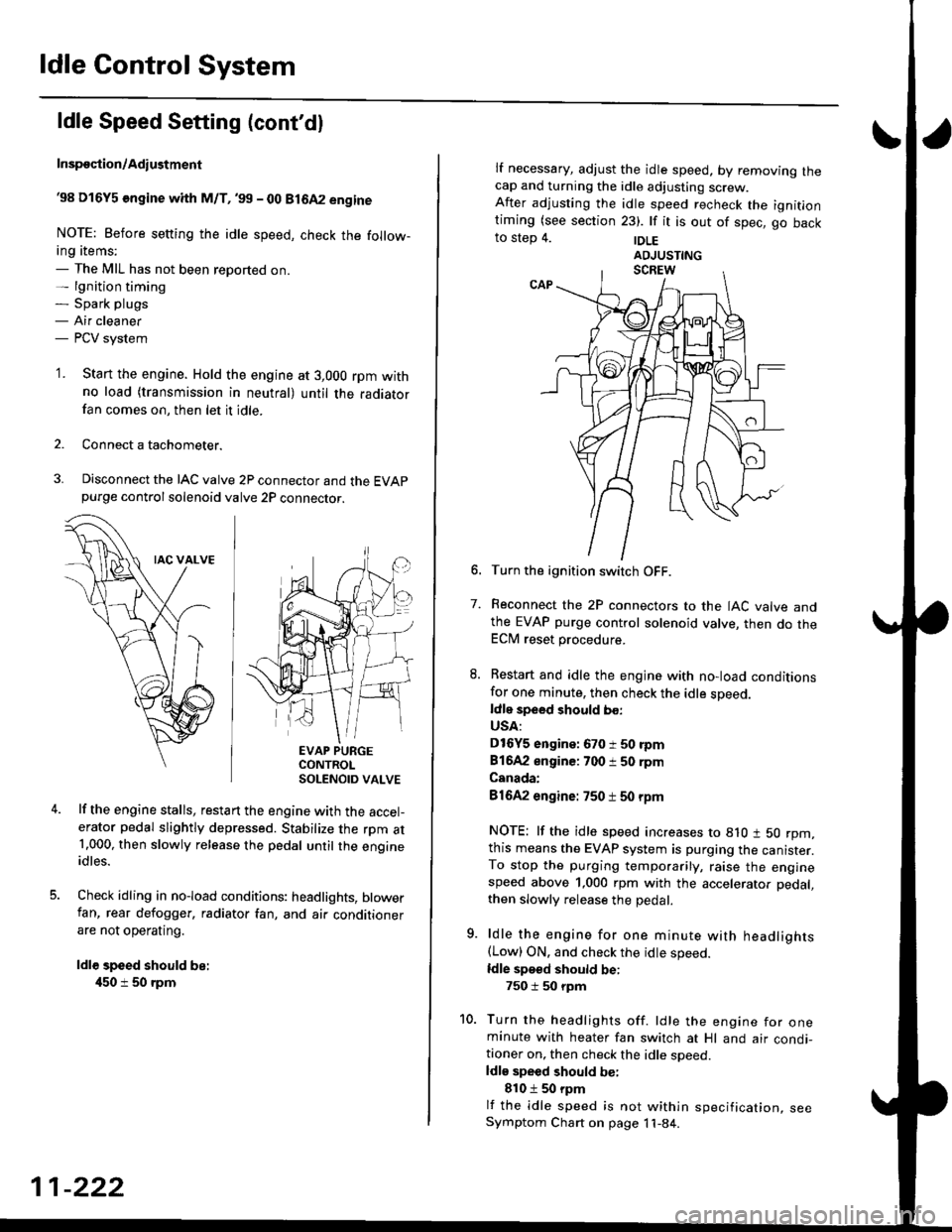

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

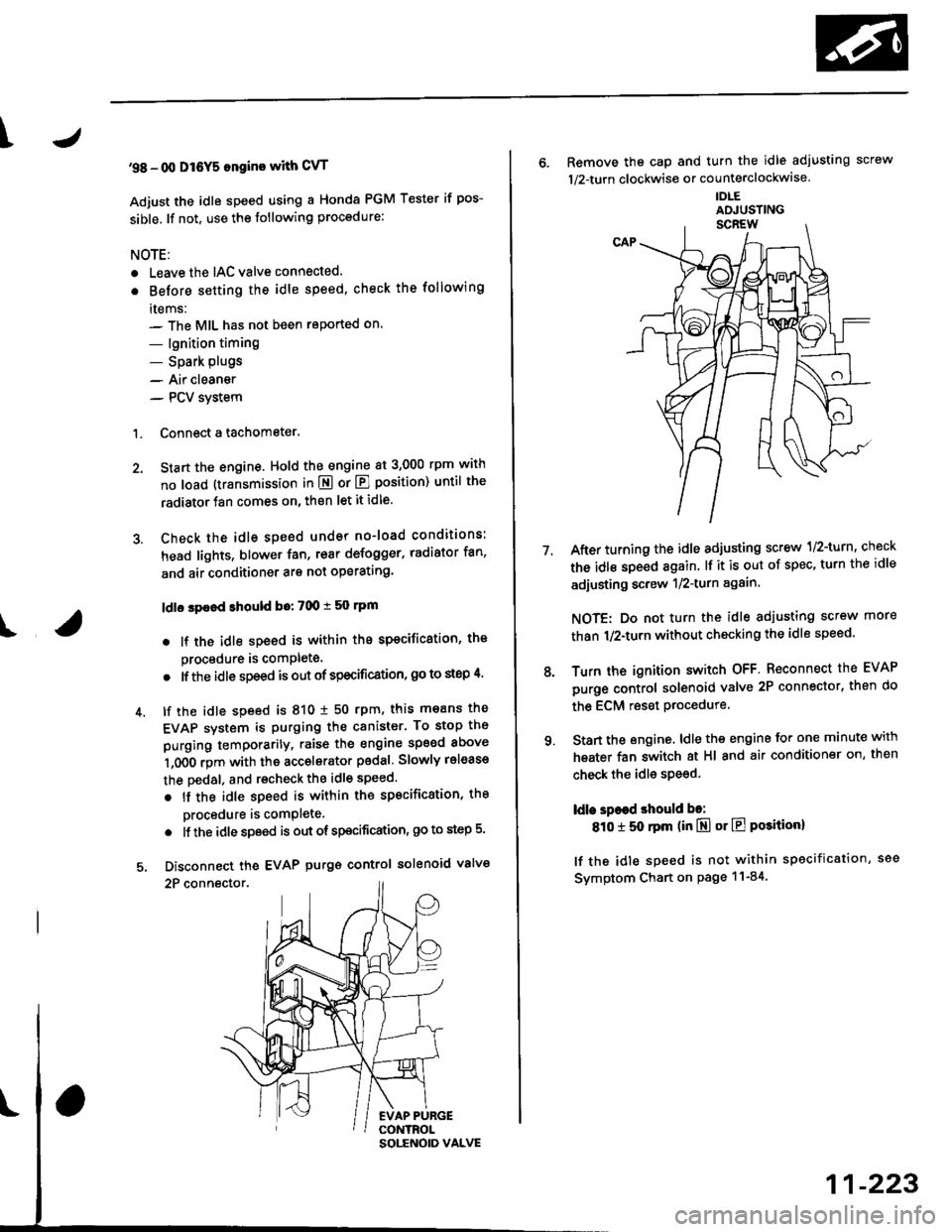

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 521 of 2189

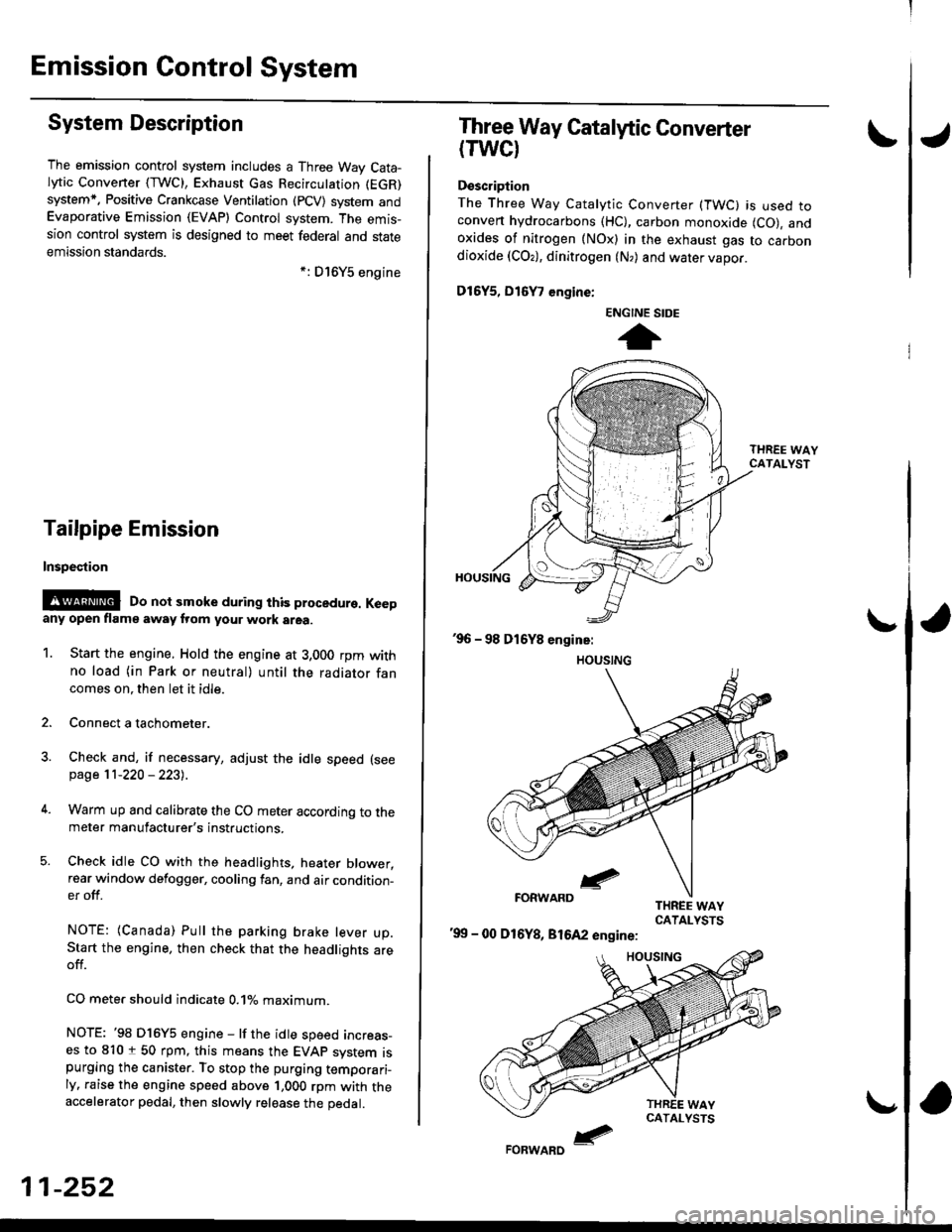

Emission Gontrol System

System Description

The emission control system includes a Three Way Cata-lytic Convener (TWC), Exhaust Gas Recirculation (EGR)

system,. Positive Crankcase Ventilation (pCV) system andEvaporative Emission (EVAP) Control system. The emis-sion control system is designed to meet federal and stateemission standards.*: D16Y5 engine

Tailpipe Emission

Inspestion

@@ Do not smoke during ihis procedure. Keepany open flame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm withno load (in Park or neutral) until the radiator fancomes on. then let it idle.

2. Connect a tachometer.

Check and, if necessary, adjust the idle speed (see

page 11-220 - 223).

Warm up and calibrate the CO meter according to themeter manufacturer's instructions.

Check idle CO with the headlights, heater blower,rear window defogger, cooling fan, and air condition-er off.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

CO mete. should indicate 0.1% maximum.

NOTE: '98 Dl6Y5 engine - lf the idle speed incress-es to 8101 50 rpm, this means the EVAp system ispurging the canister. To stop the purging temporari-ly. raise the engine speed above 1,000 rpm with theaccelerator pedal, then slowly release the pedal.

11-252

eFORWARD -

Three Way Catalytic Converter

(TWCI

Doscription

The Three Way Catalytic Converter (TWC) is used toconven hydrocarbons (HC), carbon monoxide (CO), andoxides of nitrogen (NOx) in the exhaust gas to carbondioxide (COr), dinitrogen (N,) and water vapor.

