check engine HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 120 of 1139

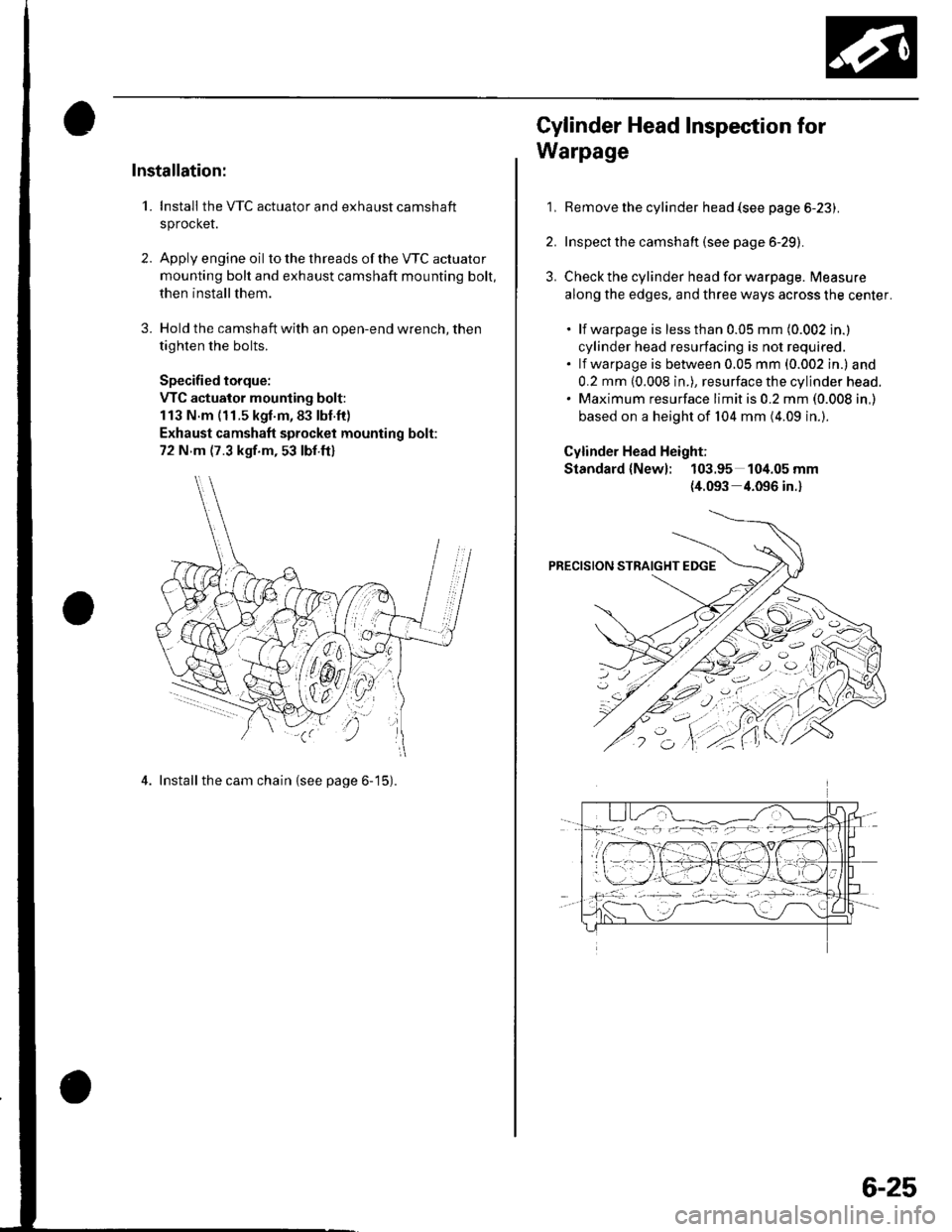

Installation:

1. Install the VTC actuator and exhaust camshaft

sprocket.

2. Apply engine oil to the th reads of the VTC actuato r

mounting bolt and exhaust camshaft mounting bolt,

then install them.

3. Hold the camshaft with an open-end wrench, then

tighten the bolts.

Specified torque:

VTC actuator mounting bolt:

113 N.m (11.5 kgl.m,83 lbl.ft)

Exhaust camshaft sprocket mounting bolt:

72 N m (7.3 kgf.m, 53 lbf.ft)

4. Install the cam chain {see page 6-15).

1,

Cylinder Head Inspection for

Warpage

Remove the cylinder head {see page 6-23).

Inspect the camshaft (see page 6-29).

Check the cylinder head for warpage. Measure

along the edges, and three ways across the center.

. lf warpage is less than 0.05 mm (0.002 in.)

cylinder head resurfacing is not required.. lf warpage is between 0.05 mm (0.002 in.) and

0.2 mm (0.008 in.), resurface the cylinder head.. Maximum resurface limit is 0.2 mm (0.008 in,)

based on a height of 104 mm (4.09 in.).

Cylinder Head Height;

