cooling HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 196 of 1139

Cooling System

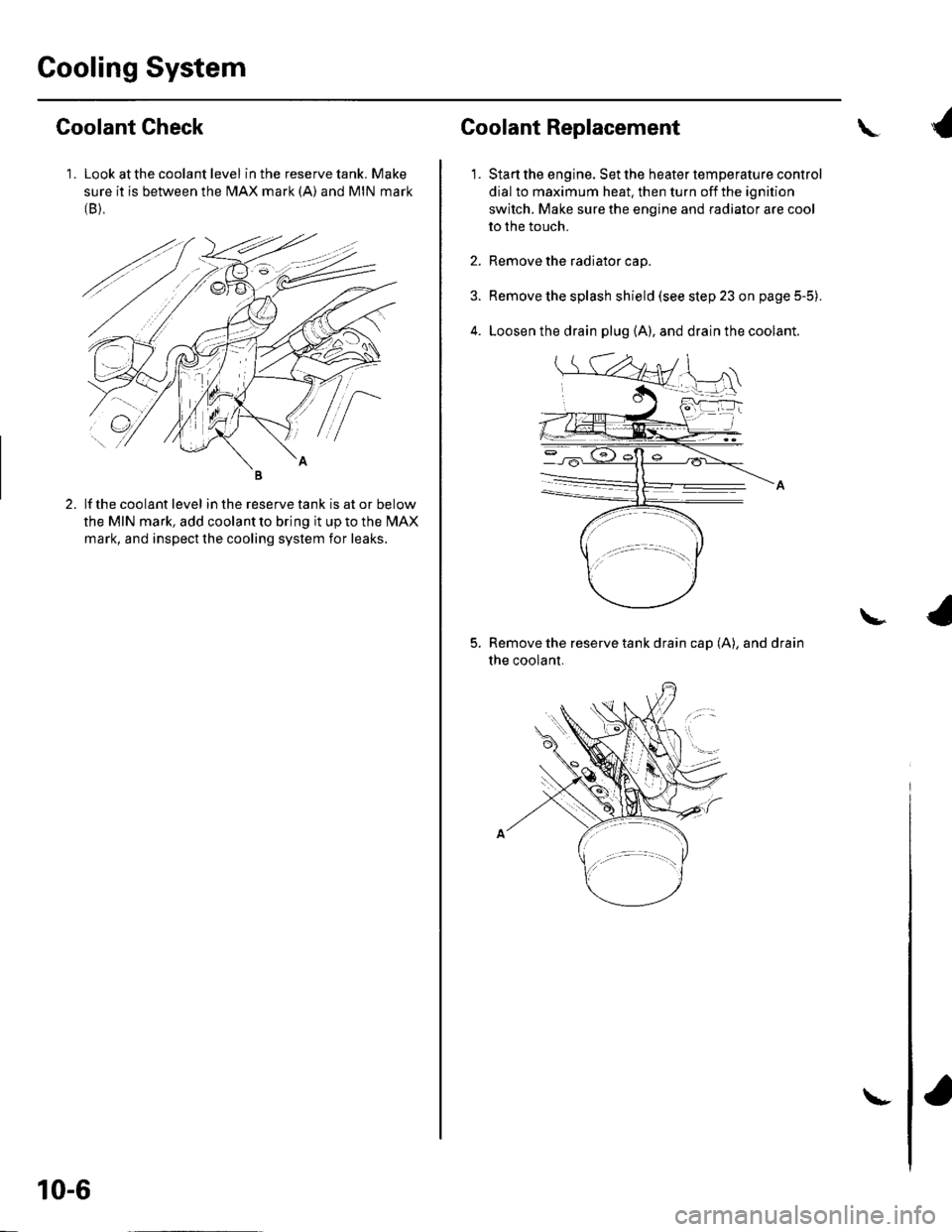

1 . Look at the coolant level in the reserve tank. Make

sure it is between the MAX mark (A) and MIN mark(B),

Goolant Check

lf the coolant level in the reserve tank is at or below

the MIN mark, add coolant to bring it up to the l\4AX

mark, and inspect the cooling system for leaks.

10-6

\-

Coolant Replacement

1.

\

Start the engine. Set the heater temperature control

dial to maximum heat. then turn off the ignition

switch. Make sure the engine and radiator are cool

to the touch.

Remove the radiator cap.

Remove the splash shield (see step 23 on page 5-5).

