fuel HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 88 of 1139

Engine Assembly

Engine Removal (cont'd)

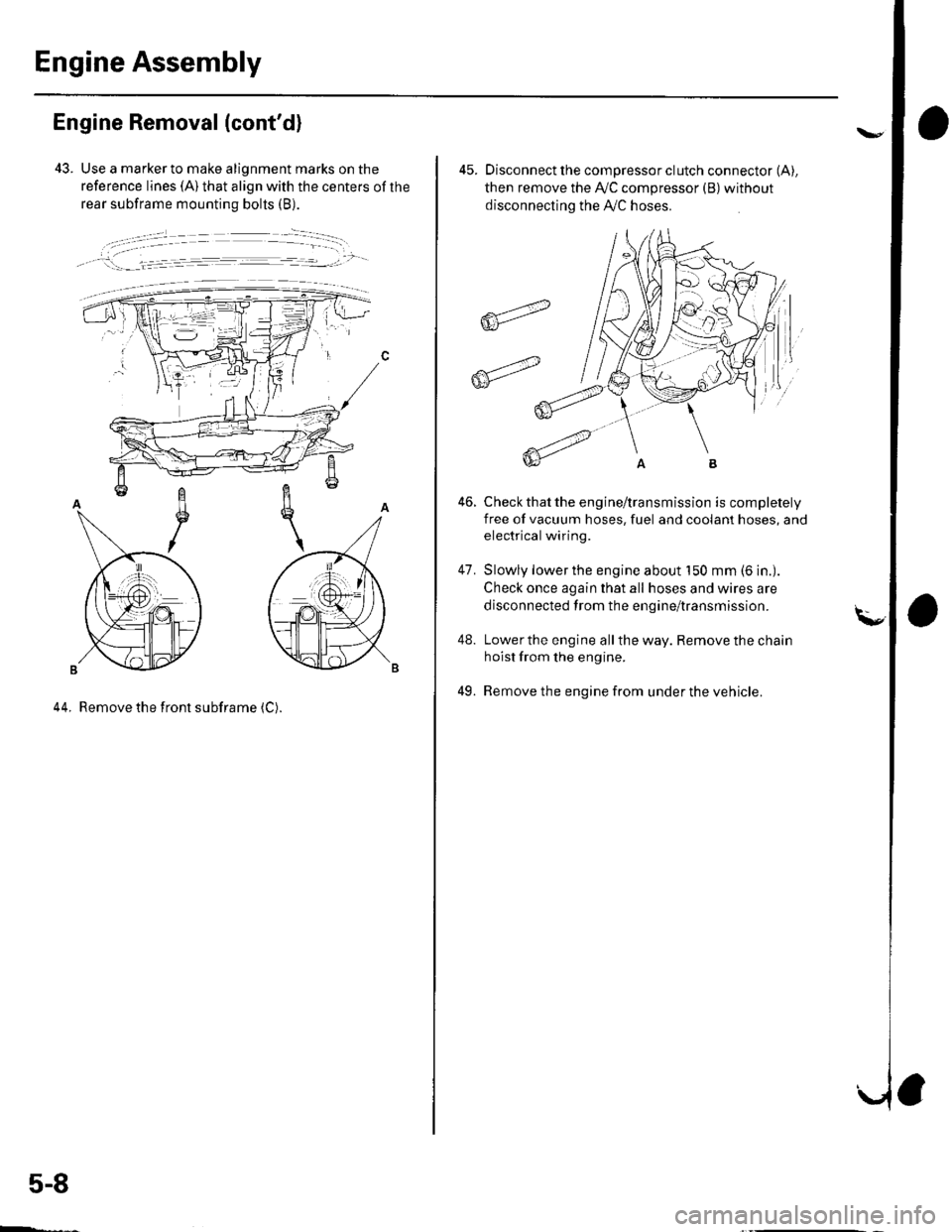

43. Use a marker to make alignment marks on the

reference lines (A) that align with the centers of the

rear subframe mounting bolts (B).

, !:_- _l.= :r -- ---.-','- -

44. Remove the front subframe (C).

5-8

ffi4

ffit'"

45. Disconnect the compressor clutch connector (A),

then remove the Ay'C compressor (B)without

disconnecting the A'./C hoses.

Check that the engine/transmission is completely

free of vacuum hoses, fuel and coolant hoses, and

electrical wiring.

Slowly lower the engine about 150 mm (6 in.).

Check once again that all hoses and wires are

disconnected trom the engine/transmission.

Lower the engine all the way. Remove the chain

hoist from the engine.

Remove the engine from under the vehicle.

46.

47.

48.

49.

Page 92 of 1139

Engine Assembly

18.

Engine Installation {cont'dl

10 x 1.25 mm33 N.m {3.i1kgf.m,25 tbt.ftl

19.

20.

