brake HONDA CIVIC 2003 7.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 651 of 1139

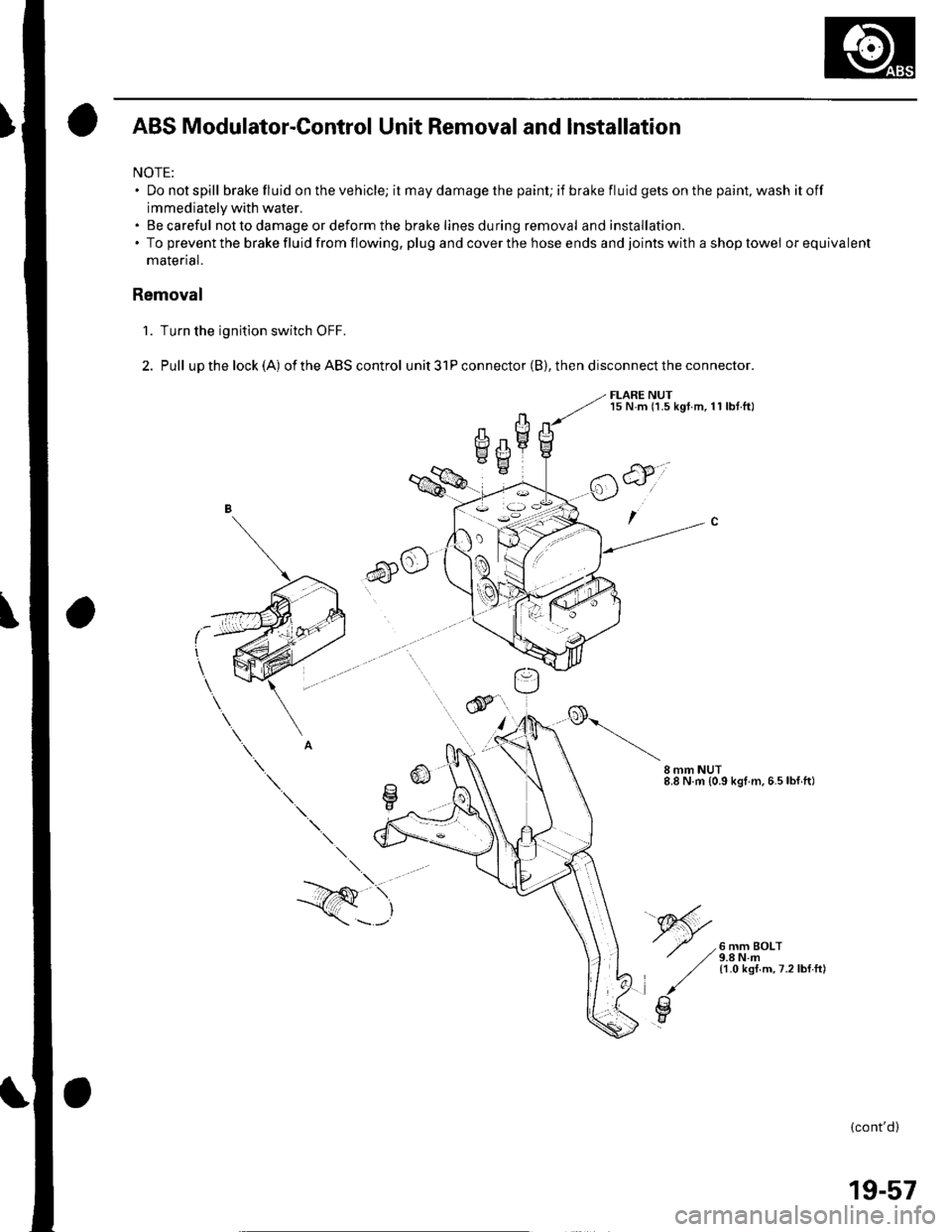

ABS Modulator-Control Unit Removal and lnstallation

NOTE:. Donotspill brake fluid on the vehicle; it may damage the painU if brakefluidgetsonthepaint,washitoff

immediately with water.. Becareful not to damage or deform the brake lines during removal and installation.. To prevent the brake fluid from flowing, plug and cover the hose ends and joints with a shop towel orequivalent

malenal.

Removal

'1. Turn the ignition switch OFF.

2. Pull upthelock(A) oftheABScontrol unit3lPconnector(B),thendisconnecttheconnector.

FLARE NUTl5 N.m (1.5 kgt.m,11 lbt.ftl

6)o

CII mm NUT8.8 N.m {0.9 kgl m.6.5lbf ft)

6 mm BOLT9.8 N.m11.0 ksf.m,7.2lbf.ft)

\.

--/Q \,

\---'

(cont'd)

19-57

Page 652 of 1139

ABS Gomponents

ABS Modulator-Control Unit Removal and Installation {cont'dl

3. Disconnectthe six brake lines.

4. Remove the two I mm nuts.

5. Remove the ABS modulator-control unit (C).

Installation

'1. InstalltheABS modulatorcontrol unit, then tighten the two 8 mm nuts.

2. Align the connecting surface ofthe ABS control unit 3'lP connector.

3. PushinthelockoftheABScontrol unit 31P connector until you hear it click into place. then connect the connector.

4. Connect the six brake Iines.

5. Bleed the brake system, starting with the front wheels.

6. Connect the PGM Tester, and do the solenoid function test for each wheel.

7. Bleed the brake system again, staning with the front wheels.

8. Start the engine, and check that the ABS indicator and brake system indicator go off.

9. Disconnect the Honda PGM Tester. Test-drive the vehicle, and check that the ABS indicator and brake qvqtem

indicator do not come on.

