ecm HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 993 of 1139

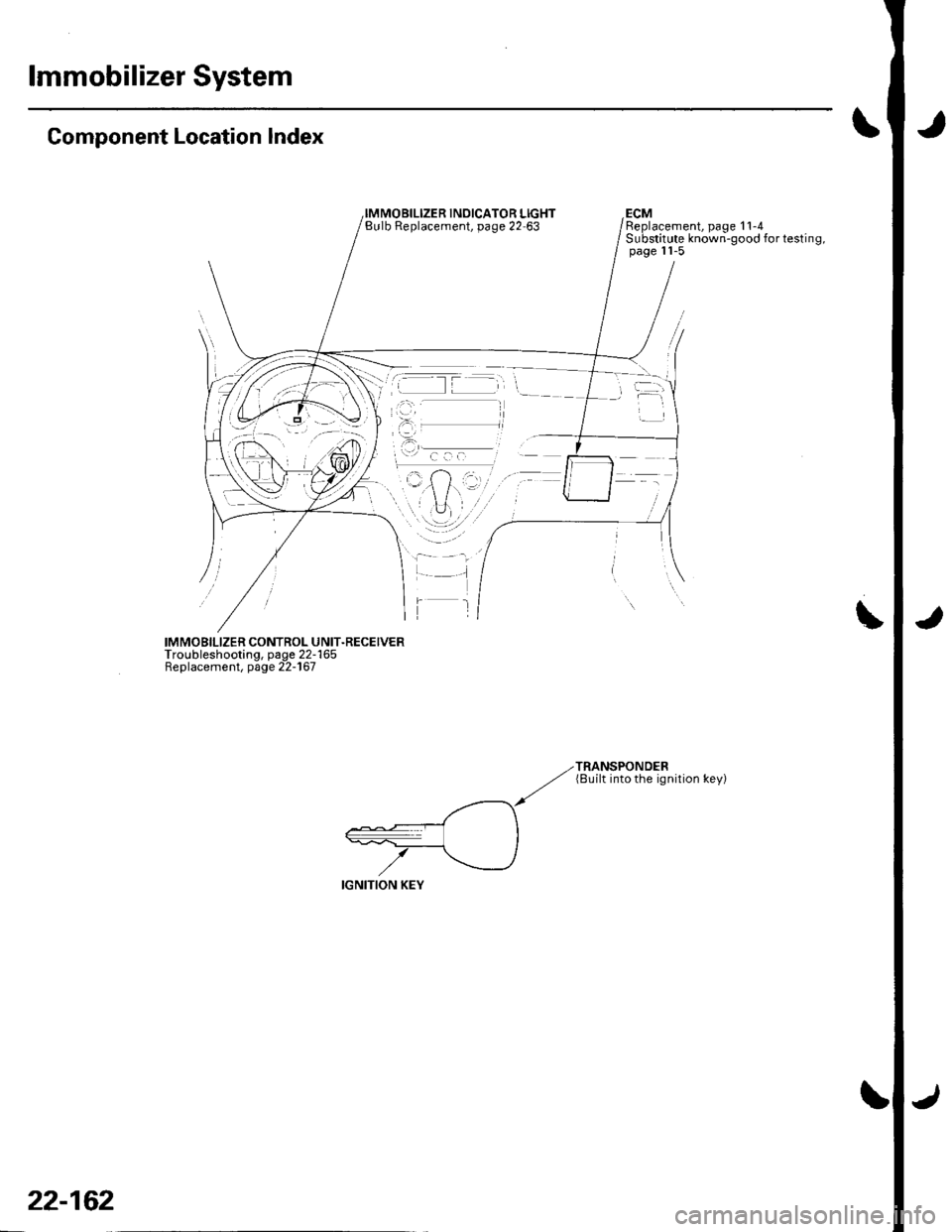

lmmobilizer System

Component Location Index

INOICATOR LIGHTBulb Replacement, page 22 63ECMReplacement, page 11-4Substitute known-good for testing,page 11-5

IMMOBILIZER CONTROL UNIT.RECEIVERTroubleshooting, page 22-165Replacement, page 22-167

TRANSPONDER(8uilt into the ignition key)

