tie rod HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 552 of 1139

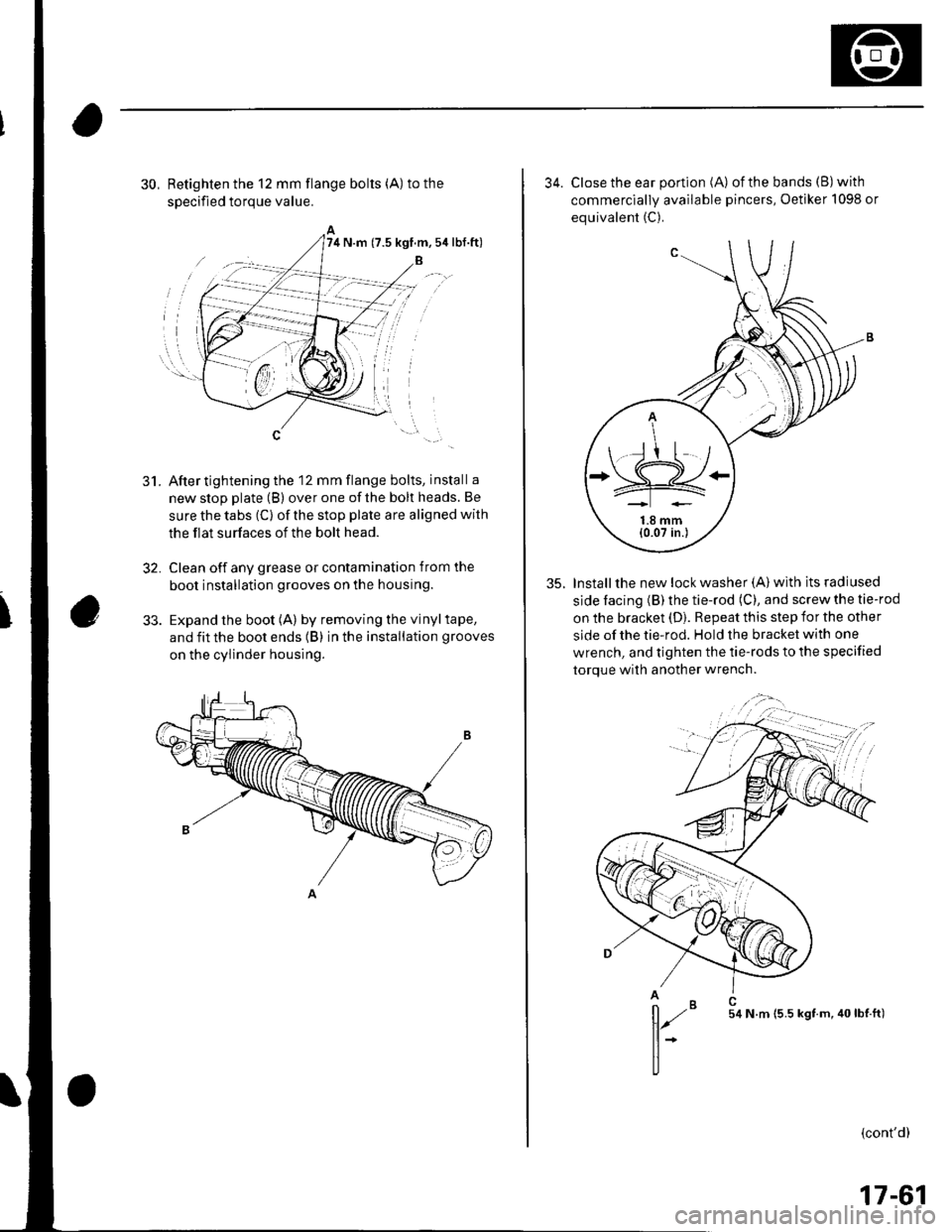

30, Retighten the 12 mm flange bolts (A) to the

soecified toroue value.

After tightening the 12 mm flange bolts, install a

new stop plate (B) over one of the bolt heads. Be

sure the tabs (C) of the stop plate are aligned with

the flat surfaces of the bolt head.

Clean off any grease or contamination from the

boot installation grooves on the housing.

Expand the boot (A) by removing the vinyltape,

and fit the boot ends (B) in the installation grooves

on the cylinder housing.

5t.

32,

74 N.m (7.5 kgf.m,5ir lbf.ft)

34. Close the ear portion (A) ofthe bands (B)with

commerciallv available pincers, Oetiker 1098 or

equivalent (C).

35. Installthe new lock washer (A) with its radiused

side facing (B) the tie-rod (C), and screw the tie-rod

on the bracket (D). Repeat this step for the other

side of the tie-rod. Hold the bracket with one

wrench, and tighten the tie-rods to the specified

torque with another wrench.

,,";=-...,.,

(cont'd)

*=,,',

17-61

Page 554 of 1139

Steering Gearbox Installation

2.

