Intake manifold HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 185 of 1139

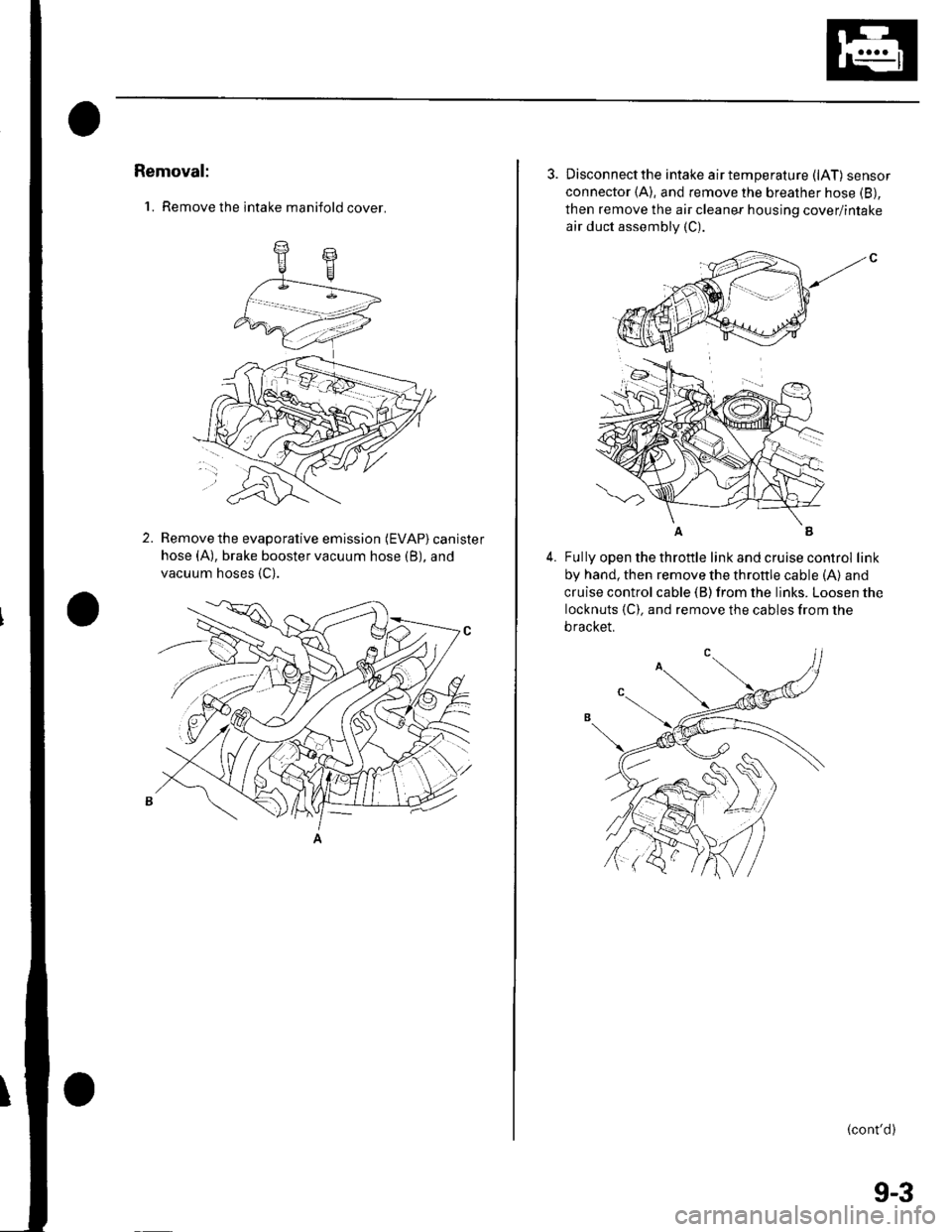

Removal:

'1. Remove the intake manifold cover.

2.Remove the evaporative emission (EVAP) canister

hose (A), brake booster vacuum hose (B), and

vacuum hoses {C).

3. Disconnectthe intake airtemperature (lAT) sensor

connector (A), and remove the breather hose (B),

then remove the air cleaner housing cover/intake

air duct assembly (C).

4.Fully open the throttle link and cruise control link

by hand, then remove the throttle cable (A) and

cruise control cable (B) from the links. Loosen the

locknuts {C). and remove the cables from the

bracket.

(cont'd)

