crankshaft HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 111 of 1139

Gylinder Head

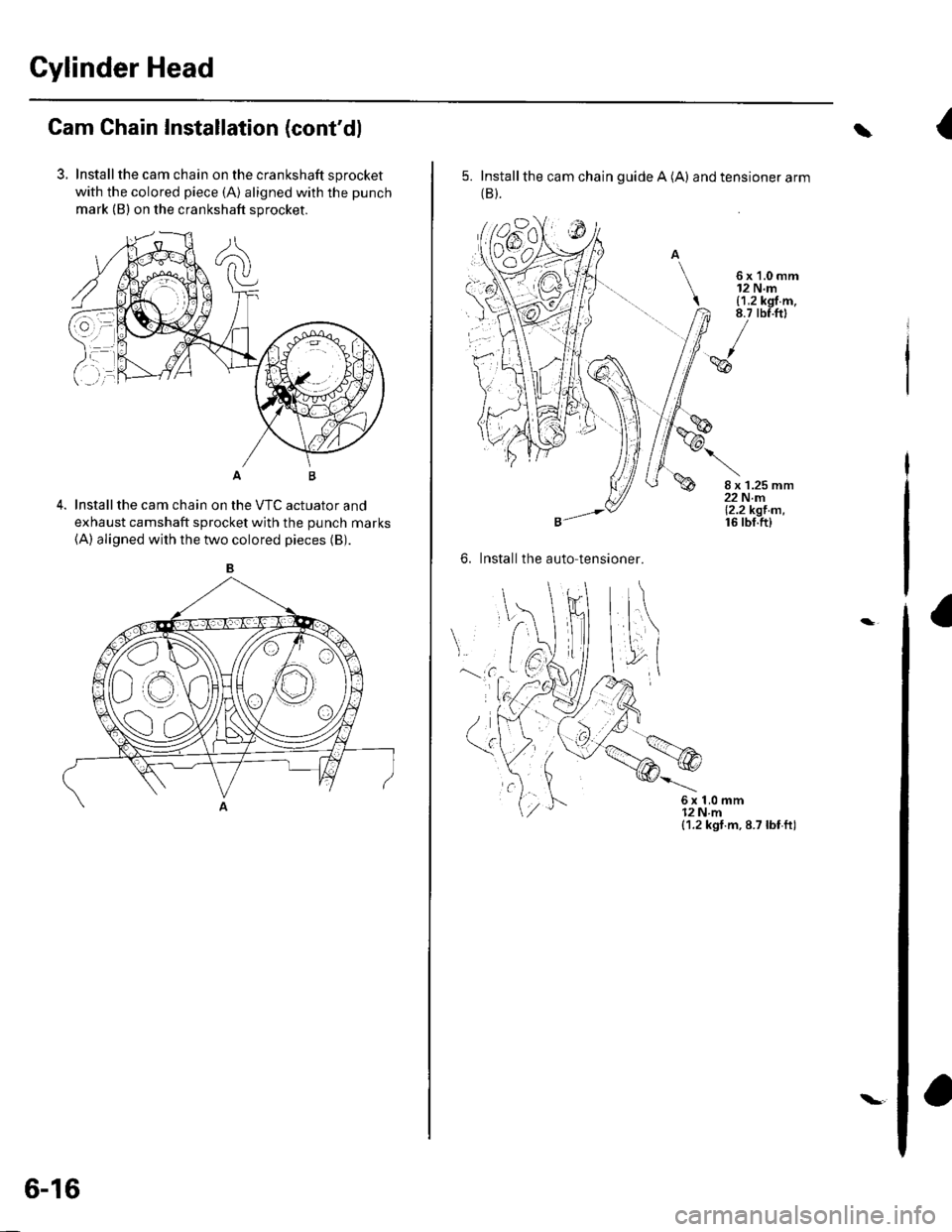

Cam Chain Installation (cont'dl

3. Installthe cam chain on the crankshaft sprocket

with the colored piece (A) aligned with the punch

mark (B) on the crankshaft sprocket.

Installthe cam chain on the VTC actuator and

exhaust camshaft sprocket with the punch marks(A) aligned with the two colored pieces (B).

B

6-16

{\

5. Installthe cam chain guide A (A) and tensioner arm(B).

6x1.0mm12 N.m{1,2 kgf.m,8.7 tbf.ftt

I'6

8 x 1.25 mm22 N.m12.2kgt.m,16 tbf.ft)

6. Install the auto-tensi

6x1,0mm12Nm(1.2 kgt.m, 8.7 lbf ti)