D15Y5, D16

, engine:

'99 - 00 D16Y8, 81642 engine:

ENGINE SIDE

t

Page 584 of 2189

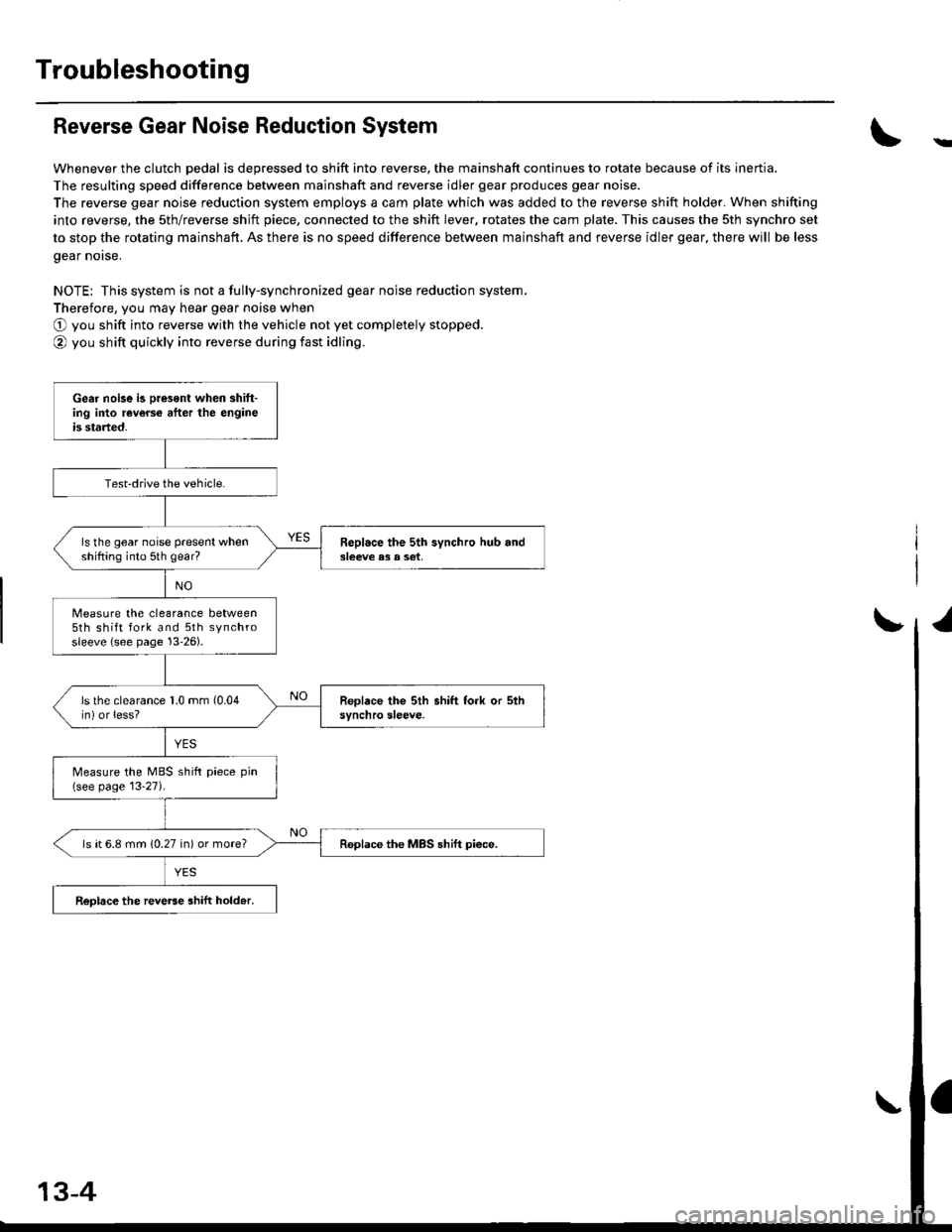

Troubleshooting

Reverse Gear Noise Reduction System

Whenever the clutch pedal is depressed to shift into reverse, the mainshaft continues to rotate because of its inertia.

The resulting speed difference between mainshaft and reverse idler gear produces gear noise.

The reverse gear noise reduction system employs a cam plate which was added to the reverse shift holder. When shifting

into reverse, the sth/reverse shjft piece, connected to the shift lever, rotates the cam plate. This causes the sth synchro set

to stop the rotating mainshaft. As there is no speed difference between mainshaft and reverse idler gear, there will be less

gear norse.

NOTE: This system is not a fully-synchronized gear noise reduction system.

Therefore, you may hear gear noise when

O you shift into reverse with the vehicle not yet completely stopped.

@ you shift quickly into reverse during fast idling.

-

Gear noise is oresent when shift-ing into reverce after the engineis started.