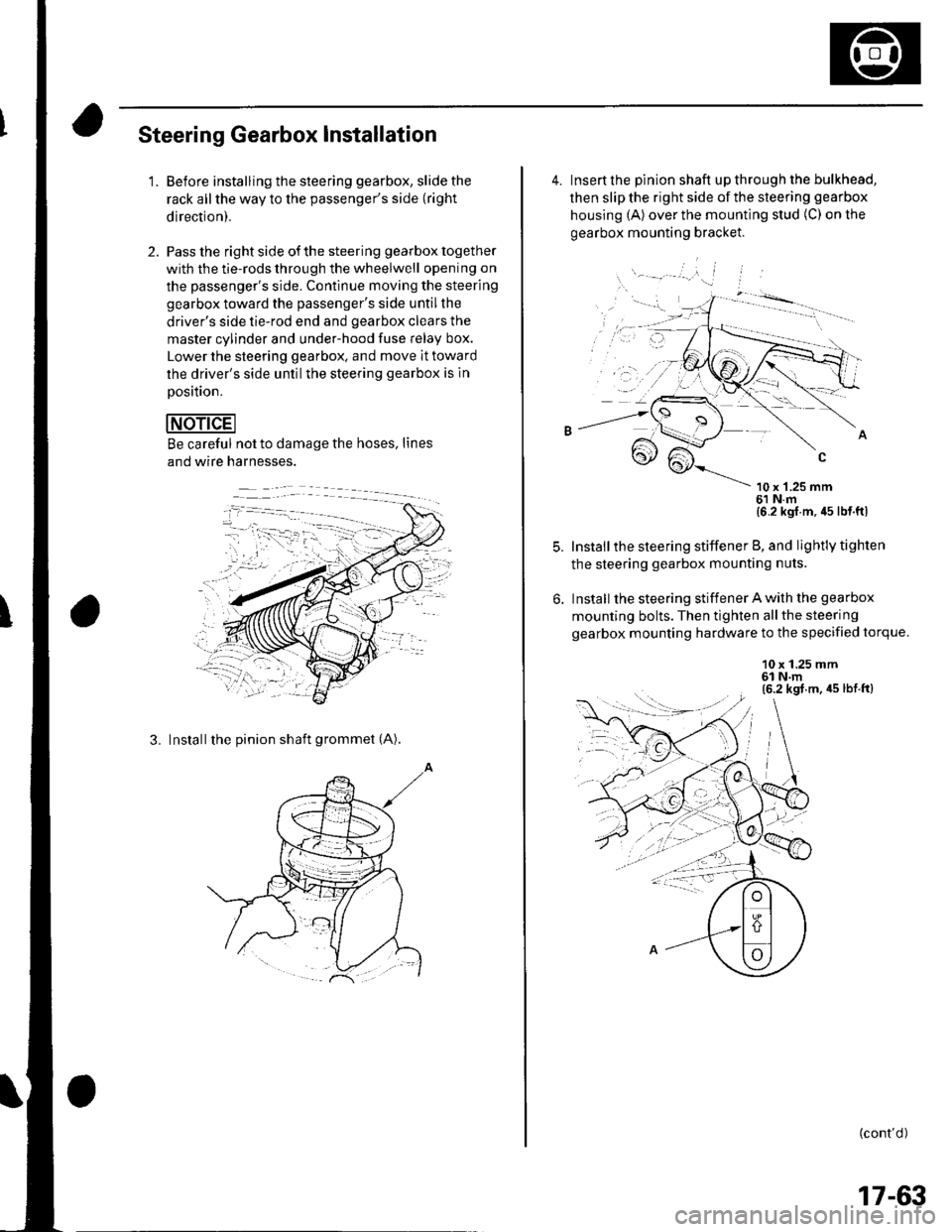

'1.Before installing the steering gearbox, slide the

rack all the way to the passenger's side (right

direction).

Pass the right side of the steering gearbox together

with the tie-rods through the wheelwell opening on

the passenger's side. Continue moving the steering

gearbox toward the passenger's side untilthe

driver's side tie-rod end and gearbox clears the

master cylinder and under-hood fuse Ielay box.

Lower the steering gearbox. and move it toward

the driver's side untilthe steering gearbox is ln

Dosition.

Be careful not to damage the hoses, lines

and wire harnesses.

3. Installthe pinion shaft grommet (A).

4. Insert the pinion shaft up through the bulkhead,

then slip the right side of the steering gearbox

housing (A) over the mounting stud (C) on the

gearbox mounting bracket.

\- --' '.'', i

10 x '1.25 mm61 N.m{6 2 kgl m, 45 lb{ ftl

Install the steering stiffener B, and lightly tighten

the steering gearbox mounting nuts.

Install the steering stiffener A with the gearbox

mounting bolts. Then tighten allthe steering

gearbox mounting hardware to the specified torque.

10 x 1.25 mm6l N.m(6.2 kgt.m, 45 lbt.ft)

: --.-{..

(cont'd )

:-1....

