kpa HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 260 of 1139

DTC P0108: MAP Sensor Circuit High Voltage

'1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

2. Check the MAP with the scan tool.

le about 101 kPa (780 nmHg, 30 in.Hg) ot highet,

or about 2.9 V or higher indicated?

YES Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the MAP sensor and at the ECM.I

3. Turn the ignition switch OFF.

4. Disconnectthe MAP sensor 3P connector.

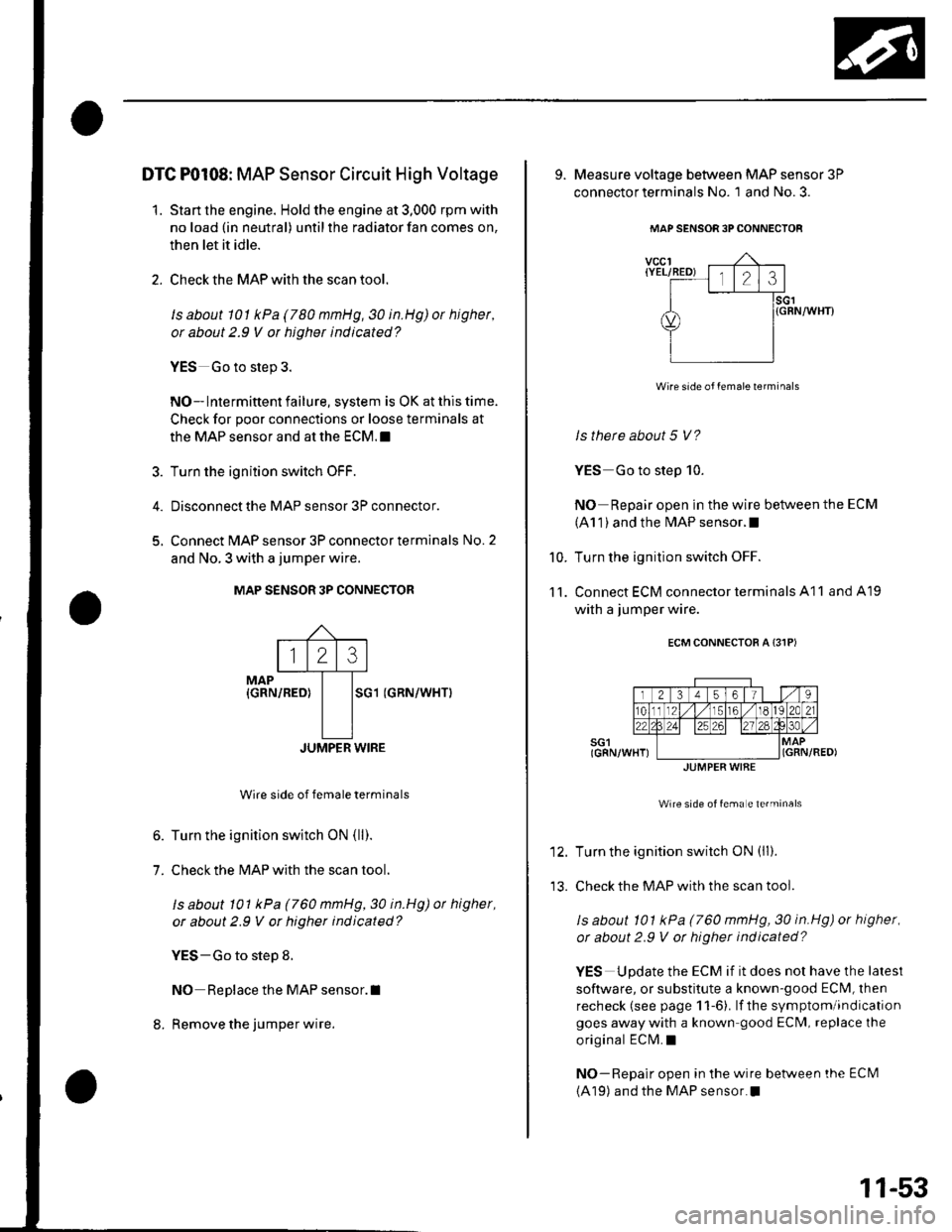

5, Connect MAP sensor 3P connector terminals No. 2

and No. 3 with a jumper wire.

MAP S€NSOR 3P CONNECTOR

MAP{GRN/REO}SG1 (GRN/WHTI

JUMPER WIRE

Wire side of female terminals

6. Turn the ignition switch ON (ll).

7. Check the MAP with the scan tool.

ls about 101 kPa (760 mmHg,30 in.Hg) ot higher,

or about 2.9 V or higher indicated?

YES-Go to step 8.

