Motor HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 963 of 1139

Power Windows

1.

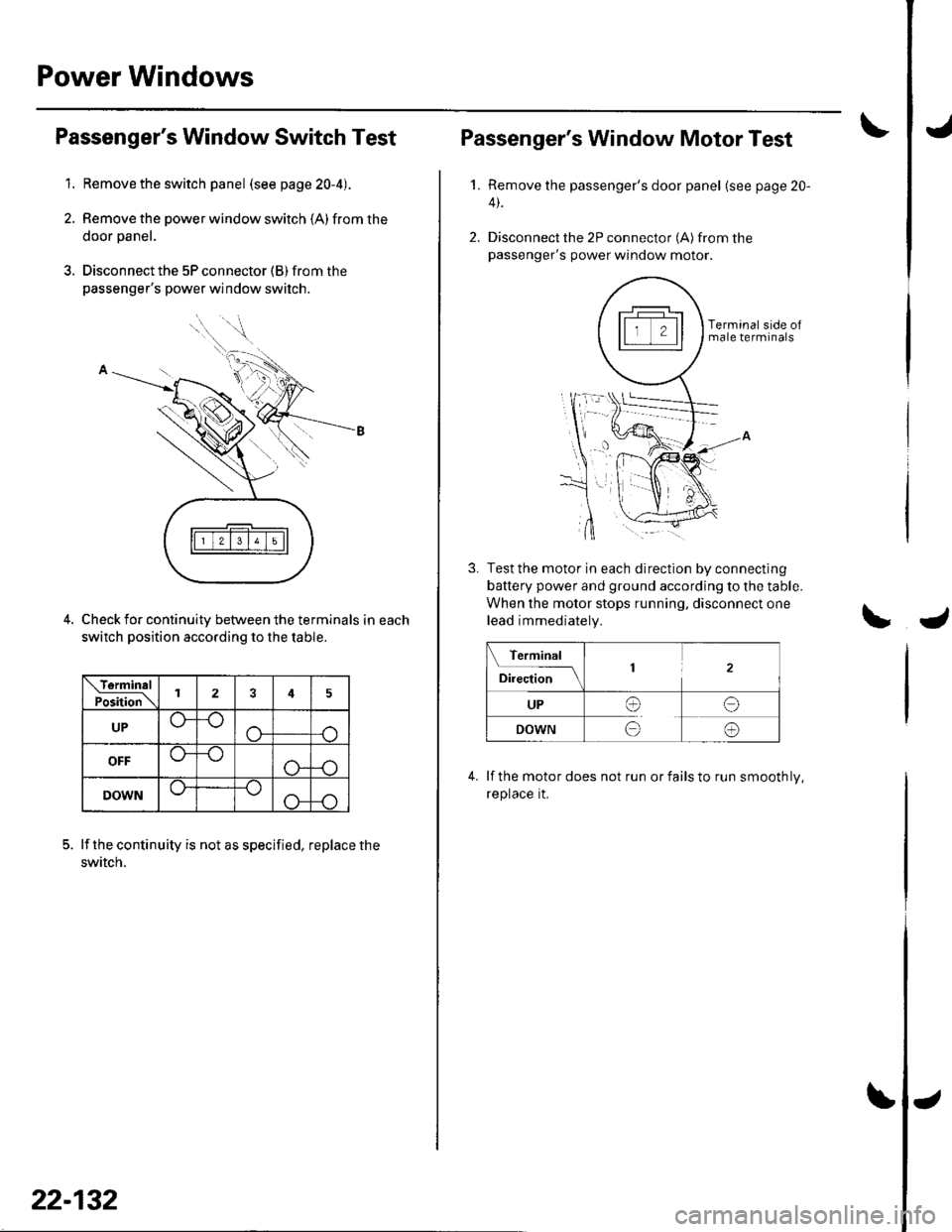

Passenger's Window Switch Test

Remove the switch panel (see page 20-4).

Remove the power window switch (A) from the

door panel.

Disconnect the 5P connector (B) from the

passenger's power window switch.

Check for continuity between the terminals in each

switch position according to the table.

lf the continuity is not as specified, replace the

swtlcn.

tfiTtTtT;Etll' '-r--r-,Jl

\TorminalPoiition\124

UP

OFF

DOWN

22-132

Passenger's Window Motor Test

1.Remove the passenger's door panel (see page 20-

4).

Disconnect the 2P connector (A) from thepassenger's power window motor.

Terminal side ofmale terminals

Test the motor in each direction by connecting

battery power and ground according to the table.

When the motor stops running, disconnect one

lead immediately.

Terminal

Dl*;;;__\1

UPI

o

o

DOWNo

lf the motor does not run or fails to run smooth ly,

reptace rt.

