battery HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 1113 of 1139

sRs

6.

SRS Indicator Circuit Troubleshooting (cont'dl

7.

Disconnect SRS unit connector C (8P) from the SRS

unit {see step 7 on page 23-22).

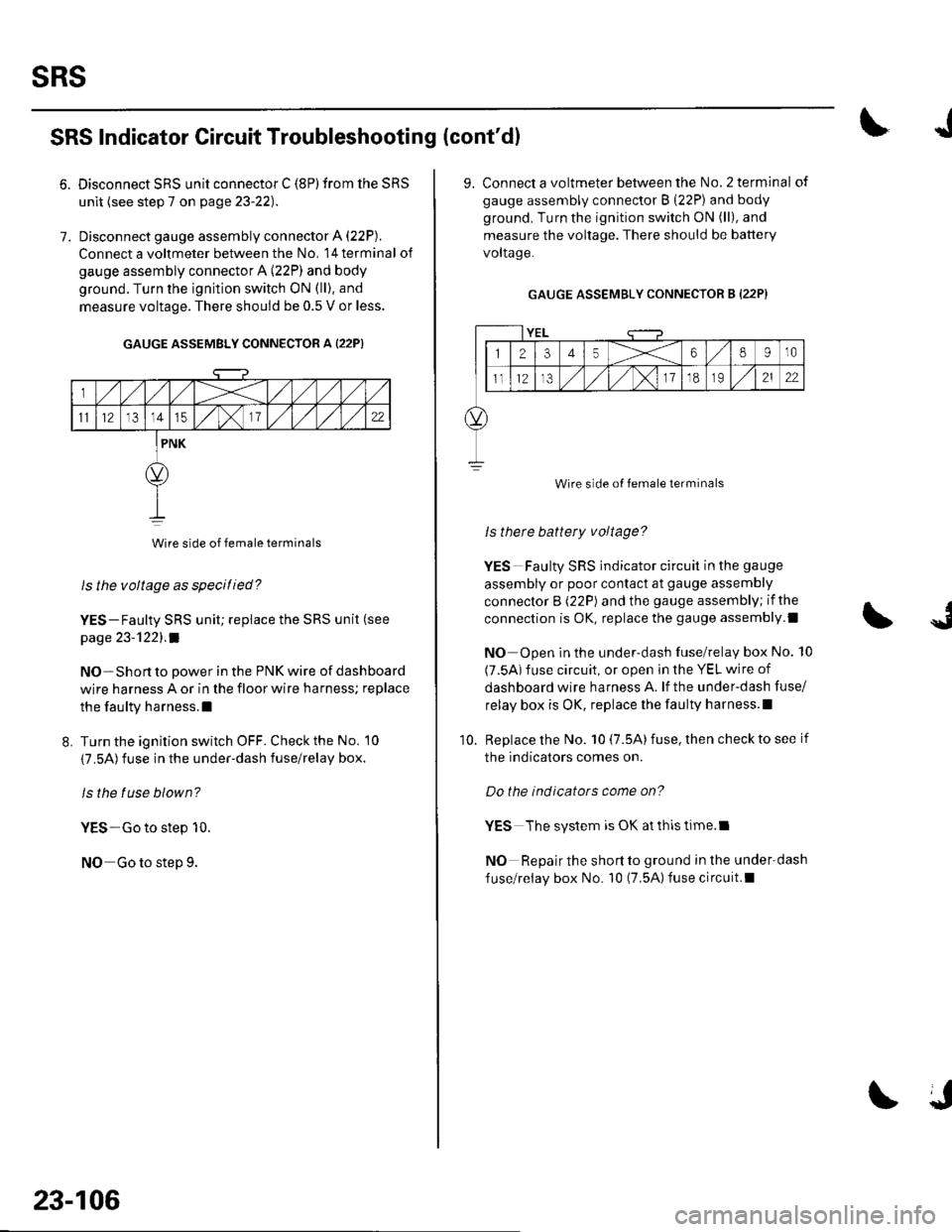

Disconnect gauge assembly connector A (22P).

Connect a voltmeter between the No, l4terminal of

gauge assembly connector A (22P) and body

ground. Turn the ignition switch ON (ll), and

measure voltage. There should be 0.5 V or less.

GAUGE ASSEMBLY CONNECTOR A {22P)

Wire side of female terminals

ls the voltage as specitied?

YES-Faulty SRS unit; replace the SRS unit (see

page 23-'l22l.a

NO-Short to power in the PNK wire of dashboard

wire harness A or in the floor wire harness; replace

the faulty harness.l

L Turn the ignition switch OFF. Check the No. 10

{7.5A)fuse in the under-dash fuse/relay box.

ls the tuse blown?

YES-Go to step 10.

NO Go to step 9.