NO Replace the MAP sensor.I

8. Remove the jumper wire.

123

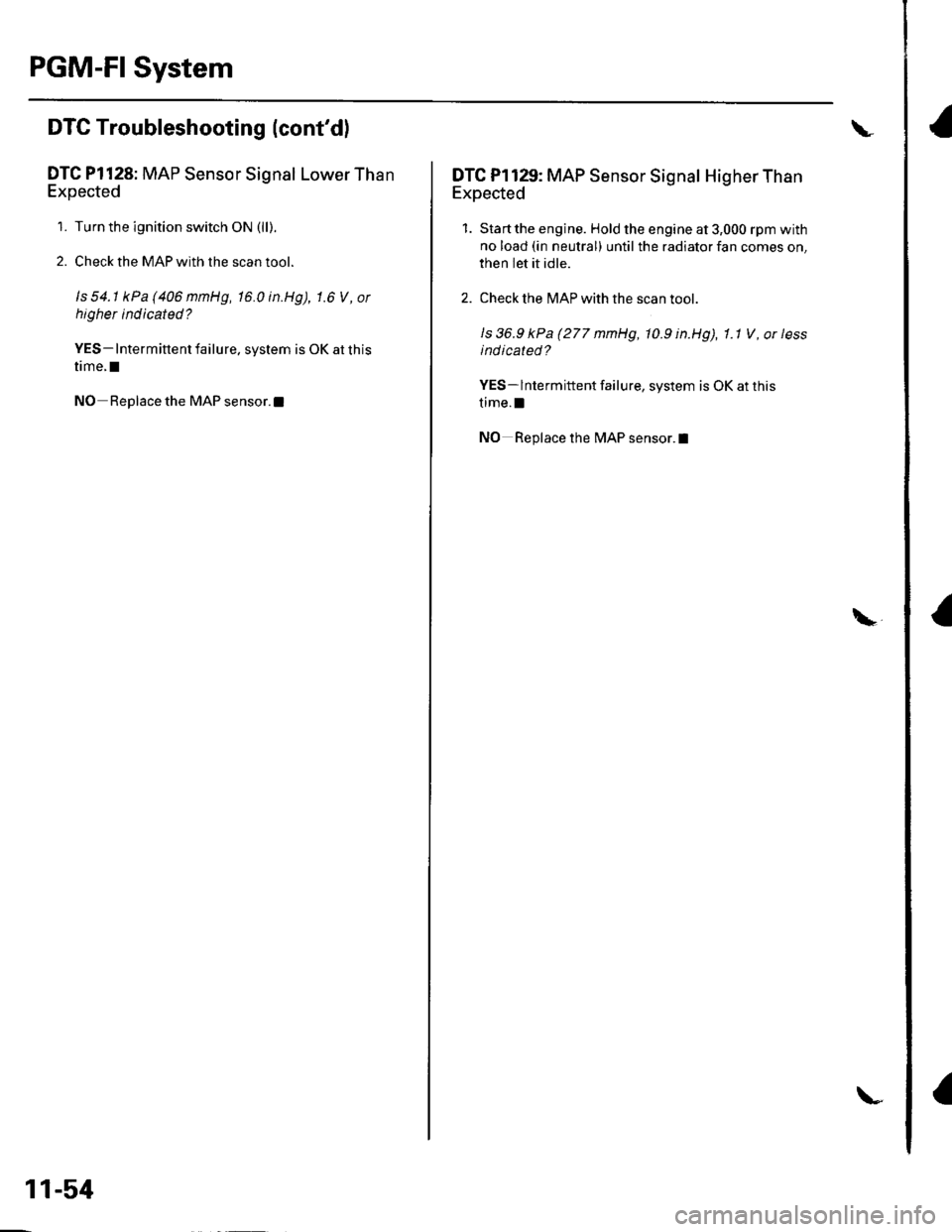

9. Measure voltage between MAP sensor 3P

connector terminals No. 1 and No. 3.

MAP SENSOR 3PCONNECTOF

vccl{YEL/RED) l,lo cll.l.rl

I lsct

d) l{GRN/wHrr

YIilll

Wire side of female lerminals

ls there about 5 V?

YES Go to step 10.

NO Repair open in the wire between the ECM

(A1 1 ) and the MAP sensor.I

Turn the ignition switch OFF.

Connect ECM connector terminals A11 and A19

with a jumper wire.

ECM CONNECTOR A {31PI

Wire side of fema e te.minals

Turn the ignition switch ON (ll).

Check the MAP with the scan tool.

ls about 101 kPa (760 mmHg, 30 in.Hg) or higher,

or about 2.9 V ot higher indicated?

YES Update the ECM if it does not have the lalest

software, or substitute a known-good ECM, lhen

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known good ECM, replace the

original ECM.I

NO-Repair open in the wire betlveen the ECI\il

(A19) and the MAP sensor.I

10.

11.

JUMPER WIAE

11-53

Page 261 of 1139

PGM-FI System

a

DTC Troubleshooting (cont'dl

DTC Pl128: MAP Sensor Signal Lower Than

Expected

1. Turn the ignition switch ON (ll).

2. Check the MAP with the scan tool.

ls 54.1 kPa(406mmHg, 16.0in.Hg), 1.6 V, or

higher indicated?

YES- Intermittent failure. system is OK at this

time.I

NO Replace the MAP sensor.l

11-54

\

\

DTC Pl129: MAP Sensor Signal Higher Than

Expected

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then Iet it idle.

2. Check the MAP with the scan toot.

ls 36.9 kPa (277 mmHg, 10.9 in.Hg), 1.1 V , or less

indicated?