17-63

Page 556 of 1139

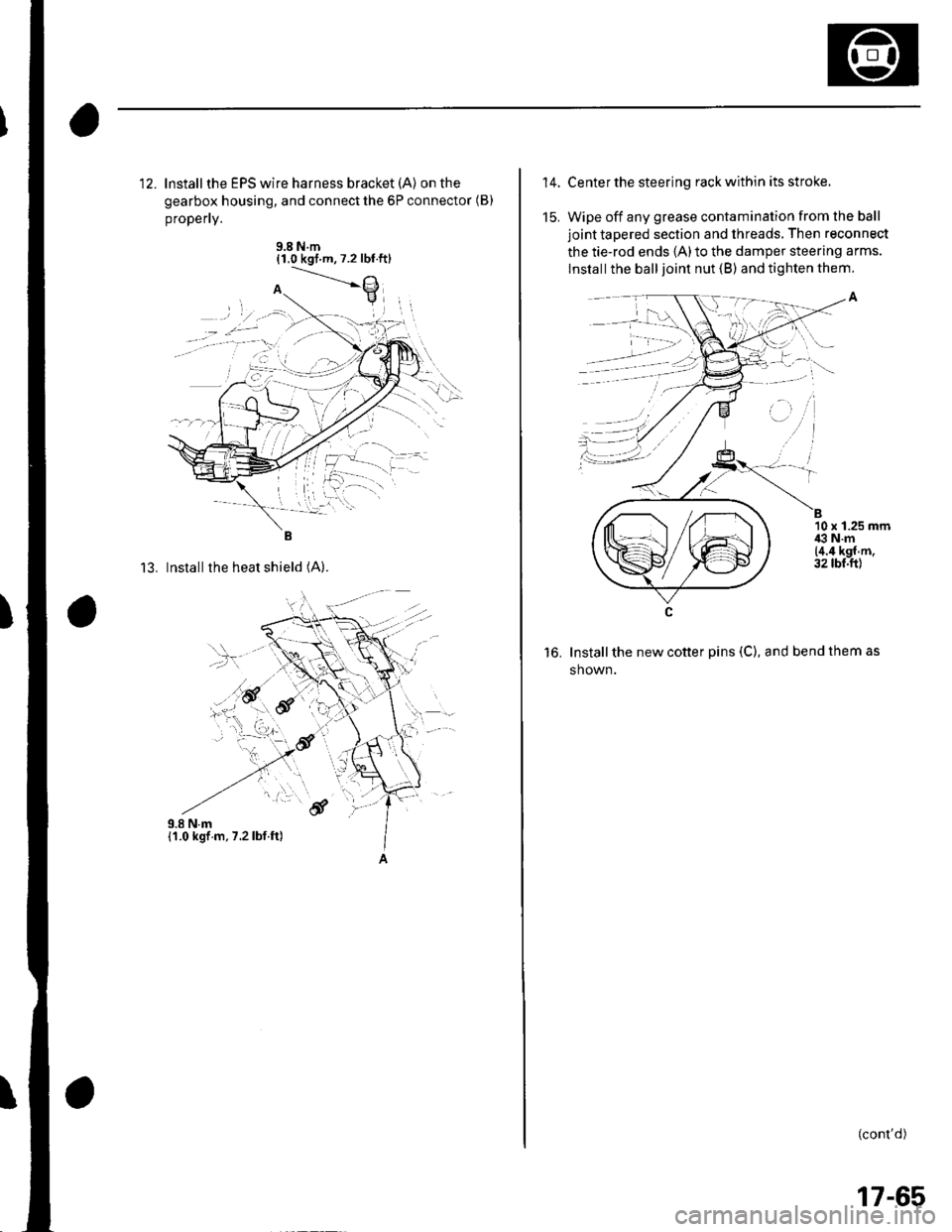

12. lnstallthe EPS wire harness bracket (A) on the

gearbox housing, and connect the 6P connector (B)

propefly.

9.8 N.m{1.0 kgt m,7.2 lbt.ftl

13. Installthe heat shield (A).

,.!,..''6f

14.

15.

Center the steering rack within its stroke.

Wipe off any grease contamination from lhe ball

joint tapered section and threads. Then reconnect

the tie-rod ends 1A)to the damper steering arms.

lnstall the ball joint nut (B) and tighten them.

Install the new cotter pins (C), and bend them as

shown.

(cont'd)

B10 x 1.25 mmi€ N.m{4.4 kgf.m.32 tbt.ftl

to.

, -', ''l

:1)

17-65

Page 557 of 1139

EPS Components

4

17.

18.

Steering Gearbox Installation (cont'dl

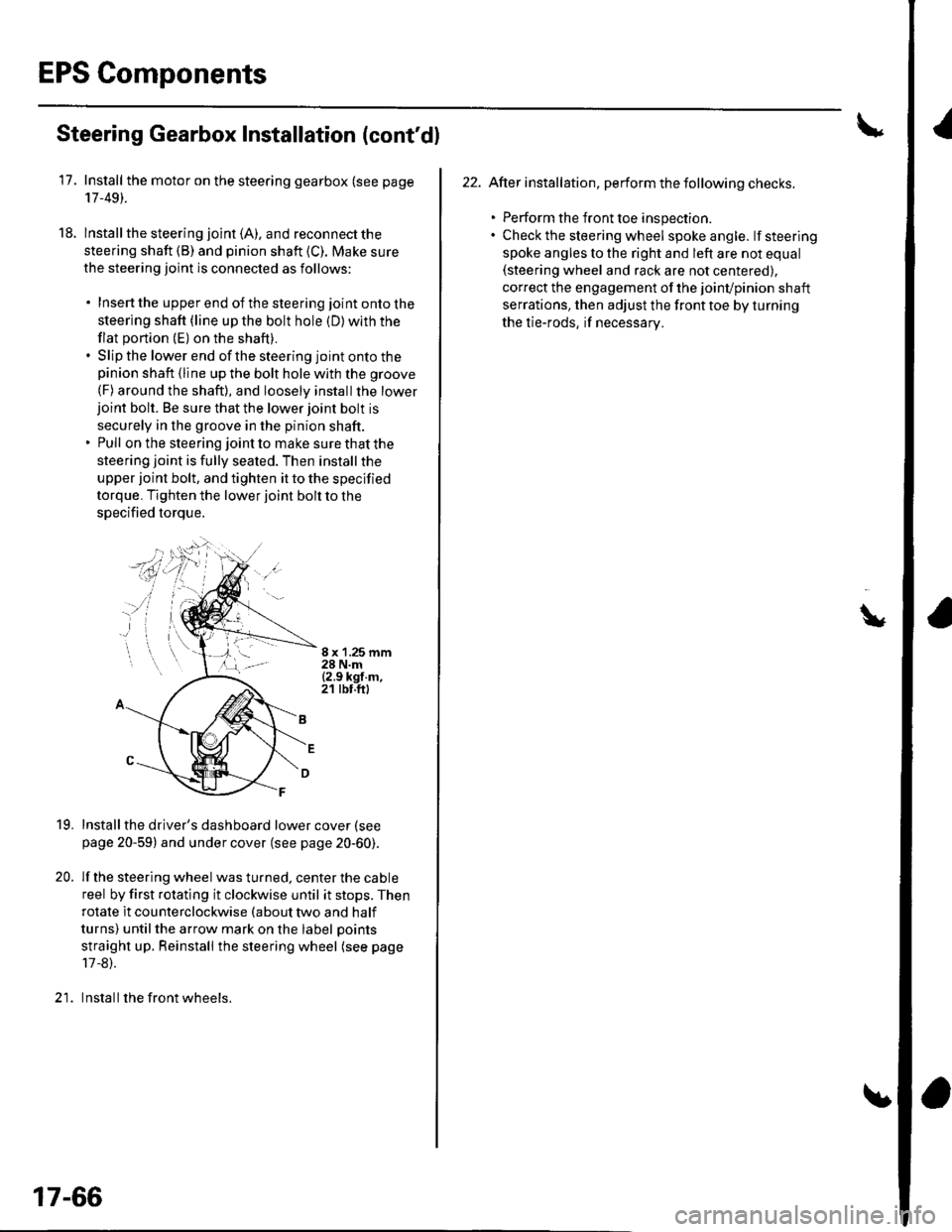

Install the motor on the steering gearbox (see page

17-49).

