Transmission HONDA CIVIC 2002 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 438 of 1139

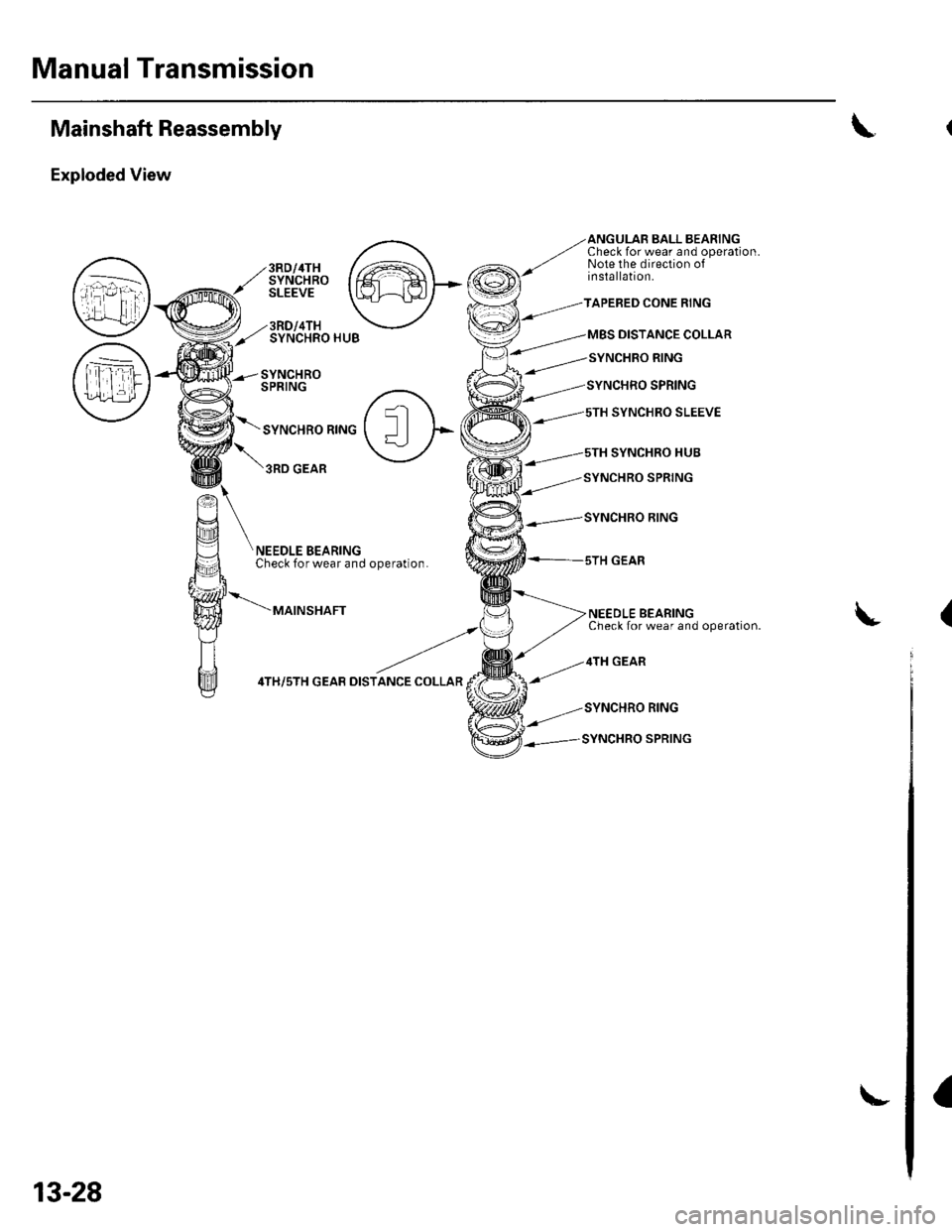

Manual Transmission

Mainshaft Reassembly

Exploded View

A

QJ'

frfl

Y7

ANGULAB BALL BEARINGCheck for wear and operation.Note the direction ofinstallation.3RD/4THSYNCHROSLEEVE

3RD/4THSYNCHRO HUB

SYNCHROSPRING

SYNCHRO RING

TAPEBED CONE RING

MBS DISTANCE COLLAR

SYNCHRO SLEEVE

NEEDLE BEARINGCheck for wear and operation.

GEAR

SYNCHRO RING

SYNCHRO SPRING

NEEDLE BEARINGCheck for wear and operation.