a

a

Page 114 of 1139

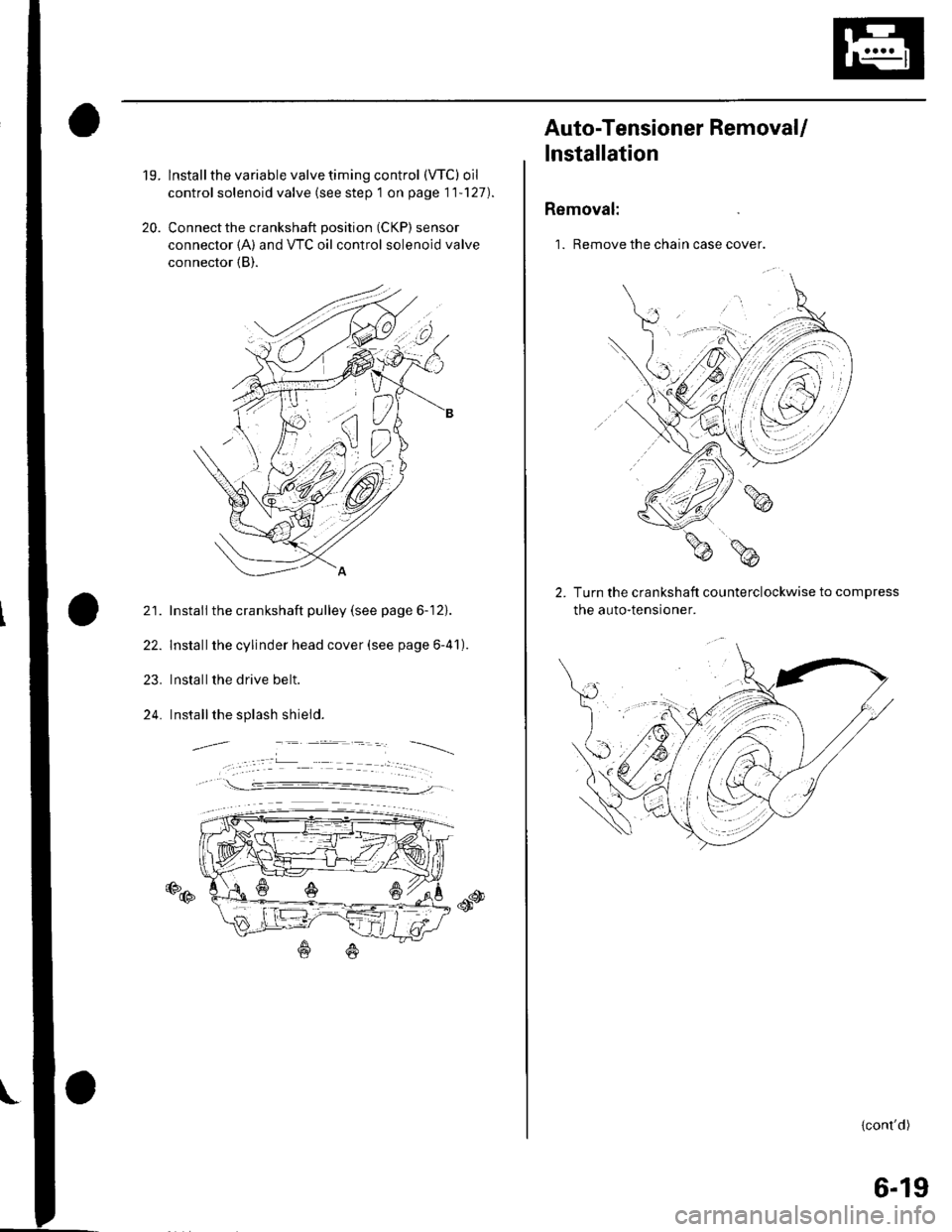

19.

20.

lnstall the variable valve timing control (VTC) oil

control solenoid valve (see step 1 on page 11'127).

Connect the crankshaft position (CKP) sensor

connector {A) and VTC oil control solenoid valve

connector (B).

21. Install the crankshaft pulley (see page 6-12).

22. Installthe cylinder head cover (see page 6-41).

23. Installthe drive belt.

24. Installthe splash shield.

€D@

Auto-Tensioner RemovaU

lnstallation

Removal:

1. Remove the chain case cover.

Turn the crankshaft counterclockwise to compress

the auto-tensroner.

{cont'd)