19-58

Page 653 of 1139

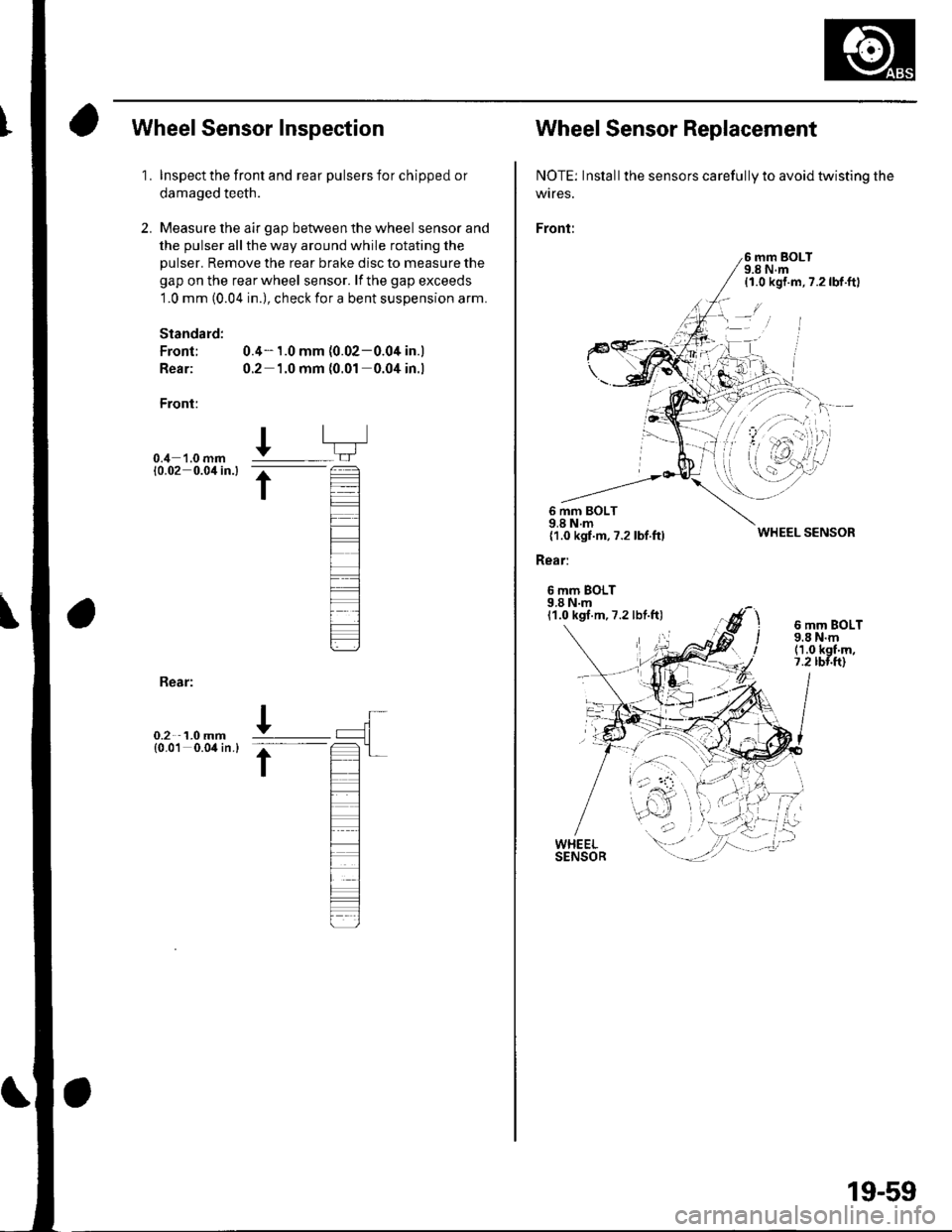

Wheel Sensor Inspection

1.

2.

Inspect the front and rear pulsers for chipped or

damaged teeth.

Measure the air gap between the wheel sensor and

the pulser all the way around while rotating the

pulser. Remove the rear brake disc to measure the

gap on the rear wheel sensor. lf the gap exceeds

1.0 mm (0.04 in.), check for a bent suspension arm.

Standard:

Front; 0.4- 1.0 mm (0.02-0.04 in.)

Rear: 0.2 1.0 mm (0.01 0.04 in.l

Front:

0.4 '1.0 mm10.02 0.0'l in.l

I

t

Bear:

0.2 1.0 mm{0.01 0.04 in.}

Wheel Sensor Replacement

NOTE: Inslall the sensors carefully to avoid twisting the

wtres.

Front:

6 mm BOLT9.8 N.m{1.0 kgf.m,7.2lbf.ftl

6 mm BOLT9.8 N.m{1.0 kgf.m,7.2 lbf.ftl

Rear:

6 mm BOLT9.8 N.m11.0 kgf.m,7.2 lbf.ft)

WHEEL SENSOR

6 mm BOLT9.8 N.m(1.0 kgf'm,7.2 rbr.ft)

