wheel HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 639 of 1139

\

DTC Troubleshooting

DTC 11, 13, 15, 17: Wheel Sensor

(Open/Short to Body Ground/Short to Power)

1. Disconnect the ABS control unit 31P connector.

2. Sta rt the engine.

3. Measure the voltage between the appropriate

wheel sensor (*)circuitterminal of theABS

control unit 31P connector and body ground (see

table).

DTCADpropriate Terminal

11 (Rioht-front)No.5: FRS (t)

13 (Left-front)No, 7: FLS (*)

15 {Riqht-rear}No. 2: RRS (*)

17 (Left-rear)No.9 RtS (f )

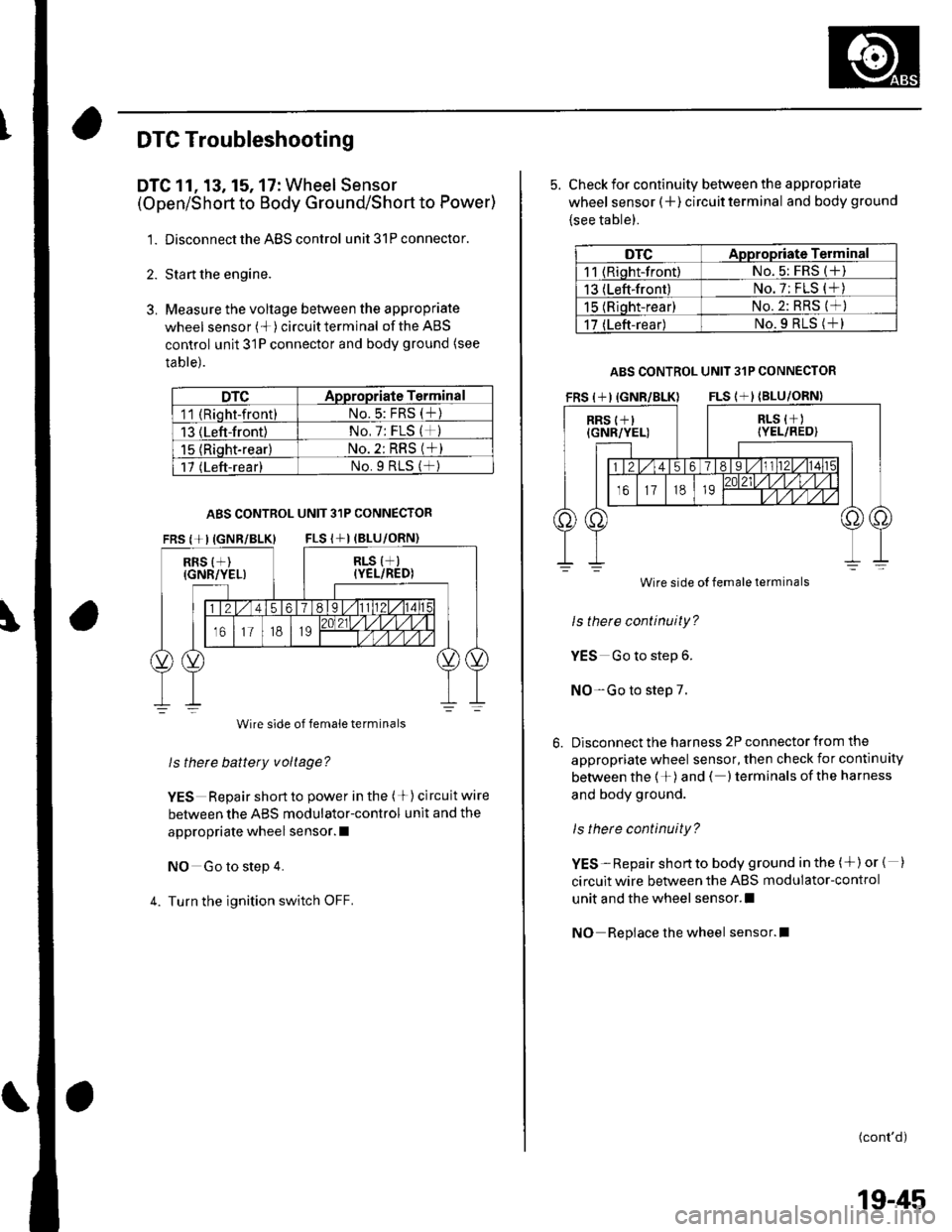

ABS CONTROL UNIT 31P CONNECTOR

FRS {+IIGNR/BLK} FLS I+I (BLU

RRS {+)(GNR/YEL)

Wire side of female terminals

ls thete battery voltage?

YES Repair short to power in the (+) circuit wire

between the ABS modulator-control unit and the

appropriate wheel sensor. I

NO Go to step 4.

4. Turn the ignition switch OFF.

5. Check for continuity between the appropriate

wheel sensor (+ ) circuit terminal and body ground

{see table).

DTCAppropriate Terminal

11 (Riqht-front)No. 5: FRS (+)

13 (Left-front)No. 7: FLS (*)

15 (Rioht-rear)No.2: RRS (*)

17 (Left-rear)No.9 RLS (+l

ABS CONTROL UNIT 31P CONNECTOR

Wire side

ls there continuity?

YES Go to step 6.

NO-Go to step 7.

Disconnect the harness 2P connector from the

appropriate wheel sensor, then check for continuity

between the 1+)and ( )terminals ofthe harness

and body ground.

ls there continuity?