6-19

Page 115 of 1139

Gylinder Head

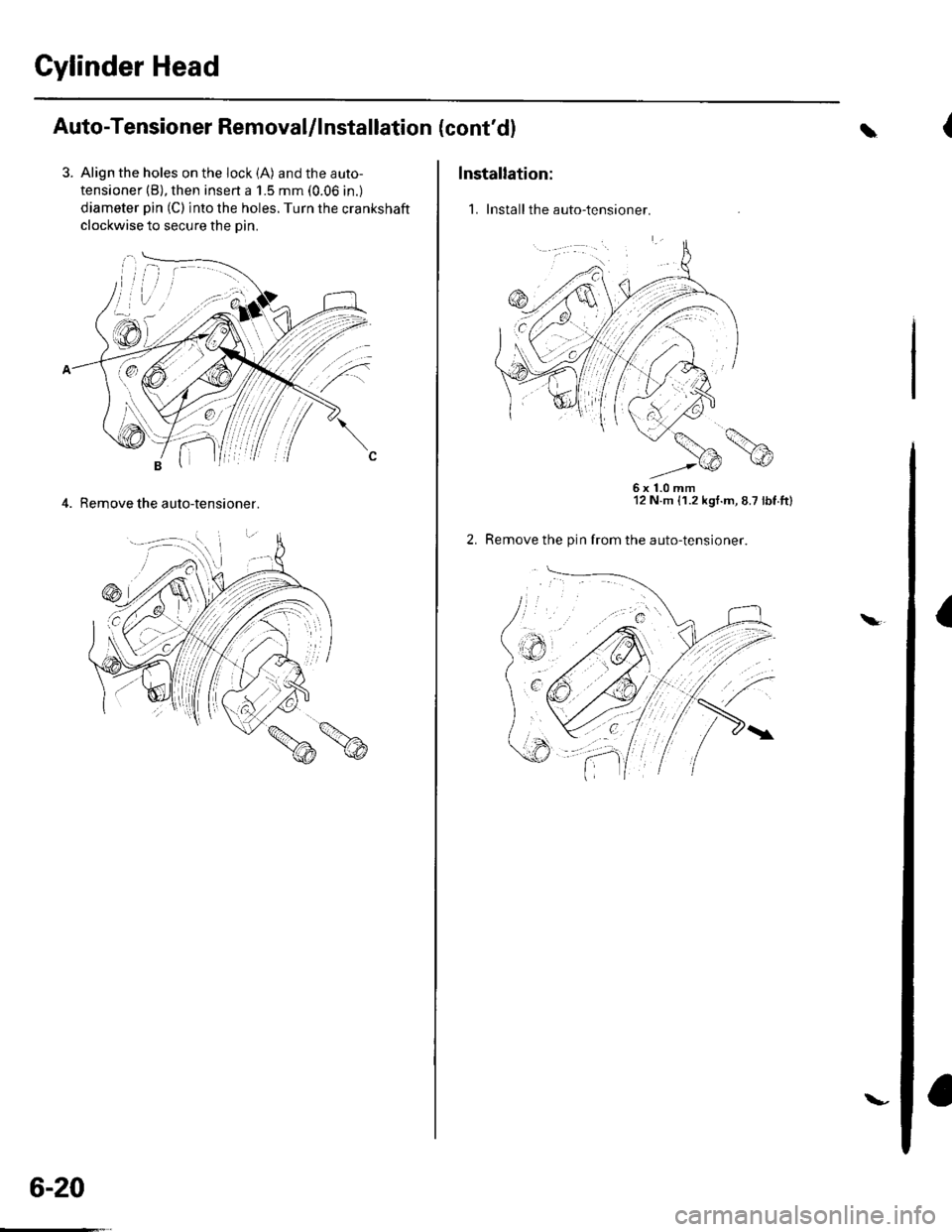

Auto-Tensioner Removal/l nstallation

3. Align the holes on the lock (A) and the auto-

tensioner (B), then insert a 1.5 mm (0.06 in.)

diameter pin (C) into the holes. Turn the crankshaft

clockwise to secure the oin.

4. Remove the auto-tensioner.

6-20

\-

(cont'dl

Installation:

1. Install the auto-tensioner.

\

6x1.0mm12 N.m {1.2 kgt.m, 8.7 lbt.tt)

Remove the pin from the auto-tensioner.

