steering wheel HONDA CIVIC 2002 7.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 557 of 1139

EPS Components

4

17.

18.

Steering Gearbox Installation (cont'dl

Install the motor on the steering gearbox (see page

17-49).

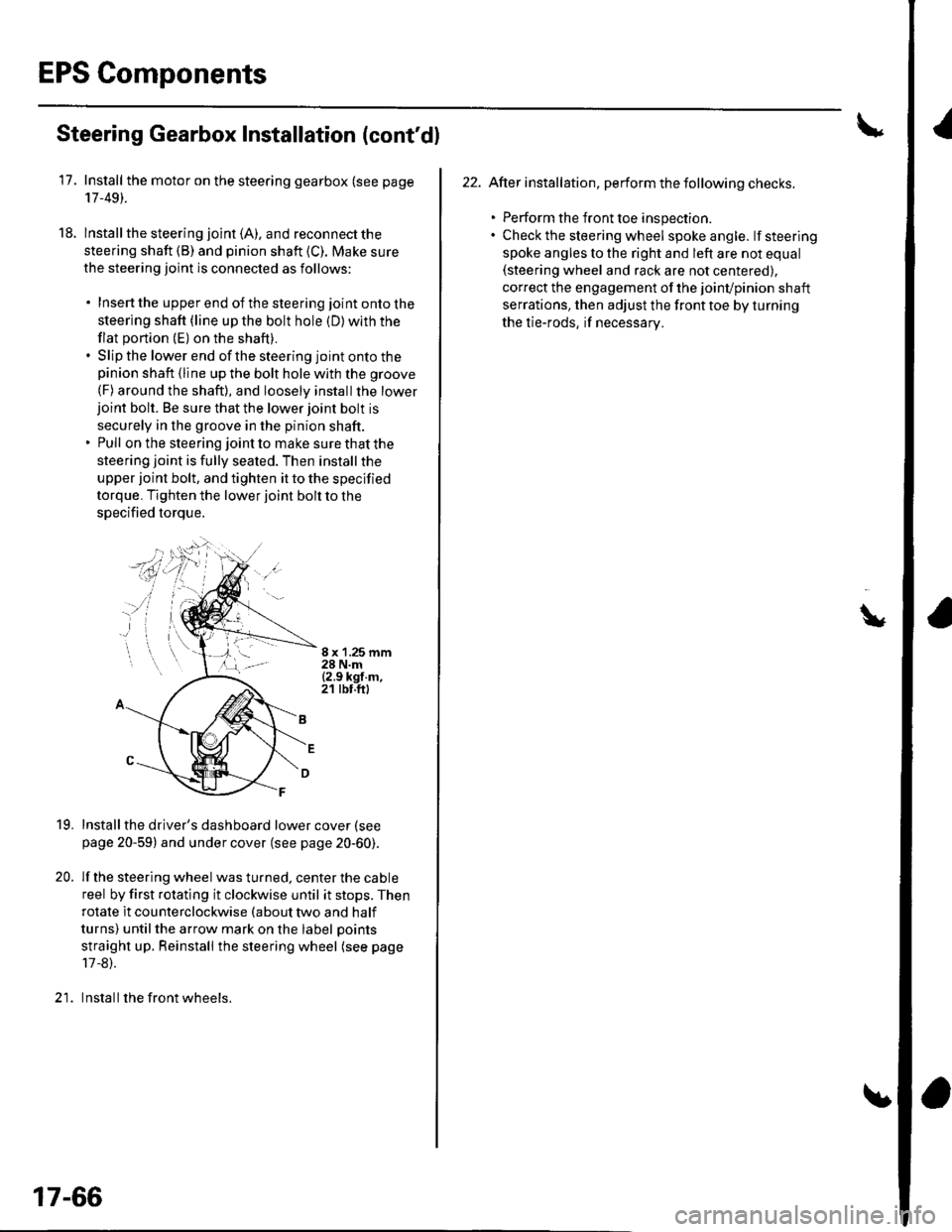

lnstall the steering joint (A). and reconnect the

steering shaft (B) and pinion shaft (C). Make sure

the steering joint is connected as follows:

. Insertthe upperend of thesteering jointontothe

steering shaft (line up the bolt hole (D) with the

flat portion (E) on the shaft).. Slip the lower end of the steering joint onto thepinion shaft (line up the bolt hole with the groove

(F) around the shaft), and loosely installthe lowerjoint bolt. Be sure that the lower joint bolt is

securely in the groove in the pinion shaft.. Pull on the steering joint to make sure that the

steering joint is fully seated. Then install the

upper joint bolt, and tighten it to the specified

torque. Tighten the lower joint bolt to the

specified torque.

8 x '1.25 mm28 N.m{2.9 kgf.m,21 tbt.ft)

19.

20.

Installthe driver's dashboard lower cover (see

page 20-59) and under cover (see page 20-60).

lf the steering wheel was turned, center the cable

reel by first rotating it clockwise until it stops. Then

rotate it counterclockwise (about two and half

turns) untilthe arrow mark on the label points

straight up. Reinstall the steering wheel (see page

17 -8).

Install the front wheels.)1

17-66

22. After installation, perform the following checks.

. Perform the front toe inspection.. Check the steering wheel spokeangle. lfsteering

spoke angles to the right and left are not equal(steering wheel and rack are not centered),

correct the engagement of the joinvpinion shaft

serrations, then adjust the front toe by turning

the tie-rods, if necessarv.

