engine electrical HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 14 of 1139

ne

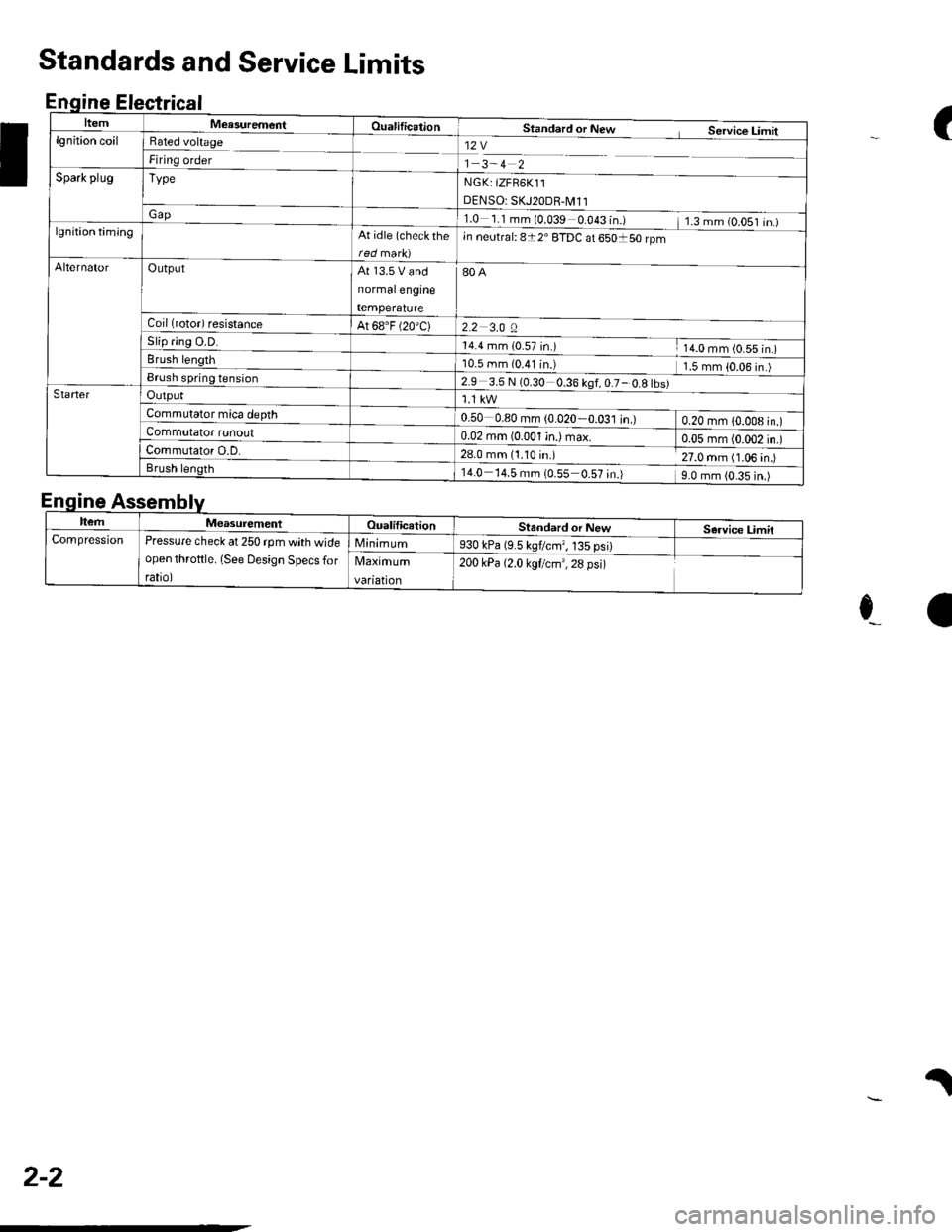

ItemMeasurementOualificationStandard or New Service Limitlgnition coilRated voltage

Firing order12V

1 3-4 2

NGK: tZFB6K11

DENSO: SKJ20DR-M11

1.0 1.1mm(0.039 0.043 in.) 1.3mm(O.OS1 in.)

Spark plugType

Gap

lgnition timingAt idle (check rhein neutral: 8t2' ETDC at 650150 rpm

AlternatorOutputAt 13.5 V and

normalengine

temperature

80A

2.2 3.0 ACoil lrotor) resistanceAt 68.F (20'C)

5|lp flng u.u.14.4 mm {0_57 in.) 14.0 mm (0.55 in.)Brush length10.5 mm (0.41 in.l 1.5 mm {0.06 in.)Brush spring tension2.9 3.5 N (0.30 0.36 kgf,0.7-0.8 tbs)StarterOutput

Commutator mica depth0.50 0.80 mm (0.020-0.031 in.) 0.20 mm 1O.OO8 in.)Commutator tunouto:BlalqryL4i) max o.o5 mm (0.002 in.)Commutator O.D.28.0 mm (1.10 in.) 27.0 mm (1.06 in.)Brush length14.0 14.5 mm {0.55 0.57 in.) 9.0 mm {0.35 in.)

(

I

Standards and Service Limits

Enqine Electrical

E

e_a

.l

nqtne

ItemMeasurementOualificationStandard or NewService LimitCompressionPressure check at 250 rpm with wide

open throftle. (See Design Specs for

rato,

Minimum930 kPa (9.5 kgflcmr, 135 psi)

Maximum

vanatton

200 kPa {2.0 kgf/cm',28 psi)

2-2

Page 36 of 1139

\.