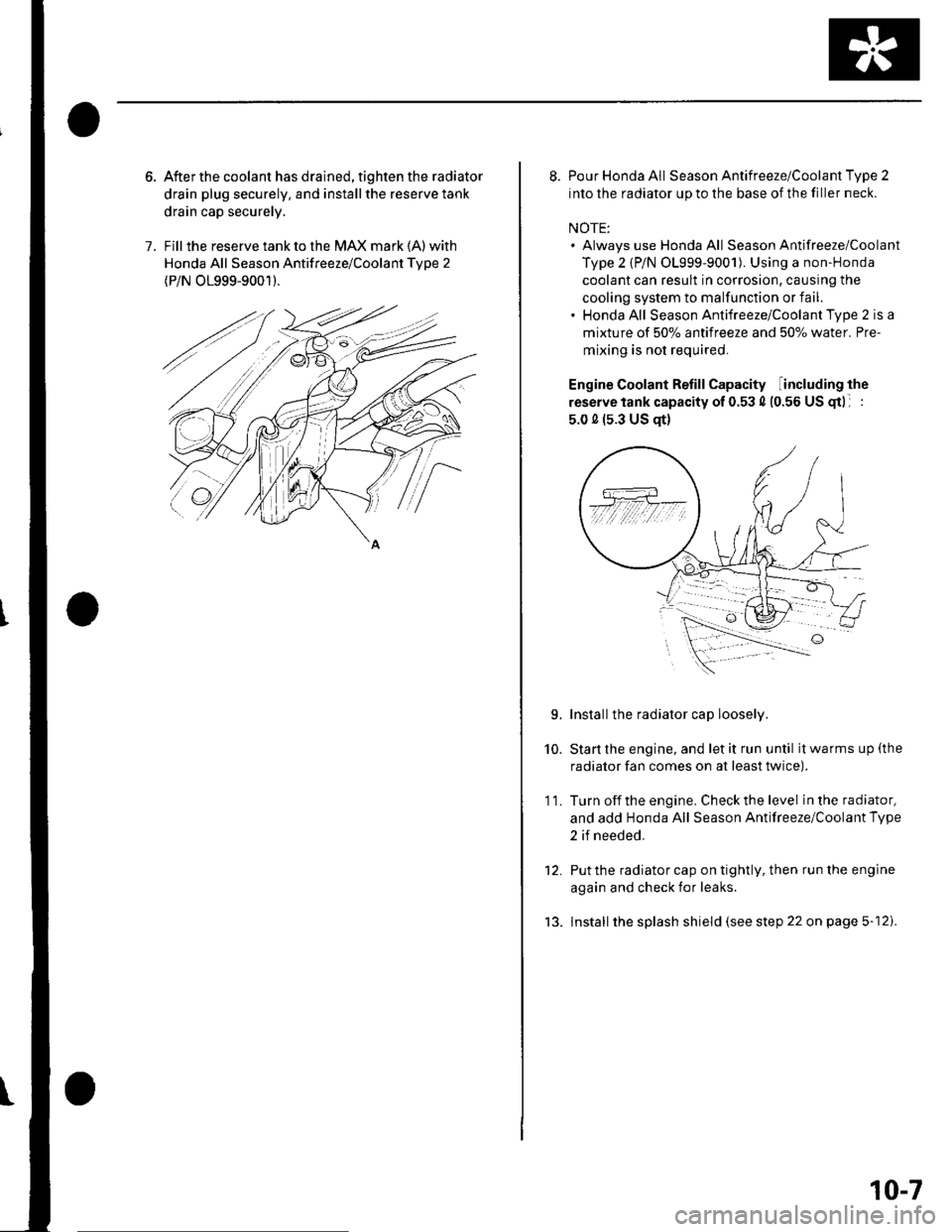

Loosen the drain plug (A), and drain the coolant.

Remove the reserve tank drain cap (A), and drain

the coolant.

\

Page 197 of 1139

1.

After the coolant has drained, tighten the radiator

drain plug securely. and installthe reserve tank

drain cap securely.

Fill the reserve tank to the MAX mark (A) with

Honda All Season Antifreeze/Coolant Tvpe 2

(P/N O1999-9001).

8. Pour Honda All Season Antifreeze/Coolant Type 2

into the radiator up to the base of the filler neck.

NOTE:. Always use Honda All Season Antifreeze/Coolant

Type 2 {P/N 01999-9001). Using a non-Honda

coolant can result in corrosion, causing the

cooling system to malfunction or fail.. Honda All Season Antifreeze/Coolant Type 2 is a

mixture of 50% antifreeze and 507o water. Pre-

mixing is not required.

Engine Coolant Refill Capacity including the

reserve tank capacity of 0.53 4 (0.56 US gtl :

5.0 0 (s.3 US qt)

Installthe radiator cap loosely.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

Turn off the engine. Check the level in the radiator,

and add Honda All Season Antifreeze/Coolant Type

2 if needed.