Standard {New}: 103.95 104.05 mm

{4.093 4.096 in.}

6-25

Page 129 of 1139

Cylinder Head

Valve Guide Replacement (cont'dl

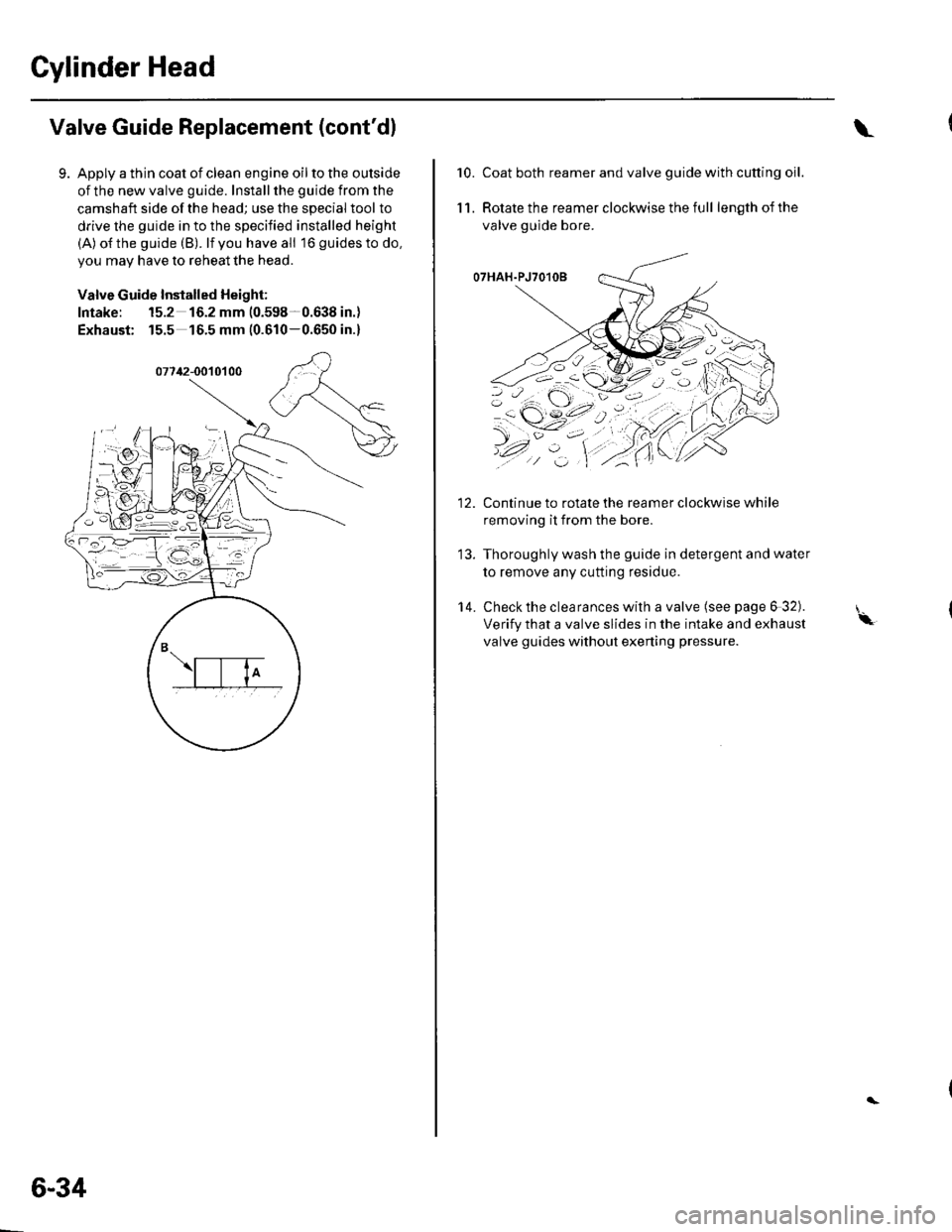

Apply a thin coat of clean engine oil to the outside

of the new valve guide. Install the guide from the

camshaft side of the head; use the special tool to

drive the guide in to the specified installed height

(A) o{the guide (B). lf you have all 16 guidesto do,

you may have to reheat the head.

Valve Guide Installed Height:

Intake: 15.2 16.2 mm (0.598-0.638 in.)

Exhaust: 15.5 16.5 mm (0.610-0.650 in.)

6-34

\

10.Coat both reamer and valve guide with cutting oil.

Rotate the reamer clockwise the full length of the

valve guide bore.

O7HAH.PJ7O1OB

Continue to rotate the reamer clockwise while

removing it from the bore.

Thoroughly wash the guide in detergent and water

to remove any cutting residue.

Check the clearances with a valve (see page 6 32).

Verify that a valve slides in the intake and exhaust

valve guides without exening pressure.

11.

14.