a\

Page 134 of 1139

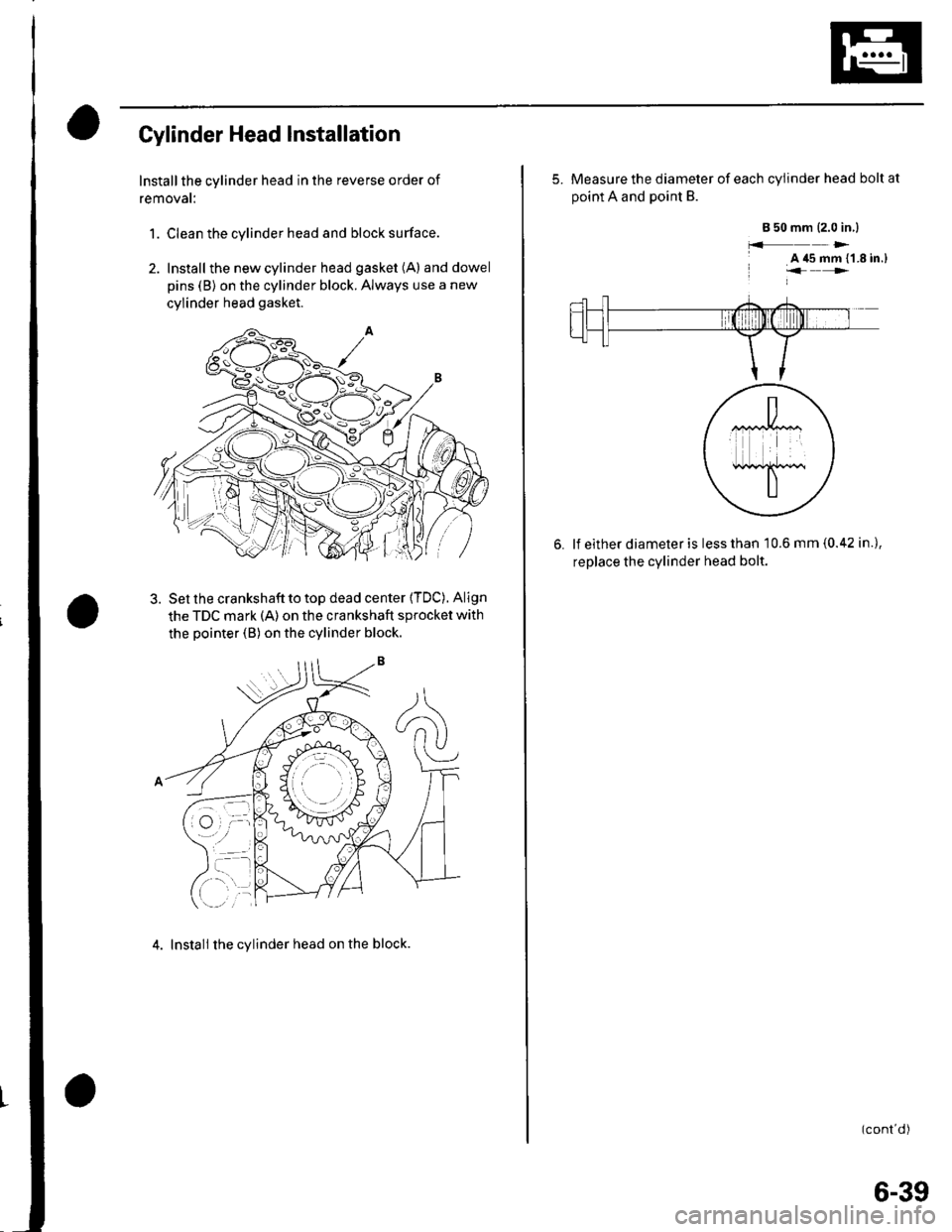

Cylinder Head Installation

Install the cylinder head in the reverse order of

removat:

1. Clean the cylinder head and block surface.

2. Install the new cylinder head gasket (A) anddowel

pins (B) on the cylinder block. Always use a new

cylinder head gasket.

Set the crankshaft to top dead center {TDC). Align

the TDC mark (A) on the crankshaft sprocket with

the pointer (B) on the cylinder block.

4. Install the cylinder head on the block.

5. Measure the diameter of each cylinder head bolt at

ooint A and Doint B.

a 50 mm (2.0 in.l

f.f )>-

A '15 mm {'1.8 in.)"<>.

lf either diameter is less than 10.6 mm {0.42 in.),

replace the cvlinder head bolt.

(cont d)