Page 965 of 1139

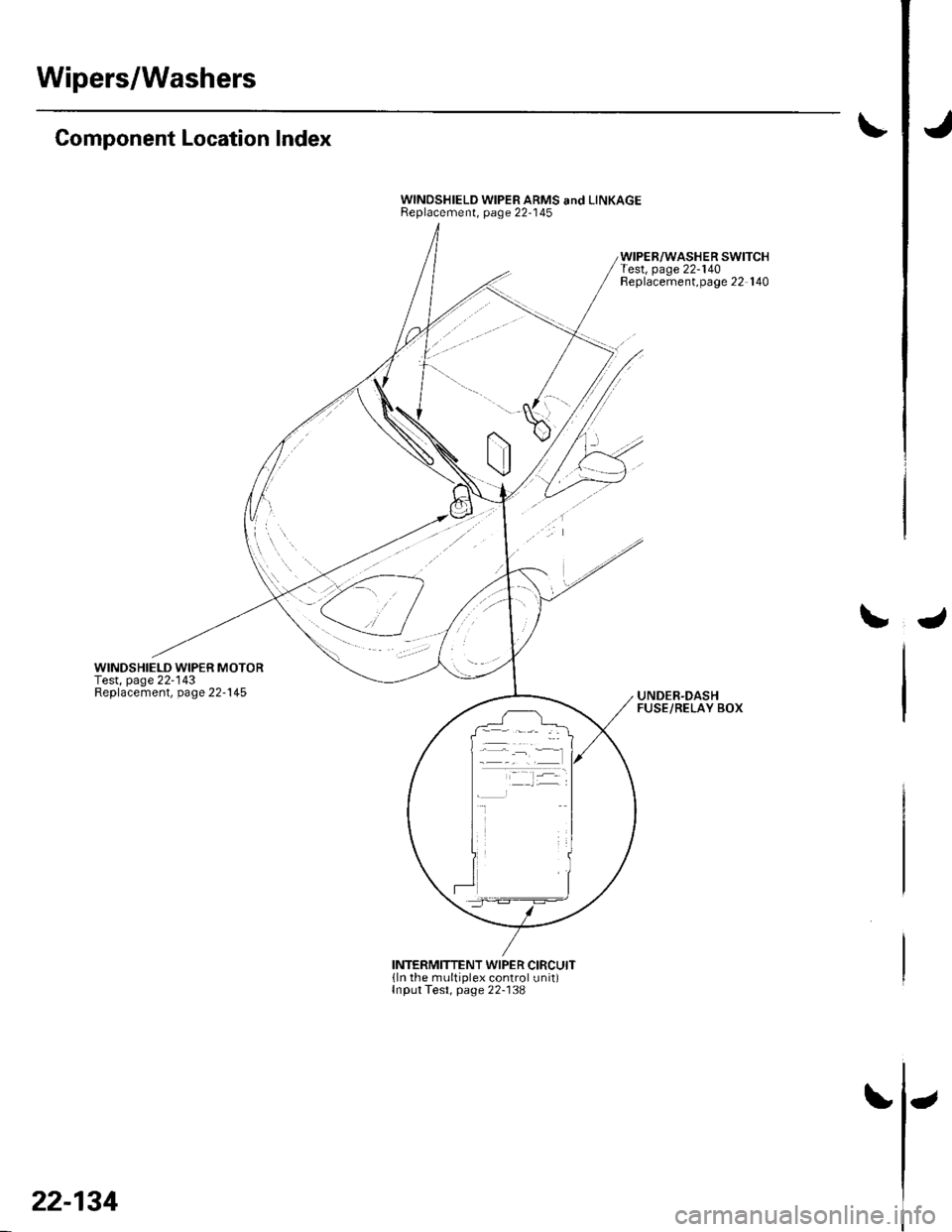

Wipers/Washers

Component Location Index

WINDSHIELD WIPER MOTORTest, page 22-'143Replacement, page 22-145

WINDSHIELD WIPER ARMS and LINKAGEReplacement, page 22-'145

WIPER/WASHER SWITCHTest, page 22-140Replacement,page 22 140

UNDER.DASHFUSE/RELAY BOX

INTERMITTENT WIPER CIRCUITlln the multiplex control unit)Input Test, page 22-138

22-134

Page 966 of 1139

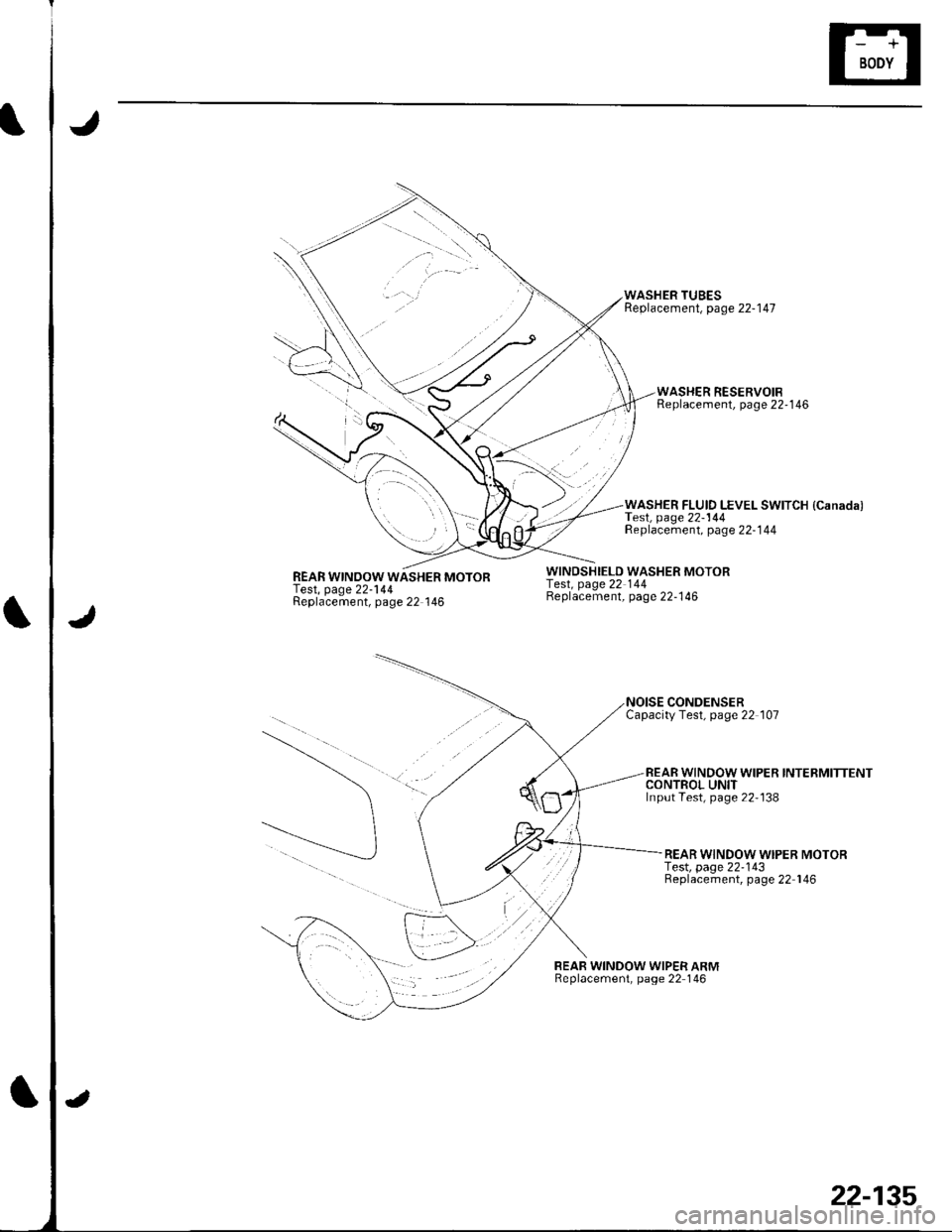

REAR WINOOW WASHER MOTORTest, page 22-144Replacement, page 22 146

WINDSHIELD WASHER MOTORfesl, page 22 144Beplacement, page 22-146

WASHER TUBESReplacement, page 22-147

CONDENSERCapacityTest, page 22 107

BEAR WINDOW WIPER ARMReplacement, page 22 146

WASHER RESERVOIBReplacement, page 22'146

WASHER FLUID LEVEL SWITCH {Canada)TesI, page22-144Replacement, page 22-144

REAR WINDOW WIPER INTERMITTENTCONTROL UNITInput Test, page 22'138