YES-Repair shortto body ground in the (+)or { )

circuit wire between the ABS modulator-control

unit and the wheel sensor.l

NO Repiace the wheel sensor.l

(cont'd)

Wire side of female terminals

19-45

Page 640 of 1139

ABS Components

DTC Troubleshooting (cont'dl

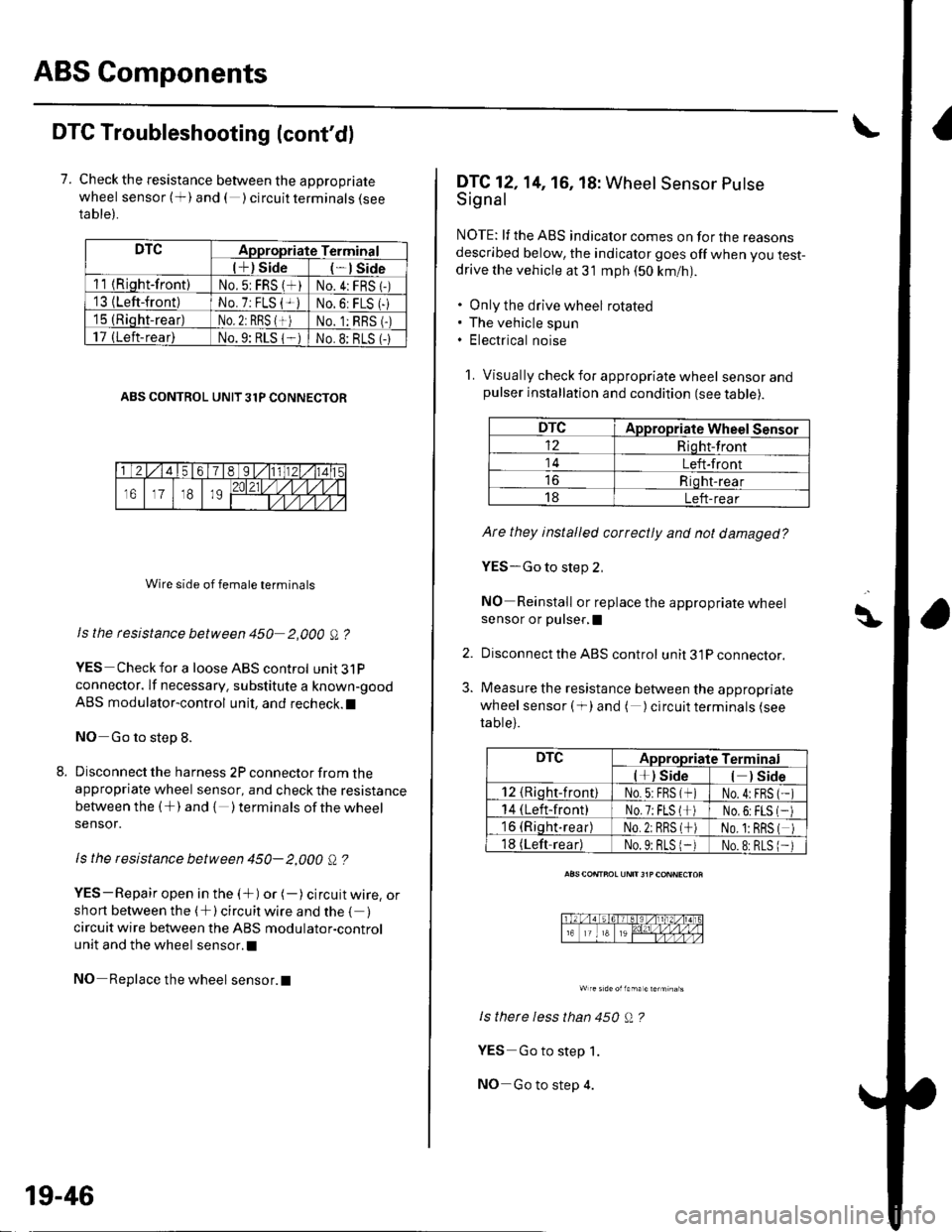

7. Check the resistance between the appropriate

wheel sensor (+) and ( ) circuit terminals {seeta ble).

DTCAppropriate Terminal

l+) Side*lSide

11 {Riqht-front)No.5: FRS (*)No.4:FRS 1-)'13 {Left-front)No. 7: FLS {+iNo.6: FLS (-

15 (Rioht-rear)No. 2: RBS {+)No. 1:RBS (-)

17 (Left-rear)No.9: RLS 1-No.8: BLS (-

ABS CONTROL UNIT 31P CONNECTOR

Wire side of female terminals

Is the rcsistance between 450 2,000 A ?

YES Check for a loose ABS control unit3lP

connector. lf necessary. substitute a known-good

ABS modulator-control unit, and recheck.l

NO Go to step 8.

Disconnect the harness 2P connector from theappropriate wheel sensor, and check the resistance

between the (+) and { )terminalsof thewheel

sensor.

ls the resistance between 450- 2,000 Q ?

YES-Repair open in the (+) or (-) circuit wire, orshort between the (+) circuit wire and the { )circuit wire between the ABS modulator-control

unit and the wheel sensor.l

NO Replace the wheel sensor.l

19-46

DTC12,14, 16, 18: Wheel Sensor Putse

Signal

NOTE: lf the ABS indicator comes on for the reasonsdescribed below, the indicator goes off when you test-drive the vehicle at 31 mph (50 km/nl.