23-106

J

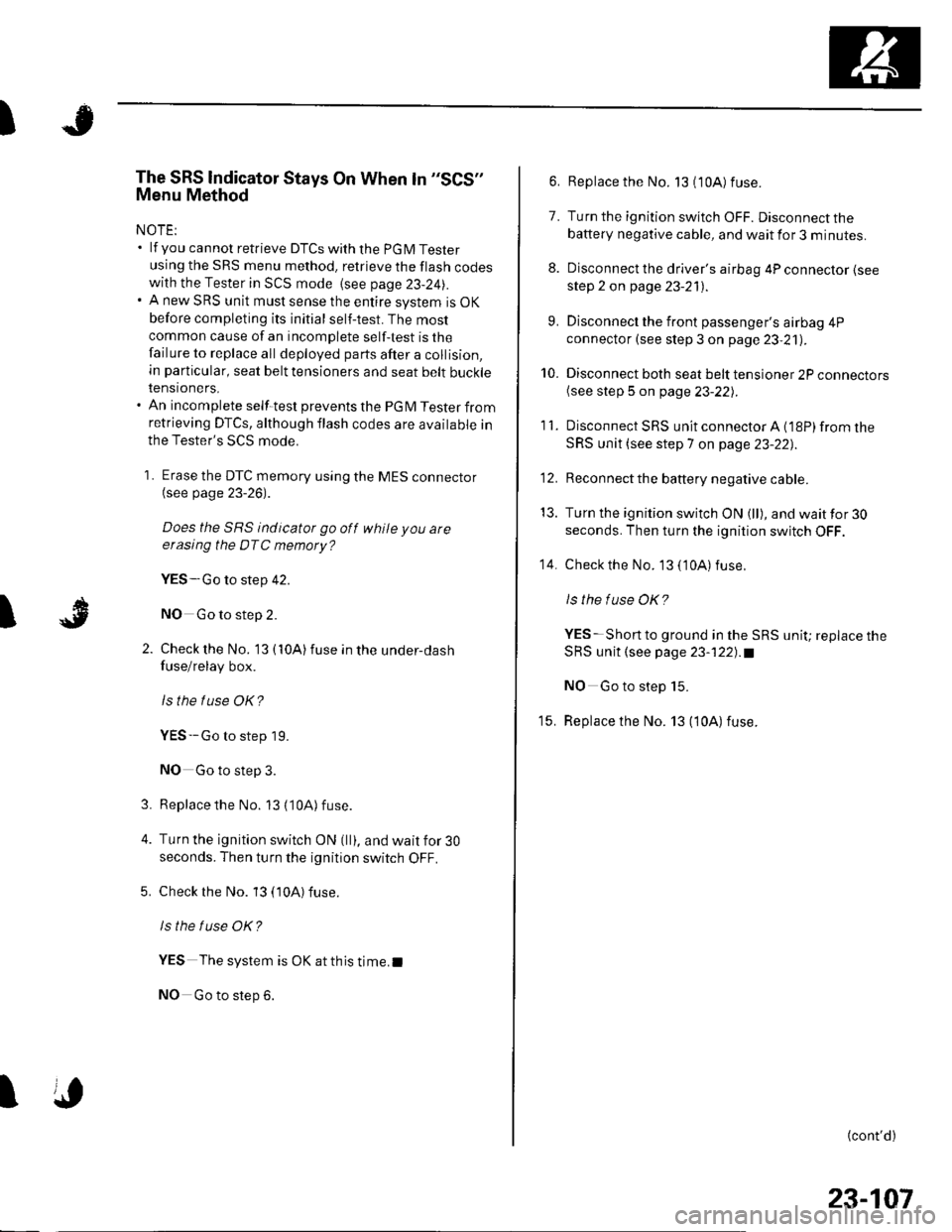

9. Connect a voltmeter between the No.2 terminal of

gauge assembly connector B (22P) and body

ground. Turn the ignition switch ON (ll), and

measure the voltage. There should be battery

voltaqe.

GAUGE ASSEMBLY CONNECTOR B (22P}

YEL

12345X68910

ll12,/ ,/,/x11o2122

Wire side of female terminals

ls therc battery voltage?

YES Faulty SRS indicator circuit in the gauge

assembly or poor contact at gauge assembly

connector B (22P) and the gauge assembly; if the

connection is OK, replace the gauge assembly.l

NO Open in the under-dash fuse/relay box No. 10

(7.5A) fuse circuit, or open in the YEL wire of

dashboard wire harness A. lf the under-dash fuse/

relay box is OK, replace lhe faulty harness.l

Replace the No. 10 (7.5A) fuse, then check to see if

the indicators comes on.

Do the indicators come on?

YES The system is OK at thls time.l

NO Repair the short to ground in the under-dash

fuse/relay box No. 10 (7.5A)fuse circuit.l

10.

Page 1114 of 1139

JI

I

The SRS lndicator Stays On When ln "SCS"

Menu Method

NOTE:. lf you cannot retrieve DTCSwith the PGM Tester

using the SRS menu method. retrieve the flash codeswith the Tester in SCS mode {see page 23-24|,.. A new SRS unit must sense the entire system is OK

before completing its initial self-test. The most

common cause of an incomplete self-test is the

failure to replace all deployed parts after a collision,

in particular, seat belt tensioners and seat belt buckletenstoners.. An incomplete self-test prevents the PGM Tester fromretrieving DTCS, although flash codes are available in

the Tester's SCS mode.

1 . Erase the DTC memory using the MES connector(see page 23-26).

Does the SRS indicator go off while you are

erasing the DTC memory?

YES-Go to step 42.

NO Go to step 2.

Check the No. '13 { 10A) fuse in the under-dash

fuse/relay box.

lsthe f use OK?

YES--Go to step 19.

NO Go to step 3.

Replacethe No. 13 (10A) fuse.

Turn the ignition switch ON (ll), and wait for 30

seconds. Then turn the ignition switch OFF.

Check rhe No. 13 (10A) fuse.

ls the f use OK?

YES The system is OK at this time.I

NO Go to step 6.

3.

I

6. Replace the No. 13 (10A) fuse.

7. Turn the ignition switch OFF. Disconnect the

battery negative cable, and wait for 3 minutes.

8. Disconnect the driver's airbag 4P connector (see

step 2 on page 23-21).

9. Disconnect the front passenger's airbag 4P

connector (see step 3 on page 23,21).

10. Disconnect both seat belt tensioner 2P connectors(see step 5 on page 23-221.

'11. DisconnectSRS unitconnectorA{18P)fromthe

SRS unit (see step 7 on page 23-22],.

'12. Reconnect the battery negative cable.

13. Turn the ignition switch ON (ll), and wait for 30

seconds. Then turn the ignition switch OFF.

14. Checkthe No. 13 ('10A) fuse.

ls the f use OK?

YES-Short to ground in the SRS unit; replace the

SRS unit (see page 23-122).a

NO Go to step 15.

15. Replace the No. 13 (10A) fuse.

{cont'd)

23-107

Page 1115 of 1139

sRs

from the under-dash fuse/relav bor.

11.

18.

