oil pressure HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 214 of 1139

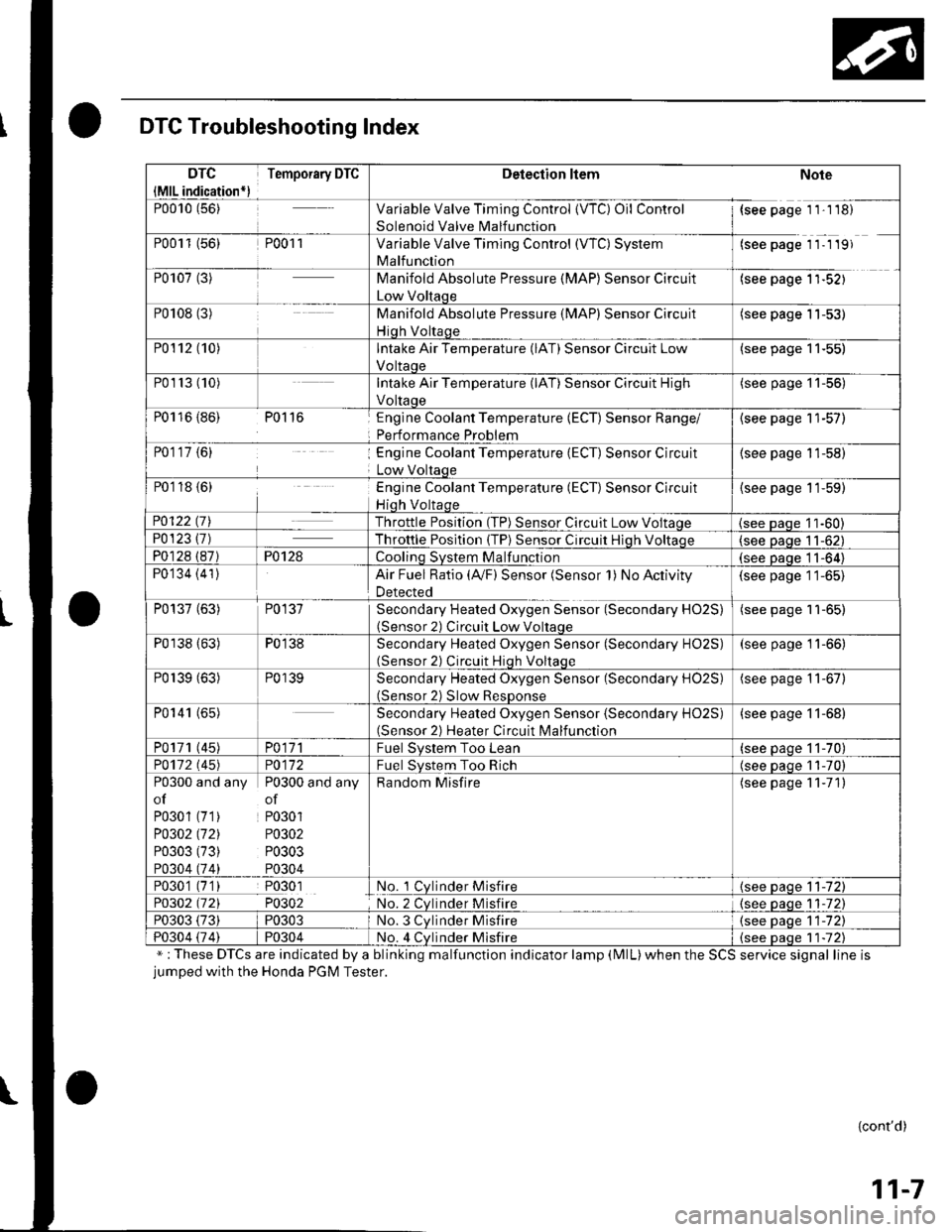

DTC Troubleshooting Index

";These DTCs are indicated by a blinking malfunction indicator lamp (MlL)when the SCS service signal line isjumped with the Honda PGM Tester.

{cont'd)

11-7

DTC

{MlL indication*)

Temporary DTCDetection ltemNote

P0010 (56)Variable Valve Timing Control {VTC) Oil Control

Solenoid Valve Malfunction

{see page 1 1'1 18)

P0011 (56)P001 1Variable Valve Timing Control (WC) System

Malfunction

(see page 11- 1 19)

P0107 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Low Voltaqe

(see page 1'l-521

P0108 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Hiqh Voltaqe

(see page 11-53)

P0112 (10)Intake Air Temperature (lAT) Sensor Circuit Low

Voltaoe

(see page 11-55)

P01r3 (10)Intake Air Temperature (lAT) Sensor Circuit High

Voltaoe

(see page '11-56)

P0116 {86) P0116Englne Coolant Temperature (ECT) Sensor Range/

Performance Problem

{see page 11-57)

P0117 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Low Voltaqe

(see page 11-58)

P0118 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Hiqh Voltaqe

{see page 11-59)

P0122 t7\Throttle Position (TP) Sensor Circuit Low Voltaqe(see Daqe 11-60)P0123 {7)Throttle Posltion (TP) Sensor Circuit Hiqh Voltaoe(see paqe 11-62)

P0128 (87)P0128Coolinq SVStem Malfunction(see Daqe 11-64)

P0134 (41)Air Fuel Ratio (Ay'F) Sensor (Sensor 1) No Activity

Detected

(see page 11-65)

P0137 (63)P0137Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Low Voltaqe

(see page 11-65)

P0138 (63)P0138Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Hiqh Voltaqe

(see page 11-66)

P0139 (63)P0139Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Slow ResDonse

(see page 11-67)

P0141 (65)Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Heater Circuit Malfunction

(see page 11-68)

P0171 (45)PO\11Fuel Svstem Too Lean(see paqe 11-70)

PO112 l'45)PO\l2Fuel System Too Rich(see oaoe 11-70)

P0300 and any P0300 and any

of of

P0301 (71) P0301

PO302 (721 P0302

P0303 (73) P0303

P0304 (74) P0304

Random Misfire(see page 11-71)

P0301 (7'1) P0301No. 1 Cylnder Misfire{see page 11-72)

P0302 (721 P0302No. 2 Cvlnder Misfire{see paqe 1 1-72)

P0303 (73)P0303No. 3 Cvlnder Misfire(see oaqe 11-72)

P0304 {74)P0304No. 4 Cvlnder Misfire{see Daqe 1 1-72)