6-39

Page 139 of 1139

Engine Mechanical

Engine Block

Soecial Tools ............. 7 -2

Comoonent Location Index ......................................... 7-3

Connecting Rod and Crankshaft End Play

InsDection .............. 7-5

Crankshaft Main Bearing Replacement ...................... 7-6

Connecting Rod Bearing Replacement ...................... 7-8

Oil Pan Removal ....................... .......... 7-11

Crankshaft and Piston Removal ........ 7-12

Crankshaft Inspection ........................ 7-14

Block and Piston Insoection ........................................ 7-15

Cyfinder Honing ............ .".................... 7 -'17

Piston, Pin and Connecting Rod Replacement .......... 7-18

Piston Ring Replacement ................... 7 -21

Piston lnstallation .................... ........... 7-23

Connecting Rod Bolt Inspection .......' 7 -24

Crankshaft lnstallation .....................'. 7-24

Oil Pan lnstallation .................. ........... 7 -27

Transmission End Crankshaft Seal

lnstallation-ln Car ................... ........' 7 -28

Page 141 of 1139

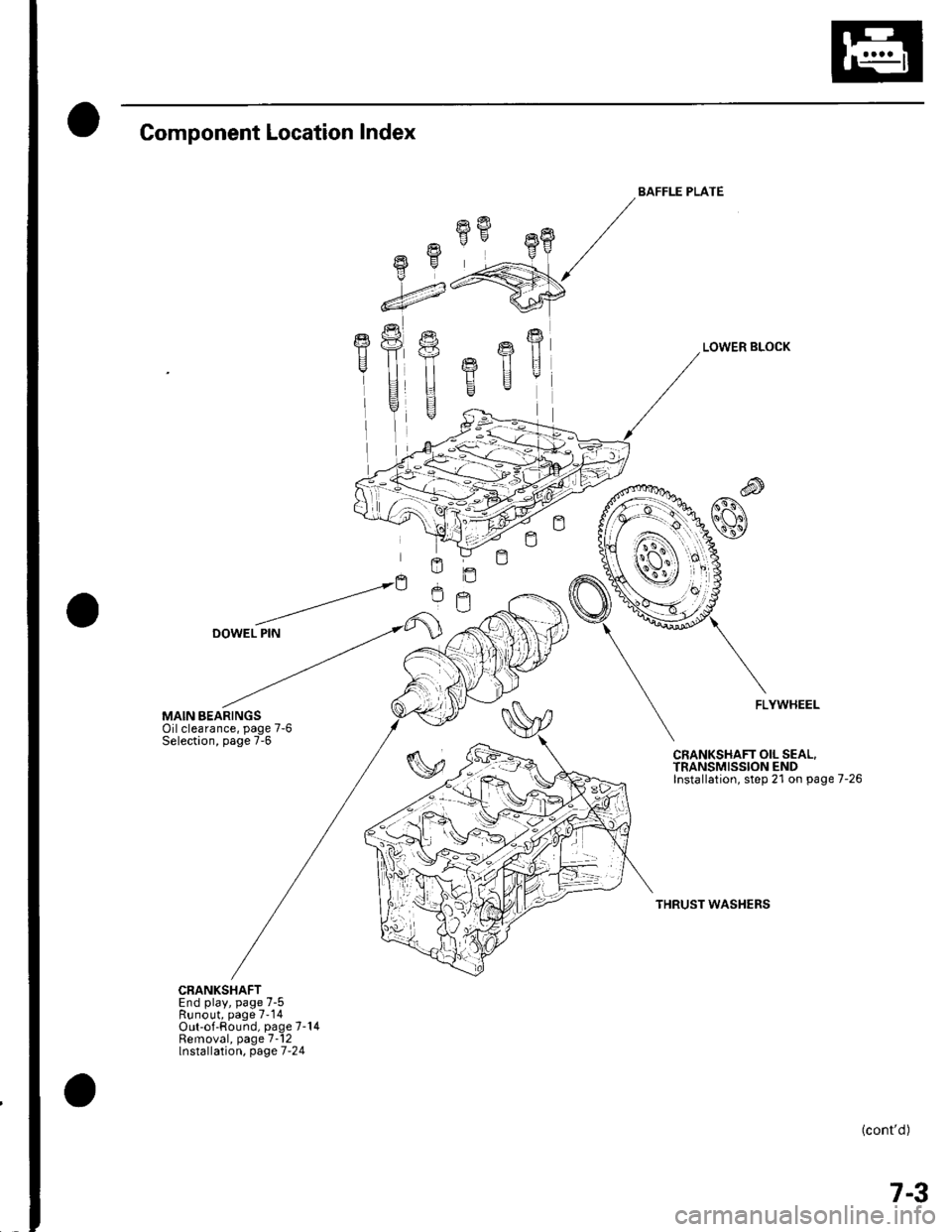

Component Location Index

MAIN BEARINGSOilclearance, page 7-6Selection, page 7-6

CRANKSHAFTEnd play, page 7-5Runout, page 7-14Out-of-Round, page 7-14Removal, page 7-12lnstallation, page 7-24

fifr"8

-4

E

I

BAFFLE PLATE

LOWER BLOCK

FLYWHEEL

CRANKSHAFT OIL SEAL.TRANSMISSION ENDInstallation, step 21 on page 7-26

THRUST WASHERS

(cont'd)

7-3

Page 143 of 1139

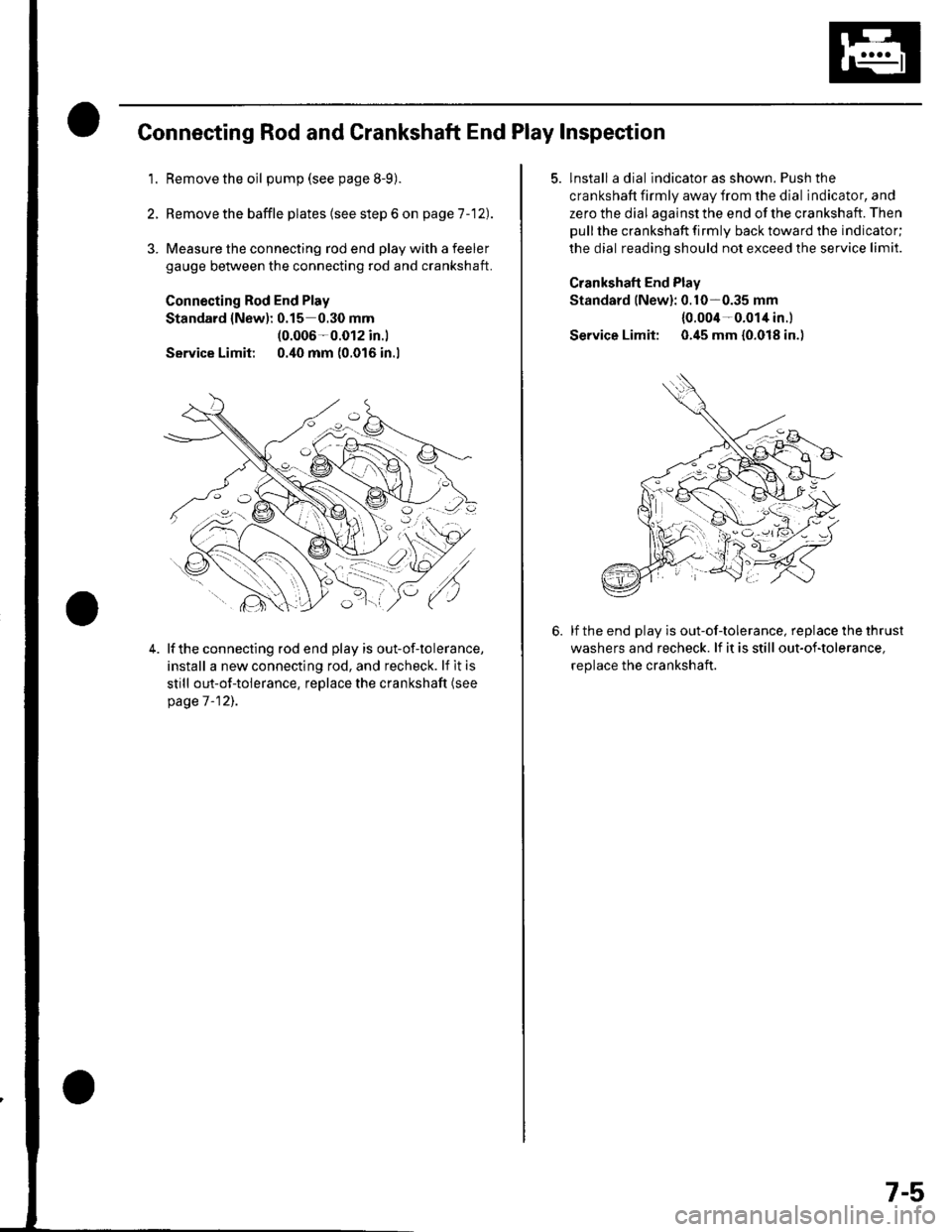

Connecting Rod and Crankshaft End Play Inspection

1.Remove the oil pump (see page 8-9).