SRS Indicator Circuit Troubleshooting (cont'd)

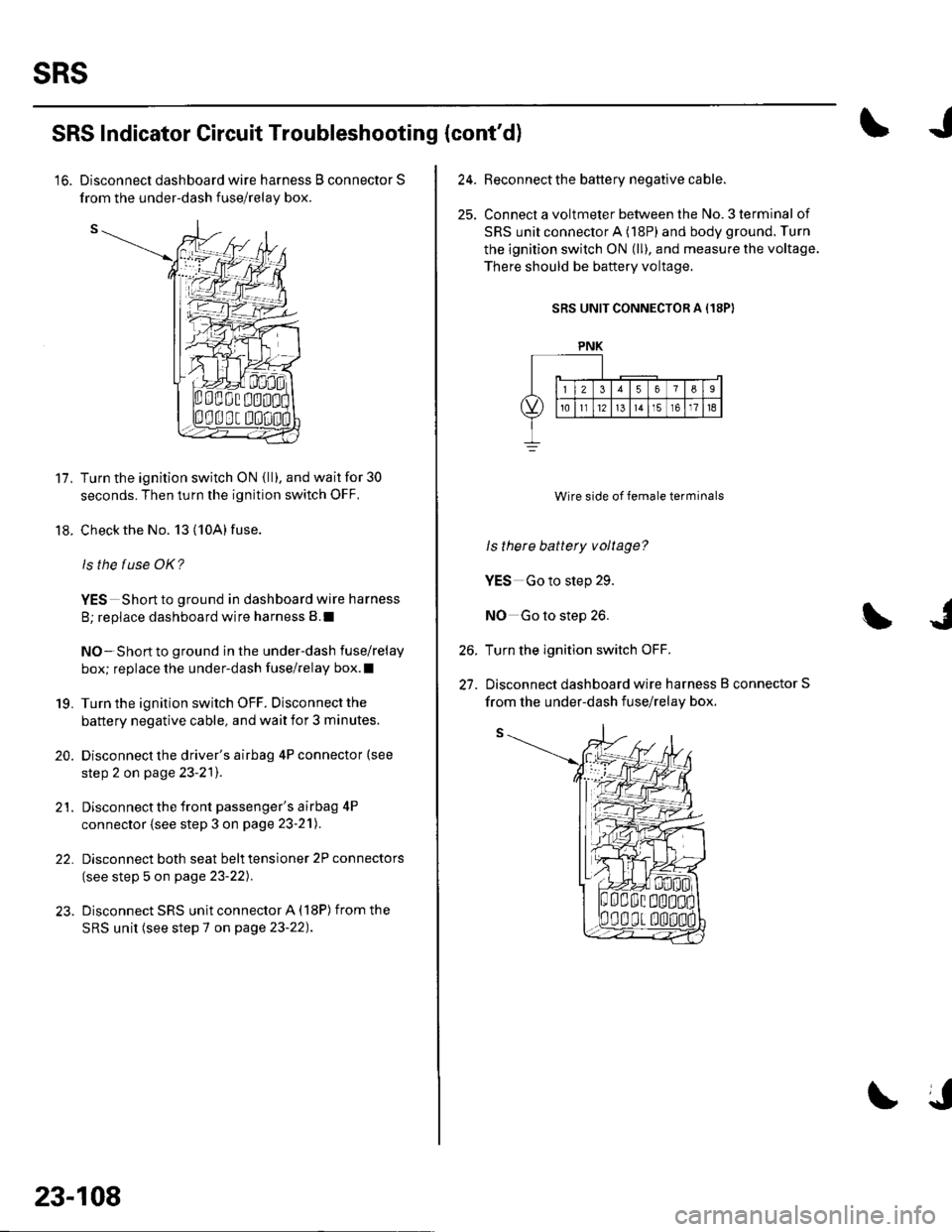

'16. Disconnect dashboard wire harness B connector S

Turn the ignition switch ON {ll), and wait for 30

seconds. Then turn the ignition switch OFF,

Check the No. 13 (10A) fuse.

ls the f use OK?

YES Short to ground in dashboard wire harness

B; replace dashboard wire harness B.I

NO-Short to ground in the under-dash fuse/relay

box; replace the under-dash fuse/relay box.l

Turn the ignition switch OFF. Disconnect the

battery negative cable, and wait for 3 minutes.

Disconnect the driver's airbag 4P connector (see

step 2 on page 23-2'l).

Disconnect the front passenger's airbag 4P

connector (see step 3 on page 23-21).

Disconnect both seat belt tensioner 2P connectors

(see step 5 on page 23-22).

Disconnect SRS unit connector A (18P) from the

SRS unit (see step 7 on page 23-22).

19.

20.

21.

22.

23-108

24.Beconnect the battery negative cable.

Connect a voltmeter between the No. 3 terminal of

SRS unit connector A (18P) and body ground. Turn

the ignition switch ON (ll), and measure the voltage.

There should be baftery voltage.

SRS UNIT CONNECTOR A (18PI

Wire side of female terminals

ls there battery voltage?

YES Go to step 29.

NO Go to step 26.

Turn the ignition switch OFF.

Disconnect dashboard wire harness B connector S

26.

27.

PNK

from the under-dash fuse/relav box.