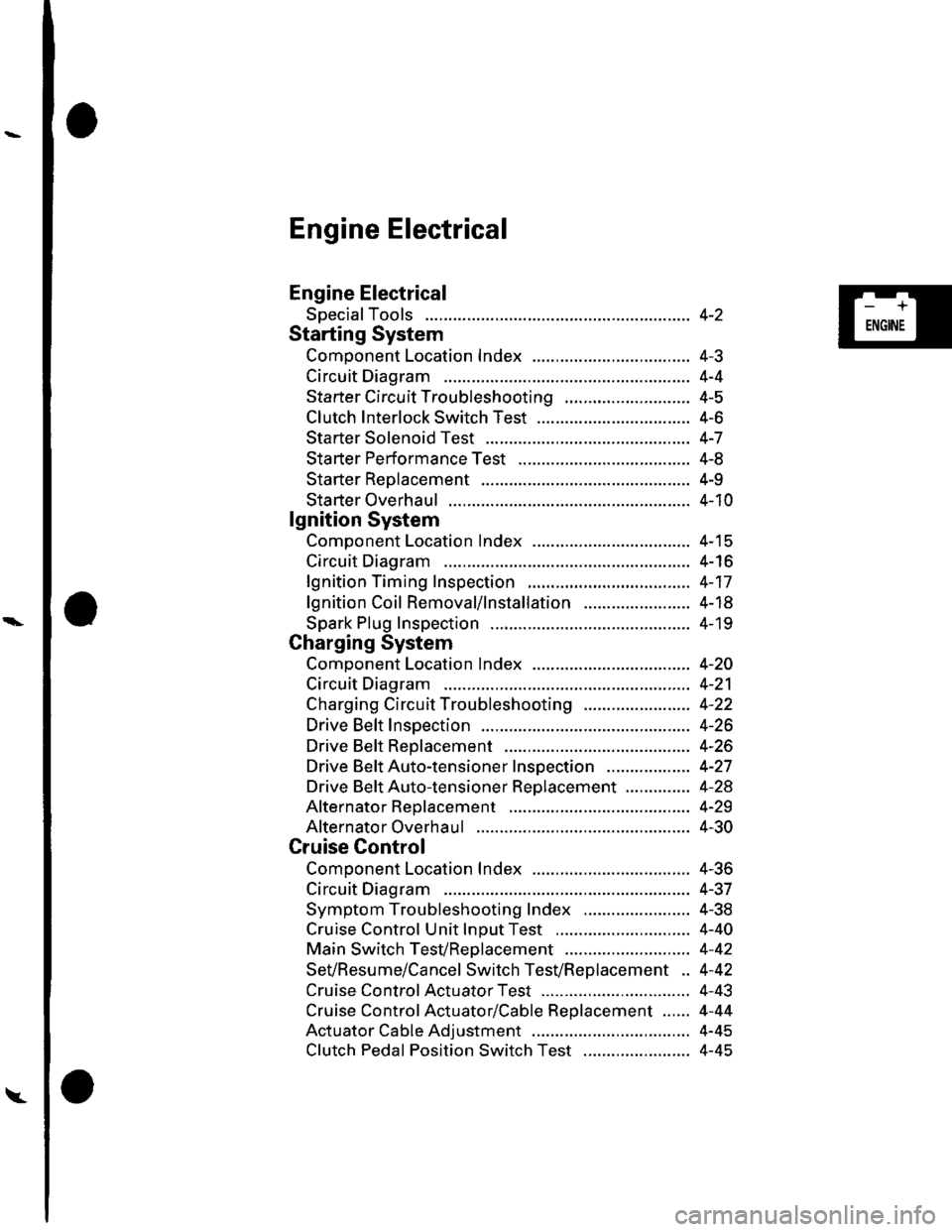

Engine Electrical

Engine Electrical

SpecialTools

Starting System

Comoonent Location Index ...............

Circuit Diagram

Starter Circu it Troubleshooting

Clutch Interlock Switch Test

Starter Solenoid Test ..............

Sta rter Performance Test

Starter Reolacement ...............

Starter Overhaul .......................

lgnition System

Component Location Index ...............

Circuit Diagram

lgnition Timing Inspection

lgnition Coil Removal/1nsta11ation .......................

