Tdc sensor HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 99 of 1139

![HONDA CIVIC 2002 7.G Workshop Manual Cylinder Head

Component Location Index (contd)

CAMSHAFT POSITIONICMP} SENSOR

TOP DEAD CENTER(TDC) SENSOR

CAMSHAFTHOLDER

f\

fr

T

F]

Fg

Y

R

LI

CAM CHAINGUIDE B

/EEI

g----- -"-oowetew

EXHAUST CAMSHAFTSP HONDA CIVIC 2002 7.G Workshop Manual Cylinder Head

Component Location Index (contd)

CAMSHAFT POSITIONICMP} SENSOR

TOP DEAD CENTER(TDC) SENSOR

CAMSHAFTHOLDER

f\

fr

T

F]

Fg

Y

R

LI

CAM CHAINGUIDE B

/EEI

g----- -"-oowetew

EXHAUST CAMSHAFTSP](/img/13/5744/w960_5744-98.png)

Cylinder Head

Component Location Index (cont'd)

CAMSHAFT POSITIONICMP} SENSOR

TOP DEAD CENTER(TDC) SENSOR

CAMSHAFTHOLDER

f\

fr

T

F]

Fg

Y

R

LI

CAM CHAINGUIDE B

/EEI

g----- -"-oowetew

EXHAUST CAMSHAFTSPROCKETRemoval, page 6 24Installation, page 6-25

EXHAUST CAMSHAFT

ROCKER ARMASSEMBLYOverhaul, page 6 27Inspection, page 6-28

6-4

Page 118 of 1139

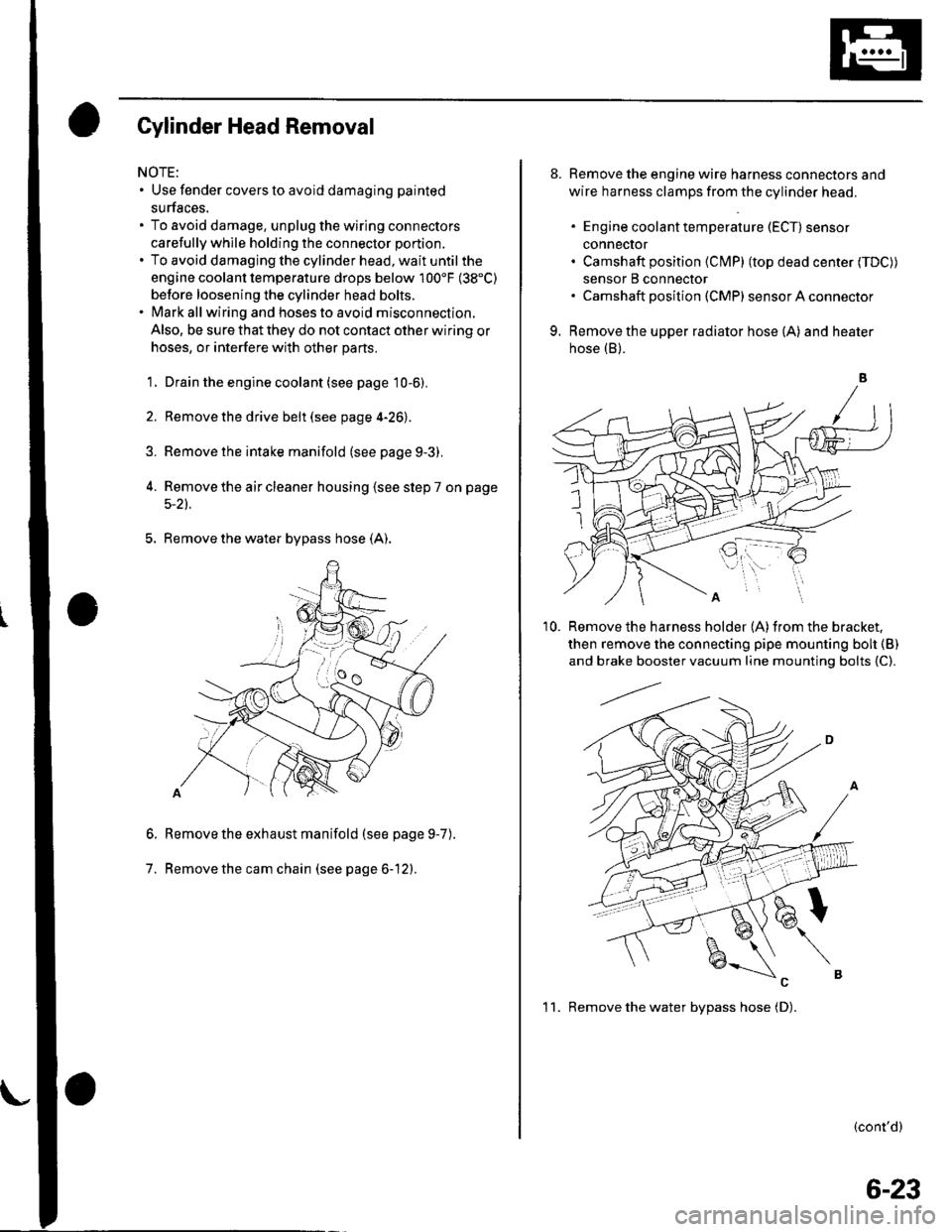

Gylinder Head Removal

NOTE:. Use fender covers to avoid damaging painted

surfaces.