Page 217 of 1139

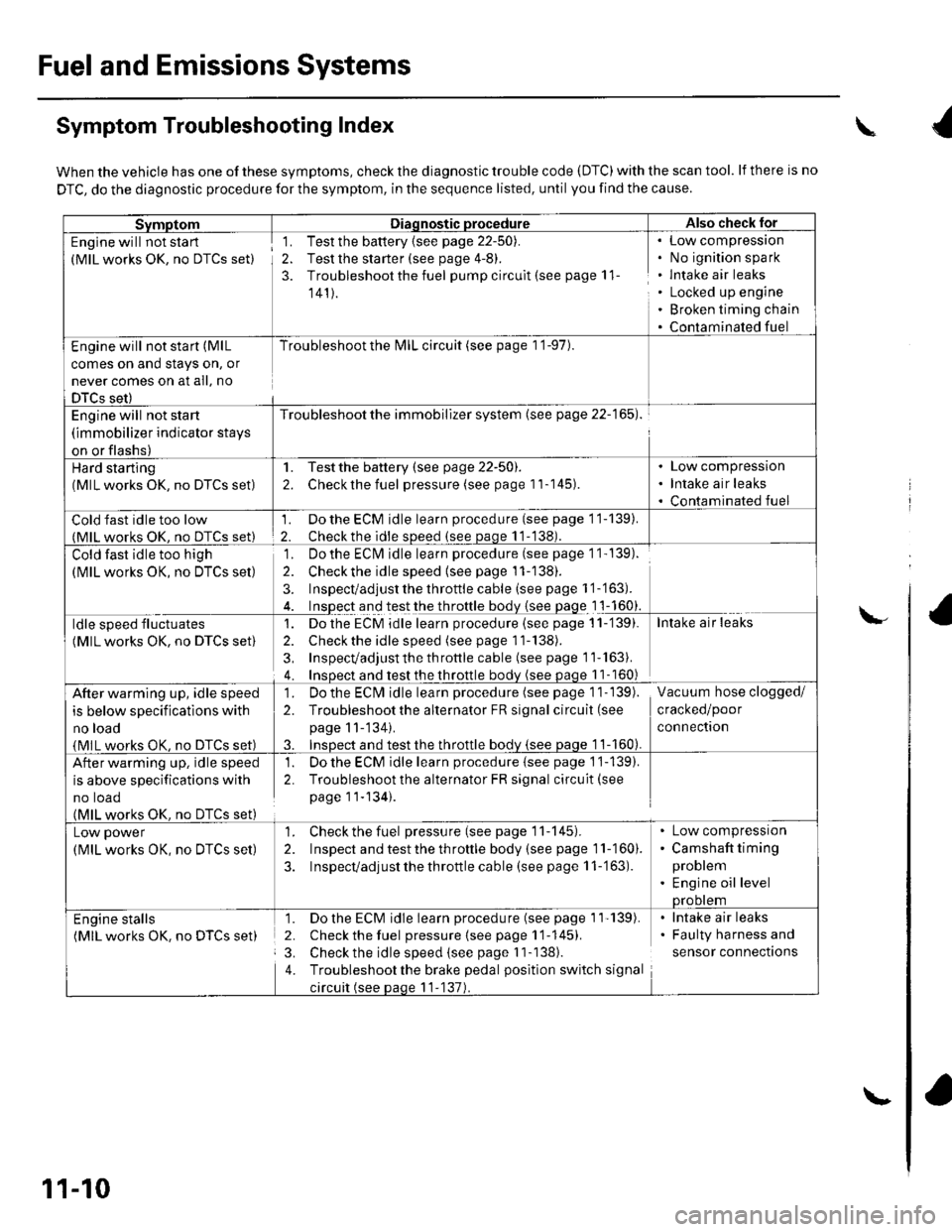

Fuel and Emissions Systems

Symptom Troubleshooting Index

When the vehicle has one of these symptoms, check the diagnostic trouble code (DTC) with the scan tool. lf there is no

DTC, do the diagnostic procedure for the symptom, in the sequence listed, until you find the cause.

SvmotomDiaqnostic procedureAlso check lor

Engine will not sta rt

(MlL works OK, no DTCS set)

1. Test the battery {see page 22-50).

2. Test the starter (see page 4-8).

3. Troubleshoot the fuel pump circult (see page 11

141).

Low compressron

No ignition spark

lntake air leaks

Locked up engine

Broken timing chain

Contaminated fuel

Engine will not start (MlL

comes on and stays on, or

never comes on at all, no

DTCS set)

Troubleshoot the l\4lL circuit (see page 1 '1-97).

Engine will not start

(immobilizer indicator stays

on or flashs)

Troubleshoot the immobilizer system (see page 22-165).

Hard starting(MlL works OK, no DTCS set)

1. Testthe battery (see page 22-50).

2. Checkthe fuel pressure (see page 11-145).

Low compression

Intake air leaks

Contaminated fuel

Cold fast idle too low(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 11-139).

2. Checkthe idle sDeed (see paqe 11-138).

Cold fast idle too high

(MlL works OK, no DTCS set)

Do the ECI\4 idle learn procedure (see page 1 1- 139).

Checkthe idle speed {see page 11-138).

Inspect/adjust the throttle cable (see page 1 '1-'163).

Inspect and test the throttle body {see page 1 1-160}.

']�

2.

3.

ldle speed fluctuates

(MlL works OK, no DTCS set)

1. Dothe ECM idle learn procedure (see page 11-'139).

2. Check the idle speed (see page 11-138).

3, Inspecvadjust th e throttle cable (see page 11''163).

4. Insoect and test the throttle bodv (see paqe 11- 160)

Intake air leaks

After warming up, idle speed

is below specifications with

no load

{MlL works OK, no DTCS set)

1. Do the ECIVI idle learn procedure (see page 1 1- 139).

2. Troubleshootthe alternator FR signal circuit (see

page 11-'134).

3. InsDect and test the throttle bodv {see paqe 1 1-160).

Vacuum hose clogged/

cracked/poor

connectron

After warming up, idle speed

is above specifications with

no toao(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure {see page 1'j-139).

2. Troubleshoot the alternator FR signal circuit(see

page 11-134).

Low power

(MlL works OK, no DTCS set)

1. Check the fuel pressure(seepagell-145).

2. Inspect and test the th roftle body (see page 11-160).

3. Inspecvadjust the throttle cable (see page 11-'163).

Low compressron

Camshaft timing

problem

Engine oil levelprootem

Engine stalls(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 1'l'139).