19-59

Page 679 of 1139

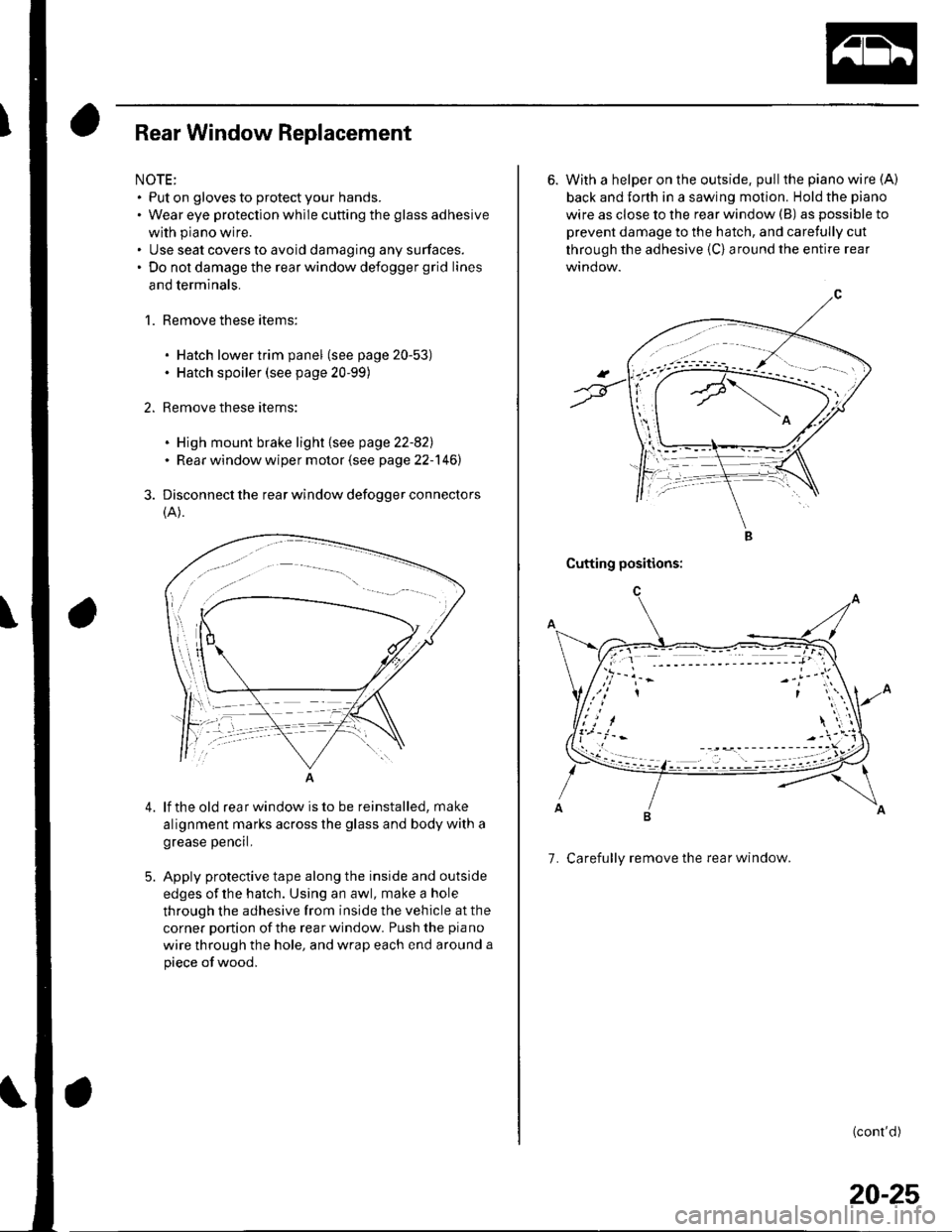

Rear Window Replacement

NOTE:. Put on gloves to protect your hands.. Wear eye protection while cutting the glass adhesive

with piano wire.. Use seat covers to avoid damaging any surfaces.. Do not damage the rear window defogger grid lines

and terminals.

1.Remove these items:

. Hatch lower trim panel (see page 20-53). Hatch spoiler (see page 20-99)

Remove these items:

. High mount brake light {see page 22-821. Rear window wiper motor {see page 22-1461

Disconnect the rear window defogger connectors

(A).

4.lf the old rear window is to be reinstalled, make

alignment marks across the glass and body with a

grease pencrl,

Apply protective tape along the inside and outside

edges of the hatch. Using an awl, make a hole

through the adhesive from inside the vehicle at the

corner portion of the rearwindow. Push the piano

wire through the hole, and wrap each end around a

piece of wood,

6. With a helper on the outside, pull the piano wire (A)

back and Jorth in a sawing motion. Hold the piano

wire as close to the rear window (B) as possible to

prevent damage to the hatch, and carefully cut

through the adhesive {C} around the entire rear

Cutting positions:

7. Carefully remove the rear window.

(cont'd)