To avoid damage, unplug the wiring connectors

carefully whlle holding the connector portion.

To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100'F (38"C)

betore loosening the cylinder head bolts.

Mark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

'1.

2.

3.

Drain the engine coolant (see page 10-6).

Remove the drive belt (see page 4-26).

Remove the intake manifold {see page 9-3).

Remove the air cleaner housing (see step 7 on page

5-2t.

5. Remove the water bypass hose (A).

Remove the exhaust manifold (see page 9-7

Remove the cam chain (see page 6-12).

6.

7.

).

8. Remove the engine wire harness connectors and

wire harness clamps from the cylinder head.

. Engine coolant temperature (ECT) sensor

conneclor. Camshaft position (Cl\4P) (top dead center (TDC))

sensor B connector. Camshaft posilion (CMP) sensor A connector

9. Remove the upper radiator hose (A) and heater

hose (B).

'10. Remove the harness holder (A)from the bracket,

then remove the connecting pipe mounting boh {B)

and brake booster vacuum line mounting bolts {C).

(cont'd)

1 1. Remove the water bvpass hose (D).

6-23

Page 208 of 1139

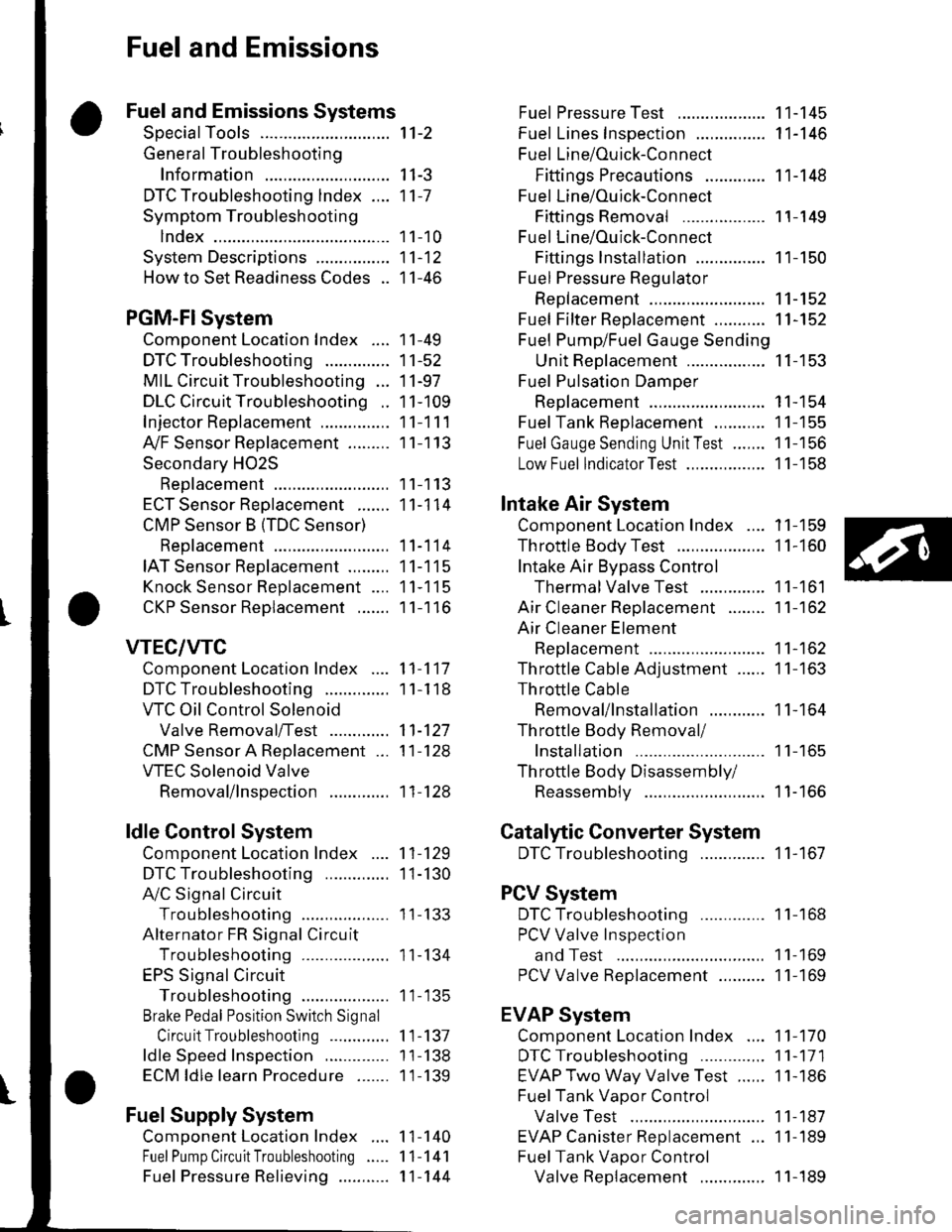

Fuel and Emissions

Fuel and Emissions Systems

SpecialTools

General Troubleshooting

Information

DTC Troubleshooting lndex ....