22-162

Page 994 of 1139

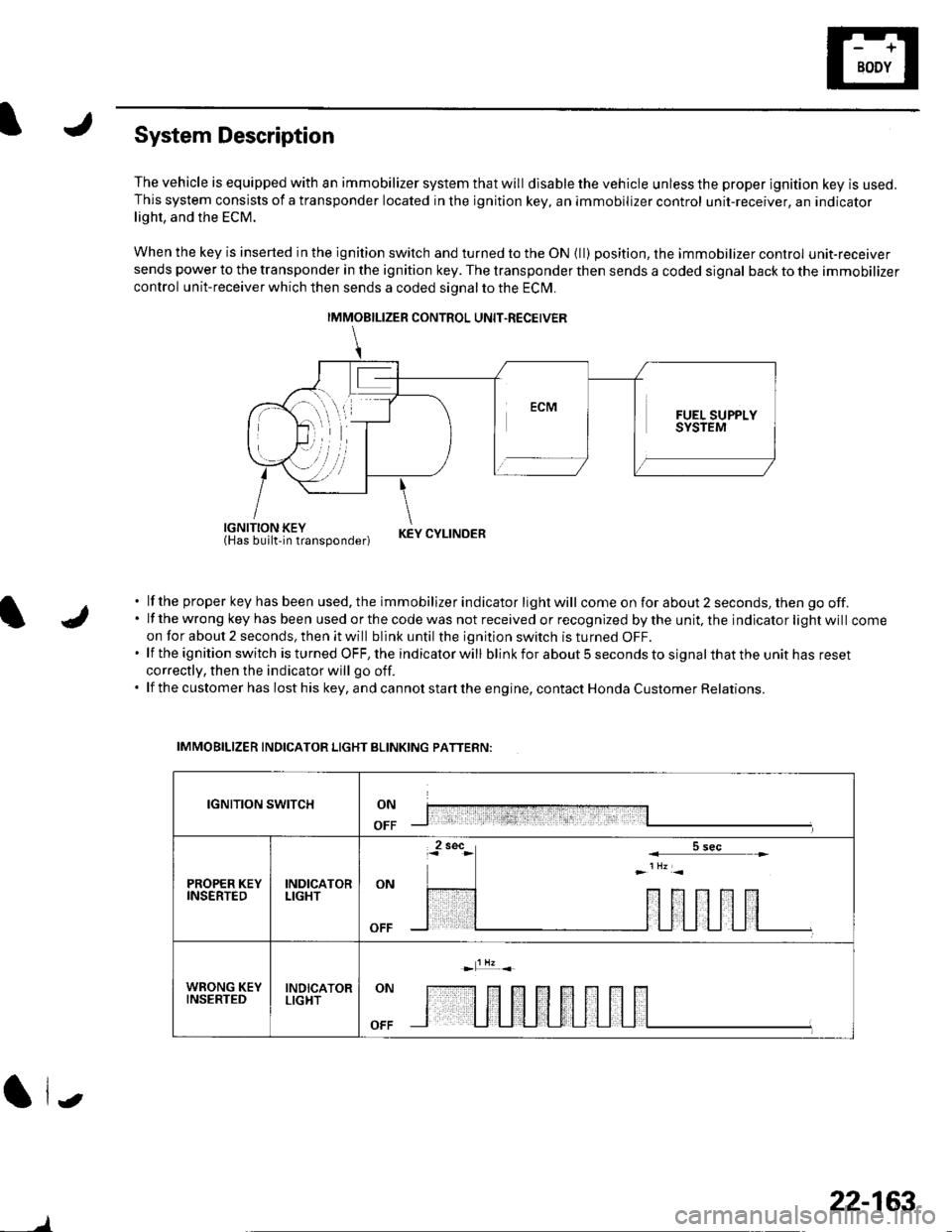

System Description

The vehicle is equipped with an immobilizer system that will disable the vehicle unless the proper ignition key is used.This system consists of a transponder located in the ignition key, an immobilizer control unit-receiver, an indicatorlight, and the ECM.

When the key is inserted in the ignition switch and turned to the ON {ll) position, the immobilizer control unit-receiversends power to the transponder in the ignition key. The transponder then sends a coded signal back to the immobilizer

control unit-receiver which then sends a coded signal to the ECI\4.

iEl'JUiliii'tlun"oona"|.r KEYCYLTNDER

lf the proper key has been used, the immobilizer indicator light will come on for about 2 seconds, then go off.lf the wrong key has been used or the code was not received or recognized by the unit, the indicator light will comeon for about 2 seconds, then it will blink until the ignition switch is turned OFF.lf the ignition switch is turned OFF, the indicator will blink for about 5 seconds to signal that the unit has reset

correctly, then the indicator will go off.

lf the customer has lost his key, and cannot start the engine, contact Honda Customer Relations.

IMMOBILIZER INDICATOR LIGHT BLINKING PATTERN:

IGNITION SWITCHON

OFF

PROPER KEYINSERTEDINDICATORLIGHTON

WRONG KEYINSERTEDINDICATORLIGHTON

OFF

(| i.,

IMMOBILIZER CONTROL UNIT.RECEIVER

)

22-163

Page 996 of 1139

)

