switch HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 74 of 1139

svmptomDiagnostic procedureAlso check for

Set speed does not

cancel when main switch

is oushed OFF

1. Check main switch (see page 4-42)

2. Check cruise control unit (see page 4-40)

Short to power in

the LT GRN wire.

Set speed does not

cancel when CANCEL

button is pushed

1. Check SET/RESU ME/CANCEL switch (see page 4-42)

2. Check cruise control unit (see page 4-40)

Open circuit, loose

or disconnected

terminals:

GRYiRED,

LT GRN/BLK

Set speed will not

resume when RESUME

button is pushed (with

main switch on, and set

speed temporarily

cancelled by pressing the

brake Dedal)

1. Check SET/RESU ME/CANCEL switch (see page 4-42)

2. Check cruise control unit {see page 4-40)

Open circuit, loose

or disconnected

terminals:

LT GRN/BLK

4-39

Page 75 of 1139

Cruise Gontrol

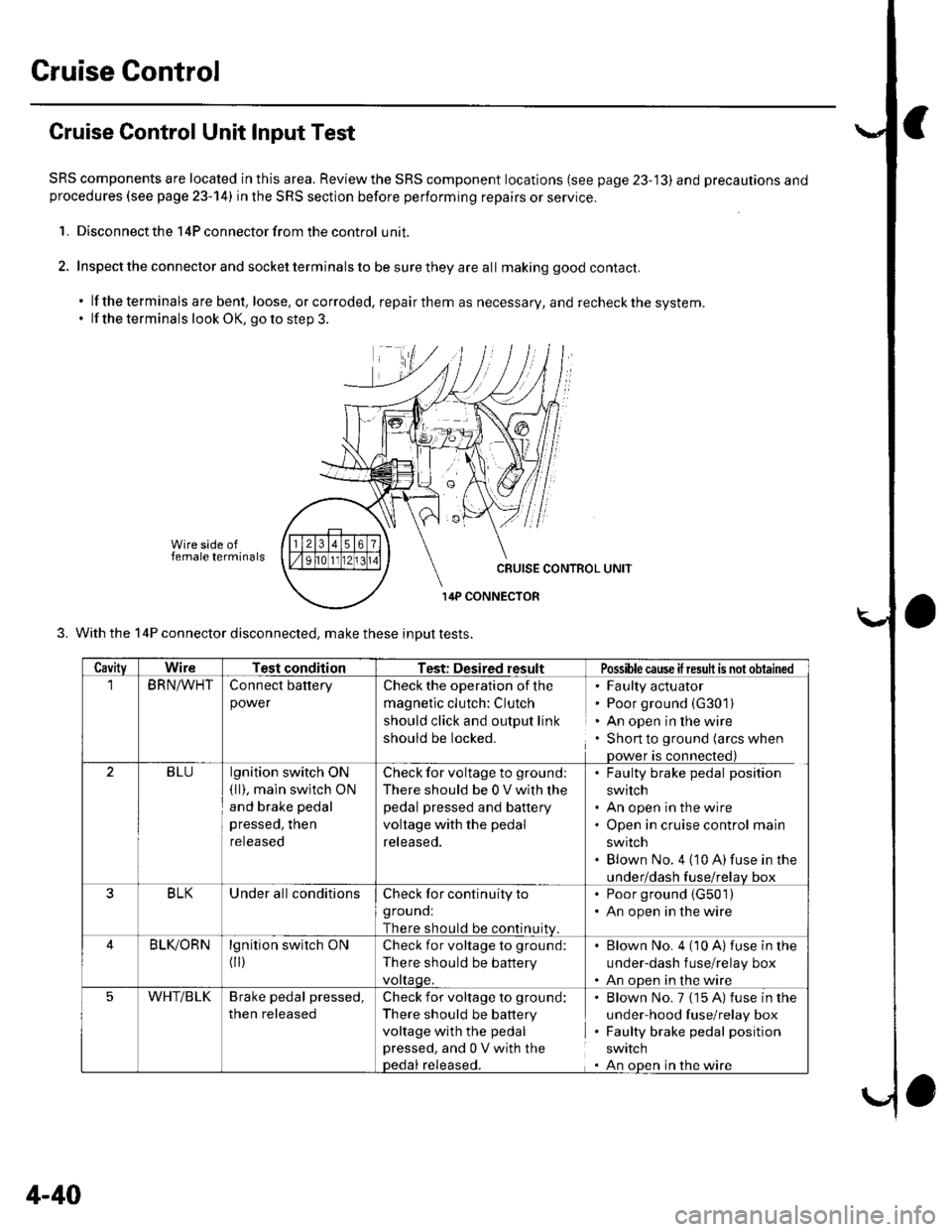

Cruise Control Unit Input Test

SRS components are located in this area. Reviewthe SRS component locations (see page 23-'13) and precautions andprocedures (see page 23-14) in the SRS section before performing repairs or service.