REAR WINDOW WIPER MOTORf e$, page 22-143Replacement, page 22 146

22-135

Page 970 of 1139

\

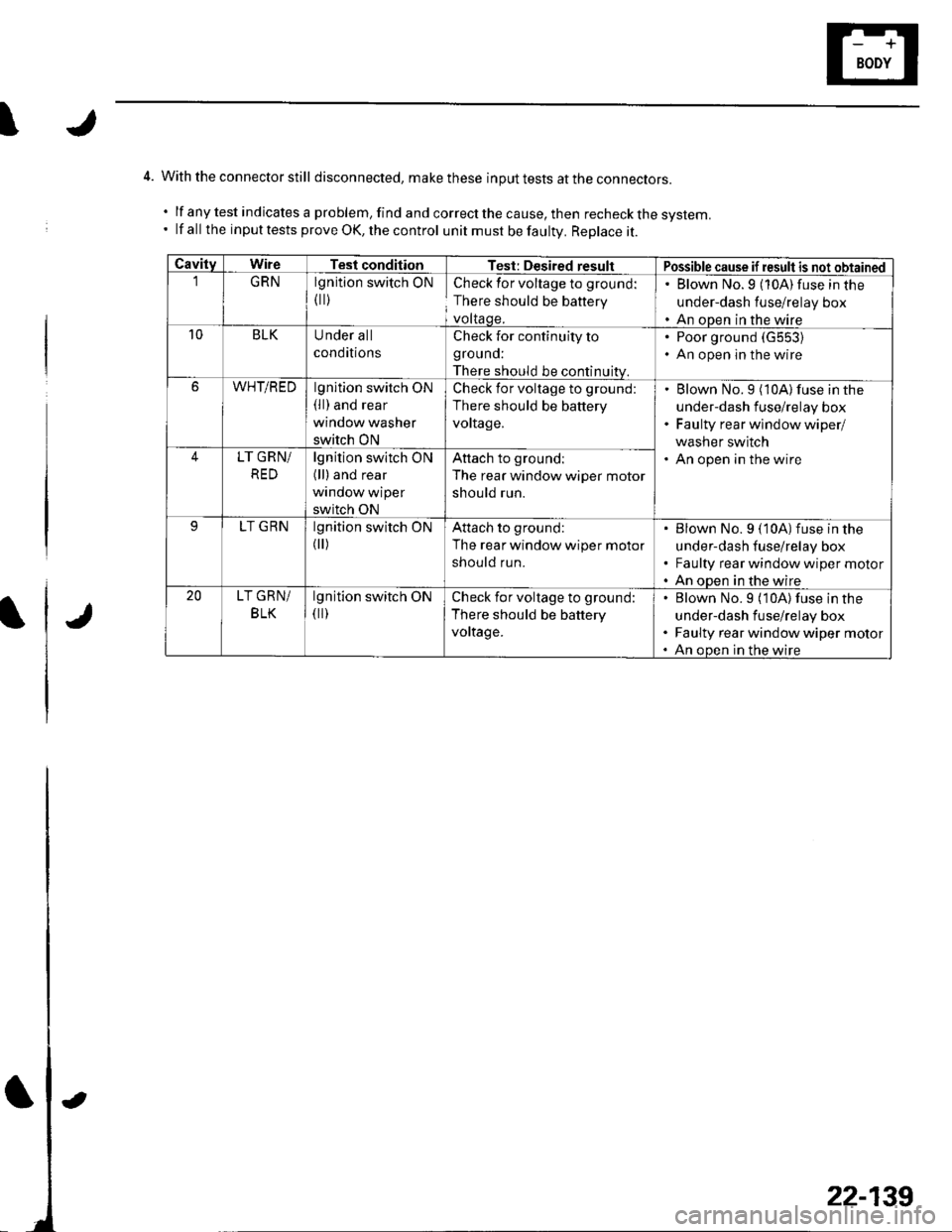

4. With the connector still disconnected, makethese input tests at the con necrors.

.lfanytestindicatesaproblem,findandcorrectthecause,thenrecheckthesystem.

' lf all the input tests prove OK, the control unit must be faultv. Replace it.

CavitvWireTesl conditionTest: Desired resultPossible cause if result is not obtainedGRNlgnition switch ON

flr)

Check for voltage to ground:

There should be battery

voltaqe.

. Blown No.9 (10A)fuse in the

under-dash fuse/relay box. An open in the wire10BLKUnder all

conditions

Check for continuity to

grouno:

There should be continuitv.

Poor ground (G553)

An open in the wire

6WHT/REDlgnition switch ON(ll) and rear

window washer

switch ON

Check for voltage to ground:

There should be battery

vortage.