Page 1120 of 1139

A

\'l9

Driver's Airbag Replacement

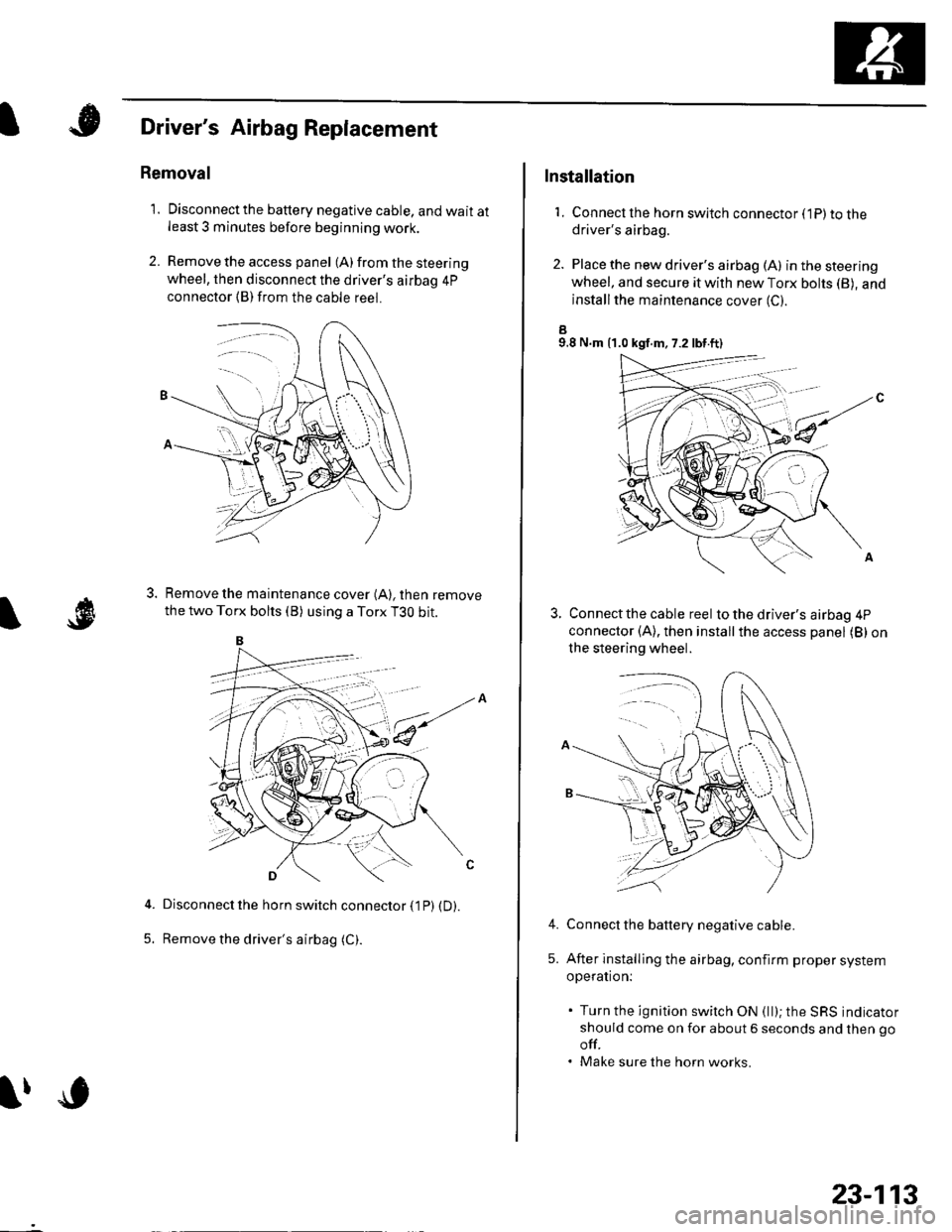

Removal

1. Disconnectthe battery negative cable, and wait atleast 3 minutes before beginning work.

2. Remove the access panel (A) from the steering

wheel, then disconnect the driver's airbag 4p

connector (B)from the cable reel.

Remove the maintenance cover (A), then remove

the two Torx bolts (B) using a Torx T3O bit.

Disconnect the horn switch connector (1P) (D).

Remove the driver's airbag (C).5.

lfc

23-113

Installation

1. Connect lhe horn switch connector (1P) to thedriver's airbag.

2. Place the new driver's airbag (A) inthesteering

wheel, and secure it with new Torx bohs (B), and

installthe maintenance cover (C).

a9.8 N.m {1.0 kgf.m, 7.2 lbt.ft)

Connect the cable reel to the driver's airbag 4P

connector (A), then installthe access panel (B) on

the steering wheel.

Connect the battery negative cable.

After installing the airbag, confirm proper system

operation:

. Turn the ignition switch ON (ll); the SRS indicator

should come on for about 6 seconds and then go

off.. Make sure the horn works.

4.

5.