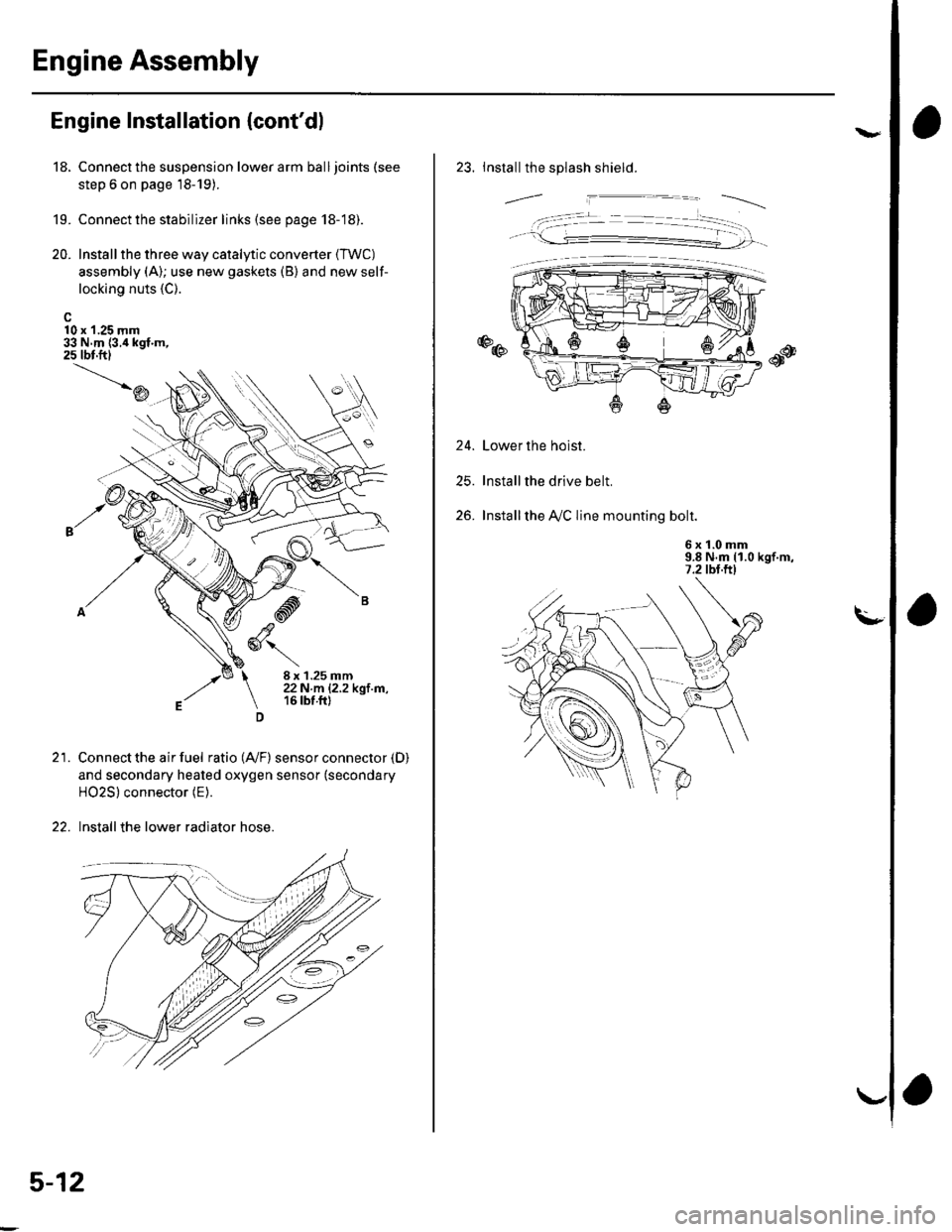

Connect the suspension lower arm ball joints (see

step 6 on page 18-19).

Connect the stabilizer links (see page 18-18).

Install the three way catalytic converter (TWC)

assembly (A); use new gaskets (B) and new self-

locking nuts {C).

\D

21.

-d

,ry6\

8 x 1.25 mm22N.m |.2.2kgl m,16 tbt.ft)

Connect the air fuel ratio (4,/F) sensor connector (D)

and secondary heated oxygen sensor (secondary

HO2S) connector (E).

Install the lower radiator hose.

5-12

va

23. Installthe splash shield.

24.

25.

26.

Lower the hoist.

Installthe drive belt.

Installthe A,/C line mounting bolt.