YES- lntermittent failure, system is OK at this

time.l

NO Replace the MAP sensor.l

\

Page 332 of 1139

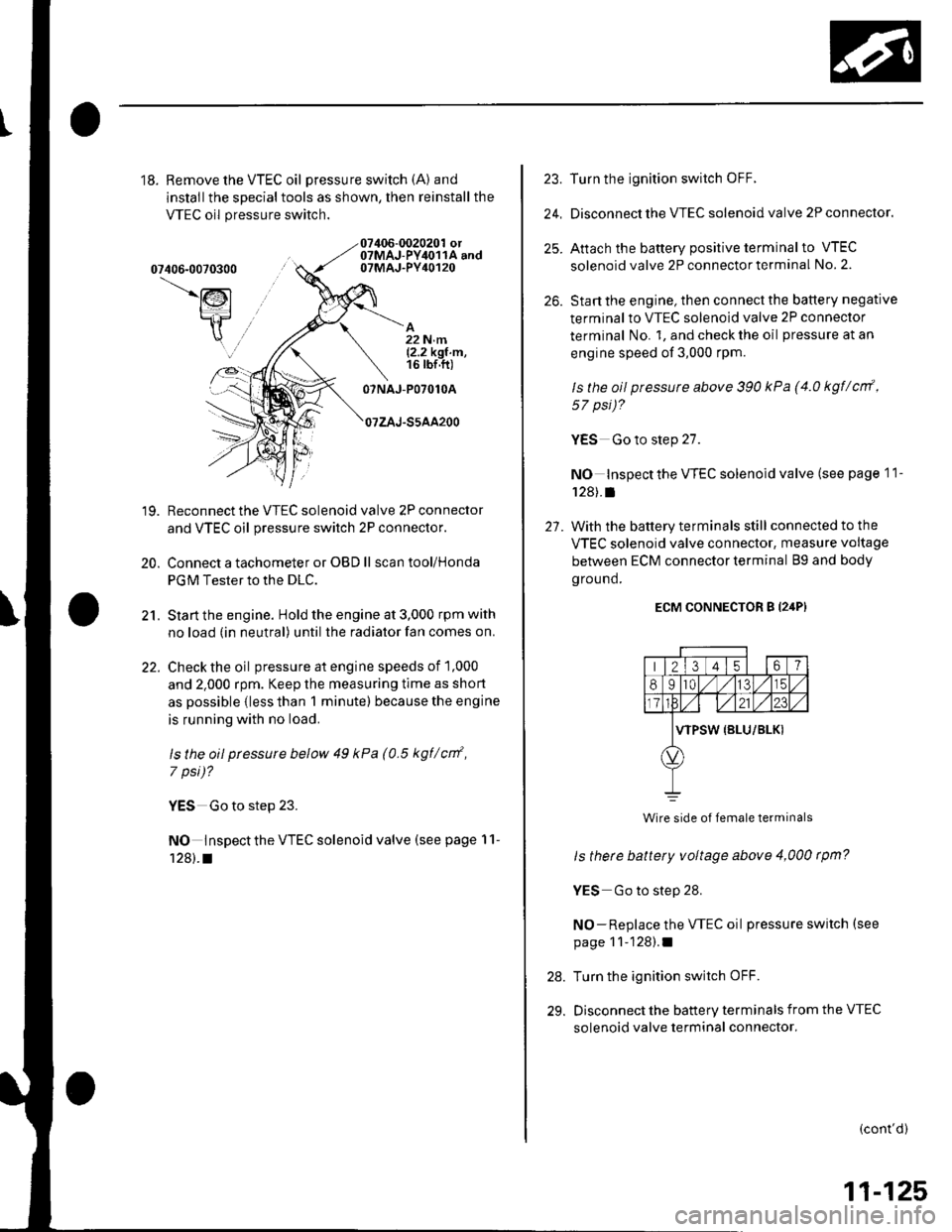

18.Remove the VTEC oil pressure switch (A) and

installthe specialtools as shown, then reinstall the

VTEC oil pressure switch.

07406-0070300

\lsl

t:={

R

07406-0020201 ot07MAJ-PY,lo11A and07MAJ-PY40120

A22 N.ml2.2kgt.m,16 rbf.ft)

19.

20.

21.

22.

07NAJ-P07010A

Reconnect the VTEC solenoid valve 2P connector

and VTEC oil pressure switch 2P connector.

Connect a tachometer or OBD ll scan tool/Honda

PGM Tester to the DLC.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

Checkthe oil pressure at engine speeds of 1,000

and 2.000 rpm. Keep the measuring time as shon

as possible {less than 1 minute) because the engine

is running with no load.

ls the oil ptessure below 49 kPa (0.5 kgf/cnf,

7 psi)?

YES Go to step 23.

NO Inspect the VTEC solenoid valve (see page 11-'t28l.a

23.

24.

25.

26.

Turn the ignition switch OFF.

Disconnect the VTEC solenoid valve 2P connector.

Aftach the battery positive terminalto VTEC

solenoid valve 2P connector terminal No. 2.

Start the engine, then connect the battery negative

terminalto VTEC solenoid valve 2P connector

terminal No. 1, and check the oil pressure at an

engine speed of 3,000 rpm.

ls the oil pressure above 390 kPa (4.0 kgt/crtf ,

57 psi)?

YES Go to step 27.

NO Inspectthe VTEC solenoid valve (see page I1-

12Al.a

27. With the battery terminals still connectedtothe

VTEC solenoid valve connector, measure voltage

between ECM connector terminal 89 and bodv

oround.

ECM CONNECTOR B {24P)

ls there battery voltage above 4,000 tpm?

YES Go to step 28.

NO-Replace the VTEC oil pressure switch (see

page 11'128).1

Turn the ignition switch OFF.

Disconnect the battery terminals from the VTEC

solenoid valve terminal connector.

(cont'd)

28.

29.

Wire side of female terminals

11-125

Page 352 of 1139

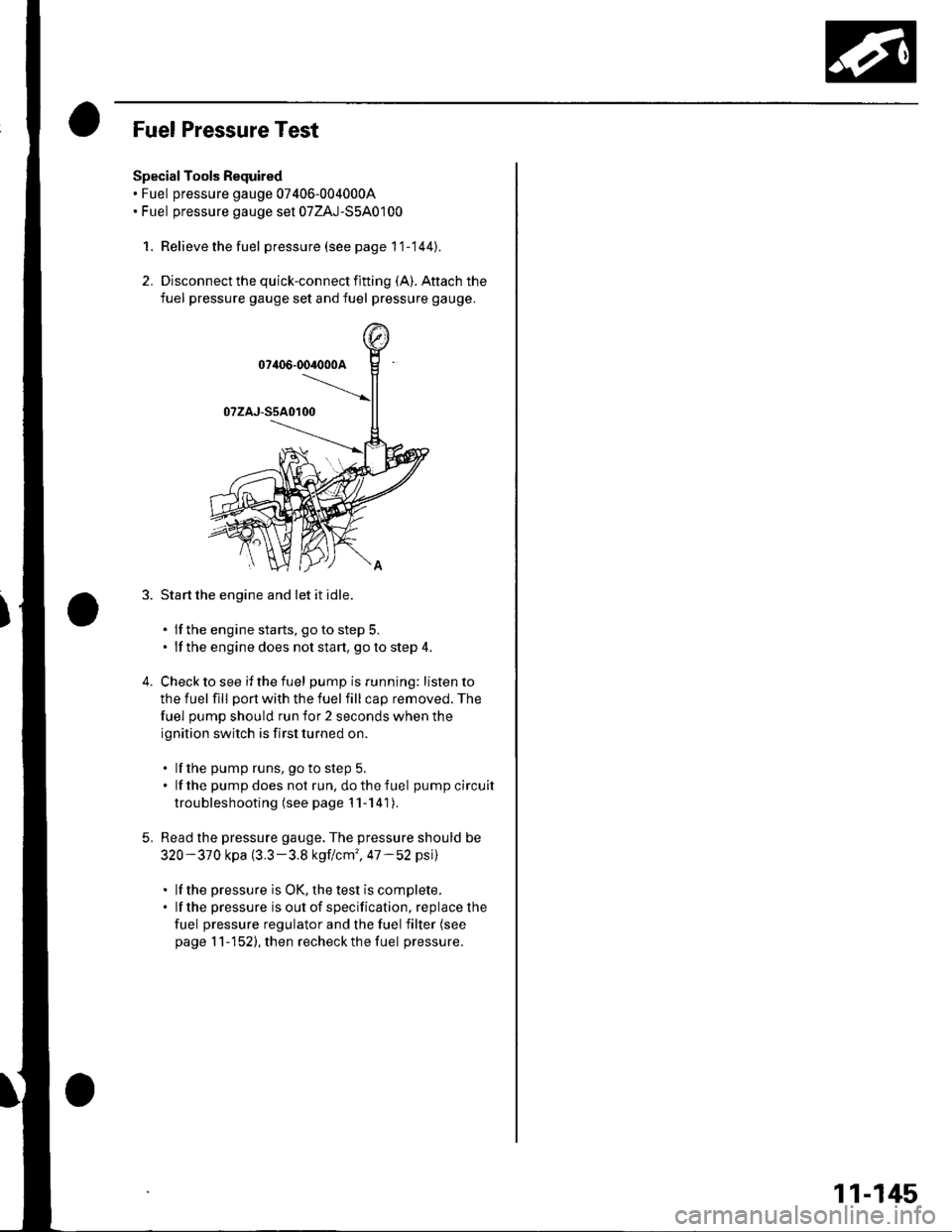

Fuel Pressure Test

Special Tools Required. Fuel pressure gauge 07406-0040004. Fuel pressure gauge sel 07ZAJ-S5A0100

1. Relieve the fuel pressure (see page 1'1-144).

2. Disconnect the quick-connect fitting (A). Aftach the

fuel pressure gauge set and fuel pressure gauge.