Blown No.9 (10A) fuse in the

under-dash fuse/relay box

Faulty rear wlndow wiper/

washer switch

An open in the wire4LT GRN/

RED

lgnition switch ON(ll) and rear

window wiper

switch ON

Attach to groundl

The rear window wiper motor

should run.

LT GRNlgnition switch ON

flr)

Attach to ground:

The rear window wiper motor

should run.

Blown No. 9 (10A)fuse in the

under-dash fuse/relay box

Faulty rear window wiper motor

An open in the wire20LT GRN/

BLK

lgnition switch ON(ll)Check for voltage to ground:

There should be battery

voltage.

Blown No.9 (10A) fuse in the

under-dash fuse/relay box

Faulty rear window wiper motor

An oDen in the wire

22-139

Page 973 of 1139

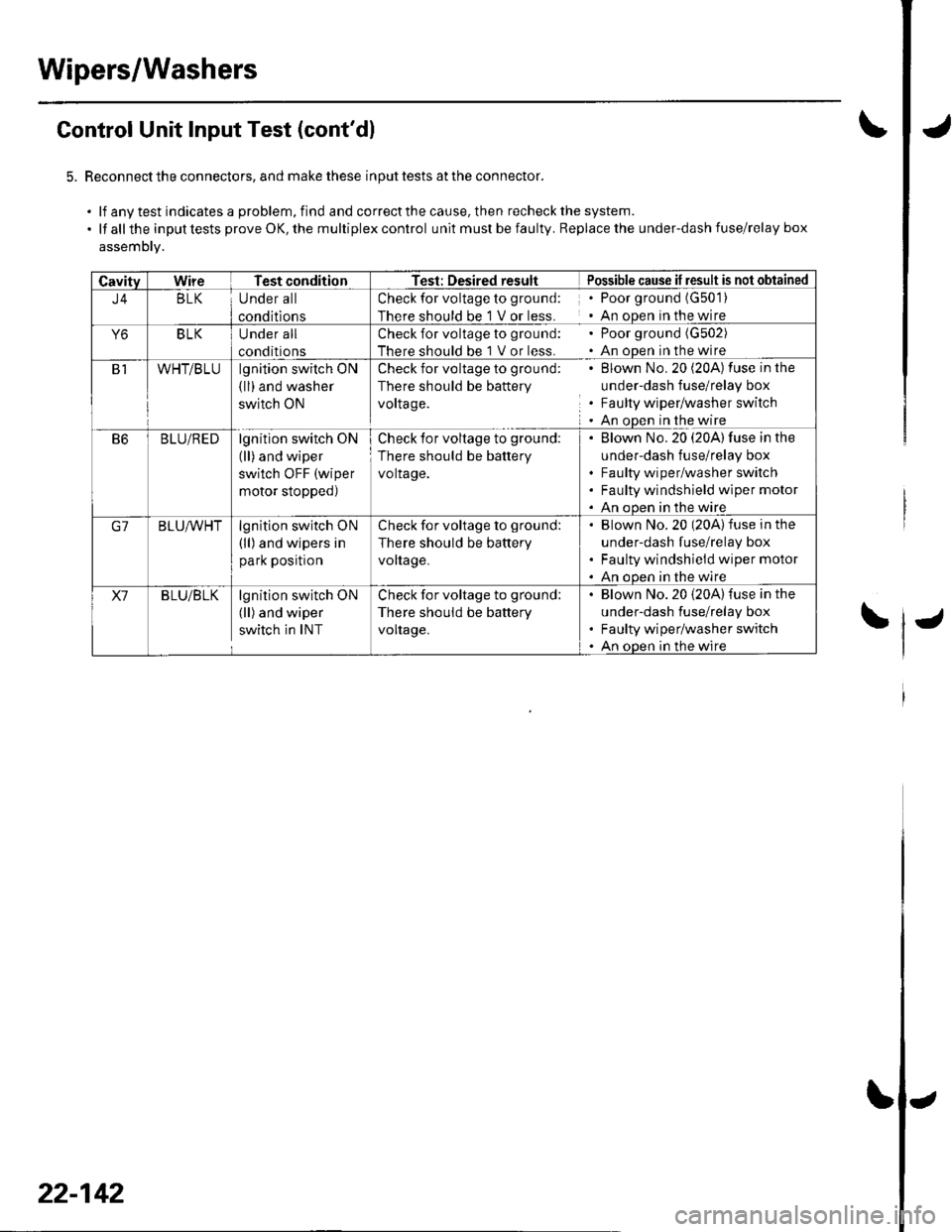

Wipers/Washers

Control Unit Input Test (cont'dl

5. Reconnect the connectors, and make these input tests at the connector.

.lfanytestindicatesaproblem,findandcorrectthecause,thenrecheckthesystem.

.lfalltheinputtestsproveOK,themultiplexcontrol unit must be faulty. Replace the under-dash fuse/relay box

assembly.

CavityWireTest conditionTest: Desired resultPossible cause if result is not obtained

J4BLKU nder all

conditlons

Check for voltage to ground: . Poor ground (G501)

There should be 1V or less. . AnoDeninthewire

Y6BLKU nder all

conditions

Check for voltage to ground: . Poor ground (G502)

There should be 1 V or less. . An oDen in the wire

BIWHTiBLUlgnition switch ON

{ll) and washer

switch ON

Check for voltage to ground:

There should be battery

vortage.

Blown No. 20 (20A) fuse in the

under-dash fuse/relay box

Faulty wiper/washer switch

An open in the wire

E'0BLU/REDlgnition switch ON

(ll) and wiper

switch OFF (wiper

motor stopped)

Check for voltage to ground:

There should be battery

voltage.

Blown No. 20 (20A) fuse in the

under-dash fuse/relay box

Faulty wiper/washer switch

Faulty windshield wiper motor

An open in the wire

G7BLUA/VHTlgnition switch ON(ll) and wipers in

park position

Check for voltage to ground:

There should be battery

voltage.