1. Disconnect the 14P connector from the control unit.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, orcorroded, repairthem as necessary, and recheckthe system.. lf the terminals look OK, go to step 3.

Wire side offemale terminals

3. With the 14P connector disconnected, make these inDut tests.

CavityWireTest conditionTest: Desired resultPossiblecause ifresuh is not obtained

BRN/WHTConnect battery

power

Check the operation of the

magnetic clutch: Clutch

should click and output link

should be locked.

' Faulty actuator. Poor ground (G301)

. An open in the wire. Shon to ground (arcs when

Dower is connected)

2BLUlgnition switch ON(ll), main swltch ON

and brake pedal

pressed, then

reteaseo

Check for voltage to ground;

There should be 0 V with lhe

pedal pressed and battery

voltage with the pedal

released.

. Faulty brake pedal position

switch. An open in the wire. Open in cruise control main

swrtcn. Blown No. 4 (10 A)fuse in the

under/dash fuse/relav box

3BLKUnder all conditionsCheck for continuity to

grouno:

There should be continuitv

. Poor ground (G501)

. An open in the wire

BLIVORNlgnition switch ON

flr)

Check for voltage to ground:

There should be battery

vottaqe.

Blown No. 4 (10 A)fuse in the

under-dash f use/relay box

An oDen in the wire

5WHT/BLKBrake pedal pressed,

then released

Check for voltage to ground:

There should be battery

voltage with the pedal

pressed, and 0 V with thepedal released.

Blown No. 7 {15 A) fuse in the

under-hood fuse/relay box

Faulty brake pedal position

SWIICN

An oDen in the wire

4-40

Page 76 of 1139

CavityWireTest conditionTest: Desired resultPossible cause il result is not obtained

6GRYiREDSet button pushedCheck for voltage to ground:

There should be battery

voltage,

When testing terminal No.6,

there should be no voltage on

terminal No. 7.

Blown No.7 (15 A)fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume/cancel

swrtch

Faulty cable reel

An open in the wire

Shon to ground (horn sounds

when button is pressed)

7LT GRN/

BLK

Resume button

pusneo

Check for voltage to ground:

There should be battery

voltage.

When testing terminal No.7,

there should be no voltage on

terminal No. 6.

BRNConnect battery

power to the BRN

terminal and ground

to the BRNIVEL

termrnal

Check the operation of the

actuator motor: You should

be able to hear the motor.

. Faulty actuator. An open in the wire11BRNI/EL

10B LUIVE Llgnition switch ON

0r)

Attach to groundi

Cruise indicator light in the

gauge assembly should come

on.

Blown No. 10 (7.5 A) fuse in

the under-dash fuse/relay box

Blown cruise indicator bulfl

Faulty gauge assembly

An open in the wire

12BLU/VVHTlgnition switch ON

(ll) and main switch

ON; raise the front of

the vehicle, and

rotate one wheel

slowly while holding

the other wheel

Check for voltage between

thE BLU/VVHT (+) ANd BLK

( )terminals:

Thereshouldbe0 5Vor

more repeatedly.

Faulty VSS

An open in the wire

Short to ground

13LT GRNlgnition switch oN

{ll) and main switch

ON

Check for voltage to ground:

There should be battery

voltage.

Blown No. 4 (10 A)fuse in the

under-dash fuse/relay box

Faulty main switch

An oDen in the wire

14LT BLUClutch pedal

reteaseo

Check for continuity to

grouno:

There should be continuity.

NOTE:There should be no

continuity when the clutch

oedal is Dressed.

Faulty clutch pedal position

swtlcn

Poor ground (G501)

Incorrect clutch switch

adjustment

An open in the wire

lf any test indicates a problem, find and correct the cause, then recheck the system. lf all the input tests prove OK,

the cruise control unit may be faulty. Substitute a known-good cruise control unit and retest. lf the system works

properly, replace the cruise control unit.