20-25

Page 710 of 1139

Interior Trim

Carpet Replacement (cont'dl

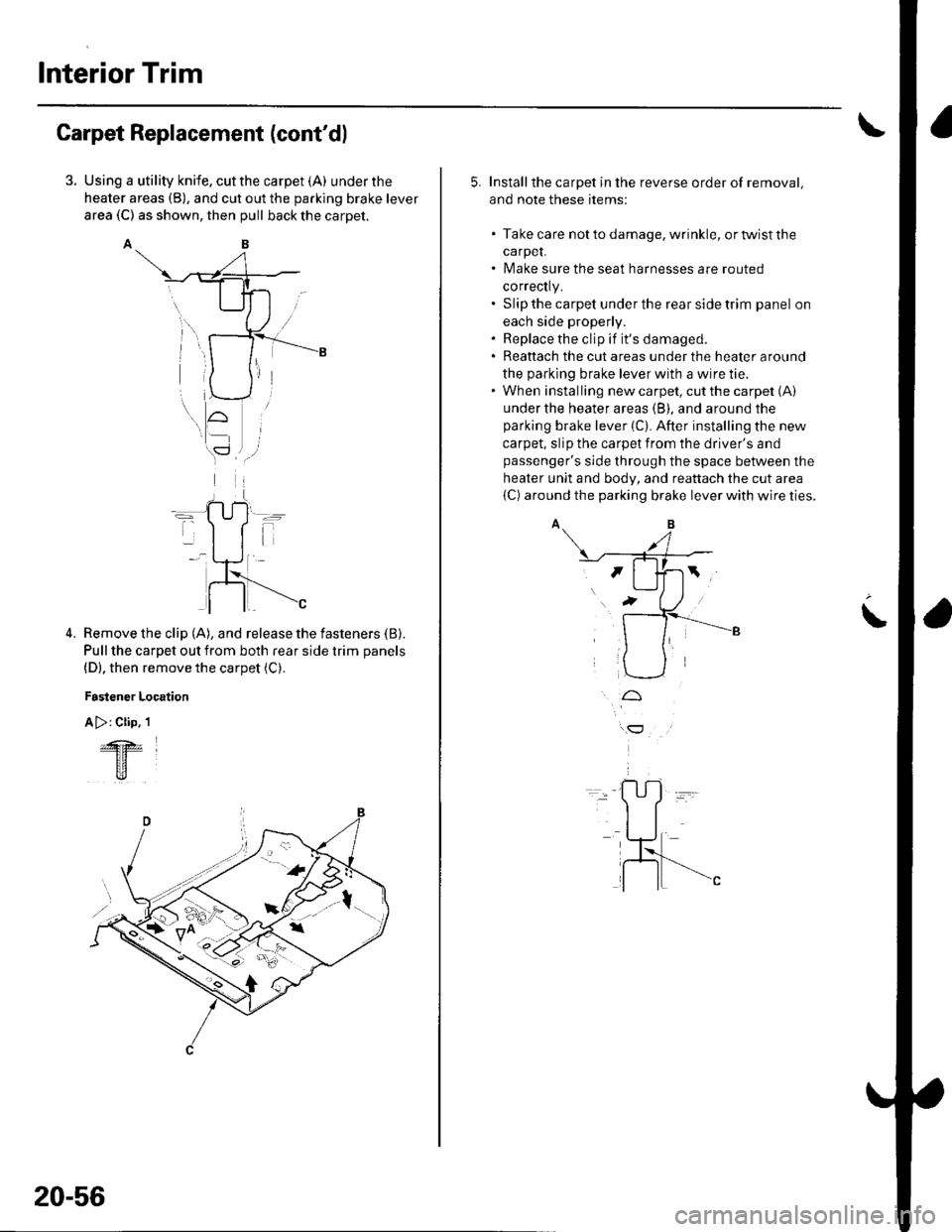

Using a utility knife, cut the carpet (A) under the

heater areas (B), and cut out the parking brake lever

area (C) as shown, then pull back the carpet.

AB

Remove the clip (A), and release the fasteners (B).

Pull the carpet out from both rear side trim panels

(D), then remove the carpet (C).

Fastener Location

A >: Clip. 1

4.

&z

tr

20-56

5. Installthe carpet in the reverse order of removal,

and note these items:

. Take care notto damage, wrinkle, ortwistthe

carpeL. Make sure the seat harnesses are routed

correctly.. Slip the carpet under the rear side trim panel on

each side properly.. Replace the clip if it's damaged.. Reattach the cut areas under the heater around

the parking brake lever with a wire tie.. When installing new carpet, cut the carpet (A)

under the heater areas (B), and around the

parking brake lever (C). After installing the new

carpet, slip the carpet from the driver's and

passenger's side through the space between the

heater unit and body, and reattach the cut area

{C) around the parking brake lever with wire ties.

t

Page 721 of 1139

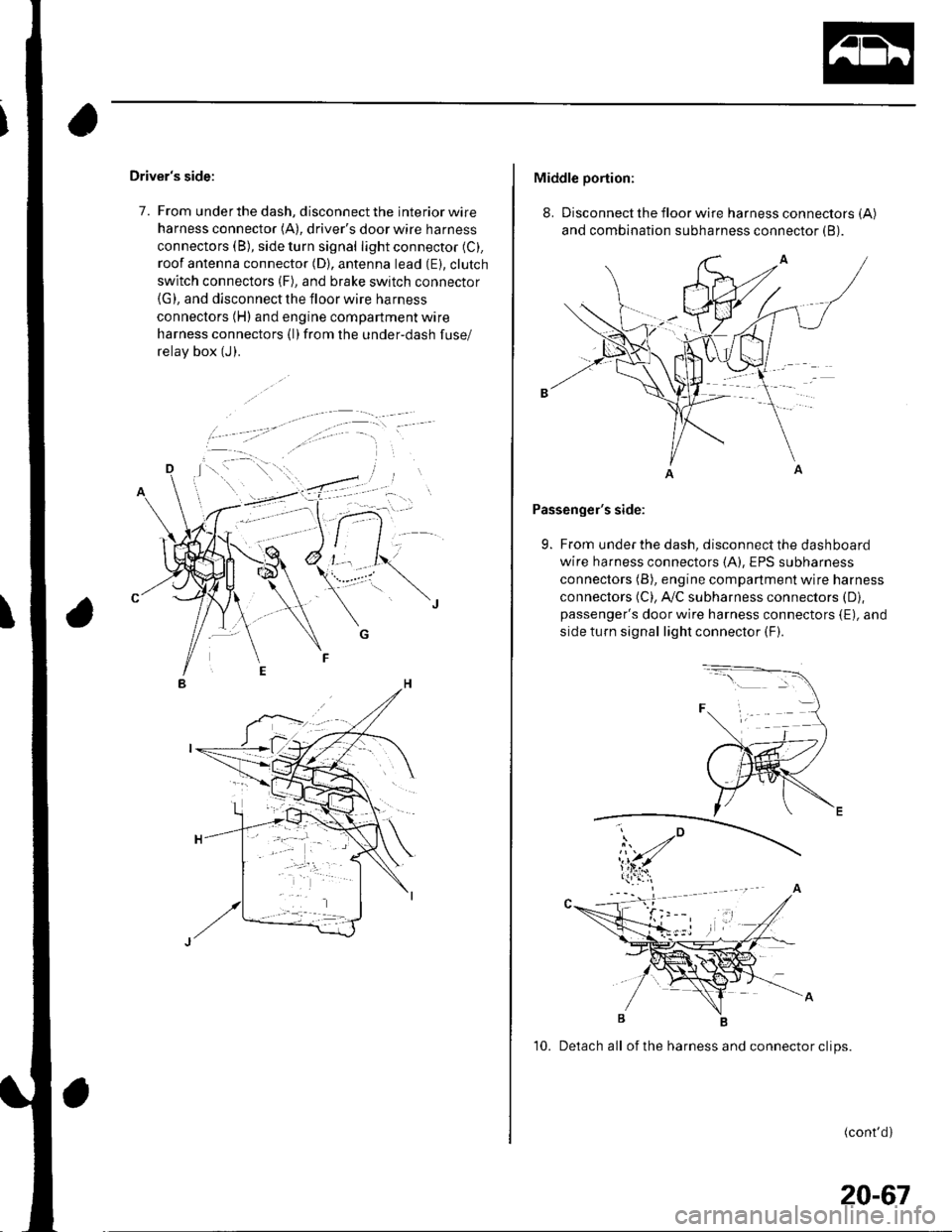

Driver's side:

7. From under the dash, disconnect the interior wire

harness connector (A), driver's door wire harness

connectors (B), side turn signal light connector (C).

roof antenna connector (D), antenna lead (E). clutch

switch connectors (F), and brake switch connector(G), and disconnect the floor wire harness

connectors (H) and engine compartment wire

harness connectors (l)from the under-dash fuse/

relav box (J).