. Only the drive wheel rotated. The vehicle spun. Electrical noise

1. Visually check for appropriate wheel sensorandpulser installation and condition (see table).

DTCAppropriate Wheel Sensor

12Riqht-front

14Left-front

Riqht-rear

18Left-rear

Ate they installed correctly and not damaged?

YES-Go to step 2,

NO Reinstall or replace the appropriate wheelsensor or pulser,I

Disconnect the ABS control unit 31P connector.

Measure the resistance between the appropriate

wheel sensor ( f) and ( ) circuit terminals (see

table).

ls therc less than 450 Q ?

YES Go to step 1.

NO-Go to step 4.

\\|D

2.

3.

DTCAppropriate Terminal

l*) Side) Side

12 {Rioht-front)No.5:FBS (*No.4:FBS

14 (Left-front)No.7;FLS l*No,6:FLS

16 (Riqht.rear)No.2: RRS (*No. 1:BRS

18 (Left-readNo.9: BLS 1-No.8:RLS

Page 641 of 1139

4. Check for continuity between the appropriate

wheel sensor (+) circuittermlnal and otherwheel

sensor (+) circuit terminals (see table).

DTCAppropiate

Terminal

Other Terminal

12No.5:

FRW (*i

No.7No.2No.9

'14No.7:

FLW IT.)

No.5No.2No.9

toNo.2;

RRW (T-)

No.5No.7No.9

18No.9:

RLW (*)No.5No. 7No.2

ls there continuity?

YES Repair short in the wires between the

appropriate wheel sensor and the other wheel

sensor harnesses.l

NO Clear the DTC, disconnect the Honda PGM

Tester, and test-drive the vehicle. lf the ABS

indicator comes on and the same DTC is indicated,

replace the ABS modulator-control unit.l

Disconnect the harness 2P connector from the

appropriate wheel sensor and check the resistance

between the (+) side and the (-) side ofthe wheel

sensor.

ls there less than 450 Q ?

YES Replace the wheel sensor.

NO- Repair short to wire between the appropriate

wheel sensor (+) and (-)circuits.l

DTC 21: Continuous Operation (Chipped

pulser)

1. Clear the DTC, then disconnect the Honda PGM

tesler.

2. Test-drive the vehicle at 19 mph (30 km/h) or more.

Doesthe ABS indicator come on and is DTC 21

ind icated?

YES Go to step 3.

NO The system is OK at this time.l

3. Check the pulser gear for a chipped tooth.

ls the pulser OK?

YES Check for a loose ABS control unit 31P

connector. lf necessary, substitute a known-good

ABS modulator-control unit, and recheck.l

NO Replace the driveshaft or hub unit (chipped

pulser gear).1

1g-47

Page 652 of 1139

ABS Gomponents

ABS Modulator-Control Unit Removal and Installation {cont'dl

3. Disconnectthe six brake lines.

4. Remove the two I mm nuts.

5. Remove the ABS modulator-control unit (C).

Installation

'1. InstalltheABS modulatorcontrol unit, then tighten the two 8 mm nuts.

2. Align the connecting surface ofthe ABS control unit 3'lP connector.

3. PushinthelockoftheABScontrol unit 31P connector until you hear it click into place. then connect the connector.

4. Connect the six brake Iines.

5. Bleed the brake system, starting with the front wheels.

6. Connect the PGM Tester, and do the solenoid function test for each wheel.

7. Bleed the brake system again, staning with the front wheels.

8. Start the engine, and check that the ABS indicator and brake system indicator go off.

9. Disconnect the Honda PGM Tester. Test-drive the vehicle, and check that the ABS indicator and brake qvqtem

indicator do not come on.