Spark Plug Inspection

Charging System

Component Location Index .................................. 4-2O

Circuit Diagram ........................... 4-21

Charging Circuit Troubleshooting ....................... 4-22

Drive Belt Inspection ................... 4-26

Drive Beft Replacement .............. 4-26

Drive BeftAuto-tensioner Inspection .................. 4-27

Drive Beft Auto-tensioner Replacement .............. 4-28

Alternator Reolacement ............. 4-29

Alternator Overhaul ................ .... 4-30

Cruise Control

Component Location Index .................................. 4-36

Circuit Diagram ........................... 4-37

Symptom Troubleshooting Index ....................... 4-38

Cruise Control Unit lnDut Test ............................. 4-40

Main Switch TesVReolacement ........................... 4-42

SeVResume/Cancel Switch TesVReplacement .. 4-42

Cruise Control Actuator Test ...... 4-43

Cruise Control Actuator/Cable Replacement ...... 4-44

Actuator Cable Adjustment .................................. 4-45

Clutch Pedal Position Switch Test ....................... 4-45

4-2

4-J

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-15

4-16

4-17

4-18

4- 19

-+

ENGINE

Page 37 of 1139

Engine Electrical

SpecialTools

I

NumberTool NumberDescriptionotv

o

@

07746-0010400

07749-0010000

Attachment, 52 x 55 mm

Driver

1

1

\C

4-2

(a

Page 40 of 1139

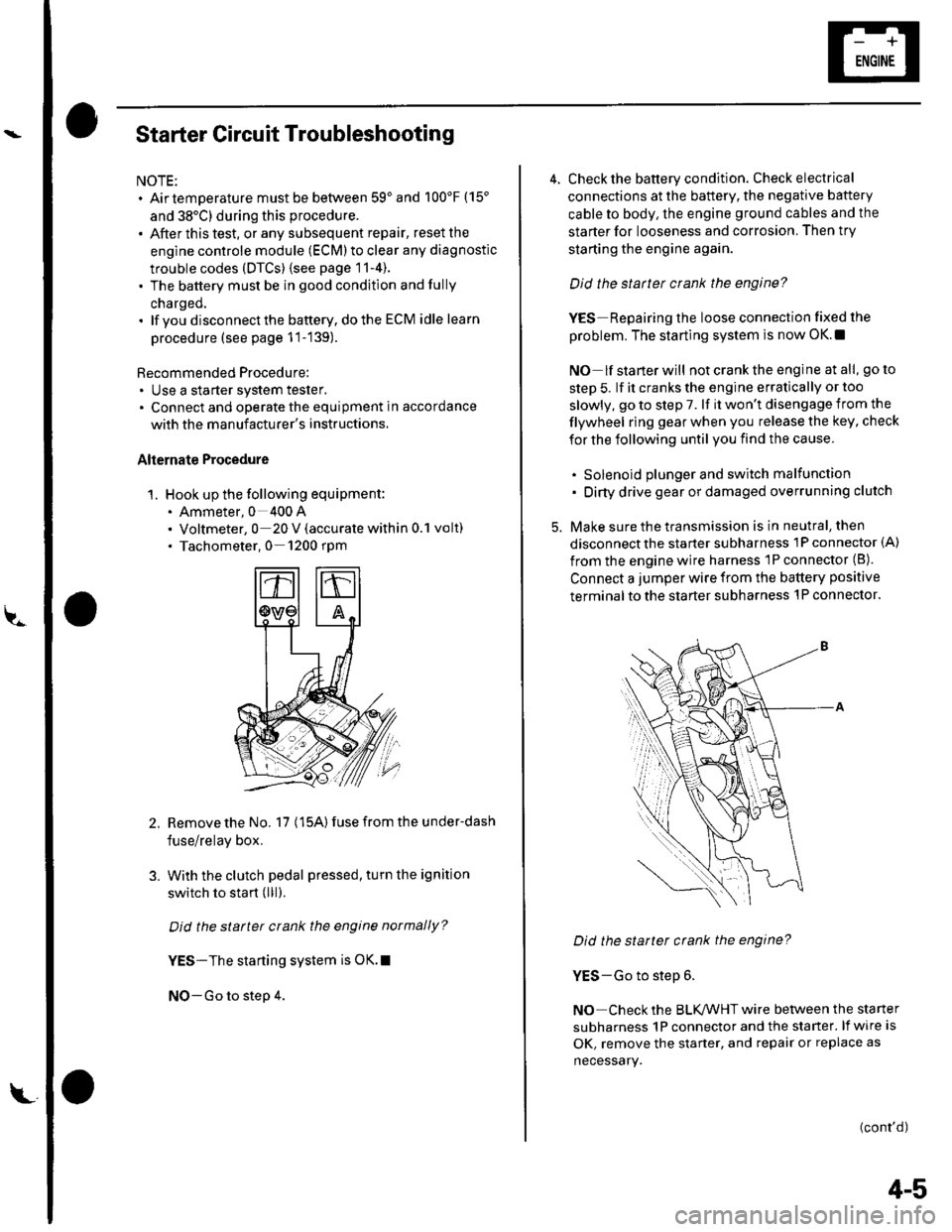

Starter Circuit Troubleshooting

NOTE:. Airtemperature must be between 59'and 100'F (15'

and 38'C) during this procedure.

. After this test, or any subsequent repair, reset the

engine controle module (ECM) to clear any diagnostlc

trouble codes (DTCS) {see page 11-4).. The battery must be in good condition and fully

charged.. lf you disconnect the baftery, do the ECM idle learn

procedure (see page 11-139).

Recommended Procedure:. Use a starter system tester.. Connect and operate the equipment in accordance

with the manuf acturer's instructions.

Alternate Procedure

1. Hook up the following equipment:. Ammeter, 0 400 A. Voltmeter, 0 20 V (accurate within 0.1 volt). Tachometer,0 1200 rpm

2.Remove the No. 17 (15A) fuse from the under-dash

fuse/relay box.

With the clutch pedal pressed, turn the ignition

switch to start (lll).

Did the starter crank the engine normally?

YES-The starting system is OK.I

NO-Go to step 4.

3.

L

4-5

4. Check the battery condition. Check electrical

connections at the battery, the negative baftery

cable to body, the engine ground cables and the

starter for looseness and corrosion. Then try

starting the engine again.

Did the statter crank the engine?

YES Repairing the loose connection fixed the

problem. The starting system is now OK.!

NO lf starterwill notcranktheengine atall, goto

step 5. lf it cranks the engine erratically or too

slowly, go to step 7. lf it won't disengage from the

flywheel ring gear when you release the key, check

for the following until you find the cause.

. Solenoid plunger and switch malfunction. Dirty drive gear or damaged overrunning clutch

5. Make sure the transmission is in neutral, then

disconnect the starter subharness 1P connector (A)

from the engine wire harness 'lP connector (B).

Connect a jumper wire from the battery positive

terminal to the starter subharness 'l P connector.

Did the starter crank the engine?

YES-Go to step 6.

NO Check the BLK,ANHT wire between the starter

subharness 1P connector and the starter. lf wire is

OK, remove the starter, and repair or replace as

necessary.

(cont'd)

Page 59 of 1139

Gharging System

Charging Circuit Troubleshooting (cont'd)

6. Start the engine. Hold the engine at 3,000 rpm with

no load (in Neutral) until the radiator fan comes on,

then let it idle.

7. Raise the engine speed to 2,000 rpm, and hold it

there.

8. Turn the headlights (high beam) on, and measure

voltage at the under-hood fuse/relay box terminal.

ls the voltage between 13.9 and 15.1 v?

YES-Go to step 9.

NO Repair or replace the alternator components

(see page 4-30).1

9. Read the amperage at '13.5 V.

NOTE: Adjust the voltage by turning the blower

motor, rear window defogger, brake lights. etc. ON.

ls the amperage 604 ot morc?

YES-Alternator/regulator operation is OK. I

NO Repair or replace the alternator components(see page 4-30).1

4-24

\,

Alternator Control System Test

NOTE: After troubleshooting, perform the engine

control module (ECM) idle learn procedure (see page

11-139).

1 . Check for proper operation of the electrical load

detector (ELD) by checking the malfunction

indicator lamp (MlL) (see page 1 l-3). lf a DTC is

present, diagnose and repair the cause before

continuing with this test.