\

Page 558 of 1139

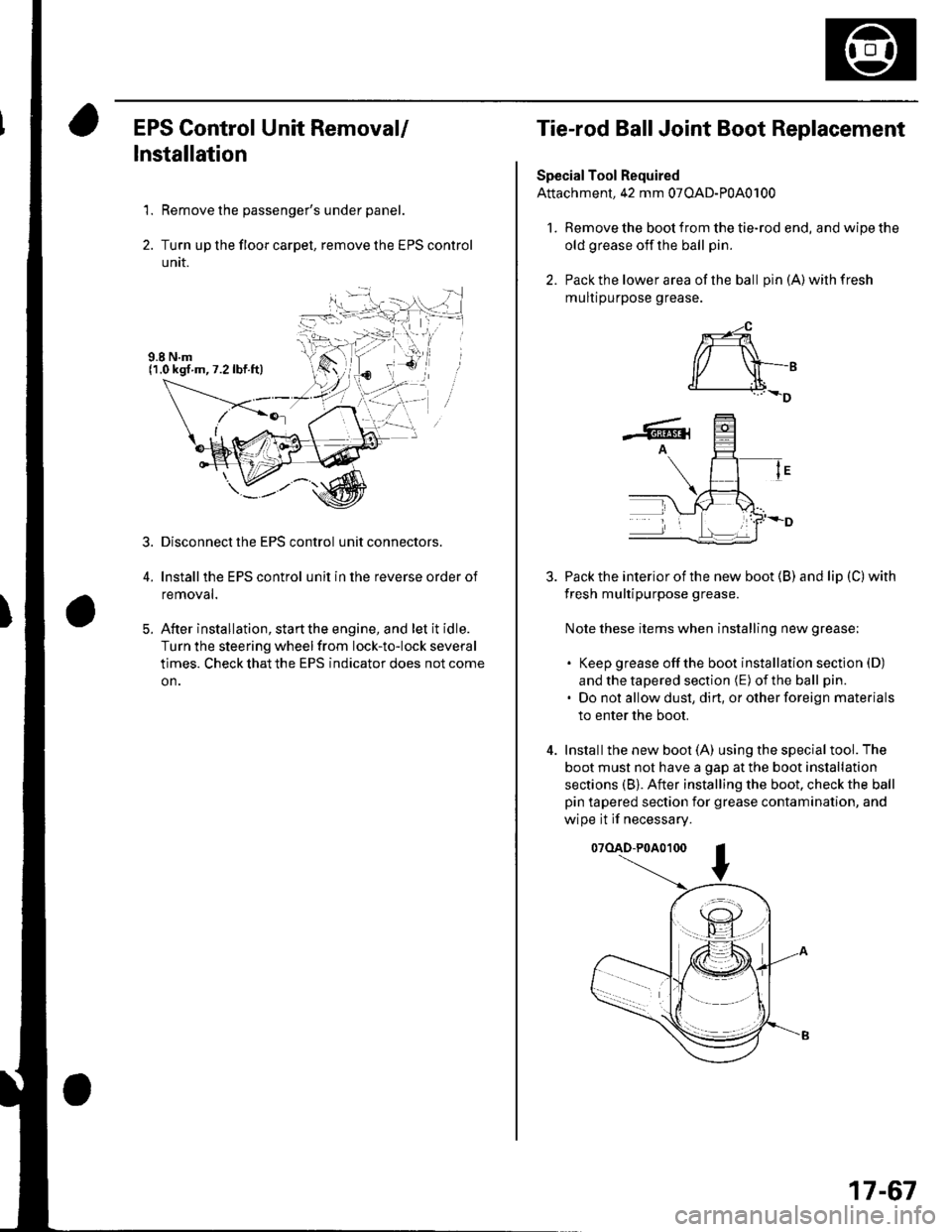

EPS Control Unit Removal/

Installation

1. Remove the passenger's under panel.

2. Turn up the floor carpel, remove lhe EPS control

untr.

Disconnect the EPS control unit connectors.

lnstallthe EPS control unit in the reverse order of

removal.

After installation, start the engine, and let it idle.

Turn the steering wheelfrom lock-to-lock several

times. Check that the EPS indicator does not come

on.

3.

E

Tie-rod Ball Joint Boot Replacement

Special Tool Required

Attachment, 42 mm 07OAD-P0A0100

l. Remove the boot from the tie-rod end, and wipe the

old grease off the ball pin.

2. Pack the lower area of the ball pin(A)wilhfresh

mulr purpose grease.

3. Pack the interior of the new boot (B) and lip (C) with

fresh multipurpose grease.

Note these items when installing new grease;

. Keep grease offthe boot installation section (D)

and the tapered section (E) of the ball pin.

. Do not allow dust, dirt, or other foreign materials

to enter the boot.

4. Installthe new boot (A) using the specialtool. The

boot must not have a gap at the boot installation

sections (B). After installing the boot. check the ball

pin tapered section for grease contamination, and

wipe it if necessary.