(

9-3

Page 186 of 1139

Intake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'dl

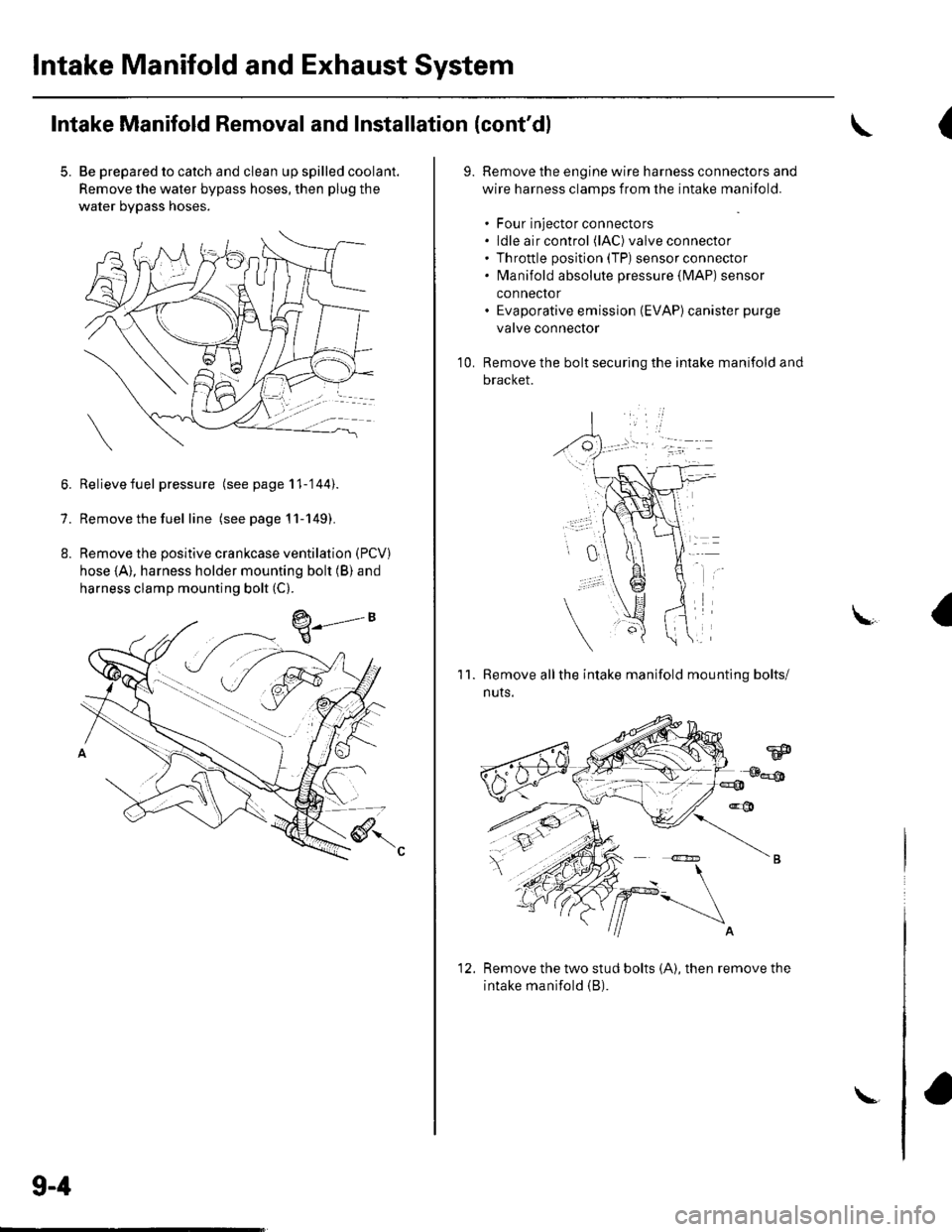

5. Be prepared to catch and clean up spilled coolant.

Remove the water bypass hoses, then plug the

water bypass hoses.

6. Relievefuel pressure (see page 11-'144).

7. Remove the fuel line (seepagell-149).

8. Remove the positive crankcase ventilation (PCV)

hose (A), harness holder mounting bolt (B) and

harness clamp mounting bolt (C).

9-4

\-

(

9.Remove the engine wire harness connectors and

wire harness clamps from the intake manifold.

. Four injector connectors. ldle air control (lAC) valve connector. Throttle position (TP) sensor connector. fvlanifold absolute pressure {lvlAP) sensor

connector. Evaporative emission (EVAP)canister purge

valve connector

Remove the bolt securing the intake manifold and

bracket.

'1 0.

11.Remove allthe intake manifold mounting bolts/

nuts.

Remove the two stud bolts (A), then remove the

intake manifold (B).

1'>

Page 187 of 1139

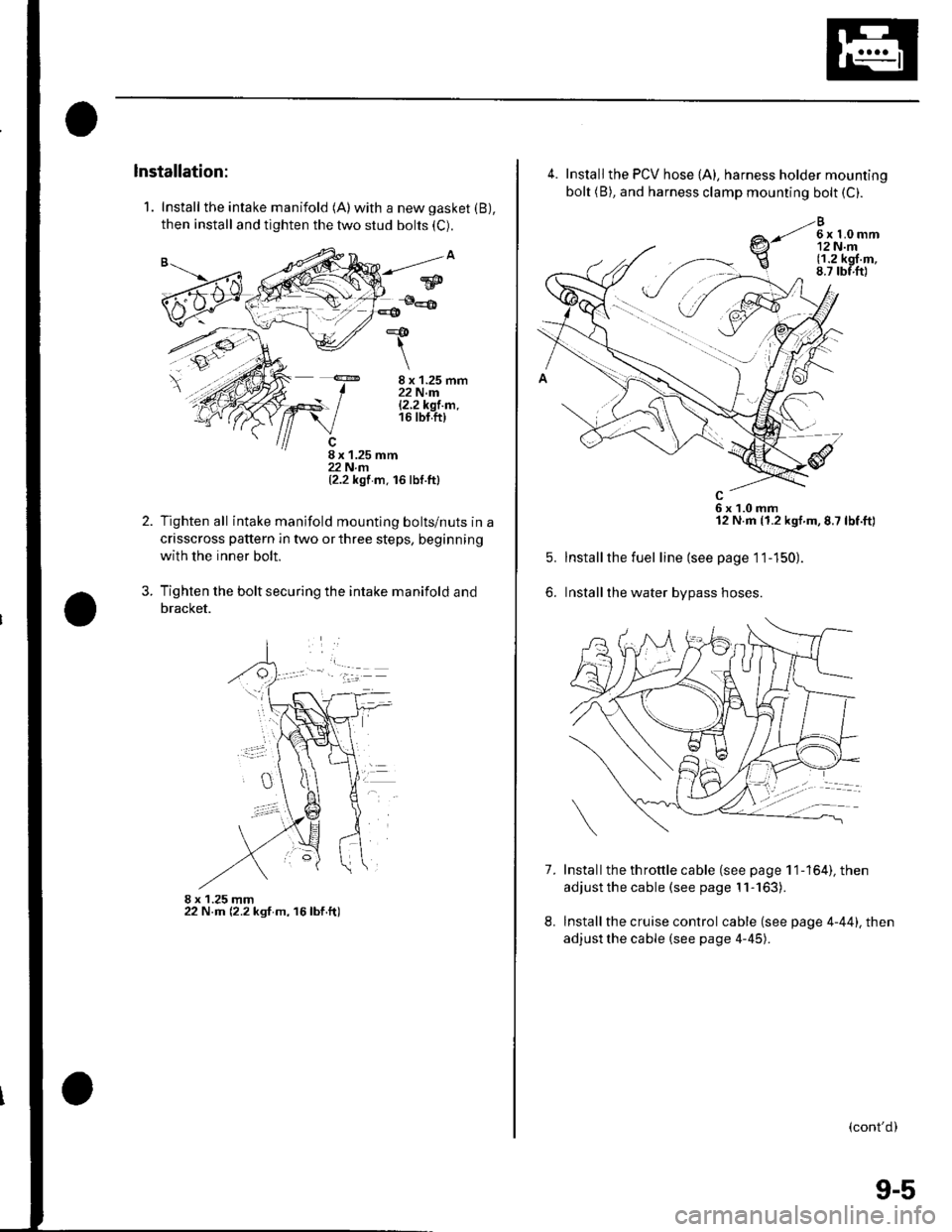

1. Install the intake manifold (A)with a new gasket (B),

then install and tighten the two stud bolts (C).

8 x 1.25 mm22 N.m|.2.2k91.m.16 tbt.ft)

8 x 1.25 mm22 N.rn(2.2 kgf m. 16 lbf.ttl

Tighten all intake manifold mountlng bolts/nuts in a

crisscross pattern in two or three steps, beginning

with the inner bolt.

Tighten the bolt securing the intake manifold and

bracket.

8 x 1.25 mm22 N.m (2.2 ksf m, 16lbf.ft)

*&

\

2.

?

w

4.

7.

5.

6.

Install the PCV hose {A), harness holder mounting

bolt (B), and harness clamp mounting bolt (C).

e-li*h,r

6x1.0mm12 N.m (1.2 kgf.m,8.7 lbf.ft)

Installthe fuel line (see page 11-150).