MAINSHAFT

4TH/5TH GEAB DISTANCE COLLAR

\(

a

13-28

Page 440 of 1139

Manual Transmission

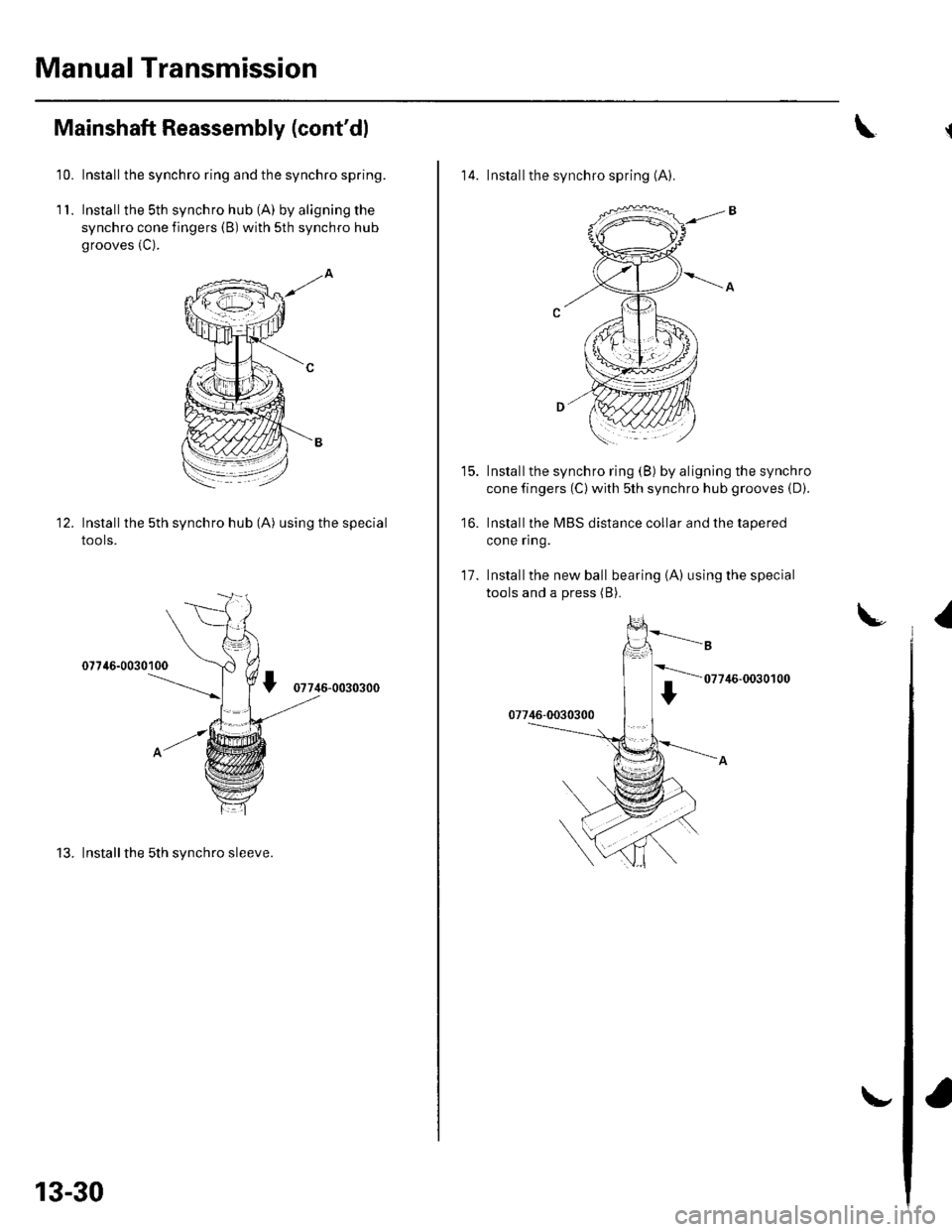

Mainshaft Reassembly (cont'dl

10. Installthe synchro ring and the synchro spring.

1 '1. Installthe sth synchro hub (A) by aligning the

synchro cone fingers (B) with sth synchro hub

grooves (C).

Installthe 5th synchro hub (A) using the special

tools.

07746-0030100

07746-0030300

13. Installthe 5th synchro sleeve.

12.

13-30

\.

\

14. Installthe synchro spring (A).

Installthe synchro ring (B) by aligning the synchro

cone fingers (C) with sth synchro hub grooves (D).

Installthe MBS distance collar and the tapered

cone ring.

Installthe new ball bearing {A) using the special

tools and a press (B).

t5.

16.

11.