I

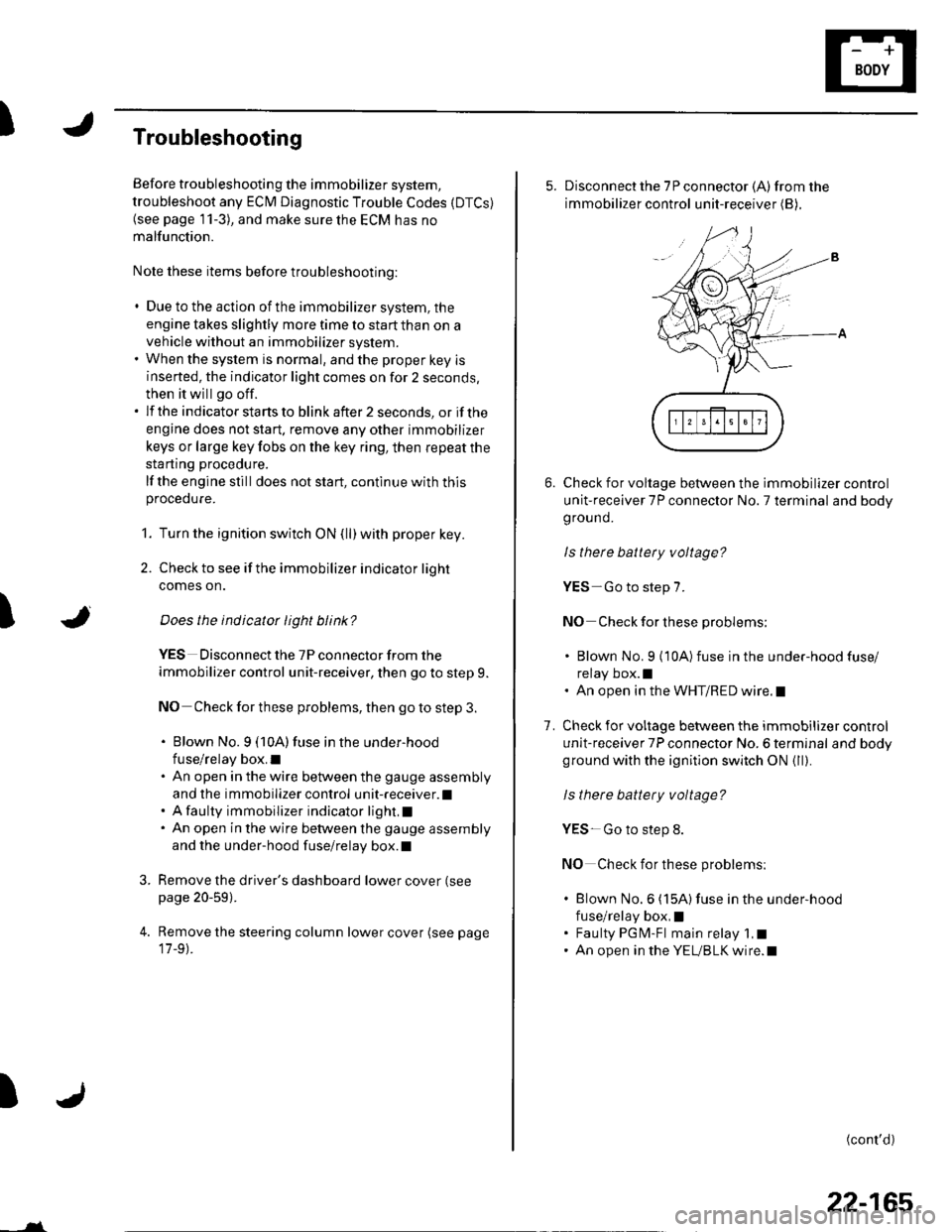

Troubleshooting

Before troubleshooting the immobilizer system,

troubleshoot any EClvl Diagnostic Trouble Codes (DTCS)

(see page 11-3), and make sure the ECM has no

malfunction.

Note these items before trou bleshooting:

. Due to the action of the immobilizer system, the

engine takes slightly more time to start than on a

vehicle without an immobilizer system.. When the system is normal, and the proper key is

inserted, the indicator light comes on for 2 seconds,

then it will go off.. If the indicatorstartsto blink after 2 seconds, or if the

engine does not start. remove any other immobilizer

keys or large key fobs on the key ring, then repeat the

starting procedure.

lf the engine still does not start, continue with thisprocedure.

1. Turn the ignition switch ON {ll) with proper key.

2. Check to see if the immobilizer indicator light

comes on.

Does the indicator light blink?

YES Disconnect the 7P connector from the

immobilizer control unit-receiver, then go to step 9.

NO Check for these problems, then go to step 3.

. Blown No. 9 (10A)fuse in the under-hood

fuse/relay box.I. An open in the wire between the gauge assembly

and the immobilizer control unit-receiver.l. A faulty immobilizer indicator light,I. An open in the wire between the gauge assembly

and the under-hood fuse/relay box.l

Remove the driver's dashboard lower cover (see

page 20-59).

Remove the steering column lower cover (see page

11-9).

l

-_--t

22-165

5. Disconnect the 7P connector (A)from the

immobilizer control unit-receiver (B),

Check for voltage between the immobilizer control

unit-receiver 7P connector No. 7 terminal and body

ground.

ls there battery voltage?

YES-Go to step 7.

NO Check for these problems;

. Blown No. 9 {10A)fuse in the under-hood fuse/

relay box.l. An open in the WHT/RED wire.l

Check for voltage between the immobilizer control

unit-receiver 7P connector No. 6 terminal and bodyground with the ignition switch ON {ll).

ls there battery voltage?

YES- Go to step 8.

NO Check for these problems:

. Blown No.6 (15A)fuse in the under-hood

fuse/relay box,I. Faulty PGM-Fl main relay 1,t. An open in the YEUBLK wire.l

1.

(cont'd)