07(lAD-P0A0100

*-4

r/ \-,d______i.l+_D

-6rA

17-67

Page 565 of 1139

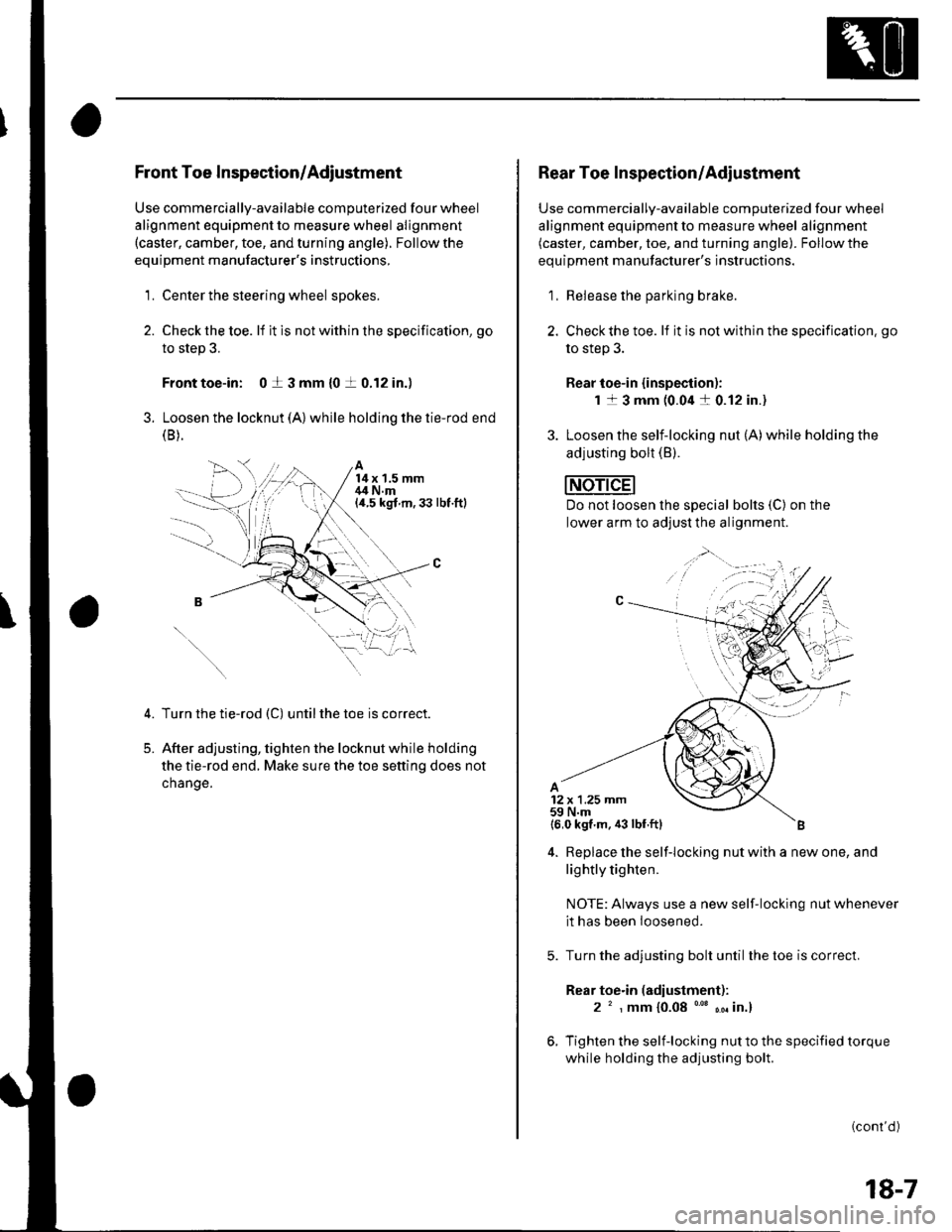

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions,

1. Center the steering wheel spokes.

2. Checkthetoe. lf it is not with in the specif ication, go

to step 3.

Front toe-in: 0 t 3 mm {0 t 0.12 in.)

3. Loosen the locknut (A) while holding the tie-rod end(B ).

A14x 1.5 mm,14 N.m(a.5 kgt m,33 lbt.ftl

5.

Turn the tie-rod (C) untilthe toe is correct.

After adjusting, tighten the locknut while holding

the tie-rod end. Make sure the toe setting does not

change.

1,;

Rear Toe Inspection/Adiustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions.

1, Release the parking brake.

2. Checkthe toe. lf it is not within the specification. go

to step 3.

Rear toe-in {inspection):

1 1 3 mm (0.04 a 0.12 in.)

3. Loosen the self-locking nut (A)while holding the

adjusting bolt (B).

Do not loosen lhe special bolts (C) on the

lower arm to adjust the alignment.

4. Replace the self-locking nut with a new one, and

lightly tighten.

NOTE: Always use a new self-locking nut whenever

it has been loosened.

Turn the adjusting bolt until the toe is correct.

Rear toe.in (adiustment):

2 ' , mm {0.08 "' ,. in.}

Tighten the self-locking nut to the specified torque

while holding the adjusting bolt.

(cont'd )