19-58

Page 653 of 1139

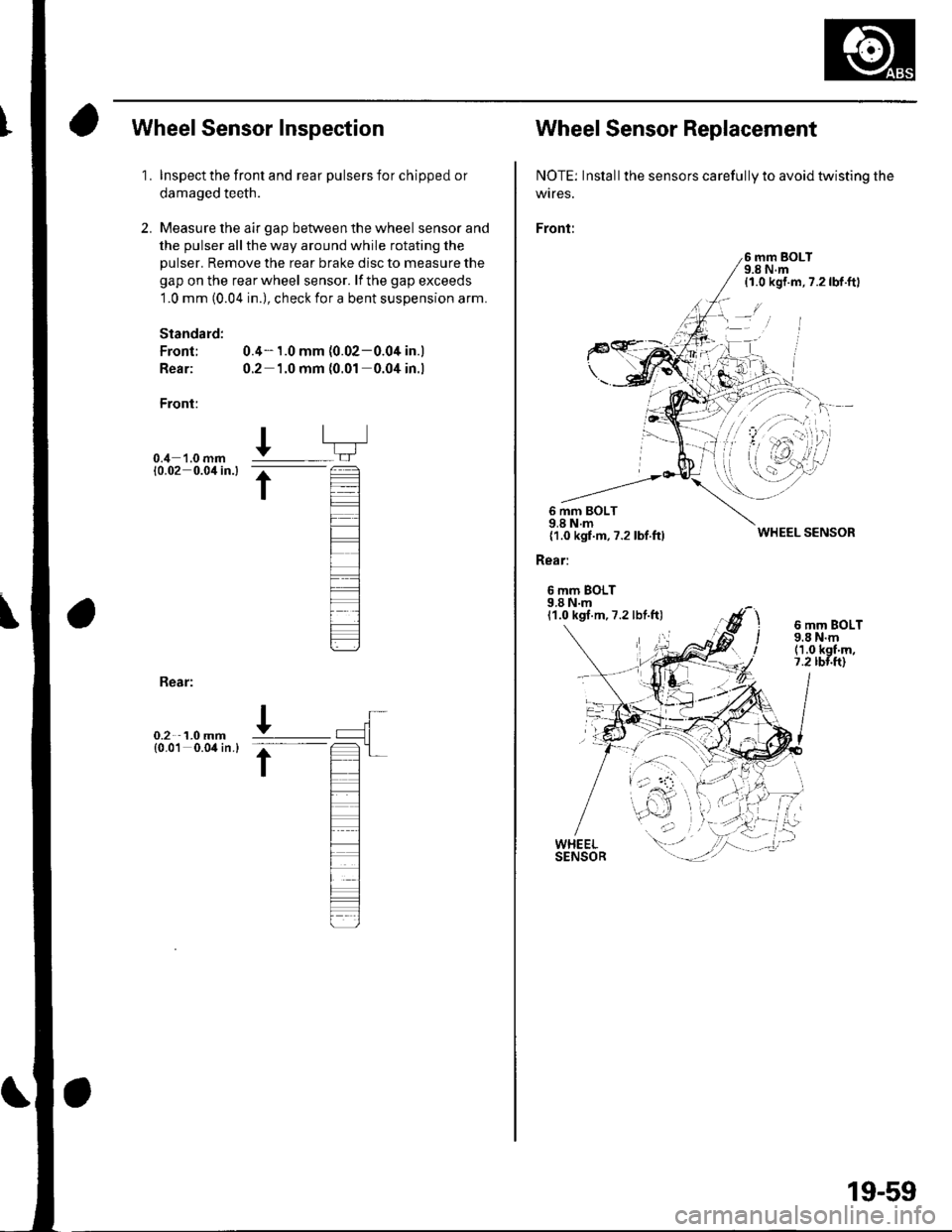

Wheel Sensor Inspection

1.

2.

Inspect the front and rear pulsers for chipped or

damaged teeth.

Measure the air gap between the wheel sensor and

the pulser all the way around while rotating the

pulser. Remove the rear brake disc to measure the

gap on the rear wheel sensor. lf the gap exceeds

1.0 mm (0.04 in.), check for a bent suspension arm.

Standard:

Front; 0.4- 1.0 mm (0.02-0.04 in.)

Rear: 0.2 1.0 mm (0.01 0.04 in.l

Front:

0.4 '1.0 mm10.02 0.0'l in.l

I

t

Bear:

0.2 1.0 mm{0.01 0.04 in.}

Wheel Sensor Replacement

NOTE: Inslall the sensors carefully to avoid twisting the

wtres.

Front:

6 mm BOLT9.8 N.m{1.0 kgf.m,7.2lbf.ftl

6 mm BOLT9.8 N.m{1.0 kgf.m,7.2 lbf.ftl

Rear:

6 mm BOLT9.8 N.m11.0 kgf.m,7.2 lbf.ft)

WHEEL SENSOR

6 mm BOLT9.8 N.m(1.0 kgf'm,7.2 rbr.ft)