Installthe water bypass hoses.

Install the th rottle cable (see page 1 1-164), then

adjust the cable (see page 11-163).

Install the cruise control cable (see page 4-44). then

adjust the cable (see page 4-45).

8.

(cont'd)

9-5

Page 188 of 1139

lntake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'd)

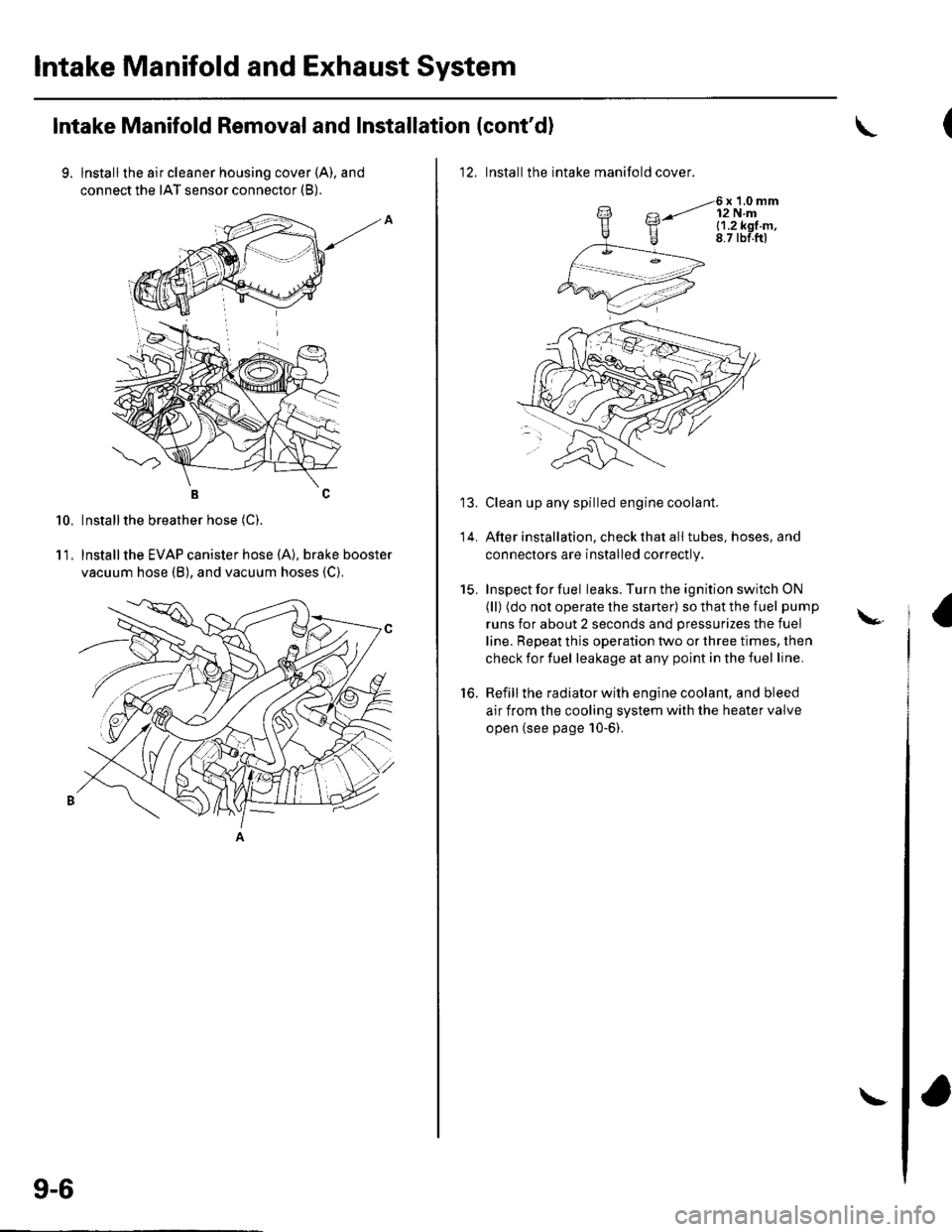

9. lnstallthe air cleaner housing cover (A), and

connect the IAT sensor connector (B).

BC

Installthe breather hose (C).

lnstallthe EVAP canister hose (A), brake booster

vacuum hose (B), and vacuum hoses {C).

10.

11.

9-6

\

12. Installthe intake manifold cover.

6x1.0mm12 N.ml.1.2k91.m,8.7 tbf.ftl

Clean up any spilled engine coolant.

After installation, check that all tubes, hoses, and

connectors are installed correctly.

Inspect for fuel leaks. Turn the ignition switch ON

(ll) (do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

to.