Put the radiator cap on tightly, then run the engine

again and check for leaks.

lnstall the splash shield (see step 22 on page 5-12).

10.

11.

L

tJ.

10-7

Page 198 of 1139

Gooling System

Thermostat Replacement

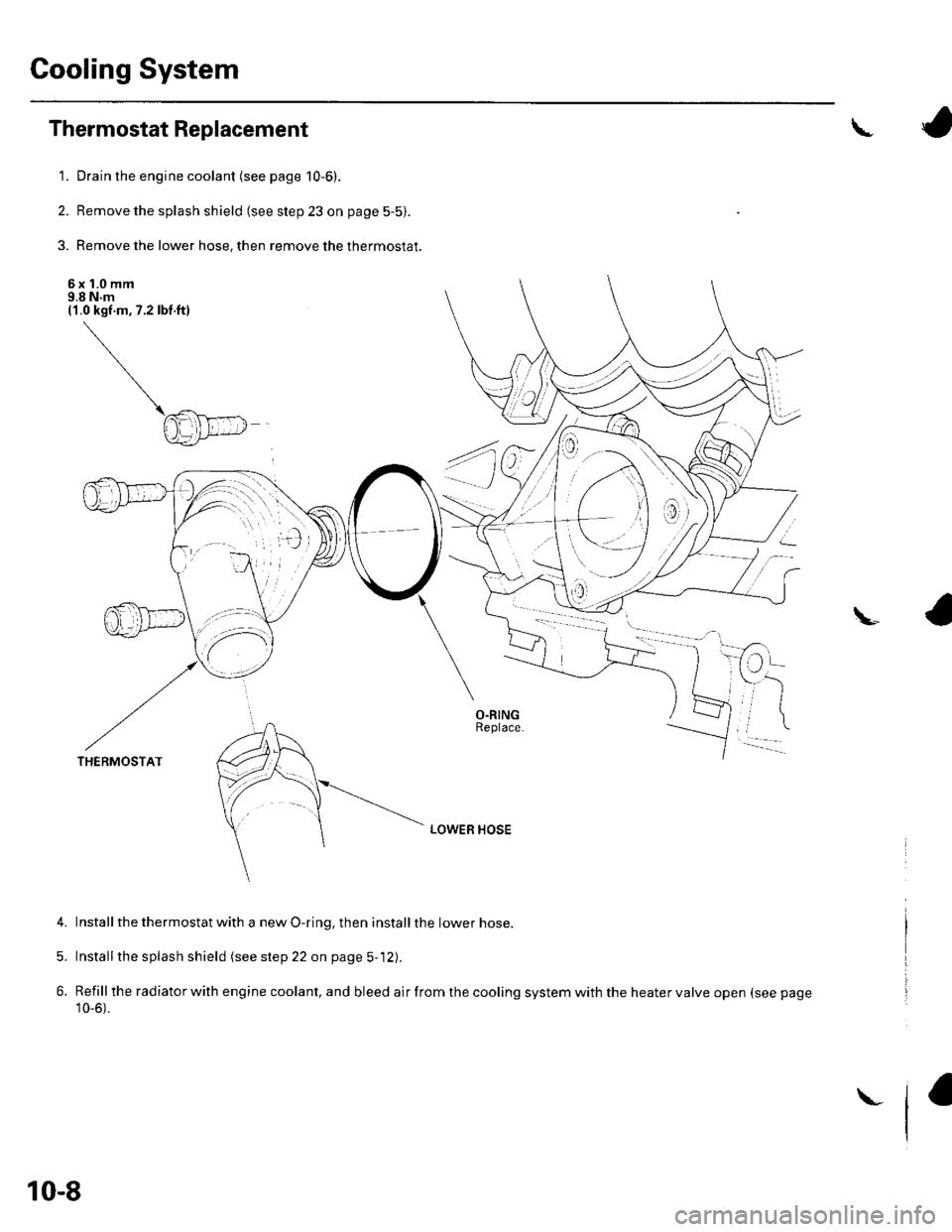

1. Drain the engine coolant (see page 10-6).

2. Remove the splash shield (see step 23 on page 5-5).

3. Remove the lower hose, then remove the thermostat.

6x 1.0 mm9.8 N.m(1.0 kgf.m,7.2lbf ft)

a

u

i*

-

LOWER HOSE

4. Installthe thermostat with a new O-ring, then installthe lower hose.

5. Installthe splash shield (see step 22 on page 5-12).

6. Refillthe radiator with engine coolant, and bleed air from the cooling system with the heater valve open (see page

10_6).