Middle portion:

8. Disconnect the floor wire harness connectors (A)

and combination subharness connector (B).

Passenger's side:

9. From under the dash, disconnect the dashboard

wire harness connectors (A), EPS subharness

connectors (B), engine compartment wire harness

connectors (C), A,/C subharness connectors (D),

passenger's door wire harness connectors {E), and

side turn signal light connector (F).

10. Detach all of the harness and connector clips.

(cont'd)

20-67

Page 753 of 1139

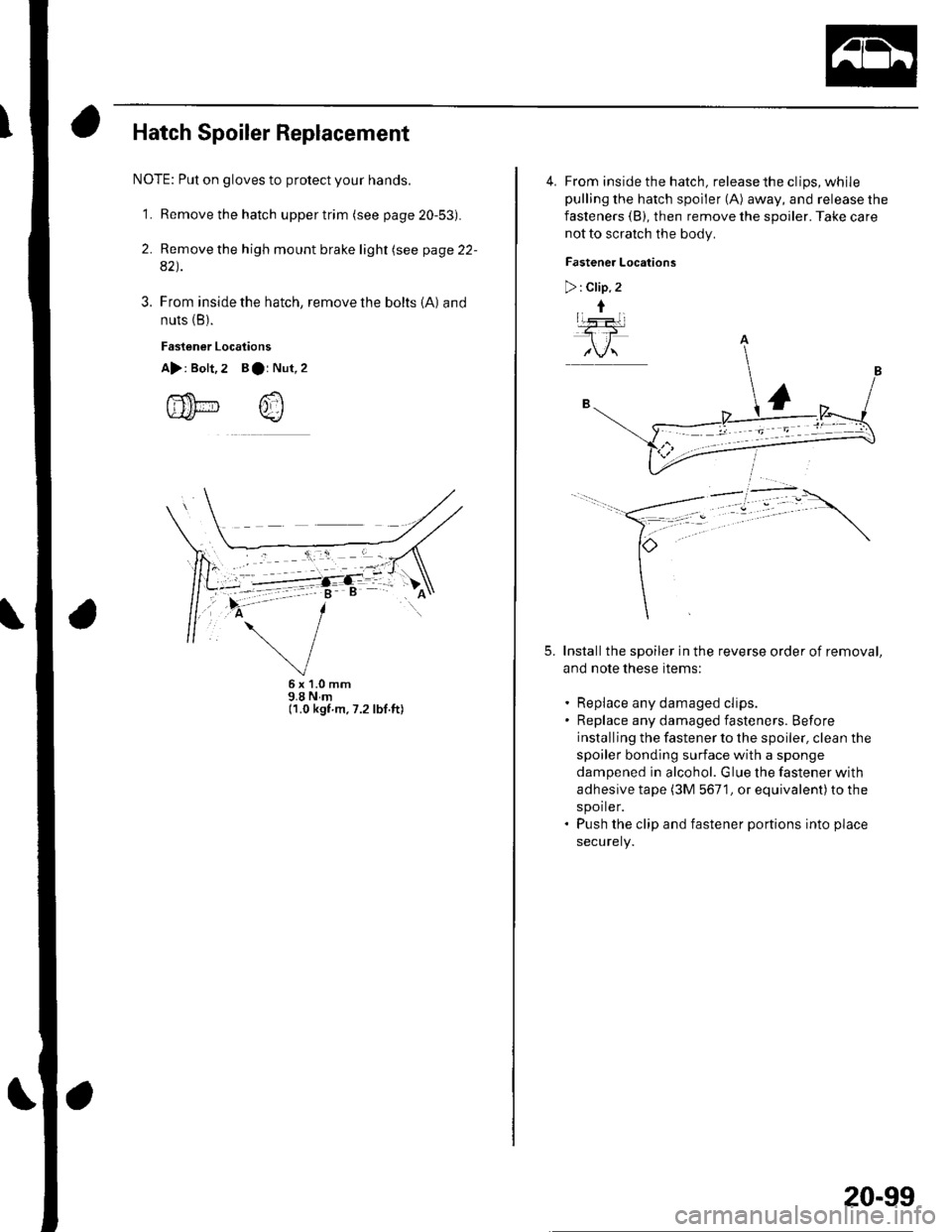

Hatch Spoiler Replacement

NOTE: Put on gloves to protect your hands.

'l. Remove the hatch upper trim (see page 20-53).

2. Remove the high mount brake light (see page 22-

82).

3. From inside the hatch, remove the bolts {A} and

nuts (B).

Fastener Locaiions

A>: Bolt,2 Bar Nut,

fi'f$t-- /,fluLt* v_/

5x1.0mm9.8Nm(1.0 kgf.m.7.2 lbf.ft)

$.A

4. From inside the hatch, release the clips, whilepulling the hatch spoiler (A) away, and release the

fasteners (B), then remove the spoiler. Take care

not to scratch the body.

Fastener Locations

>: Clip. 2

t

Installthe spoiler in the reverse order of removal,

and note these items:

Replace any damaged clips.

Replace any damaged fasteners. Before

installing the fastener to the spoiler, clean the

spoiler bonding surface with a sponge

dampened in alcohol. Glue the fastener with

adhesive tape (3M 5671, or equivalent)to the

spoiler.

