gearbox HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 514 of 1139

![HONDA CIVIC 2002 7.G User Guide Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check fo]

EPS indicator does not

come on

EPS lndicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not go

off and no DTC i HONDA CIVIC 2002 7.G User Guide Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check fo]

EPS indicator does not

come on

EPS lndicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not go

off and no DTC i](/img/13/5744/w960_5744-513.png)

Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check fo]

EPS indicator does not

come on

EPS lndicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not go

off and no DTC is stored

EPS Indicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not stay

on, no DTC is stored, and

there is no power assist

1. Check the motor wires between the EPS control unit and the

motor for a short to ground. Repair as needed.

2. lf the motor wires are OK, replace the steering gearbox

{short in the motor).

17-23

Page 520 of 1139

'I 1.Substitute a known-good EPS control unit, and

connect the all disconnected connectors.

Sta rt the engine.

Does the EPS indicator come on?

YES Go to step 13.

NO Check for loose EPS control unitconnectors. lf

necessary, replace the EPS control unit and

retest.l

Stop the engine, and verify the DTC.

ls DTCl2 indicated?

YES Check for loose torque sensor connectors.

lf necessary, substitute a known-good steering

gearbox and recheck.l

NO-Perform the appropriate troubleshooting for

the code indicated. !

12.

13.

DTC 16: Torque Sensor VT3 and W6

1. Clear the DTC.

2. Start the engine.

3. Wait at least 10 seconds.

Does the EPS indicator come on?

YES Go to step 4.

NO Check for loose wires or poor connnections. lf

the connections are good, the system is OK at this

time.l

4. Stop the engine, and verify the DTC.

ls DTC16 indicated?

YES-Go to step 5.

NO Perform the appropriate troubleshooting for

the code indicated. t

5. Make sure the ignition switch is OFF, then

disconnect EPS control unit connector C (20P) and

the torque sensor 6P connector.

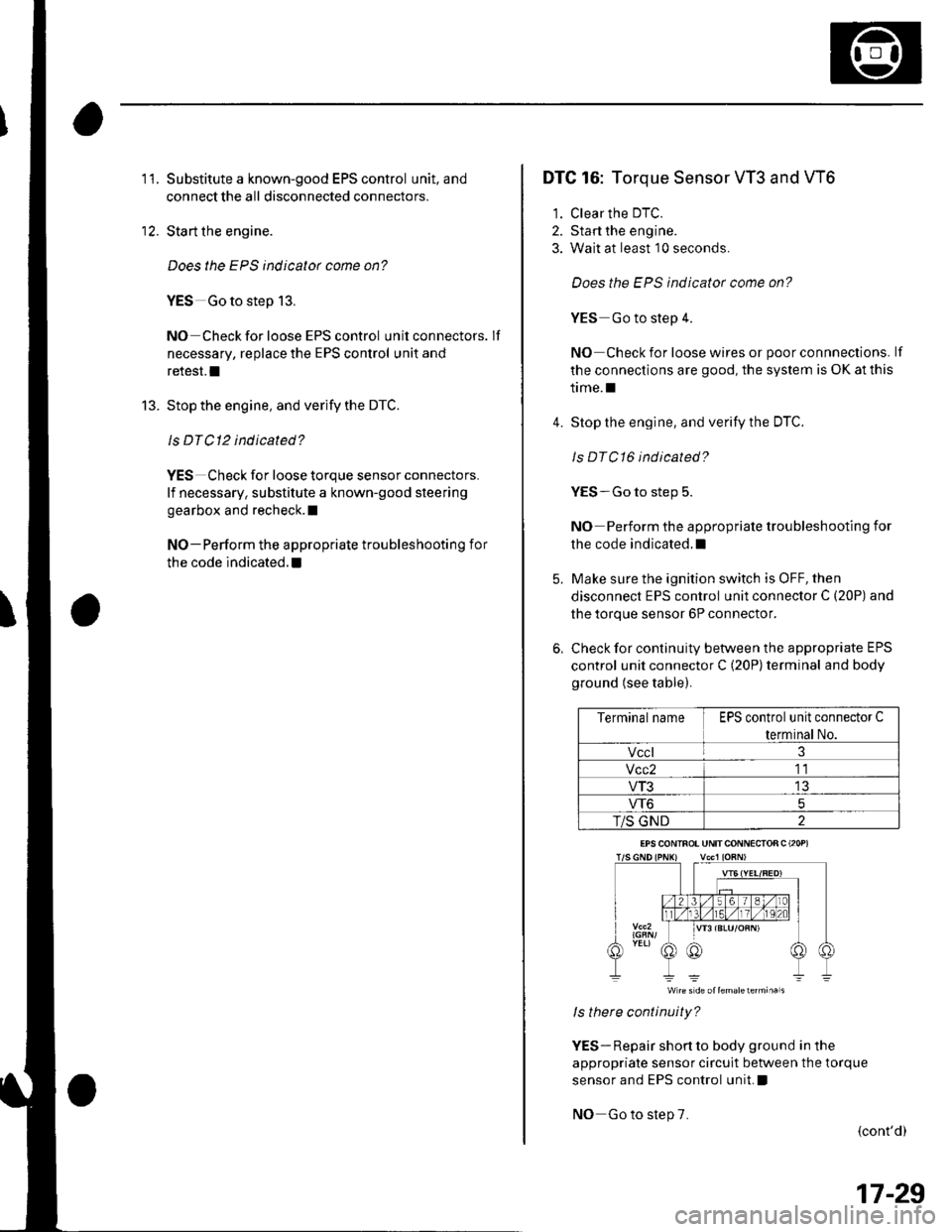

6, Check for continuity between the appropriate EPS

control unit connector C (20P) terminal and body

ground (see table).