THERMOSTAT

10-8

\_

Page 200 of 1139

Cooling System

Radiator and Fans Replacement

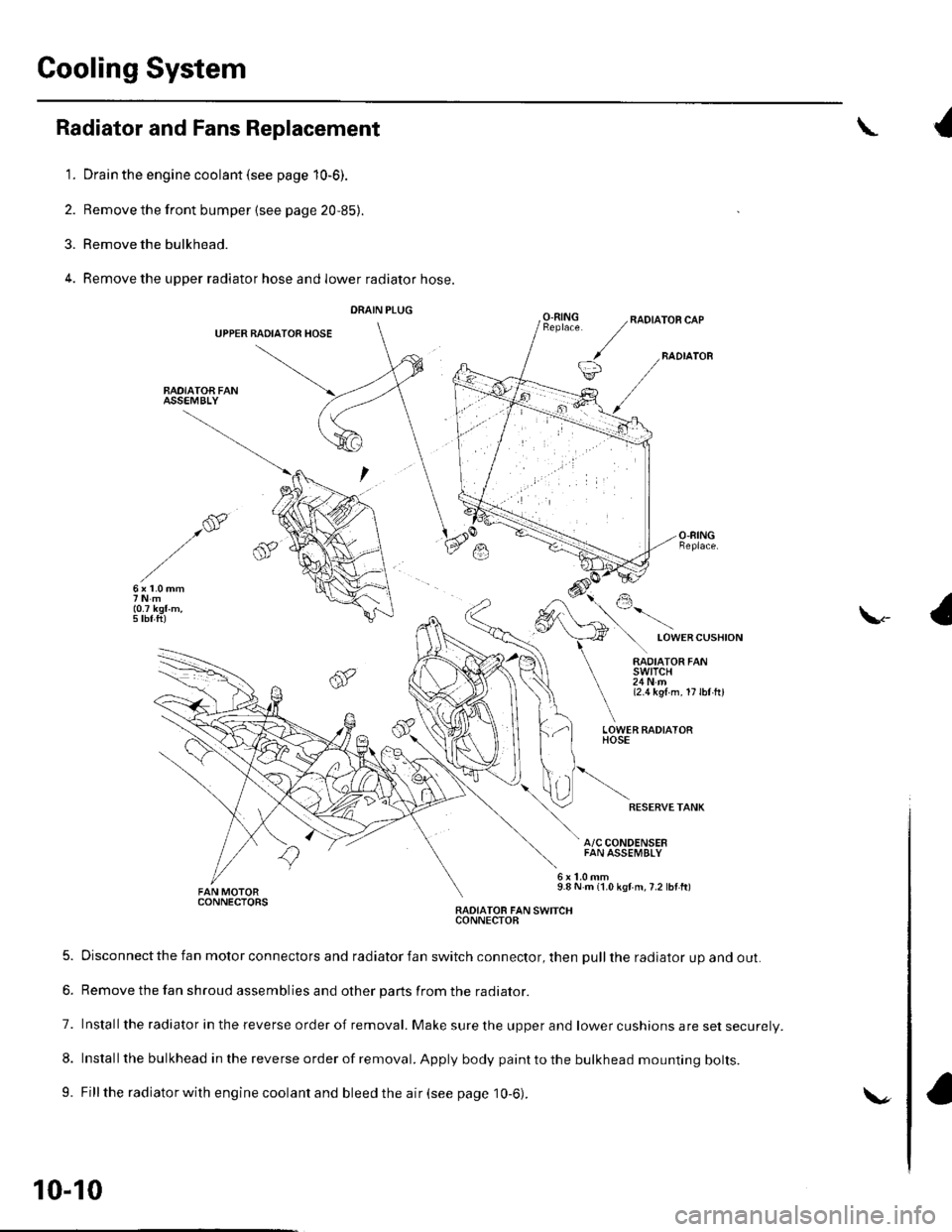

1. Drain the engine coolant (see page 10-6).

2. Remove the front bumper {see page 20,85).

3. Remove the bulkhead.

4. Remove the upper radiator hose and lower radiator hose.

DRAIN PLUG

UPPER BADIATOR HOSE

BAOIATOA FANASSEMBLY

{

O.RINGRADIATOR CAP

BADIATOB

LOWERCUSHION

\-

RADIATOR FANswtTcH24Nm{2.1t kgl m. 17lbl hl

LOWER FADIATORHOSE

RESERVETANK

A/C CONDENSERFAN ASSEMBLY

9.8 N m {1.0 kgf m,7.2 lbf ft)CONNECTORSRADIATOB FAN SWITCHCONNECTOB

5. Disconnect the fan motor connectors and radiator fan switch connector, then pull the radiator up and out.

6. Remove the fan shroud assemblies and other parts from the radiator.

7. Installthe radiator in the reverse order of removal. Make sure the upper and lower cushions are set securelV.

8. Install the bulkhead in the reverse order of removal. Apply body paint to the bulkhead mounting bolts.

9. Fill the radiator with engine coolant and bleed the air (see page 10-6).

10-10

\.