Symptom Troubleshooting

1ndex...............

System Descriptions ................

Howto Set Readiness Codes ..

PGM-FlSystem

Component Location Index ....

DTC Troubleshooting ..............

MIL Circuit Troubleshooting ...

DLC Circuit Troubleshooting ..

Injector Replacement ...............

A,/F Sensor Replacement .........

Secondary HO2S

Replacement

ECT Sensor Reolacement .......

CMP Sensor B {TDC Sensor)

Replacement

IAT Sensor Replacement .........

Knock Sensor Replacement ....

CKP Sensor Reolacement .......

VTEC/VTC

Comoonent Location Index ....

DTC Troubleshooting ..............

VTC Oil Control Solenoid

Valve Removal/Test .............

CMP Sensor A Replacement ...

VTEC Solenoid Valve

Removal/lnsoection .............

ldle Control System

Component Location Index

DTC Troubleshooting ..............

A,/C Signal Circuit

TroubleshootinS ...................

Alternator FR Signal Circu it

TroubleshootinS ...................

EPS Signal Circuit

TroubleshootinS ...................

Brake Pedal Position Switch Signal

Circuit Troubleshooting .............

ldle Speed Inspection

ECM ldle learn Procedure .......

Fuel Supply System

Component Location Index

Fuel Pump Circuit Troubleshooting

1't-2

I I-J

11-7

1 1-10

11-12

11-46

11-49

11-52

11-97

11-109

11-111

11-113

11-113

11-114

11-114

11-115

11-115

11-116

11-117

1 1-1 18

11-127

11-128

11-128

11-129

1I-130

I t- t55

11-134

1 1- 135

1 1-137

1 1-138

1 1-139

1 1-140

11-141

11-144

Fuel PressureTest ................... 11-145

Fuel Lines Inspection ............... 11-146

Fuel Line/Ouick-Connect

Fittings Precautions ............. 1 1-148

Fuel Line/Ou ick-Con nect

Fittings Removal .................. 1 1-149

Fuel Line/Ou ick-Con nect

Fittings lnstallation ............... 11-150

Fuel Pressure Regu lator

Replacement ......................... 11-152

Fuel Fifter Replacement ........... 11-152

Fuel Pump/Fuel Gauge Sending

UnitReDlacement ................. 11-153

Fuel Pulsation Damoer

Rep1acement ......................... 11-154

Fuel Tank Reolacement ........... 11-155

Fuel GaugeSending UnitTest ....... 11-156

Low Fuel lndicatorTest ................. 1 1-158

Intake Air System

Comoonent Location Index .... 11-159

Throttle BodyTest ................... 11-160

Intake Air Bypass Control

Thermal Valve Test .............. 11-161

Air Cleaner Reolacement ........ 11-162

Air Cleaner Element

Reolacement ......................... 11-162

Throttle Cable Adjustment ...... 11-163

Th rottle Cable

Removal/lnstallation ............ 1 1-164

Th rottle Body Removal/

Installation .. 11-165

Th rottle Body Disassembly/

Reassemblv .......................... 11-166

Catalytic Converter System

DTC Troubleshooting .............. 1 1-167

PCV System

DTC Troubleshooting .............. 1 1-168

PCV Valve InsDection

and Test ...... 1 1- 169

PCV Valve Reolacement .......... 11-169

EVAP System

Component Location Index .... 11-170

DTCTroubleshooting .............. 11-171

EVAP Two Way Valve Test ...... 11-186

Fuel Tank Vaoor Control

Valve Test ... 11-187

EVAP Canister Replacement ... 11-189

Fuel Tank Vaoor Control

Valve Reolacement .............. 1 1-189Fuel Pressu re Relieving ...........