Remove the baffle plates (see step 6 on page 1 -12).

3. Measure the connecting rod end play with a feeler

gauge between the connecting rod and crankshaft.

Connecting Rod End Play

Standard {New): 0.15 0.30 mm(0.006-0.012 in.l

Service Limit 0.40 mm (0.016 in.l

4.lf the connecting rod end play is out-of-tolerance,

install a new connecting rod, and recheck. lf it is

still out-of-tolerance, replace the crankshaft (see

page 7 -12],.

5. lnstall a dial indicator as shown. Push the

crankshaft firmly away from the dial indicator, and

zero the dial against the end of the crankshaft. Then

pull the crankshaft firmly back toward the indicator;

the dial reading should not exceed the service limit.

Crankshaft End Plav

Standard lNew): 0.10-0.35 mm

{0.004-0.014 in.l

Service Limit: 0.45 mm {0.018 in.)

lf the end play is out-of-tolerance, replace the thrust

washers and recheck. lf it is still out-of-tolerance,

replace the crankshaft.

7-5

Page 144 of 1139

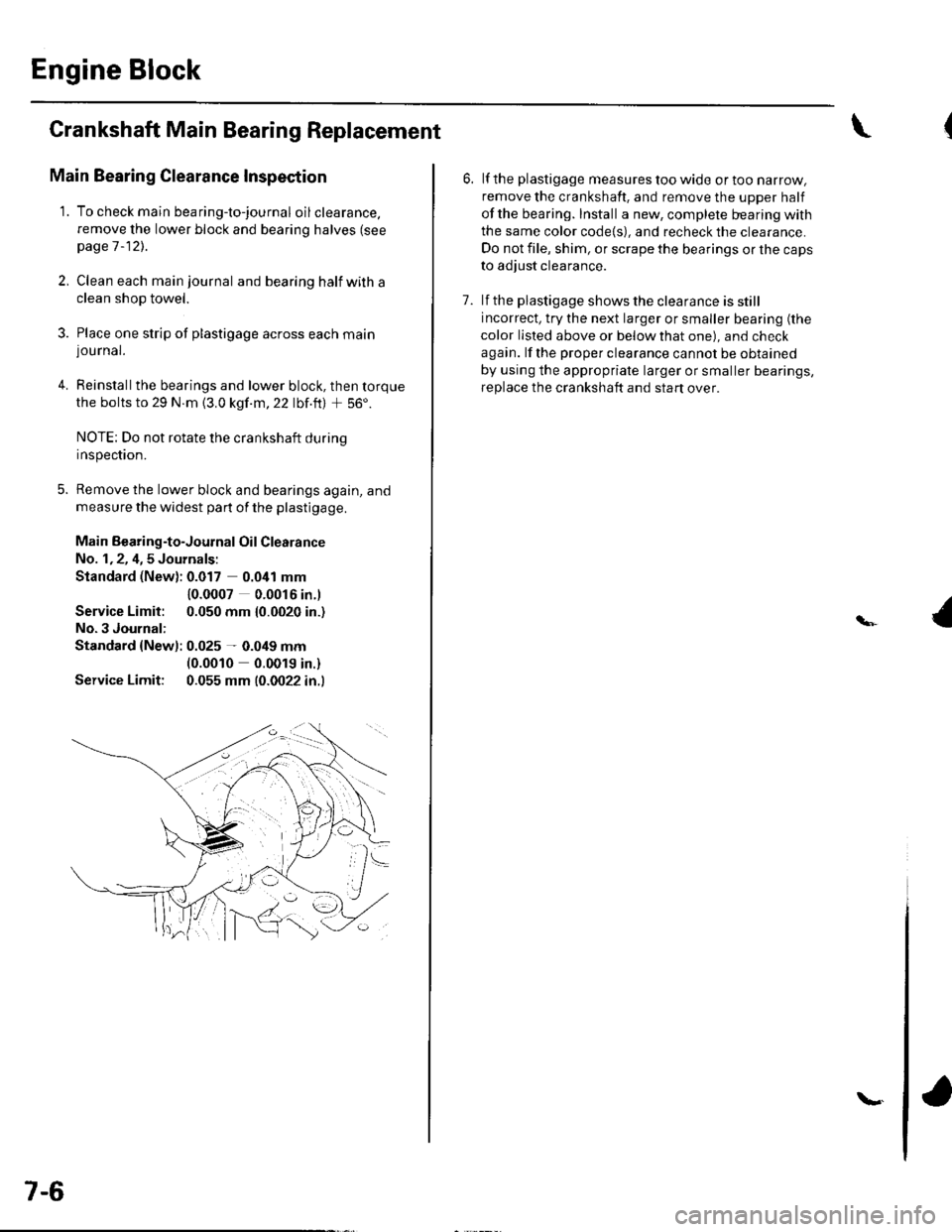

Engine Block

Crankshaft Main Bearing Replacement

Main Bearing Clearance Inspection

1. To check main bea ring-to-jou rna I oil clearance.

remove the lower block and bearing halves (see

page 1 -12)..

2, Clean each main journal and bearing half witha

clean shop towel.

3. Place one strip of plastigage across each main

lou rnal.

4. Reinstallthe bearings and lower block, then torque

the bolts to 29 N.m {3.0 kgf.m,22 lbf.ft) + 56'.

NOTE: Do not rotate the crankshaft during

Inspeclton.

5. Remove the lower block and bearings again, and

measure the widest part of the plastigage.