lnstall the steering joint (A). and reconnect the

steering shaft (B) and pinion shaft (C). Make sure

the steering joint is connected as follows:

. Insertthe upperend of thesteering jointontothe

steering shaft (line up the bolt hole (D) with the

flat portion (E) on the shaft).. Slip the lower end of the steering joint onto thepinion shaft (line up the bolt hole with the groove

(F) around the shaft), and loosely installthe lowerjoint bolt. Be sure that the lower joint bolt is

securely in the groove in the pinion shaft.. Pull on the steering joint to make sure that the

steering joint is fully seated. Then install the

upper joint bolt, and tighten it to the specified

torque. Tighten the lower joint bolt to the

specified torque.

8 x '1.25 mm28 N.m{2.9 kgf.m,21 tbt.ft)

19.

20.

Installthe driver's dashboard lower cover (see

page 20-59) and under cover (see page 20-60).

lf the steering wheel was turned, center the cable

reel by first rotating it clockwise until it stops. Then

rotate it counterclockwise (about two and half

turns) untilthe arrow mark on the label points

straight up. Reinstall the steering wheel (see page

17 -8).

Install the front wheels.)1

17-66

22. After installation, perform the following checks.

. Perform the front toe inspection.. Check the steering wheel spokeangle. lfsteering

spoke angles to the right and left are not equal(steering wheel and rack are not centered),

correct the engagement of the joinvpinion shaft

serrations, then adjust the front toe by turning

the tie-rods, if necessarv.

\

Page 558 of 1139

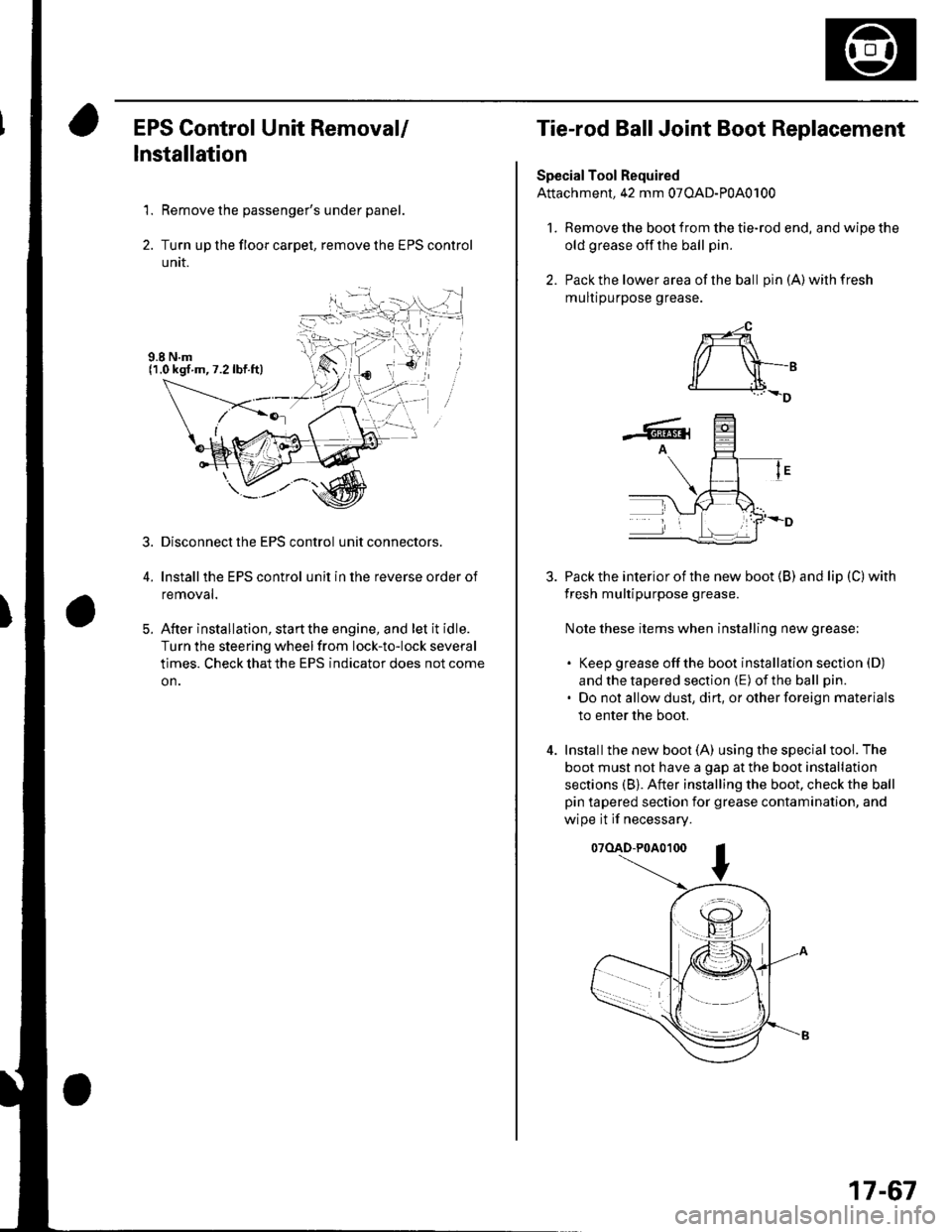

EPS Control Unit Removal/

Installation

1. Remove the passenger's under panel.

2. Turn up the floor carpel, remove lhe EPS control

untr.

Disconnect the EPS control unit connectors.

lnstallthe EPS control unit in the reverse order of

removal.

After installation, start the engine, and let it idle.

Turn the steering wheelfrom lock-to-lock several

times. Check that the EPS indicator does not come

on.

3.