2. Check the fuel pressure{seepagell-145).

3. Check the idle speed (see page I 1-138).

4. Troubleshootthe brake pedal position switch signal

circuit (see paqe 11-137).

lntake air leaks

Faulty harness and

sensor connections

\

\-

11-10

\-

Page 227 of 1139

![HONDA CIVIC 2002 7.G User Guide Fuel and Emissions Systems

System Descriptions {contd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV

HONDA CIVIC 2002 7.G User Guide Fuel and Emissions Systems

System Descriptions {contd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV](/img/13/5744/w960_5744-226.png)

Fuel and Emissions Systems

System Descriptions {cont'd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV

'15

TPS16AFS_18

VSS

19IVAP20vcc221vccl

22AFSHTC+

23LG225

Ct\.4PA

26CMPB(rDc)

27IGPLS428IGPLS329IGPLS230IGPLS,I

NOTE: Standard battery voltage is 12 V.

JorminalnumberWirecolor[€rminal namoDescriptionSignal

19GRN/REDMAP (MANIFOLDABSOLUTE PRESSURESENSOR)

Detects MAP sensor signalWith ignition switch ON (ll):about3 VAt idle: about 1.0 V (depending on enginespeed)

20YEUBLUVCC2 (SENSOR VOLTAGE)Provides sensor voltageWith ignition switch ON {ll): about 5 VWith ionition switch OFF: about0V21YEUREDVCC] (SENSOB VOLTAGE)Provides sensor voltageWith ignition switch ON {ll): about 5 VWith ionition switch OFF: about0V22AFSHTC - (AIR FUELRATIO (A"iFiSENSORHEATER CONTROL + SIDE)

Detects a,/F sensor heatervoltageWith ign;tion switch ON lll): banery voltage

23BRN?ryE LLG2 (LOGIC GROUNDround for the ECM circuLessthan 1.0 V at alltimes24BRN?ryE L1(Lround for the ECM circuLess than '1.0 V at alltimes25B LU,^/VHTCMP A (CAMSHAFT

POSITION SENSOR A)Detects CMP sensor AstonalWith engine running: pulses

26GRNCMP B CAMSHAFTPOSITION (CMP)SENSOBB (TDC (TOP DEAD CENTERSENSORi)

Detects CMP sensor 8 (TDc

sensor)With engine running: pulses

27BRNIGPLS4 {No. 4IGNITIONCOIL PULSE)Drives No, 4 ignition coiWith ignition switch ON (ll)r about 0 vWith engine running: pulses28WHT/BLUIGPLS3 {No.3IGNITIONCOIL PULSE)Orives No.3 rgnition coi

29BLU/REDlGPLS2lNo.2 IGNITIONCOIL PTJLSE)Drives No.2 ignition coil

30YEUGRNIGPLSI (No. 1 IGNITIONco

PlltsF)Drives No. I ignition coil

11-20

\.

a

a

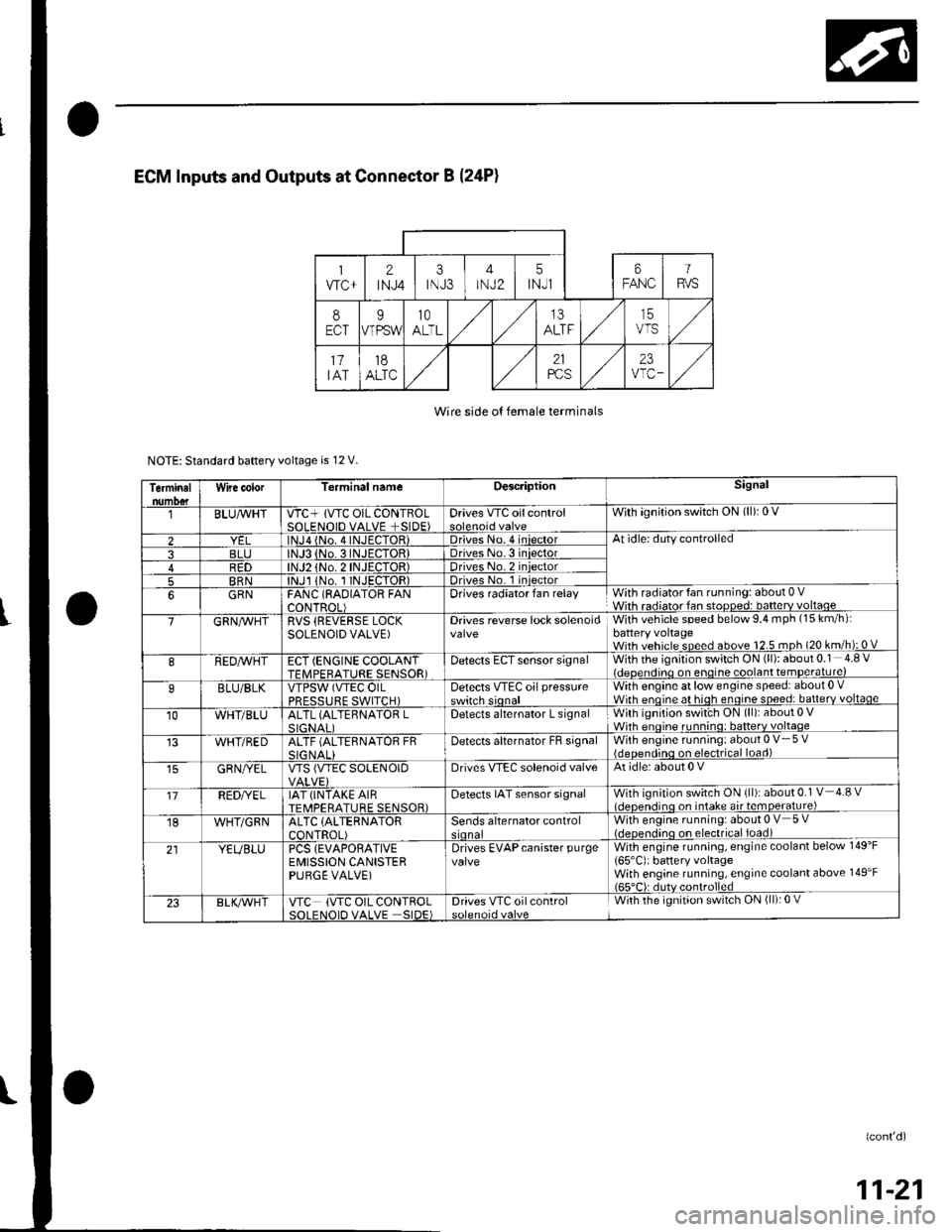

Page 228 of 1139

Wire side o{ female terminals

NOTE: Standard baftery voltage is 12 V.