Blown No.20 (20A)fuse in the

under-dash fuse/relay box

Faulty windshield wiper motor

An ooen in the wire

x1BLU/BLKlgnition switch ON(ll) and wiper

switch in INT

Check for voltage to ground:

There should be battery

voltage.

Blown No.20 (20A)fuse in the

under-dash fuse/relay box

Faulty wiper/washer switch

An oDen in the wire

\J

\J

L

22-142

J

Page 974 of 1139

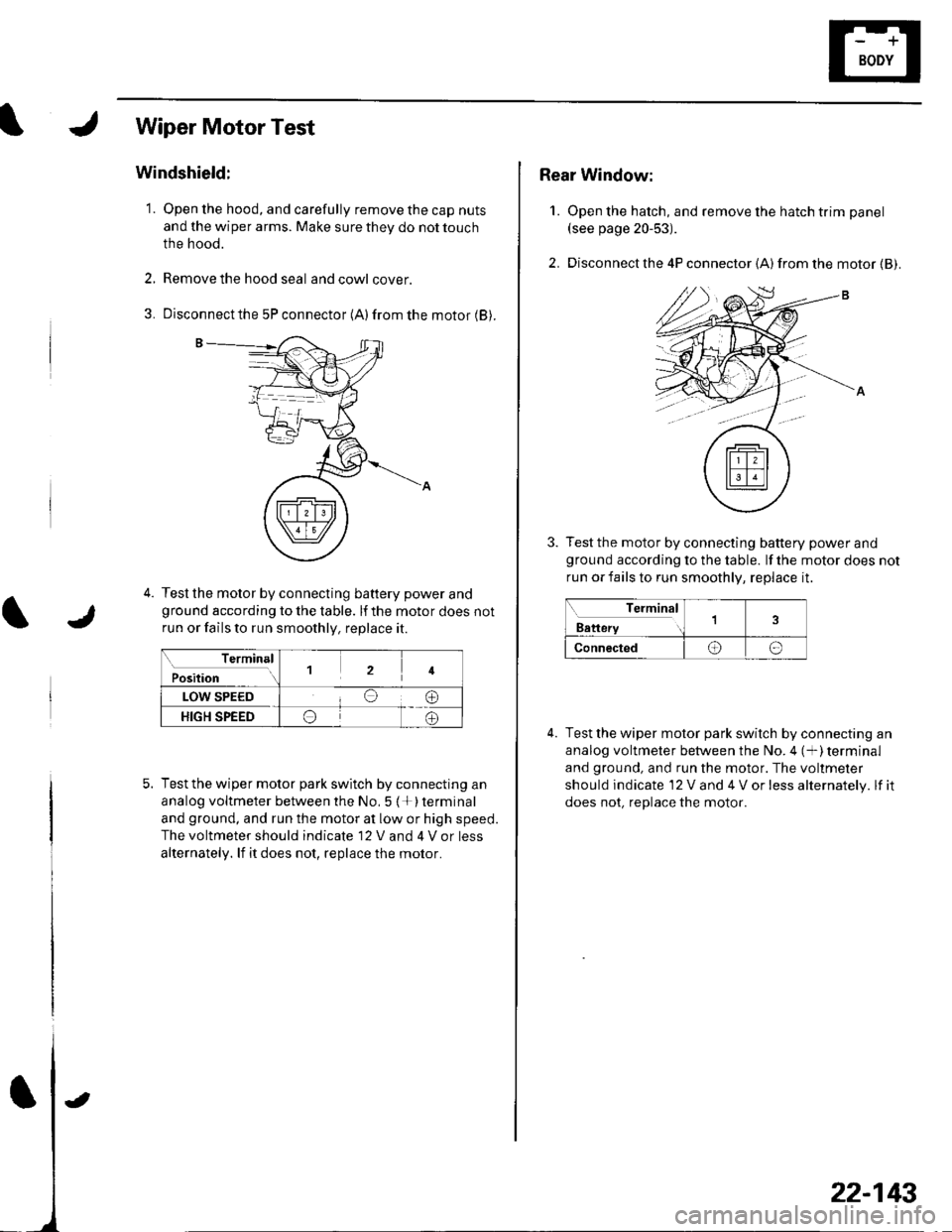

Wiper Motor Test

Windshield:

1. Open the hood, and carefully remove the cap nuts

and the wiper arms. Make sure they do not touch

the hood.

2, Remove the hood seal andcowl cover.

3. Disconnectthe 5P connector (A)from the motor (B).

Test the motor by connecting battery power andground according to the table. lf the motor does not

run or fails to run smoothly, replace it.

P-"-,tion

Terminal124

LOW SPEEDOO

HIGH SPEEDoo

5.Test the wiper motor park switch by connecting an

analog voltmeter between the No, 5 (+)terminal

and ground, and run the motor at low or high speed.

The voltmeter should indicate 12 V and 4 V or less

alternately. lf it does not, replace the motor.

.l

j

J

22-143

Rear Window:

1. Open the hatch, and remove the hatch trim panel

(see page 20-53).

2. Disconnectthe 4P connector {A) from the motor {B).

Test the motor by connecting battery power andground according to the table. lf the motor does not

run or fails to run smoothly, replace it.

Telminal

Battery

Connected@o

Test the wiper motor park switch by connecting an

analog voltmeter between the No. 4 (+)terminal

and ground, and run the motor. The voltmeter

should indicate 12 V and 4 V or less alternatelv. lf it

does not, reolace the motor.

4.