E

Tie-rod Ball Joint Boot Replacement

Special Tool Required

Attachment, 42 mm 07OAD-P0A0100

l. Remove the boot from the tie-rod end, and wipe the

old grease off the ball pin.

2. Pack the lower area of the ball pin(A)wilhfresh

mulr purpose grease.

3. Pack the interior of the new boot (B) and lip (C) with

fresh multipurpose grease.

Note these items when installing new grease;

. Keep grease offthe boot installation section (D)

and the tapered section (E) of the ball pin.

. Do not allow dust, dirt, or other foreign materials

to enter the boot.

4. Installthe new boot (A) using the specialtool. The

boot must not have a gap at the boot installation

sections (B). After installing the boot. check the ball

pin tapered section for grease contamination, and

wipe it if necessary.

07(lAD-P0A0100

*-4

r/ \-,d______i.l+_D

-6rA

17-67

Page 565 of 1139

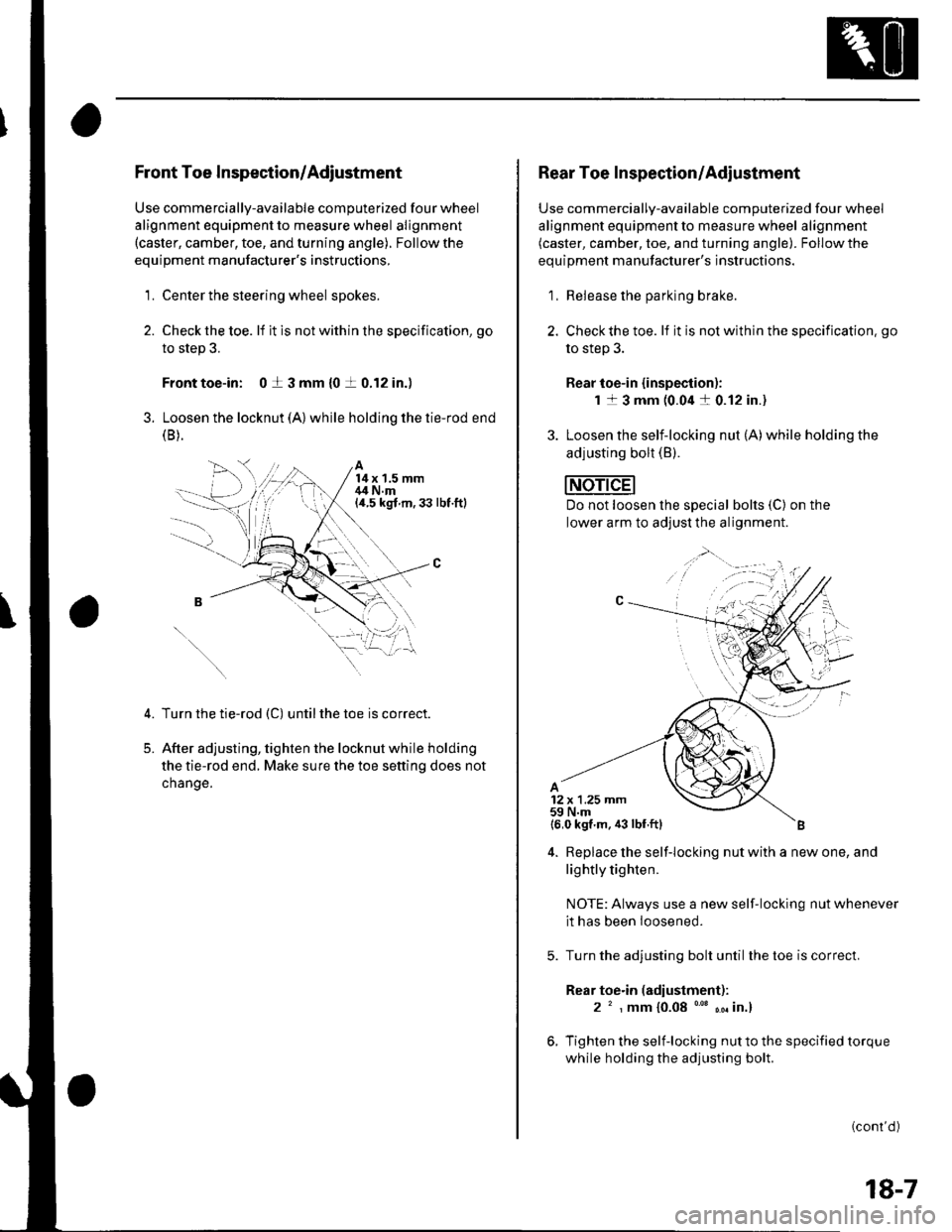

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions,

1. Center the steering wheel spokes.

2. Checkthetoe. lf it is not with in the specif ication, go

to step 3.

Front toe-in: 0 t 3 mm {0 t 0.12 in.)

3. Loosen the locknut (A) while holding the tie-rod end(B ).

A14x 1.5 mm,14 N.m(a.5 kgt m,33 lbt.ftl

5.

Turn the tie-rod (C) untilthe toe is correct.

After adjusting, tighten the locknut while holding

the tie-rod end. Make sure the toe setting does not

change.

1,;

Rear Toe Inspection/Adiustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment(caster, camber, toe, and turning angle). Follow the

equipment manufacturer's instructions.

1, Release the parking brake.

2. Checkthe toe. lf it is not within the specification. go

to step 3.

Rear toe-in {inspection):

1 1 3 mm (0.04 a 0.12 in.)

3. Loosen the self-locking nut (A)while holding the

adjusting bolt (B).

Do not loosen lhe special bolts (C) on the

lower arm to adjust the alignment.

4. Replace the self-locking nut with a new one, and

lightly tighten.

NOTE: Always use a new self-locking nut whenever

it has been loosened.

Turn the adjusting bolt until the toe is correct.

Rear toe.in (adiustment):

2 ' , mm {0.08 "' ,. in.}

Tighten the self-locking nut to the specified torque

while holding the adjusting bolt.