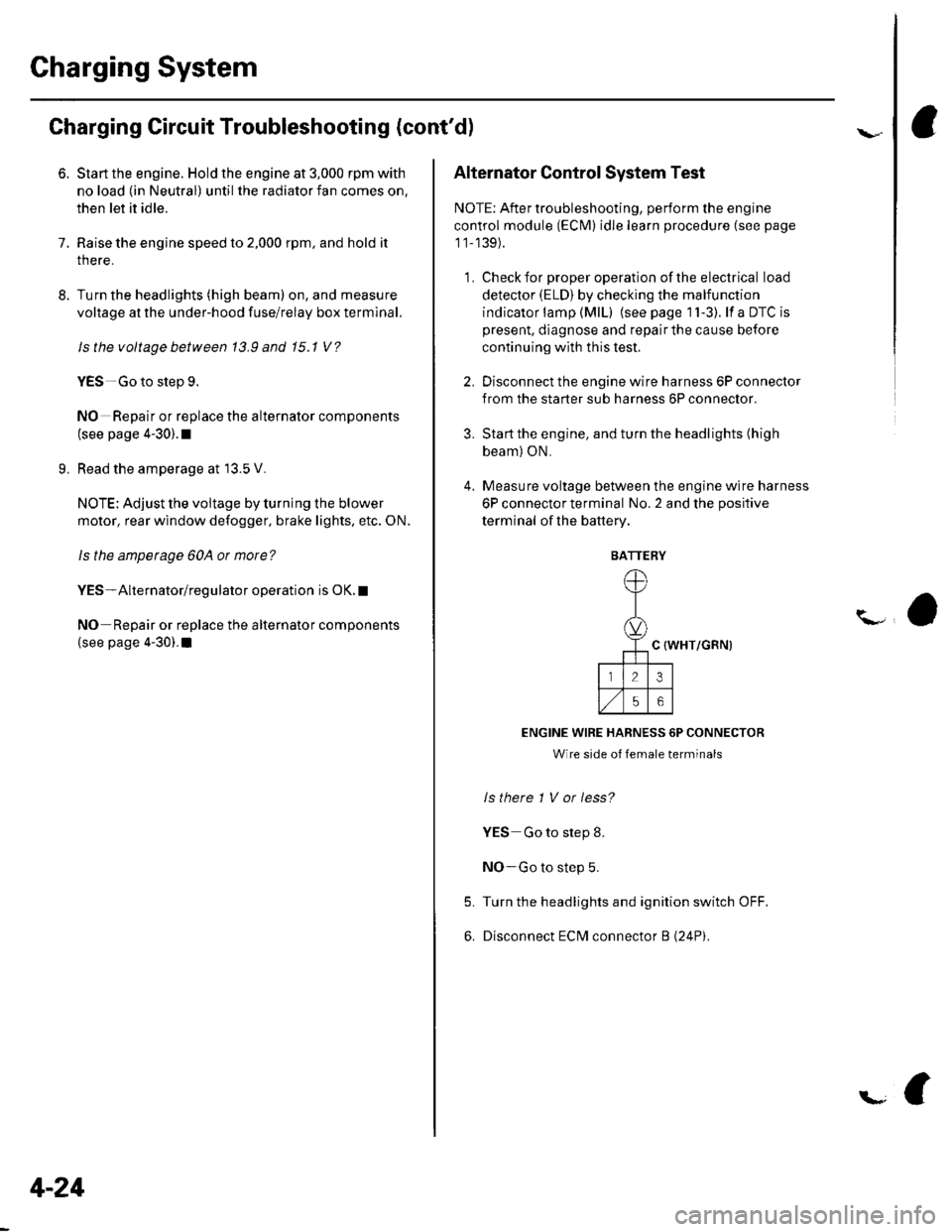

2. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

3. Start the engine, and turn the headlights (high

beam) ON,

4. Measure voltage between the engine wire harness

6P connector terminal No. 2 and the positive

terminal of lhe battery.

C {WHT/GRN)

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side of female terminals

ls there 1 V or less?

YES Go to step 8.

NO-Go to step 5.

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

5.

6.

BATTERY

Page 88 of 1139

Engine Assembly

Engine Removal (cont'd)