4-41

Page 77 of 1139

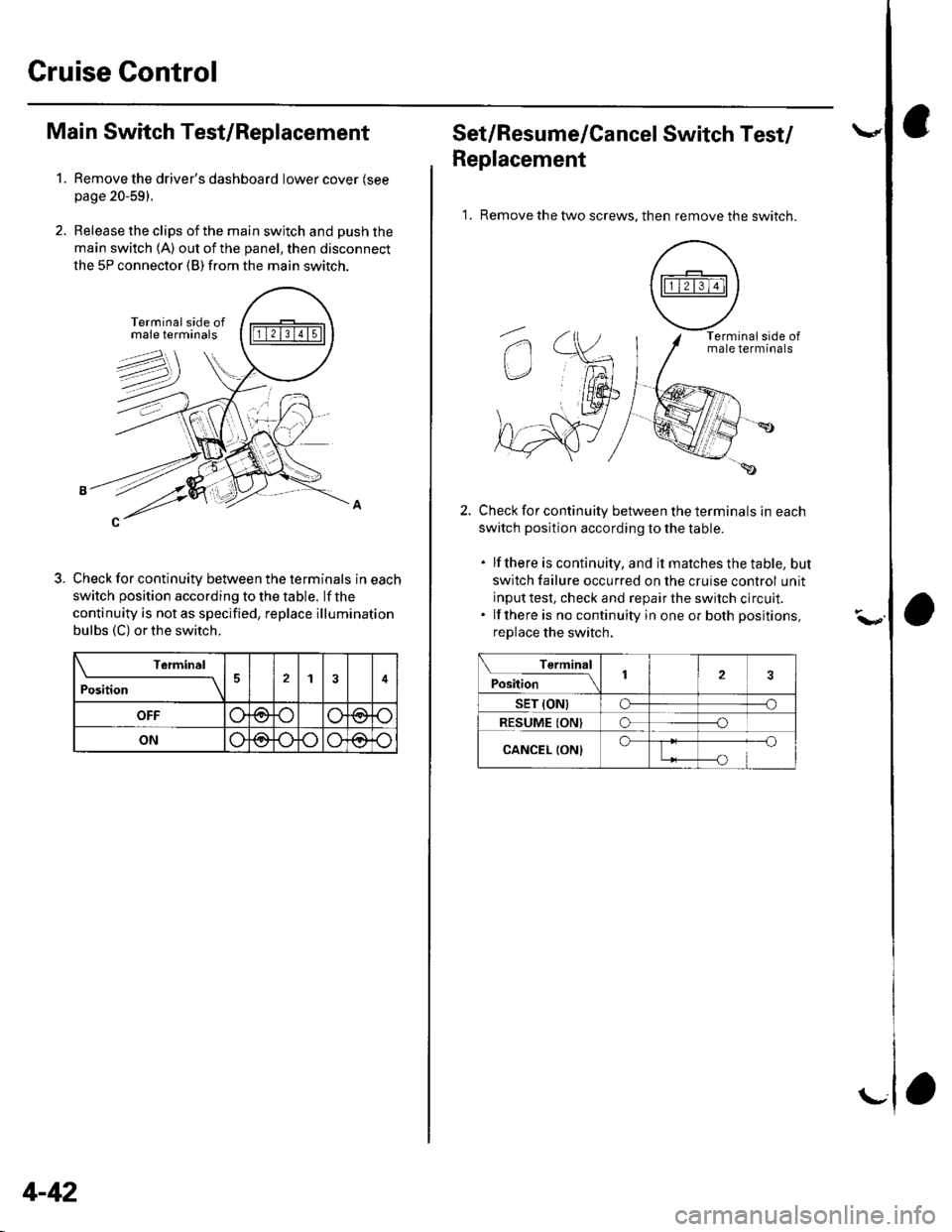

Cruise Control

1.

Main Switch Test/Replacement

Remove the driver's dashboard lower cover (see

page 20-59).

Release the clips of the main switch and push the

main switch 1A) out of the panel, then disconnect

the 5P connector (B) from the main switch.

Check for continuity between the terminals in each

switch position according to the table. lf the

continuity is not as specified, replace illumination

bulbs (C) or the switch.

\-------11v1

Position14

OFF(9@

ONo@o\Jo

4-42

r\--

Set/Resume/Cancel Switch Test/

Replacement

1. Remove the two screws. then remove the switch.

Check for continuity between the terminals in each

switch position according to the table.

. lfthere is continuity, and it matches the table, but

switch failure occurred on the cruise control unit

input test, check and repair the switch circult.. lf there is no continuity in one or both positions,

replace the switch.