Page 1121 of 1139

sRs

Front Passenger's Airbag Replacement

Removal

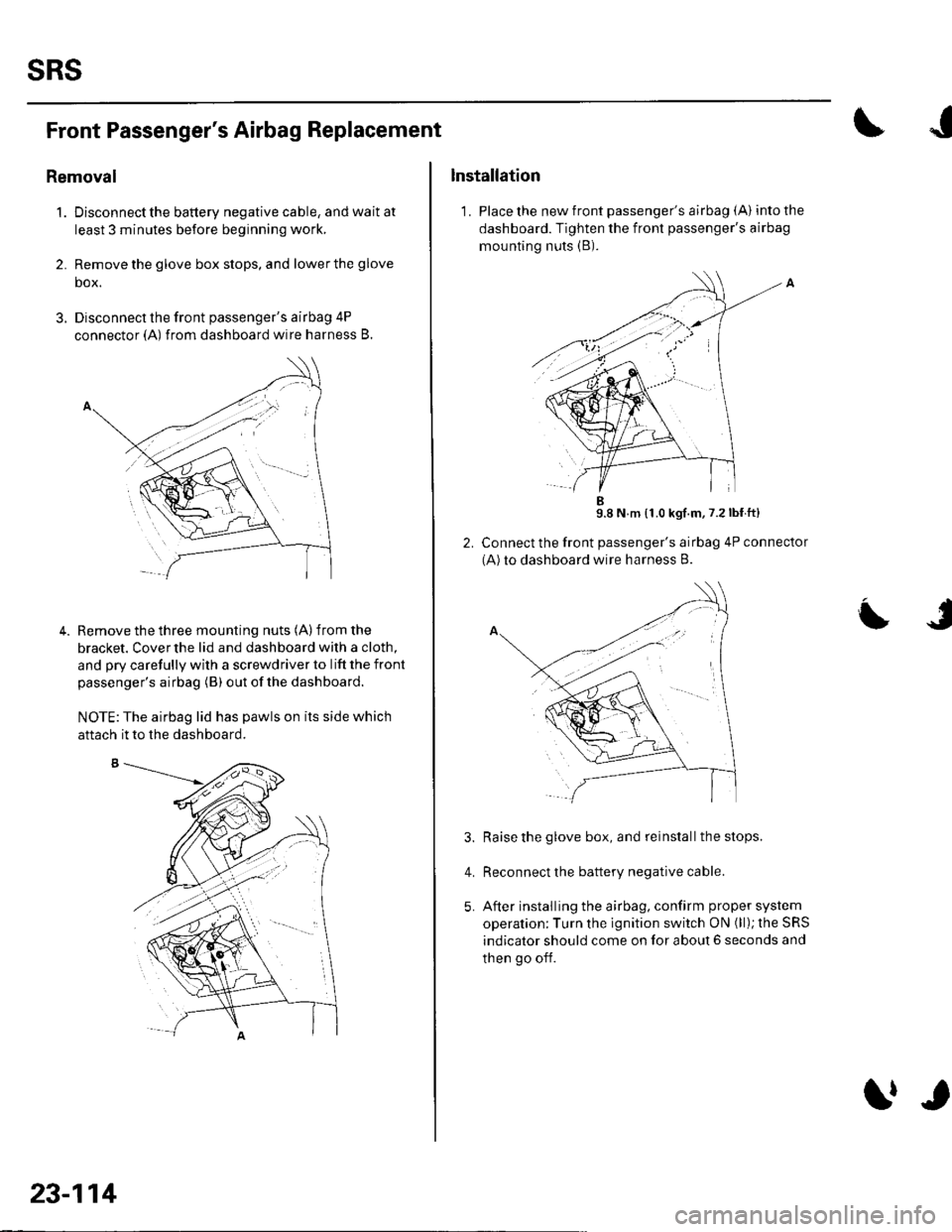

1. Disconnectthe battery negative cable, and wait at

least 3 minutes before beginning work,

2. Remove the glove box stops, and lower the glove

box.

3. Disconnect the front passenger's airbag 4P

connector (A) from dashboard wire harness B.

Remove the three mounting nuts (A) from the

bracket. Cover the lid and dashboard with a cloth,

and pry carefully with a screwdriver to lift the front

passenger's airbag (B) out ofthe dashboard.

NOTE:The airbag lid has pawls on its side which

4.

aftach it to the dashboard.

23-114

trr

Installation

1. Place the new front passenger's airbag (A) into the

dashboard. Tighten the front passenger's airbag

mounting nuts (B).

9.8 N m {1.0 kgf.m,7.2lbf ft}

Connect the front passenger's airbag 4P connector

(A)to dashboard wire harness B.

Raise the glove box, and reinstall the stops.

Reconnect the battery negative cable.

After installing the airbag, confirm proper system

operation; Turn the ignition switch ON (ll); the SRS

indicator should come on for about 6 seconds and

then go off.

L

4.

Page 1122 of 1139

)Side Airbag Replacement

)

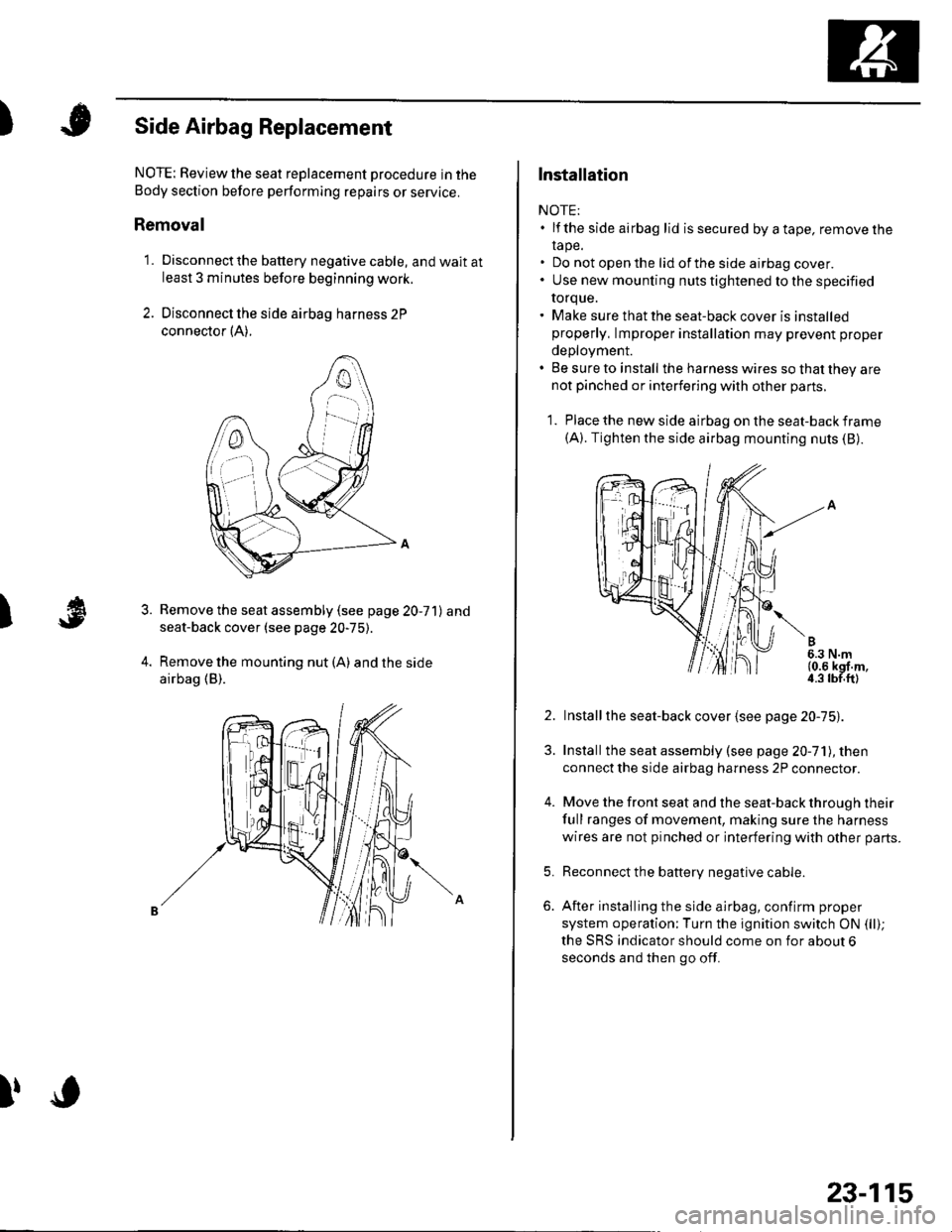

NOTE: Review the seat replacement pro6edure in the

Body section before pertorming repairs or service.

Removal

1. Disconnectthe battery negative cable, and wait atleast 3 minutes before beginning work.

2. Disconnect the side airbag harness 2P

connector {A).