6 x '!.0 mm9.8 N.m (1.0 kgf.m,7.2 tbt.ftl

. -t- --�- --�--r

Page 93 of 1139

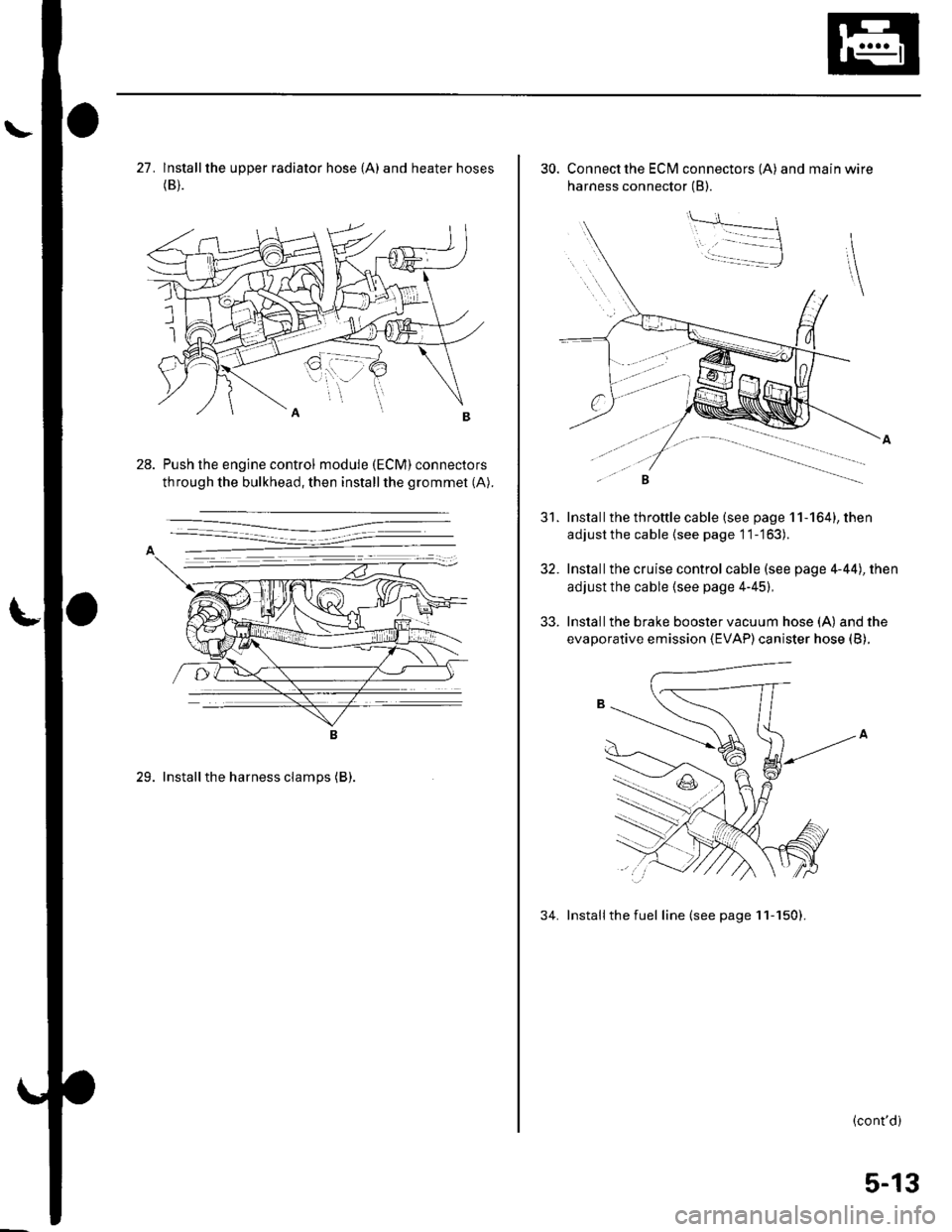

27. lnstallthe upper radiator hose {A) and heater hoses(B).

Push the engine control module (ECM) connectors

through the bulkhead, then installthe grommet (A).

29. Installthe harness clamps (B).

30. Connect the ECI\4 connectors (A) and main wire

harness connector (B).

Install the throttle cable (see page 11-164), then

adjustthe cable {see page 11-'163).

Installthe cruise control cable (see page 4-44), then

adjust the cable (see page 4-45),

Install the brake booster vacuum hose (A) and the

evaporative emission (EVAP) canister hose (B).

34. Installthe fuel line (see page 11-150).

31.

32.

33.

(cont'd)

5-13

Page 95 of 1139

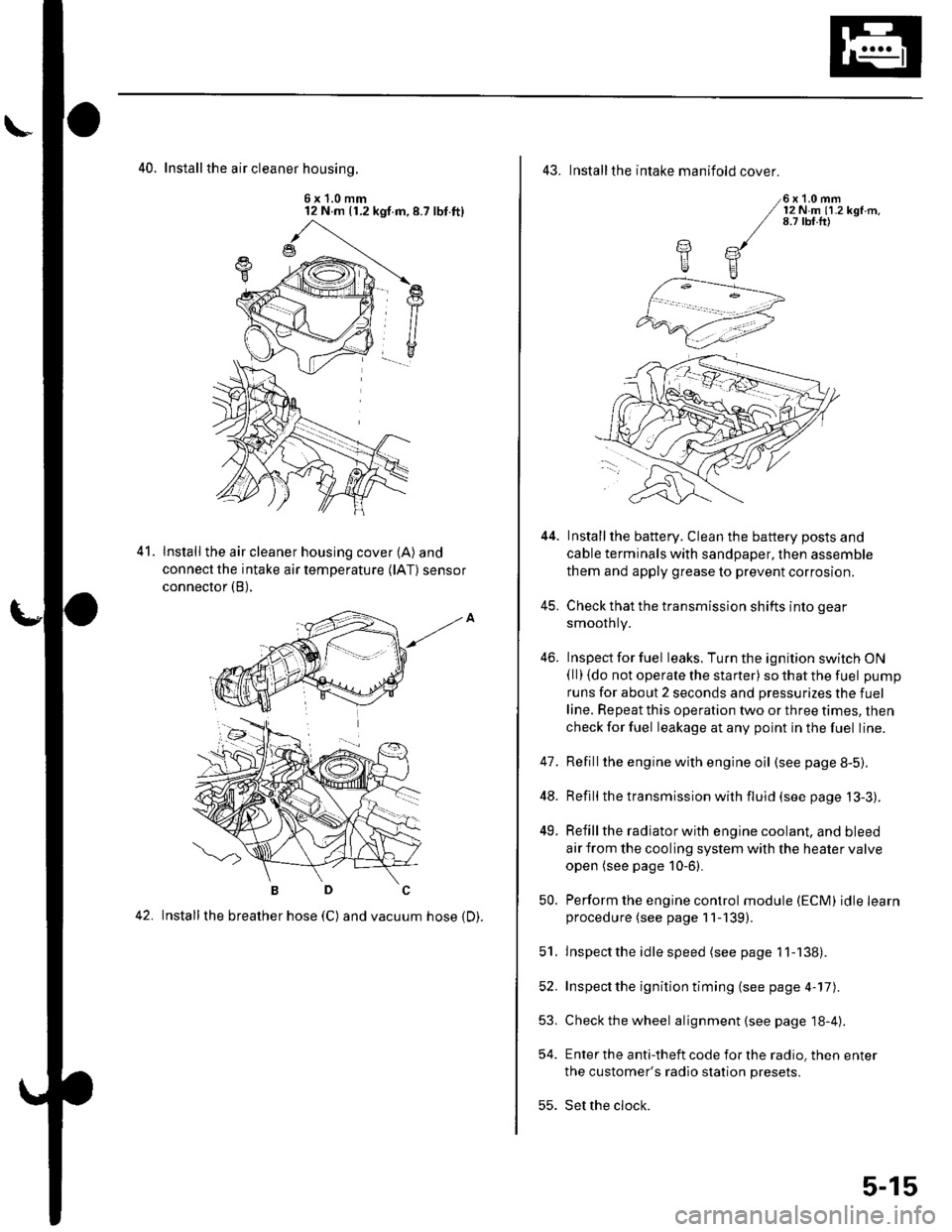

40. Install the air cleaner housinq.

6x1.0mm12 N m (1.2 kgf.m,8.7 lbt.ft)