Terminal

;"itl* '\2

sET (ONtCF--o

RESUME ION)o--o

CANCEL {ON}o

Page 80 of 1139

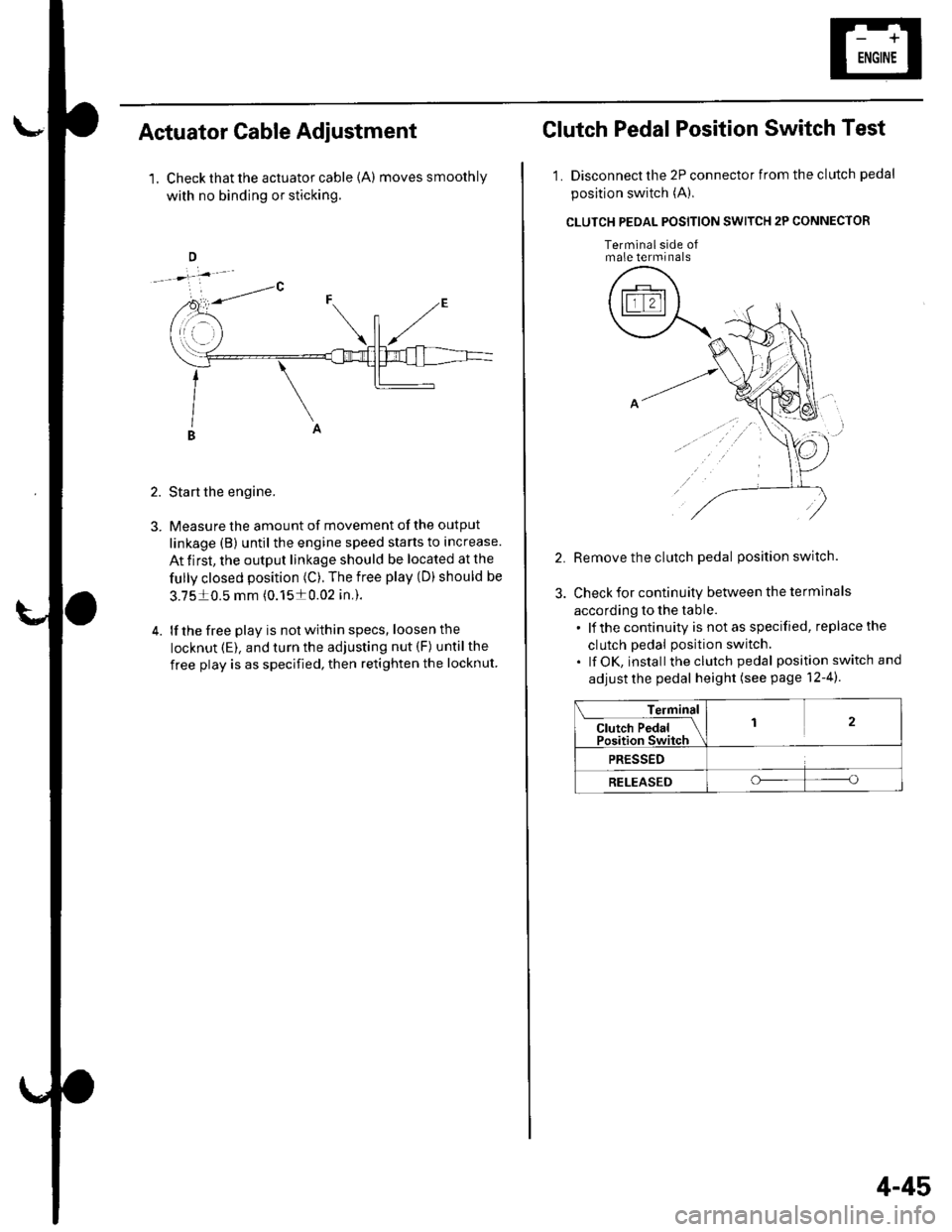

Actuator Cable Adiustment

1. Check that the actuator cable {A) moves smoothly

with no binding or sticking.

2. Start the engine.

3. Measure the amount of movement of the output

linkage (B) until the engine speed starts to increase.

At first, the output linkage should be located at the

fully closed position (C). The free play (D) should be

3.7510.5 mm (0.1510.02 in,).

4. lf the free play is not within specs, loosenthe

locknut (E). and turn the adjusting nut (F) untilthe

free play is as specified, then retighten the locknut

Clutch Pedal Position Switch Test

1. Disconnect the 2P connector from the clutch pedal

position switch (A),

CLUTCH PEOAL POSITION SWITCH 2P CONNECTOR

Terminalside ofmale terminals

Remove the clutch pedal position switch.

Check for continuity between the terminals

according to the table.. lf the continuity is not as specified, replace the

clutch pedal position switch.. lf OK, install theclutch pedal position switch and

adjust the pedal height (see page 12-4).