18-7

Page 566 of 1139

Front and Rear Suspension

Wheel Alignment (cont'dl

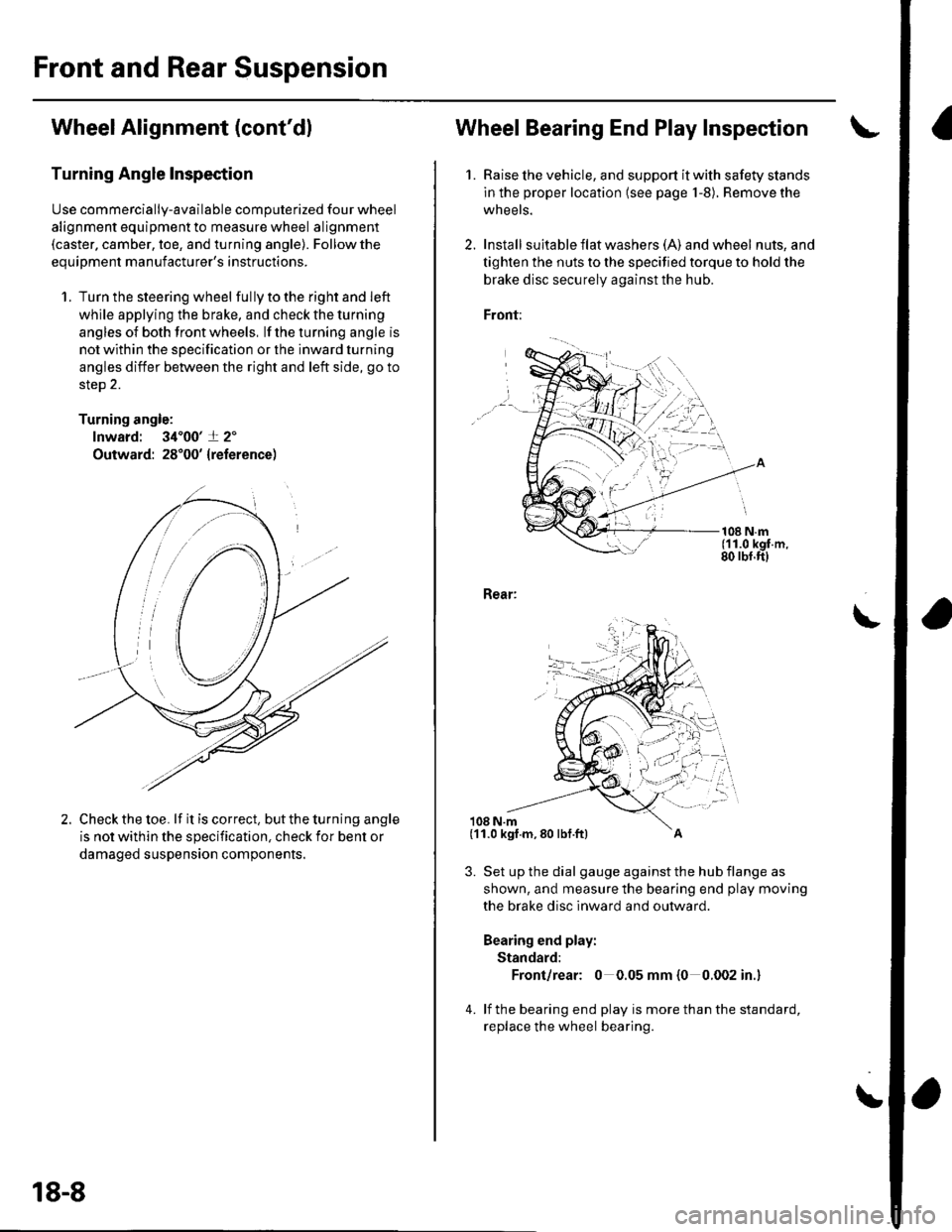

Turning Angle Inspection

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster. camber, toe, and turning angle). Followthe

equiDment manufacturer's instructions.

1. Turn the steering wheel fullytotherightandleft

while applying the brake, and check the turning

angles of both front wheels, lf the turning angle is

not within the specification or the inward turning

angles differ between the right and left side, go to

steD 2.

Turning angle:

lnward: 34'00'+ 2'

Outward: 28'00' {reference)

Check the toe. lf it is correct, but the turning angle

is not within the specification, check ior bent or

damaged suspension components,

18-8

Wheel Bearing End Play Inspec'tion

1. Raise lhe vehicle, and support it with safety stands

in the proper location (see page 1-8). Remove the

wheels.

2. Install suita ble f lat washe rs (A) and wheel nuts, and

tighten the nuts to the specified torque to hold the

brake disc securely against the hub.

Front:

108 N.m(11.0 kgf.m,80 rbf.ft)

Rear:

108 N.m

3. Set up the dial gauge against the hub flange as

shown, and measure the bearing end play moving

the brake disc inward and outward.

Bearing end play:

Standard:

Front/rear: 0 0.05 mm {0 0.002 in.}

4. lf the bearing end play is more than the standard,

replace the wheel bearing.

\

(11.0 kgf.m,80 lbf.ft)