Page 216 of 1139

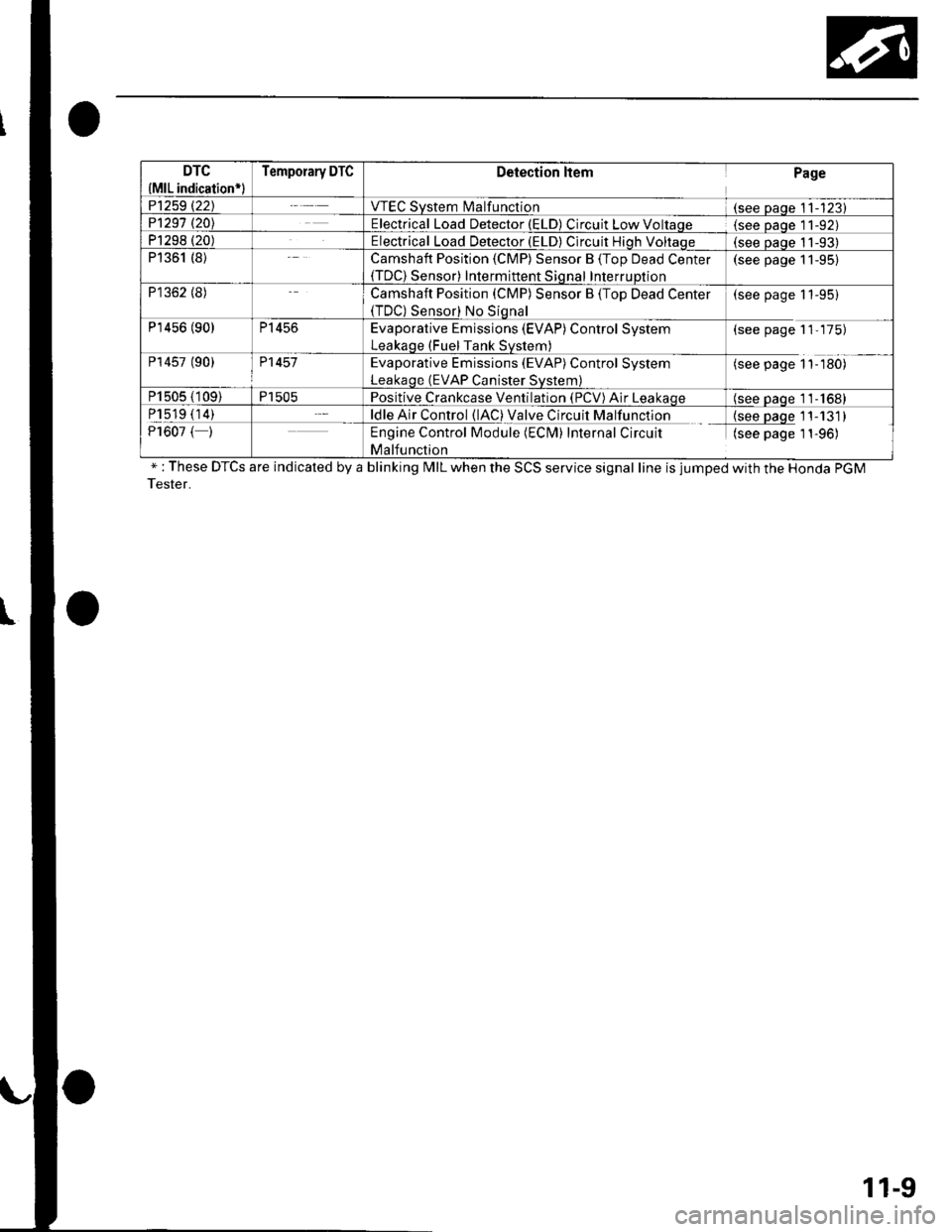

DTC

{MlL indication*l

Temporary DTCDetection ltemPage

P1259 t22JVTEC System l\4alfunction(see Daqe 11-123)P1291 t20\Electrical Load Detector (ELD) Circuit Low Voltaqe(see Daqe l1-92)P1298 (20)Electrical Load Detector (ELD) Circuit Hiqh Voltaqe(see oaoe 11-93)P1361 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) Intermittent Sional InterruDtion

(see page 11-95)

P1362 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) No Siqnal

(see page 11-95)

P'r456 (90)P1456Evaporative Emissions (EVAP) Control System

Leakaqe (Fuel Tank Svstem)

(see page 11-175)

P14s7 (90)P1457Evaporative Emissions (EVAP) Control System

Leakaqe (EVAP Canister Svstem)

(see page 1'l-180)

P1505 (109)P1505Positive Crankcase Ventilation (PCV) Air Leakaqe(see oaqe 11-1681

P1519 (14)ldle Air Control (lAC) Valve Circuit Malfunction{see paqe 11-131)P1607 ( )Engine Control Module (ECM) Internal Circuit

Malfunction

(see page 1 1-96)

" : These DTCS are indicated by a blinking MIL when the SCS service signal line is jumped with the Honda PGM

Tester.