Main Bearing-to-Journal Oil Clearance

No. 1,2, 4,5 Journals:

Standard (New): 0.017 0.041 mm

Service Limit:

No.3 Journal:

10.0007 0.0016 in.l

0.050 mm {0.0020 in.)

Standard {Newl: 0.025 - 0.049 mm(0.0010 0.0019 in.)

Service Limit: 0.055 mm (0.0022 in.l

7-6

\.

6. lf the plastigage measures too wide or too narrow,

remove the crankshaft. and remove the upper half

ofthe bearing. Install a new, complete bearing with

the same color code{s), and recheck the clearance.

Do not file, shim, or scrape the bearings or the caps

to adjust clearance.

7. lf the plastigage shows the clearance is still

incorrect, try the next larger or smaller bearing (the

color listed above or below that one), and check

again. lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

Page 145 of 1139

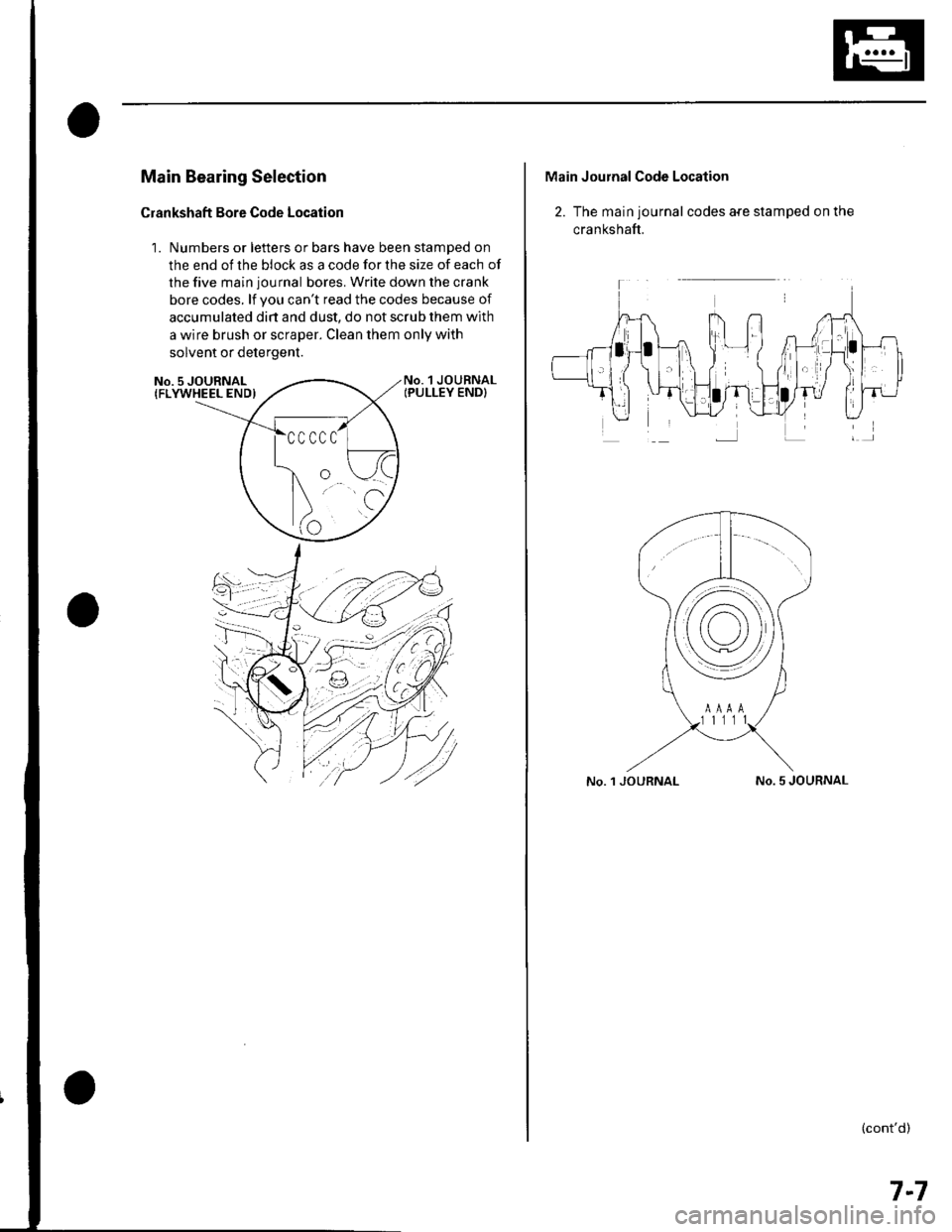

Main Bearing Selection

Crankshaft Bore Code Location

1. Numbers or letters or bars have been stamped on

the end of the block as a code for the size of each of

the five main journal bores. Write down the crank

bore codes. lf you can't read the codes because of

accumulated dirt and dust, do not scrub them with

a wire brush or scraper. Clean them only with

solvent or detergent.

No. 1 JOURNALIPULLEY END}No. 5 JOURNAL{FLYWHEEL END)

Main Journal Code Location

2. The main journal codes a{e stamped on the

cra n kshaft.