Page 579 of 1139

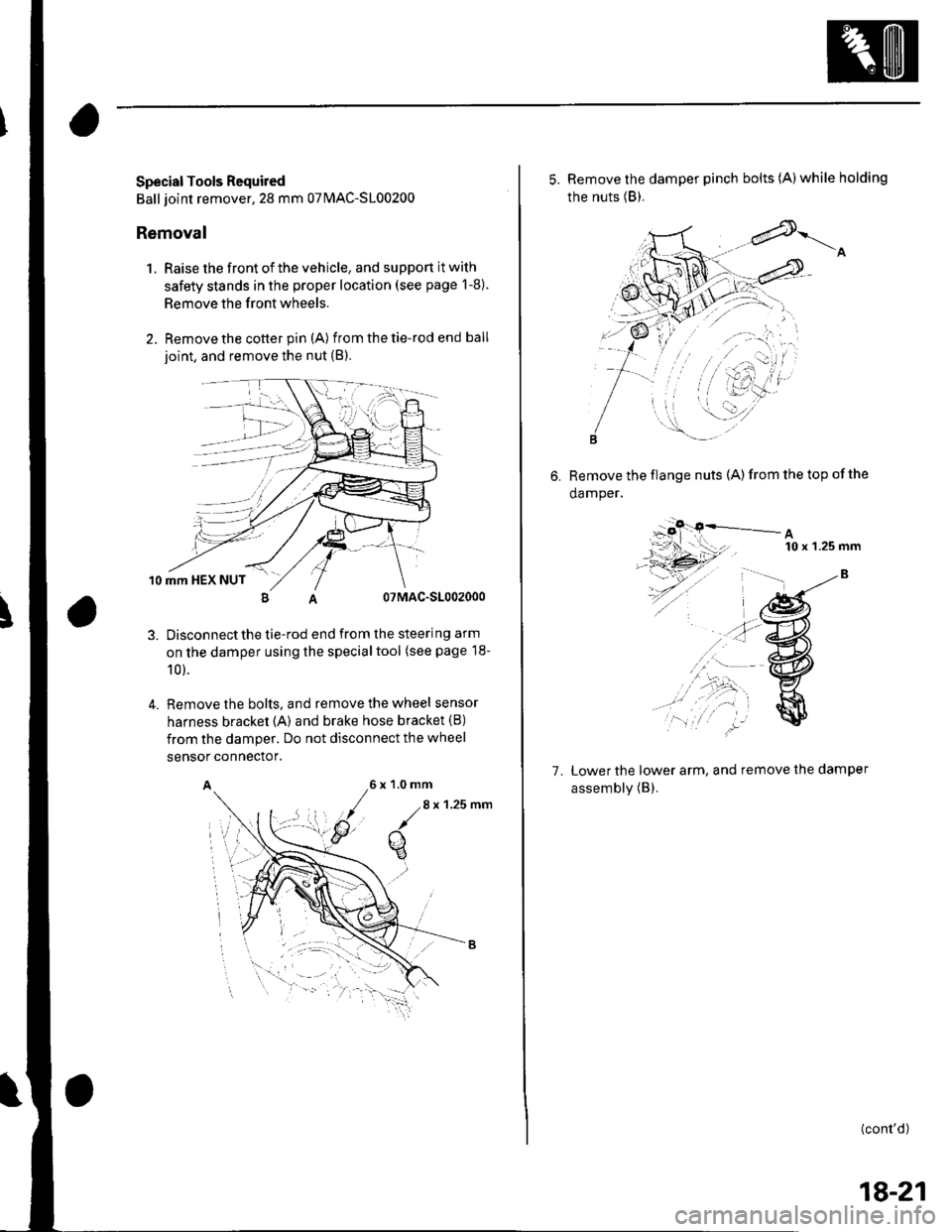

Special Tools Required

Ball joint remover,28 mm 07MAC-S100200

Removal

1. Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Remove the cotter pin (A) from the tie-rod end ball

ioint, and remove the nut (B).

10 mm HEX NUT

07MAC-S1002000

Disconnectthe tie-rod end from the steering arm

on the damper using the specialtool (see page 18-

10 ).

Remove the bolts, and remove the wheel sensor

harness bracket {A) and brake hose bracket (B)

from the damper. Do not disconnect the wheel

4.

sensor connector.

A6x1.0mm

/.8

x 1.25 nm

q

5. Remove the damper pinch bolts (A)while holding

the nuts (B).

6. Remove the flange nuts (A)from the top ofthe

damper,

A10 x 'l.25 mm

7. Lower the lower arm, and remove the damper

assembly (B).

(cont'd)

18-21

Page 583 of 1139

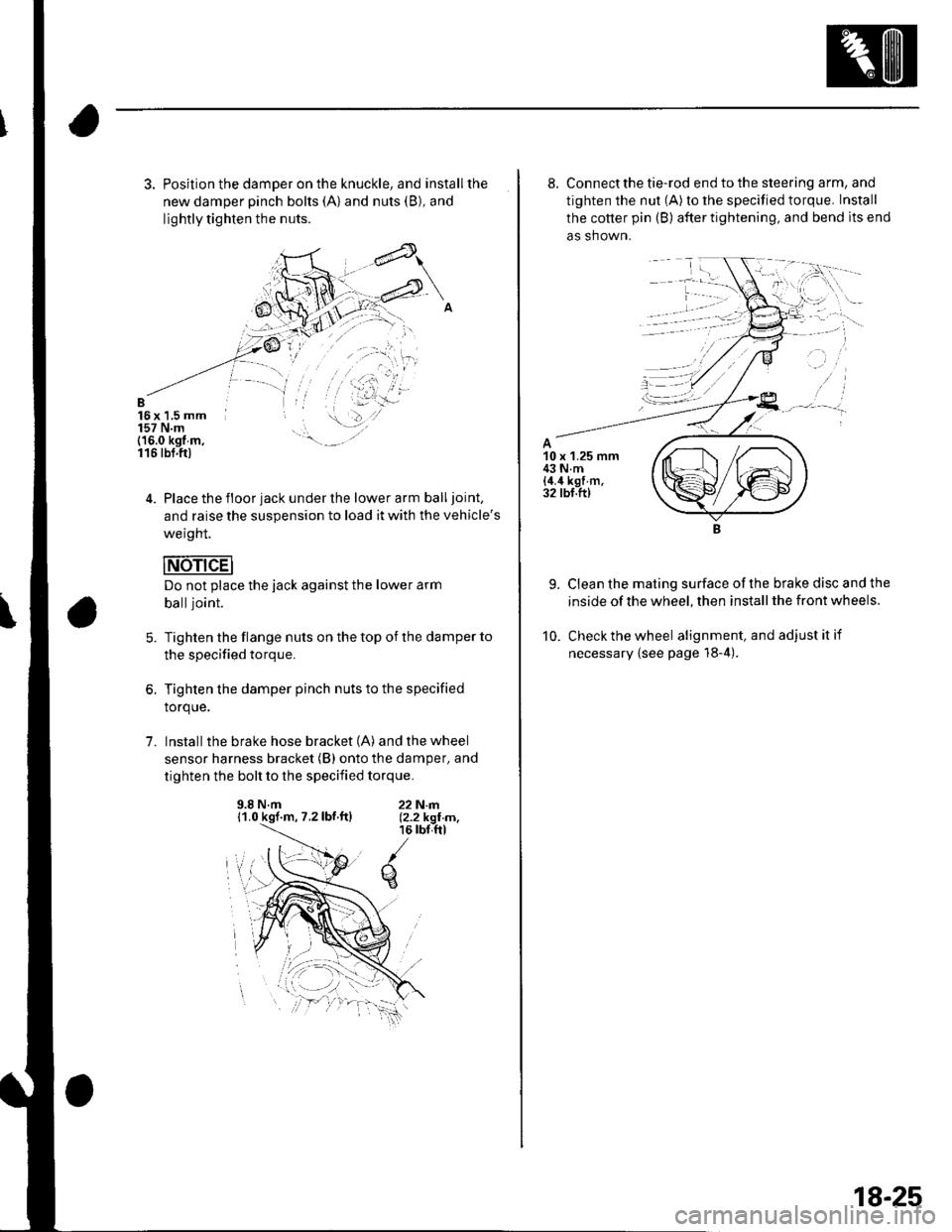

3. Position the damper on the knuckle, and installthe

new damper pinch bolts (A) and nuts (B), and

lightly tighten the nuts.