Start the engine and let it idle.

. lf the engine starts, goto step 5.. lf the engine does not start, goto step 4.

Check to see if the fuel pump is running: listen to

the fuel fill port with the fuel fill cap removed. The

fuel pump should run for 2 seconds when the

ignition switch is first turned on.

. lf the pump runs, go to step 5.. lf the pump does not run, do the fuel pump circuit

troubleshooting (see page 1 1-1 41 ).

Read the pressure gauge. The pressure should be

320-370 kpa (3.3-3.8 kgf/cm', a7-52 psi)

. lf the pressure is OK, the test is complete.. lf the pressure is out of specification, replace the

fuel pressure regulator and the fuel filter (see

page 11-152), then recheck the fuel pressure.

5.

11-145

Page 359 of 1139

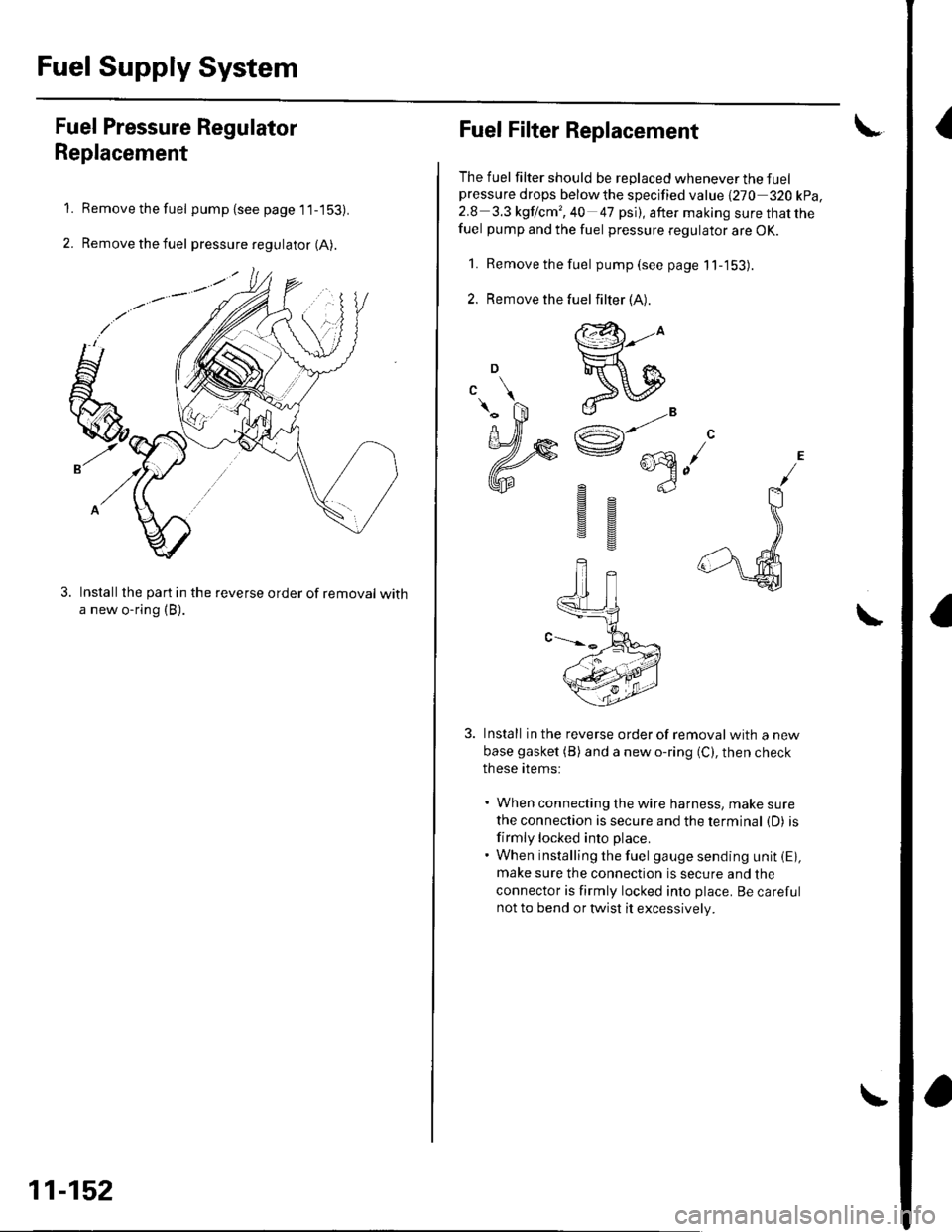

Fuel Supply System

{Fuel Pressure Regulator

Replacement

Remove the fuel pump (see page 1 1-153).

Remove the fuel pressure regulator (A).

Installthe part in the reverse order of removal witha new o-ring (B).

1.

2.

11-152

Fuel Filter Replacement

The fuel filter should be replaced whenever the fuelpressure drops belowthe specified value {270 320 kpa,2.8 3.3 kgf lcm', 40 47 psi), after making sure that thefuel pump and the fuel pressure regulator are OK.

1. Remove the fuel pump(seepagell-'153).

2. Remove the

Install in the reverse order of removalwith a new

base gasket (B) and a new o-ring (C), then check

these items:

' When connecting the wire harness, make sure

the connection is secure and the terminal (D) is

firmly locked into place.. When installing the fuel gauge sending unit iE),make sure the connection is secure and the

connector is firmly locked into place. Be carefulnot to bend or twist it excessively.

\

fuel filter (A).