'-\

Page 132 of 1139

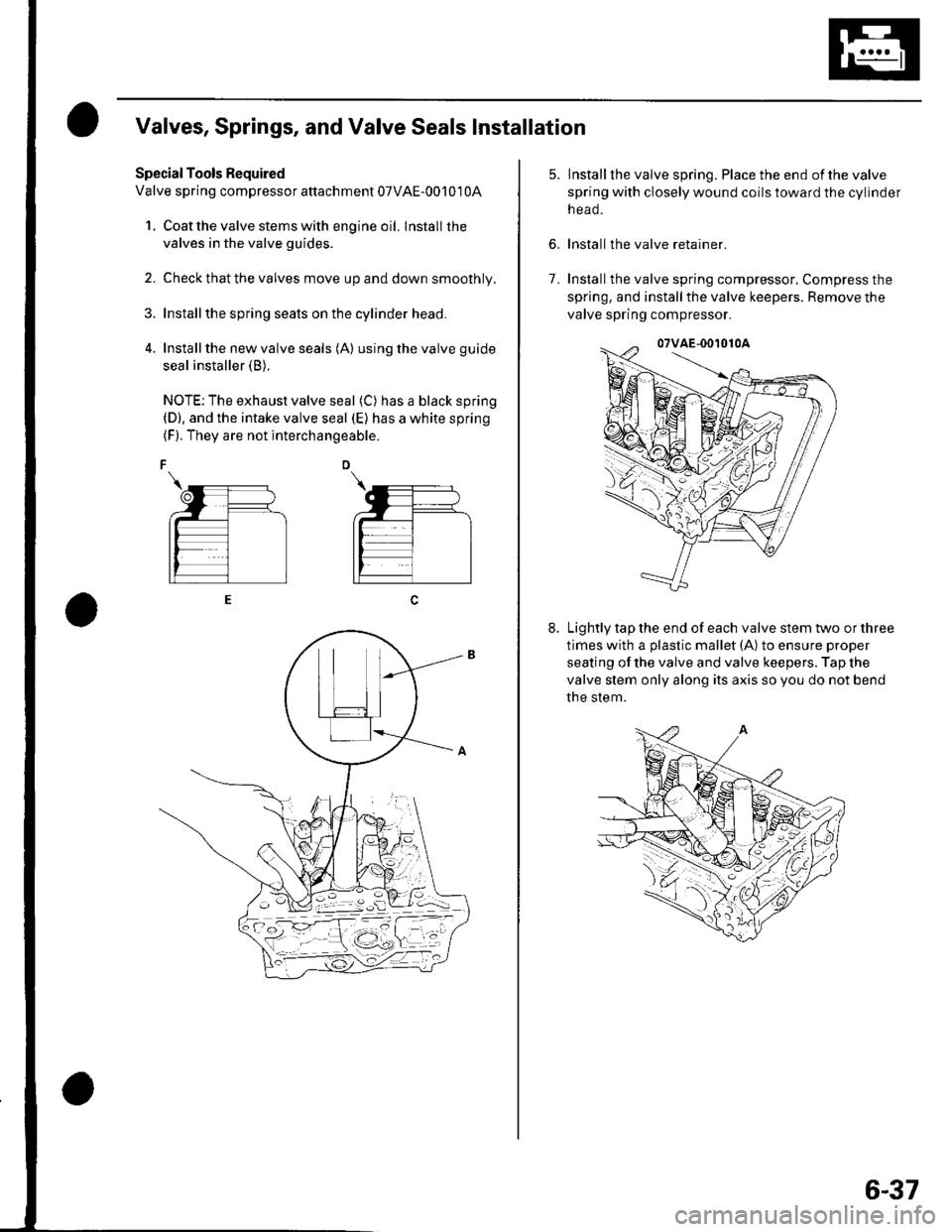

Valves, Springs, and Valve Seals Installation

Special Tools Required

Valve spring compressor attachment 07VAE-00101 0A

1. Coat the valve stems with engine oil. lnstall the

valves in the valve guides.

2. Check that the valves move up and down smoothly.

Installthe spring seats on the cylinder head.

Install the new valve seals (A) using the valve guide

seal installer (B).

NOTE: The exhaust valve seal (C) has a black spring(D), and the intake valve seal (E) has a white spring(F). They are not interchangeable.

6.

lnstallthe valve spring. Place the end ofthe valve

spring with closely wound coils toward the cylinder

n eao.

Install the valve retainer.

Installthe valve spring compressor, Compress the

spring, and install the valve keepers. Remove the

valve spring compressor.

Lightly tap the end of each valve stem two or three

times with a plastic mallet (A) to ensure proper

seating of the valve and valve keepers. Tap the

valve stem only along its axis so you do not bend

the stem.

7.