U1

07746-0030100

Page 442 of 1139

Manual Transmission

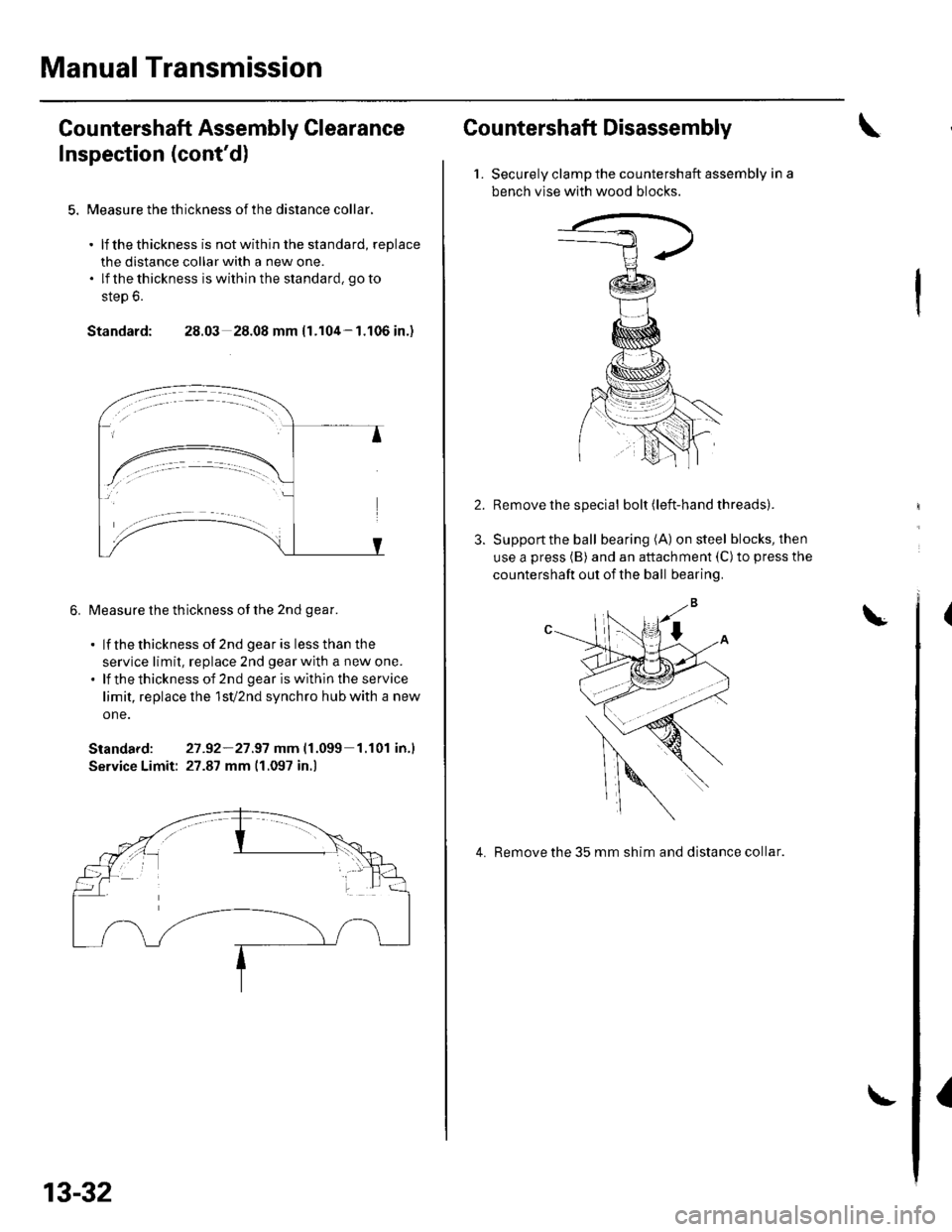

Countershaft Assembly Clearance

Inspection (cont'd)

5. Measure the th ickness of the distance collar.

. lf thethickness is notwithin the standard, replace

the distance collar with a new one.. lf thethickness iswithinthe standard, goto

step 6.

Standard: 28.03 28.08 mm {1.104-1.106 in.)

6. Measure the thickness of the 2nd qear.

. lf thethickness of 2nd gearis lessthan the

service limit, replace 2nd gear with a new one.. lf thethicknessof 2nd geariswithintheservice

limit, replace lhe 1sV2nd synchro hub with a new

one.

Standard: 27 -92-21.97 mm|.1.099 1.r01 in.l

Service Limit: 27.87 mm 11.097 in.)

13-32

Countershaft Disassembly

1.Securely clamp the countershaft assembly in a

bench vlse with wood blocks.

Remove the special bolt (left-hand threads).

Support the ball bearing (A) on steel blocks, then

use a press (B) and an attachment (C)to press the

countershaft out of the ball bearing.

4. Remove the 35 mm shim and distance collar.

I

Page 443 of 1139

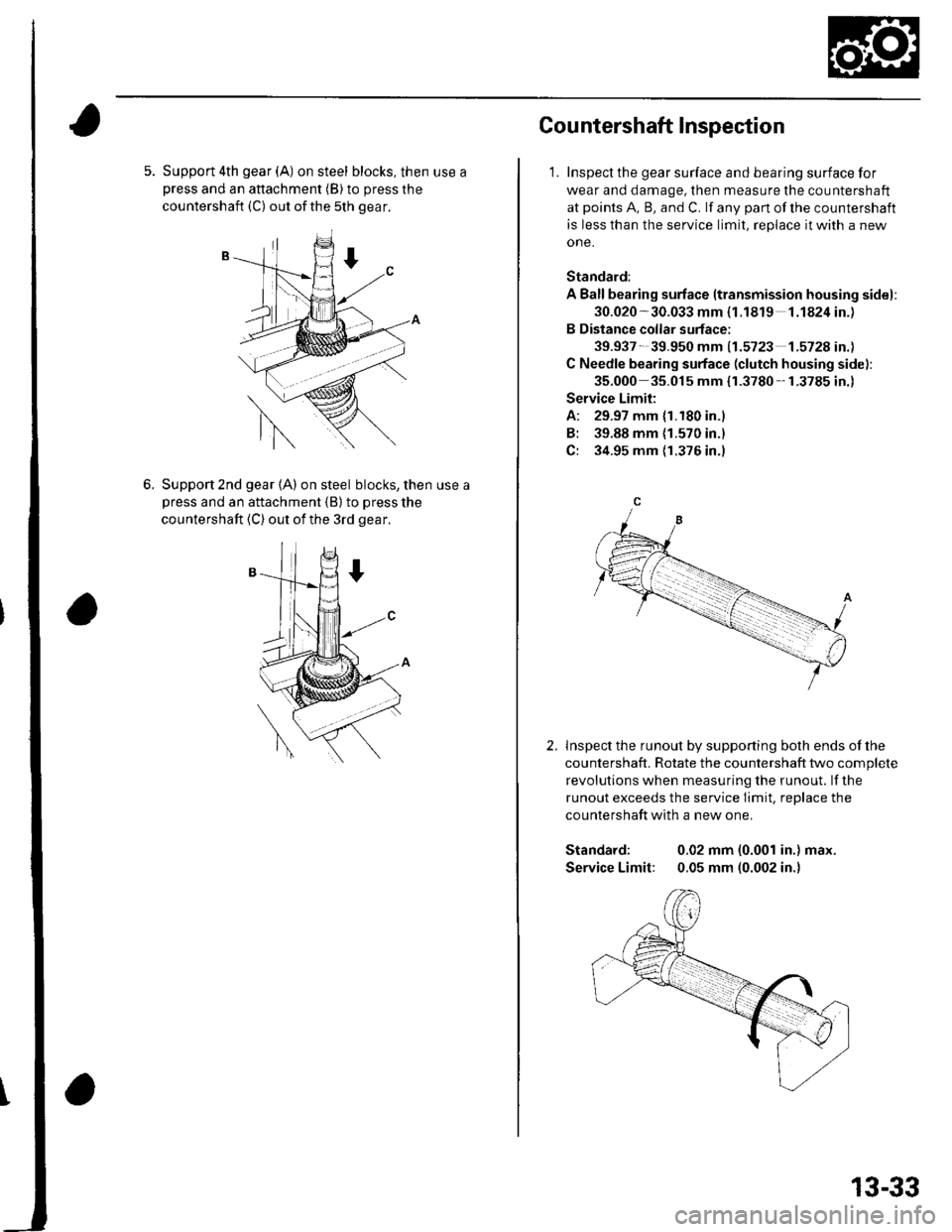

5. Support 4th gear (A) on steel blocks, then use apress and an attachment (B) to press the

countershaft (C) out ofthe 5th gear.