@-to

ReIJ

e"^AR^ ...\e @n-)

gs

sg

Page 386 of 1139

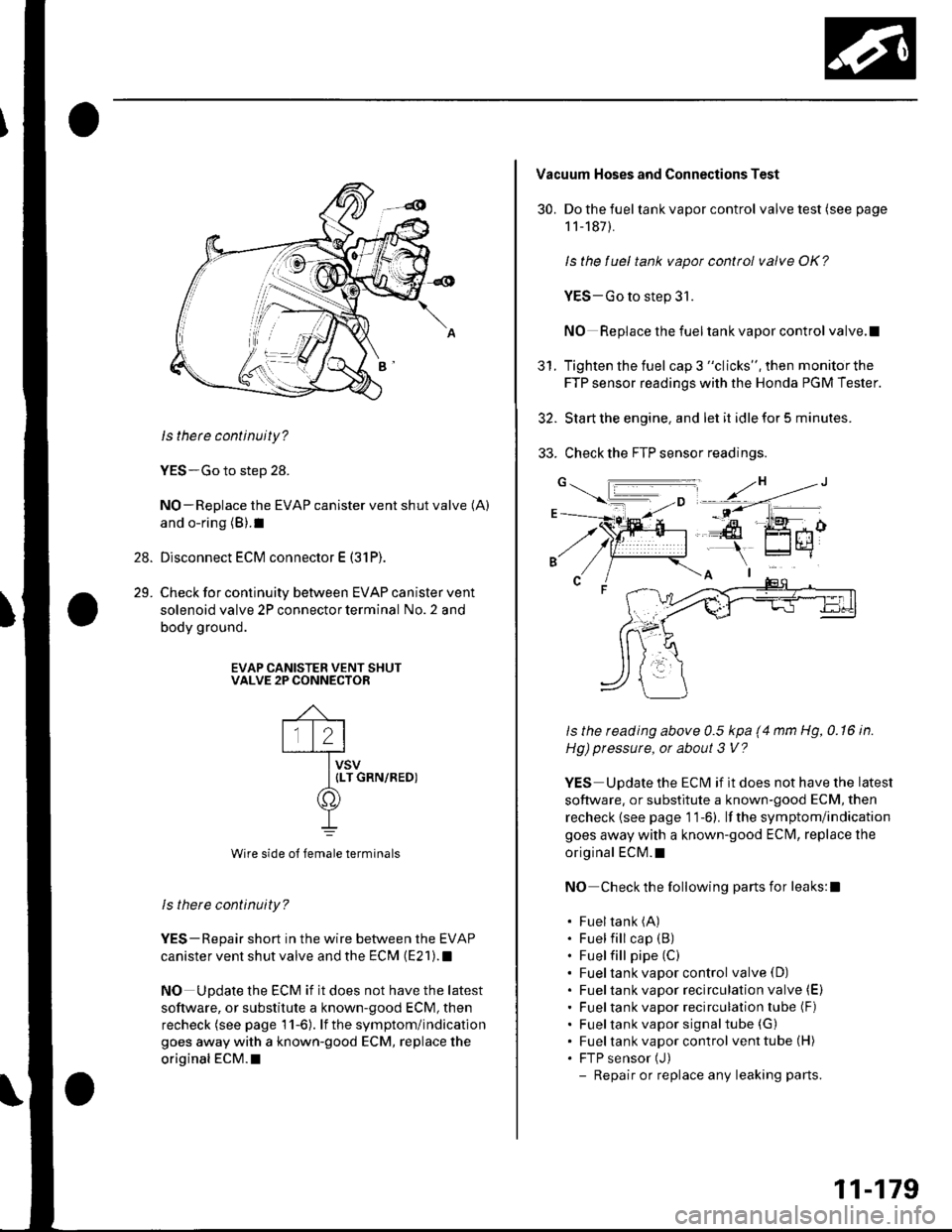

28.

29.

ls thete continuity?

YES-Go to step 28.

NO-Replace the EVAP canister vent shut valve (A)

and o-ring (B).1

Disconnect ECM connector E (31P).

Check for continuity between EVAP canister vent

solenoid valve 2P connector terminal No. 2 and

body ground.

EVAP CANISTER VENT SHUTVALVE 2P CONNECTOR

Wire side o{ female terminals

ls there continuity?

YES-Repair short in the wire between the EVAP

canister vent shut valve and the ECM (E21).1

NO Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

30.

Vacuum Hoses and Connections Test

Do the fuel tank vapor control valve test (see page

1 1-187).

ls the fuel tank vapot control valve OK?

YES-Go to step 31.

NO Replace the fueltank vapor control valve.l

Tighten the fuel cap 3 "clicks", then monitorthe

FTP sensor readings with the Honda PGM Tester.

Start the engine. and let it idle for 5 minutes.

Check the FTP sensor readings.

ls the reading above 0.5 kpa (4 mm Hg, 0.16 in.

Hg) pressure, or about 3 V?

YES Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck {see page 1 1-6). lf the symptom/indication

goes away with a known-good ECfvl, replace the

original ECM.t

NO Check the following parts for leaks:l

. Fueltank (A)

. Fuel fill cap (B)

. Fuel fill pipe (C)

. Fueltank vapor control valve(D). Fueltank vapor recirculation valve (E)

. Fueltank vapor recirculation tube (F)

. Fueltank vapor signaltube (G)

. Fueltank vapor control venttube(H). FTP sensor (J)

- Repair or replace any leaking parts.

5t.