6-37

Page 136 of 1139

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

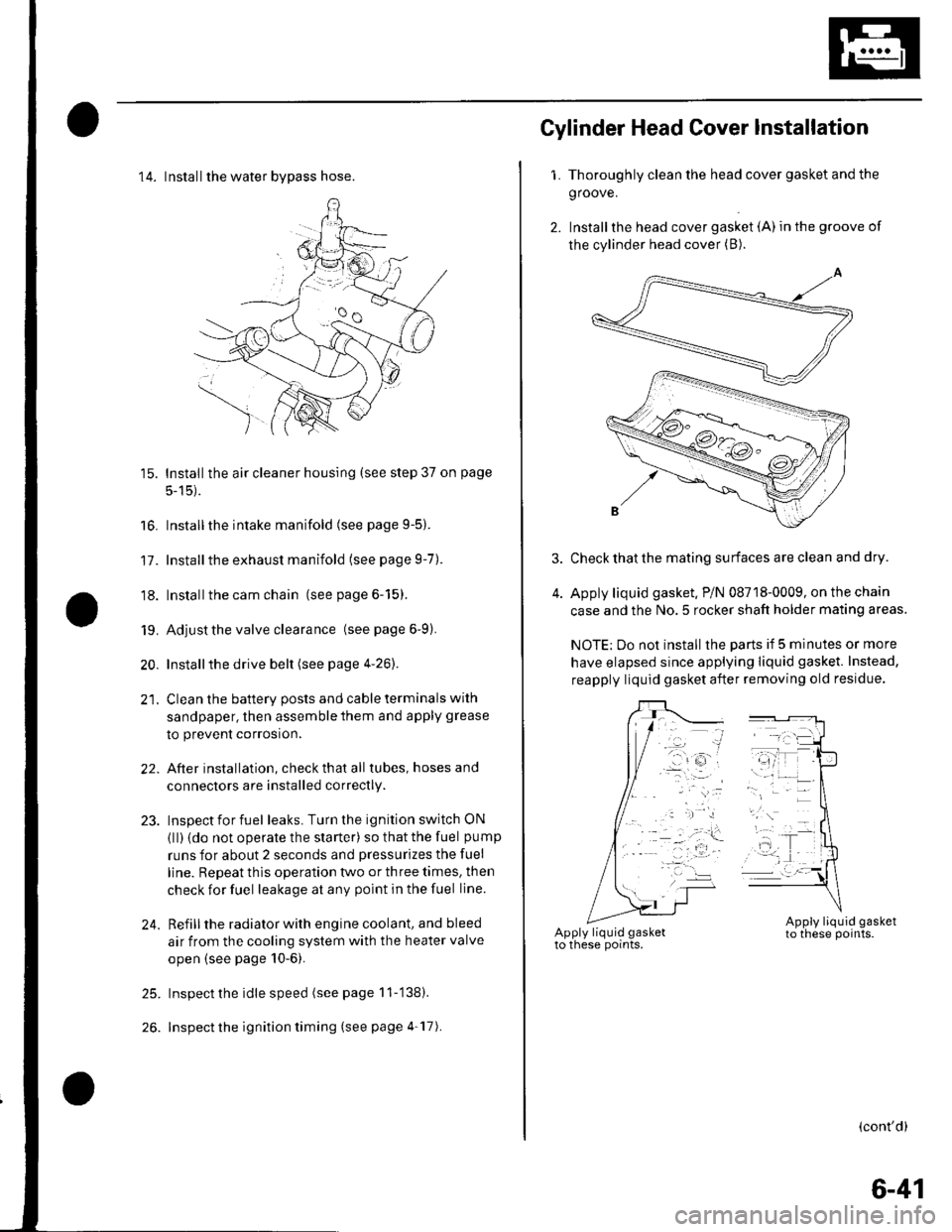

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 138 of 1139

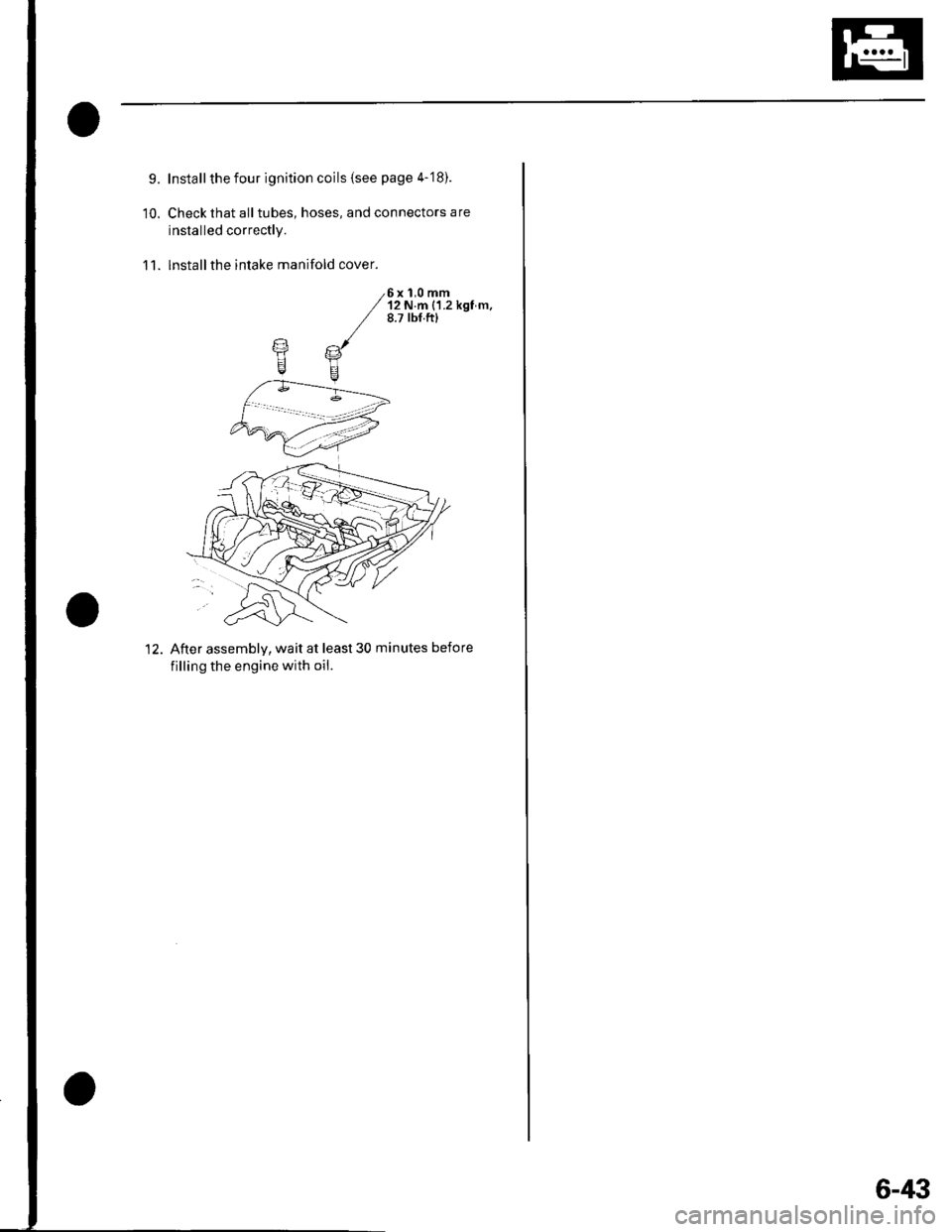

9.

10.

Install the four ignition coils (see page 4-'18).

Check that all tubes, hoses, and connectors are

installed correctly.

lnstallthe intake manifold cover.11.

6x 1,0 mm'12 N.m {1.2 kgf m.8.7 tbf.ftl

12. After assemblv, wait at least 30 minutes before

filling the engine with oil.