(cont'd )

18-7

Page 579 of 1139

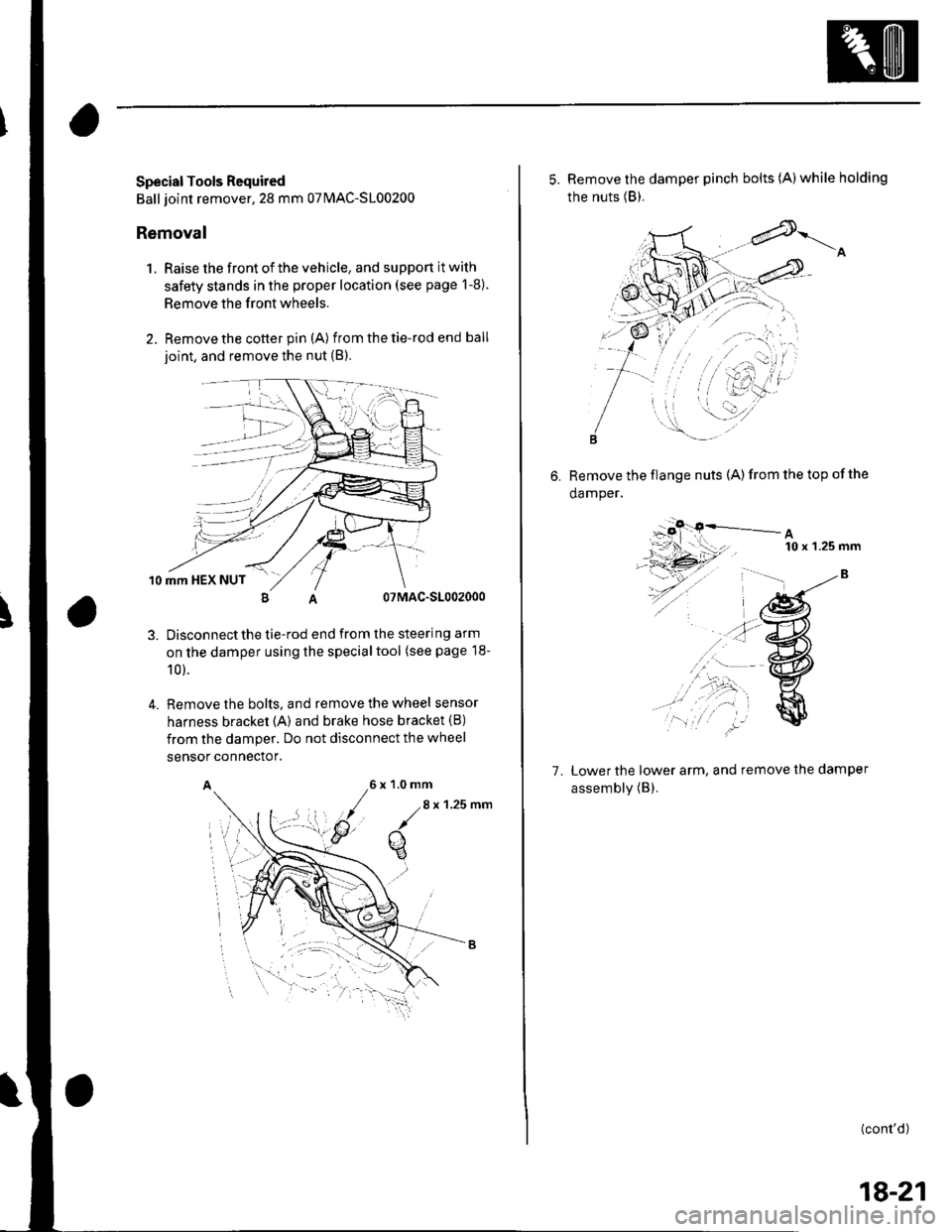

Special Tools Required

Ball joint remover,28 mm 07MAC-S100200

Removal

1. Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Remove the cotter pin (A) from the tie-rod end ball

ioint, and remove the nut (B).

10 mm HEX NUT

07MAC-S1002000

Disconnectthe tie-rod end from the steering arm

on the damper using the specialtool (see page 18-

10 ).

Remove the bolts, and remove the wheel sensor

harness bracket {A) and brake hose bracket (B)

from the damper. Do not disconnect the wheel

4.

sensor connector.

A6x1.0mm

/.8

x 1.25 nm

q

5. Remove the damper pinch bolts (A)while holding

the nuts (B).

6. Remove the flange nuts (A)from the top ofthe

damper,

A10 x 'l.25 mm

7. Lower the lower arm, and remove the damper

assembly (B).

(cont'd)