B16x 1,5 mm157 N.m(16.0 kgt m,116 tbt.ftl

4. Place the floor jack under the lower arm balljoint,

and raise the suspension to load it with the vehicle's

weight.

Do not place the jack against the lower arm

balljoint.

Tighten the flange nuts on the top of the damper to

the specified torque.

Tighten the damper pinch nuts to the specified

torque.

Install the brake hose bracket (A) and the wheel

sensor harness bracket (B) onto the damper, and

tighten the bolt to the specified torque.

5.

1.

9.8 N.m11.0 kgf.m, 7.2lbf.ftl22N|rl.12.2 kgI m,16 rbr,ftl

q

8. Connect the tie-rod end to the steering arm, and

tighten the nut (A) to the specified torque. Install

the cotter pin (B) after tightening, and bend lts end

as shown.

9. Clean the mating surface ofthe brake disc and the

inside of the wheel, then install the front wheels.

10. Check the wheel alignment, and adjustitif

necessary {see page 18-4).

18-25

Page 599 of 1139

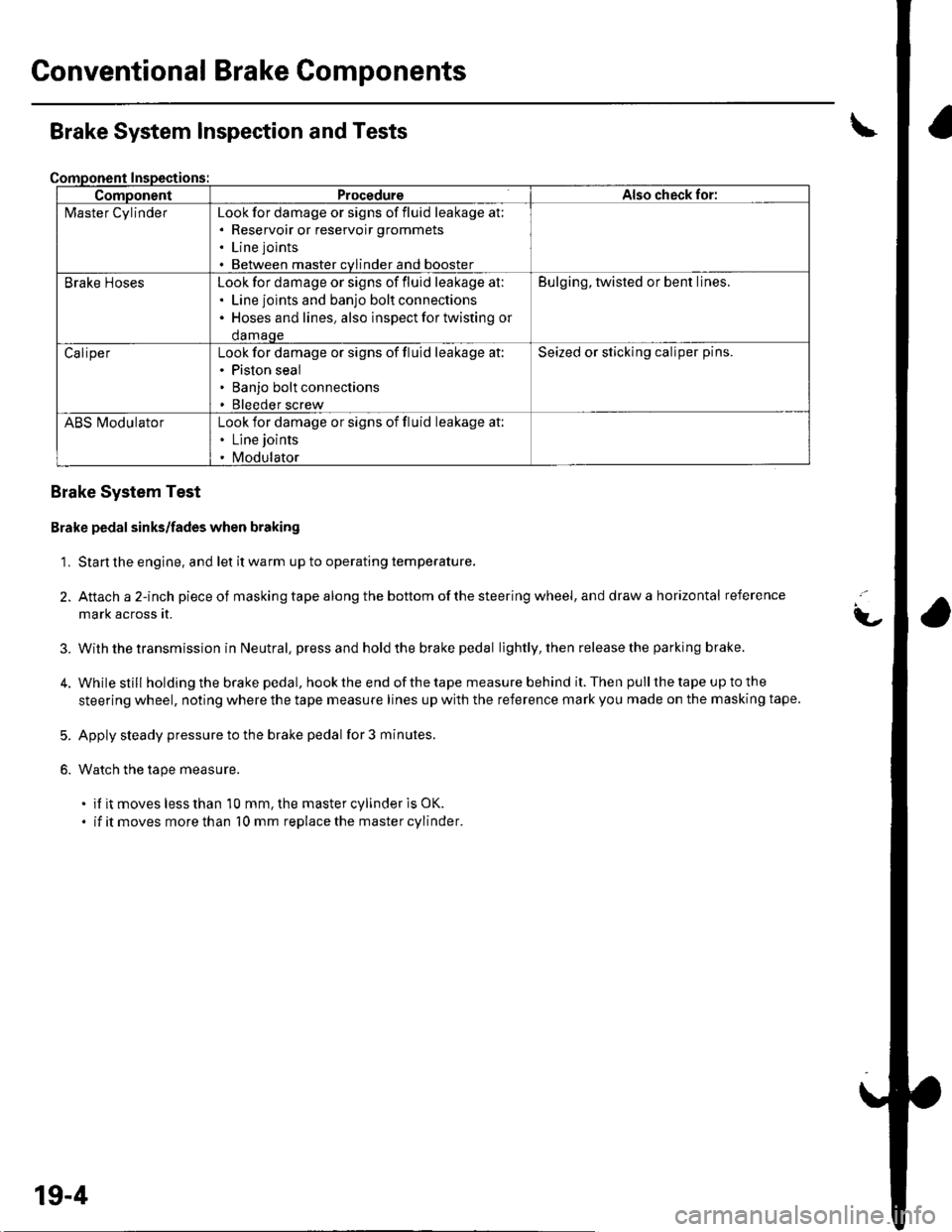

Gonventional Brake Components

ComponentProcedureAlso check for:

l\4aster CylinderLook for damage or signs of fluid leakage at;. Reservoir or reservoir grommets

. Line joints

. Between master cvlinder and booster

Brake HosesLook for damage or signs of fluid leakage at:. Line joints and banjo bolt connections. Hoses and lines. also inspect for twisting or

damaqe

Bulging, twisted or bent lines.

CaliperLook for damage or signs of fluid leakage at:. Piston seal. Banjo bolt connections. Bleeder screw

Seized or sticking caliper pins.