\-

Page 214 of 1139

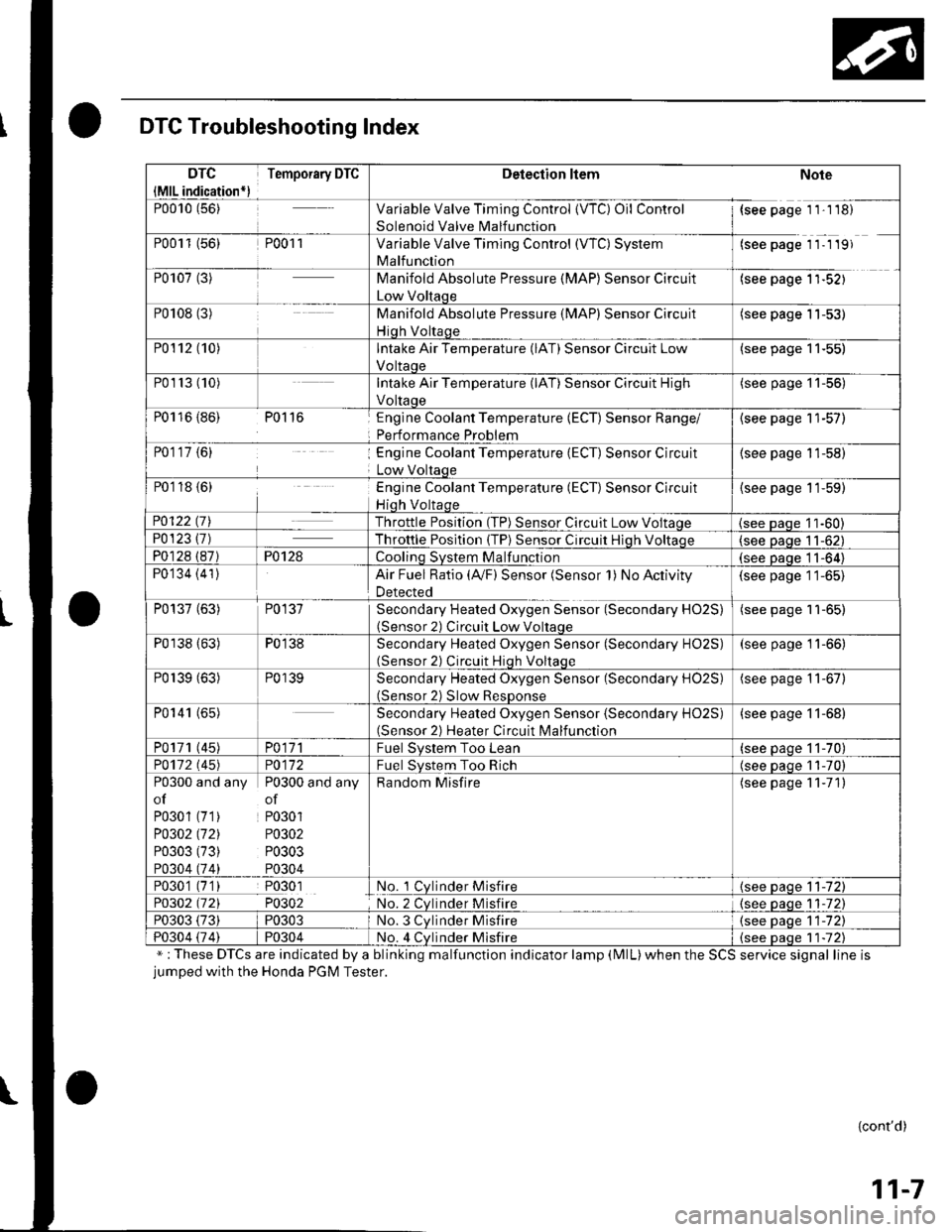

DTC Troubleshooting Index

";These DTCs are indicated by a blinking malfunction indicator lamp (MlL)when the SCS service signal line isjumped with the Honda PGM Tester.

{cont'd)

11-7

DTC

{MlL indication*)

Temporary DTCDetection ltemNote

P0010 (56)Variable Valve Timing Control {VTC) Oil Control

Solenoid Valve Malfunction

{see page 1 1'1 18)

P0011 (56)P001 1Variable Valve Timing Control (WC) System

Malfunction

(see page 11- 1 19)

P0107 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Low Voltaqe

(see page 1'l-521

P0108 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Hiqh Voltaqe

(see page 11-53)

P0112 (10)Intake Air Temperature (lAT) Sensor Circuit Low

Voltaoe

(see page 11-55)

P01r3 (10)Intake Air Temperature (lAT) Sensor Circuit High

Voltaoe

(see page '11-56)

P0116 {86) P0116Englne Coolant Temperature (ECT) Sensor Range/

Performance Problem

{see page 11-57)

P0117 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Low Voltaqe

(see page 11-58)

P0118 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Hiqh Voltaqe

{see page 11-59)

P0122 t7\Throttle Position (TP) Sensor Circuit Low Voltaqe(see Daqe 11-60)P0123 {7)Throttle Posltion (TP) Sensor Circuit Hiqh Voltaoe(see paqe 11-62)

P0128 (87)P0128Coolinq SVStem Malfunction(see Daqe 11-64)

P0134 (41)Air Fuel Ratio (Ay'F) Sensor (Sensor 1) No Activity

Detected

(see page 11-65)

P0137 (63)P0137Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Low Voltaqe

(see page 11-65)

P0138 (63)P0138Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Hiqh Voltaqe

(see page 11-66)

P0139 (63)P0139Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Slow ResDonse

(see page 11-67)

P0141 (65)Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Heater Circuit Malfunction

(see page 11-68)

P0171 (45)PO\11Fuel Svstem Too Lean(see paqe 11-70)

PO112 l'45)PO\l2Fuel System Too Rich(see oaoe 11-70)

P0300 and any P0300 and any

of of

P0301 (71) P0301

PO302 (721 P0302

P0303 (73) P0303

P0304 (74) P0304

Random Misfire(see page 11-71)

P0301 (7'1) P0301No. 1 Cylnder Misfire{see page 11-72)

P0302 (721 P0302No. 2 Cvlnder Misfire{see paqe 1 1-72)

P0303 (73)P0303No. 3 Cvlnder Misfire(see oaqe 11-72)

P0304 {74)P0304No. 4 Cvlnder Misfire{see Daqe 1 1-72)