Terminalnumo€tWire color[erminal nameDescriptionSignal

BLUAvHTVTC+ lVTC OIL CONTBOLSOLENOID VALVE +SIDE)Drives VTC oilcontrolWith ignition switch ON (ll): 0 V

2lNJa {No. 4INJECTOR)Driveso. 4 iniectorAt idle: duty controlled

3BLJo.3INJECTORIDriveso.3 iniector4R1)TOR)Driveso.2 iniector

5BRNlNJl 1No. I INJECTOR)Drives No. 1 iniector

6GRNFANC (RAOIATOR FANCONTROL)Drives radiator fan relayWith radiator fan running: about 0 VWith radiator fan stopped: batterv voltaoe

7GRN/vVHTRVS (REVERSE LOCKSOLENOID VALVE)Drives reverse lock solenoidWith vehicle speed below 9.4 mph (15 km/h):battery voltageWith vehicle speed above 12.5 mph (20 km/h): 0 V

8REDAVHTECT (ENGINE COOLANTTFMPFRATURE SENSOR)Detects ECT sensor signalWith the ignition switch ON (ll): about 0.1 4.8 Videoendino on enoine coolant temDerature)

9BLU/BLKVTPSW (VTEC OILPRFSSTIRF SWITCH)Detects VTEc oil pressureswitch sionalWith engine at low engine speed: about 0 .Wirh enoine at hioh enoine soeed: batterv voltaqe

10WHT/BLUALTL (ALTEBNATOR LSIGNAI IDetects alternator L signalWith ignition swit'ch ON (ll): about 0 VWhh enoine runnino: batterv voltaqe

WHT/REDALTF (ALTERNATOR FRSIG NALIDetecls alternator FB signalWith engine running: about 0 V- 5 V{deoendinq on electrical load)

GRN/YELVTS {VTEC SOLENOIDDrives VIEC solenoid valveAt idle: about 0 V

'17REDI/ELIAT (INTAKE AIRTEMPERATURE SENSOR)Detects IAT sensor signalWith ignition switch ON {ll): about 0.1 V 4.8 vl.lcnen.iino on intake air temoerature)

18WHT/GRNALTC (ALTERNATOR

CONTROL)Sends alternator controlWith engine running: about 0 V 5 V(.lcocn.lino on electrical ioad)

21YEUBLUPCS {EVAPORATIVEEMISSION CANISTERPURGE VALVE)

Drives EVAPcanister purgevalveWith engine running, engine coolant below 149'F

165'C): battery voltageWith engine running, engine coolant above 149'F165"C): dutv controlled

23BLK/Vr'HTVTC (VTC OIL CONTROLSOI FNOID VALVE SIDE)Drives VTC oilcontrolWith the ignition switch ON (ll): 0 V

(confd)

11-21

Page 236 of 1139

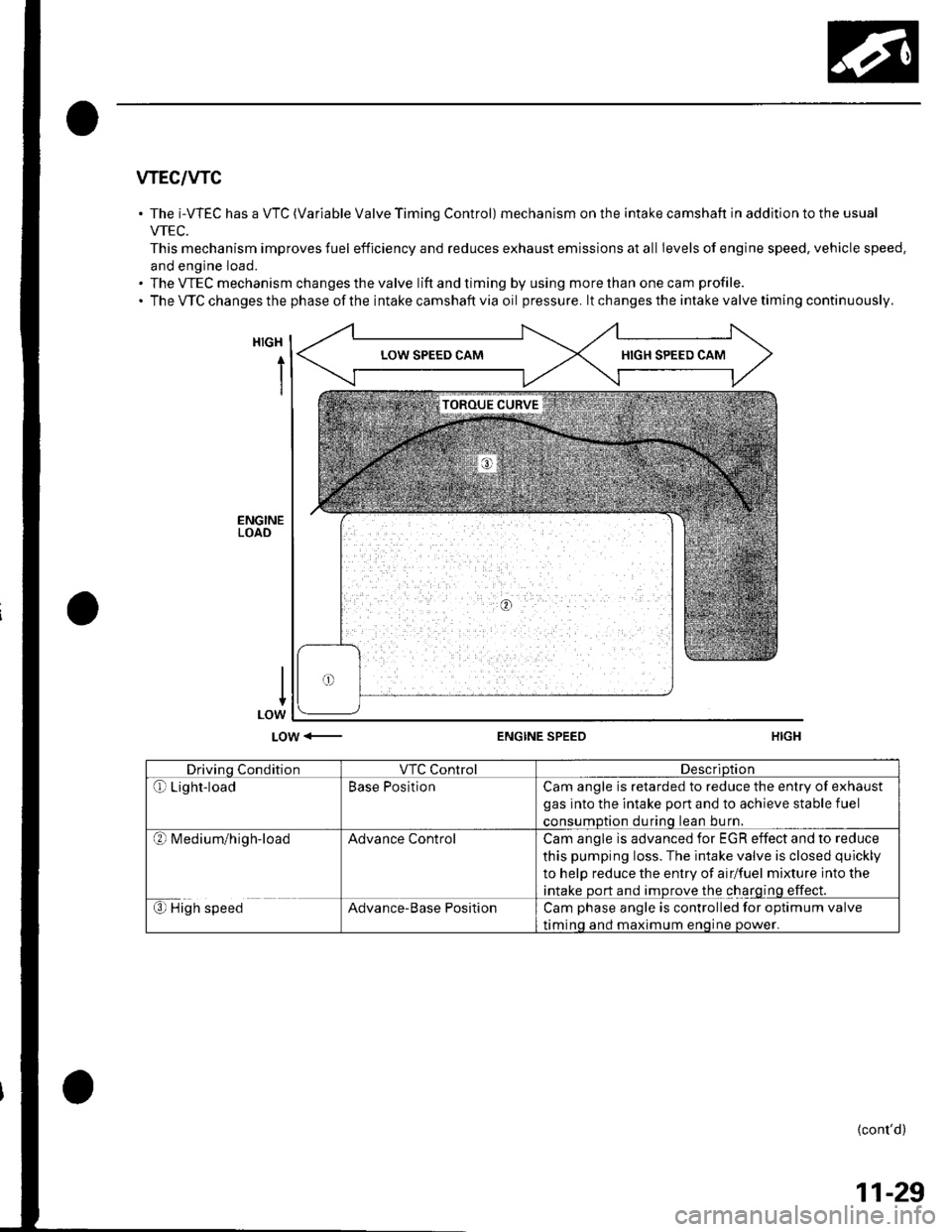

wEc/wc

The i-WEC has a VTC (Variable Valve Timing Control) mechanism on the intake camshaft in addition to the usual

VTEC.