Remove the seat assembly (see page 20-71) and

seat-back cover (see page 20-75).

Remove the mounting nut (A) and the side

airbag (B).

3.

l,o

23-115

Installation

NOTE:. lf the side airbag lid issecured byatape, removelhe

rape.. Do not open the lid of the side airbag cover.. Use new mounting nuts tightened to the specified

torque.. Make sure that the seat-back cover is installedproperly, lmproper installation may prevent proper

deployment.. Be sure to install the harness wires so that they arenot pinched or interfering with other parts.

1. Place the new side airbag on the seat-back frame(A). Tighten the side airbag mounting nuts (B).

2. Installthe seat-back cover {see page 20-75).

3. Installthe seat assembly (see page 20-71), then

connect the side airbag harness 2P connector.

4. Move the front seat and the seat-back through their

full ranges of movement, making sure the harness

wires are not pinched or interfering with other parts.

5. Reconnect the battery negative cable.

6. After installing the side airbag, confirm proper

system operation;Turn the ignition switch ON (ll);

the SRS indicator should come on for about 6

seconds and then go off.

Page 1123 of 1139

sRs

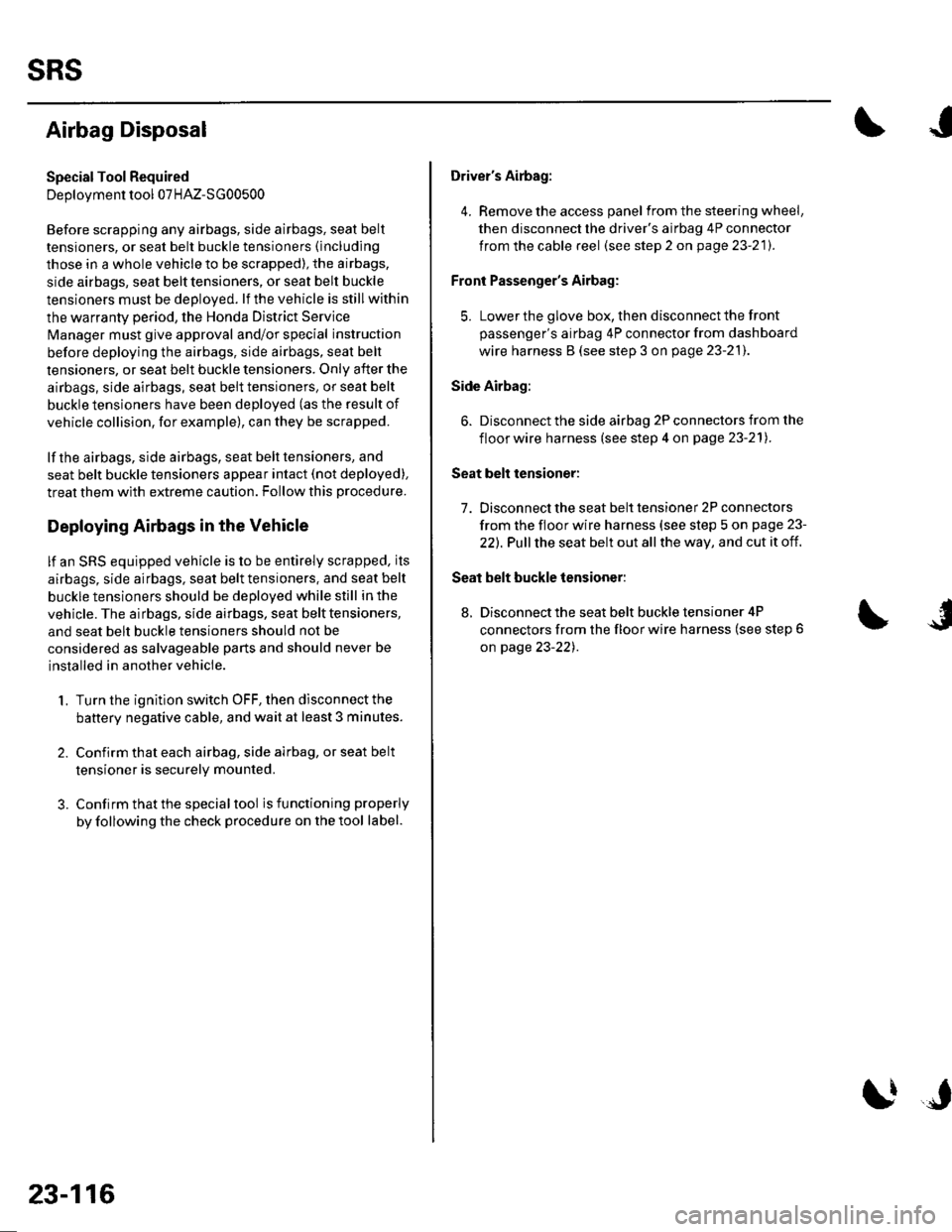

Airbag Disposal

Special Tool Required

Deployment tool 07HAz-SG00500

Before scrapping any airbags, side airbags, seat belt

tensioners, or seat belt buckle tensioners (including

those in a whole vehicle to be scrapped), the airbags,

side airbags, seat belt tensioners, or seat belt buckle

tensioners must be deployed. lf the vehicle is still within

the warranty period, the Honda District Service

Manager must give approval and/or special instruction

before deploying the airbags, side airbags, seat belt

tensioners, or seat belt buckle tensioners. Only after the

airbags, side airbags, seat belt tensioners, or seat belt

buckle tensioners have been deployed (as the result of

vehicle collision, for example), can they be scrapped.

lf the airbags, side airbags, seat belt tensioners, and

seat belt buckle tensioners appear intact (not deployed),

treat them with extreme caution. Follow this Drocedure.

Deploying Airbags in the Vehicle

lf an SRS equipped vehicle is to be entirely scrapped, its

airbags, side airbags. seat belt tensioners. and seat belt

buckle tensioners should be deoloved while still in the

vehicle. The airbags, side airbags, seat belttensioners,

and seat belt buckle tensioners should not be

considered as salvageable parts and should never be

installed in another vehicle.

1. Turn the ignition switch OFF, then disconnect the

battery negative cable, and wait at least 3 minutes.