Terminal

Cl"t"h P"d"l IPosition Switch

12

PRESSED

RELEASEDoo

4-45

Page 95 of 1139

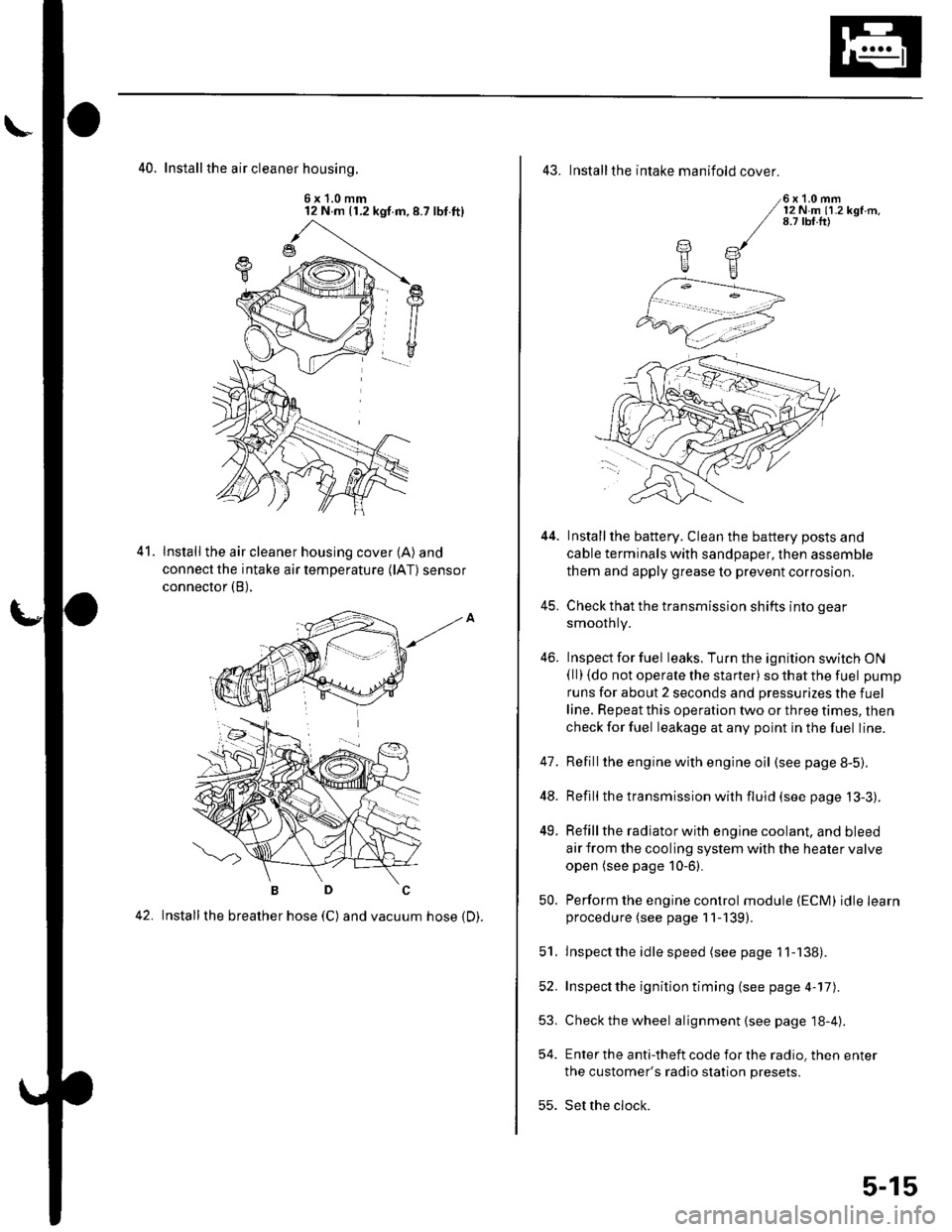

40. Install the air cleaner housinq.

6x1.0mm12 N m (1.2 kgf.m,8.7 lbt.ft)

Install the air cleaner housing cover (A) and

connect the intake air temperature (lAT) sensor

connector (B),

42. Installthe breather hose (C) and vacuum hose 1D).

41.

43. Installthe intake manifold cover.

6x1.0mm12Nm11.2kgf.m.8.7 tbf.ft)

Installthe battery. Clean the battery posts and

cable terminals with sandpaper, then assemble

them and apply grease to prevent corrosion.

Check that the transmission shifts into gear

smoothly.

Inspect for fuel leaks. Turn the ignition switch ON(ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refillthe engine with engine oil (see page 8-5).

Refill the transmission with fluid (see page 13-3).

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

Perform the engine control module (ECM) idle learnprocedure (see page 11-139).

Inspect the idle speed (see page 1 1-138).

Inspect the ignition timing (see page 4-17).

Check the wheel alignment {see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

YE

44.

41.

]tE

46.

48.

49.

52.

53.

54.

50.

51.

55.