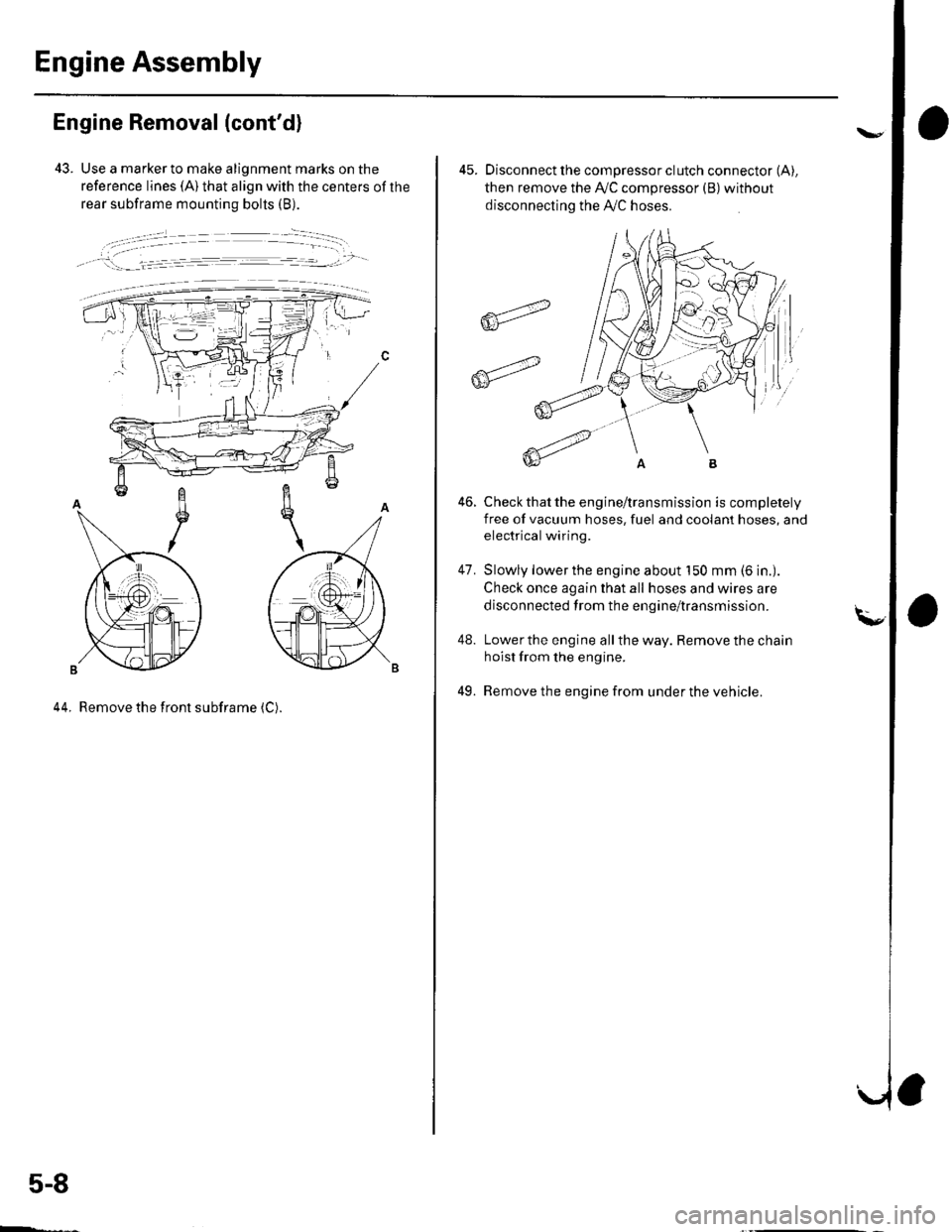

43. Use a marker to make alignment marks on the

reference lines (A) that align with the centers of the

rear subframe mounting bolts (B).

, !:_- _l.= :r -- ---.-','- -

44. Remove the front subframe (C).

5-8

ffi4

ffit'"

45. Disconnect the compressor clutch connector (A),

then remove the Ay'C compressor (B)without

disconnecting the A'./C hoses.

Check that the engine/transmission is completely

free of vacuum hoses, fuel and coolant hoses, and

electrical wiring.

Slowly lower the engine about 150 mm (6 in.).

Check once again that all hoses and wires are

disconnected trom the engine/transmission.

Lower the engine all the way. Remove the chain

hoist from the engine.

Remove the engine from under the vehicle.

46.

47.

48.

49.

Page 210 of 1139

General Troubleshooting Information

Intermittent Failures

The term "intermittent failure" means a svstem mav

have had a failure. but it checks OK now. lf the

Malfunction Indicator Lamp (MlL) on the dash does not

come on, check for Door connections or loose terminals

at all connectors related to the circuit that Vou are

troubleshooting.

Opens and Shorts

"Ooen" and "Short" are common electrical terms. An

open is a break in a wire or at a connection. A short is

an accidental connection of a wire to ground or to

another wire. In simple electronics, this usually means

something won't work at all. With complex electronics(such as ECMs)this can sometimes mean something

works, but not the way it's supposed to.

How to Use the PGM Tester or a Scan Tool

lf the MIL {Malfunction Indicator Lamp} has come on

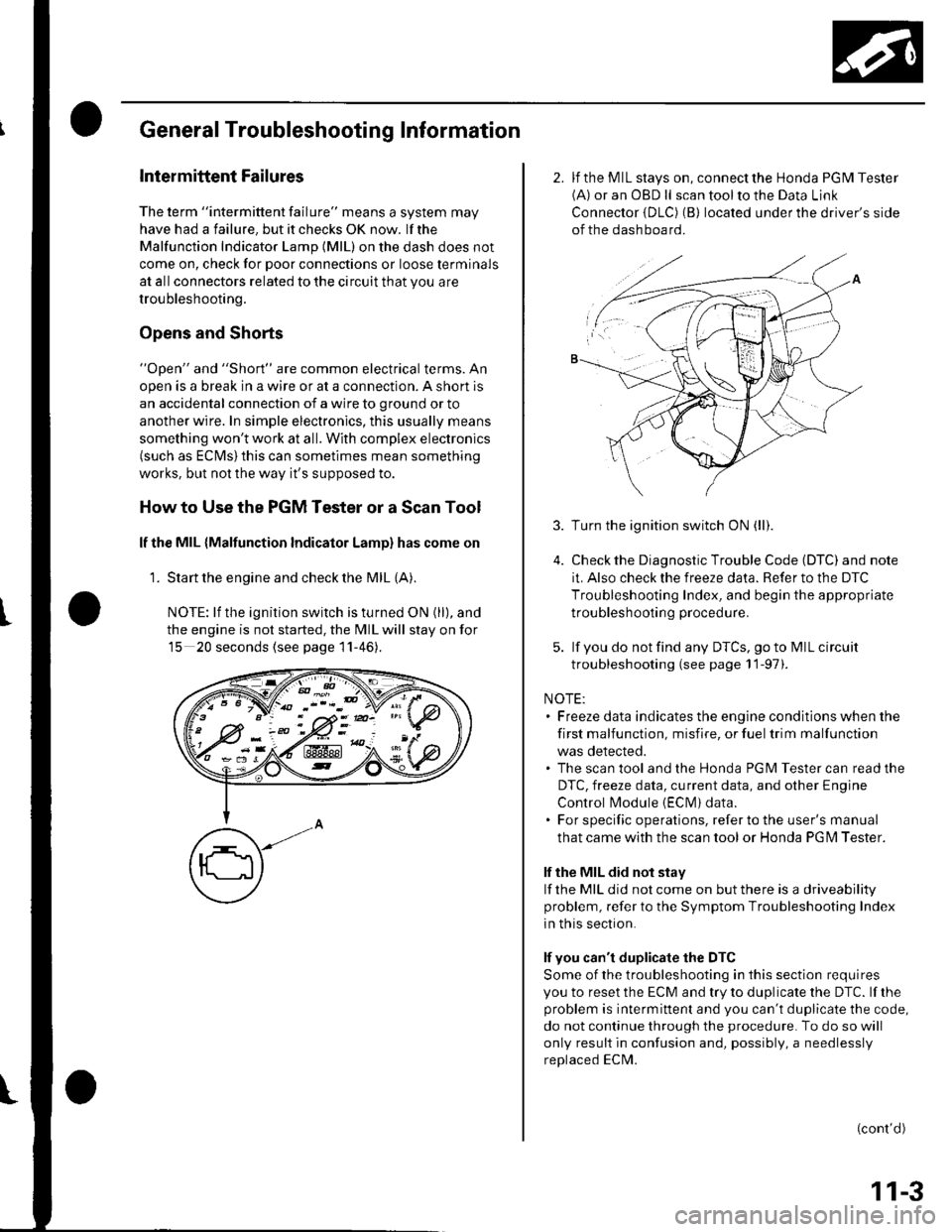

'1. Start the engine and check the MIL {A).