6.Support 2nd gear (A) on steel blocks, then use a

Dress and an attachment {B} to press the

countershaft (C) out of the 3rd gear.

Cou ntershaft lnspection

1. Inspect the gear surface and bearing surface for

wear and damage, then measure the countershaft

at points A, B, and C. lf any part of the countershaft

is less than the service limit, replace it with a new

one.

Standard:

A Ballbearing surface ltransmission housing sidel:

30.020 -30.033 mm {1.1819 1.1824in.)

B Distance collar surface;

39.937- 39.950 mm 11.5723 1.572A in.l

C Needle bearing surface (clutch housing side):

35.000 35.015 mm {r.3780-1.3785 in.)

Service Limit:

A: 29.97 mm {1.180 in.)

B: 39.88 mm {1.570 in.l

C: 34.95 mm {1.376 in.)

lnspect the runout by supporting both ends of lhe

countershaft. Rotate the countershaft two complete

revolutions when measuring the runout. lf the

runout exceeds the service Iimit, replace the

countershaft with a new one.

Standard: 0.02 mm (0.001 in.) max.

Service Limit: 0.05 mm (0.002 in.)

2.

13-33

Page 444 of 1139

Manual Transmission

(

(

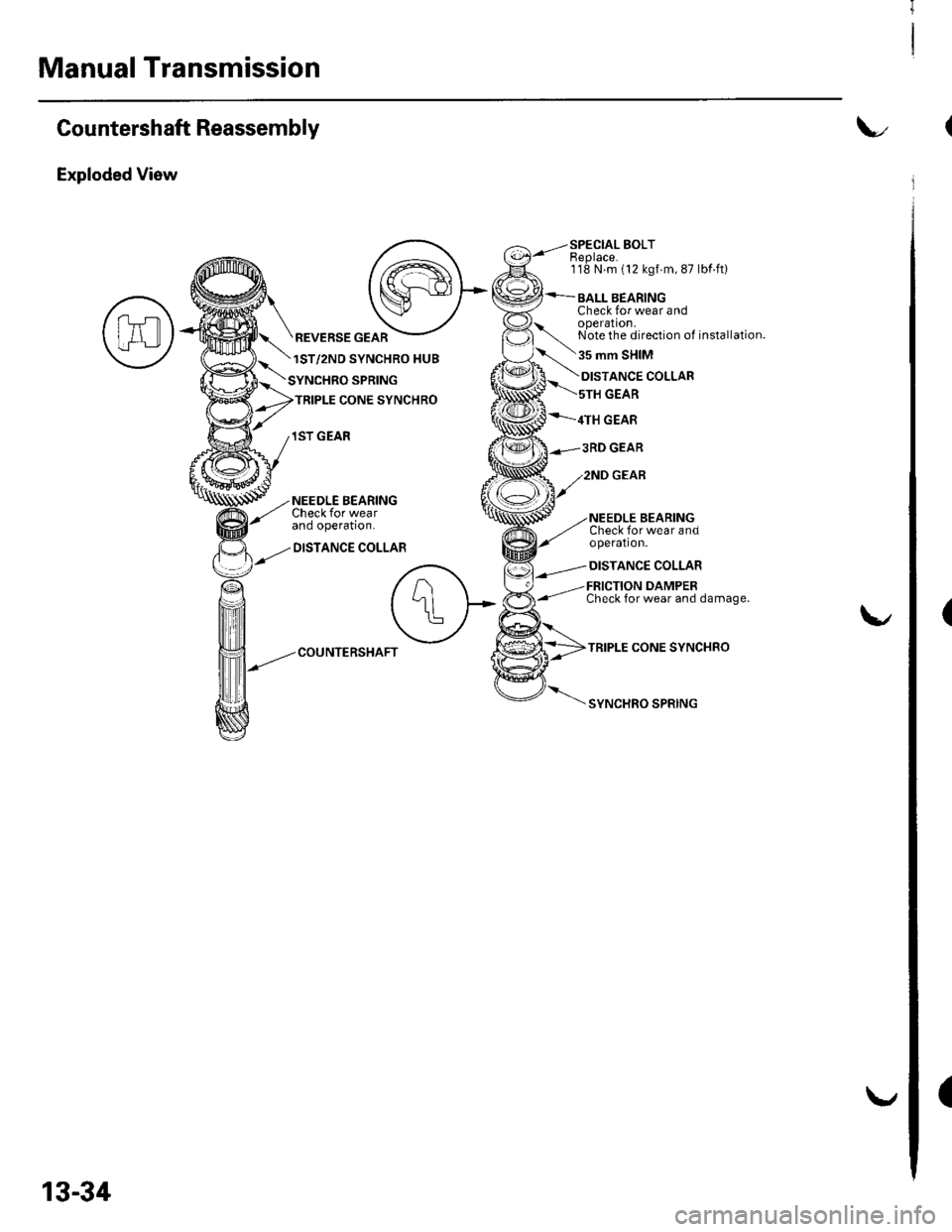

Countershaft Reassembly

Exploded View

SPECIAL BOLTEeplace.118 N.m (12 kgf m, 87 lbf ft)

BALL BEARINGCheck for wear andoperation.Note the direction of installation.

35 mm SHIM

REVERSE GEAR

1ST/2ND SYNCHRO HUB

SPRING

TRIPLE CONE SYNCHRO

1ST GEAR

NEEDLE BEARINGCheck for wearano opera!on.

DISTANCE COLLAR

ANCE COLLAR

GEAR

4TH GEAR

Check for wear andoperation.