Page 202 of 1139

Fan Controls

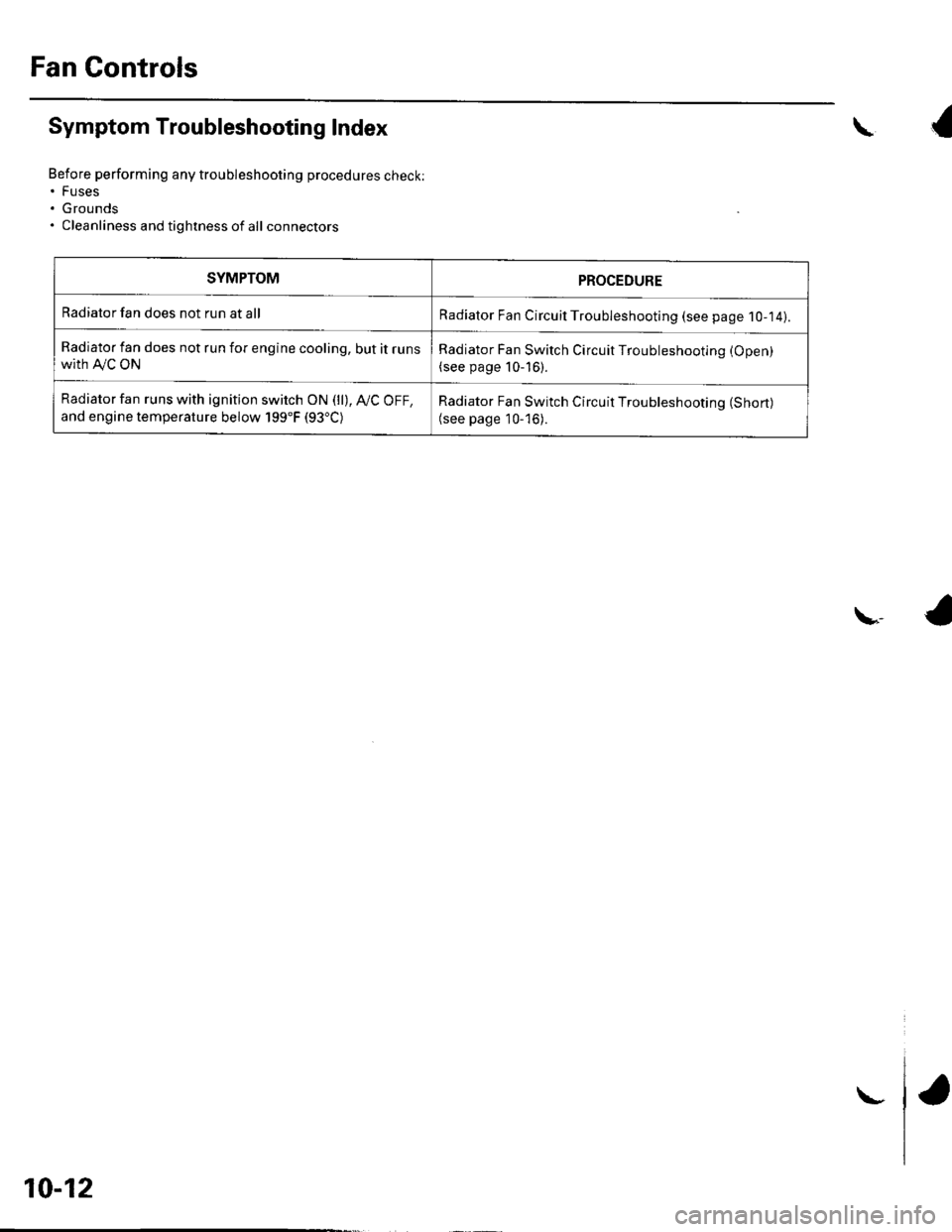

Symptom Troubleshooting Index

Before performing any troubleshooting procedures check:. Fuses. Grounds. Cleanliness and tightness of all connectors

\{

\,4

SYMPTOMPROCEDURE

Radiator fan does not run at allRadiator Fan Circuil Troubleshooting (see page 1O-14).