5-15

Page 101 of 1139

Cylinder Head

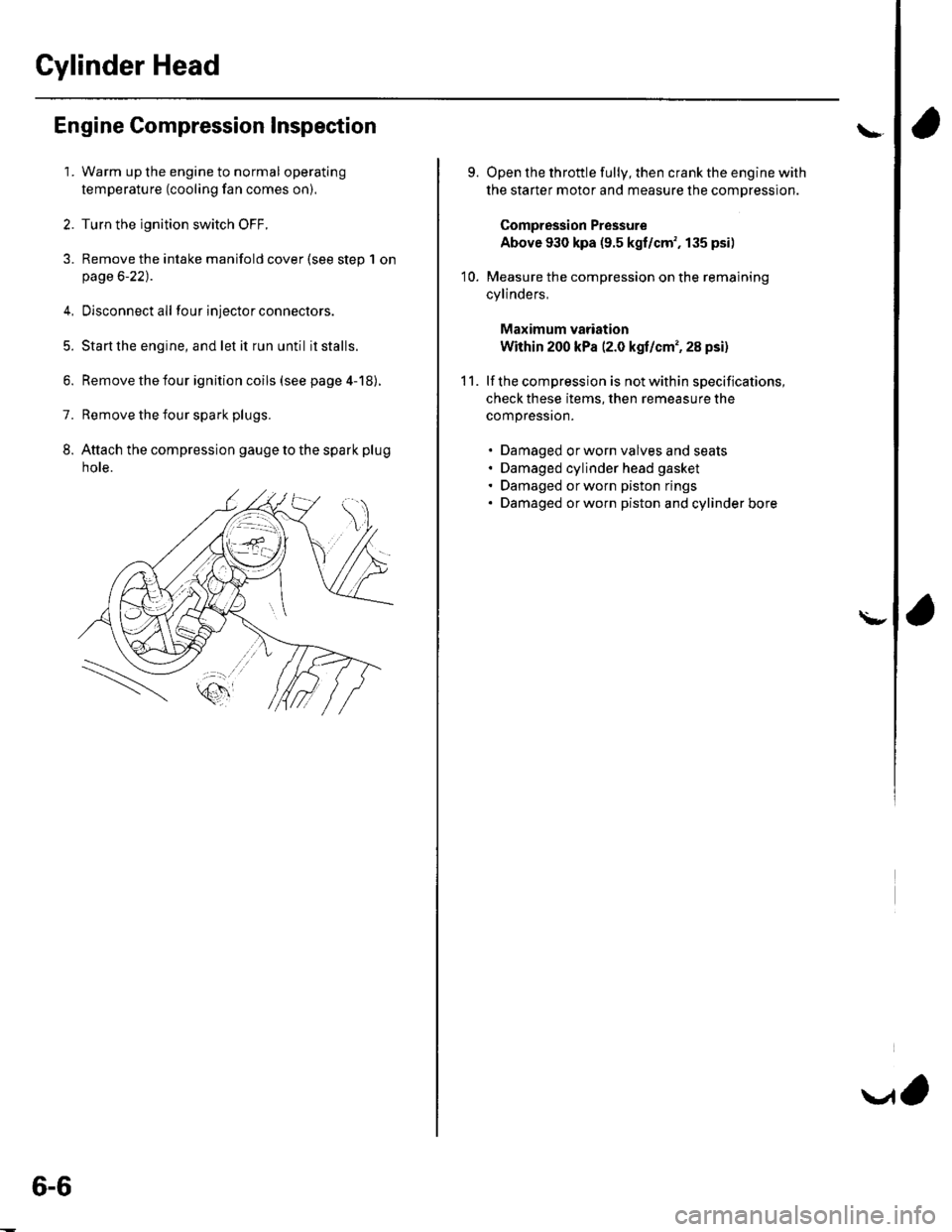

Engine Compression Inspection

1. Warm up the engine to normal operating

temperature (cooling fan comes on).

2. Turn the ignition switch OFF.

3. Remove the intake manifold cover (see step 1 onpage 6-22).

4, Disconnect all four injector connectors.

5. Start the engine, and let it run until it stalls.

6. Remove the iour ignition coils (see page 4-18).

7. Remove the four spark plugs.

8. Attach the compression gauge to the spark plug

note.

6-6

V,

\

9.

10.

Open the throttle fully, then crank the engine with

the starter motor and measure the compression.

Compression Pressure

Above 930 kpa (9.5 kgf/cm', 135 psi)

Measure the compression on the remaining

cylinders,

Maximum vadation

Within 200 kPa (2.0 kgf/cm', 28 psi)

lf the compression is not within specifications,

check these items, then remeasure the

compressron.

. Damaged orworn valves and seats. Damaged cylinder head gasket. Damaged or worn piston rings. Damaged orworn piston and cylinder bore

11.