Terminal nameEPS control unit connector C

terminal No.

Vccl3

Vcc211

VT313

VT65

T/S GND2

W re s d€ oltemalelermi.als

ls there continuity?

YES- Repair short to body ground in the

appropriate sensor circuit between the torque

sensor and EPS control unit, !

NO Go to step 7.

{cont'd)

EPS CONINOT UNITCONNECIOR C (2OP)

17-29

Page 522 of 1139

11.

't2.

Substitute a known-good EPS control unit, and

reconnect the disconnected connectors.

Sta rt the engine.

Does the EPS indicator come on?

YES Go to step 13.

NO Check for loose or poor connections at the

EPS control unit and the torque sensor conneclors.

lf the connections are good, replace the EPS control

unit and recheck.I

Stop the engine, and verify the DTC.

ls DTC16 indicated?

YES Replace the steering gearbox and recheck.l

NO Perform the appropriate troubleshooting for

the code indicated.l

13.

DTC 17: Torque Sensor Vccl

DTC 18: Torque Sensor Vcc2

1. Clear the DTC.

2. Start the engine.

3. Wait at least 10 seconds.

4.

Does the EPS indicator come on?

YES Go to step 4.

NO Check for loose wires or poor connections. lf

the connections are good, the system is OK at this

time.I

Stop the engine, and verify the DTC.

Is DTCl7 or DTCl8 indicated?

YES Go to step 5.

NO Do the troubleshooting for the DTc

indicated.I

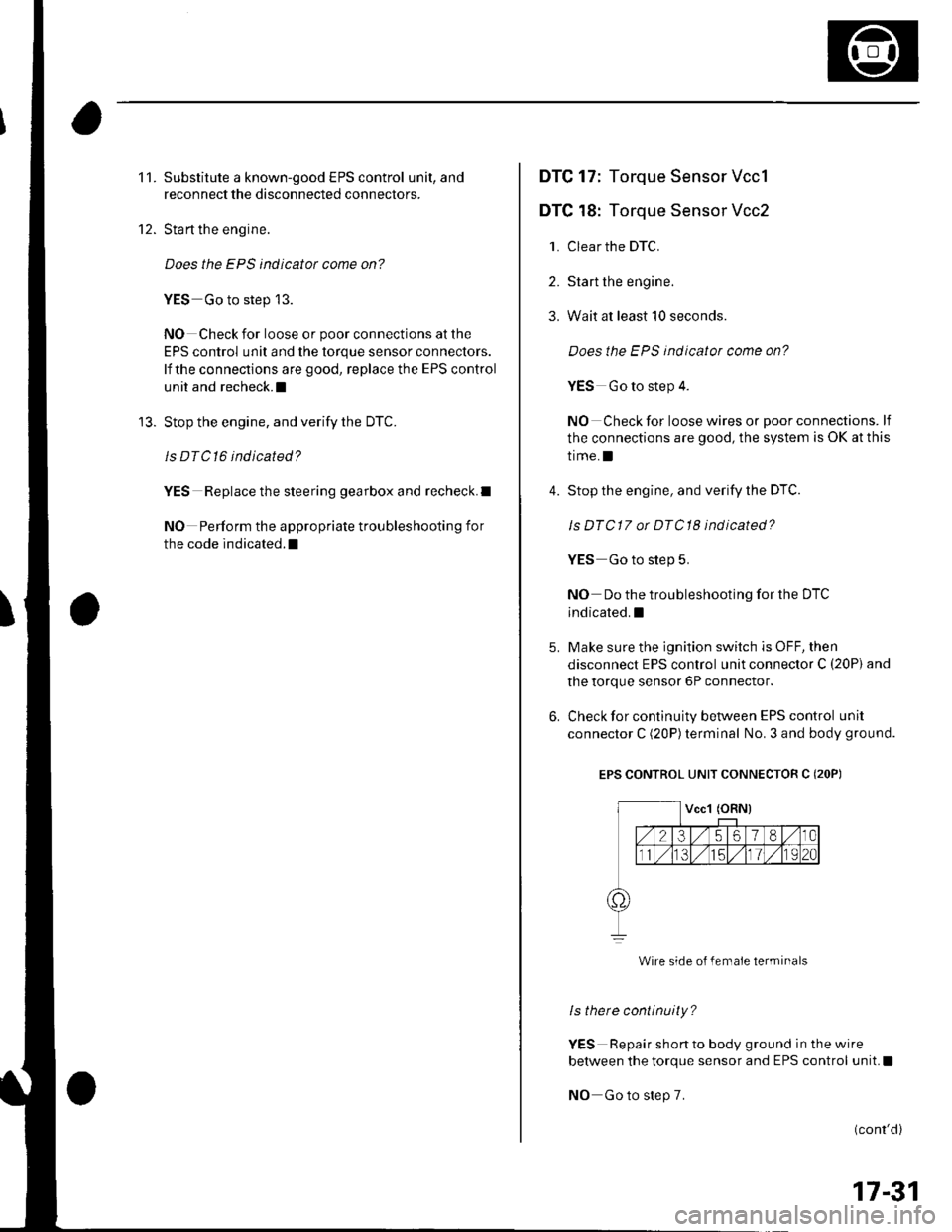

Make sure the ignition switch is OFF, then

disconnect EPS control unit connector C (20P) and

the torque sensor 6P connector.