Radiator fan does not run for engine cooling, but it runswith A,/C ON

Radiator Fan Switch Circuit Troubleshooting (Open)

(see page 10-16).

Radiator fan runs with ignition switch ON (ll), Ay'C OFF,

and engine temperature below 199"F (93"C)Radiator Fan Switch Circuit Troubleshooting (Short)

(see page 10-'16).

10-12

\-

Page 207 of 1139

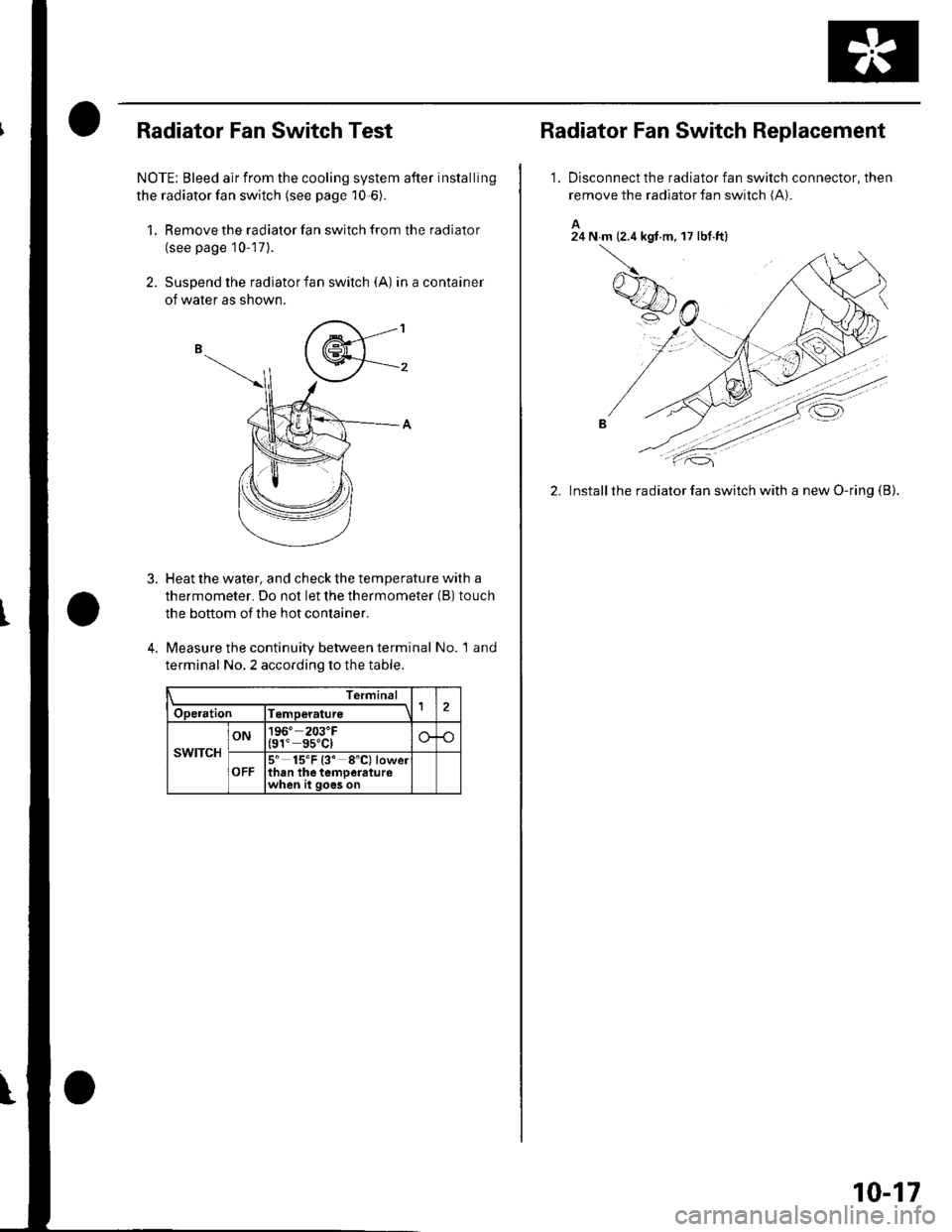

Radiator Fan Switch Test

NOTE: Bleed air from the cooling system after installing

the radiator fan switch (see page 10-6).

1, Remove the radiator fan switch from the radiator

(see page 10-17).

2. Suspend the radiator fan switch (A) inacontainer

of water as shown.

3. Heat the water, and check the temperature with a

thermometer. Do not let the thermometer (B) touch

the bottom of the hot conlainer.