NOTE: lf the ignition switch is turned ON (ll), and

the engine is not started, the MIL will stay on for

15 20 seconds (see page 11-46).

K-> ;"PN/.- -::: - -d V-: !

w:ix&K#

2. lf the MIL stays on, connect the Honda PGM Tester(A) or an OBD ll scan tool to the Data Link

Connector {DLC) (B) located under the driver's side

of the dashboard.

3.

5.

Turn the ignition switch ON (ll).

Check the Diagnostic Trouble Code (DTC) and note

it. Also check the freeze data. Refer to the DTC

Troubleshooting Index, and begin the appropriate

troubleshooting procedure.

lf you do not find any DTCS, go to MIL circuit

troubleshooting (see page 11-97).

NOTE:. Freeze data indicates the engine conditions when the

first malfunction, misfire, or fuel trim malfunction

was detected.. The scan tool and the Honda PGM Tester can read the

DTC, freeze data, current data, and other Engine

Control l\4odule {EClvl) data.. For specific operations, refer to the user's manual

that came with the scan tool or Honda PG l\4 Tester.

lf the MIL did not stay

lf the MIL did not come on but there is a driveability

problem, refer to the Symptom Troubleshooting Index

in this section.

lf you can't duplicate the DTC

Some of the troubleshooting in this section requires

you to reset the ECM and try to duplicate the DTC. lf rhe

problem is intermittent and you can't duplicate the code,

do not continue through the procedure. To do so will

only result in confusion and, possibly, a needlessly

replaced ECM.

(cont'd)

11-3

Page 213 of 1139

Fuel and Emissions Systems

General Troubleshooting Information (cont'd)

ECM Updating and Substitution for Testing

Special Tools Bequired

Honda Interface Module (HlM) EOS05435570

Use this procedure when you have to substitute a

known-good ECM in a troubleshooting procedure.

U pdate the ECM only if the ECN4 does not already have

the latest software loaded,

NOTE;. lMake sure the battery is fully charged before you

update the ECN4.. To prevent ECM damage during the update, do not

turn the ignition switch OFF, and do not use any of

the vehicle's electrical devices (light, horn, radio, etc. ).

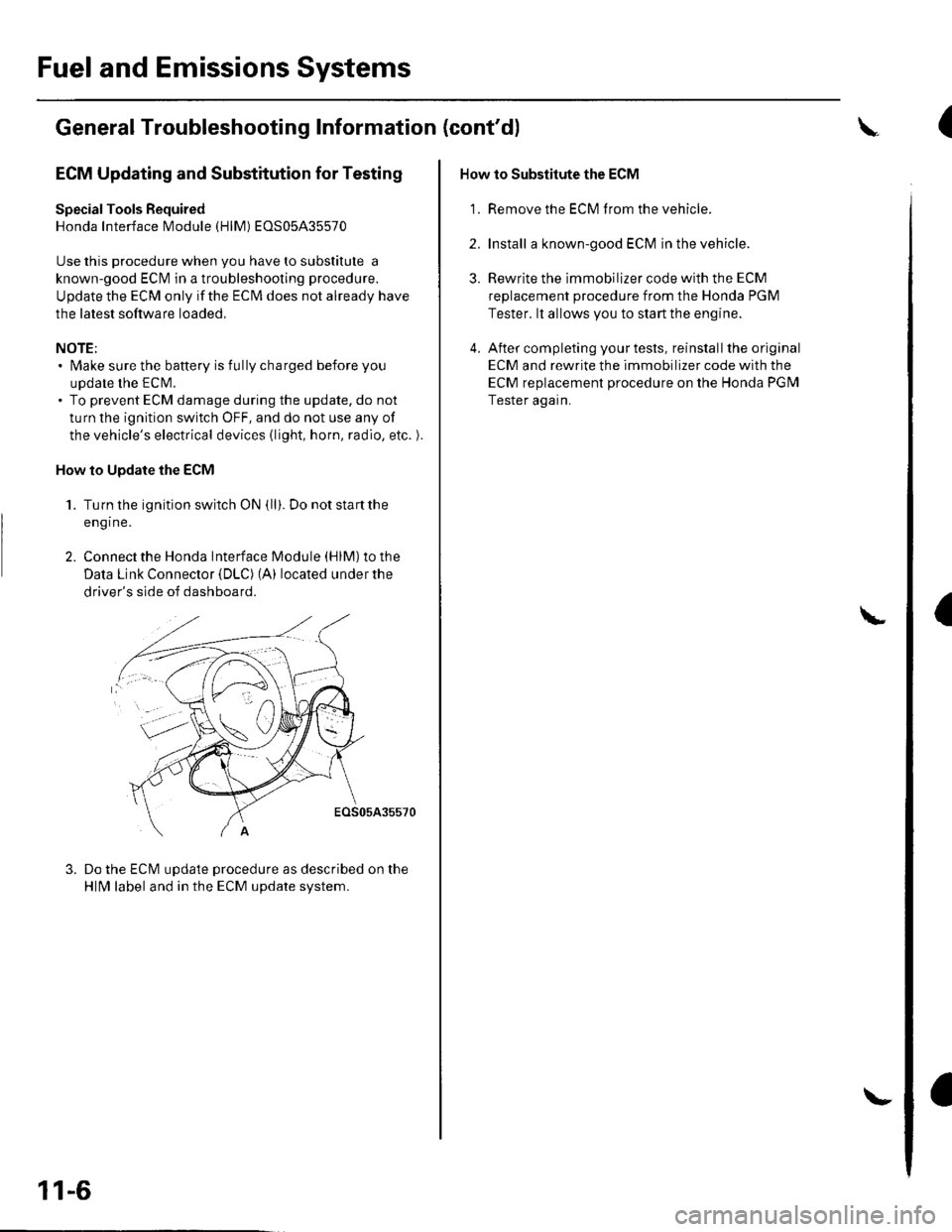

How to Update the ECM

1. Turn the ignition switch ON (ll). Do not startthe

eng Ine.