Check for continuity between EPS control unit

connector C (20P)terminal No. 3 and body ground.

EPS CONTROL UNIT CONNECTOR C (2OP)

Wire side o{ female terminals

ls there continuity?

YES Repair shon to body ground in the wire

between the torque sensor and EPS control unit.I

NO Go to step 7.

(cont'd)

17-31

Page 523 of 1139

EPS Components

DTC Troubleshooting (cont'dl

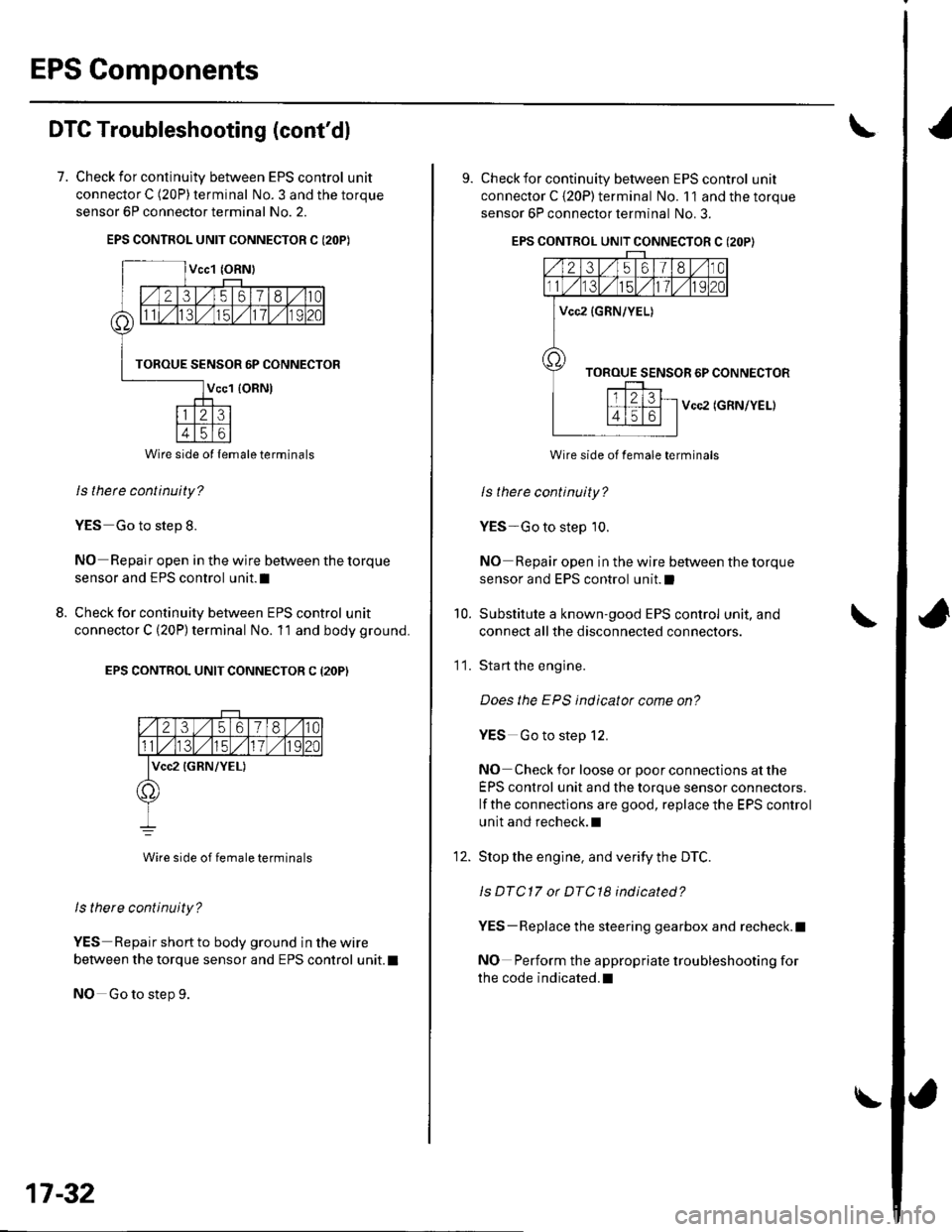

7. Check for continulty between EPS control unit

connector C (20P) terminal No. 3 and the torque

sensor 6P connector terminal No. 2.

EPS CONTROL UNIT CONNECTOR C I2OP)

ls thete continuity?

YES Go to step 8.

NO Repair open in the wire between the torque

sensor and EPS control unit.I

Check for continuity between EPS control unit

connector C (20P) terminal No. 11 and body ground.

EPS CONTROL UNIT CONNECTOR C (2OP)

2356180

lvcc2 {GRN/YEL)

Wire side of female terminals

ls there continuity?

YES Repair short to body ground in the wire

between the torque sensor and EPS control unit. t

NO Go to step 9.

8.