19-59

Page 754 of 1139

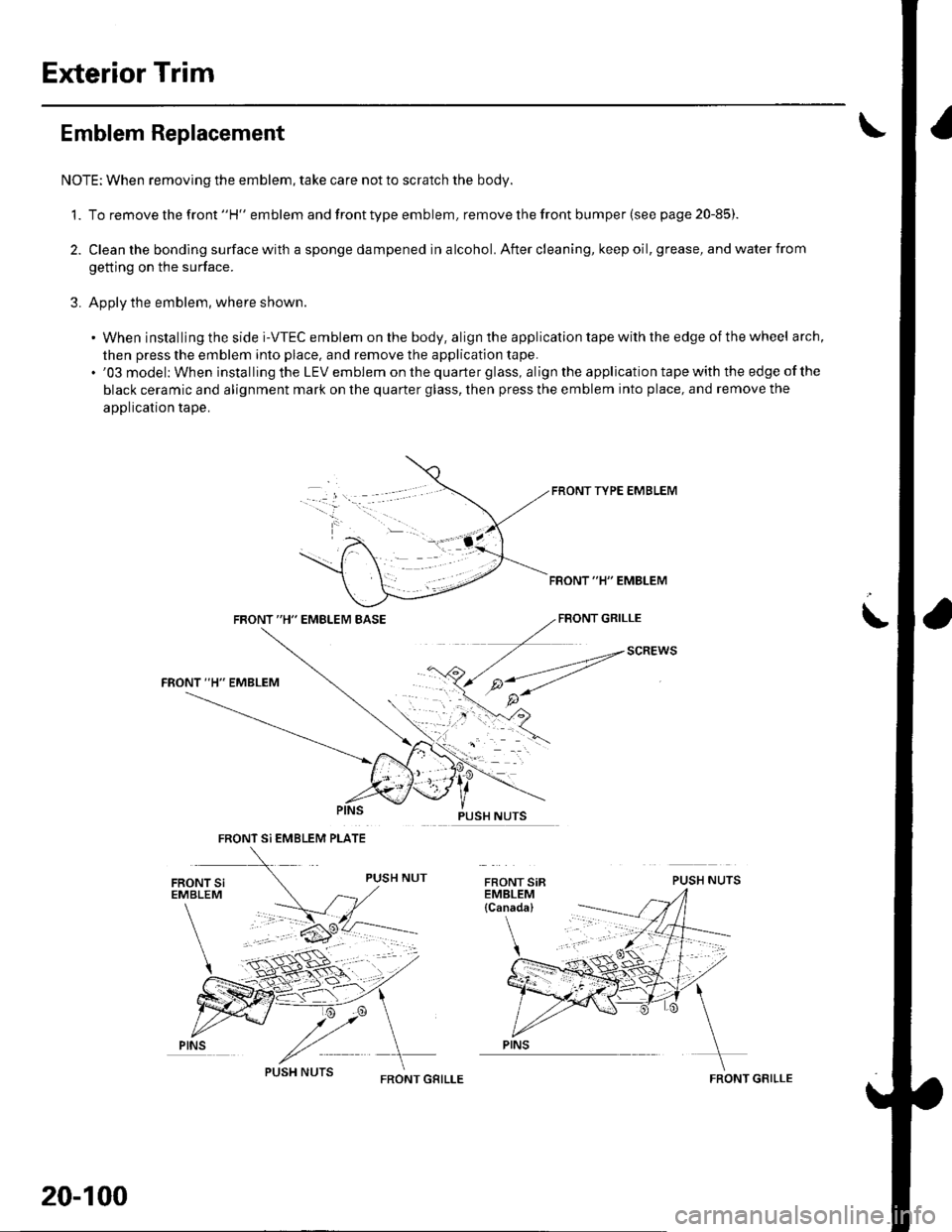

Exterior Trim

Emblem Replacement

NOTE: When removing the emblem, take care not to scratch the body.

1. To remove the front "H" emblem and front type emblem, remove the front bumper (see page 20-85)

2. Clean the bonding surface with a sponge dampened in alcohol. After cleaning, keep oil, grease, and water from

getting on the surface.

3. Apply the emblem, where shown.

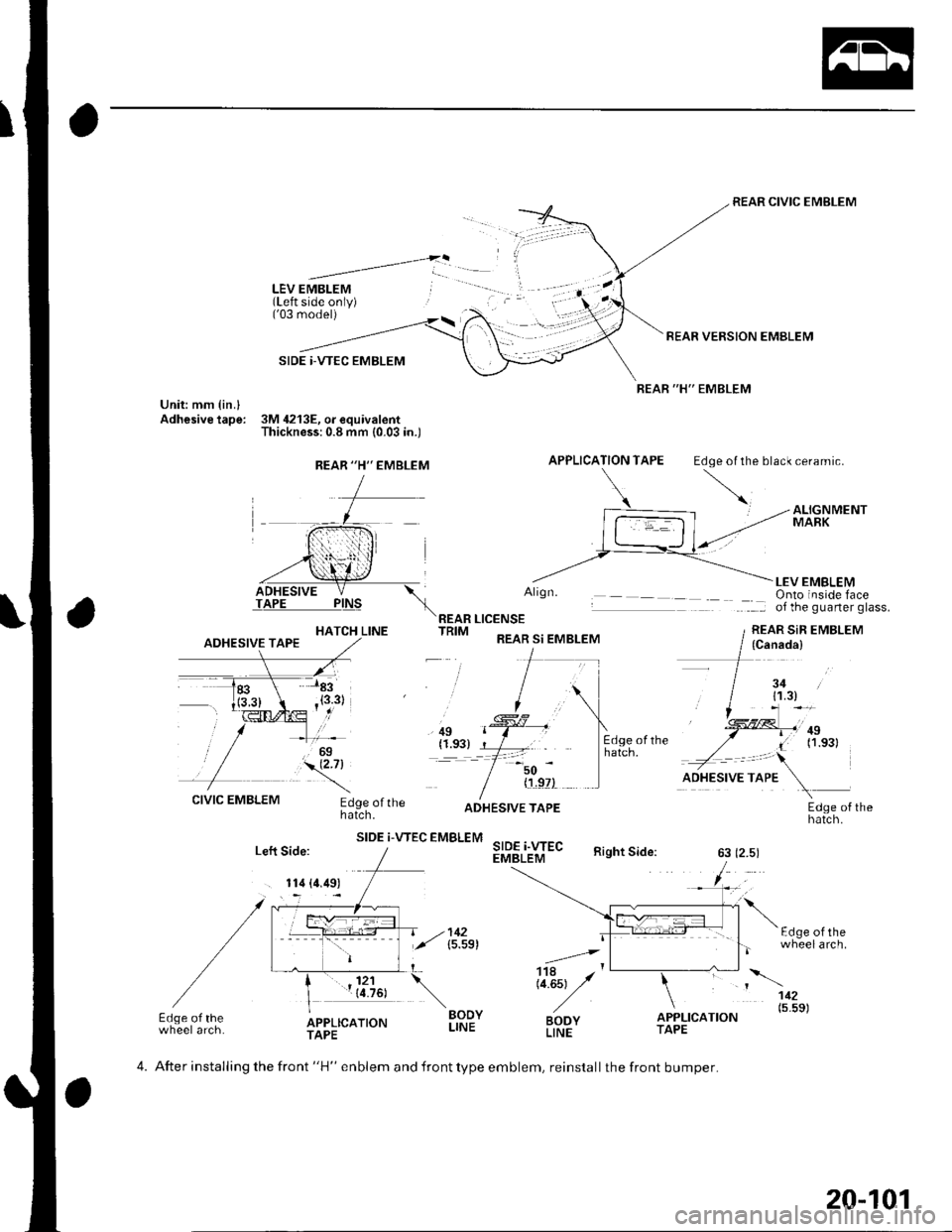

. When installing the side i-VTEC emblem on the body, align the application tape with the edge of the wheel arch,

then press the emblem into place, and remove the application tape.. '03 model: When installing the LEV emblem on the quarter glass, align the application tape with the edge of the

black ceramic and alignment mark on the quarter glass, then press the emblem into place, and remove the

application tape.