DISTANCE COLLAR

FRICTION DAMPERCheck for wear and damage.

TRIPLE CONE SYNCHRO

SYNCHRO SPRING

COUNTERSHAFT

13-34

Page 446 of 1139

Manual Transmission

10.

Countershaft Reassembly (cont'dl

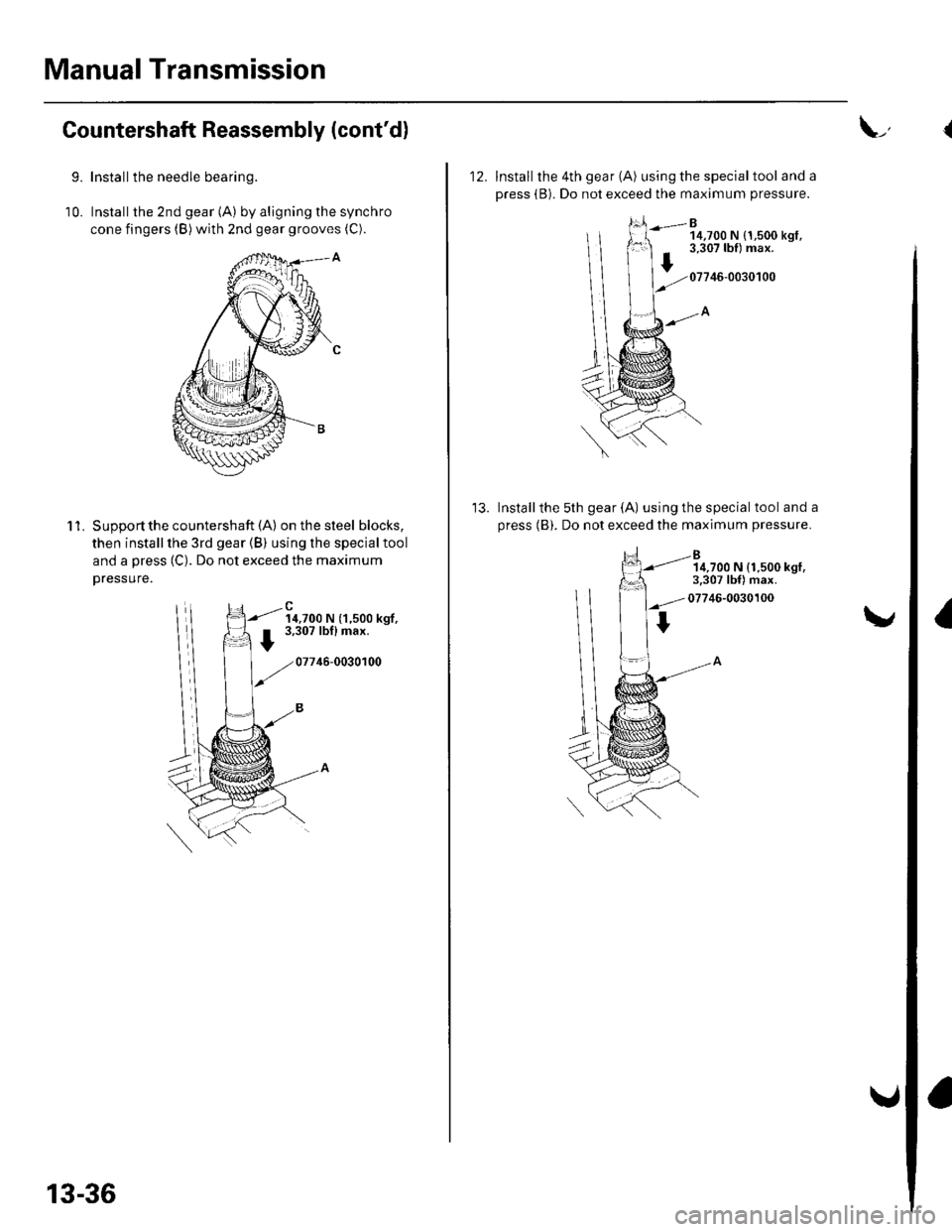

9.Install the needle bearing.

Installthe 2nd gear (A) by aligning the synchro

cone fingers (B) with znd gear grooves (C).

'l 1.Supoort the countershaft (A) on the steel blocks,

then install the 3rd gear (B) using the special tool

and a press (C). Do not exceed the maximum

Dressure.

14,700 N (1,500 kgf,3,307 lbflmax.

07746-0030100

13-36

L,

12. Install the 4th gear (A) using the specialtool and a

press (B). Do not exceed the maximum pressure.

B14,700 N {1,500 kgt,3,307 lbf) max.

07746-0030100

Installthe 5th gear (A) using the special tool and a

press (B). Do not exceed the maximum pressure.

14,700 N (1.500 kgl,3.307 lbf) max.

07746-0030100

I

Page 448 of 1139

Manual Transmission

Countershaft Reassembly (cont'd)