11-9

Page 223 of 1139

![HONDA CIVIC 2002 7.G Workshop Manual Fuel and Emissions Systems

aSystem Descriptions (contdl

ECM Electrical Connections

\

No. INJECTOR

No,2INJECTOR

No.3 INJEC]OB

No./tINJECTOF

MAPSENSON

TPSENSOR

IATSENSOR

ECTSENSOB

\

CMP SENSOR B(TDC S HONDA CIVIC 2002 7.G Workshop Manual Fuel and Emissions Systems

aSystem Descriptions (contdl

ECM Electrical Connections

\

No. INJECTOR

No,2INJECTOR

No.3 INJEC]OB

No./tINJECTOF

MAPSENSON

TPSENSOR

IATSENSOR

ECTSENSOB

\

CMP SENSOR B(TDC S](/img/13/5744/w960_5744-222.png)

Fuel and Emissions Systems

aSystem Descriptions (cont'dl

ECM Electrical Connections

\

No. INJECTOR

No,2INJECTOR

No.3 INJEC]OB

No./tINJECTOF

MAPSENSON

TPSENSOR

IATSENSOR

ECTSENSOB

\'

CMP SENSOR B(TDC SENSOSJ

CKPSENSOR

11-16

F€VERSE LOCKSOLENOIDVAIVE

\-

Page 227 of 1139

![HONDA CIVIC 2002 7.G Workshop Manual Fuel and Emissions Systems

System Descriptions {contd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV

HONDA CIVIC 2002 7.G Workshop Manual Fuel and Emissions Systems

System Descriptions {contd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV](/img/13/5744/w960_5744-226.png)

Fuel and Emissions Systems

System Descriptions {cont'd)

ECM Inputs and Outputs at Connector A (31P)

\. il

Wire side of female terminals

\.

1AFS]TC2

GP2

3IGPl4PG25PG.16AFS+1

CKP

IKS

10SG211sG1

12IACV

'15

TPS16AFS_18

VSS

19IVAP20vcc221vccl

22AFSHTC+

23LG225

Ct\.4PA

26CMPB(rDc)

27IGPLS428IGPLS329IGPLS230IGPLS,I

NOTE: Standard battery voltage is 12 V.

JorminalnumberWirecolor[€rminal namoDescriptionSignal

19GRN/REDMAP (MANIFOLDABSOLUTE PRESSURESENSOR)

Detects MAP sensor signalWith ignition switch ON (ll):about3 VAt idle: about 1.0 V (depending on enginespeed)

20YEUBLUVCC2 (SENSOR VOLTAGE)Provides sensor voltageWith ignition switch ON {ll): about 5 VWith ionition switch OFF: about0V21YEUREDVCC] (SENSOB VOLTAGE)Provides sensor voltageWith ignition switch ON {ll): about 5 VWith ionition switch OFF: about0V22AFSHTC - (AIR FUELRATIO (A"iFiSENSORHEATER CONTROL + SIDE)

Detects a,/F sensor heatervoltageWith ign;tion switch ON lll): banery voltage

23BRN?ryE LLG2 (LOGIC GROUNDround for the ECM circuLessthan 1.0 V at alltimes24BRN?ryE L1(Lround for the ECM circuLess than '1.0 V at alltimes25B LU,^/VHTCMP A (CAMSHAFT

POSITION SENSOR A)Detects CMP sensor AstonalWith engine running: pulses

26GRNCMP B CAMSHAFTPOSITION (CMP)SENSOBB (TDC (TOP DEAD CENTERSENSORi)

Detects CMP sensor 8 (TDc

sensor)With engine running: pulses

27BRNIGPLS4 {No. 4IGNITIONCOIL PULSE)Drives No, 4 ignition coiWith ignition switch ON (ll)r about 0 vWith engine running: pulses28WHT/BLUIGPLS3 {No.3IGNITIONCOIL PULSE)Orives No.3 rgnition coi

29BLU/REDlGPLS2lNo.2 IGNITIONCOIL PTJLSE)Drives No.2 ignition coil

30YEUGRNIGPLSI (No. 1 IGNITIONco

PlltsF)Drives No. I ignition coil

11-20

\.