Page 997 of 1139

lmmobilizer System

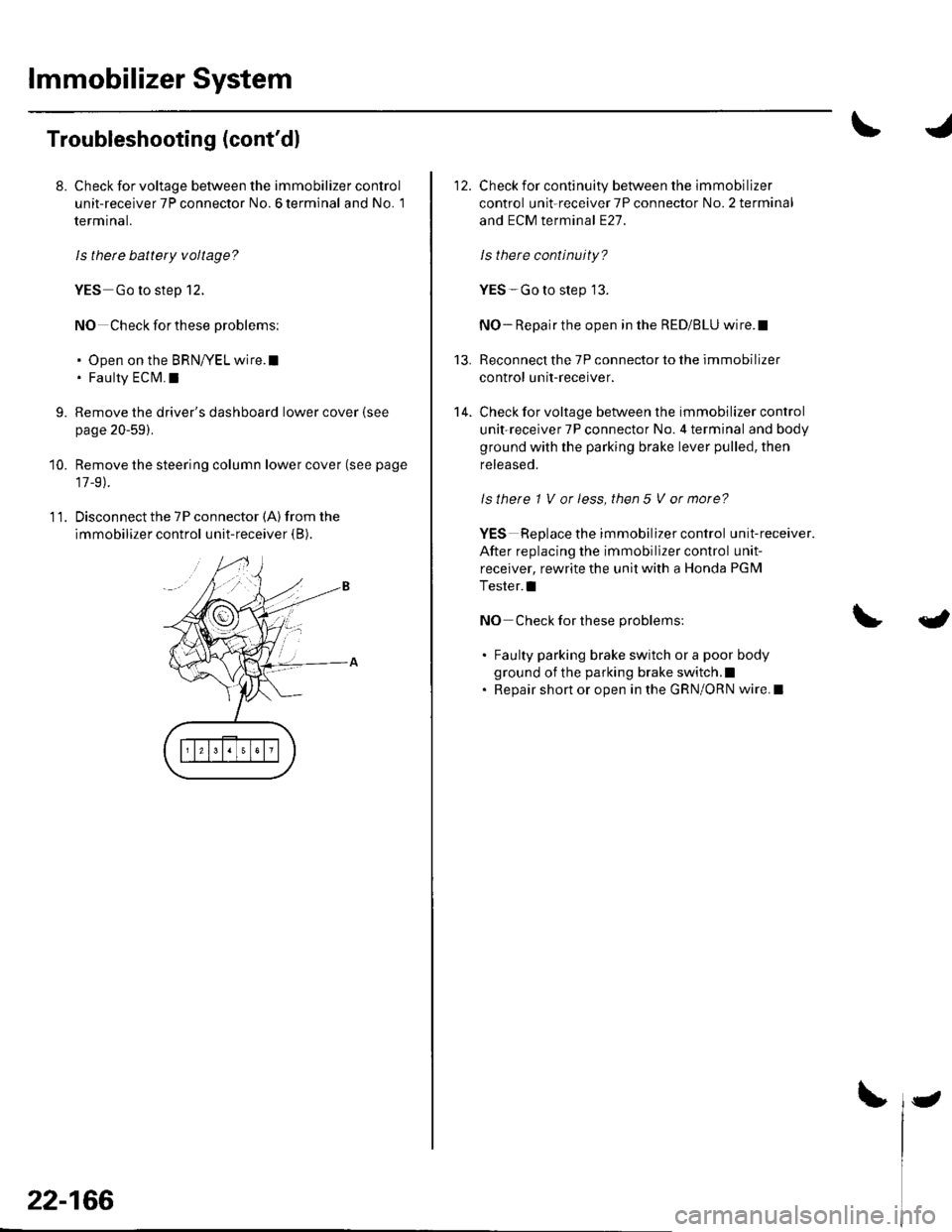

Troubleshooting (cont'dl

8. Check for voltage betvveen the immobilizer control

unit-receiver 7P connector No. 6 terminal and No. 1

rermlnat.

ls thete battery voltage?

YES Go to step 12.

NO Check for these problems,

. Open on the BRNI/EL wire.l. Faulty ECM.I

9. Remove the driver's dashboard lower cover (see

page 20-59).

10. Remove the steering column lower cover (see page

17-9).

11. Disconnect the 7P connector (A) from the

immobilizer control unit-receiver (B).

22-166

-

Check for continuity between the immobilizer

control unit-receiver 7P connector No. 2 terminal

and ECM terminal E27.

ls there continuity?

YES-Go to step 13.

NO- Repair the open in the RED/BLU wire.I

Reconnect the 7P connector to the immobilizer

control unit-receiver.

Check for voltage between the immobilizer control

unit-receiver 7P connector No. 4 terminal and body

ground with the parking brake lever pulled, then

released.

ls there 1 V or less, then 5 V or more?

YES Replace the immobilizer control unit-receiver.

After replacing the immobillzer control unit-

receiver, rewrite the unit with a Honda PGM

Tester.l

NO Check for these problems:

. Faulty parking brake switch or a poor body

ground of the parking brake switch.l. Repair short or open in the GRN/ORN wire. I

13.

14.

{

Page 999 of 1139

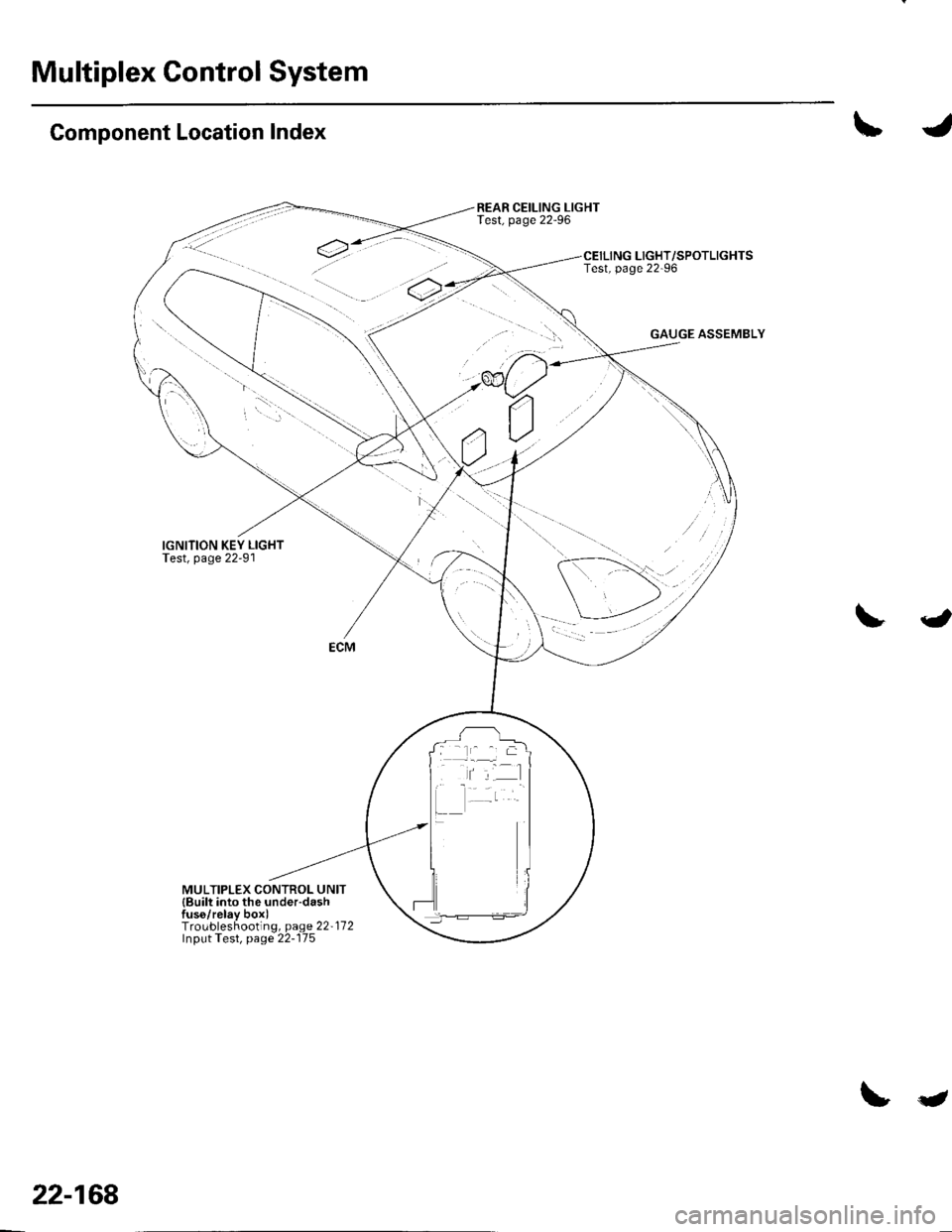

Multiplex Control System

Component Location Index

IGNITION KEY LIGHTTest, page 22'91

lr, J

REAR CEILING LIGHTTest, page 22'96

LIGHT/SPOTLIGHTSTest, page 22-96

GAUGE ASSEMBLY

ECM

MULTIPLEX CONTROL UNIT{Built into the under-dashfus6/relav boxlTroubleshooting, page 22'172Input Test, page 22-175