Page 220 of 1139

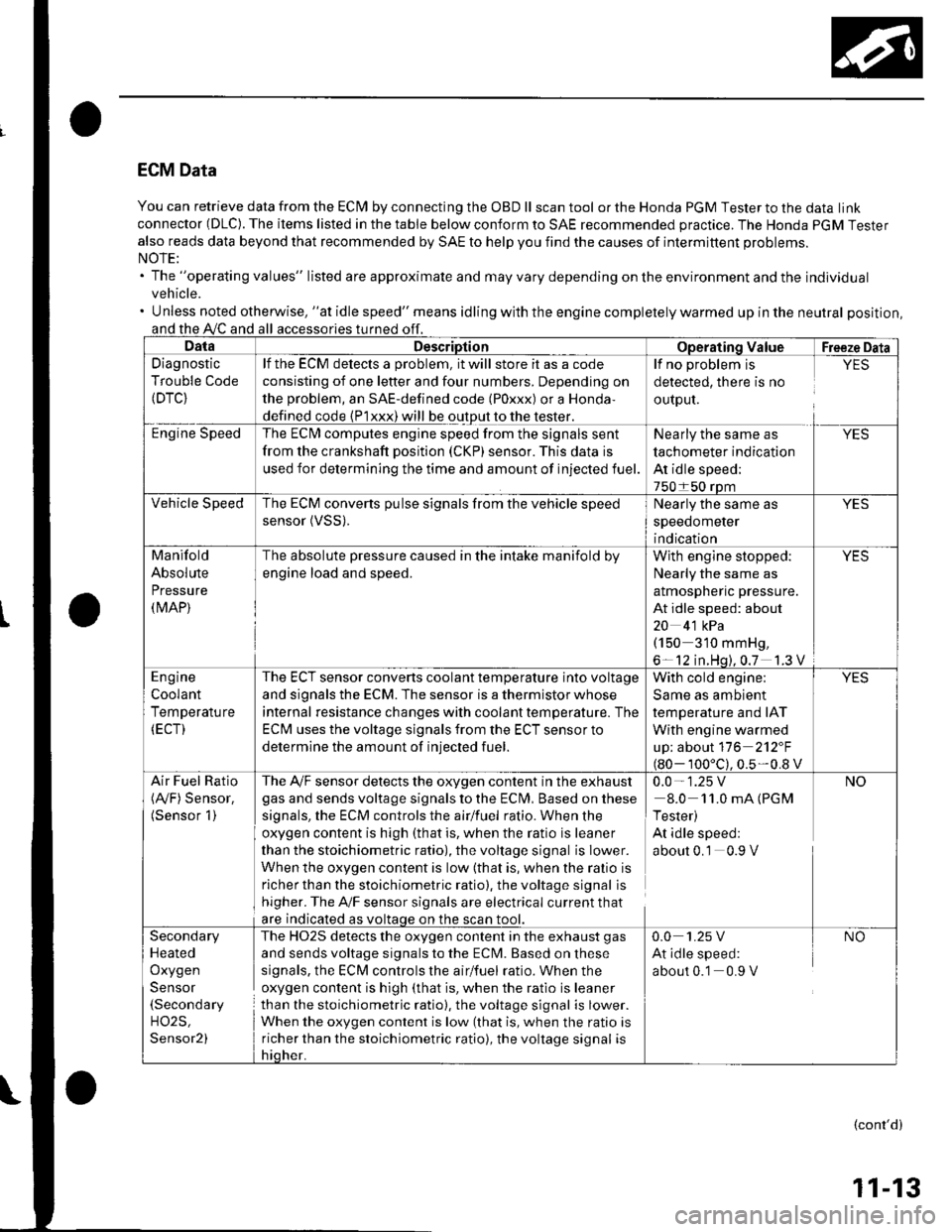

ECM Data

You can retrieve data from the ECI\4 by connecting the OBD ll scan tool or the Honda PGM Tester to the data link

connector (DLC). The items listed in the table below conform to SAE recommended practice. The Honda PGM Tester

also reads data beyond that recommended by SAE to help you find the causes of intermittent problems.

The "operating values" listed are approximate and may vary depending on the environment and the individual

vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up in the neutral position,

and the A,/C and all

Diagnostic

Trouble Code(DTC}

lf the ECM delects a problem, it will store it as a code

consisting of one letter and four numbers. Depending on

the problem, an SAE-defined code (Poxxx) or a Honda,

defined code {P1xxx) will be output to the tester.

The ECI\4 computes engine speed from the signals sent

from the crankshaft position (CKP) sensor. This data is

used for determining the time and amount of injected fuel.

detected, there is no

ourpul.

lf no problem is YES

Nearly the same as

tachometer indication

At idle speed;

The ECM converts pulse signals from the vehicle speed

sensor (VSS).Nearly the same as

speedometer

indication

Manifold

Absolute

Pressure(MAP)

The absolute pressure caused in the intake manifold by

engine load and speed.

With engine stopped: YES

Nearly the same as

almospnenc pressure.

At idle speed: about

20 4'1 kPa(150 310 mmHg,

6- 12 in.Hq).0.7 1.3 V

The ECT sensor converts coolant temperature into voltage

and signals the ECM. The sensor is a thermistor whose

internal resistance changes with coolant tempetature. The

ECM uses the voltage signals from the ECT sensor to

determine the amount of injected fuel.

With cold engine:

Same as ambient

temperature and IAT

With engine warmed

up; about 116 2'12"F

100'c).0.5-0.8 v

Air Fuel Ratio The A,/F sensor detects the oxygen content in the exha ust 0.0 - 1 .25 V(Ay'F) Sensor. gas and sends voltage signals to the Eclvl, Basedonthese 8.0 11.0mA(PGM(Sensor 1) signals, the ECM controls the airlfuel ratio. When the I Tester)

oxygen content is high (that is, when the ratio is leaner At idle speed:

than the stoichiometric ratio), the voltage signal is Iower. about 0.1 0.9 V

When the oxygen content is low (that is, when the ralio is

richer than the stoichiometric ratio). the voltage signal is

higher. The A'lF sensor signals are electrical current that

are indicated as voltaqe on the

The HO2S detects the oxygen content in the exhaust gas

and sends voltage signals to the ECM. Based on these

signals, the ECM controls the airlfuel ratio. When the

oxygen content is high (that is, when the ratio is leaner

than the stoichiometric ratio), the voltage signal is lower.

When the oxygen content is low (that is, when the ratio is

richer than the stoichiometric ratio), the voltage signal is

Secondary

Heated

Oxygen

Sensor(Secondary

H02S,

Sensor2)

0.0 1.25 V NO

At idle speed:

about 0.1 0.9 V

(cont'd)