2. Connect the Honda lnterface Module (HlM) to the

Data Link Connector {DLC) (A) located under the

driver's side of dashboard.

EOS05A35570

Do the ECM update procedure as described on the

HlN4 label and in the ECM update system.

11-6

\-

How to Substitute the ECM

'1. Remove the ECM f rom the vehicle.

2. Install a known-good ECM in the vehicle.

3. Rewrite the immobilizer code with the ECM

replacement procedure from the Honda PGM

Tester. lt allows you to start the engine.

4. After completing your tests, reinstall the original

ECM and rewrite the immobilizer code with the

ECM replacement procedure on the Honda PGM

Tester again.

L

(

I

Page 216 of 1139

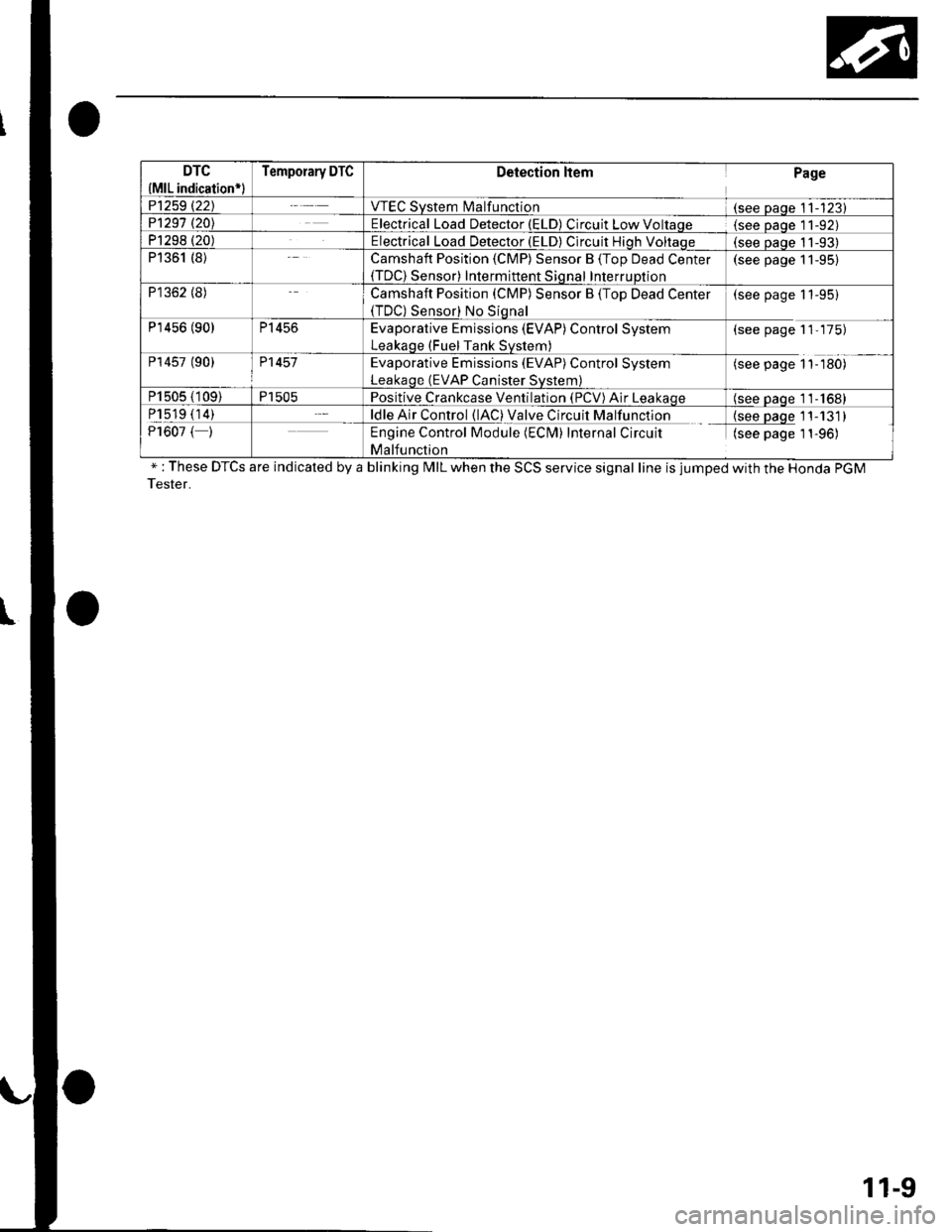

DTC

{MlL indication*l

Temporary DTCDetection ltemPage

P1259 t22JVTEC System l\4alfunction(see Daqe 11-123)P1291 t20\Electrical Load Detector (ELD) Circuit Low Voltaqe(see Daqe l1-92)P1298 (20)Electrical Load Detector (ELD) Circuit Hiqh Voltaqe(see oaoe 11-93)P1361 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) Intermittent Sional InterruDtion

(see page 11-95)

P1362 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) No Siqnal

(see page 11-95)

P'r456 (90)P1456Evaporative Emissions (EVAP) Control System

Leakaqe (Fuel Tank Svstem)

(see page 11-175)

P14s7 (90)P1457Evaporative Emissions (EVAP) Control System

Leakaqe (EVAP Canister Svstem)

(see page 1'l-180)

P1505 (109)P1505Positive Crankcase Ventilation (PCV) Air Leakaqe(see oaqe 11-1681

P1519 (14)ldle Air Control (lAC) Valve Circuit Malfunction{see paqe 11-131)P1607 ( )Engine Control Module (ECM) Internal Circuit

Malfunction

(see page 1 1-96)

" : These DTCS are indicated by a blinking MIL when the SCS service signal line is jumped with the Honda PGM

Tester.