Wire side ol lemale terminals

17-32

\

9. Check for continuity between EPS control unit

connector C {20P) terminal No. 11 and the torque

sensor 6P connector terminal No. 3.

EPS CONTROL UNIT CONNECTOR C (2OP}

Vcc2 (GRN/YEL)

Wire side of female terminals

ls therc continuity?

YES-Go to step 10.

NO Repair open in the wire between the torque

sensor and EPS control unit.l

Substitute a known-good EPS control unit, and

connect all the disconnected connectors.

Sta rt the engine.

Does the EPS indicator come on?

YES Go to step 12.

NO Check for loose or poor connections at the

EPS control unit and the torque sensor connectors.

lf the connections are good, replace the EPS control

unit and recheck.l

Stop the engine, and verity the DTC.

ls DTC17 or DTC18 indicated?

YES-Replace the steering gearbox and recheck.l

NO Perform the appropriate troubleshooting for

the code indicated.l

10.

11.

12.

Page 528 of 1139

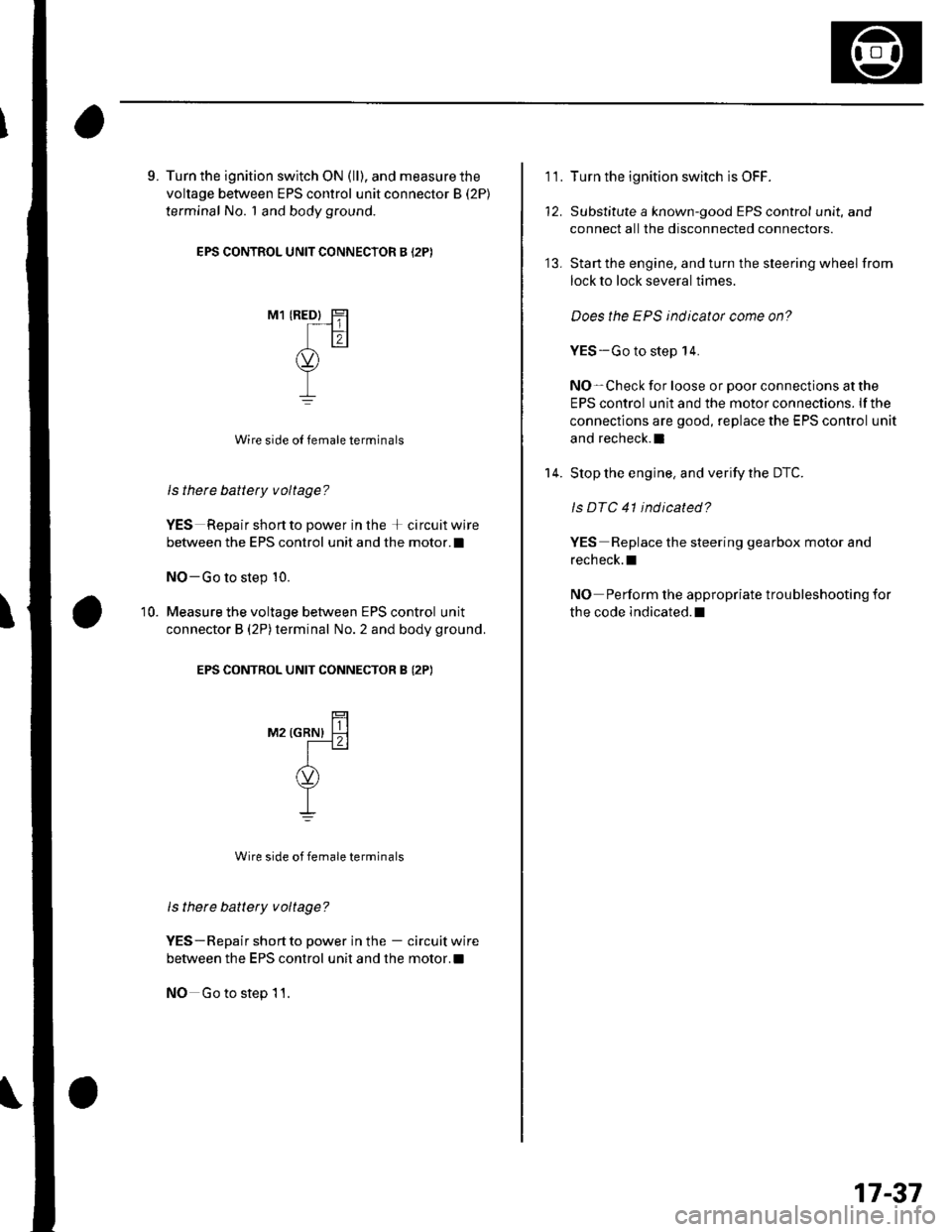

9. Turn the ignition switch ON (ll), and measure the

voltage between EPS control unit connector B (2P)

terminal No. 1 and body ground

EPS CONTROL UNIT CONNECTOR B (2P)

M1 IREDI Hr-_ -1 ||

tr,<.)\uL,/Y

I

Wire side oI female terminals

Is there battety voltage?

YES Repair short to power in the + circuit wire

between the EPS control unit and the motor.I

NO-Go to step 10.

Measure the voltage between EPS control unit

connector B (2P)terminal No.2 and body ground.