This mechanism improves fuel efficiency and reduces exhaust emissions at all Ievels of engine speed, vehicle speed.

and engine load.

The VTEC mechanism changes the valve lift and timing by using more than one cam profile.

The VTC changes the phase of the intake camshaft via oil pressure. lt changes the intake valve timing continuously.

HIGH

i

LOW <-ENGINE SPEED

Drivino ConditionVTC ControlDescriDtion

Qr Light-loadBase PositionCam angle is retarded to reduce the entry of exhaust

gas into the intake port and to achieve stable fuel

consumDtion durinq lean bu rn.

?l M ed iu m/h ig h-loadAdvance ControlCam angle is advanced for EGR effect and to reduce

this pumping loss. The intake valve is closed quickly

to help reduce the entry of airlfuel mixture into the

intake port and improve the charging effect.

€) High speedAdvance-Base PositionCam phase angle is controlled for optimum valve

timinq and maximum enoine oower.

{cont'd)

11-29

Page 304 of 1139

MIL Circuit Troubleshooting

1. Connect an OBD ll scan tool/Honda PGM Tester

(see page 11-3).

2. Turn the ignition switch ON (ll) and read the OBD ll

scan tool/Honda PGM Tester.

Does the OBD ll scan tool/Honda PGM Tester

communicate with the ECM?

YES Go to step 3.

NO Go to troubleshooting " DLC Circuit

Troubleshooting" (see page 11-109).

3. Check the OBD ll scan tool/Honda PGM Testerfor

DTCs.

Are any DTCs ind icated?

YES Go to the DTC Troubleshooting Index.

NO-Go to step 4.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON (ll)and watch the

lMalfunction Indicator Lamp (MlL).

Does the MIL come on and stay on for more than

20 seconds aftet turning the ignition switch

oN (tr)?

YES lf the MIL always comes on and stays on, go

to step 76. But if the lMlL sometimes works

normally, first check for these problems.

. An intermittent short in the wire between the

ECIM (E29) and the data link connector (DLC).

. An intermittent short in the wire between the

ECM (E31) and the gauge assembly.

NO lf the MIL is always off, go to step 6. But if the

lvllL sometimes works normally, first check for

these problems.

. A loose No. 10 METER (7.5A) fuse in the under

dash fuse/relay box.. A loose No. 20 lG (40A) (Canada: 50A)Iuse in the

under-hood fuse/relay box.. A ioose No. 6 ECU (ECM) (15A) fuse in the under-

hood fuse/relay box.

. A loose No. 17 FUEL PUMP (15A)fuse in the

under-dash fuse/relay box.. A poor connection at ECM terminal E31.. An intermittent open in the GRN/ORN wire

between the ECM (E31) and the gauge assembly.. An intermittent short in the wire between the

ECM (A21) and the manifold absolute pressure

(MAP) sensor.. An intermittent short in the wire between the

ECI\4 (A20) and the throttle posilion (TPi sensor.. An intermittent short in the wire between the

ECM (E5) and the fuel tank pressure (FTP) sensor.

6. Turn the ignition switch OFF.

7. Turn the ignition switch ON (ll).

ls the low oil pressure light on?

YES Go to step 10.

NO-Go to step 8.

8. Inspectthe No. 10 l\4ETER (7.5A)fuse inthe under-

dash fuse/relay box.

ls the luse OK?

YES Go to step L

NO Repair shon in the wire between No. 10

METER (7.5A)fuse and the gauge assembly. Also

replacethe No. 10 METER {7.5A) fuse.l

9. Inspect the No. 20 lG1 (40A) (Canada: 50A) fuse in

the under-hood fuse/relay box.

ls the f use OK?

YES Repair open in the wire between the No. 20

lG (40A) {Canadar 50A)fuse and the gauge

assembly. lf the wire is OK, test the ignition switch

{see page 22 53).

NO Repair short in the wire between No. 20 lG

(40A) lCanada: 50A)fuse and the under'dash fusel

relay box. Also replace the No.20 lG (40Ai

(Canada: 50A) fuse.I

(conr'd)

11-97

Page 319 of 1139

PGM-FI System

Injector Replacement (cont'd)