6-43

Page 144 of 1139

Engine Block

Crankshaft Main Bearing Replacement

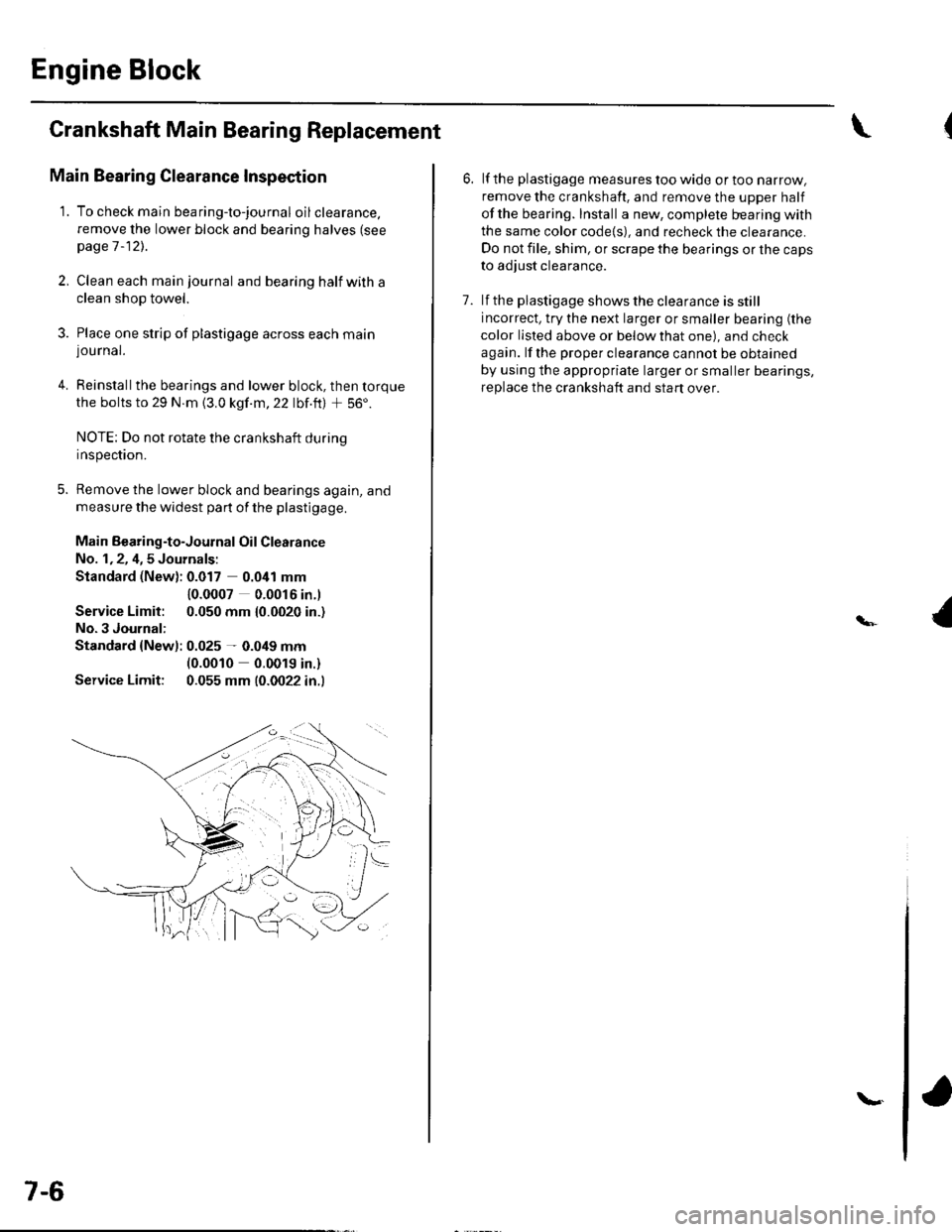

Main Bearing Clearance Inspection

1. To check main bea ring-to-jou rna I oil clearance.

remove the lower block and bearing halves (see

page 1 -12)..

2, Clean each main journal and bearing half witha

clean shop towel.

3. Place one strip of plastigage across each main

lou rnal.

4. Reinstallthe bearings and lower block, then torque

the bolts to 29 N.m {3.0 kgf.m,22 lbf.ft) + 56'.

NOTE: Do not rotate the crankshaft during

Inspeclton.

5. Remove the lower block and bearings again, and

measure the widest part of the plastigage.

Main Bearing-to-Journal Oil Clearance

No. 1,2, 4,5 Journals:

Standard (New): 0.017 0.041 mm

Service Limit:

No.3 Journal:

10.0007 0.0016 in.l

0.050 mm {0.0020 in.)

Standard {Newl: 0.025 - 0.049 mm(0.0010 0.0019 in.)

Service Limit: 0.055 mm (0.0022 in.l

7-6

\.

6. lf the plastigage measures too wide or too narrow,

remove the crankshaft. and remove the upper half

ofthe bearing. Install a new, complete bearing with

the same color code{s), and recheck the clearance.

Do not file, shim, or scrape the bearings or the caps

to adjust clearance.

7. lf the plastigage shows the clearance is still

incorrect, try the next larger or smaller bearing (the

color listed above or below that one), and check

again. lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

Page 147 of 1139

8.

9.

lf the plastigage measures too wide or too narrow,

remove the upper half of the bearing, install a new,

complete bearing with the same color code(s), and

recheck the clearance. Do not file. shim, or scrape

the bearings or the caps to adjust clearance.

lf the plastigage shows the clearance is still

incorrect, try the next larger or smaller bearing (the

color listed above or below that one), and check

clearance agaln. lf the proper clearance cannot be

obtained by using the appropriate larger or smaller

bearing, replace the crankshaft and stan over.