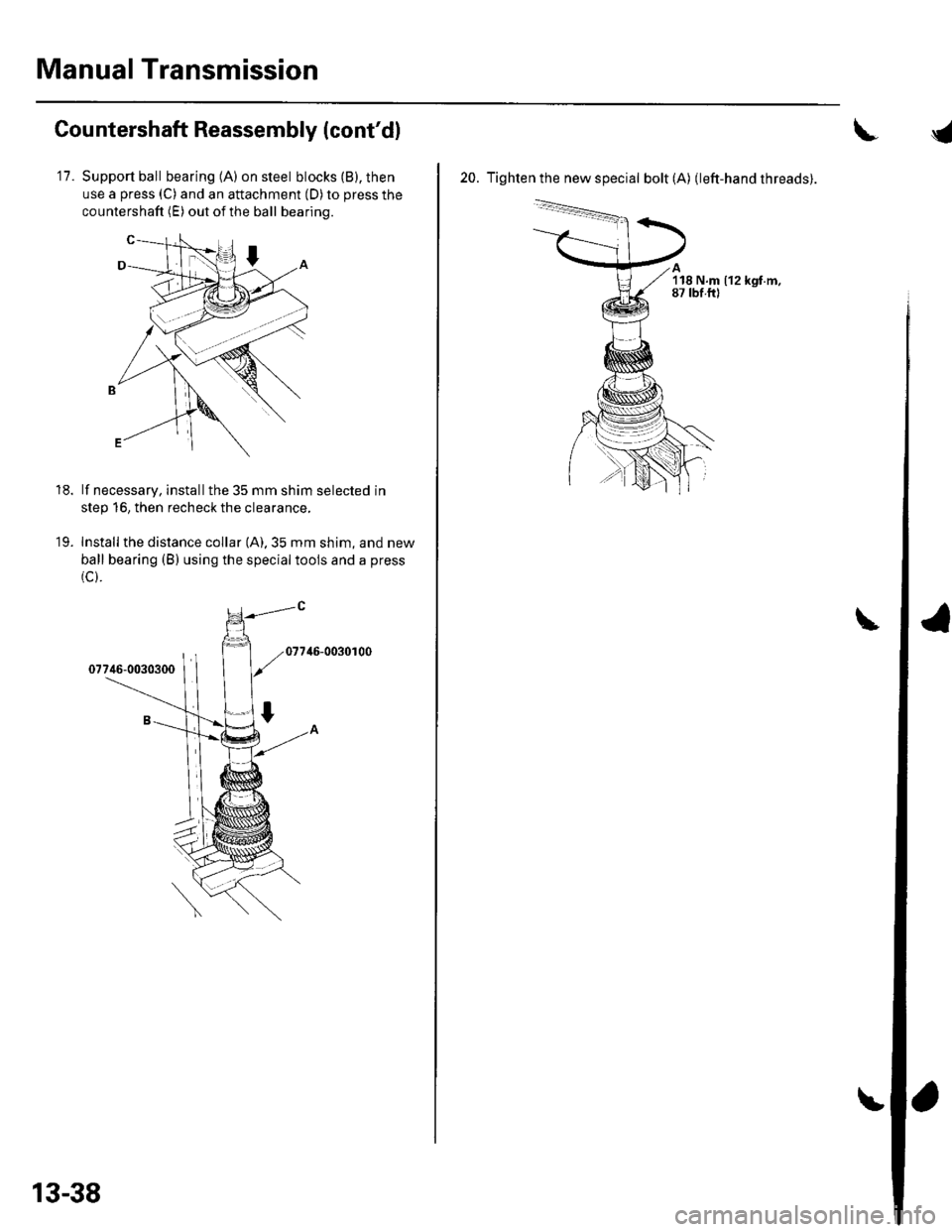

11.Support ball bearing (A) on steel blocks (B), then

use a press (C) and an attachment (D) to press the

countershaft (E) out of the ball bearing.

lf necessary, installthe 35 mm shim selected in

step 16, then recheck the clearance,

Install the distance collar (A).35 mm shim, and new

ball bearing (B) using the specialtools and a press

(c).

46-0030r00

18.

19.