Page 975 of 1139

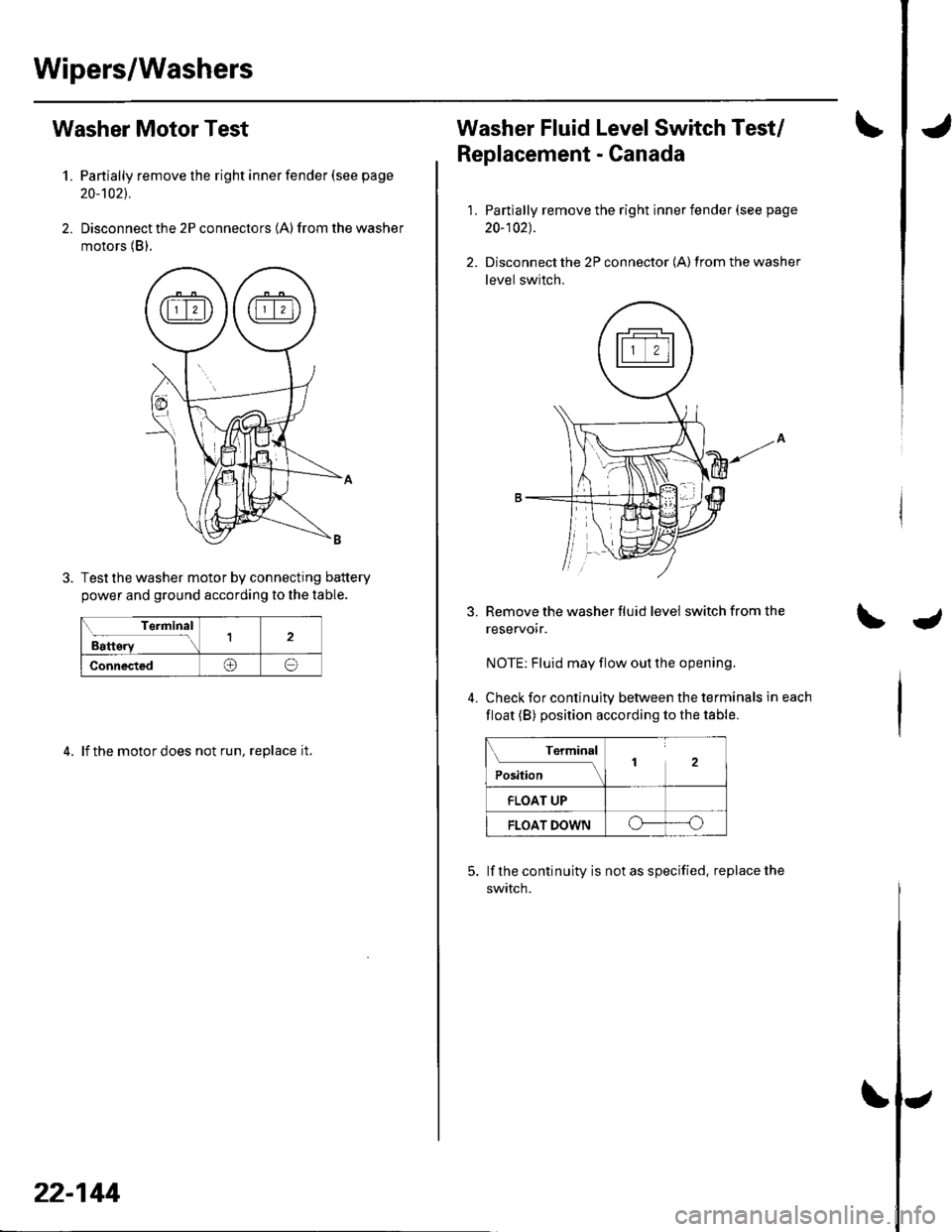

Wipers/Washers

Washer Motor Test

1. Partially remove the right inner fender (see page

20-'t021.

2. Disconnect the 2P connectors (A) from the washer

motors (B).

Test the washer motor by connecting battery

power and ground according to the lable.

Terminal

Battery12

Connected@o

4. lf the motor does not run, replace it,

22-144

Washer Fluid Level Switch Test/

Replacement - Canada

1.

3.

4.

Partially remove the right inner fender (see page

20-102).

Disconnect the 2P connector {A) from the washer

level switch.

Remove the washer fluid level switch from the

reservoir.

NOTE: Fluid may flow out the opening.

Check for continuity between the terminals in each

float (B) position according to the table.

Terminal

Position2

FLOAT UP

FLOAT DOWNo----o

lf the continuity is not as specified. replace the

swtTcn.