11-9

Page 220 of 1139

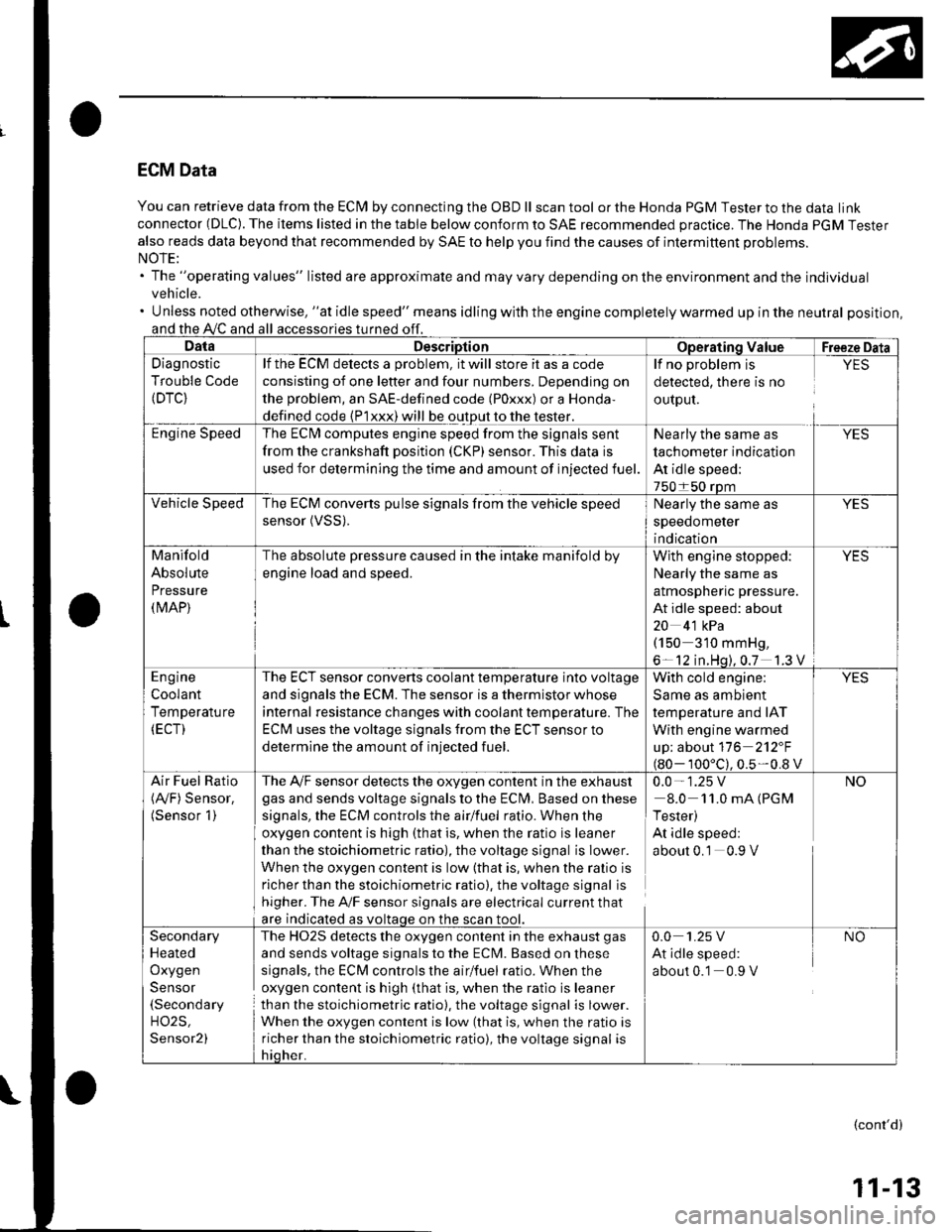

ECM Data

You can retrieve data from the ECI\4 by connecting the OBD ll scan tool or the Honda PGM Tester to the data link

connector (DLC). The items listed in the table below conform to SAE recommended practice. The Honda PGM Tester

also reads data beyond that recommended by SAE to help you find the causes of intermittent problems.

The "operating values" listed are approximate and may vary depending on the environment and the individual

vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up in the neutral position,

and the A,/C and all

Diagnostic

Trouble Code(DTC}

lf the ECM delects a problem, it will store it as a code

consisting of one letter and four numbers. Depending on

the problem, an SAE-defined code (Poxxx) or a Honda,

defined code {P1xxx) will be output to the tester.

The ECI\4 computes engine speed from the signals sent

from the crankshaft position (CKP) sensor. This data is

used for determining the time and amount of injected fuel.

detected, there is no

ourpul.

lf no problem is YES

Nearly the same as

tachometer indication

At idle speed;

The ECM converts pulse signals from the vehicle speed

sensor (VSS).Nearly the same as

speedometer

indication

Manifold

Absolute

Pressure(MAP)

The absolute pressure caused in the intake manifold by

engine load and speed.

With engine stopped: YES

Nearly the same as

almospnenc pressure.

At idle speed: about

20 4'1 kPa(150 310 mmHg,

6- 12 in.Hq).0.7 1.3 V

The ECT sensor converts coolant temperature into voltage

and signals the ECM. The sensor is a thermistor whose

internal resistance changes with coolant tempetature. The

ECM uses the voltage signals from the ECT sensor to

determine the amount of injected fuel.

With cold engine:

Same as ambient

temperature and IAT

With engine warmed

up; about 116 2'12"F

100'c).0.5-0.8 v

Air Fuel Ratio The A,/F sensor detects the oxygen content in the exha ust 0.0 - 1 .25 V(Ay'F) Sensor. gas and sends voltage signals to the Eclvl, Basedonthese 8.0 11.0mA(PGM(Sensor 1) signals, the ECM controls the airlfuel ratio. When the I Tester)

oxygen content is high (that is, when the ratio is leaner At idle speed:

than the stoichiometric ratio), the voltage signal is Iower. about 0.1 0.9 V

When the oxygen content is low (that is, when the ralio is

richer than the stoichiometric ratio). the voltage signal is

higher. The A'lF sensor signals are electrical current that

are indicated as voltaqe on the

The HO2S detects the oxygen content in the exhaust gas

and sends voltage signals to the ECM. Based on these

signals, the ECM controls the airlfuel ratio. When the

oxygen content is high (that is, when the ratio is leaner

than the stoichiometric ratio), the voltage signal is lower.

When the oxygen content is low (that is, when the ratio is

richer than the stoichiometric ratio), the voltage signal is

Secondary

Heated

Oxygen

Sensor(Secondary

H02S,

Sensor2)

0.0 1.25 V NO

At idle speed:

about 0.1 0.9 V

(cont'd)

11-13