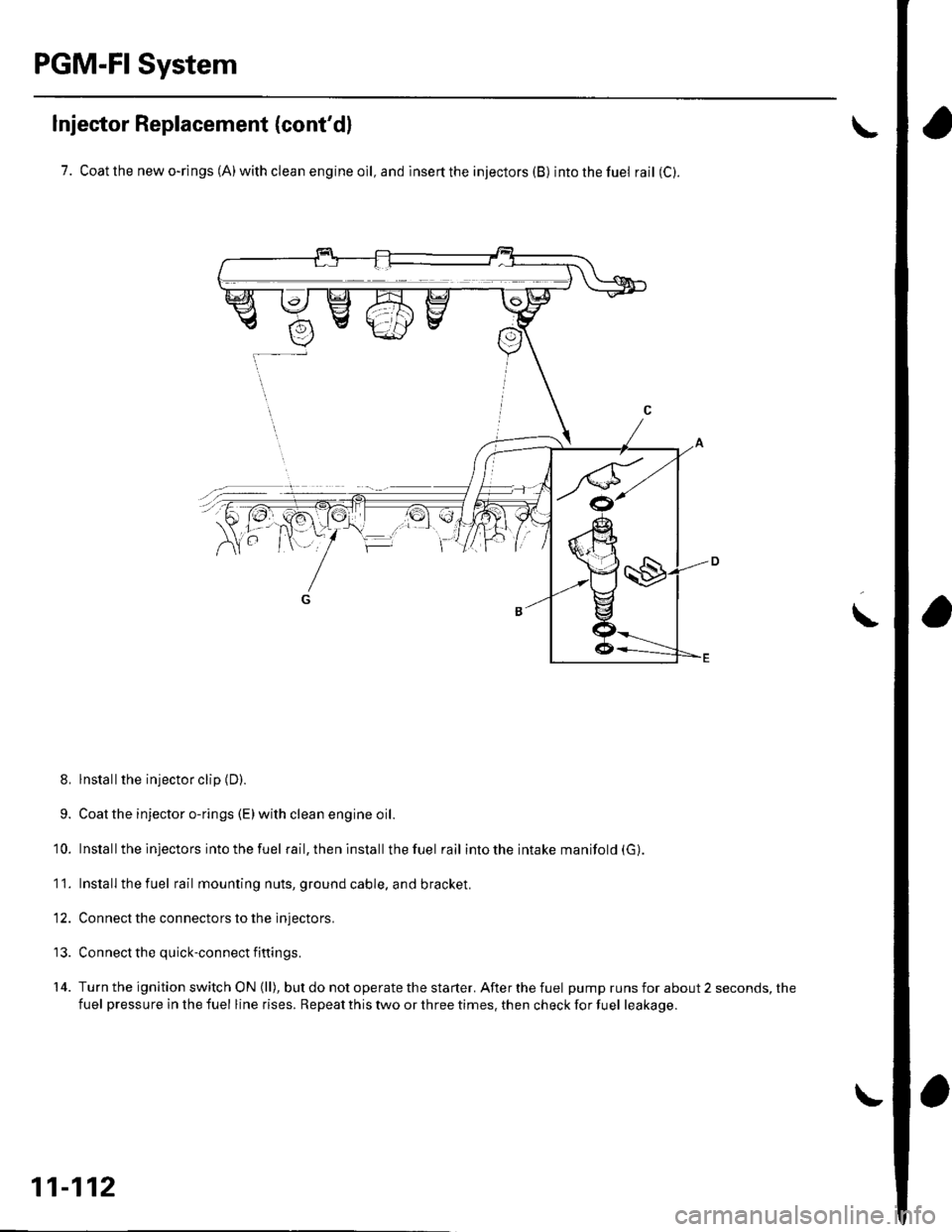

7. Coatthenewo-rings(A)withcleanengineoll,andinserttheinjectors(B) intothefuel rail (C).

8, lnstall the injector clip {D).

9. Coat the injector o-rings (E)with clean engine oil.

10. Installthe injectors intothefuel rail, then install the fuel rail intotheintakemanifold(G).

1 '1. Install the fuel rail mounting nuts, ground cable. and bracket.

12. Connect the connectors to the injectors.

13. Connect the quick-connect fittings.

14. Turnthe ignition switch ON (ll), butdo notoperatethe starter. Afterthefuel pump runs for about 2 seconds, the

fuel pressure in the fuel line rises. Repeat this two or three times. then check for fuel leakage.

\

11-112

Page 326 of 1139

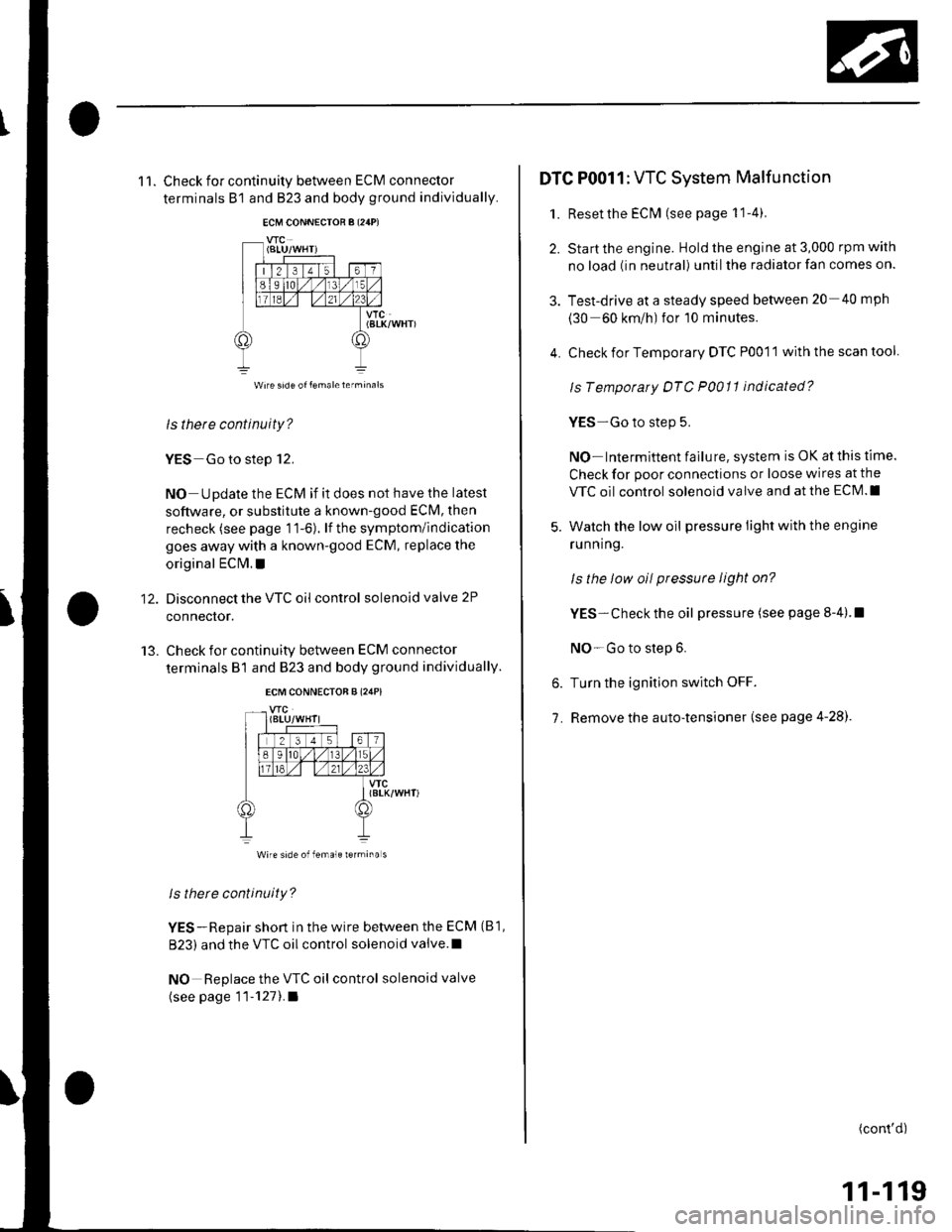

11. Check for continuity between ECM connector

terminals B1 and B23 and body ground individually.