a

a

Page 232 of 1139

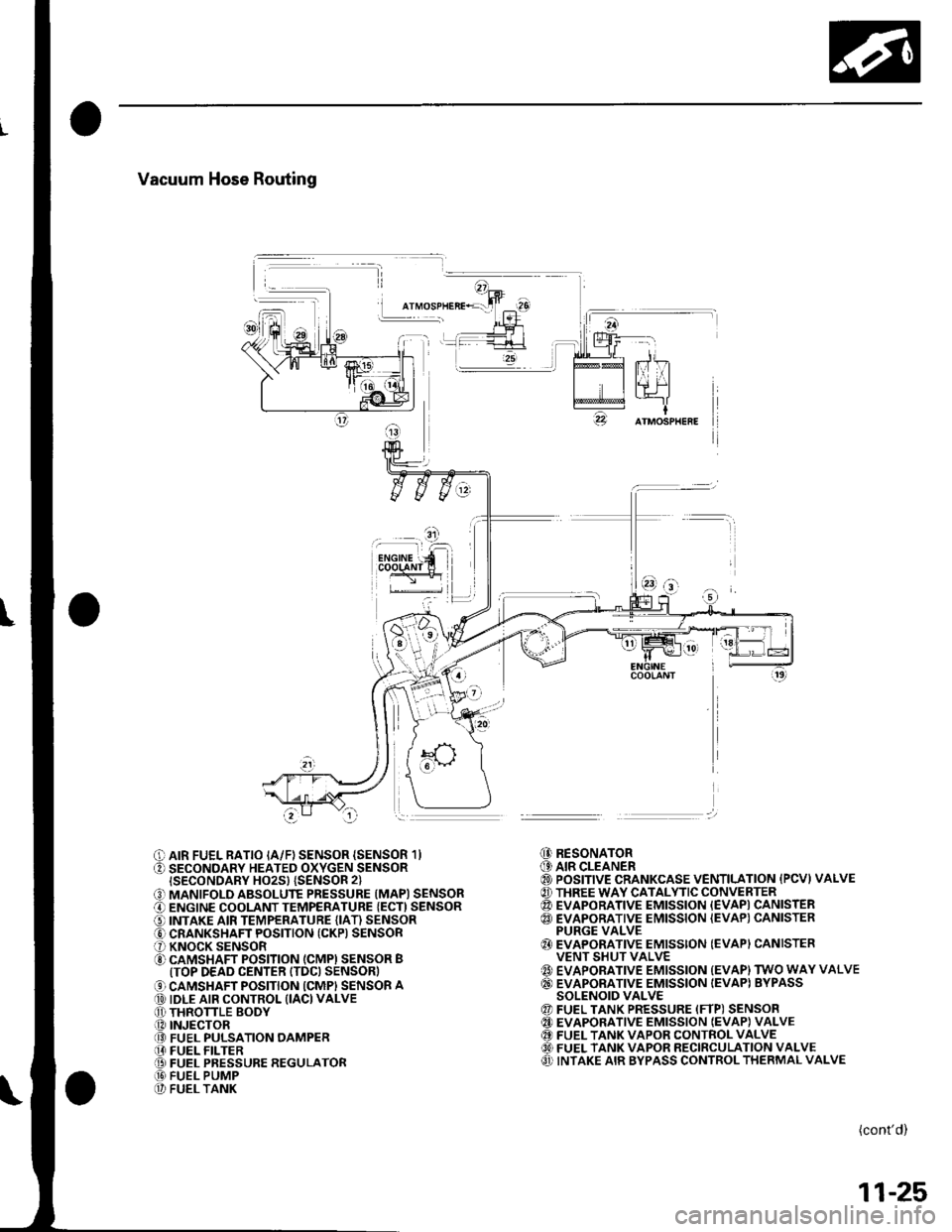

Vacuum Hose Routing

I

O AIR FUEL RATIO IA/F) SENSOR {SENSOR 1}O SECONDARY HEATED OXYGEN SENSORISECONDARY HO2S} {SENSOR 2}

O MANIFOLD ABSOLUTE PRESSURE (MAPI SENSORO ENGINE COOLANT TEMPERATURE {ECT) SENSORO INTAKE AIR TEMPERATURE (IAT) SENSORO CRANKSHAFT POSITION (CKP) SENSORO KNOCK SENSORO CAMSHAFT POSITION (CMPI SENSOR BITOP DEAD CENTER ITDC) SENSOR)

O CAMSHAFT POSITION ICMPI SENSOR A@ IDLE AIR CONTROL (IACI VALVEO THRONLE BODY.O INJECTOR@ FUEL PULSATION OAMPER[I FUEL FILTER@ FUEL PRESSURE REGULATOR@ FUEL PUMP@ FUEL TANK

@ RESONATOR(9 AIR CLEANER@ POSITIVE CRANKCASE VENTILATION {PCVI VALVE@ THREE WAY CATALYTIC CONVERTER@ EVAPORATIVE EMISSION {EVAPI CANISTER@ EVAPORATIVE EMISSION {EVAP) CANISTERPURGE VALVE{} EVAPORATIVE EMISSION (EVAPI CANISTERVENT SHUT VALVE{' EVAPORATIVE EMISSION {EVAP) TWO WAY VALVE@ EVAPORATIVE EMISSION IEVAPI BYPASSSOLENOID VALVE@ FUEL TANK PRESSURE (FTP) SENSOR@ EVAPORATIVE EMISSION IEVAP} VALVE@ FUEL TANK VAPOR CONTROL VALVE60) FUEL TANK VAPOR RECIRCULATION VALVEO INTAKE AIR BYPASS CONTROL THERMAL VALVE

(cont'd)

11-25

Page 233 of 1139

Fuel and Emissions Systems

System Descriptions (cont'd)