Install the air cleaner housing cover (A) and

connect the intake air temperature (lAT) sensor

connector (B),

42. Installthe breather hose (C) and vacuum hose 1D).

41.

43. Installthe intake manifold cover.

6x1.0mm12Nm11.2kgf.m.8.7 tbf.ft)

Installthe battery. Clean the battery posts and

cable terminals with sandpaper, then assemble

them and apply grease to prevent corrosion.

Check that the transmission shifts into gear

smoothly.

Inspect for fuel leaks. Turn the ignition switch ON(ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refillthe engine with engine oil (see page 8-5).

Refill the transmission with fluid (see page 13-3).

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

Perform the engine control module (ECM) idle learnprocedure (see page 11-139).

Inspect the idle speed (see page 1 1-138).

Inspect the ignition timing (see page 4-17).

Check the wheel alignment {see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

YE

44.

41.

]tE

46.

48.

49.

52.

53.

54.

50.

51.

55.

5-15

Page 136 of 1139

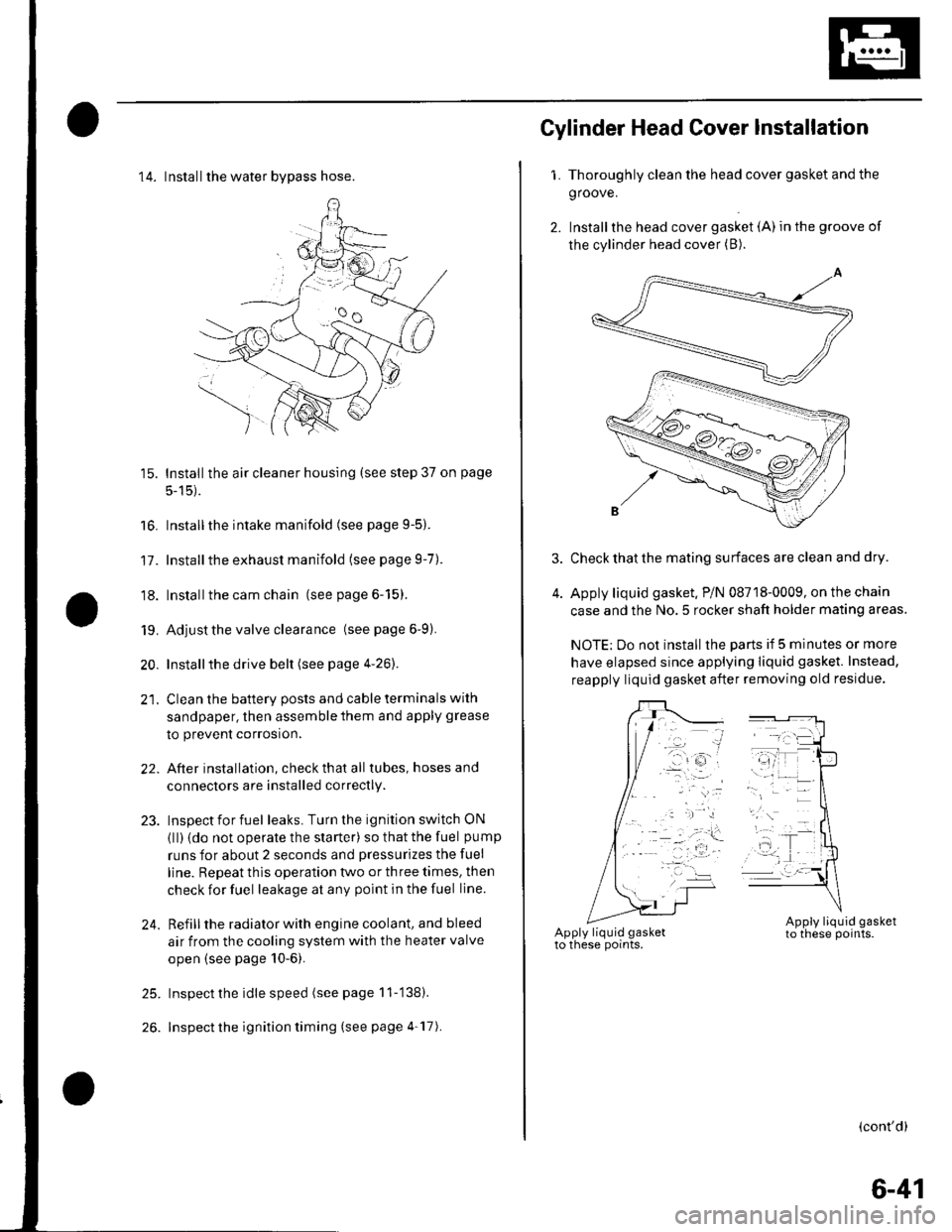

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 186 of 1139

Intake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'dl

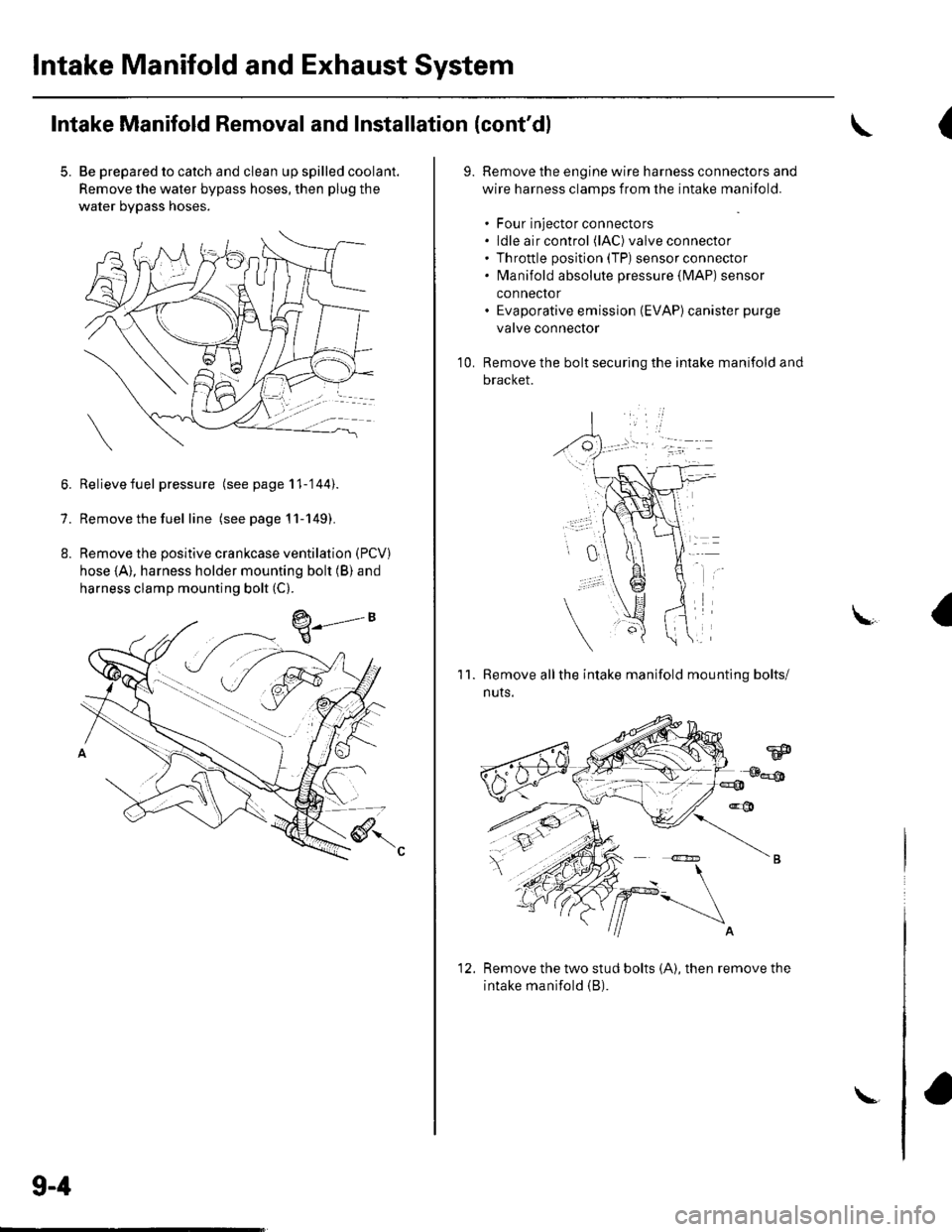

5. Be prepared to catch and clean up spilled coolant.

Remove the water bypass hoses, then plug the

water bypass hoses.

6. Relievefuel pressure (see page 11-'144).

7. Remove the fuel line (seepagell-149).

8. Remove the positive crankcase ventilation (PCV)

hose (A), harness holder mounting bolt (B) and

harness clamp mounting bolt (C).

9-4

\-

(

9.Remove the engine wire harness connectors and

wire harness clamps from the intake manifold.

. Four injector connectors. ldle air control (lAC) valve connector. Throttle position (TP) sensor connector. fvlanifold absolute pressure {lvlAP) sensor

connector. Evaporative emission (EVAP)canister purge

valve connector

Remove the bolt securing the intake manifold and

bracket.

'1 0.

11.Remove allthe intake manifold mounting bolts/

nuts.

Remove the two stud bolts (A), then remove the

intake manifold (B).