Page 976 of 1139

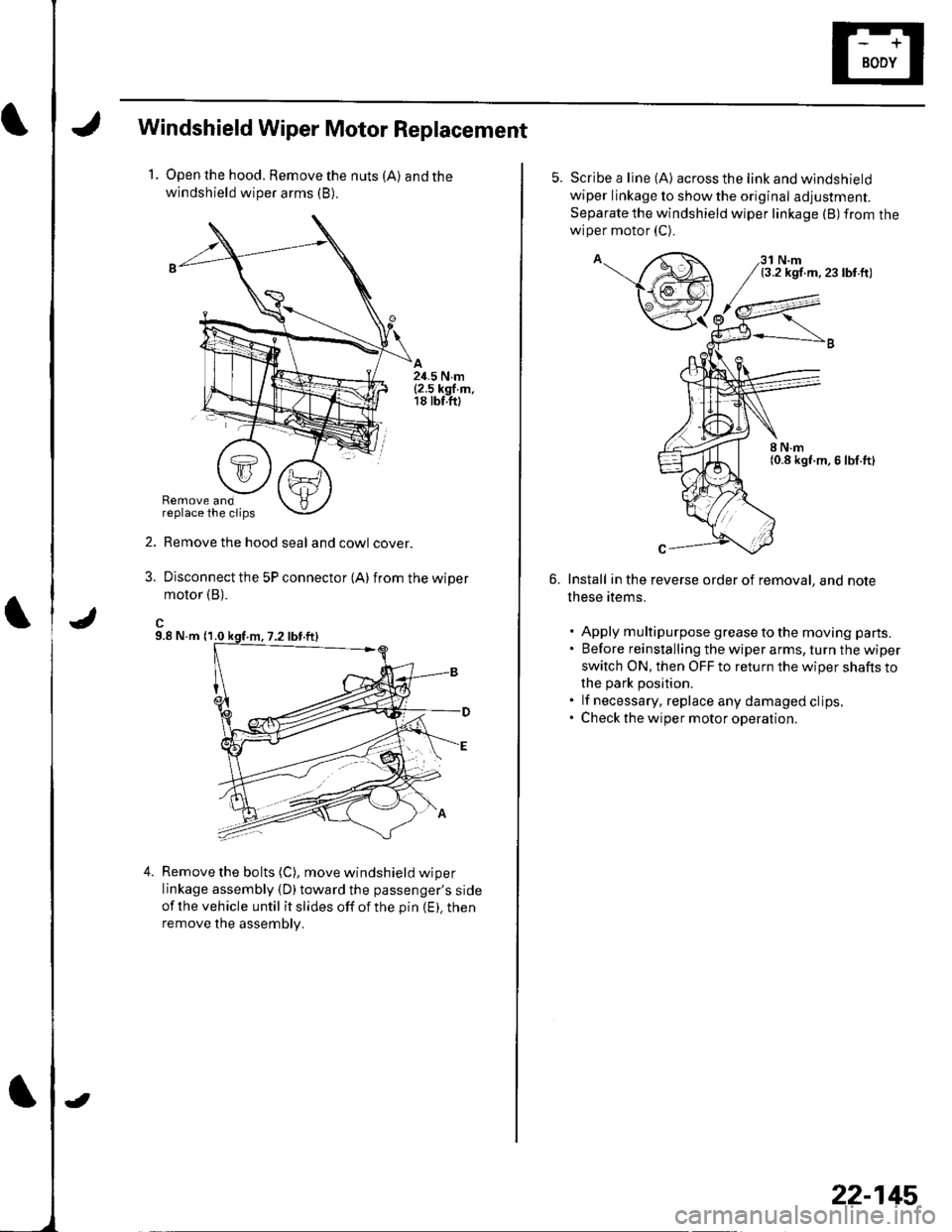

Windshield Wiper Motor Replacement

1.Open the hood. Remove the nuts (A) and the

windshield wiper arms (B).

Remove the hood seal and cowl cover.

Djsconnect the 5P connector (A) from the wiper

motor (B).

9.8 N.m (1.0

Remove the bolts (C), move windshield wiper

linkage assembly {D)toward the passenger's side

of the vehicle until it slides off of the pin (E), then

remove the assembly.

5. Scribe a line (A) across the link and wlndshield

wiper linkage to show the original adjustment.

Separate the windshield wiper linkage (B) from the

wiper motor (C).

N.m(3.2 ksf.m, 23 lbt.ft)

Install in the reverse order of removal, and note

lhese items.

Apply multipurpose grease to the moving parts.

Before reinstalling the wiper arms, turn the wiper

switch ON, then OFF to return the wiper shafts tothe oark oosition.

lf necessary, replace any damaged clips,

Check the wioer motor oDeration.

22-145

Page 977 of 1139

Wipers/Washers

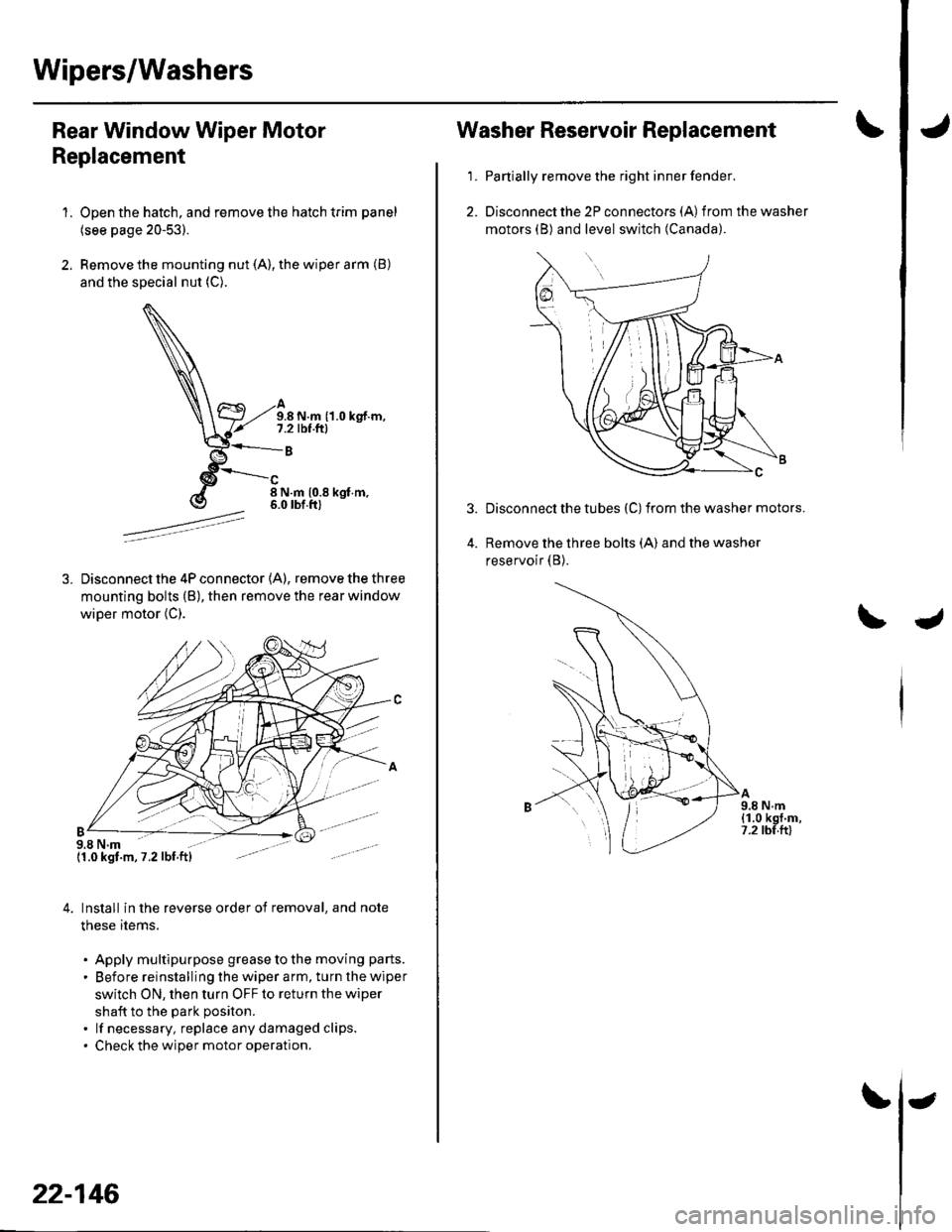

Rear Window Wiper Motor

Replacement

1.