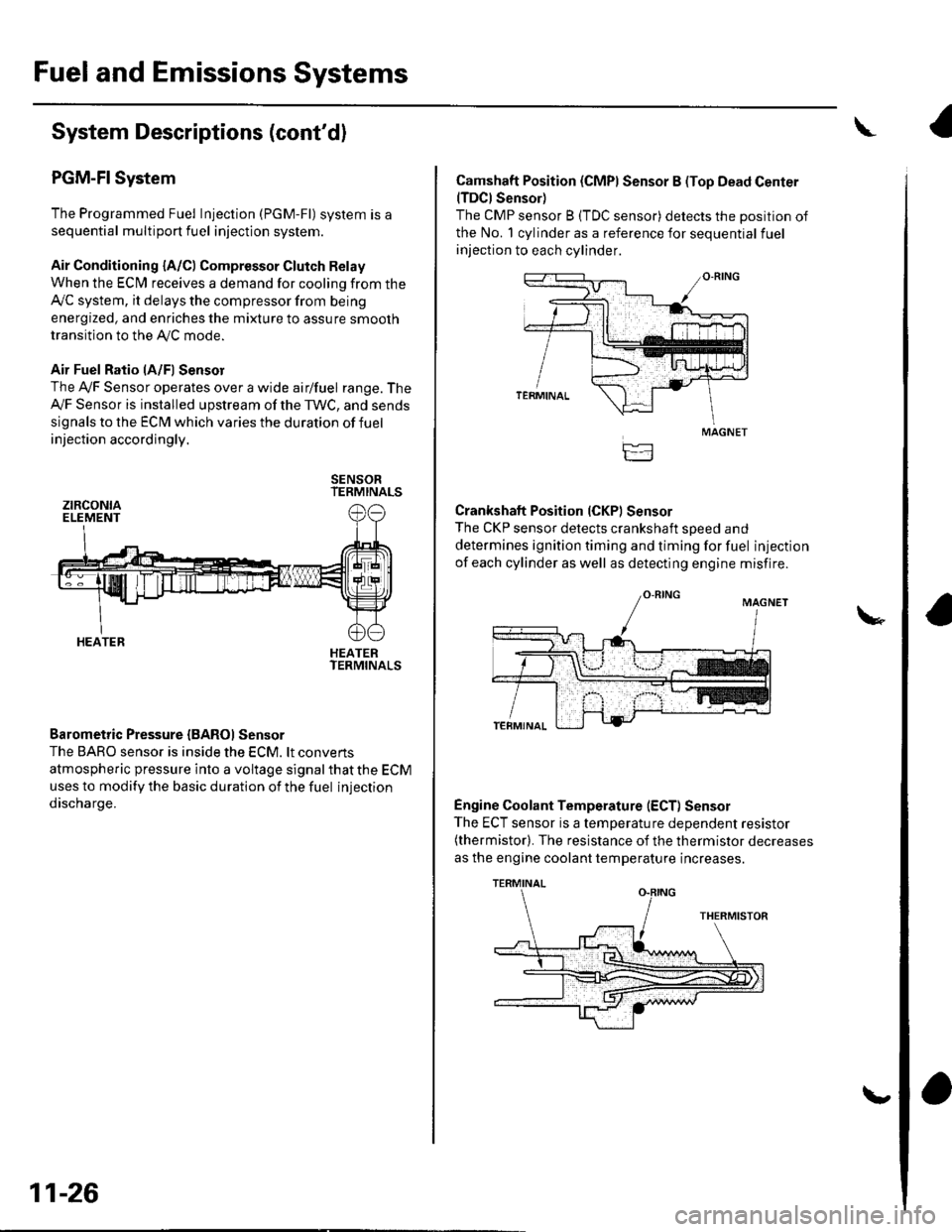

PGM-FI System

The Programmed Fuel Injection (PGM-Fl) system is a

sequential multiport fuel injection system.

Air Conditioning {A/C) Compressor Glutch Relay

When the ECfM receives a demand for cooling from the

Ay'C system, it delays the compressor from being

energized, and enriches the mixture to assure smooth

transition to the AVC mode.

Air Fuel Ratio lA/Fl Sensor

The Ay'F Sensor operates over a wide airlfuel range. The

Ay'F Sensor is installed upstream of the TWC, and sends

signals to the ECM which varies the duration of fuel

injection accordingly.

SENSORTERMINALS

HEATERTERMINALS

Barometric Pressure {BAROI Sensor

The BARO sensor is inside the ECM. lt convens

atmospheric pressure into a voltage signal that the ECM

uses to modify the basic duration of the fuel injection

discharge.

ztRcoNtaELEMENT

HEATER

11-26

\,

Camshaft Position (CMPI Sensor B (Top Dead Center(TDCI Sensor)

The CMP sensor B (TDC sensor) detects the position of

the No. 1 cylinder as a reference for sequential fuel

injection to each cylinder.

Crankshaft Position (CKPI Sensor

The CKP sensor detects crankshaft soeed and

determines ignition timing and timing for fuel injection

of each cylinder as well as detecting engine misfire.

Engine Coolant Temperature (ECT) Sensor

The ECT sensor is a temperature dependent resistor(thermistor). The resistance of the thermistor decreases

as the engine coolant temperature increases.