11-13

Page 221 of 1139

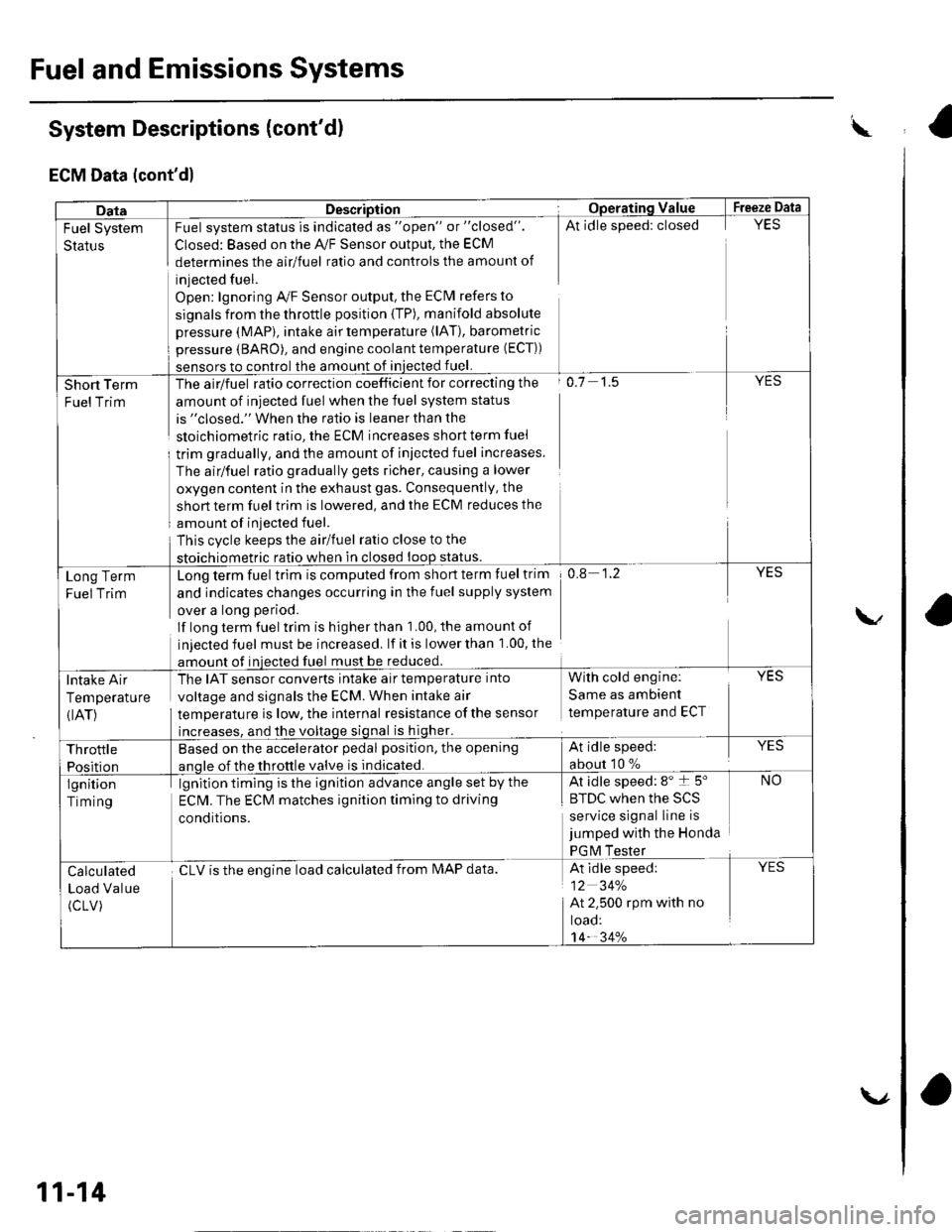

Fuel and Emissions Systems

System Descriptions (cont'd)

ECM Data (cont'd)

w

DataDescriptionOpera'ting ValueFreeze Data

Fuel System

Status

Fuel system status is indicated as "open" or "closed".

Closed: Based on the A,/F Sensor output, the ECM

determines the airlfuel ratio and controls the amount of

injected fuel.

Open: lgnoring Ay'F Sensor output, the ECM refers to

signals from the throttle position {TP), manifold absolute

pressure (MAP), intake air temperature (lAT), barometric

pressure (BARO), and engine coolant temperature (ECT))

sensors to control the amount of iniected fuel.

At idle speed: closedYES

Short Term

FuelTrim

The airlfuel ratio correction coefficient for correcting the

amount of injected fuel when the fuel system status

is "closed." When the ratio is leaner than the

sloichiometric ratio, the ECM increases short term fuel

trim gradually, and the amount of iniected fuel increases.

The airlfuel ratio gradually gets richer, causing a lower

oxygen content in the exhaust gas. Consequently, the

short term fuel trim is lowered, and the ECM reduces the

amount of injected fuel.

This cvcle keeps the airlfuel ratio close to the

stoichiometric ratio when in closed loop status.

o.7 1.5YES

Long Term

Fuel Trim

Long term fuel trim is computed from short term fuel trim

and indicates changes occurring in the fuel supply system

over a long period.

lf long term fuel trlm is higher than 1.00, the amounl of

injected fuel must be increased. lf it is lower than 1.00, the

amount of injected fuel must be reduced.

0.8 1.2YES

Intake Air

Temperature

{IAT)

The IAT sensor converts intake air temperature into

voltage and signals the ECM. When intake air

temperature is low, the internal resistance ofthe sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient

temperature and ECT

YES

Throttle

Position

Based on the accelerator pedal position, the opening

anole of the throttle valve is indicated.

At idle speed:

about 10 %

YES

lgnition

Timing

lgnition timing is the ignition advance angle set by the

ECM. The ECM matches ignition timing to driving

conditions.

At idle speed: 8" t 5"

|' tuL wnen rne >L)

service signal line is

jumped with the Honda

PGM Tester

NO

Calculated

Load Value

(cLV)

cLV is the enoine load calculated from IMAP data.At idle speed:

12 34%

At 2.500 rpm with no

toao:'t4- 34%

YES

11-14

\.,

ra

Page 232 of 1139

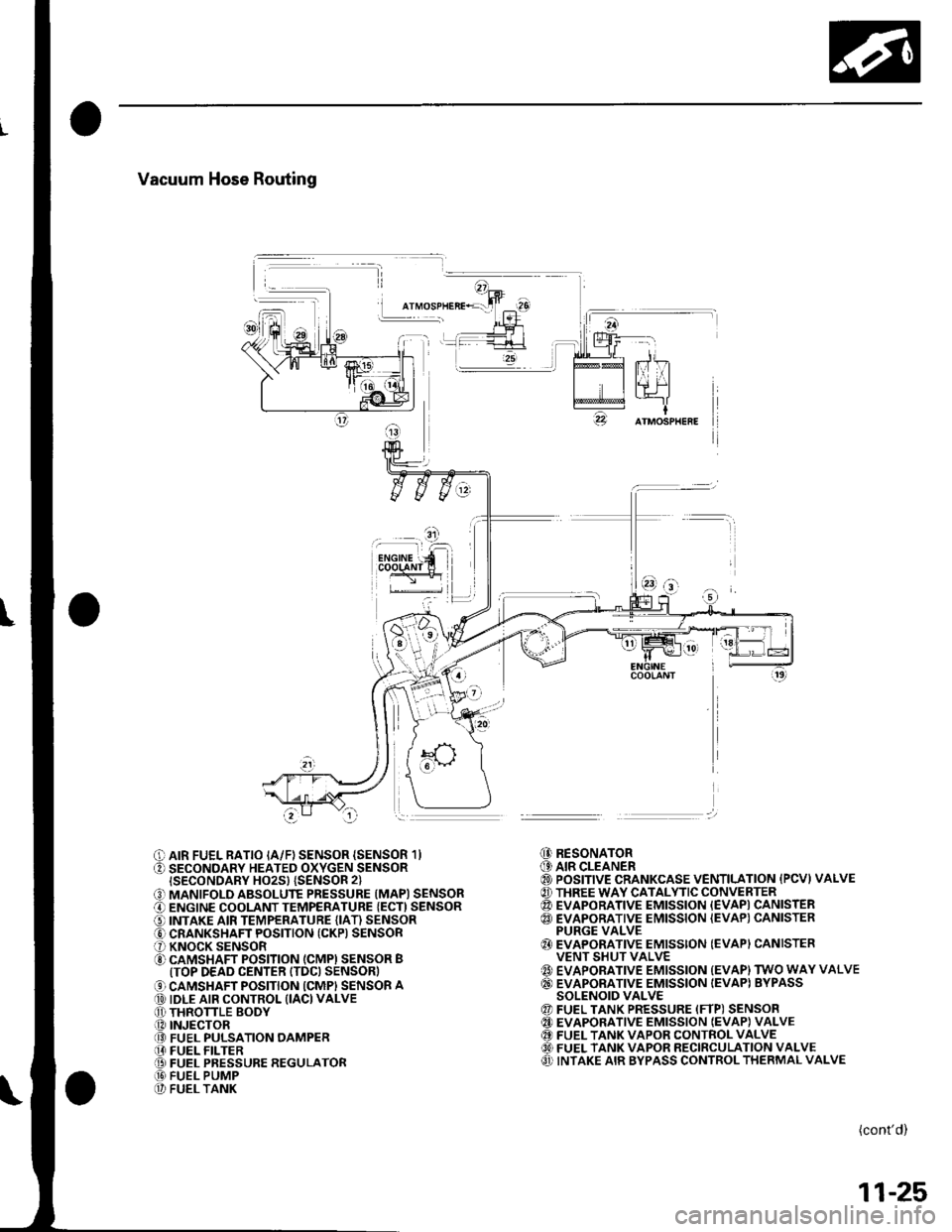

Vacuum Hose Routing

I

O AIR FUEL RATIO IA/F) SENSOR {SENSOR 1}O SECONDARY HEATED OXYGEN SENSORISECONDARY HO2S} {SENSOR 2}

O MANIFOLD ABSOLUTE PRESSURE (MAPI SENSORO ENGINE COOLANT TEMPERATURE {ECT) SENSORO INTAKE AIR TEMPERATURE (IAT) SENSORO CRANKSHAFT POSITION (CKP) SENSORO KNOCK SENSORO CAMSHAFT POSITION (CMPI SENSOR BITOP DEAD CENTER ITDC) SENSOR)