ABS l\ilodulatorLook for damage or signs of fluid leakage at:. Line joints

. Modulator

Brake System Inspection and Tests

Brake System Test

Brake pedal sinks/fades when braking

1. Start the engine, and let it warm up to operating temperature.

2. Attach a 2-inch pieceof masking tape along the bottom of the steering wheel, and draw a horizontal reference

mark across it.

With the transmission in Neutral, press and hold the brake pedal lightly, then release the parking brake.

While still holding the brake pedal, hook the end of the tape measure behind it. Then pull the tape up to the

steering wheel, noting where the tape measure lines up with the reference mark you made on the masking tape.

Apply steady pressure to the brake pedal for 3 minutes.

Watch the tape measure.

. if it moves less than 10 mm, the master cylinder is OK.

. if it moves more than 10 mm replace the master cylinder.

t-

3.

5.

6.

19-4

Page 954 of 1139

I

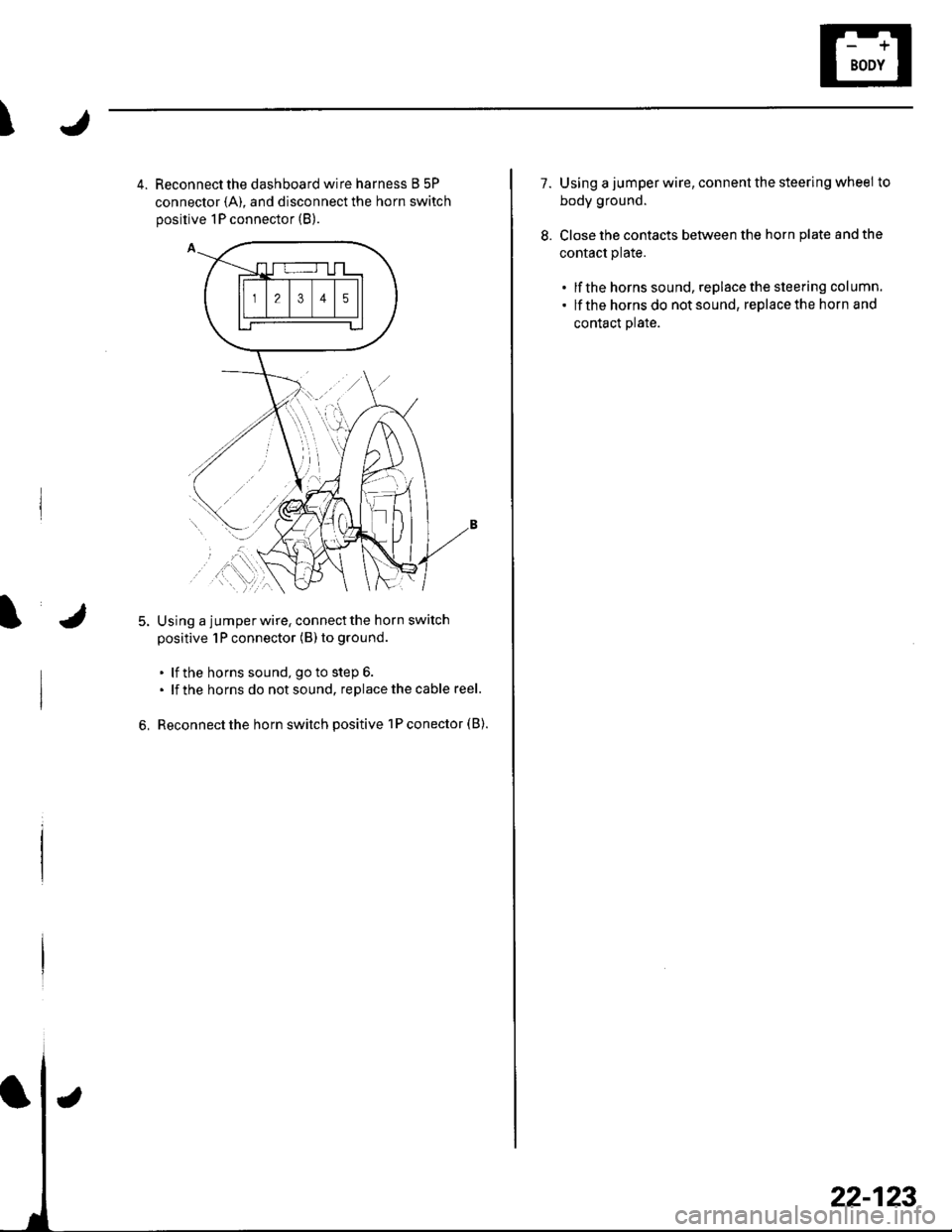

4. Reconnect the dashboard wire harness B 5P

connector {A), and disconnect the horn switch

positive 1P connector (B).

Using a jumperwire, connectthe horn switch

positive 1P connector (B) to ground

. lf the horns sound, go to step 6.. lf the horns do notsound, replacethecable reel.

Reconnect the horn switch positive 1P conector (B).6,

22-123

1.Using a jumper wire, connent the steering wheel to

body ground.

Close the contacts between the horn plate and the

contact plate.

. lf the horns sound, replacethe steering column.. lf the hornsdo notsound, replacethe horn and

contact plate.

8.

Page 1021 of 1139

sRs

Precautions and Procedures

General Precautions

Please read the following precautions carefully beforeperforming airbag system service. Observe theinstructions described in this manual. or the airbags

could accidentally deploy and cause damage or injuries.

. Except when performing electrical inspections.

always turn the ignition switch OFF, disconnect the

negative cable from the battery, and wait at least 3minutes before beginning work.