VTC(BtK/WHT)

ls there continuity?

YES Go to step 12.

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original EClvl. !

Disconnect the VTC oil control solenoid valve 2P

connector.

Check for continuity between ECM connector

terminals B1 and 823 and body ground individually.

12.

13.

vfc(8LK/WHT)

Wire side of female rermina s

ls there continuity?

YES-Repair short in the wire between the ECM (B1,

B23) and the VTC oil control solenoid valve.l

NO Replace the VTC oil control solenoid valve

(see page 11-1211.a

4.

DTC P0011: VTC System Malfunction

1. Reset the EClvl (see page 1 1-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

3. Test-drive at a steady speed between 20 40 mph

(30 60 km/h) for 10 minutes.

Check for Temporary DTC P0011 with the scan tool

ls Tempotaty DTC P0011 indicated?

YES-Go to step 5.

NO- Intermittent failu re, system is OK at this time.

Check for poor connections or loose wires at the

VTC oil control solenoid valve and at the ECM.I

Watch the low oil pressure light with the engine

ru n n ing.

ls the low oil pressute light on?

YES- Check the oil pressure (see page 8-4).I

NO-Go to step 6.

Turn the ignition switch OFF.

Remove the auto-tensioner (see page 4-28).

6.

7.

(cont'd)

11-119

Page 330 of 1139

DTC Pl259: WEC System Malf unction

SpecialTools Required. Pressure gauge adapter 07NAJ P07010A

. A/T low pressure gauge w/panel 07406-0070300. A/T pressure hose 07406-0020201. Av/T pressure hose,2,210 mm 07IMAJ-PY4o11A

. l"/T pressure adapter 07MAJ-PY40120

. Oil pressure hose 07ZAJ-S54,4200

1. Reset the ECM (see page 11-4).

2. Check the engine oil level, and refill ifnecessary.

3. Start the engine. Hold the engine at 3,000 rpm with

no load {in neutral) until the radiator fan comes on.

4. Road testthe vehicle:

Accelerate in the 1st gear to an engine speed over

4.000 rpm. Hold the speed for at least 2 seconds. lf

DTC P1259 is not repeated during the first road test,

repeat the test two more times.

ls DTC P1259 indicated?

YES Go to step 5.

NO-lntermittent failure, system is OK at this time

Check the oil consumption if oil was added in step

2. Check for poor connections or loose terminals at

the VTEC solenoid valve, the VTEC oil pressure

switch, and at the ECI\4. I

5, Turn the ignitjon switch OFF.

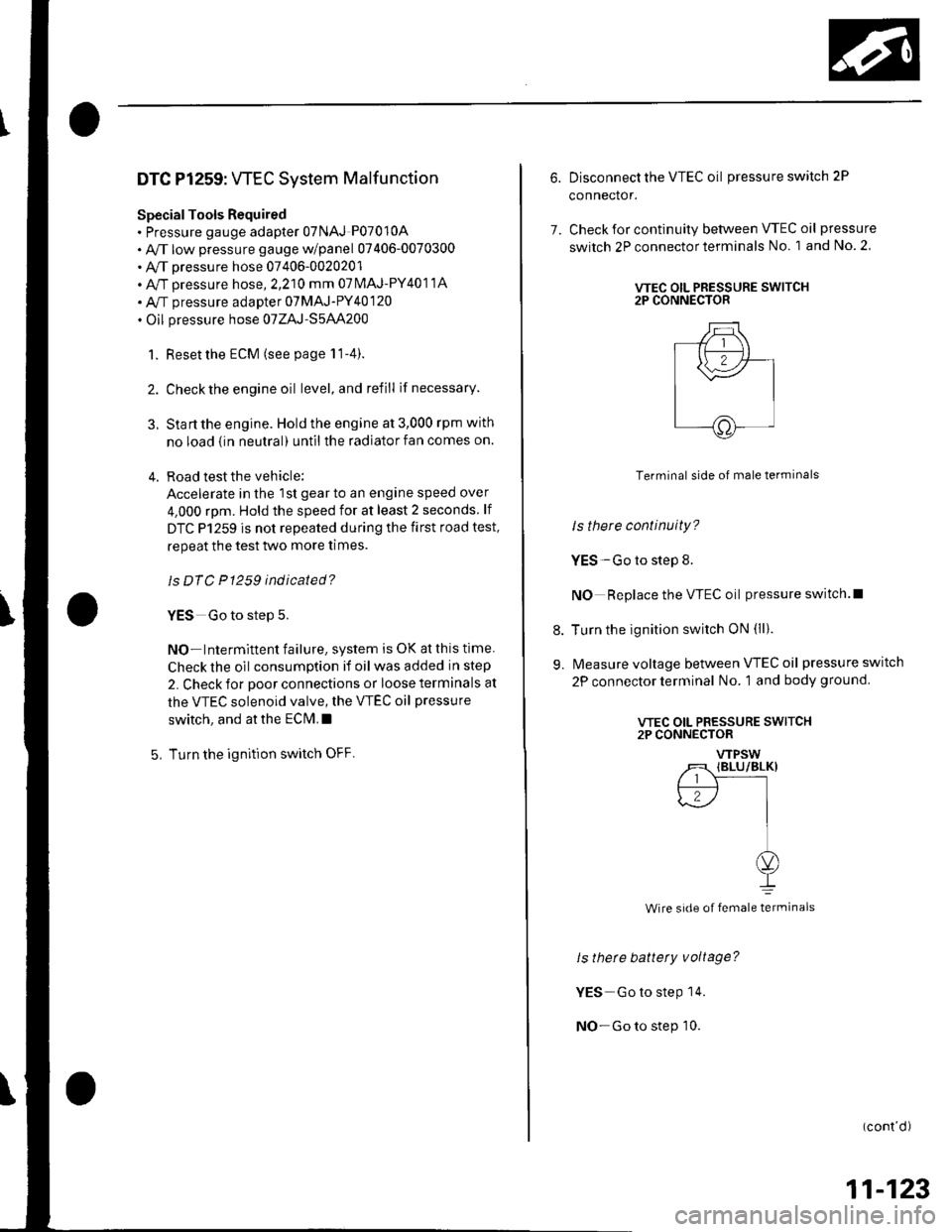

6. Disconnect the VTEC oil pressureswitch 2P

connector.