22-168

t

Page 1002 of 1139

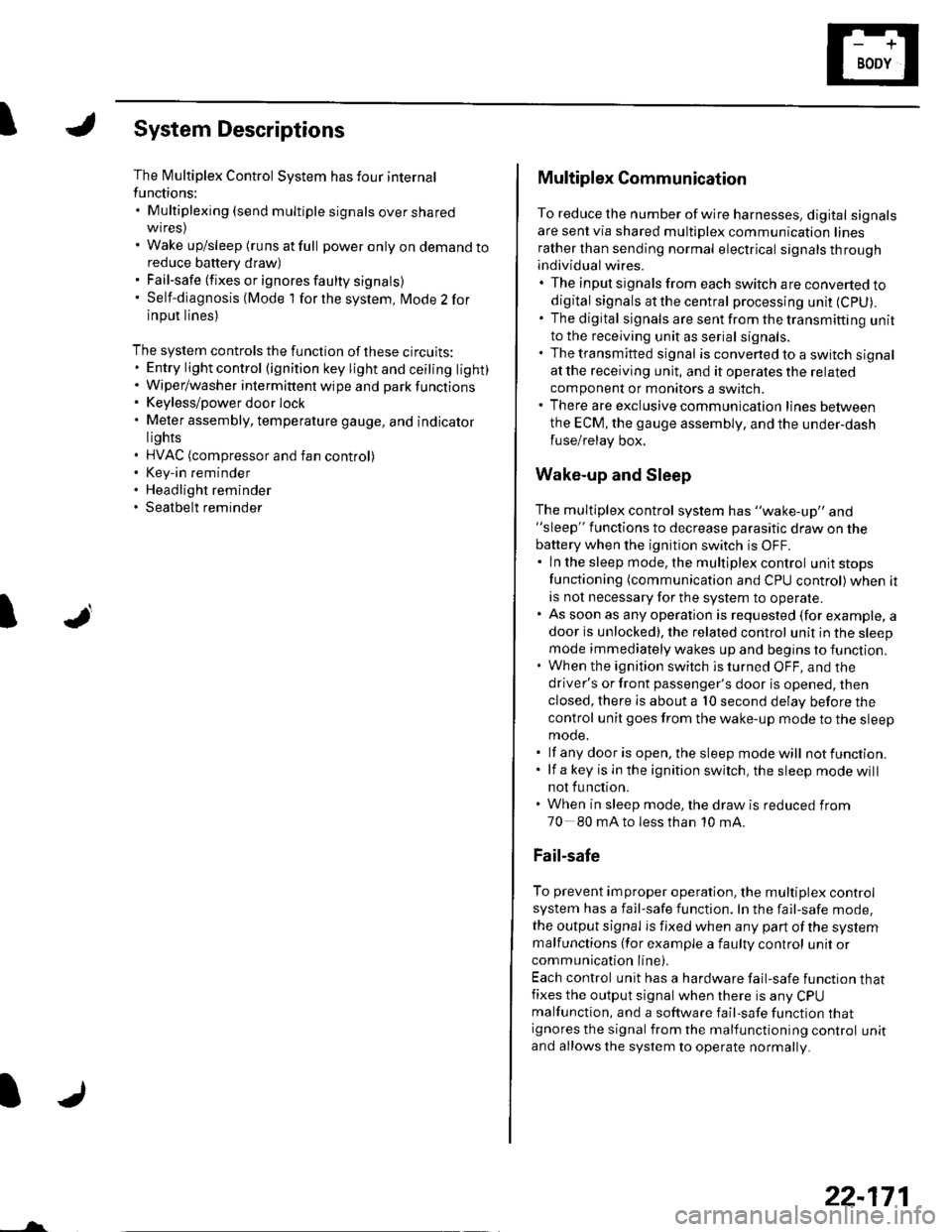

ISystem Descriptions

The Multiplex Control System has four internal

functions:. Multiplexing (send multiple signals over sharedwtres). Wake up/sleep (runs at full power only on demand toreduce battery draw). Fail-safe (fixes or ignores faulty signals). Self-diagnosis (Mode 1 for the system, Mode 2 for

input lines)

The system controls the function of these circuits:. Entry lightcontrol (ignition key lightandceiting light). Wiper/washer intermittent wipe and park functions. Keyless/power door lock. Meter assembly, temperature gauge, and indicator

lights. HVAC (compressor and fan control). Key-in reminder. Headlight reminder. Seatbelt reminder

JI

/ar

22-171

Multiplex Communication

To reduce the number of wire harnesses, digital signals

are sent via shared multiplex communication linesrather than sending normal electrical signals throughindividual wires.. The input signals from each switch are converted todigital signals at the central processing unit (CpU).. The digital signalsaresentfromthetransmitting unitto the receiving unit as serial signals.. The transmitted signal is converted to a switch signalat the receiving unit, and it operates the related

component or monitors a swltch.. There are exclusive communicalion lines between

the ECM, the gauge assembly, and the under,dash

fuse/relay box.

Wake-up and Sleep

The multiplex control system has "wake-up" and"sleep" functions to decrease parasitic draw on the

battery when the ignition switch is OFF.. ln the sleep mode, the multiplex control unit stops

functioning (communication and CPU control) when it

is not necessary for the system to operate.. As soon as any operation is requested (for example, adoor is unlocked), the related control unit in the sleep

mode immediately wakes up and begins to function.. When the ignition switch is turned OFF, and the

driver's or front passenger's door is opened, then

closed, there is about a 10 second delay before the

control unit goes from the wake-up mode to the sleepmode.. lf any door is open, the sleep mode will not function.. lf a key is in the ignition switch, the sleep mode will

not function.. When in sleep mode, the draw is reduced from

70 80 mA to less than 10 mA.