11-179

Page 393 of 1139

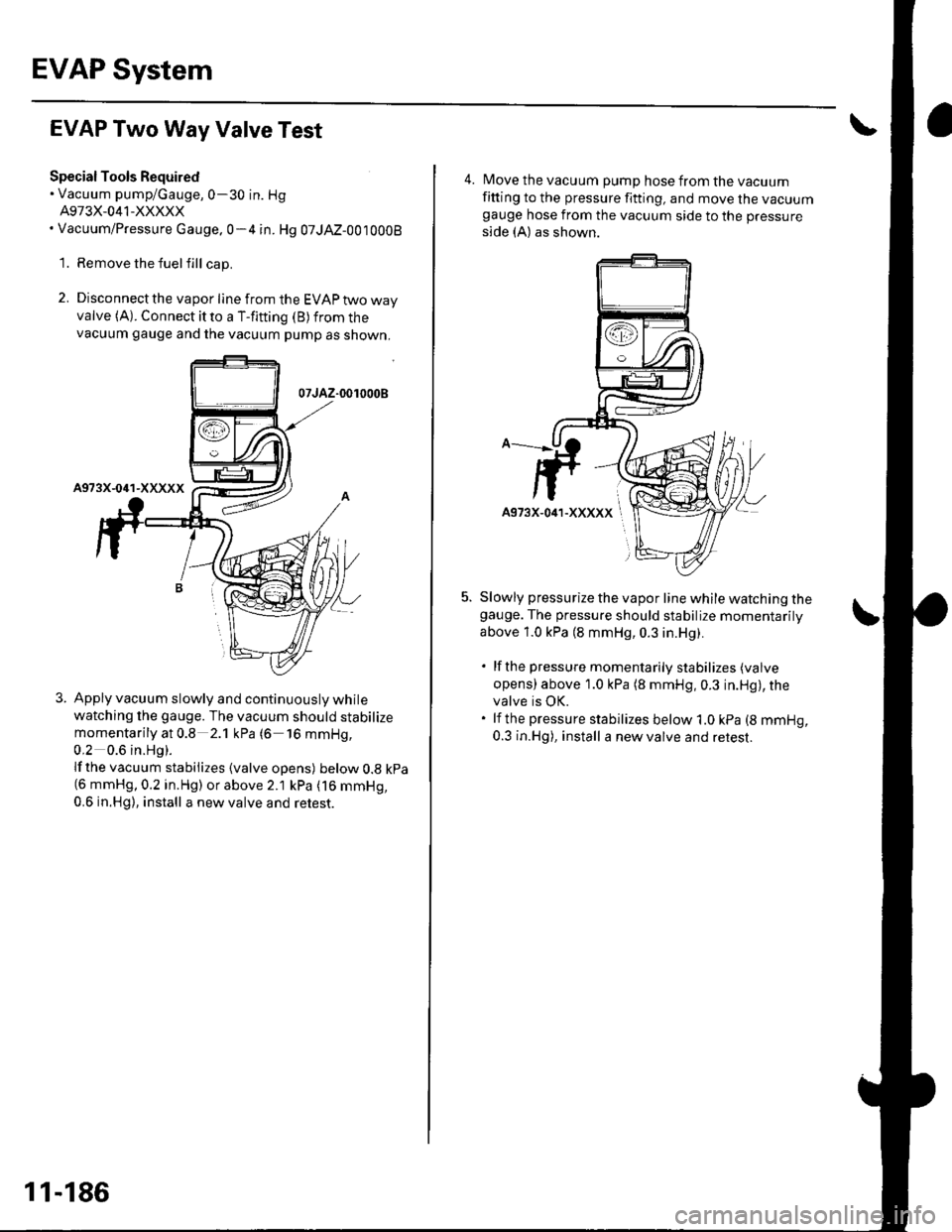

EVAP System

EVAP Two Way Valve Test

Special Tools Required. Vacuum pump/Gauge,0-30 in. Hg

A973X-041-XXXXX. Vacuum/Pressure cauge.0-4 in. Hg 07JAZ-0010008

1. Remove the fuelfill cap.

2. Disconnect the vapor line from the EVAP two wayvalve (A). Connect it to a T-fitting (B) from thevacuum gauge and the vacuum pump as shown,

07JAZ-0010008

Apply vacuum slowly and continuously while

watching the gauge. The vacuum should stabilize

momentarily at 0.8 2.1 kPa (6 16 mmHg,

0,2 0.6 in.Hg).

lf the vacuum stabilizes {valve opens) below 0.8 kpa(6 mmHg,0.2 in.Hg) or above 2.1 kPa (16 mmHg,

0.6 in.Hg), install a new valve and retest.

11-186

4. Move the vacuum pump hose from the vacuumfitting to the pressure fitting, and move the vacuumgauge hose from the vacuum side to the pressure

side (A) as shown.

Slowly pressurize the vapor line while watching thegauge. The pressure should stabilize momentarilV

above 1.0 kPa (8 mmHg, 0.3 in.Hg).

. lfthe pressure momentarily stabilizes (valve

opens) above 1.0 kPa (8 mmHg,0.3 in.Hg), thevalve is OK.. lf the pressure stabilizes below 1.0 kPa (8 mmHg,

0.3 in.Hg), install a new valve and retest.