No. 1 JOURNALNo. 5 JOURNAL

(cont'd)

7-7

Page 146 of 1139

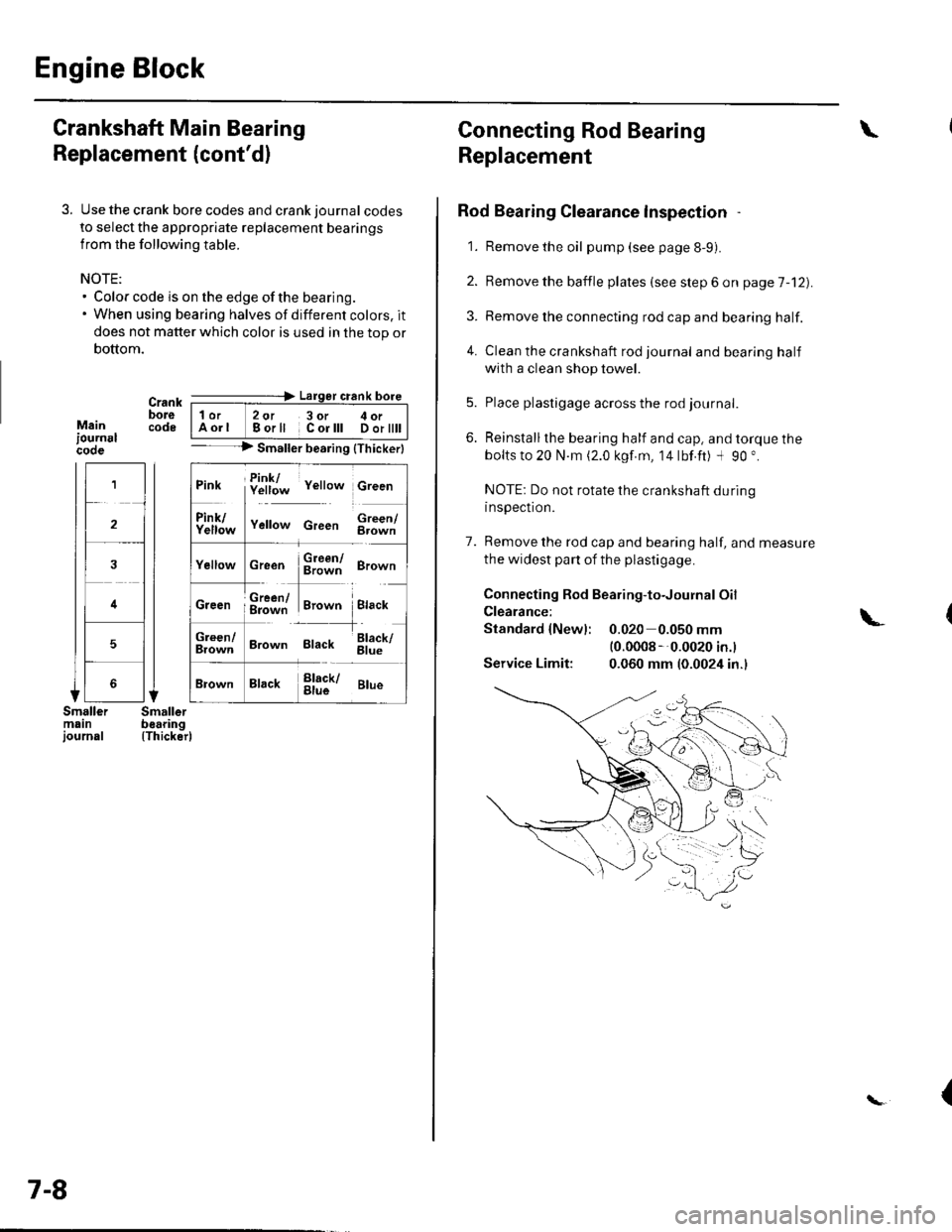

Engine Block

Crankshaft Main Bearing

Replacement (cont'd)

3. Use the crank bore codes and crank journal codes

to select the appropriate replacement bearings

from the following table.

NOTE:. Color code is on the edge of the bearing.. When using bearing halves of different colors. it

does not matter which color is used in the top or

bottom.

Mainiournslcooe

Crank ---=-> Lalger crank bore

bore | 1or 2ot 3or c oi__-lcode IAorl Borll Corlll Dortttt I-- --> Smaller bearing {Thickerl

(Thicker)

1

2

4

5

Pink f!1f;* v"rro* c,""n

ll

f111f;,," v"no* c,""" $;;fl

cr""n $ffi ero-n

ffi#Tr,.*" i.,""*Creen ; g=jiff;i Brown Black

;;lT]*

'---l-'o"*,

Brown Black 6il;

Brack !l;kr ar*

7-8

Connecting Rod Bearing

Replacement

Rod Bearing Clearance lnspection

1. Remove the oil pump (see page 8-9).

2. Bemove the baffle plates (see step 6 on page 7-12).

3. Remove the connecting rod cap and bearing half.

4. Clean the crankshaft rod journal andbearinghalf

with a clean shop towel.

5. Place plastigage across the rod journal.

6. Reinstallthe bearing half and cap, and torque the

bolts to 20 N.m (2.0 kgf.m, 14lbf.ft) -l 90 ".

NOTE: Do not rotate the crankshaft during

inspection.

7. Remove the rod cap and bearing half, and measure

the widest part of the plastigage.

Connecting Rod Bearing-to-Journal Oil

Clearance:

Standard {Newl: 0.020 0.050 mm(0.0008 --0.0020 in.l

Service Limit: 0.060 mm (0.0024 in.)

\

\-

{