Fail-safe

To prevent improper operation, the multiplex controlsystem has a fail-safe function. In the fail-safe mode,

the output signal js fixed when any part of the systemmalfunctions (for example a faulty control unit orcommunication line).

Each control unit has a hardware fail-safe function thatfixes the output signal when there is any CPUmalfunction, and a software fail-safe function thatignores the signal from the malfunctioning control unitand allows the system to operate normally.

Page 1004 of 1139

I

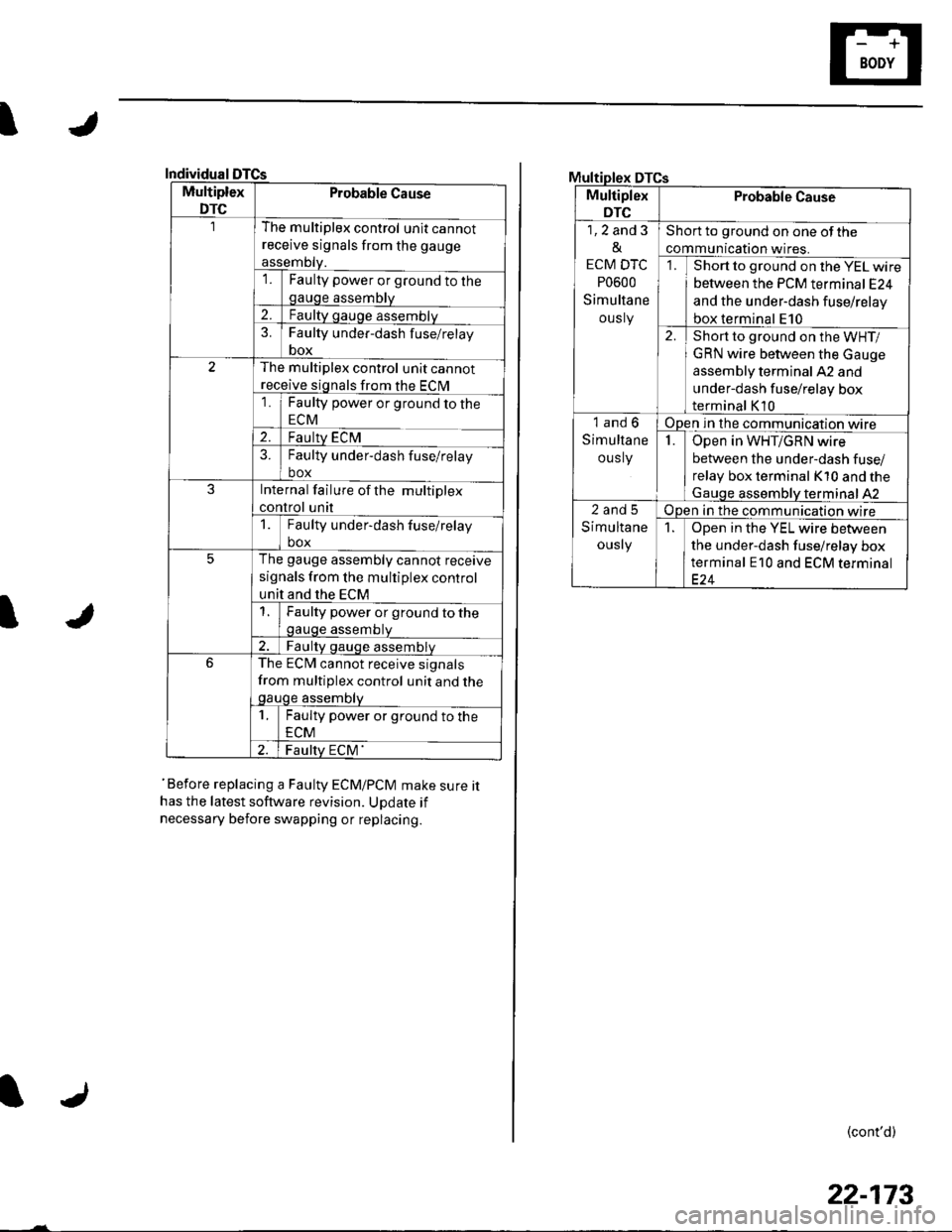

Individual

Multiplex

DTC

Probable Cause

The multiplex control unit cannot

receive signals from the gauge

assemDty.'lFaulty power or ground to thegauge assembly

2.Faulty gauge assemblv

3.Faulty under-dash f use/relay

box

The multiplex control unit cannot

receive signals from the ECM

1Faulty power or ground to the

ECM

2.Faulty ECM?Faulty under-dash fuse/relay

box

JInternal failure of the multiplex

control unit

1Faulty under-dash fuse/relay

box

5The gauge assembly cannot receive

signals from the multiplex control

unit and the ECM

Faulty power or ground to thegauge assembtv

Faulty qauge assemblv

6The ECM cannot receive signals

from multiplex control unit and thegauge assembty

1Faulty power or ground to the

ECM

Faulty ECM'

I

'Before replacing a Faulty ECM/PCM make sure ithas the latest software revision. UDdate if

necessary before swapping or replacing.

DTCs

Multiplex

DTC

Probable Cause

1,2 and 3

&

ECM DTC

P0600

Simultane

ously

Short to ground on one of the

communication wires.