Test-drive the vehicle.

ls the gear noise present whenshifting into 5th gear?Beplace the 5th synchro hub and3leeve e3 a set,

Measure the clearance between5th shift fork and 5th synchrosleeve {see page 13'26).

ls the clearance 1.0 mm (0.04

in) or less?

Measure the MBS shift piece pin(see page 13-27).

ls ( 6.8 mm (0.27 in) or more?Replace the MBS shift piece.

ReDlace the reve6e ahift hold.r.

13-4

Page 682 of 2189

Description

(cont'dl

Gear Selection

The shift lever has six positions: E PARK. E REVERSE, N NEUTRAL, E 1st through 4th gear ranges, E 1st through 3rdgear ranges, @ 2nd gear.

Starting is possible only in E and E positions through the use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/f, Gear Position Indicator

The Ay'T gear position indicator in the instrument panel shows which gear has been selected without having to look downat the console.

Clutch€s

The four-speed automatic transmission uses hydraulically-actuated clutches to engage or disengage the transmission gears.When hydraulic pressure is introduced into the clutch drum, the clutch piston moves. This presses the friction discs andsteel plates together, locking them so they don't slip. Power is then transmitted through the engaged clutch pack to itshub-mounted gear. Likewise, when the hydraulic pressure is bled from the clutch pack, the piston releases the friction discsand the steel plates, and they are free to slide past each other. This allows the gear to spin independently on its shaft,transmitting no power.

lst Clutch

The 1st clutch engages/disengages 1st gear, and is located at the end of the mainshaft, just behind the right sroe cover.The 1st clutch is supplied hydraulic pressure by its ATF feed pipe within the mainshaft.

2nd Clulch

The 2nd clutch engagegdisengages 2nd gear, and is located at the middle of the mainshaft. The 2nd clutch is joined

back-to-back to the 4th clutch. The 2nd clutch is supplied hydraulic pressure through the mainshaft by a circutr connect-ed to the internal hvdraulic circuit,

3rd Clutch

The 3rd clutch engages/disengages 3rd gear, and is located at the end of the countershaft. The 3rd clutch is suooliedhydraulic pressure by its ATF feed pipe within the countershaft.

ilth Clutch

The 4th clutch engages/disengages 4th gear, as well as reverse gear, and is located at the middle of the mainshaft. The4th clutch is joined back-to-back to the 2nd clutch. The 4th clutch is supplied hydraulic pressure by its ATF feed pipewith in the mainshaft.

\-a

PositionDe3cription

E PARK

E REVERSE

N NEUTRAL

E DRIVE

{1st through 4th)

Ei DRtvE('lst through 3rd)

B SECOND

Front wheels locked; park pawl engaged with pa* on countershaft. All clutches released.

Reverse; reverse selector engaged with countershaft reverse gear and 4th clutch locked.

All clutches released.

General driving; starts off in 1st, shifts automatically to 2nd, 3rd, then 4th, depending on vehiclespeed and throttle position. Downshift through 3rd, 2nd and 1st on deceleration to stop. The lock-upmechanism comes into operation in @ position in 3rd and 4th gear.

Use for rapid acceleration at highway speeds and general driving; up-hill and down,hill dfiving; stansotf in 1st, shifts automatically to 2nd, then 3rd, depending on vehicle speed and throttle position.

Downshifts through 2nd to lst on deceleration to stop. The lock-up mechanism comes into operationin 3rd gear,

Use for engine braking or better traction starting off on loose or slippery surfaces; stays in 2ndgear, does not shift up and down.

14-4

Page 797 of 2189

Pressure Testing

@I While testing, be caroful of th€ rotating front wheels.

. Make sure lifts, iacks, and satoty stands are placod properly (see section 1)'

CAUTION:

. Beforo iesting, be sure the transmission fluid is tilled to tho proper level'

. Warm up tho engine before testing'