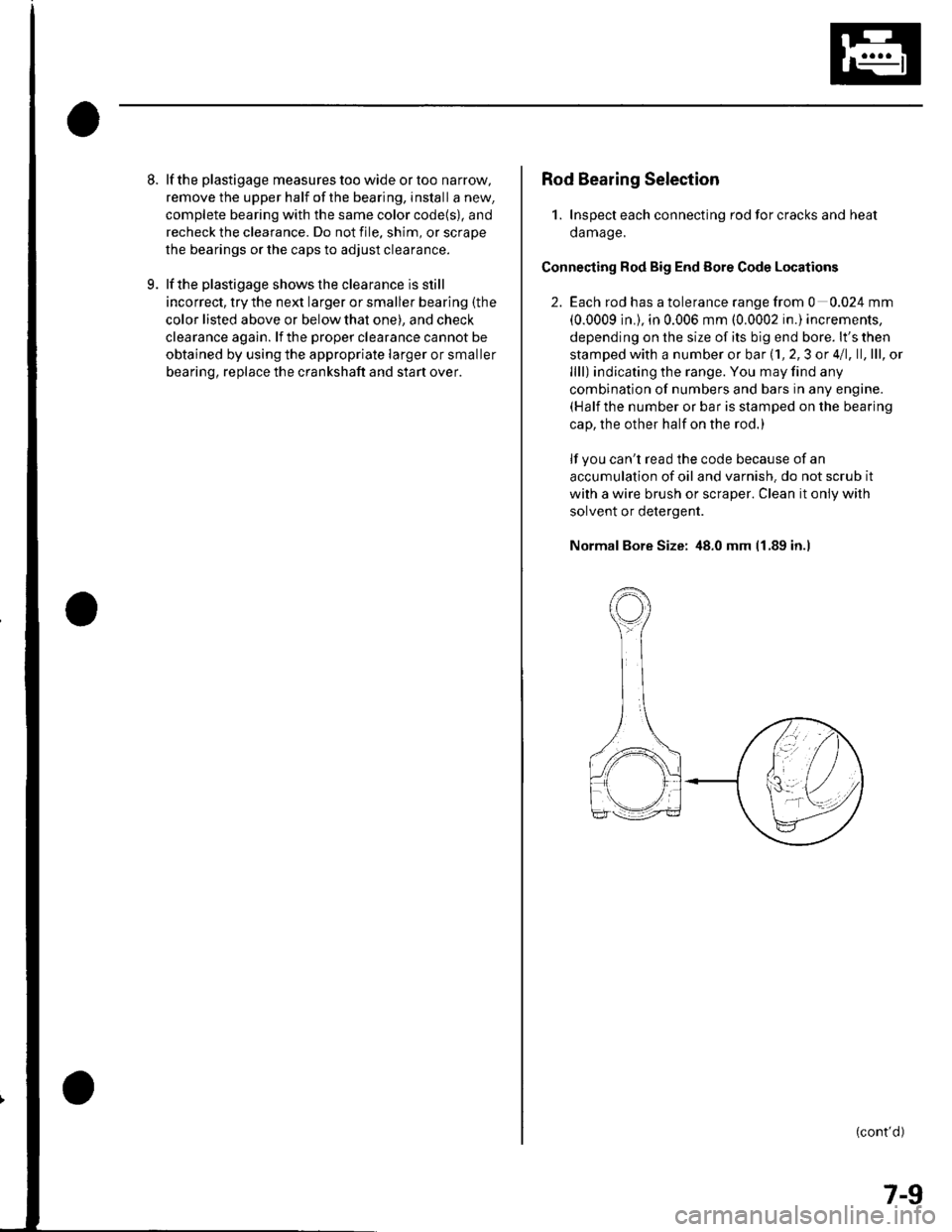

Rod Bearing Selection

1. Inspect each connecting rod for cracks and heat

damage.

Connecting Rod Big End Eore Code Locations

2. Each rod has a tolerance range from 0 0.024 mm

(0.0009 in.), in 0.006 mm (0.0002 in.) increments,

depending on the size of its big end bore. lt's then

stamped with a number or bar (1, 2,3 or 4/1, ll,lll, ol

llll) indicating the range. You may find any

combination of numbers and bars in any engine.(Half the number or bar is stamped on the bearing

cap, the other half on the rod.)

lf you can't read the code because of an

accumulation of oil and varnish. do not scrub it

with a wire brush or scraper. Clean it only with

solvent or detergent.

Normal Bore Size: 48.0 mm 11.89 in.l

(cont'd)

7-9

Page 154 of 1139

Engine Block

Block and Piston Inspection (cont'd)

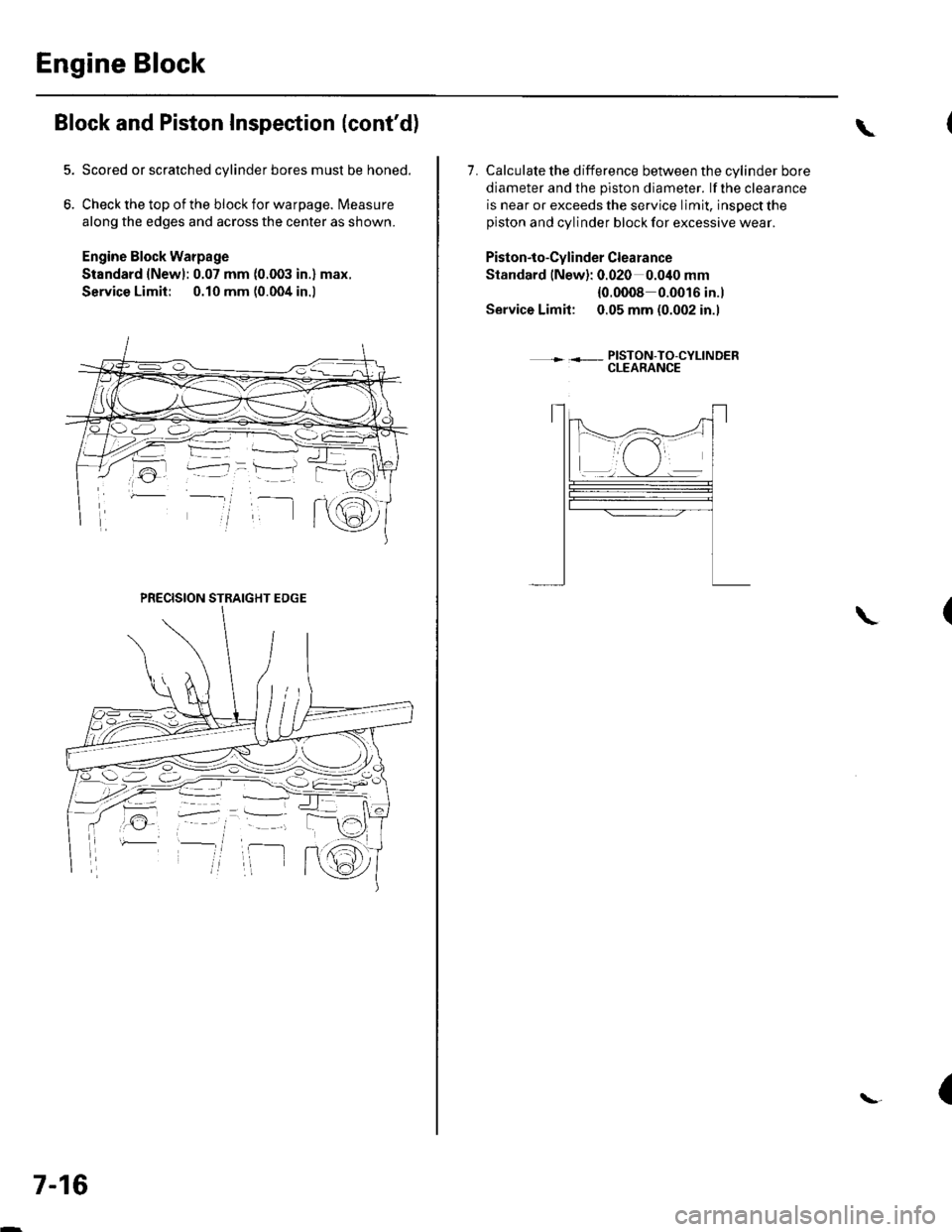

Scored or scratched cylinder bores must be honed.