Short to ground on the YEL wire

between the PCM terminal E24

and the under-dash fuse/relay

box terminal E10

2.Short to ground on the WHT/

GRN wire between the Gauge

assembly terminal A2 and

under-dash fuse/relay box

terminal K10

1and6

Simultane

ous ly

Open in the communication wire

IOpen in WHT/GRN wire

between the under-dash fuse/

relay box terminal K10 and the

Gauqe assemblV terminal 42

2and5

Simultane

ously

Open in the communication wire

1Open in the YEL wire between

the under-dash fuse/relay box

terminal E10 and ECM terminal

(cont'd)

22-173

Page 1013 of 1139

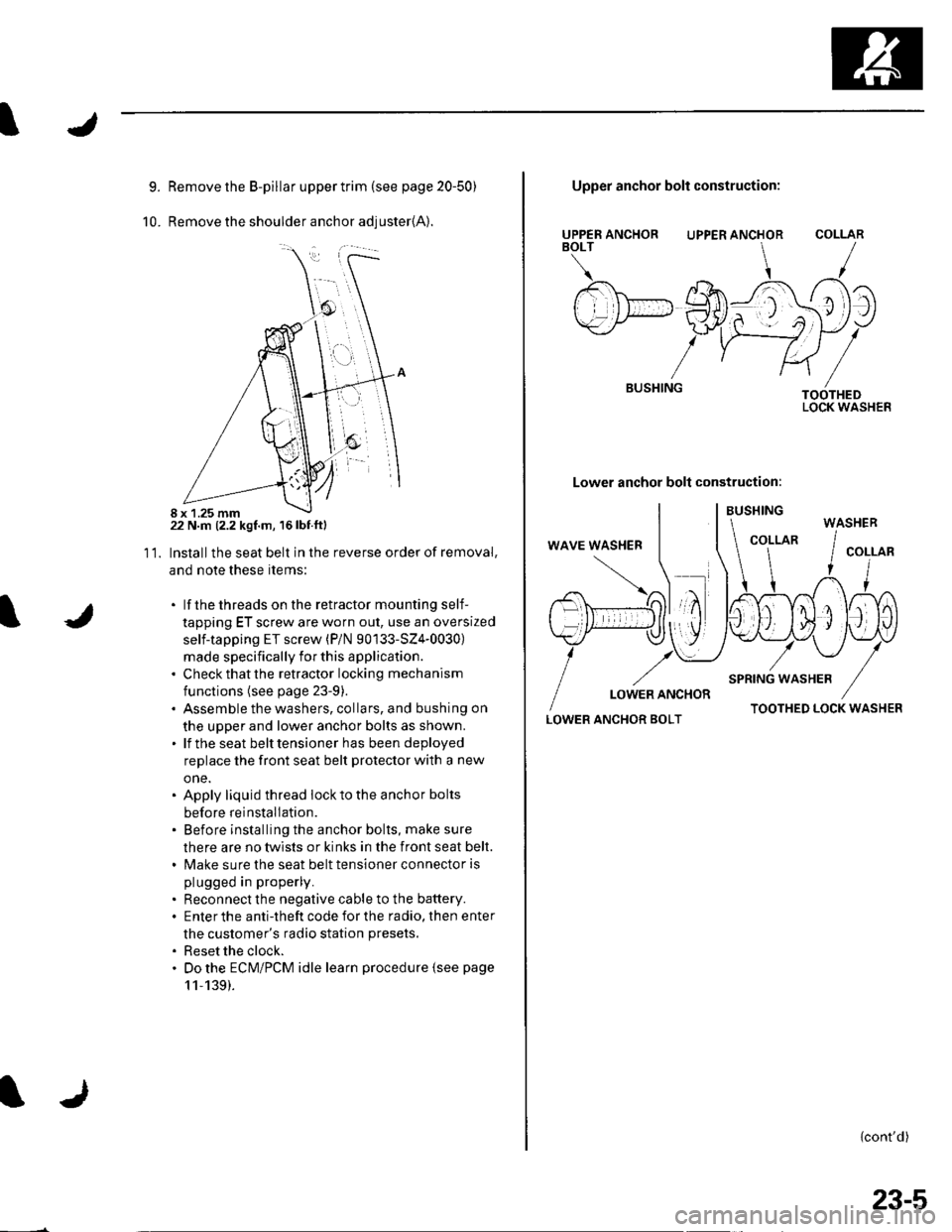

9.

10.

Remove the B-pillar upper trim {see page 20-50)

Remove the shoulder anchor adjuster{A).

22 N.m (2.2 kgf.m, 16lbf.ftl

Installthe seat belt in the reverse order of removal,

and note these items:

. lf thethreads on the retractor mounting self-

tapping ET screw are worn out, use an oversized

self-tapping ET screw (P/N 90133-SZ4-0030)

made specifically for this application.. Check that the retractor locking mechanism

functions (see page 23-9).. Assemble the washers, collars, and bushing on

the upper and lower anchor bolts as shown.. lf the seat belt tensioner has been deployed

replace the front seat belt protector with a new

one.. Apply liquid thread lock to the anchor bolts

before reinstallation.. Before installing the anchor bolts, make sure

there are no twists or kinks in the front seat belt.. Make sure the seat belt tensioner connector is

plugged in properly.

. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure {see page

11,139).

11.

8 x 1.25 mm

UPPER ANCHORBOLT

BUSHING

Upper anchor bolt construction:

UPPER ANCHOR

Lower anchor bolt construction:

COLLAR

TOOTHEDLOCK WASHER

LOWER ANCHOR BOLTTOOTHED LOCK WASHER

{cont'd)

WASHER

23-5

Page 1014 of 1139

Seat Belts

Front Seat Belt Replacement (cont'd)