13-38

20. Tighten the new special bolt (A) (left-hand threads).

'l18 N.m (12 kgf.m,87 tbf.ftl

Page 450 of 1139

Manual Transmission

Synchro Ring and Gear Inspection (cont'dl

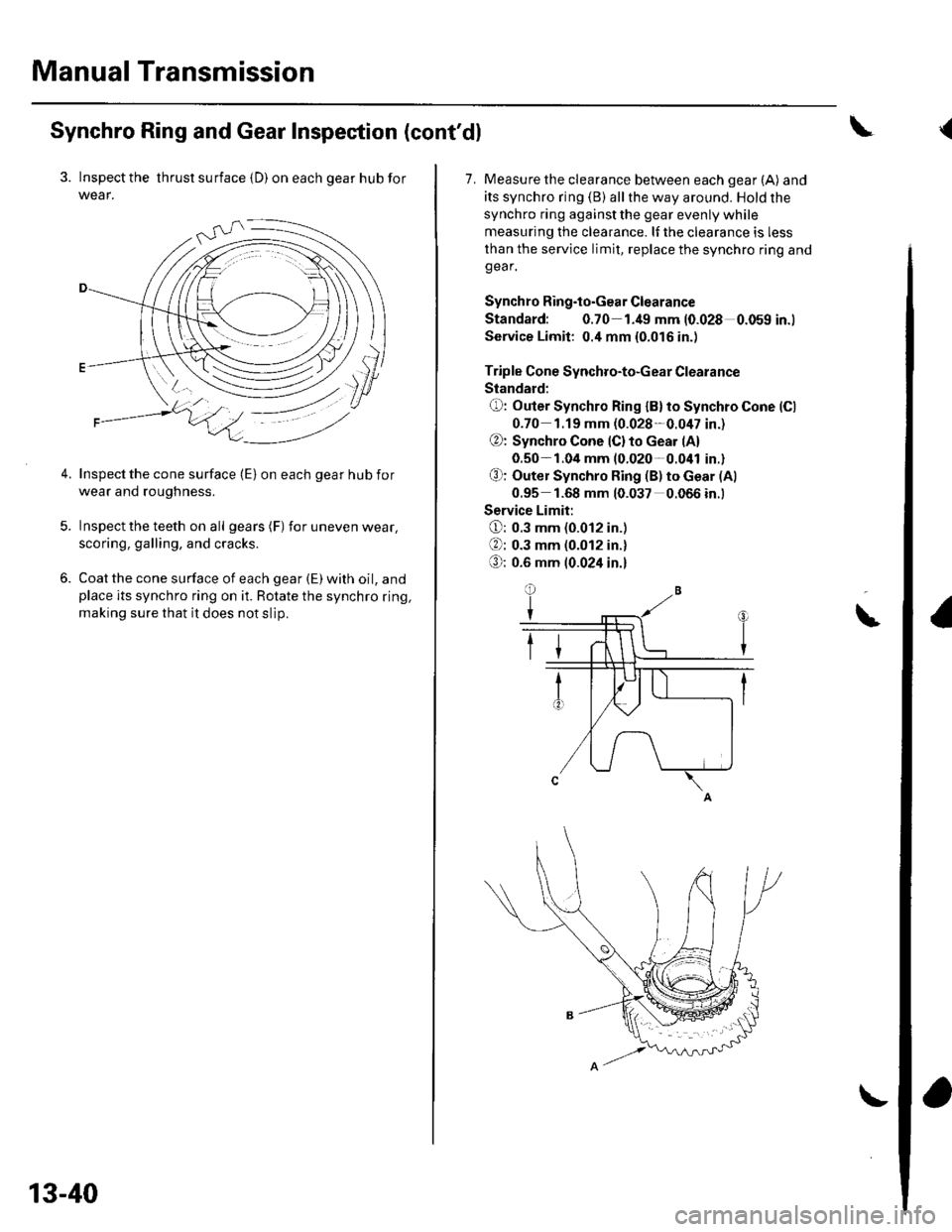

3. Inspect the thrust surface {D) on each gear hub for

wear.

Inspect the cone surface (E) on each gear hub for

wear ano rougnness.

Inspect the teeth on all gears (F) for uneven wear,

scoring, galling, and cracks.

Coat the cone surface of each gear (E) with oil, andplace its synchro ring on it. Rotate the synchro ring,

making sure that it does not slip.

13-40

\

7. Measure the clearance between each gear (A) and

its synchro ring (B) allthe way around. Hold the

synchro ring against the gear evenly while

measuring the clearance. lf the clearance is less

than the service limit, replace the synchro ring andgear.

Synchro Ring.to.Gear Clearance

Standard: 0.70 1.49 mm 10.028 0.059 in.)

Service Limit: 0.4 mm {0.016 in.)

Triple Cone Synchro-to-Gear Clearance

Slandard:

O: Outer Synchro Ring {B}to Synchro Cone (Cl

0-70 1.19 mm (0.028-0.047 in.)

@: Synchro Cone lC) to cear (A)

0.50- 1.04 mm (0.020-0.041 in.)

O: Outer Synchro Ring (B) to Gear (Al

0.95 1.68 mm 10.037 0.066 in.)

Service Limit:

O: 0.3 mm (0.012 in.)

: 0.3 mm (0.012 in.)

O; 0.6 mm 10.024 in.l

\

{

Page 451 of 1139

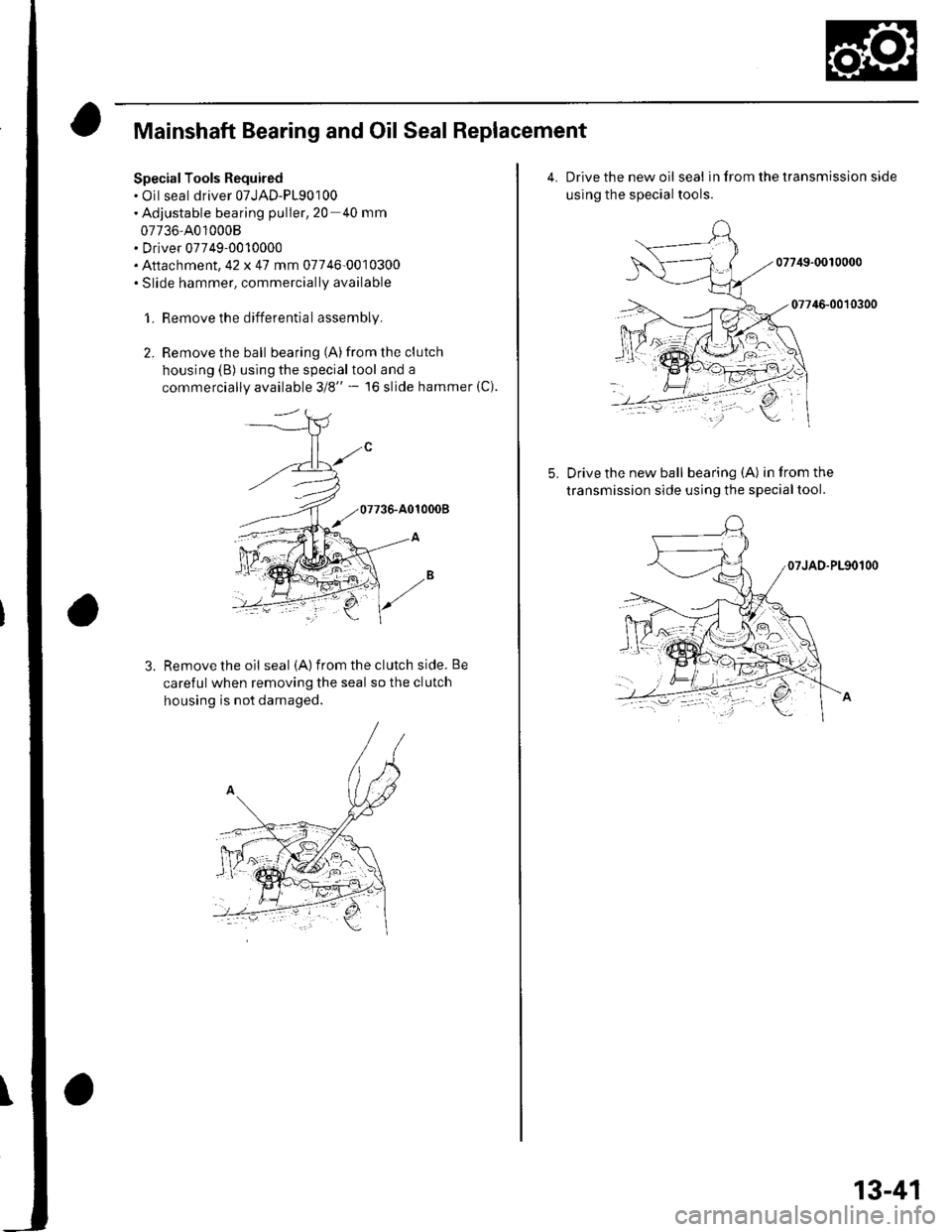

Mainshaft Bearing and Oil Seal Replacement

Special Tools Required. Oil seal driver 07JAD-P190100. Adjustable bearing puller,20 40 mm