Push the clip and fastener portions into place

securely.

5.

20-99

Page 814 of 1139

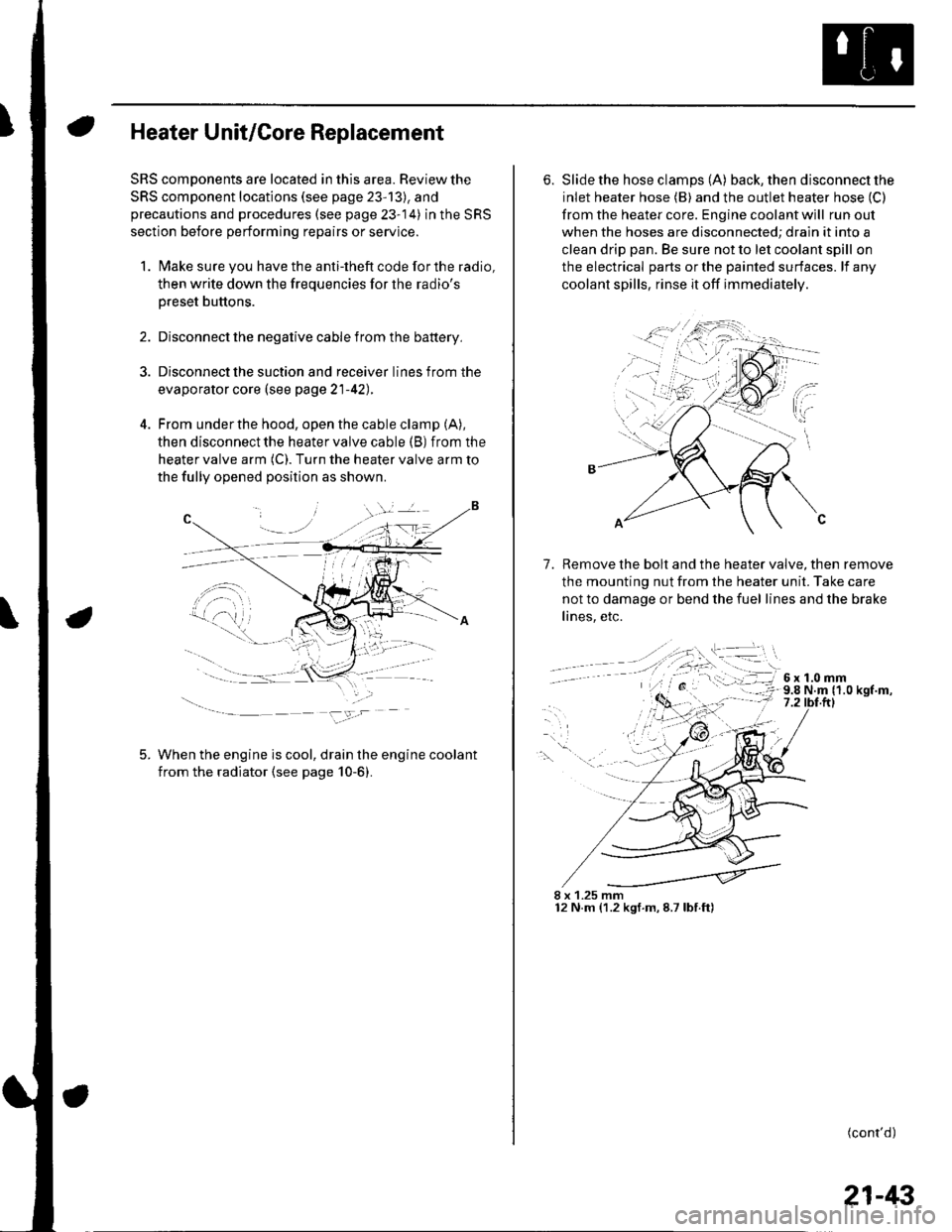

Heater Unit/Core Replacement

SRS components are located in this area. Review the

SRS component locations (see page 23'13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Make sure you have the anti-theft code forthe radio,

then write down the freouencies for the radio's

Dreset buttons.

4.

Disconnect the negative cable from the battery,

Disconnect the suction and receiver lines from the

evaporator core (see page 21-42).

From under the hood, open the cable clamp (A),

then disconnect the heater valve cable (B) from the

heater valve arm (C). Turn the heater valve arm to

the fully opened position as shown

When the engine is cool, drain the engine coolant

from the radiator (see page 10-6).

6. Slide the hose clamps (A) back, the n d isconnect the

inlet heater hose (B) and the outlet heater hose (C)

from the heater core. Engine coolant will run out

when the hoses are disconnected; drain it into a

clean drip pan. Be sure not to let coolant spill on

the electrical parts or the painted surfaces. lf any

coolant spills, rinse it off immediately.

Remove the bolt and the heater valve, then remove

the mounting nut from the heater unit. Take care

not to damage or bend the fuel lines and the brake

lines, etc.

7.

8 x 1.25 mm12 N.m (1.2 kgf.m,8.7lbf.ft)

(cont'd)