18-21

Page 583 of 1139

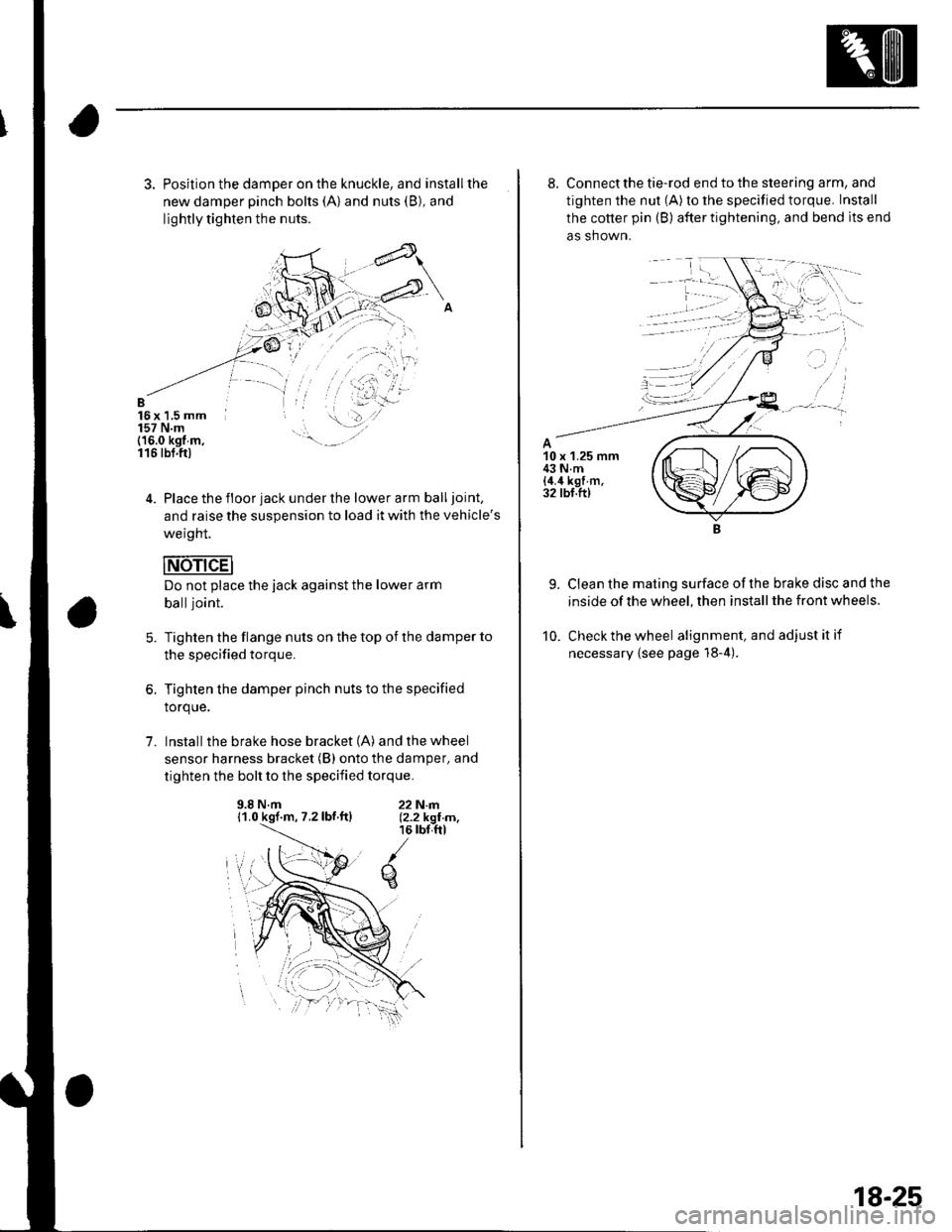

3. Position the damper on the knuckle, and installthe

new damper pinch bolts (A) and nuts (B), and

lightly tighten the nuts.

B16x 1,5 mm157 N.m(16.0 kgt m,116 tbt.ftl

4. Place the floor jack under the lower arm balljoint,

and raise the suspension to load it with the vehicle's

weight.

Do not place the jack against the lower arm

balljoint.

Tighten the flange nuts on the top of the damper to

the specified torque.

Tighten the damper pinch nuts to the specified

torque.

Install the brake hose bracket (A) and the wheel

sensor harness bracket (B) onto the damper, and

tighten the bolt to the specified torque.

5.

1.

9.8 N.m11.0 kgf.m, 7.2lbf.ftl22N|rl.12.2 kgI m,16 rbr,ftl

q

8. Connect the tie-rod end to the steering arm, and

tighten the nut (A) to the specified torque. Install

the cotter pin (B) after tightening, and bend lts end

as shown.

9. Clean the mating surface ofthe brake disc and the

inside of the wheel, then install the front wheels.

10. Check the wheel alignment, and adjustitif

necessary {see page 18-4).

18-25

Page 729 of 1139

Front Seat Cover Replacement

For some models: SRS components are located in this

area. Review the SRS component locations (see page

23 13) and the precautions and procedures (see page

23-'14) in the SRS section before performing repairs or

service,

NOTE:. Take care not to tear the seams or damage the seat

covers,. On the passenger's seat with side airbag, do not

touch the OPDS sensor in the seat-back pad, and keep

it away from oil. Oil can corrode the sensor causing it

to fail.. Put on gloves to protect your hands.