2. Confirm that each airbag, side airbag, or seat belt

tensioner is securely mounted.

3. Conf irm that the specia I tool isfunctioning properly

by following the check procedure on the tool label.

23-116

$J

Driver's Airbag:

4. Remove the access panel f rom the steering wheel,

then disconnect the driver's airbag 4P connector

from the cable reel (see step 2 on page 23-21).

Front Passenger's Airbag:

5. Lowerthe glove box, then disconnectthe front

passenger's airbag 4P connector from dashboard

wire harness B (see step 3 on page 23-211.

Side Airbag:

6. Disconnect the side airbag 2P connectors from the

floor wire harness (see step 4 on page 23-211.

Seat belt tensioner:

7. Disconnect the seat belt tensioner 2P connectors

from the floor wire harness {see step 5 on page 23-

22). Pull the seat belt out all the way, and cut it off.

Seat belt buckle tensioner:

8, Disconnect the seat belt buckle tensioner 4P

connectors from the floor wire harness (see step 6

on page 23-221.

Page 1124 of 1139

)

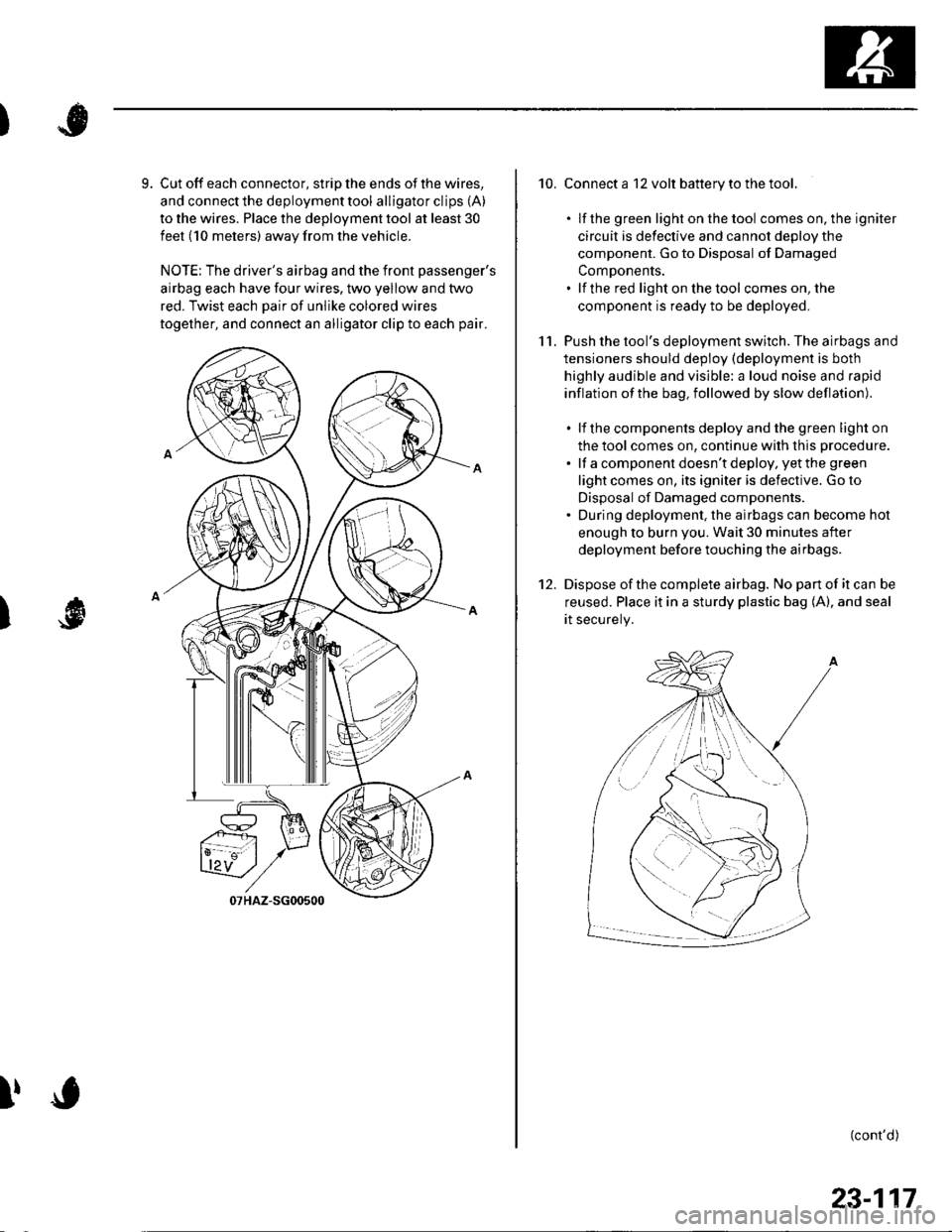

9. Cut off each connector, strip the ends of the wires,

and connect the deployment tool alligator clips (A)

to the wires. Place the deployment tool at least 30

feet (10 meters) away from the vehicle.

NOTE: The driver's airbag and the front passenger's

airbag each have four wires, two yellow and two

red. Twist each Dair of unlike colored wires

together, and connect an alligator clip to each pair.

I

!

10. Connect a 12 volt battery to the tool.

. lf the green light on the tool comes on, the igniter

circuit is defective and cannot deDlov the

component. Go to Disposal of Damaged

ComDonents.. lf the red light on the tool comes on, the

component is ready to be deployed.

11. Push the tool's deployment switch. The airbags and

tensioners should deploy (deployment is both

highly audible and visible: a loud noise and rapid

inflation of the bag, followed by slow deflation).

. lf the components deploy and the green light on

the tool comes on, continue with this procedure.

. lf a component doesn't deploy, yet the green

light comes on, its igniter is defective. Go to

Disposal of Damaged components.. During deployment, the airbags can become hot

enough to burn you. Wait 30 minutes after

deployment before touching the airbags.

12. Dispose ofthe complete airbag. No pan of it can be

reused. Place it in a sturdy plastic bag (A), and seal

rt securery.