1'>

Page 187 of 1139

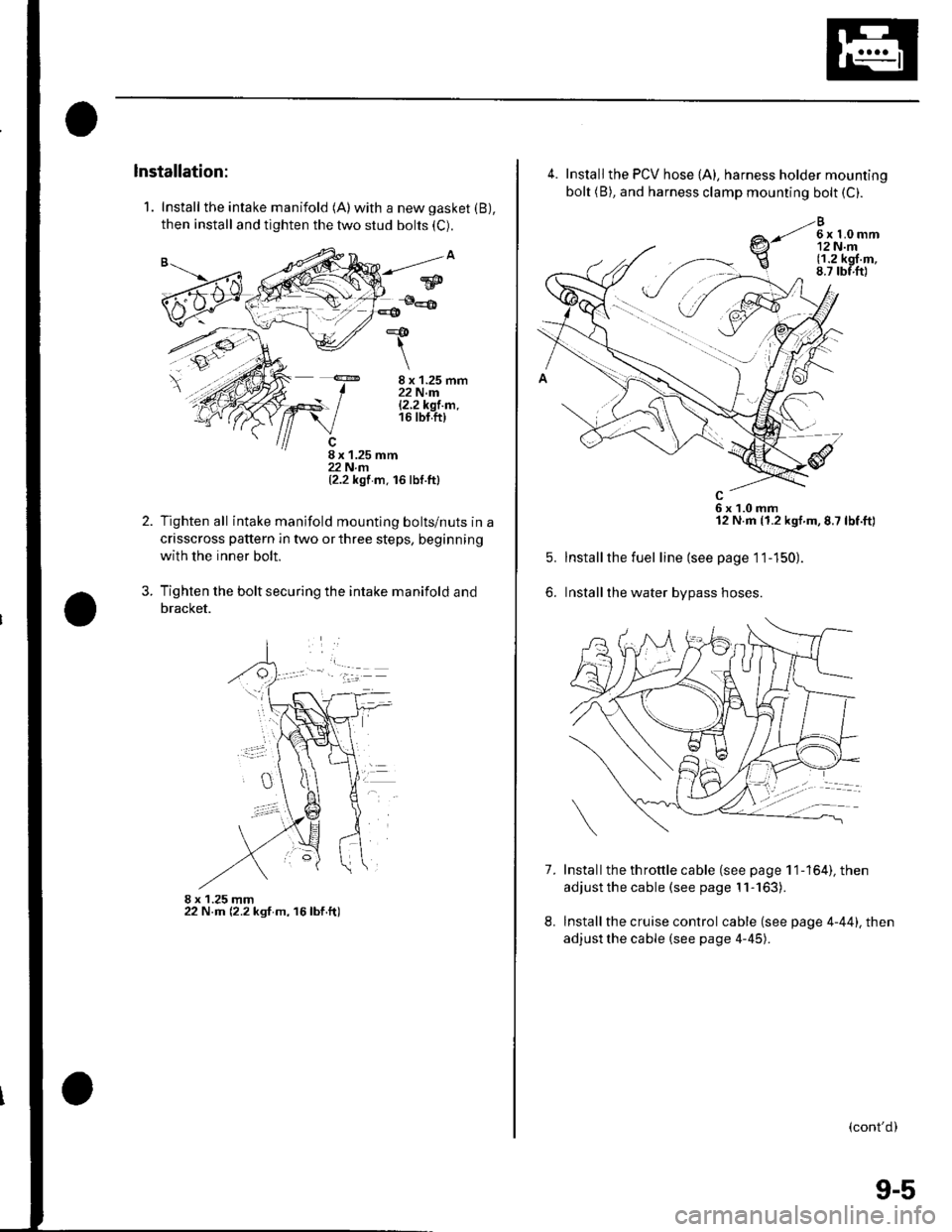

1. Install the intake manifold (A)with a new gasket (B),

then install and tighten the two stud bolts (C).

8 x 1.25 mm22 N.m|.2.2k91.m.16 tbt.ft)

8 x 1.25 mm22 N.rn(2.2 kgf m. 16 lbf.ttl

Tighten all intake manifold mountlng bolts/nuts in a

crisscross pattern in two or three steps, beginning

with the inner bolt.

Tighten the bolt securing the intake manifold and

bracket.

8 x 1.25 mm22 N.m (2.2 ksf m, 16lbf.ft)

*&

\

2.

?

w

4.

7.

5.

6.

Install the PCV hose {A), harness holder mounting

bolt (B), and harness clamp mounting bolt (C).

e-li*h,r

6x1.0mm12 N.m (1.2 kgf.m,8.7 lbf.ft)

Installthe fuel line (see page 11-150).

Installthe water bypass hoses.

Install the th rottle cable (see page 1 1-164), then

adjust the cable (see page 11-163).

Install the cruise control cable (see page 4-44). then

adjust the cable (see page 4-45).

8.

(cont'd)

9-5

Page 188 of 1139

lntake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'd)