NOTE: The memory is not erased even if the ignition

switch is turned OFF or the battery cables are

disconnected from the battery.. Use replacement pans which are manufactured to the

same standards and quality as the original parts. Do

not install used SRS parts from another vehicle. Useonly new pans when making SRS repairs.. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being

dropped or improperly handled, such as dents, cracks,

or deformation.

. Before removing any SRS parts (including the

disconnection of connectors), always disconnect the

SRS connector.. Use only a digital multimeter to check the system. lf itis not a Honda multimeter, make sure its outout is 10mA (0.01A) or less when switched to the lowest value

in the ohmmeter range. A tester with a higher output

could cause accidental deployment and possible

injury.. Do not put objects on the front passenger's airbag.. The original radio has a coded theft protection circuit.

Be sure to get the customer's radio code and write

down the frequencies for the radio's preset stations

before disconnecting the battery cable.. Before returning the vehicle to the customer, enter

the radio code. then enter the customer's radio

station presets, and set the clock. Do the engine

control module (ECM) idle learn procedure (see page

11-139).

23-14

c

Steering-related Plecautions

Cable Reel Alignment

. Misalignment of the cable reel could cause an open in

the wiring, making the SRS system and the horns

inoperative. Center the cable reel whenever the

following is performed (see step 6 on page 23-121).

- Installation of the steering wheel- Installation of the cable reel- Installation ofthe steering column- Other steering-related adjustment or installation

. Do not disassemble the cable reel.

. Do not apply grease to the cable reel.

. lf the cable reel shows any signs of damage or

contamination. replace it with a new one. For

example, it does not rotate smoothly.

Page 1028 of 1139

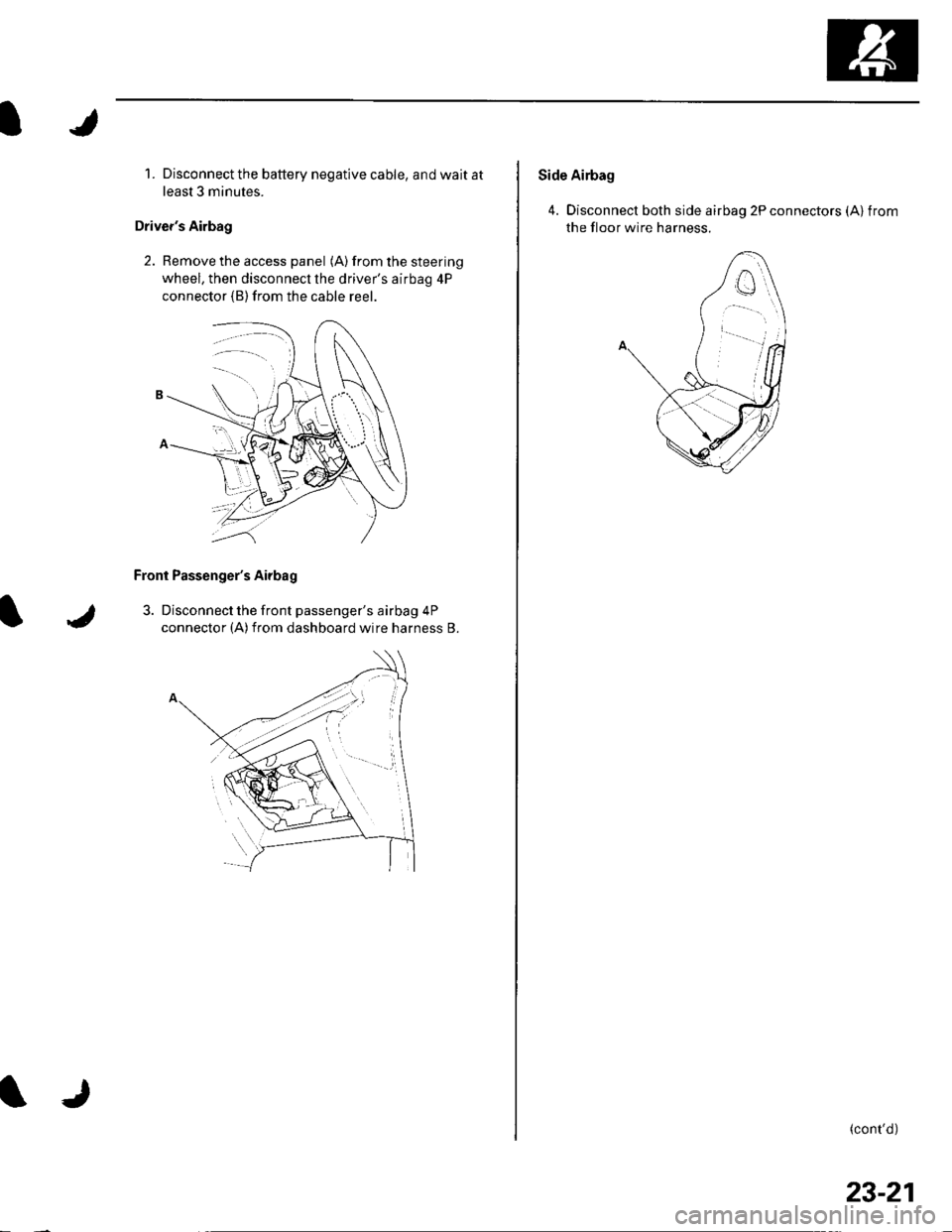

1. Disconnect the battery negative cable, and wait at

least 3 minutes.

Driver's Airbag

2. Remove the access panel (A) from the steering

wheel, then disconnecl the driver's airbag 4P

connector (B)from the cable reer.

Front Passenger's Airbag

3. Disconnect the front passenger's airbag 4P

connector (A)from dashboard wire harness B.

Side Airbag

4. Disconnect both side airbag 2P connectors (Alfrom

the floor wire harness.

(cont'd)

23-21