EPS CONTROL UNIT CONNECTOR B (2P)

10.

raz rcnrrrr l{l-t . I

I(v)

YI

Wire side of female terminals

ls there battery voltage?

YES-Repair shortto power in the - circuitwire

between the EPS control unit and the motor.!

NO Go to step 11.

11.Turn the ignition switch is OFF.

Substitute a known-good EPS control unit, and

connect all the disconnected connectors.

Start the engine, and turn the steering wheel from

lock to lock several times.

Does the EPS indicator come on?

YES-Go to step 14.

NO-Check for loose or poor connections atthe

EPS control unit and the motor connections. lfthe

connections are good, replace the EPS control unit

and recheck.l

Stop the engine, and verity the DTC.

ls DTC 41 ind icated?

YES Replace the steering gearbox motor and

recheck.l

NO Perform the appropriate troubleshooting for

the code indicated.l

13.

14.

17-37

Page 531 of 1139

EPS Gomponents

DTG Troubleshooting (cont'd)

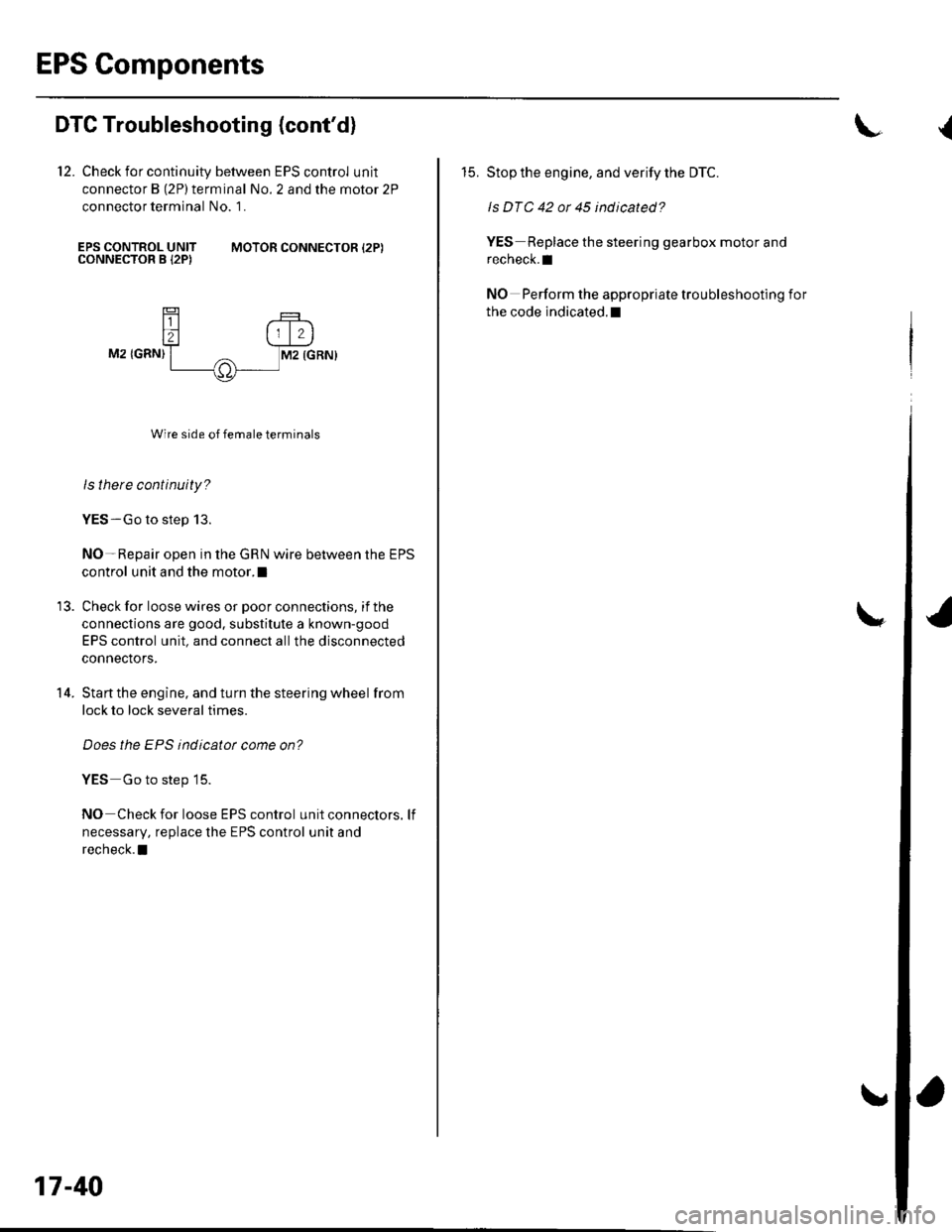

12. Check for continuity between EPS control unit

connector B (2P)terminal No. 2 and the motor 2P

connector terminal No. 1.

EPS CONTROL UNITCONNECTOR B I2PIMOTOR CONNECTOR {2P)

14.

M2 IGRN)

Wire side of female terminals

ls there continuity?

YES-Go to step 13.

NO-Repair open in the GRN wire between the EPS

control unit and the motor.l

Check for loose wires or poor connections, if the

connections are good. substitute a known-good

EPS control unit, and connect allthe disconnected

connectors.

Start the engine, and turn the steering wheel from

lock to lock several times.