21-43

Page 831 of 1139

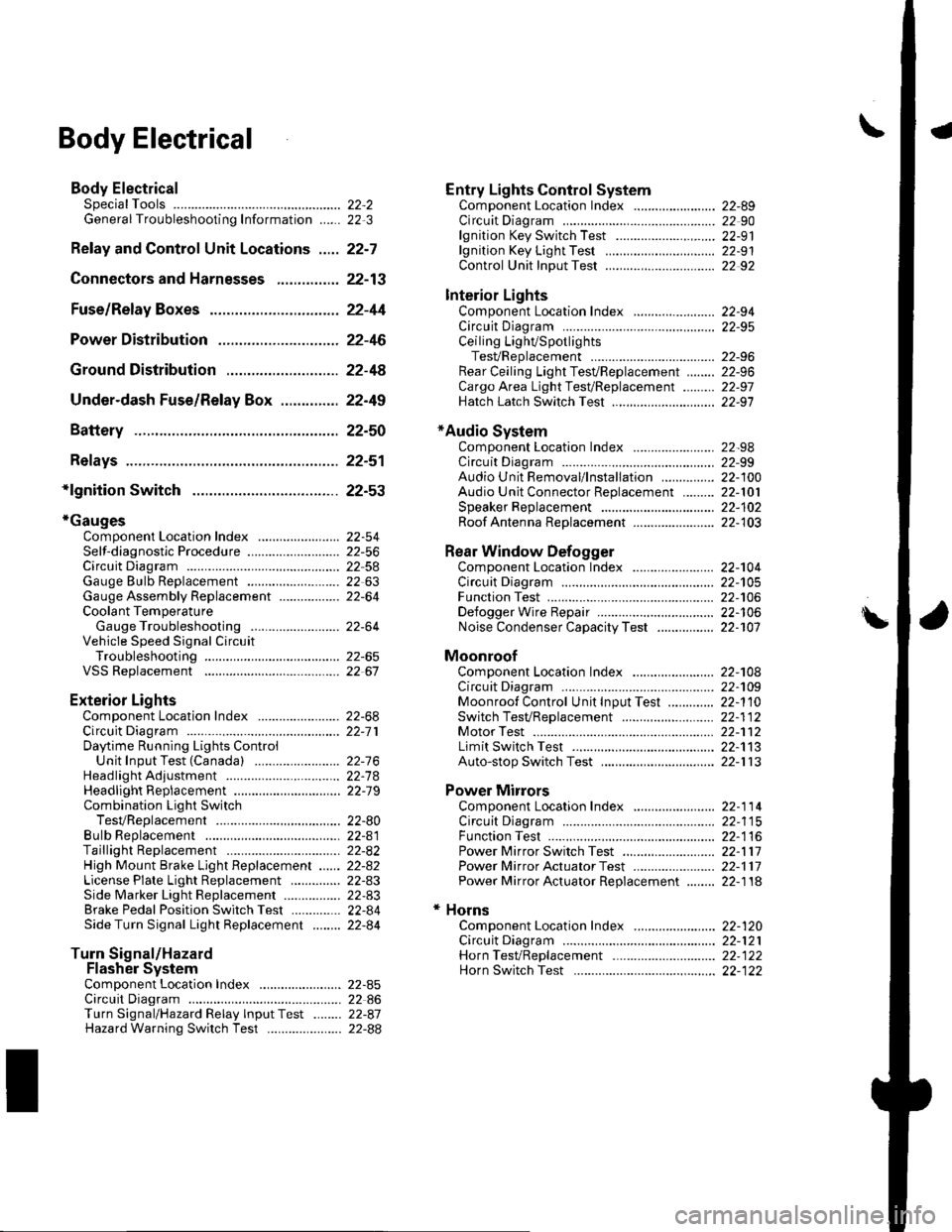

\Body Electrical

Body ElectricalSpecialToolsGeneral Troubleshooting tntorrnaiion.'......

Relay and Control Unit Locations .....

Connectors and Harnesses

Fuse/Relay Boxes ...............................

Power Distribution .............................

Ground Distribution ...........................

Under-dash Fuse/Relay Box ..............

Battery ..............

Relays ................

*lgnition Switch ..............

*Gauges

Component Location Index .......................Self-diagnostic Procedure ..........................Circuit DiagramGauge Bulb Replacement ..........................Gauge Assembly ReplacementCoolant Temperature

Gauge Troubleshooting .... ....................Vehicle Speed Signal CircuitTroubleshootingVSS Replacement

Exterior LightsComponent Location Index .......................Circuit DiagramDaytime Running Lights ControiUnit Input Test (Canada) ........................Headlight Ad,ustment .................. .. .....Headlighr Replacement ..............................Combination Light SwitchTest/ReplacementBulb ReplacementTaillight Replacement ..........................High Mount Brake Light Replacement ......License Plate Light Replacement ..............Side Marker Light Replacement ................Brake Pedal Position Switch Test ..............Side Turn Signal Light Replacement ........

Turn Signal/HazardFlasher SystemComponent Location Index .......................Circuit DiagramTurn Signal/Hazard Relay lnputTest ........Hazard Warning Switch Test

22,3

22-7

22-13

22-44

22-46

22-4A

22-49

22-50

22-51

22-53

22-5422-5622-5422 6322-64

22-64

22-6522 61

22-6822--71

22-7 622-7422-79

22-AO22-4122-8222-4222-4322-4322-4422-84

22-8�522 A622-8722-88

22-10422-105

22-10622-107

Entry Lights control systemComponent Location Index ....................... 22-89Circuit Diagram ......... 22 90lgnition Key Switch Test .....................,...... 22-9'llgnition Key Light Test ............................... 22-91Control Unit Input Test ..........,.................... 22 92

Interior LightsComponent Location Index ....................... 22-94Circuit Diagram ......... 22-95Ceiling LighVSpotlightsTesVReplacement ................................... 22-96Rear Ceiling Light TesVReplacem ent ........ 22-96Cargo Area Light Test/Replacem ent ......... 22-97Hatch Latch Switch Test ..,..,....................... 22-97

*Audio SystemComponent Location Index ....................... 22-98Circuit Diagram ......... 22,99Audio Unit Removal/lnstallation ............... 22-1OOAudio Unit Connector Replacement ......... 22-101Speaker Replacement ................................ 22-102Roof Antenna Rep1acement ....................-.. 22-103

Rear Window DefoggerComponent Location Index ...........Circuit Diasram .. ....... .. ..... ....... ...:::::.::.::.Function TestDefogger Wire Repair .................................Noise Condenser CapacityTest ................