B

Open the hatch, and remove the hatch trim panel

(see page 20-53).

Remove the mounting nut (A), the wiper arm (B)

and the special nut (C).

A9.8 N.m {1.0 kgf.m,7.2 rbf.ftl

B

8 N.m 10.8 kgt.m,6.0 rbf.ft)

Disconnect the 4P connector {A), remove the three

mounting bolts (B), then remove the rear window

wiDer motor (C).

9.8 N.m{1.0 kgt.m,7.2lbf ftl

4,Install in the reverse order oI removal, and note

these items.

Apply multipurpose grease to the moving parts.

Before reinstalling the wiper arm, turn the wiper

switch ON, then turn OFF to return the wiper

shaft to the Dark oositon.

lf necessary, replace any damaged clips.

Check the wiDer motor operation.

22-146

-

Washer Reservoir Replacement

1.Partially remove the right inner fender.

Disconnect the 2P connectors (A) irom the washer

motors (B) and level switch (Canada).

3.Disconnecl the tubes (C) from the washer motors.

Remove the three bolts (A) and the washer

reservoir (B).

A9.8 N.m(1.0 kgt.m,7.2 tbf.tt)

Page 1133 of 1139

Service Manual lndex

)s

NOTE: Referto the lollowing listto look up A/C Pressure Switch CircuitDTCS, symptoms, fuses, connectors, wire Troubleshooting ......... ...-.-....-...-.-.-....-..21-32 Bharnesses, specifications, maintenanceschedules, and general serviceinlormation:

DTC Troubleshooting Indexes

A/C Signal CircuitTroubleshooting.........................-...... 11-'133 Back-up Light SwitchTest .......................................................... 13'3A/F lAir Fuel Ratiol SensorABS/TCS Components ........................ 19-34 Replacement ....................................... 1 1-113 Back-up Li9ht3EPS Components ................................. '17-22 Circuit DiagramFueland Emissions11-i A-Dillar Corner Trim

ABS Indicator Circuit

Heating/Ventilation ................................ 21-9 Replacement ...............-.....-..............-.... 20,96 Ball Joint BootssRS ........................................................ 23-28Replacement ......

... 19-52 Ball Joints

22-75

18 16

Remova1.............-.......... . ...........18-10Symptom Troubleshooting Indexes TroubleshootingABS/TCSComponents........................ 19 35Cruise Control System ..........................4 38 ABS Modulator-contml UnitEPS Components ................................. 17-23 Bemoval/lnstallation ............................ 19-57 BettervFan Controls10,12

Accessory Powor Socket Front

Blowor Pow€r Transistor

.......22 50

Blower UnitRemoval/lnstallation ............................ 21-39

Fuel and Em issions .............................. 11-10 ABS/TCS ComoonentsHeating/Ventilation..............................21 10 Component Location Index ................. 19-30 Beverage Holder

SRS ........................................................ 23'30 CircuitDiaqram.......................... 19'42Blower MotorReplacement .....21 41

21-38

Power 0istribution ...............................22-46 TesVReplacement .............................. 22'149Under-dash Fuse/Relay Box ............... 22 45Under-hood Fuse/Belay Box ...............22 44 Accessory Power Sockets

Fuse/Relay lndexes

(to harness)

Connector and Wire Harness lndexesComponent Connectors

Circuit Oiagram .................................. 22-149

Air Cleaner......2214 Rep1acemen1.....................................11-162

Air MixControl MotorMeintenence section .................... Section 3 Replacement ......................................... 21'34 Brake CelipersTest......................21-34 Overhaul19-14,23Gene.al lnlormation section........ Section 1

21.57

Airbag. Driver's

Ahernator FR Signal CircuitTroubleshooting .... .........-..........11 134

AntennaReplacement

Inspection ............................................. 19-24Rep|acement................. .................... 19-25

Bieke Meder Cylinder

Irake Discs

A

Replacement ....................................... 23 1 'l3 Inspection .................... ................... 19-13,22Repair ...........-...................................... 23 1 16Brake Fluid Level SwitchAirbag. Front Passenger's TestBeplacement....................................... 23-1 14AIC Brake LightsComponent Location fndex ...................21-3 Altemator CircuitDiagram....................................22-74Description.....................................-....21'1'l Beplacement ................ ........................... 4 29CircuitDiagram....................................21-14 Overhaul .................................................4-30 Brake Lines and Hoses

19.10

A/C CompressolReplacement .......-...-............................. 21 -41

A/C Compr€ssor ClulchRep1acement......................................... 19-15.........22-103 Inspection ............................................. 19-16Inspecton........Overhaul ..........

A/C CondenserReplacement,.,

21-442l-49 Audio Unit

Replacement

Brake PadsRemoval/lnstallation .. ........................22-100 Inspection/Rep1acement................ 19-11,20A/C Compressor Clutch CircuitTroubleshooting ................................... 21-30 Audio Unit Connector Brake Pedal22101 Adjustment..............19,6ArfC Comoressor Relief ValvcReplacement ..........-...-.......................... 21-51 Audio/Entertainment

A/C Compr$sor Thermal Protector Circuit DiagramReplacement............-............................ 21-51

Component Location In dex .................22-9A Test .......-.............. 22-84Breke Pedal Posilion Switch

Brake Pedal Position Switch Signal Clrcuit11-137

.....21 52

A/C Condenser Fan CircuitTroubleshooting ................... . . . . . .....21-28

)s

Troubleshooting

(cont'd)