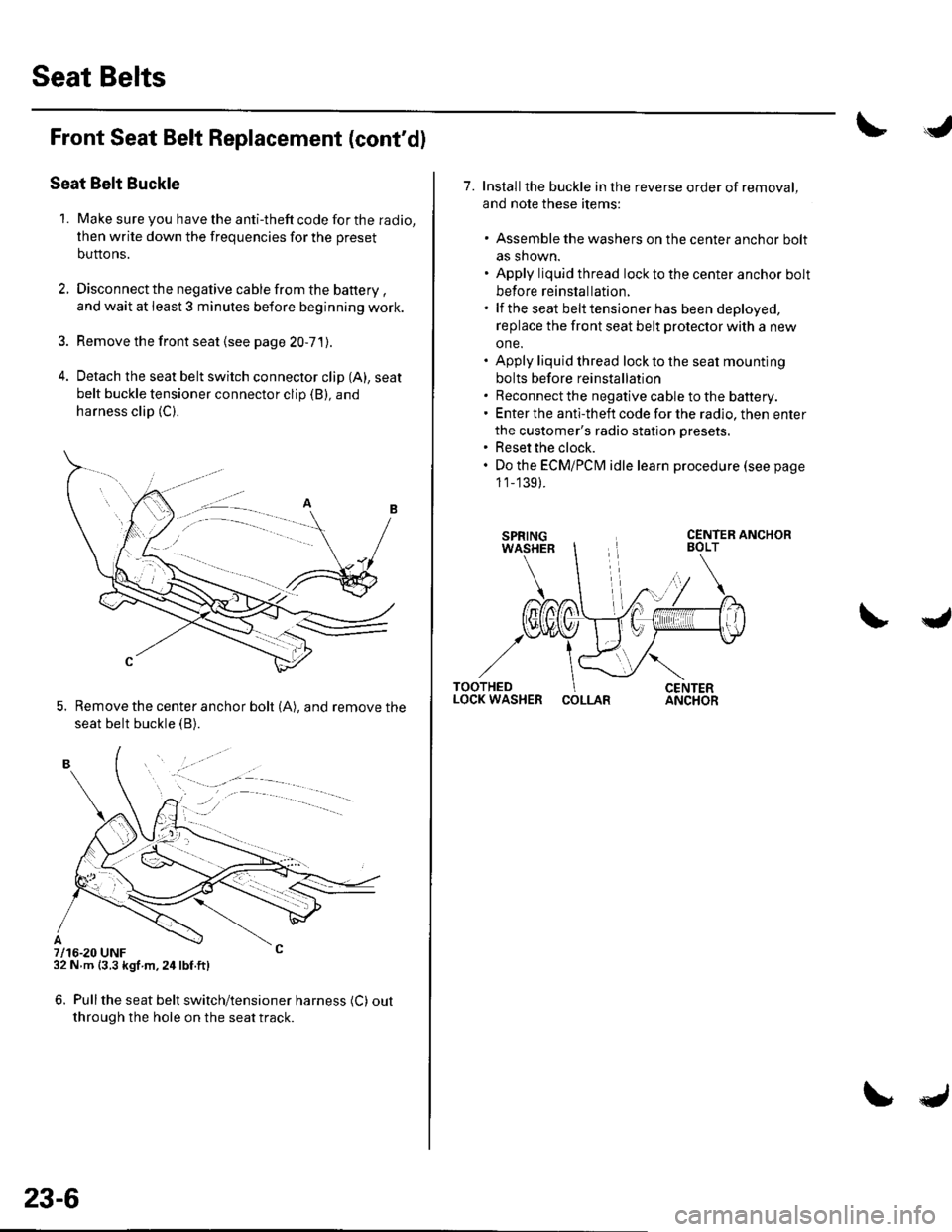

Seat Belt Buckle

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the negative cable from the battery ,and wait at least 3 minutes before beginning work.

3. Remove the front seat (see page 20-7'1).

4. Detach the seat belt switch connector clip (A), seat

belt buckle tensioner connector clip (B), and

harness clip (C).

5. Remove the center anchor bolt (A), and remove the

seat belt buckle {B).

7/16-20 UNF32 N m {3.3 kgf m,24lbf.ft)

6. Pullthe seat belt switch/tensioner harness (C) out

through the hole on the seat track.

. -.. :.a--

23-6

7. Installthe buckle in the reverse order of removal,

and note these items:

. Assemble the washers on the center anchor bolt

as shown.. Apply liquid thread lock to the center anchor bolt

before reinstallation.. lf the seat belt tensioner has been deployed,

replace the front seat belt protector with a new

one.. Apply liquid thread lock to the seat mounting

bolts before reinstallation. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.. Reset the clock.. Do the ECMiPCM idle learn procedure (see page

1 1_139).

COLLAR

Page 1021 of 1139

sRs

Precautions and Procedures

General Precautions

Please read the following precautions carefully beforeperforming airbag system service. Observe theinstructions described in this manual. or the airbags

could accidentally deploy and cause damage or injuries.

. Except when performing electrical inspections.

always turn the ignition switch OFF, disconnect the

negative cable from the battery, and wait at least 3minutes before beginning work.

NOTE: The memory is not erased even if the ignition

switch is turned OFF or the battery cables are

disconnected from the battery.. Use replacement pans which are manufactured to the

same standards and quality as the original parts. Do

not install used SRS parts from another vehicle. Useonly new pans when making SRS repairs.. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being

dropped or improperly handled, such as dents, cracks,

or deformation.

. Before removing any SRS parts (including the

disconnection of connectors), always disconnect the

SRS connector.. Use only a digital multimeter to check the system. lf itis not a Honda multimeter, make sure its outout is 10mA (0.01A) or less when switched to the lowest value

in the ohmmeter range. A tester with a higher output

could cause accidental deployment and possible

injury.. Do not put objects on the front passenger's airbag.. The original radio has a coded theft protection circuit.

Be sure to get the customer's radio code and write

down the frequencies for the radio's preset stations

before disconnecting the battery cable.. Before returning the vehicle to the customer, enter

the radio code. then enter the customer's radio

station presets, and set the clock. Do the engine

control module (ECM) idle learn procedure (see page

11-139).

23-14

c

Steering-related Plecautions

Cable Reel Alignment

. Misalignment of the cable reel could cause an open in

the wiring, making the SRS system and the horns

inoperative. Center the cable reel whenever the

following is performed (see step 6 on page 23-121).

- Installation of the steering wheel- Installation of the cable reel- Installation ofthe steering column- Other steering-related adjustment or installation

. Do not disassemble the cable reel.

. Do not apply grease to the cable reel.

. lf the cable reel shows any signs of damage or

contamination. replace it with a new one. For

example, it does not rotate smoothly.