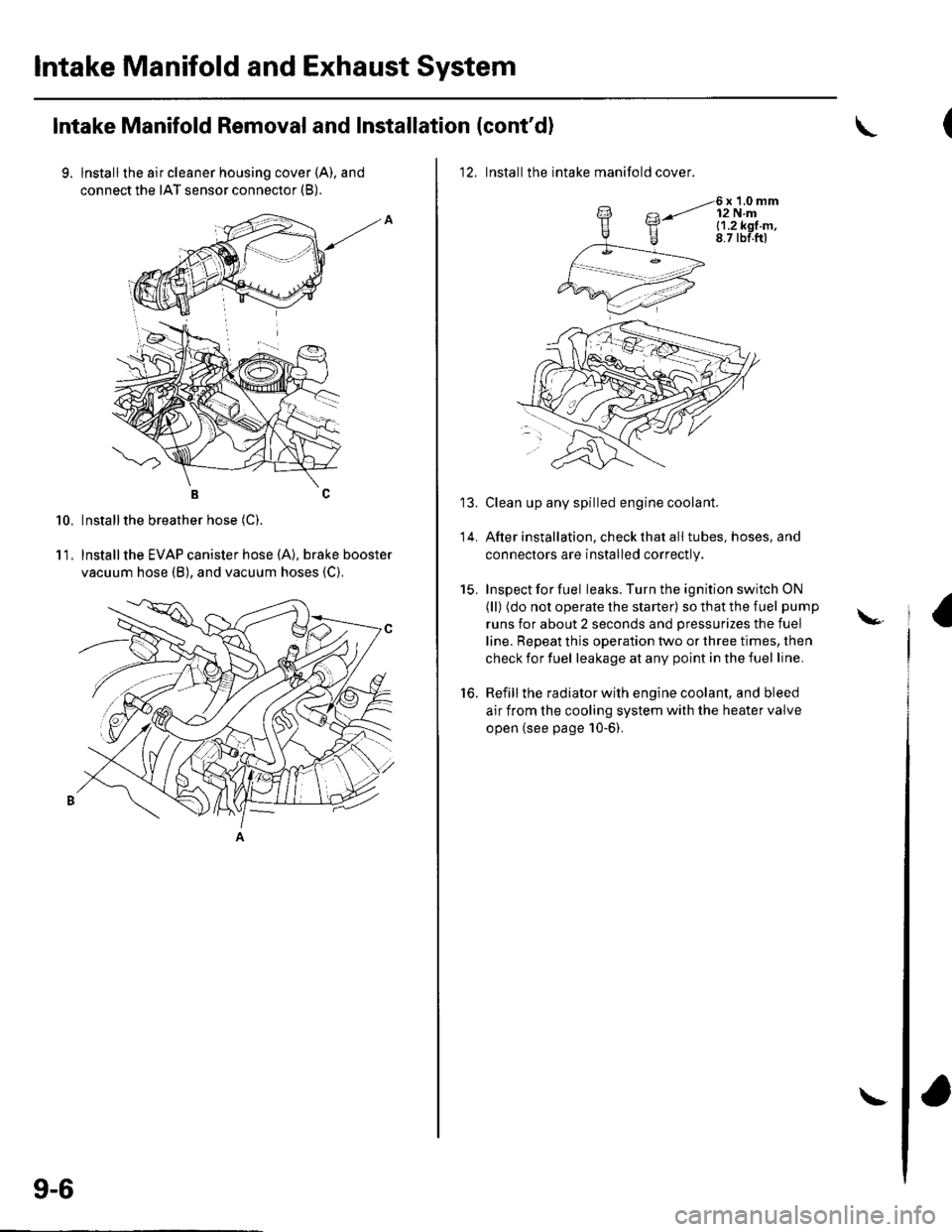

9. lnstallthe air cleaner housing cover (A), and

connect the IAT sensor connector (B).

BC

Installthe breather hose (C).

lnstallthe EVAP canister hose (A), brake booster

vacuum hose (B), and vacuum hoses {C).

10.

11.

9-6

\

12. Installthe intake manifold cover.

6x1.0mm12 N.ml.1.2k91.m,8.7 tbf.ftl

Clean up any spilled engine coolant.

After installation, check that all tubes, hoses, and

connectors are installed correctly.

Inspect for fuel leaks. Turn the ignition switch ON

(ll) (do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

to.