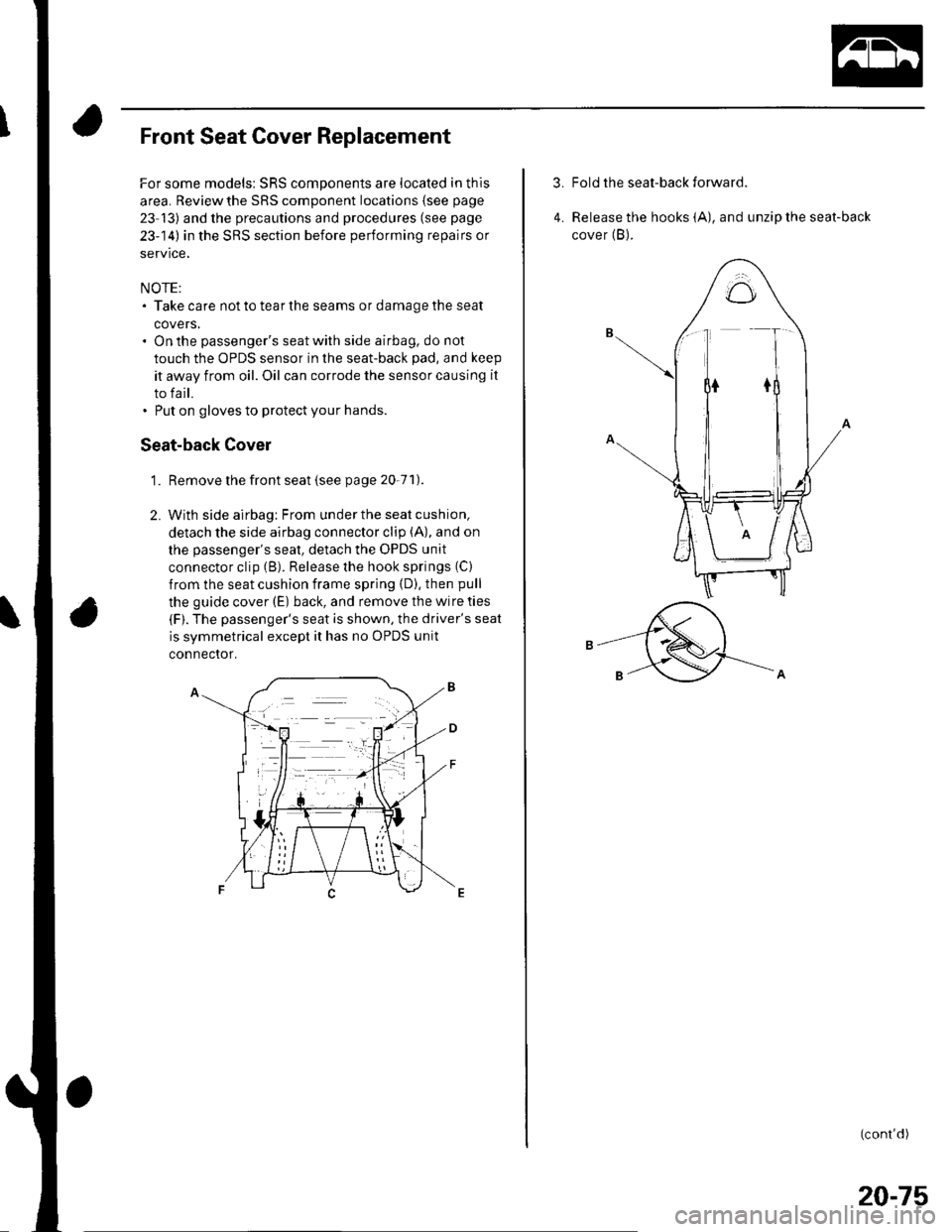

Seat-back Cover

Remove the front seat isee page 20-71).

With side airbag: From under the seat cushion,

detach the side airbag connector clip (A), and on

the passenger's seat, detach the OPDS unit

connector clip (B). Release the hook springs (C)

from the seat cushion frame spring {D), then pull

the guide cover (E) back, and remove the wire ties

(F). The passenger's seat is shown, the driver's seat

is svmmetrical except it has no OPDS unit

connector.

'L

2.

3.Fold the seat-back forward.

Release the hooks (A), and unzip the seat-back

cover (B).4.

(cont'd)

20-75

Page 1139 of 1139

SuspensionAdjustment................-............................184 VComponent Location Index................. 20-17

Windshield GlessReplacement............-..............-............. 20 19

Synchro Ring, Triple-coneInspection...............-..........................1339 ValveGuides

Synchro SleeveInspectaon/Reassemb1y ....................... 13 39

Inspection ............-.-................................ 6 32Beplacement ..........-................................ 6 33 Wiper Intermittent Control Unit,Rear WindowInput Test

T

Valve SeatsRepair ...................................................... 6 35.....22-134

WiDer Motor, Rear WindowRep1acement....................................... 22-1 46Adjustment .-.-.......Removal ...-...-......................................-... 6-31 WiDer Motor, windshield6-9

.....6-32 Test.......-..........-.....-.............................22-143Taillight

ThermostaiTest ........................

Inspec!on

Vehicle Speed Signal Circuit

VTC System

Wiper/WasheI

Wi.ing System

10 4 Troubleshooting .....-... ..........................22-65 Component Location In dex ..............22-134Replacement.....-...-....... ...................... 10 IvssThrottle BodyTest ..................Removal/lnstallation .. . . . . . .. ... 11-'165 VTC ActuatorDisassembly/Feassemb|y................-11-166 Inspection

Circuit Diagram .......................... 22-136, 131

Replacement -.............. ............ .............22 61 Wiper/Washor SwitchTesVReplacement .............................. 22-1 40

.................68 WireHarnesses

11-160

Replacement ........................................... 6 24 (Seefirstpageofthislndex)Throttle CableAdjustment ...... ...-.................... 11163 VTC Oil ConlrolSolenoid ValveRemoval/1nsta11ation..........................11164 Removal....-...-... |1-127 HowtoIn{ormation ...............................223Belay and Control UnitLocations .-....-.............. -.-.-....- 22-7, 4, 1 1, 12Beplacement.........-............................... 1767 ComponentLocationlndex.............. 11-117Tie-rod Ball Joint Boots

lnstallation

Replacement

Turn Signal/Hazard Relay

tsTiming/Cam ChainVTEC Solenoid Valve...612 Femoval/lnspection....-......................11-128................ 6 15

Timing/Cam Chain Auto-tensionelRemoval/1nsta11ation..............................6-19 W

Troubleshooting{See first page ot this Index)

Turn Signal Light

Timing/Cam Chain CaseOil SealInstallation......................-......................6,21 Washer Fluid Level SwitchTesVReplacement .............................. 22 1 44Trailing ArmsRemoval/lnstallation .............. . . . . ..... 18 33 Washer Fluid ReservoirReplacement ....................................... 22-1 46tnmComponent Location lndex ................- 20 49 Washer Motor, WindshieldRemoval/lnstallation ..-.......20 50,51,52,53 Test -..............-.............. ........................22 144

Washer Tube, WindshieldReplacement......-...-............................ 22 1 47

W.ter Outlet.........22 A4 Installation ..................-........................... '10-9

InputTest........22-87 lnstallation................ 10IWeter Passage

Wheels andTires

Turn Signal/Hazard Warning Lights Water PumpComponent Location In dex .................22 85 Inspection ........................... .. . . . ....... 10 5Circu it Diagram ................-................... 22-86 Replacement .-......................................... 10 5

U

WheelBearingsInspec|ion ....................................... ....... 18 8

Wheel Speed SensorsInspection ..-..,.,.,,.,,,,,.,.,,,...................... 19-59Replac€ment ........-....... . . . . . . .. -.... 19-59UndeFdash Fuse/R€lay BoxRemoval/lnstaf lation ............................ 22-49

Upper ArmsRemoval/|nsta11ation................. ... 18-32

],sInspect|on