Page 562 of 1139

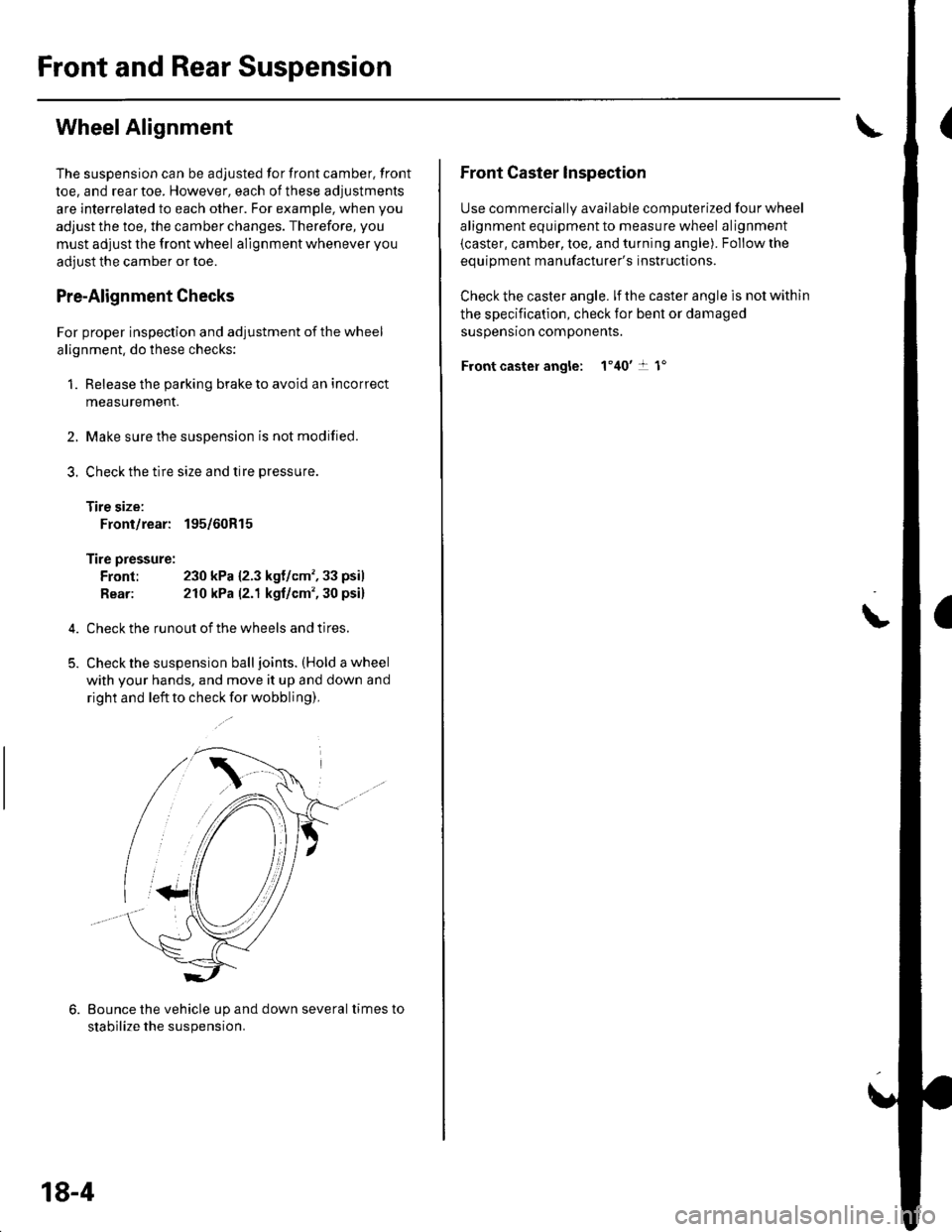

Front and Rear Suspension

WheelAlignment

The suspension can be adjusted for front camber, front

toe, and rear toe. However, each of these adjustments

are interrelated to each other. For example, when you

adjust the toe, the camber changes. Therefore, you

must adjust the front wheel alignment whenever you

adjust the camber or toe.

Pre-Alignment Checks

For proper inspection and adjustment of the wheel

alignment, do these checks:

1. Release the parking brake to avoid an incorrect

measurement.

Make sure the suspension is not modified.

Check the tire size and tire pressure

Tire size:

Front/rear: 195/60R15

Tire pressure:

Front: 230 kPa {2.3 kgf/cm',33 psil

Rear: 210 kPa |'2.1 kgf/cm', 30 psi)

Check the runout of the wheels and tires.

Check the suspension ball joints. (Hold a wheel

with your hands, and move it up and down and

right and left to check for wobbling),

2.

3.

Bounce the vehicle up and down several times to

stabilize the suspension.

18-4

Front Caster lnspection

Use commerciallv available comDuterized four wheel

alignment equipment to measure wheel alignment

(caster, camber, toe, and turning angle). Follow the

eouioment manufacturer's instructions.

Check the caster angle. lf the caster angle is not within

the specification, check for bent or damaged

susoensron comoonents.

Front caster angle: 1'40't 1"

\

Page 611 of 1139

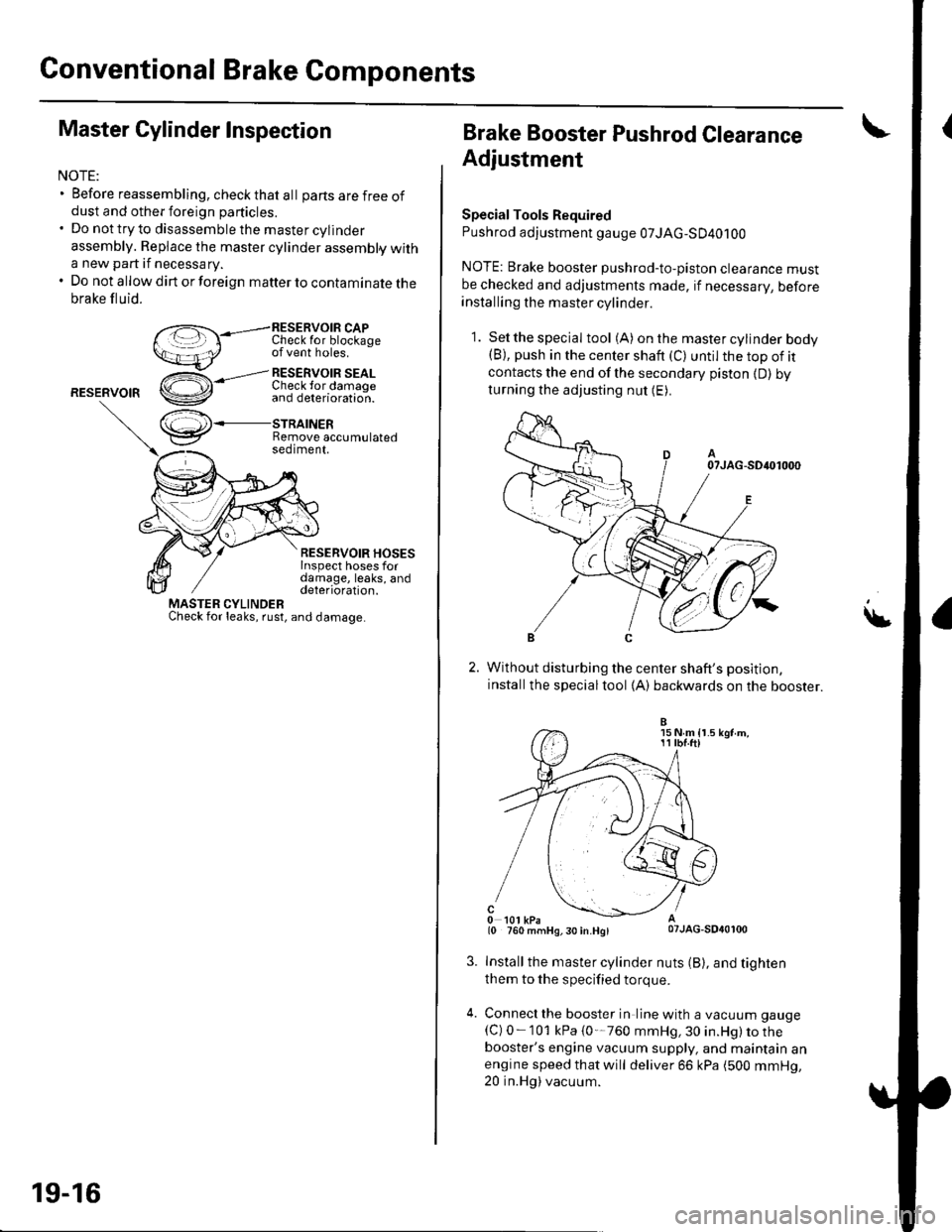

Conventional Brake Components

Master Cylinder Inspection

NOTE:. Before reassembling, check that al I parts are f ree ofdust and other foreign particles.. Do nottryto disassemblethe mastercylinder

assembly. Replace the master cylinder assembly witha new part if necessary.. Do not allow dirt or foreign matter to contaminate thebrake fluid.

RESERVOIB CAPI unecK Ior otocKageof vent holes.

RESERVOIR

,--l RESERvOIR SEALCheck lor damaoe

RESERVOIR HOSESInspect hoses fordamage, leaks, anddeterioration.

r',,.J\+

v

MASTER CYLINDERCheck for leaks, rust, and damage

and deterioration.