O CAMSHAFT POSITION ICMPI SENSOR A@ IDLE AIR CONTROL (IACI VALVEO THRONLE BODY.O INJECTOR@ FUEL PULSATION OAMPER[I FUEL FILTER@ FUEL PRESSURE REGULATOR@ FUEL PUMP@ FUEL TANK

@ RESONATOR(9 AIR CLEANER@ POSITIVE CRANKCASE VENTILATION {PCVI VALVE@ THREE WAY CATALYTIC CONVERTER@ EVAPORATIVE EMISSION {EVAPI CANISTER@ EVAPORATIVE EMISSION {EVAP) CANISTERPURGE VALVE{} EVAPORATIVE EMISSION (EVAPI CANISTERVENT SHUT VALVE{' EVAPORATIVE EMISSION {EVAP) TWO WAY VALVE@ EVAPORATIVE EMISSION IEVAPI BYPASSSOLENOID VALVE@ FUEL TANK PRESSURE (FTP) SENSOR@ EVAPORATIVE EMISSION IEVAP} VALVE@ FUEL TANK VAPOR CONTROL VALVE60) FUEL TANK VAPOR RECIRCULATION VALVEO INTAKE AIR BYPASS CONTROL THERMAL VALVE

(cont'd)

11-25

Page 234 of 1139

lgnition Timing Control

The ECM contains the memory for basic ignition timing

at various engine speeds and manifold absolute

pressure. lt also adjusts the timing according to engine

coolant temperature.

Iniector Timing and Duration

The ECM contains the memory for basic discharge

duration at various engine speeds and manifold

pressures. The basic discharge duration, after being

read out from the memory, is further modified by

signals sent from various sensors to obtain the final

discharge duration.

By monitoring long term fuel trim, the ECM detects long

term malfunctions in the fuel system and sets a

Diagnostic Trouble Code {DTC).

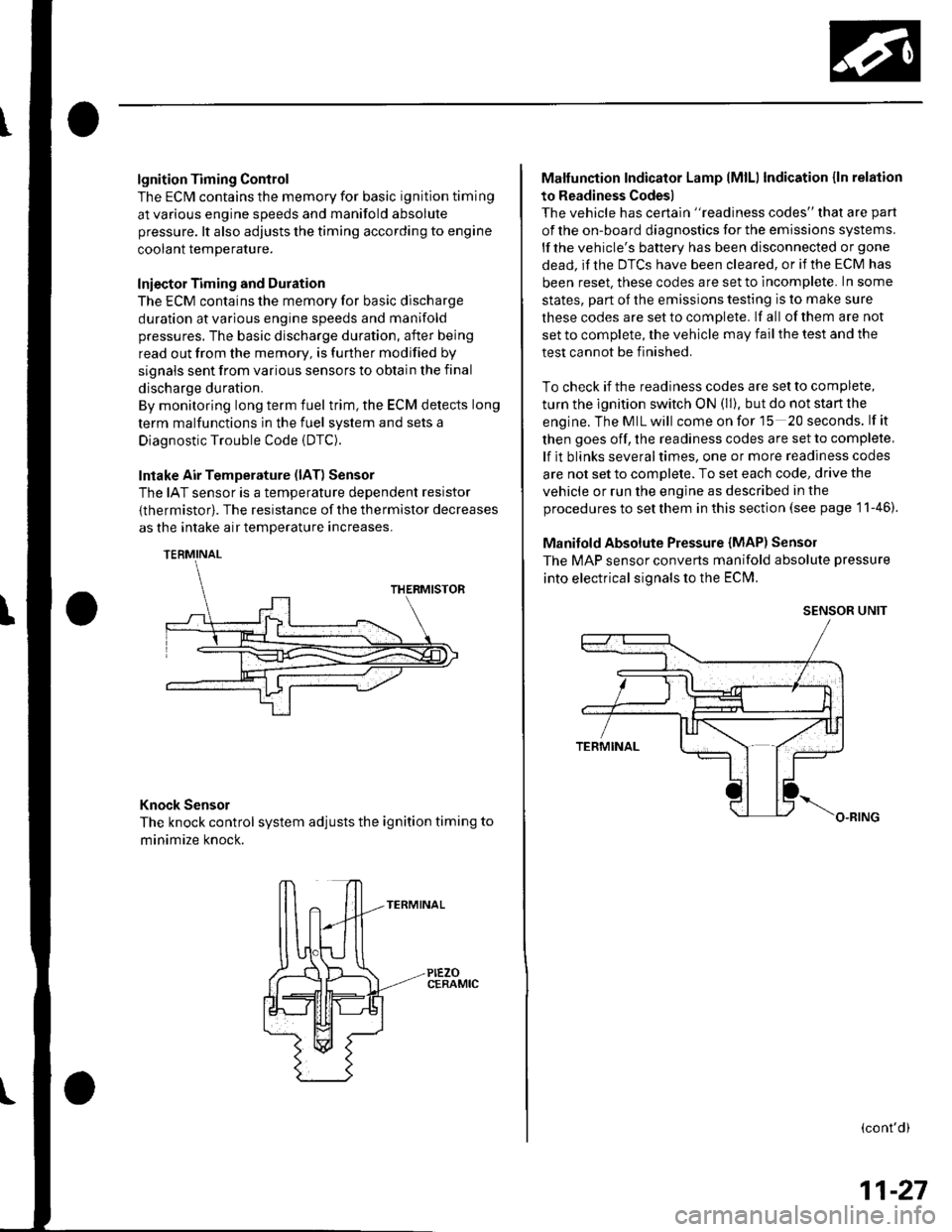

Intake Air Temperature (lAT) Sensor

The IAT sensor is a temperature dependent resistor

{thermistor). The resistance of the thermistor decreases

as the intake air temDerature increases.

Knock Sensor

The knock control system adjusts the ignition timing to

minimize knock.