\-

Page 190 of 1139

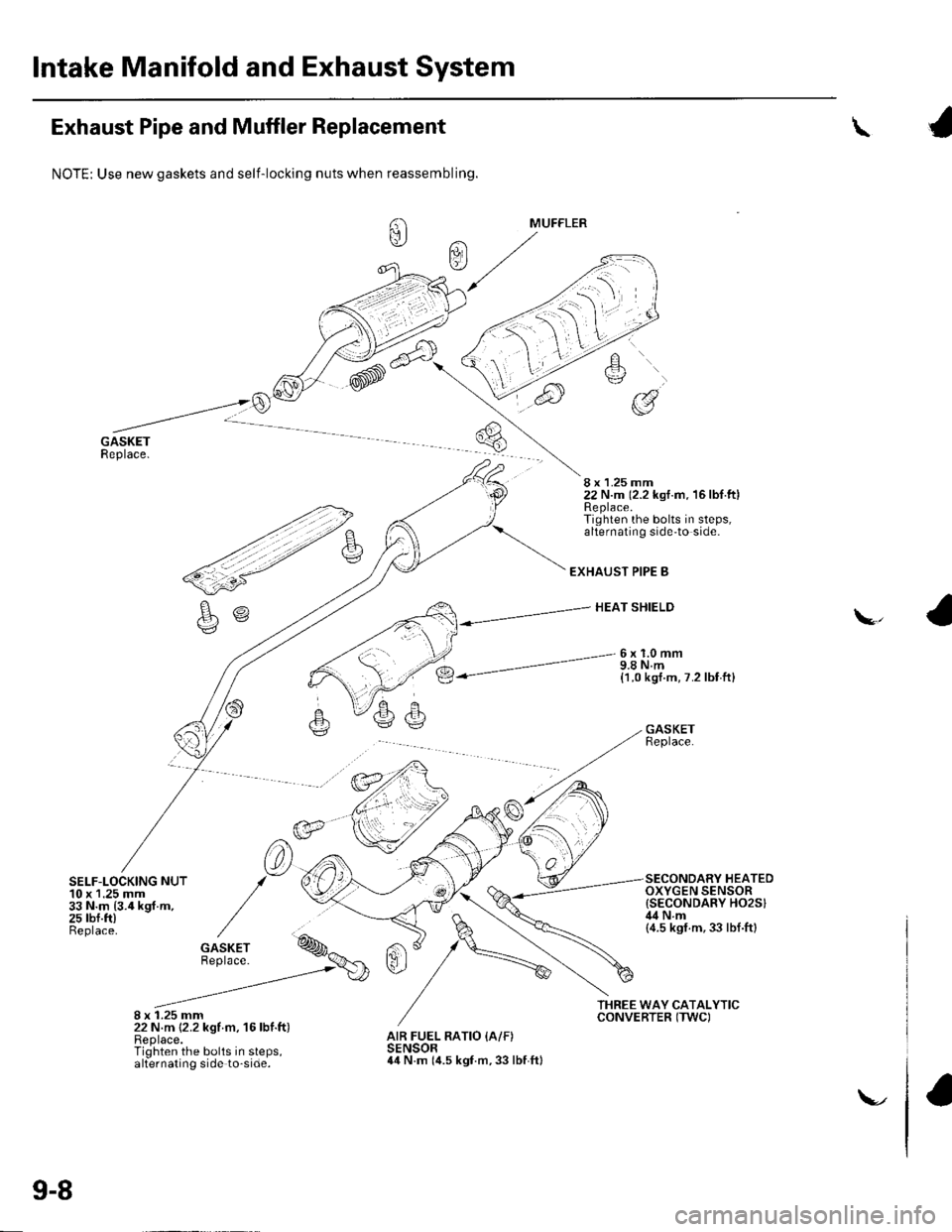

lntake Manifold and Exhaust System

Exhaust Pipe and Muffler Replacement

SELF-LOCKING NUT10 x 1.25 mm33 N.m {3.4 kgf.m,25 rbf.ft)Beplace.

8 x 1.25 mm22 N.m {2.2 kgf m, 16lbf.ft)Replace.Tighten the bolts in steps,alternating side to-side.

\

NOTE: Use new gaskets and self-locking nuts when reassembling.

8 x 1.25 mm22 N.m (2.2 kst.m. 16lbf.ftlReplace.Tighten the bolts in steps,alternating side'to side.

EXHAUST PIPE B

HEAT SHIELD\,

6x1.0mm9.8 N.m{1.0 kgt.m, 7.2 lbf ft}

GASKETReplace.

SECONDARY HEATEDOXYGEN SENSOR{SECONDARY HO2SIil4Nm(4.5 ksf.m,33 lbf.ftl

AIR FUEL RATIO {A/F)SENSOR44 N.m (it.s kgf.m, 33 lbf ftl

9-8

\-.

Page 208 of 1139

Fuel and Emissions

Fuel and Emissions Systems

SpecialTools

General Troubleshooting

Information

DTC Troubleshooting lndex ....

Symptom Troubleshooting

1ndex...............

System Descriptions ................

Howto Set Readiness Codes ..

PGM-FlSystem

Component Location Index ....

DTC Troubleshooting ..............

MIL Circuit Troubleshooting ...

DLC Circuit Troubleshooting ..

Injector Replacement ...............

A,/F Sensor Replacement .........

Secondary HO2S

Replacement

ECT Sensor Reolacement .......

CMP Sensor B {TDC Sensor)

Replacement

IAT Sensor Replacement .........

Knock Sensor Replacement ....

CKP Sensor Reolacement .......

VTEC/VTC

Comoonent Location Index ....

DTC Troubleshooting ..............

VTC Oil Control Solenoid

Valve Removal/Test .............

CMP Sensor A Replacement ...

VTEC Solenoid Valve

Removal/lnsoection .............

ldle Control System

Component Location Index

DTC Troubleshooting ..............

A,/C Signal Circuit

TroubleshootinS ...................

Alternator FR Signal Circu it

TroubleshootinS ...................

EPS Signal Circuit

TroubleshootinS ...................

Brake Pedal Position Switch Signal

Circuit Troubleshooting .............

ldle Speed Inspection

ECM ldle learn Procedure .......

Fuel Supply System

Component Location Index

Fuel Pump Circuit Troubleshooting

1't-2

I I-J

11-7

1 1-10

11-12

11-46

11-49

11-52

11-97

11-109

11-111

11-113

11-113

11-114

11-114

11-115

11-115

11-116

11-117

1 1-1 18

11-127

11-128

11-128

11-129

1I-130

I t- t55

11-134

1 1- 135

1 1-137

1 1-138

1 1-139

1 1-140

11-141

11-144

Fuel PressureTest ................... 11-145

Fuel Lines Inspection ............... 11-146

Fuel Line/Ouick-Connect

Fittings Precautions ............. 1 1-148

Fuel Line/Ou ick-Con nect

Fittings Removal .................. 1 1-149

Fuel Line/Ou ick-Con nect

Fittings lnstallation ............... 11-150

Fuel Pressure Regu lator

Replacement ......................... 11-152

Fuel Fifter Replacement ........... 11-152

Fuel Pump/Fuel Gauge Sending

UnitReDlacement ................. 11-153

Fuel Pulsation Damoer

Rep1acement ......................... 11-154

Fuel Tank Reolacement ........... 11-155

Fuel GaugeSending UnitTest ....... 11-156

Low Fuel lndicatorTest ................. 1 1-158

Intake Air System

Comoonent Location Index .... 11-159

Throttle BodyTest ................... 11-160

Intake Air Bypass Control

Thermal Valve Test .............. 11-161

Air Cleaner Reolacement ........ 11-162

Air Cleaner Element

Reolacement ......................... 11-162

Throttle Cable Adjustment ...... 11-163

Th rottle Cable

Removal/lnstallation ............ 1 1-164

Th rottle Body Removal/

Installation .. 11-165

Th rottle Body Disassembly/

Reassemblv .......................... 11-166

Catalytic Converter System

DTC Troubleshooting .............. 1 1-167

PCV System

DTC Troubleshooting .............. 1 1-168

PCV Valve InsDection

and Test ...... 1 1- 169

PCV Valve Reolacement .......... 11-169

EVAP System

Component Location Index .... 11-170

DTCTroubleshooting .............. 11-171

EVAP Two Way Valve Test ...... 11-186

Fuel Tank Vaoor Control

Valve Test ... 11-187

EVAP Canister Replacement ... 11-189

Fuel Tank Vaoor Control

Valve Reolacement .............. 1 1-189Fuel Pressu re Relieving ...........