FRONT TYPE EMBLEM

FBONT "H" EMBLEM

FRONT "H" EMBLEM BASEFBONT GRILLE

PUSH NUTS

i

SCREWS

FRONT Si EMBLEM PLATE

PINS

20-100

FRONT GRILLEFRONT GRILLE

Page 755 of 1139

LEV EMBLEM(Left side only)('03 model)

SIDE |-VTEC EMBLEM

Unit: mm {in.lAdhesive tape: 3M 4213E, o. equivalentThickness:0.8 mm (0.03 in.)

REAR CIVIC EMBLEM

REAR VERSION EMBLEM

REAR "H" EMBLEM

APPLICATION TAPE Edoe ol the black ceramic.

HATCH LINE

Align.

REAR LICENSETRIM REAR si EMBLEM

LEV EMBLEMOnto inside faceof the guarter glass.

REAR SiR EMBLEM

, ilg(1.93)=-t

50

CIVIC EMBLEMEdge ofthehatch.

SIDE i-VTEC EMBLEM

{'!,9?)

SIDE i.WECEMBLEM

ADHESIVE TAPEEdge of thehatch.

Right Side:63 (2.5)

F.l^6 ^l rh-

.=4,

Li.Est y'

BODYLINE

wheelarch.

112

BODYLINEo"f,r,ao.o" (5'5s)Edge of thewheel arch.APPLICATIONTAPETAPE

REAR "H'' EMBLEM

(Canada)

3411.3)

.,!!ll,'ntI (1.s31

Left Side:

. 114 (4.49)

4. After installing the front "H" enblem and front type emblem, reinstall the front bumper.

20-101

Page 756 of 1139

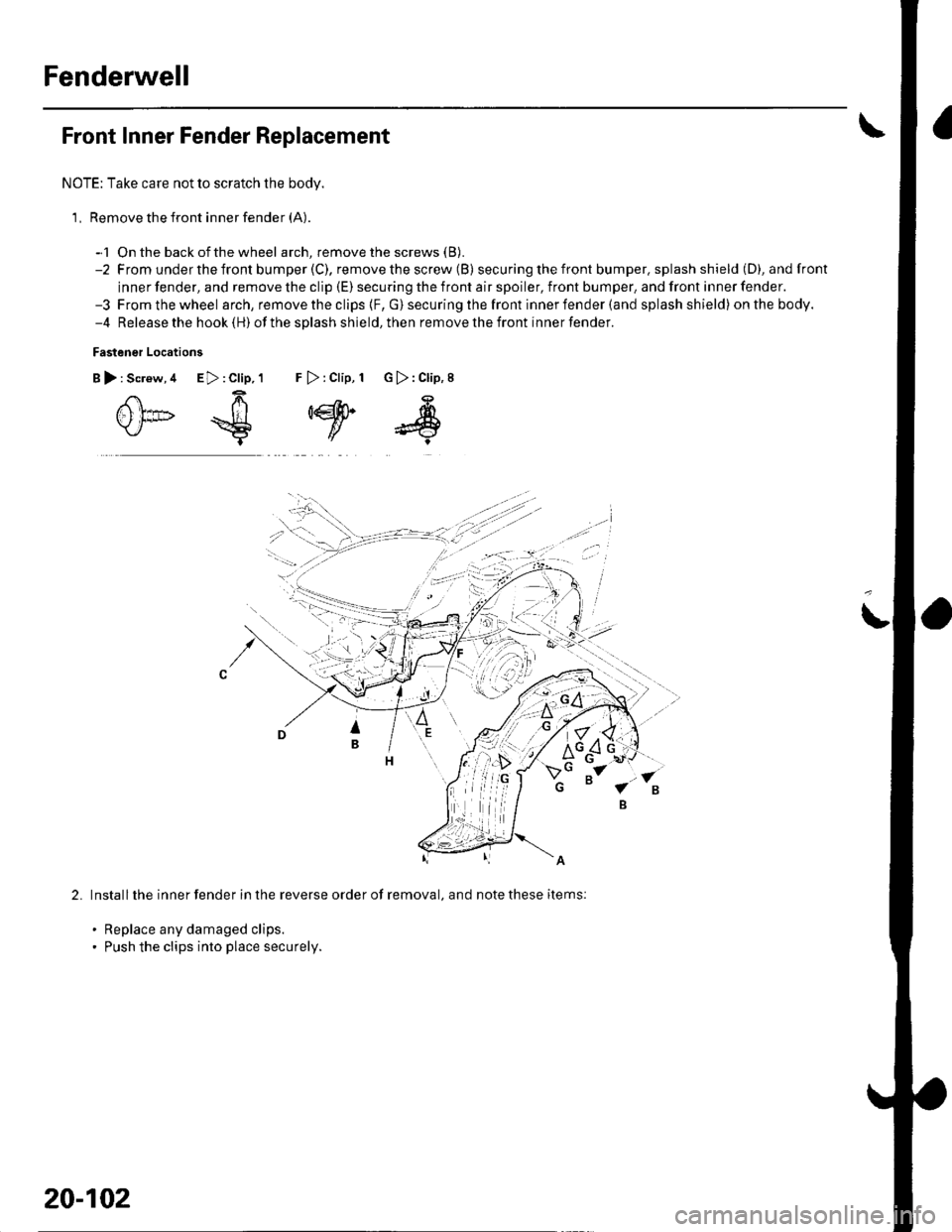

Fenderwell

Front Inner Fender Replacement

NOTE: Take care not to scratch the body.