\-

Page 136 of 1139

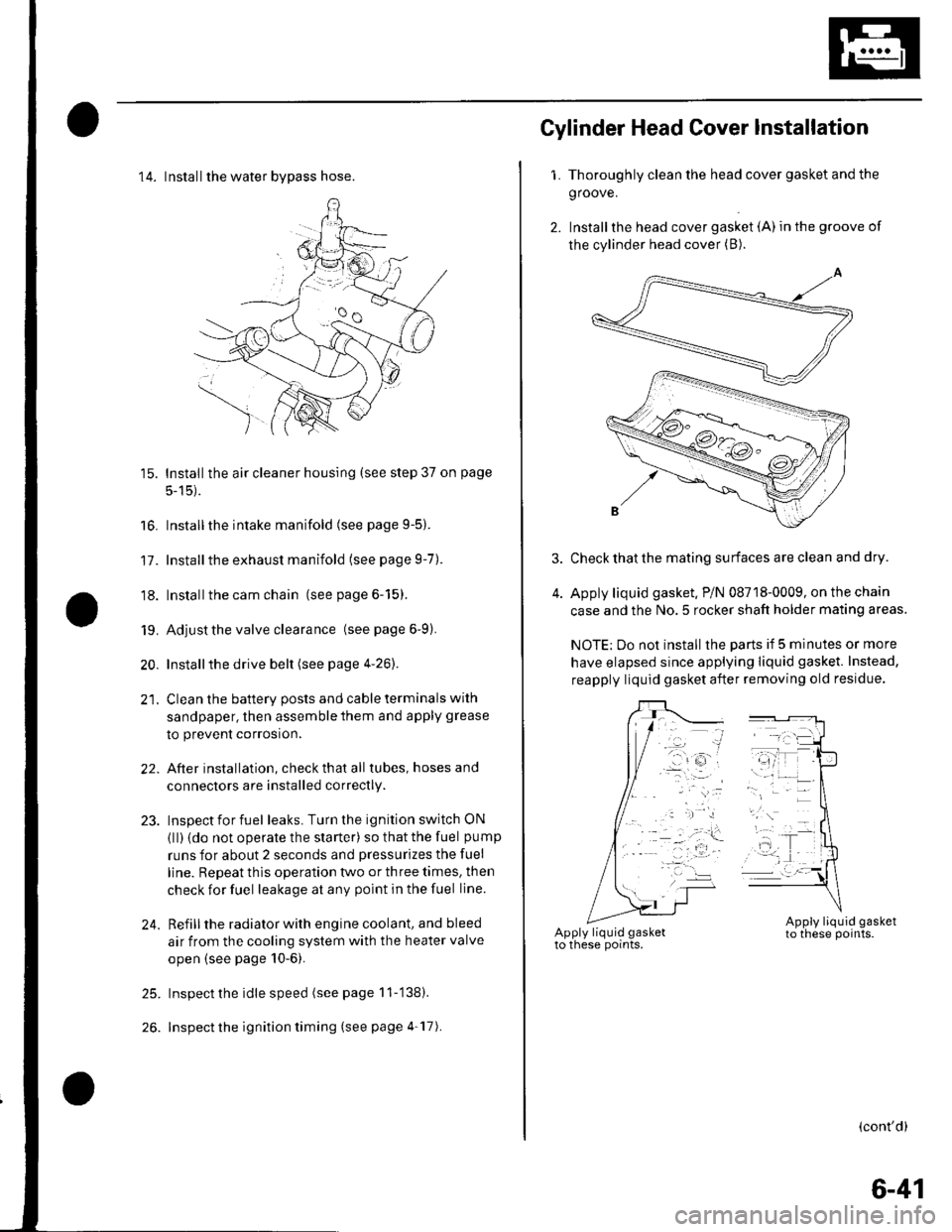

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 169 of 1139

![HONDA CIVIC 2003 7.G User Guide Component Location Index

OIL PUMPCHAIN TENSIONER

DRAIN BOLT

OIL PANRemoval, page 7 11Installataon, page 7-27

OIL PUMPOverhaLrl, page 8-8

HL]

BAFFLE PLATE

OIL FILTER FEED PIPEReplacement, page 8-7

OIL HONDA CIVIC 2003 7.G User Guide Component Location Index

OIL PUMPCHAIN TENSIONER

DRAIN BOLT

OIL PANRemoval, page 7 11Installataon, page 7-27

OIL PUMPOverhaLrl, page 8-8

HL]

BAFFLE PLATE

OIL FILTER FEED PIPEReplacement, page 8-7

OIL](/img/13/5744/w960_5744-168.png)

Component Location Index

OIL PUMPCHAIN TENSIONER

DRAIN BOLT

OIL PANRemoval, page 7 11Installataon, page 7-27

OIL PUMPOverhaLrl, page 8-8

HL]

BAFFLE PLATE

OIL FILTER FEED PIPEReplacement, page 8-7

OIL FILTERReplacement, page 8-6

OIL CONTROLORIFICE

WASHER

OIL PRESSURE SWITCHSwitch Test, page 8 4Oil Pressure test, page 8'4Replacement, page 8 16

-&\JrI

--t N\ksrarr lN-?cKEr dczt$)