1. Raise the vehicle (see section 1).

2. Warm up the engine, then stop the engine and connect a tachometer'

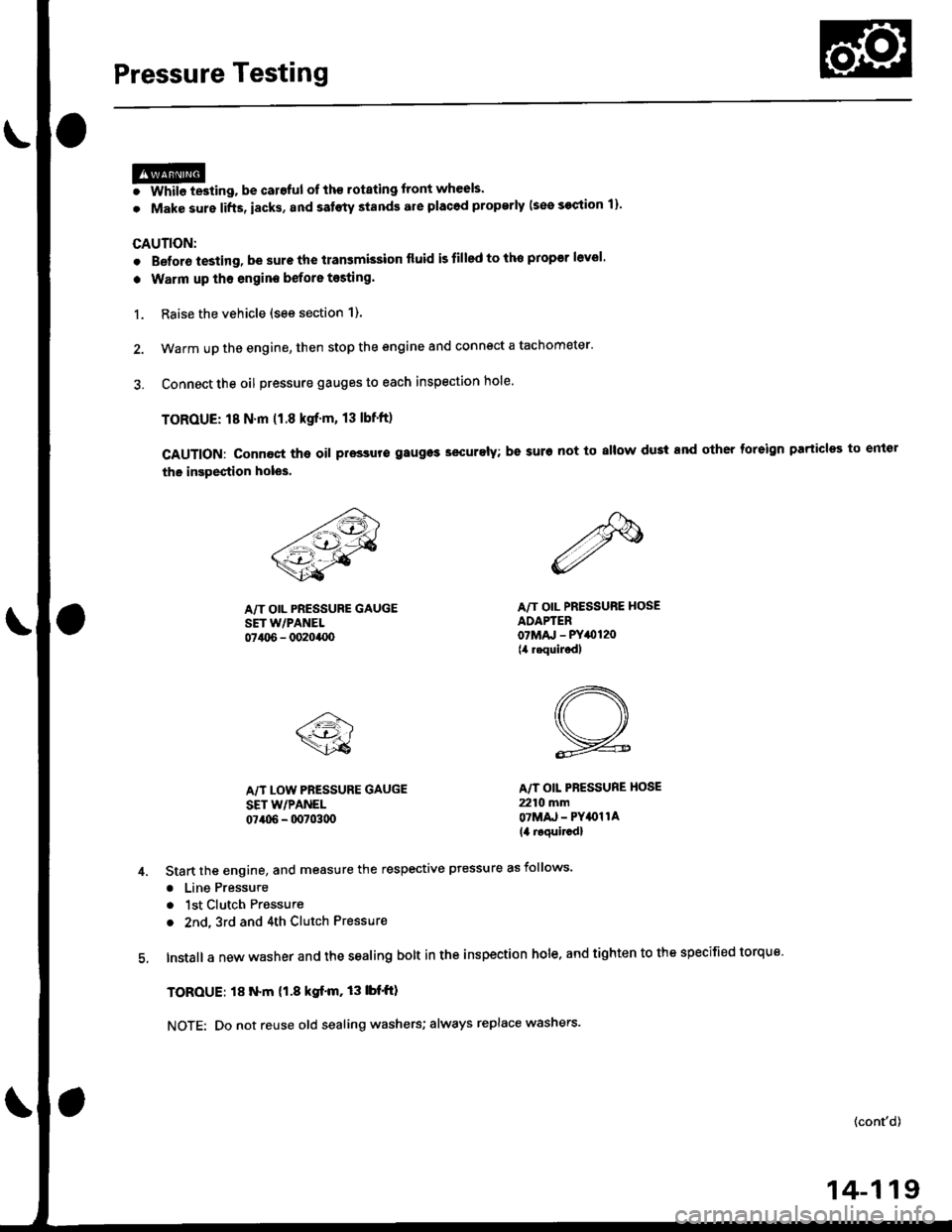

3. Connect the oil pressure gauges to each inspection hole.

TOROUE: 18 N.m (1.8 kgf'm, 13 lbnft)

cAUTloN: connact the oil pressuro gauges securely; be suro not to allow dust and other foreign Parlicles to entel

the inspestion holos'

A/T OIL PRESSURE GAUGESET w/PANEL07t06 - 0020400

A/T LOW PRESSURE GAUGE

SET WPANEL07406 - 0070300

A/T OIL PRESSURE HOSEADAPTER07Mru - PY0120(4 requiJedl

A/T OIL PBESSURE HOSE

2210 mmOTMAJ - PY4{)llA

14 roquircdl

Start the engine, and measure the respective ptessure as follows'

a Line Pressure

. 1st Clutch Pressure

. 2nd,3rd and 4th Clutch Pressure

Install a new washer and the sealing bolt in the inspection hole. and tighten to the specified torque'

TOROUE: l8 N.m (1.8 kgf'm,13lbf'ft)

NOTE: Do not reuse old sealing washers; always replace washers'

(cont'd)

14-119