MoonroofComponent Location Index ....................... 22-1OBCircuit Diagram ......... 22-109Moonroof Control Unit Input Test ............. 22-'l10Switch TesVReplacement ........,.....,........... 22-1 12Motor Test ................. 22-112Limit Swilch Test ...... 22-'l'13Auto-stop Switch Test ................................ 22-1 13

Power MirrorsComponent Location Index ....................... 22-114Circuit Diagram ......... 22-115Function Test ............. 22-116Power Mirror Switch Test .......................... 22-ll7Power Mirror Actuator Test ....................... 22-117Power Mirror Actuator Replacement ........ 22-11A

* HornsComponent Location Index ....................... 22-120Circuit Diagram ......... 22-121Horn TesVReplacement ...........................-. 22-122Horn Switch Test .,.... 22-122

\

Page 851 of 1139

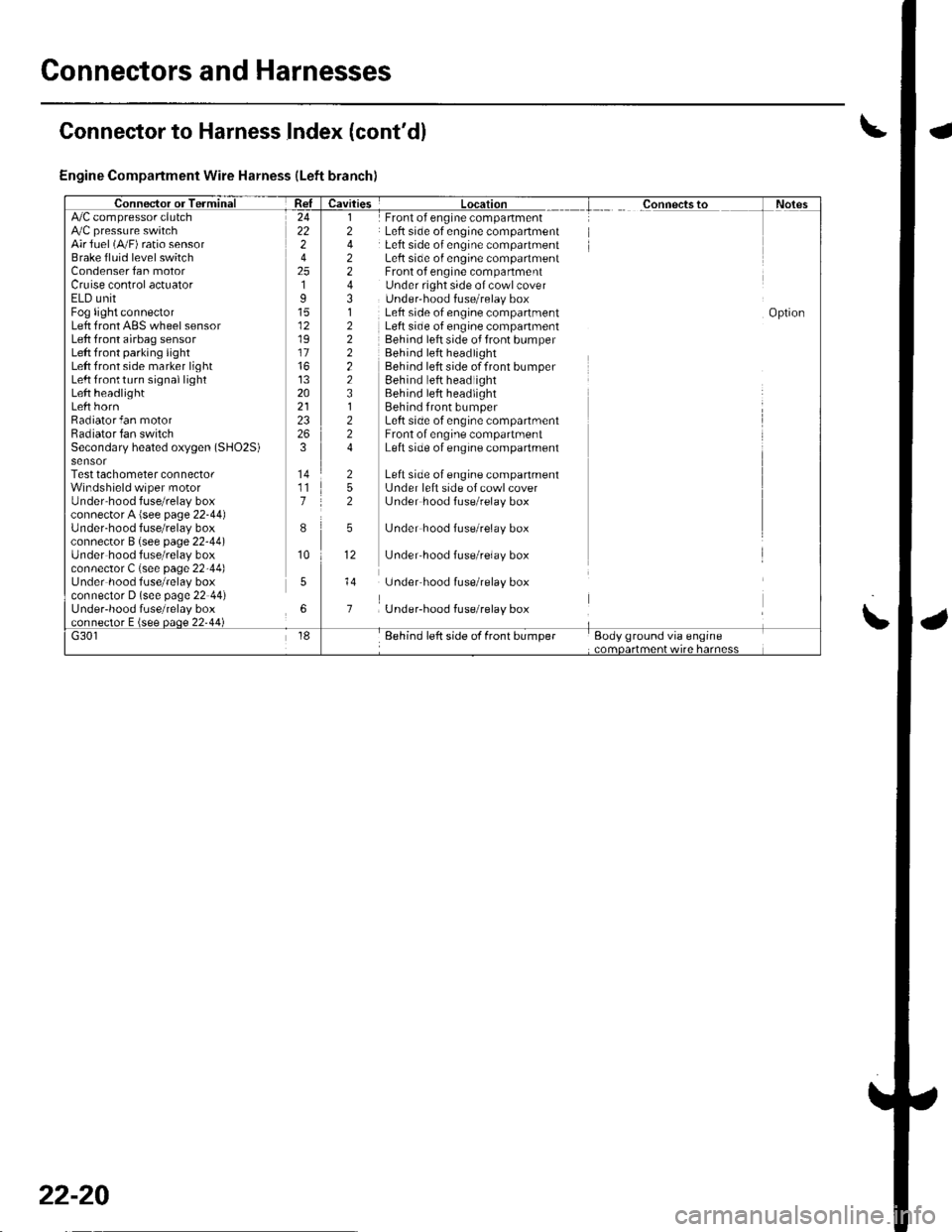

Connectors and Harnesses

Engine Compartment Wire Harness (Left branch)

AirJuel (A,,/F) ratio sensorBrake fluid level switchCondenser fan motorCruise control actuatorELD unitFog light connectorLeft front ABS wheel sensorLeft front airbag sensorLeft front parking lightLeft front side marker lightLeft lrontturn signal lightLeft headlightLeft hornRadiator fan motorRadiator fan switchSecondary heated oxygen (SHO2S)

Test tachometer connectorWindshield wiper motorUnder'hood fuse/relay boxconnector A {see page 22-44)Under-hood f use/relay boxconnector B (see page 22-44)Under hood fuse/relay boxconnector C (see page 22-44)Under hood fuse/relay boxconnector D (see page 22 44)Under-hood fuse/relay box

Front of engine companmentLeft side of engine compartmentLeft side of engine compartmentLeft side o{ engine compartmentFront of engine compartmentUnder right side of cowl coverUnder'hood f use/relay boxLeft side of engine compartmentLeft side of engine companmentBehind left side of front bumperBehind left headlightBehind left side of front bumperEehind left headlightBehind left headlightBehind front bumperLeft side of engine compartmentFront of engine compartmentLeft side of engine compartment

Left side of engine companmentL.Jnder left side of cowl coverL.Jnder hood fuse/relay box

L.Jnder hood fuse/relay box

L.Jnder'hood f use/relay box

underhood fuse/relay box

Under-hood fuse/relay box

24222

2519

12

17

13202123

3

117

I

10

5

6

l2

2243,l

222223l224

252

5

12

Connector to Harness Index (cont'dl

\

22-20