07736-4010008. Driver 07749-0010000. Attachment,42 x 47 mm 07746-0010300. Slide hammer, commercially available

1. Remove the differential assembly,

2. Remove the ball bearing (A)from the clutch

housing (B) using the specialtool and a

commercially available 3/8" - l6 slide hammer (C).

Remove the oil seal (A) from the clutch side. Be

careful when removing the seal so the clutch

housing is not damaged.

4.Drive the new oil seal in from the transmission side

using the special tools.

07749-0010000

07746-0010300

Drive the new ball bearing (A) in from the

transmission side using the specialtool.

13-41

Page 452 of 1139

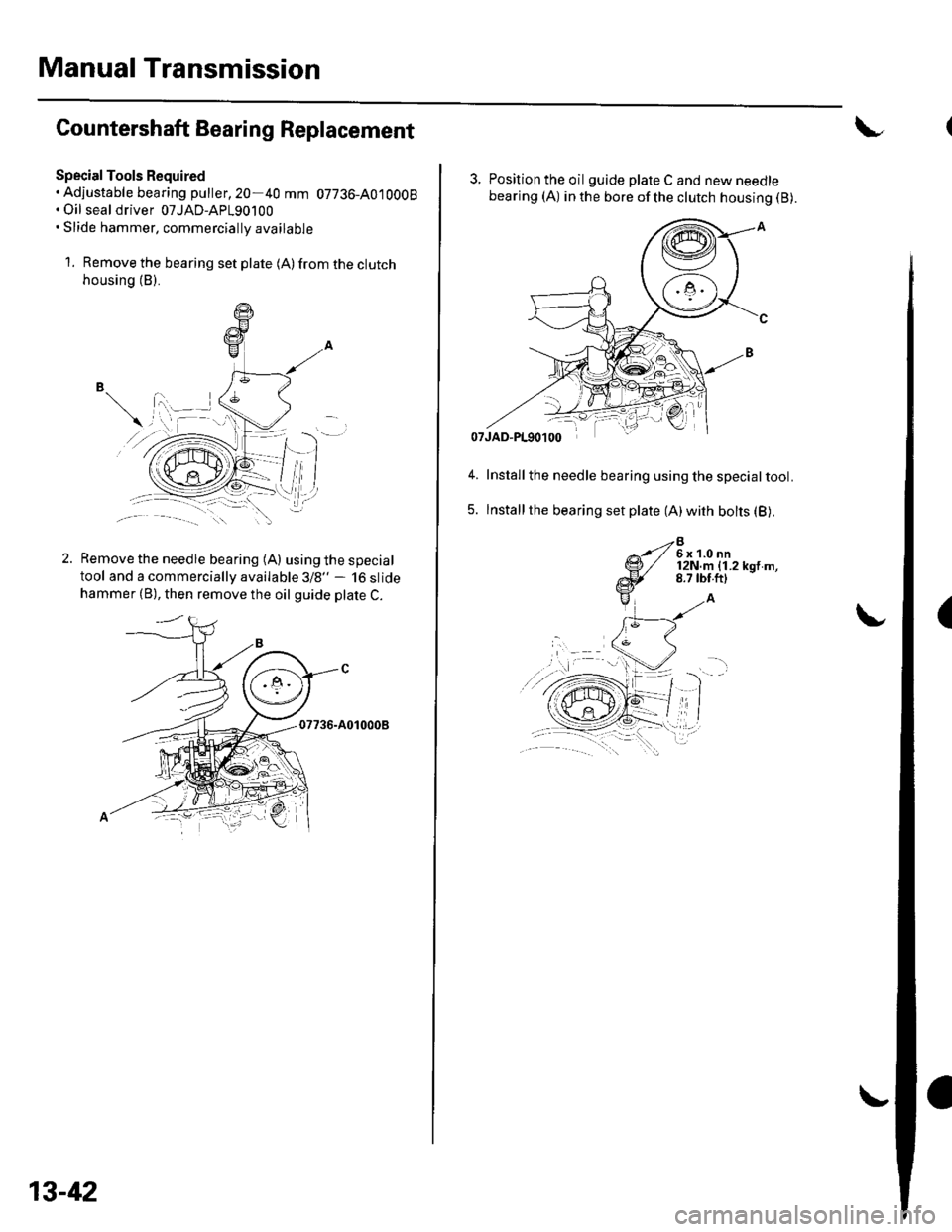

Manual Transmission

Countershaft Bearing Replacement

Special Tools Required. Adiustable bearing puller,20-40 mm 07736-A0tOOOB. Oil seal driver 07JAD-AP190100. Slide hammer, commercially available

1. Remove the bearing set plate (A)from the clutchhousing (B).

Remove the needle bearing (A) using the special

tool and a commercially available 3/8" - 16 slidehammer (B), then remove the oil guide plate C.

07736-A010008

13-42

3. Position the oil guide plate C and new needle

bearing (A) in the bore of the clutch housing (B).

Installthe needle bearing using the specialtool.

Installthe bearing set plate (A) wirh bolts (B).

B6x 1.0 nn12N.m {1.2 kgt m,8.7 tbf.ft)

(