Check the top of the block for warpage. Measure

along the edges and across the center as shown.

Engine Block Warpage

Standard lNew): 0.07 mm (0.003 in.) max.

Service Limit: 0.10 mm (0.004 in.l

PRECISION STRAIGHT EDGE

7-16

\

7. Calculate the difference between the cylinder bore

diameter and the plston diameter. lf the clearance

is near or exceeds the service limit, inspect thepiston and cvlinder block for excessive wear.

Piston-to-Cylinder Clearance

Standard lNew): 0.020 0.040 mm

{0.0008 0.0016 in.)

Service Limit: 0.05 mm (0.002 in.l

++ PISTON-TO-CYLINDERCLEARANCE

\

(

Page 159 of 1139

Piston Ring Replacement

1. Remove the piston {rom the cylinder block (see

page 7 -121.

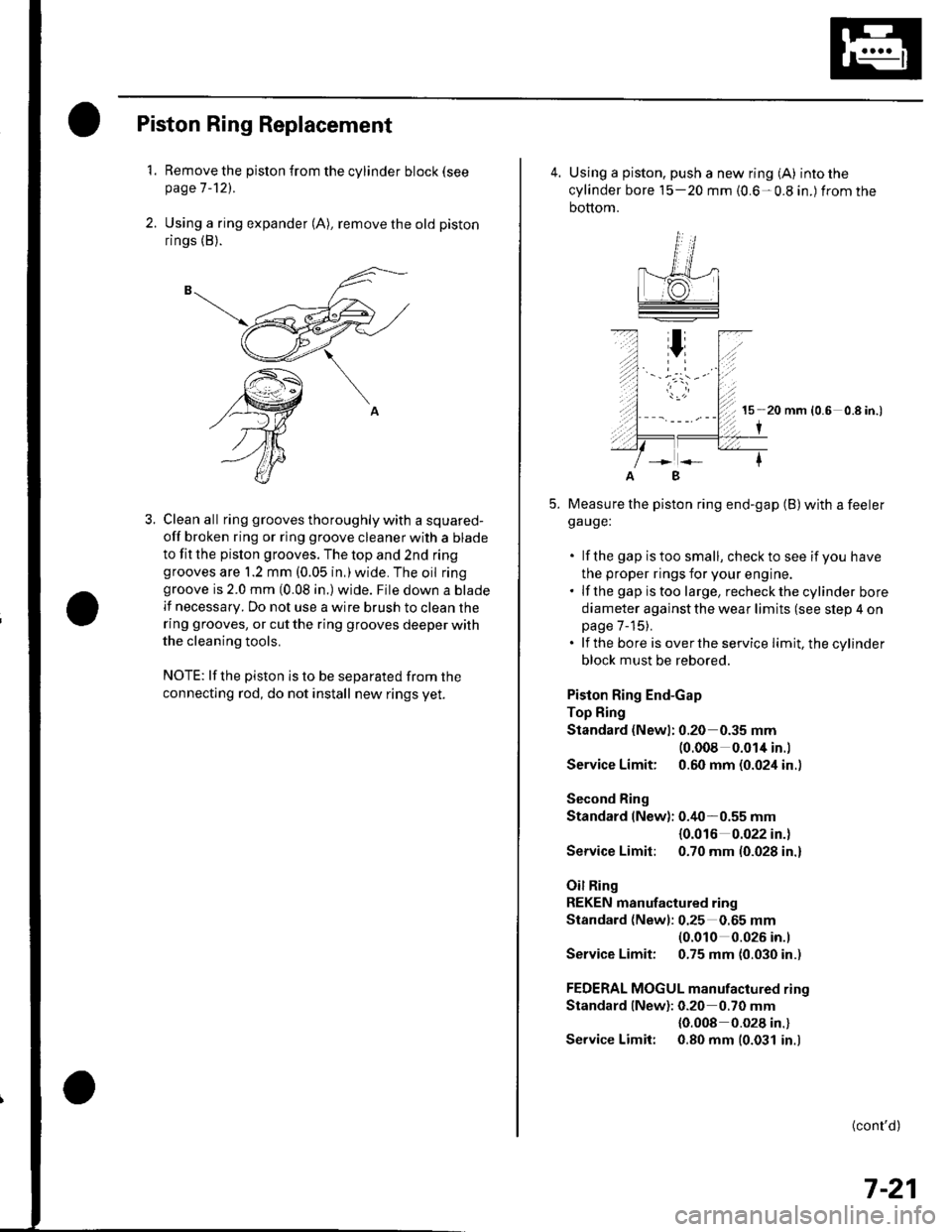

2. Using a ring expander (A), remove the old piston

rings (B).

3. Clean all ring grooves thoroughly with a squared-

off broken ring or ring groove cleaner with a blade

to fit the pislon grooves. The top and 2nd ringgrooves are 1.2 mm (0.05 in,)wide. The oil ringgroove is 2.0 mm (0.08 in.) wide. File down a blade

lf necessary. Do not use a wire brush to clean the

ring grooves, or cut the ring grooves deeper with

the cleaning tools.

NOTE: lf the piston is to be separated from the

connecting rod, do not install new rings yet.

4. Using a piston, push a new ring (A) into the

cylinder bore 15-20 mm {0.6-0.8 in.) from the

bottom.

15 20 mm (0.6 0.8 in.)

I

Measure the piston ring end-gap (B) with a feelerga uge:

. lf the gap istoo small, checkto see if you have

the proper rings for your engine.. lf the gap istoo large, recheckthecylinder bore

diameter against the wear limits (see slep 4 onpage 7-15).. lf the bore is overthe service limit, the cylinder

block must be rebored.