STRAINERRemove accumulatedseotment.

19-16

Brake Booster Pushrod Clearance

Adjustment

SpecialTools Required

Pushrod adjustment gauge 07JAG-SD40100

NOTE: Brake booster pushrod-to-piston clearance mustbe checked and adjustments made, if necessarV, beforeinstalling the master cylinder.

1. Setthespecial tool (A) onthe mastercylinder bodv(B), push in the center shaft (C) until the top of itcontacts the end of the secondary piston {D) byturning the adjusting nut (E).

Without disturbing the center shaft's position,

installthe specialtool (A) backwards on the booster.

Install the master cylinder nuts (B), and tighten

them to the specified torque.

Connecl the booster in line with a vacuum gauge

{C) 0-101 kPa {0'-760 mmHg, 30 in.Hg) to thebooster's engine vacuum supply, and maintain anengine speed that will deliver 66 kPa (500 mmHg,20 in.Hg) vacuum.

15 N m {r.511 tbf.ftl

Page 784 of 1139

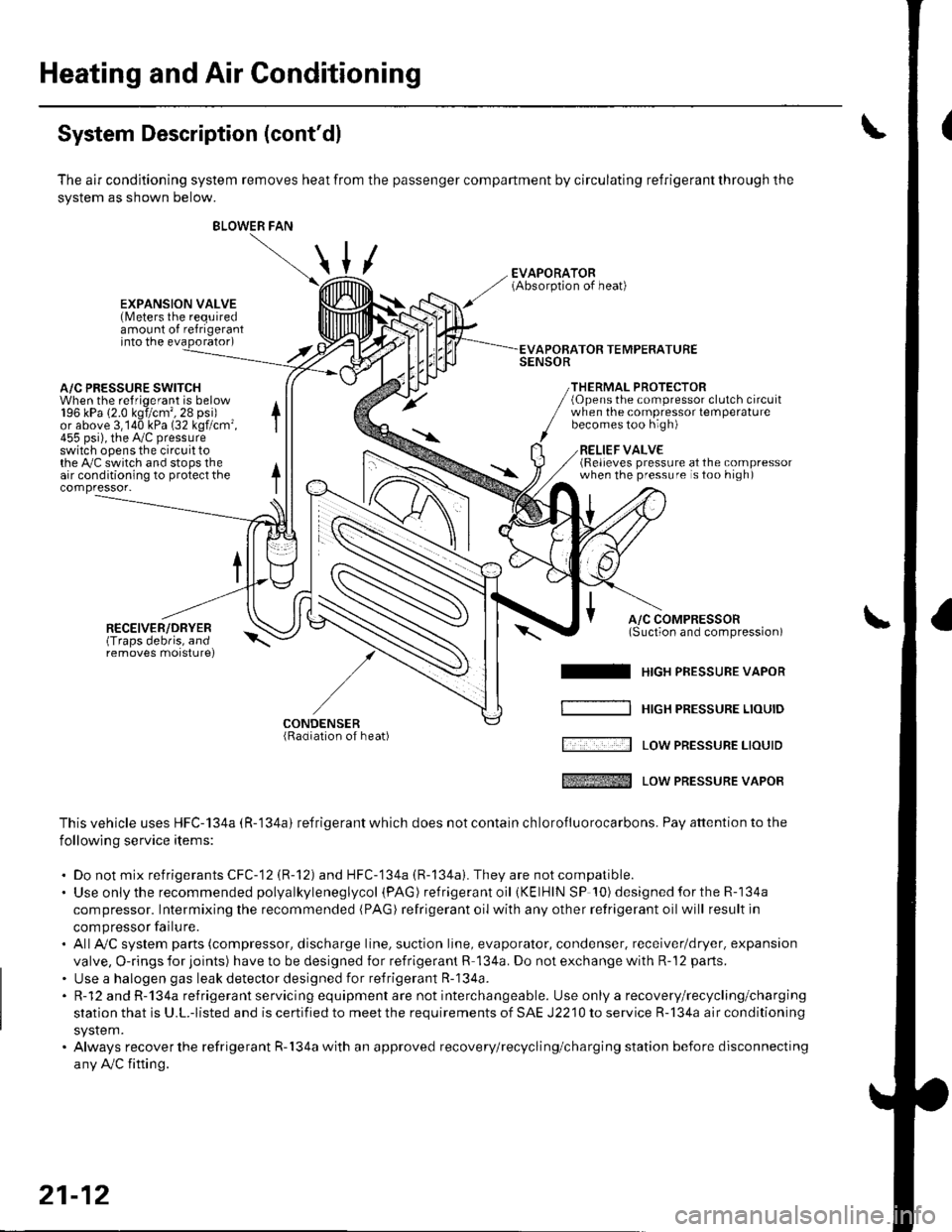

Heating and Air Gonditioning

System Description (cont'dl

The air conditioning system removes heat from the passenger compartment by circulating refrigerant through the

system as shown below.

/

BLOWER FAN

\

\,u

EXPANSION VALVE(Meters the requiredamount of refrigerantinto the evaporator)

A/C PRESSURE SWITCHWhen the refriqerant is below196 kPa (2.0 kgi/cm',28 psi)or above 3,140 kPa (32 kgf/cm'455 psi), the Py'c pressureswitch opens the circuit tothe Py'C switch and stops theair conditioning to protect thecompressor-

RECEIVER/DRYER(Traps debris, andremoves morsturel

APOBATOR TEMPERATURESENSOR

THERMAL PROTECTOR(Opens the compressor clutch circuitwhen the compressot temperaturebecomes too high)

RELIEF VALVE(Relieves pressure at the compressorwhen the pressure is too high)

A/C COMPRESSOR(Suction and comoression)\-^

I HrcH PRESSURE vAPoR

[ '.... -:--l Low PREsSUBE LrourD

tffi Low PREssURE vAPoR

This vehicle uses HFC-134a (R-'134a) refrigerant which does not contain ch lorofluorocarbons. Pay attention to the

following service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are notcompatible.. Use onlythe recommended polyalkyleneglycol (PAG ) refrigera nt oil (KElHlN SP '!0) designedfortheR-134a

compressor. Intermixing the recommended (PAG) refrigerant oil with any other retrigerant oil will result in

compressor failu re.. AllAy'C system parts (compressor, discharge line, suction line, evaporator, condenser, receiver/dryer. expansion

valve, O-rings for joints) have to be designed for refrigerant R 134a. Do not exchange with R-'12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging

station that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning

system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting

any Ay'C fifting.

/-

CONDENSER(Radiation of heat)

21-12