1, Remove the front inner fender (A).

-1 On the back ofthe wheel arch, remove the screws (B).

-2 From underthefront bumper(C), removethescrew (B) secu ring the front bumper. splash shield (D), andfront

inner fender, and remove the clip (E) securing the front air spoiler, front bumper, and front inner fender.-3 Fromthewheel arch, remove the clips {F, G) securing the front inner fender (and splash shield) onthebody.-4 Release the hook (H) ofthe splash shield,then removethefront innerfender.

Fastener Locations

B):Screw,4 E>:Clip,1 F >:Clip, 1 G):Clip,8

0*€

,w

s

2.Install the inner fender in the reverse order of removal, and note these items:

. Replace any damaged clips.. Push the clips into place securely.

20-102

Page 757 of 1139

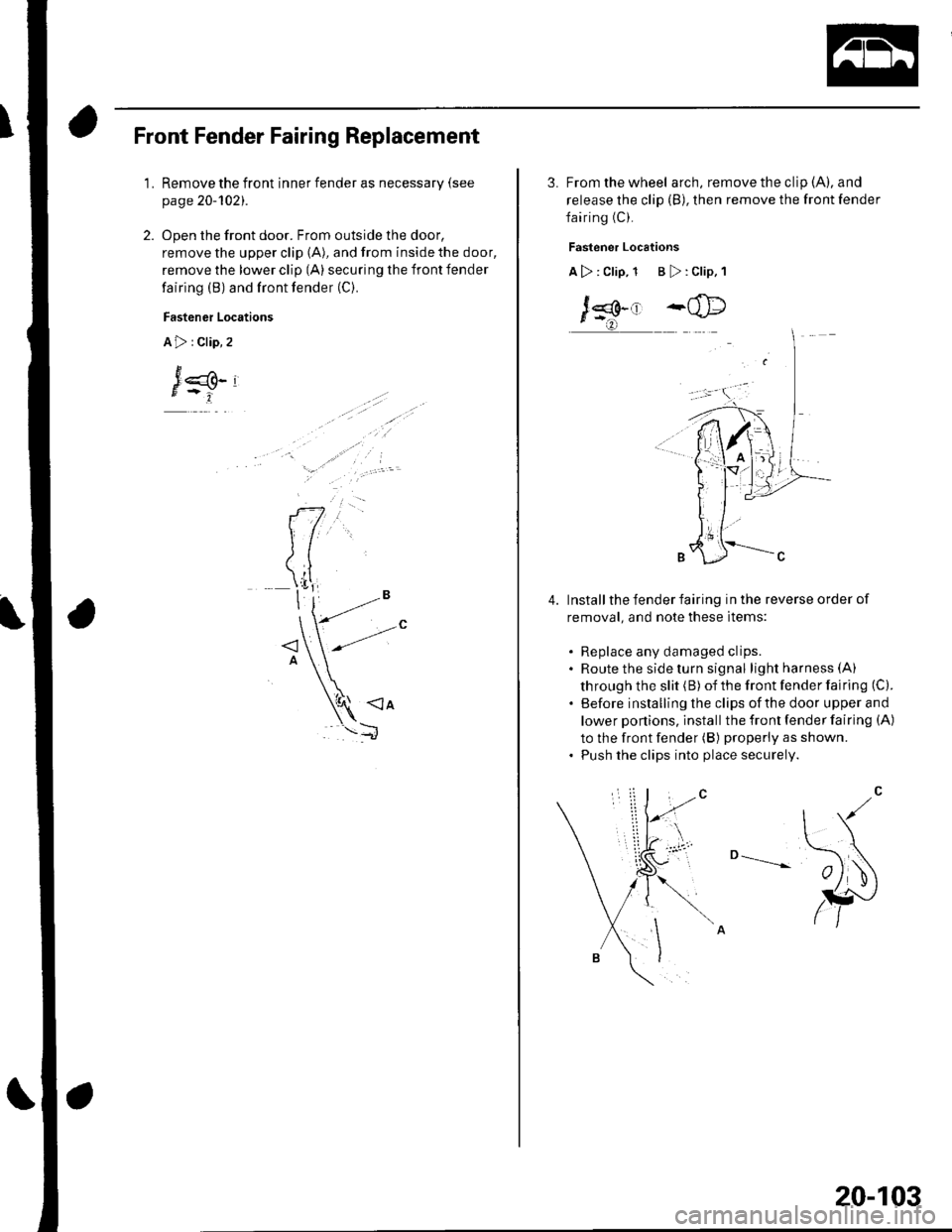

Front Fender Fairing Replacement

1.Remove the front inner fender as necessary (see

page 20-1O21.