Does the EPS indicatot come on?

YES Go to step 15.

NO Check for loose EPS control unitconnectors. lf

necessary, replace the EPS control unit and

recheck. a

17-40

L

15. Stop the engine, and verify the DTC.

ls DTC 42 or 45 indicated?

YES Replace the steering gearbox motor and

recheck.l

NO Perform the appropriate troubleshooting for

the code indicated.l

(

Page 533 of 1139

EPS Components

11.

12.

DTC Troubleshooting (cont'dl

Substitute a known-good EPS control unit, and

connect all the disconnected connectors.

Sta rt the engine, and turn the steering wheel from

lock to lock several times.

Does the EPS indicator come on?

YES Go to step 13.

NO -Check for loose or poor connections at the

EPS control unit and the motor connections. lf the

connections are good, replace the EPS control unit

and recheck.l

Stop the engine, and verity the DTC.

ls DTC 43 indicated?

YES-Replace the steering gearbox motor and

recheck. tl

NO-Perform the appropriate troubleshooting for

the code indicated.l

13.

17-42

DTC 47: EPS Control Unit lnternal Circuit(Power Relay)

1. Clear the DTC.

2. Start the engine.

Does the EPS indicator come on?

YES-Go to step 3,

NO-Check for loose wires or poor connections, lf

the connections are good, the system is OK at this

time.I

3. Stop the engine, and verify the DTC.

ls DTC 47 indicated?

YES Check for loose EPS control unit connectors.

lf necessary, substitute a known-good EPS control

unit and recheck.l

NO Perform the appropriate troubleshooting for

the code indicated.I

(

Page 540 of 1139

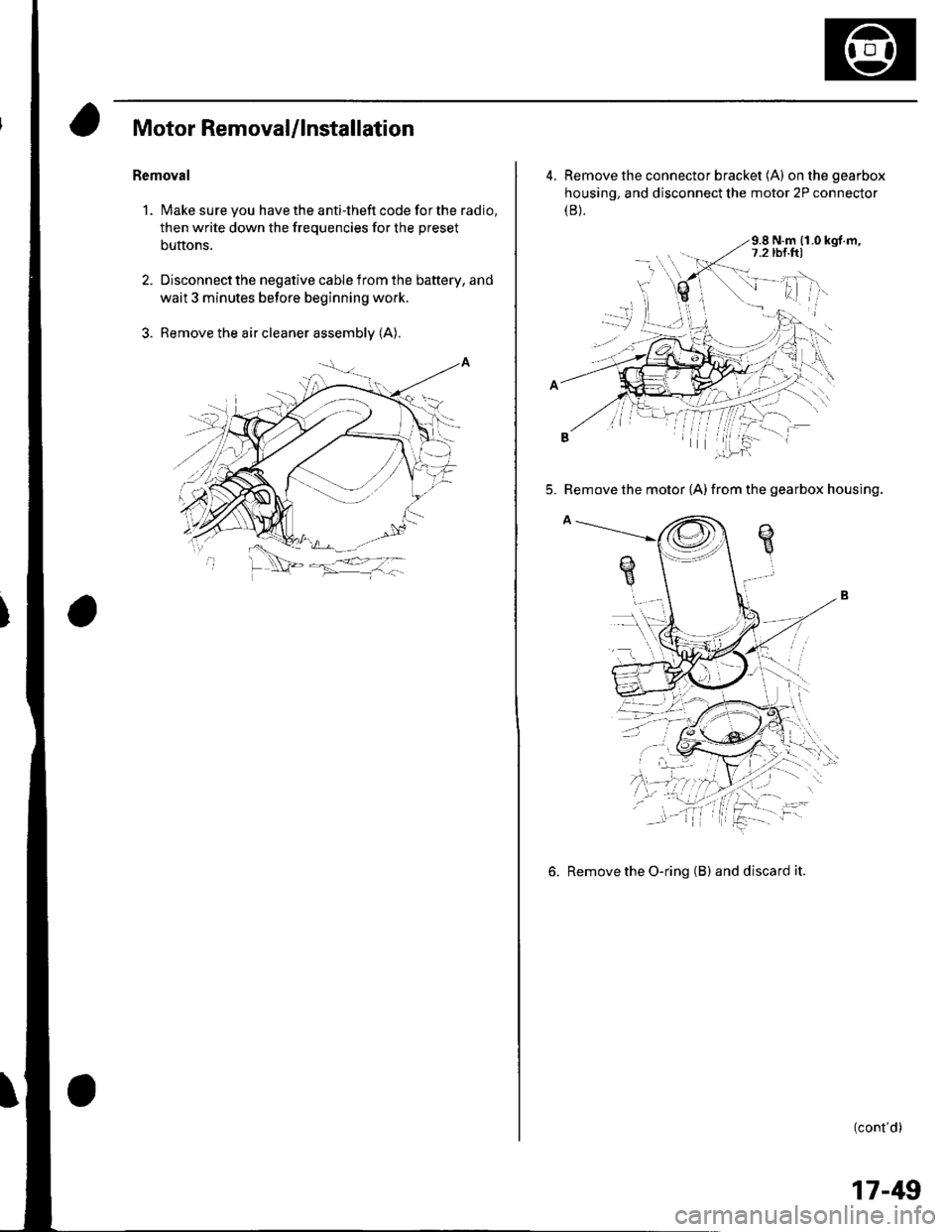

Motor Removal/lnstallation

Bemoval

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the negative cable from the battery, and

wait 3 minutes before beginning work.