Piston Ring End-Gap

Top Fing

Standard (Newl: 0.20 0.35 mm(0.008 0.014 in.l

Service Limit: 0.60 mm (0.024 in..

Second Ring

Standard (New): 0.40-0.55 mm

{0.016 0.022 in.)

Service Limit: 0.70 mm (0.028 in.)

Oil Ring

REKEN manufactured ring

Standard (Newl: 0.25 0.65 mm(0.010 0.026 in.l

Service Limit: 0.75 mm (0.030 in.)

FEDERAL MOGUL manufactured rino

Standard lNew): 0.20 0.70 mm

{0.008 0.028 in.}

Service Limit: 0.80 mm (0.031 in.)

B

(cont'd)

7-21

Page 161 of 1139

Piston Installation

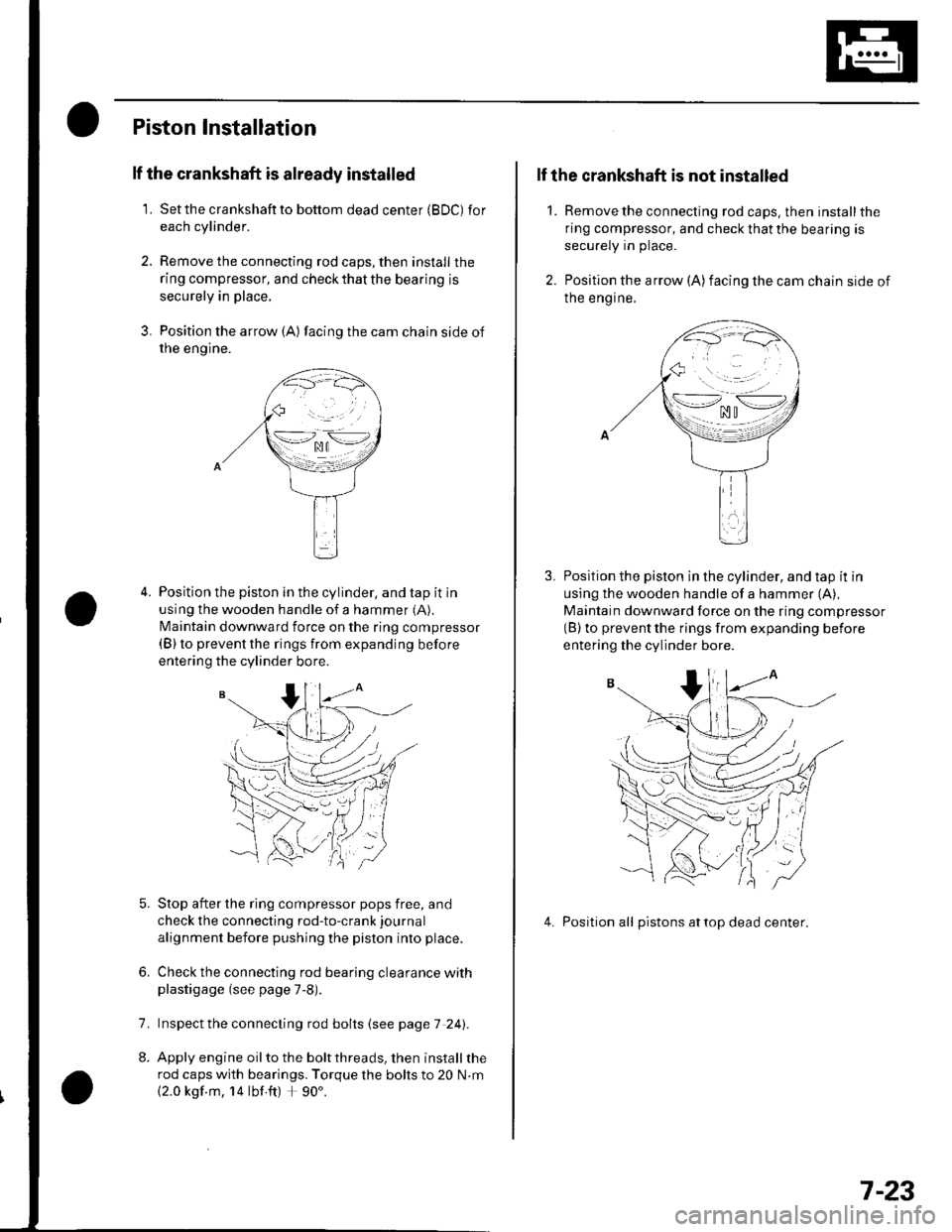

lf the crankshaft is already installed

1. Setthe crankshaftto bottom dead center (BDC) for

each cylinder.

2. Remove the connecting rod caps, then install the

ring compressor, and check that the bearing is

securely in place,

3. Position the arrow {A) facing the cam chain side of

rne engtne.

Position the piston in the cylinder, and tap it in

using the wooden handle of a hammer (A).

N4aintain downward force on the ring compressor(B) to prevent the rings from expanding before

entering the cylinder bore.

Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal

alignment before pushing the piston into place.

Check the connecting rod bearing clearance withplastigage (see page 7-8).

lnspect the connecting rod bolts (see page 7 241.

Apply engine oil to the bolt threads, then install the

rod caps with bearings. Torque the bolts to 20 N.m

{2.0 kgf m, 14 lbf ft) + 90'.

6.

7.

2.

1.

lf the crankshaft is not installed

Remove the connecting rod caps. then install the

ring compressor, and check that the bearing is

securely in place.

Position the arrow (A)facing the cam chain side of

Ine engrne.

Position the piston in the cylinder, and tap it in

using the wooden handle of a hammer (A),

Maintain downward force on the ring compressor(B) to prevent the rings from expanding before

entering the cylinder bore.

4. Position all pistons attop dead center.

\--lno n\-.--l. ^u t

>-*/zi

.,.'_\pf{

wr

(( 'V,/ :

7-23