4. Measure the continuity between terminal No. 1 and

terminal No. 2 according to the table.

Termina

Operation lTemperature1

swtTcH

ON196" 203'F(91" gs"C)

OFF5' 15'F {3' 8'C) lowelthan the temoeraturewhen it goes on

Radiator Fan Switch Replacement

1.Disconnect the radiator fan switch connector, then

remove the radiator fan switch (A).

A24 N m (2.4 kgt.m, 17 lbt.ftl

2. Installthe radiator fan switch with a new O-ring (B).

10-17

Page 233 of 1139

Fuel and Emissions Systems

System Descriptions (cont'd)

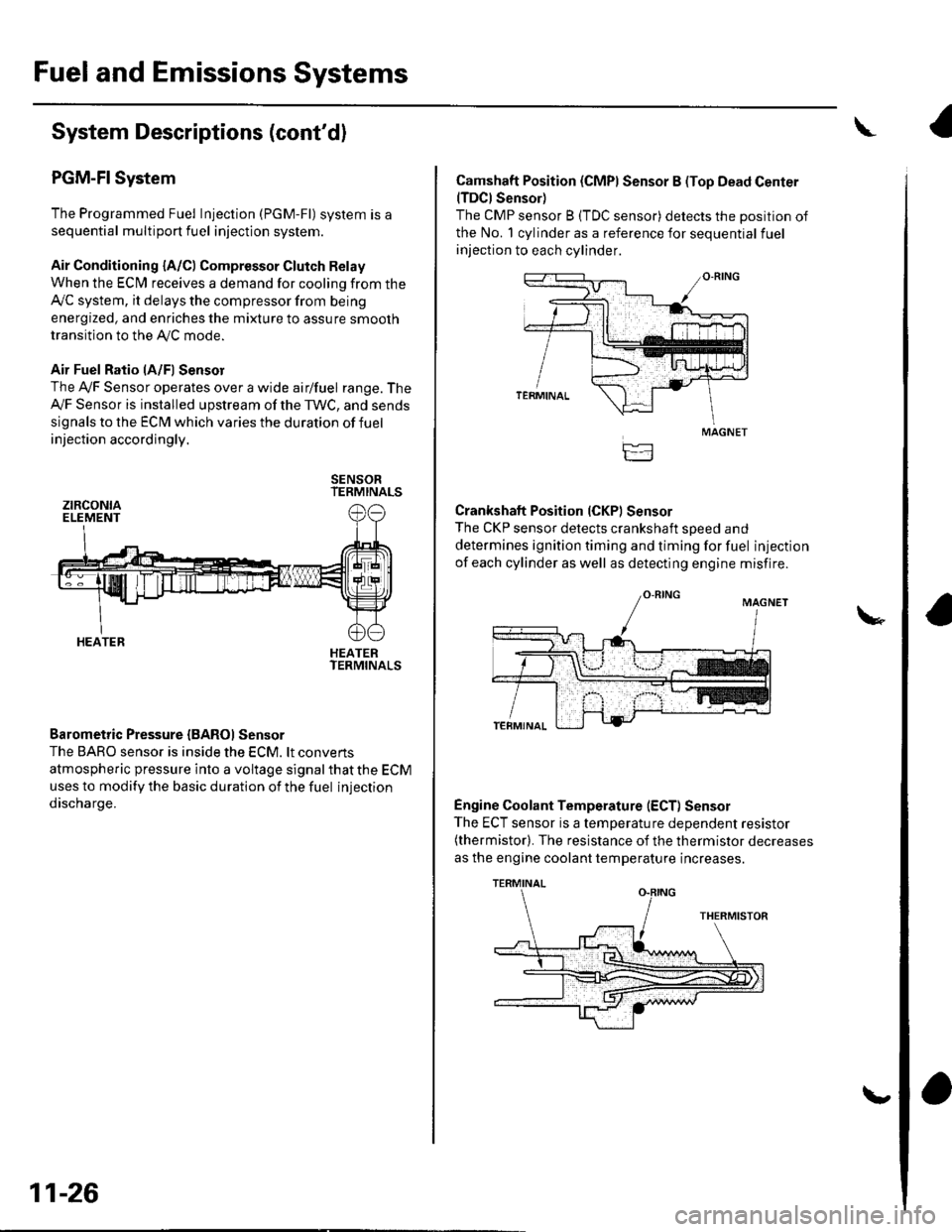

PGM-FI System

The Programmed Fuel Injection (PGM-Fl) system is a

sequential multiport fuel injection system.