3. Remove the air cleaner assembly (A).

4. Remove the connector bracket (A) onthegearbox

housing, and disconnect the motor 2P connector(B).

9.8 N.m {1.0 kgf.m,

5. Remove the motor {A) from the gearbox housing.

6. Remove the O-ring (B) and discard it.

(cont'd)

17-49

Page 541 of 1139

EPS Components

(Motor RemovaUlnstallation (cont'dl

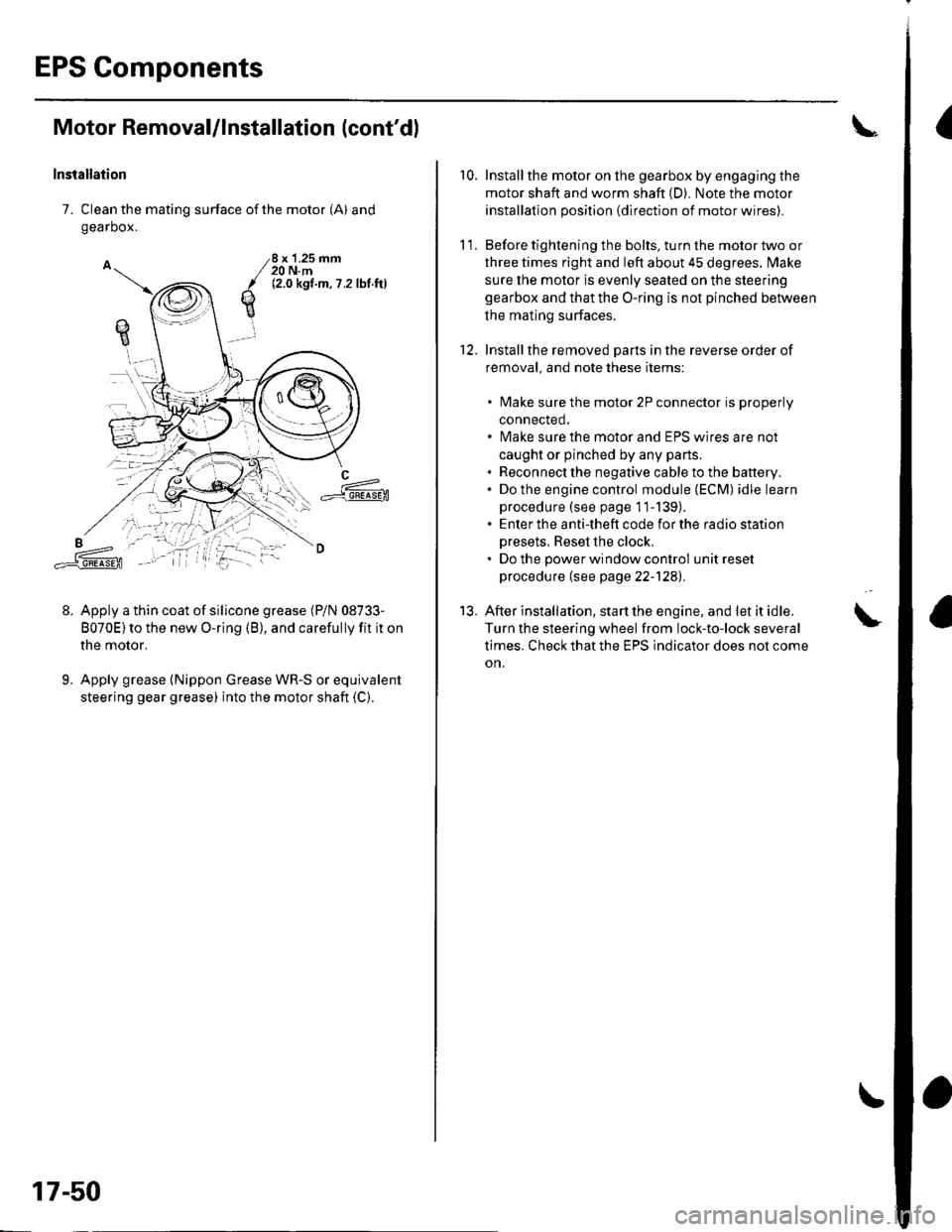

lnsiallation

7. Clean the mating surface of the motor (A) and

gearbox.

Apply a thin coat of silicone grease (P/N 08733-

8070E)to the new O-ring (B), and carefully fit it on

the motor.

Apply grease {Nippon Grease WR-S or equivalent

steering gear grease) into the motor shaft (C).

qE

8 x '1.25 mm20 N.m12.0 kgt.m,7 .2lbl ftl

L==-c].E@

9.

17-50

r0.Install the motor on the gearbox by engaging the

motor shaft and worm shaft (D). Note the motor

installation position {direction of motor wires).

Before tightening the bolts, turn the motor two or

three times right and left about 45 degrees. lvlake

sure the motor is evenly seated on the steering

gearbox and that the O-ring is not pinched betlveen

the mating surfaces.

Installthe removed Darts in the reverse order of

removal. and note these items:

lvlake sure the motor 2P connector is properly

connected.

lvlake sure the motor and EPS wires are not

caught or pinched by any parts.