(cont'd)

/:

i'..-':

23-117

Page 1125 of 1139

sRs

Airbag Disposal (cont'dl

Deploying Components Out of the Vehicle

lf an intact airbag or tensioner has been removed from

a scrapped vehicle, or has been found defective or

damaged during transit, storage, or service, it should be

deoloved as follows:

1. Confirm that the special tool isfunctioning properly

by following the check procedure on this page or

on the tool label.

2. Position the airbag face up, outdoors, on flat

ground, at least 30 feet (10 meters) from any

obstacles or DeoDle.

3. Follow steps 9 through 1 1 of the in-vehicle

deployment procedure.

Disposal of Damaged Components

1. lf installed in a vehicle, follow the removal

procedure for the driver's airbag (see page 23-113),

front passenger's airbag (see page 23-114), side

airbag (see page 23-115). seat belt tensioner (see

page 23-4), and seat belt buckle tensioner.

2. In all cases. make a short circuit by cutting,

stripping, and twisting together the two inflator

wires.

NOTE; The driver's and passenger's airbag each

have four wires: twist each pair of like-colored

wires together

Package the component in the same packaging that

the new reolacement Dart came in.

Mark the outside of the box "DAMAGED AIRBAG

NOT DEPLOYED'" ''DAMAGED SIDE AIRBAG NOT

DEPLOYED", "DAMAGED SEAT BELT TENSIONER

NOT DEPLOYED" or "DAlvlAGED SEAT BELT

BUCKLE TENSIONER NOT DEPLOYED" so it does

not get confused with your parts stock.

Contact your Honda District Service Manager for

how and where to return it for disposal.

23-118

I|J

J

Deployment Tool Check

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push the operation switch: green means the tool is

OK; red means the tool is faulty

3. Disconnectthe battery and the yellow clips.

J

Page 1126 of 1139

)

3.

4.

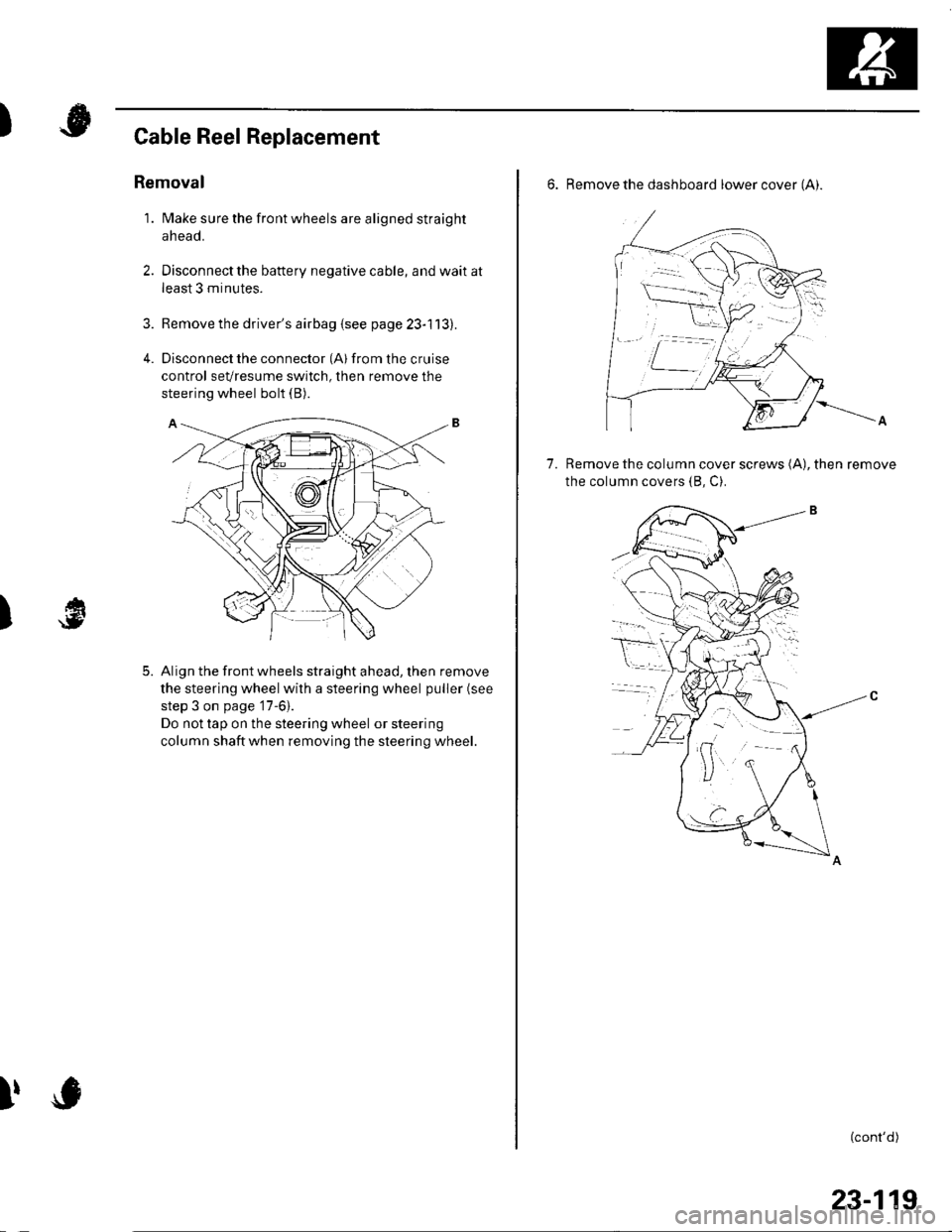

Cable Reel Replacement

Removal

1. Make sure the front wheels are aligned straight

ahead.

Disconnect the battery negative cable, and wait at

least 3 minutes.

Remove the driver's airbag {see page 23-113).

Disconnect the connector (Al from the cruise

control sevresume switch, then remove the

steering wheel bolt (B).

Align the front wheels straight ahead, then remove

the steering wheel with a steering wheel puller (see

step 3 on page '17-6).

Do not tap on the steering wheel or steering

column shaftwhen removing the steering wheel.

)

5.

I,

6. Remove the dashboard lower cover (Ai.

Remove the column cover screws (A), then remove

the column covers (8, C).

7.

(cont'd)

23-119