Air Conditioning {A/C) Compressor Glutch Relay

When the ECfM receives a demand for cooling from the

Ay'C system, it delays the compressor from being

energized, and enriches the mixture to assure smooth

transition to the AVC mode.

Air Fuel Ratio lA/Fl Sensor

The Ay'F Sensor operates over a wide airlfuel range. The

Ay'F Sensor is installed upstream of the TWC, and sends

signals to the ECM which varies the duration of fuel

injection accordingly.

SENSORTERMINALS

HEATERTERMINALS

Barometric Pressure {BAROI Sensor

The BARO sensor is inside the ECM. lt convens

atmospheric pressure into a voltage signal that the ECM

uses to modify the basic duration of the fuel injection

discharge.

ztRcoNtaELEMENT

HEATER

11-26

\,

Camshaft Position (CMPI Sensor B (Top Dead Center(TDCI Sensor)

The CMP sensor B (TDC sensor) detects the position of

the No. 1 cylinder as a reference for sequential fuel

injection to each cylinder.

Crankshaft Position (CKPI Sensor

The CKP sensor detects crankshaft soeed and

determines ignition timing and timing for fuel injection

of each cylinder as well as detecting engine misfire.

Engine Coolant Temperature (ECT) Sensor

The ECT sensor is a temperature dependent resistor(thermistor). The resistance of the thermistor decreases

as the engine coolant temperature increases.

MAGNET

TERMINAL

Page 264 of 1139

DTC P0116: ECT Sensor Range/Performance

Problem

NOTE: lf DTC P0117 and/or P0118 are stored at the

same time as DTC P0116, troubleshoot those DTCS first,

then recheck for DTC P0116,

1. Stanthe engine. Hold the engine at 3,000 rpm with

no load {in neutral) until the radiator fan comes on,

then let it idle.

2. Check the ECT with the scan tool.

ls 176- 212'F (80 100"C)or0.5 0.8V

indicated?

YES Intermittent failure. system is OK at this time.

Check the thermostat and the cooling system.l

NO-Checkthe thermostat and the cooling system.

lf they are OK, replace the ECT sensor.l

11-57

Page 271 of 1139

PGM-FI System

aDTG Troubleshootang (cont'dl

DTC P0128: Cooling System Malfunction

NOTE; lf the DTCS listed below are stored at the same

time as DTC P0128. troubleshoot those DTCS first, thenrecheck for P0128.

P0107, P0108, P1128, P1129: N4anifold absolutepressure (MAP) sensor

P] I06, P1 107, P1 108: Barometric pressure (BARO)

sensor

P1259: VTEC system

P01 16, P01 17, P01 18: Engine coolant temperature (ECT)

sensor

P01 12, P01 13: Intake air temperature (lAT) sensor

P0500: Vehicle speed sensor {VSS)P0335, P0336: Crankshaft position (CKP) sensor

P0300: Random misfire

P0301, P0302, P0303, P0304: No. 1, No. 2, No.3 or No.4

cylinder misfire

P0505: ldle control system malfunction

P1519: ldle air control (lAC)valve

DTC P0128 can occasionally set when the hood is

opened while the engine is running.

1. Check the engine coolant level

Is the engine coolant level low?

VES Refill the engine coolant. lf necessary, repair

the coolant leakage.l

NO Go to step 2.

2. Turn the ignition switch ON (ll), and make sure the

A,/C is off.

11-64

\

3. Check the radiator fan.

Does the tadiator fan keep running?

YES Checkthe rad iato r fan circuit (see page 10-

14), the radiator fan switch circuit (Short) (see page

10-'16), and the radiator fan switch (see page 10-17).

Also, inspect the ECT and IAT circuits and terminal

connections. lf the circuits, the switch, and the

connections are OK, update the ECI\4 if it does not

have the latest software. or substitute a known-good ECM, then recheck (see page 1 1-6). lf the

symptom/indication goes away with a known-good

ECM, replace the original ECM.I

NO Replace the thermostat (see page 10-8).1

Page 816 of 1139

13. Installthe heater core and the evaporator core in

the reverse order of removal.

14. Installthe heater unit in the reverse order of

removal, and note these items:

. Do not interchange the inlet and outlet heater

hoses, and installthe hose clamps securely.. Refillthe cooling system with engine coolant (see

page 10-6).. Adjust the heater valve cable (see page 2'l-461.. Make sure that there is no coolant leakage.. Make sure that there is no air leakage.. Refer to evaporator core replacement {see step 6

on page 21-42).. Do the engine control module (ECl\4) idle learn

procedure (see page 11-139).. Enter the anti-theft code for the radio, then enter

the customer's radio station Dresets.

21-45