Reconnect the negative cable to the battery.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

Enter the anti-theft code for the radio station

Dresets. Reset the clock,

Do the oower window control unit reset

procedure (see page 22-1241.

After installation, start the engine, and let it idle.

Turn the steering wheel from lock-to-lock several

times. Check that the EPS indicator does not come

on.

11.

12.

13.

Page 542 of 1139

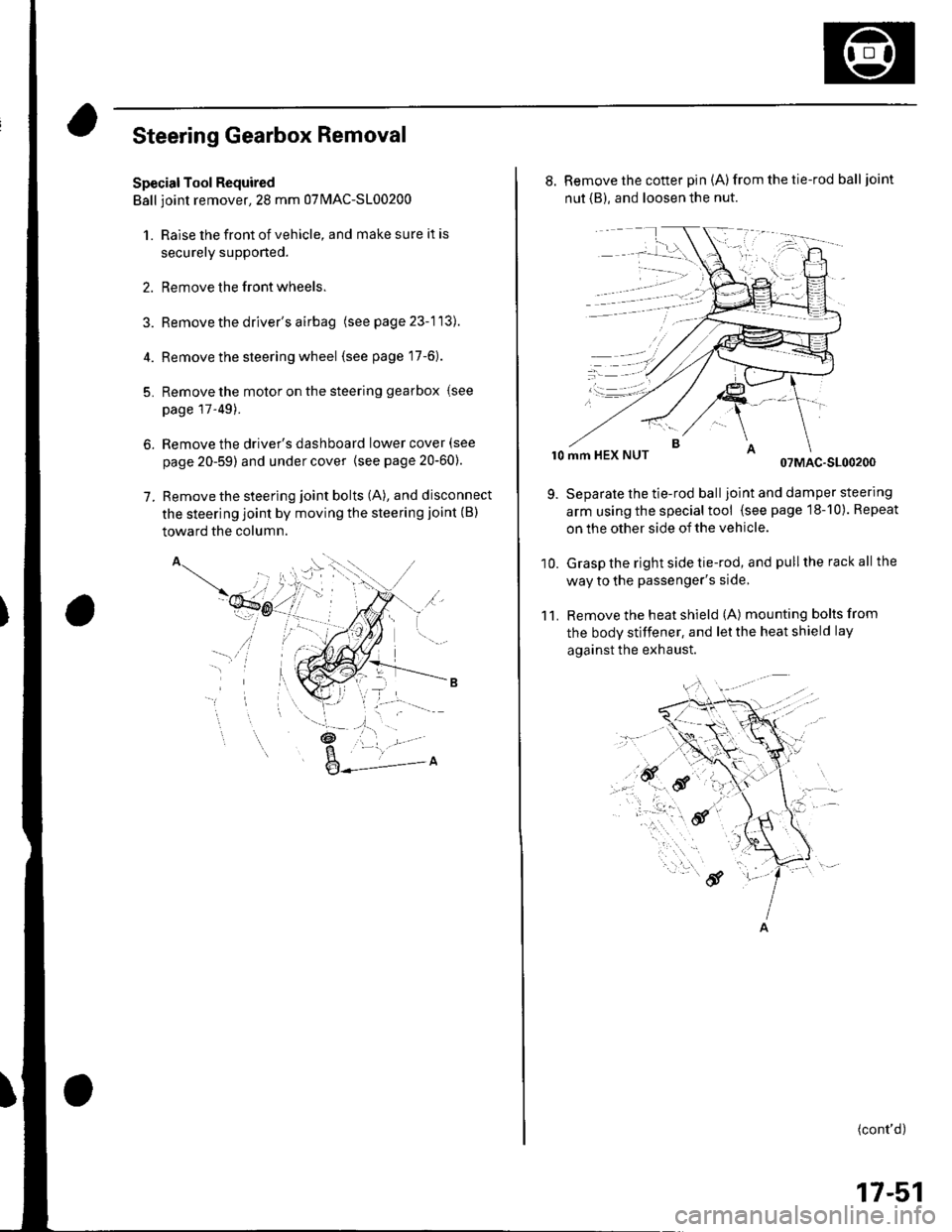

Steering Gearbox Removal

Special Tool Required

Ball ioint remover,2S mm 0TlvlAC-S100200

1. Raise the front of vehicle, and make sure it is

securely supponed.

2. Remove the front wheels.

Remove the driver's airbag (seepage23-113).

Remove the steering wheel (see page 17-6).

Remove the motor on the steering gearbox (see

page l T-49).

Remove the driver's dashboard lower cover (see

page 20-59) and under cover {see page20-60).

Remove the steering joint bolts (A), and disconnect

the steering joint by moving the steering joint (B)

toward the column.

4.

5.

6.

7.

'il

_t\

l- '/

,a.: --L -

8. Remove the cotter pin (A)from the tie-rod balljoint

nut {B), and loosen the nut.

r0 mm HEX NUT07MAC-S100200

Separate the tie-rod balljoint and damper steering

arm using the special tool (see page 18-10). Repeat

on the other side of the vehicle.

Grasp the right side tie-rod, and pull the rack all the

way to the passenger's side,

Remove the heat shield (A) mounting bolts from

the body stiffener, and let the heat shield lay

against the exhaust.

11.

9.

10.

(cont'd)

17-51