#1

\OIL PUMPCHAIN GUIDE

8-3

Page 170 of 1139

Engine Lubrication

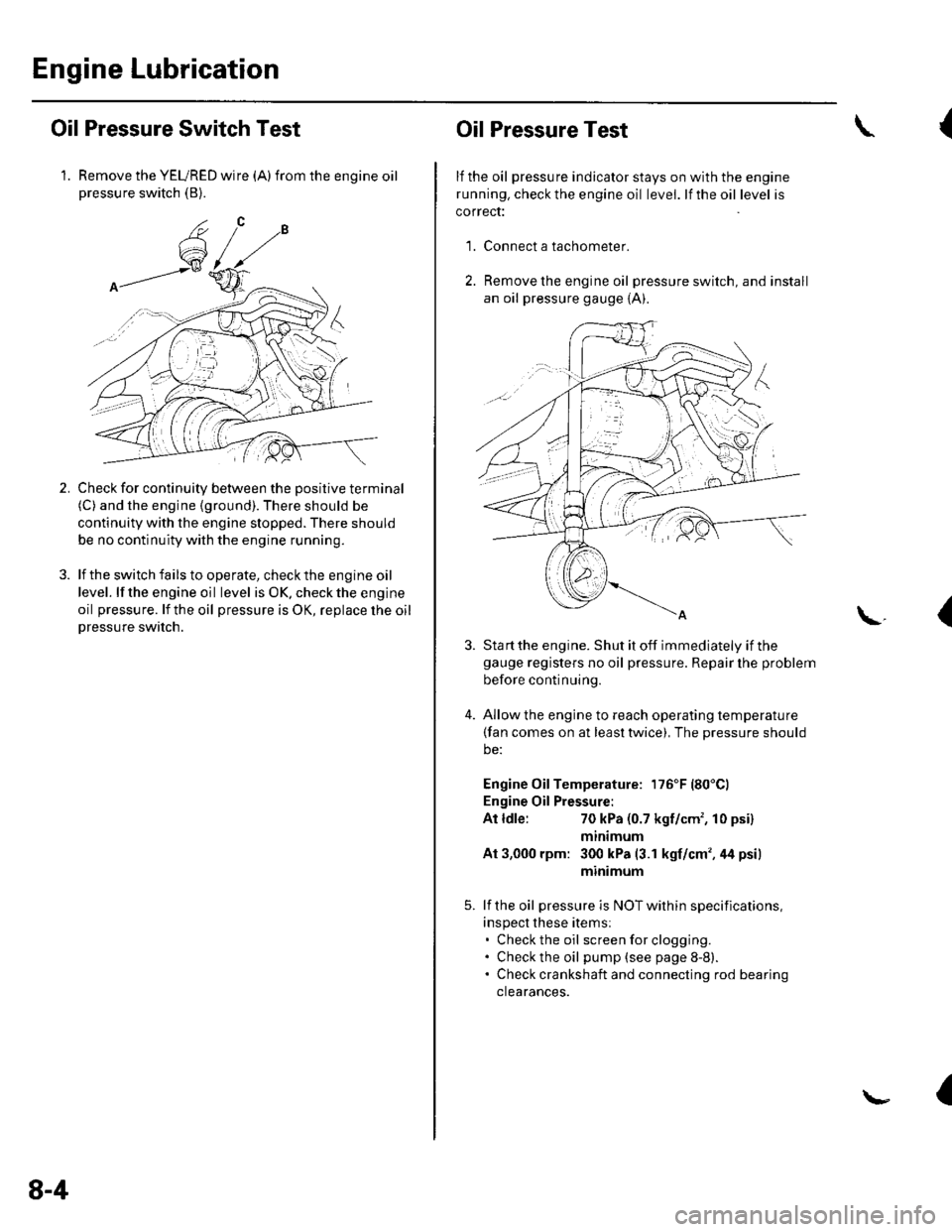

Oil Pressure Switch Test

1. Remove the YEURED wire (A)from the engine oilpressure switch (B).

Check for continuity between the positive terminal(C) and the engine (ground). There should be

continuity with the engine stopped. There should

be no continuity with the engine running.

lf the switch fails to operate, check the engine oil

level. lf the engine oil level is OK. check the engine

oil pressure. lf the oil pressure is OK, replace lhe oil

Dressure switch.

2.

8-4

Oil Pressure Test

lf the oil pressure indicator stays on with the engine

running. check the engine oil level. lf the oil level is

correct:

Connect a tachometer.

Remove the engine oil pressure switch, and install

an oil pressure gauge {A).

{

'1.

\.(

4.

Sta rt the engine. Shut it off immediately if thegauge registers no oil pressure. Repair lhe problem

before continuing.

Allow the engine to reach operating temperature(fan comes on at least twice), The pressure should

be:

Engine Oil Temperature: 176'F (80'Cl

Engine Oil Pressure:

At ldle:70 kPa (0.7 kgf/cm', 10 psi)

mtntmum

At 3,000 rpm: 300 kPa (3.1 kgf/cm',44 psi)

minimum

lf the oil pressure is NOT within specifications,

inspect these items:. Check the oil screenforclogging.. Check the oil pump (see page 8-8).. Check crankshaft and connecting rod bearing

clearances.

I