PIEZOCERAMIC

Malfunction Indicator Lamp lMlLl Indication {ln relation

to Readiness Codes)

The vehicle has certain "readiness codes" that are part

of the on-board diagnostics for the emissions systems.

lf the vehicle's baftery has been disconnected or gone

dead. if the DTCS have been cleared, or if the ECM has

been reset. these codes are set to incomplete. In some

states, part of the emissions testing is to make sure

these codes are set to comDlete. lf all of them are not

set to complete, the vehicle may fail the test and the

test cannot be finished.

To check if the readiness codes are set to complete,

turn the ignition switch ON (ll). but do not start the

engine.TheMILwill comeonforlS 20seconds. lf it

then goes off, the readiness codes are set to complete,

lf it blinks severaltimes, one or more readiness codes

are not set to comolete. To set each code, drive the

vehicle or run the engine as described in the

procedures to set them in this section (see page 1 1-46).

Manifold Absolute Pressure {MAP) Senso]

The MAP sensor converts manifold absolute pressure

into electrical signals to the ECM.

SENSOR UNIT

(cont'd)

11-27

Page 239 of 1139

Fuel and Emissions Systems

(

{

System Descriptions (cont'd)

ldle Control System

When the engine is cold, the Ay'C compressor is on, the

transmission is in gear, the brake pedal is pressed. thepower steering load is high, or the alternator is

charging, the ECIM controls current to the ldle Air

Control (lAC) valve to maintain the correct idle speed.

Refer to the System Diagram to see the functional

layout of the system.

Brake Pedal Position Switch

The brake pedal position switch signals the ECM when

the brake pedal is oressed.

Electrical Power Steering (EPS) Senser

The EPS sensor signals the ECM when the power

steering load is high.

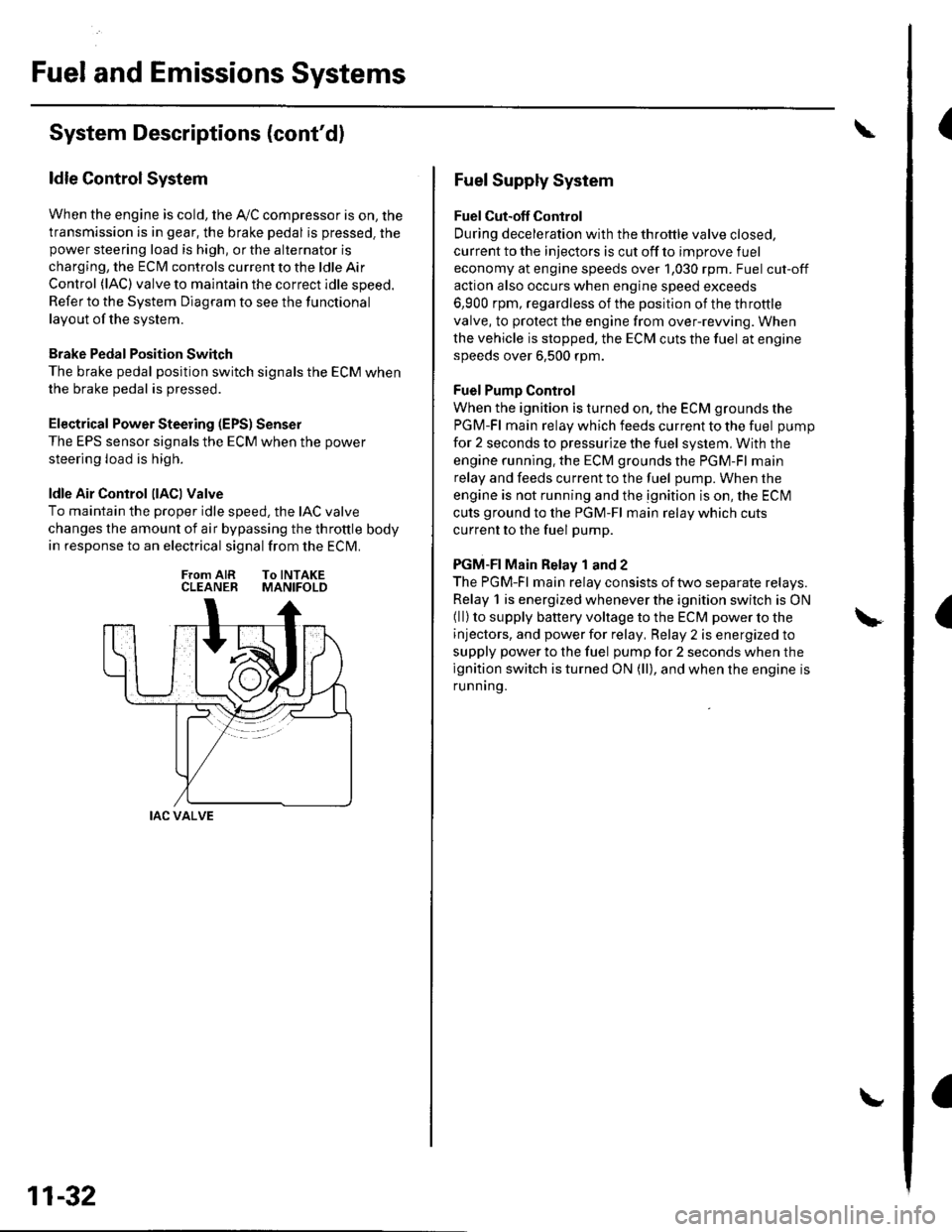

ldle Air Control llACl Valve

To maintain the proper idle speed, the IAC valve

changes the amount of air bypassing the throttle body

in response to an electrical signal from the ECM.

From AIR To INTAKECLEANER MANIFOLD

IAC VALVE

11-32

Fuel Supply System

Fuel Cut-off Control

During deceleration with the throttle valve closed,

current to the injectors is cut off to improve fuel

economy at engine speeds over 1,030 rpm. Fuel cut-off

action also occurs when engine speed exceeds

6,900 rpm, regardless of the position of the throttle

valve, to protect the engine from over-rewing. When

the vehicle is stopped. the ECM cuts the fuel at engine

speeds over 6,500 rpm.

Fuel Pump Control

When the ignition is turned on, the ECM grounds the

PGM-Fl main relay which feeds current to the fuel pump

for 2 seconds to pressurize the fuel system, With the

engine running. the ECM grounds the PGM-Fl main

relay and feeds current to the fuel pump. When the

engine is not running and the ignition is on, the ECI\4

cuts ground to the PGM-Fl main relay which cuts

current to the fuel pump.

PGM-FI Main Relay 1 and 2

The PGM-Fl main relay consists of two separate relays.

Relay 1 is energized whenever the ignition switch is ON(ll) to supply battery voltage to the ECM power to the

injectors, and power for relay, Relay 2 is energized to

supply power to the fuel pump for 2 seconds when the

ignition switch is turned ON (ll), and when the engine is

runnrng.