MAGNET

TERMINAL

Page 245 of 1139

Fuel and Emissions Systems

I

a

a

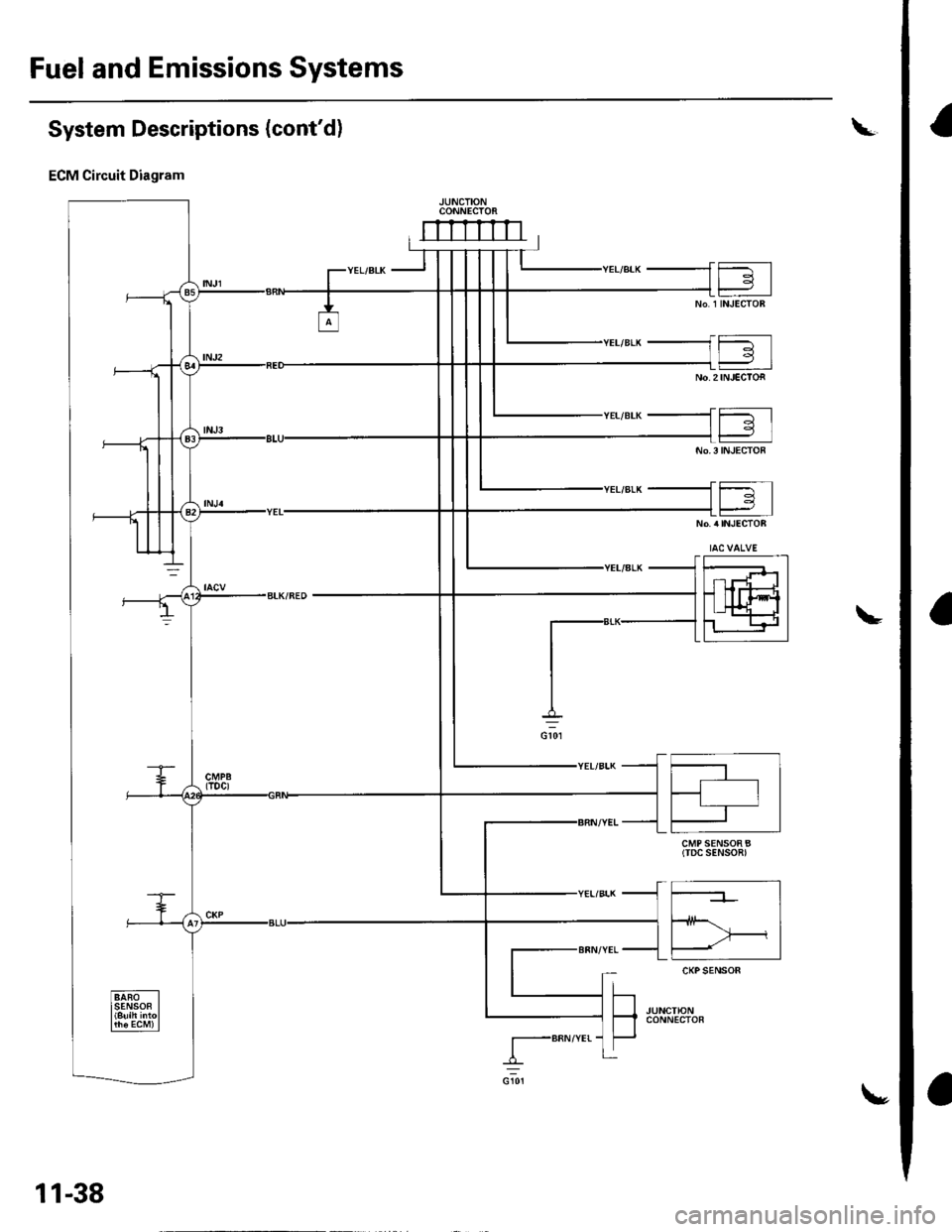

System Descriptions (cont'd)

ECM Circuit Diagram

CONNECTOi

mrrrrn

CMP SENSOR B(TDC SENSOn)

I-BRN/YEr-

11-38

\,

Page 256 of 1139

![HONDA CIVIC 2002 7.G Workshop Manual PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting, HONDA CIVIC 2002 7.G Workshop Manual PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,](/img/13/5744/w960_5744-255.png)

PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,page 1'l -92

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting,page 'l'l-55

Replacement, page 11-'l 15

f- \

rl

KNOCK SENSORTroubleshooting, page 1 1-77Beplacement, page 11 115

ENGINE COOLANT TEMPERATURE(ECTI SENSORTroubleshooting, page 1 1-57Replacement, page 11 114

MANIFOLD ABSOLUTE PRESSURE(MAP) SENSORTroubleshooting, page 1 1-52

THROTTLE POSITIONITP} SENSORTroubleshooting, page 11-60CRANKSHAFT POSITIONICKPISENSORTroubleshooting, page'l 1-78Beplacement, page 1 1-'l 16

AIR FUEL RATIO {A/F)SENSOR ISENSOR 1}Trorrbleshooting, page 1 1-84Replacement, page 11- 1 13

{cont'd)

ii'- r'1

.I11 ---:,I''.!,i(..,.?:fir-J-

.....,..:--.

11-49