7. Check for continuity between VTEC oil pressure

switch 2P connector terminals No. 1 and No. 2

VTEC OIL PRESSURE SWITCH2P CONNECTOR

Terminal side of male terminals

Is there continuity?

YES-Go to step 8.

NO Replace the VTEC oil pressure switch.l

8. Turn the ignition switch ON (ll).

9. Measure voltage between VTEC oil pressure switch

2P connector terminal No. 1 and body ground

ls there battety voltage?

YES Go to steP 14.

NO-Go to step 10.

(cont'd)

VTEC OIL PRESSURE SWITCH2P CONNECTOR

VTPSW

/T {BLU/BLK}

{.--r r-l'--.l

J II

oI

Wire side of female terminals

11-123

Page 331 of 1139

VTEC/VTC

DTC Troubleshooting (cont'd)

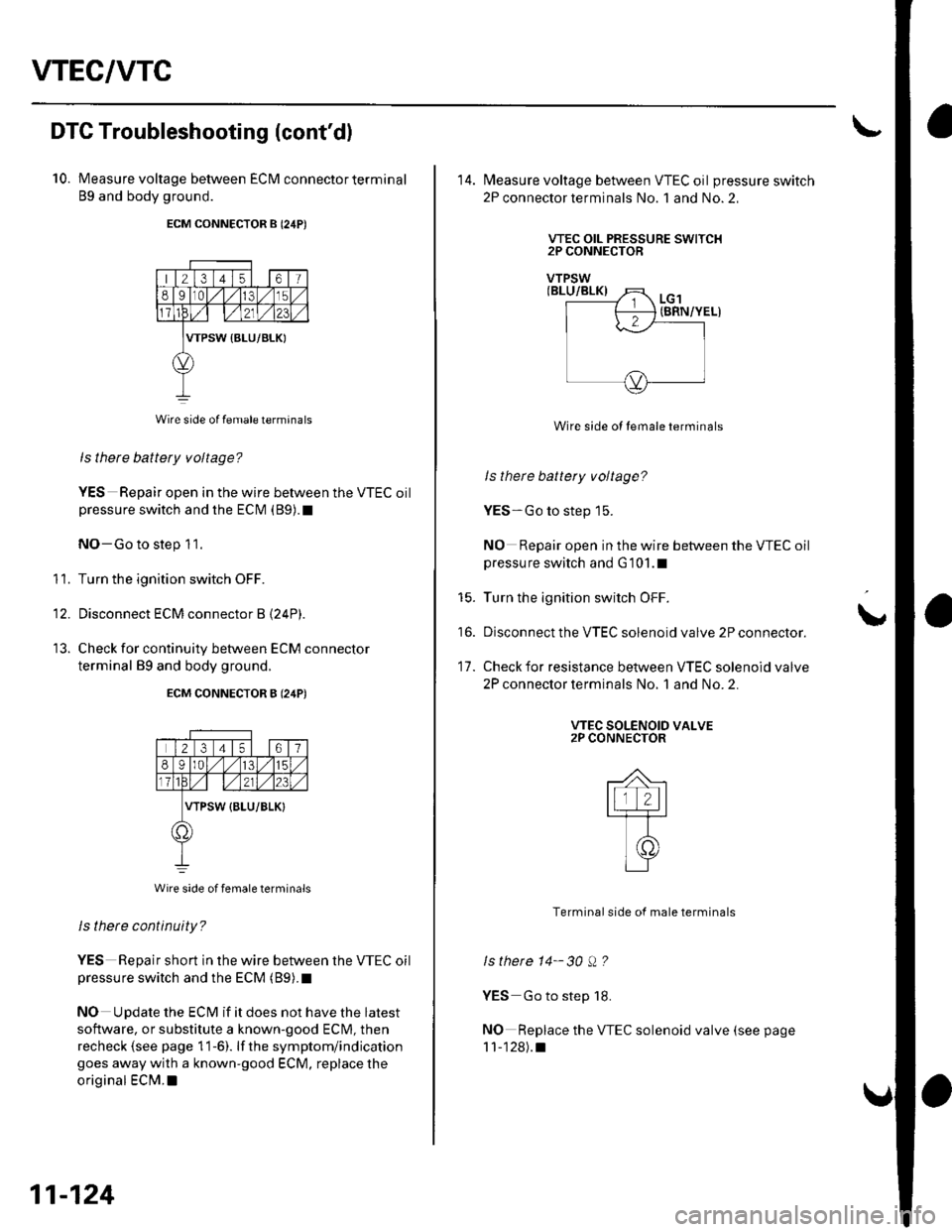

10. Measure voltage between ECM connectorterminal

89 and body ground.

ECM CONNECTOR B (24P)

213 415o1

8Iat/t/n315

WPSW {BLU/BLK}

Wire side of Iemale terminals

ls there battery voltage?

YES Repair open in the wire between the VTEC oilpressure switch and the ECM (89).t

NO-Go to step 11.

Turn the ignition switch OFF.

Disconnect ECM connector B {24P).

Check for continuity between ECM connector

terminal Bg and body ground.

ECM CONNECTOR B {24P)

2 3 41567

I9ol./ ./ 1315

VTPSW {BLU/BLK}

Wrre side of female terminals

ls there continuity?

YES Repair short in the wire between the VTEC oilpressure switch and the ECM (89).I

NO Update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECN4. !

11.

11-124

2P CONNECTOR

VTPSW(BLU/BLK)

14. fMeasure voltage between VTEC oil pressure switch

2P connector terminals No. 1 and No. 2,

VTEC OIL PRESSURE SWITCH

(BRN/YELI

Wire side of Iemale terminals

ls there battery voltage?

YES-Go to step 15.

NO Repair open in the wire between the VTEC oil

pressure switch and G 101.1

Turn the ignition switch OFF.

Disconnect the VTEC solenoid valve 2P connector.

Check for resistance between VTEC solenoid valve

2P connector terminals No, 1 and No. 2.

VTEC SOLENOID VALVE2P CONNECTOR

Terminal side of male terminals

ls there 14- 30 Sl ?

YES Go to step 18.

NO Replace the VTEC solenoid valve (see page

11-128).t

to.

17.