Open the front door. From outside the door,

remove the upper clip (A), and from inside the door,

remove the lower clip (A) securing the front fender

fairing (B) and front fender (C).

Fastener Locations

A>:Clip,2

J

3. From the wheel arch, remove the clip (A), and

release the clip (B), then remove the front fender

fairing (C).

Fastener Locations

A>: Clip, 1 B >: Clip, 1

J*.' -@

Install the fender fairing in the reverse order of

removal, and note these items:

. Replace any damaged clips.. Route the side turn signal lightharness(A)

through the slit (B) of the front fender fairing (C).

. Before installing the clips ofthe door upper and

lower ponions, install the front fender fairing (A)

to the front fender (B) properly as shown.. Push the clips into place securely.

o --____--

4.

20-103

Page 849 of 1139

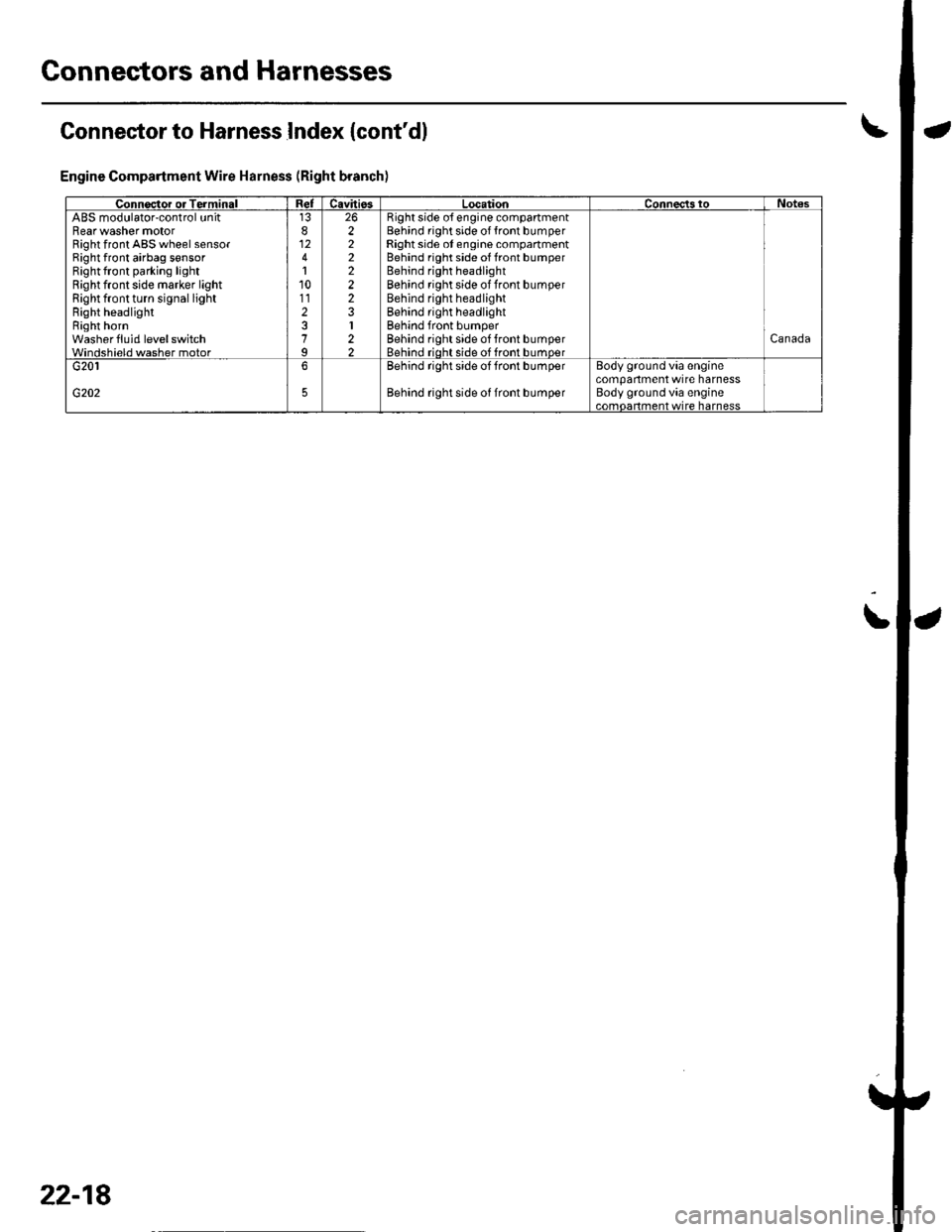

Connectors and Harnesses

Connector to Harness Index {cont'dl

Engine Compartment Wire Harness (Right branch)

\

Connsctor or TerminalCavitissLocationConnects toNotesABS modulator-control unitBearwasher motorRight front ABS wheel sensorRight front airbag s€nsorBightfront parking lightRight front side marker lightRight front turn signal lightRight headlightRight hornwash€rfluid level switchWindshield washer motor

812

110112

7

222222

I22

Bight side o{ engine compartmentBehind right side of {ront bumperRight side ot engine compartmentBehind right side of front bumperBehind right headlightBehind rightside of Jront bumperBehind right headlightBehind right headlightBehind front bumperBehind rightside of tront bumperBehind rioht side of front bumoerCanada

G202

G2016Behind rightside of tront bumper

Behind rightside of Jront bumper

Body ground via €nginecompartment wtre harnessBody ground via engine.omnerhent wire harness

22-18