Wire harness HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 543 of 1139

EPS Components

Steering Gearbox Removal (cont'd)

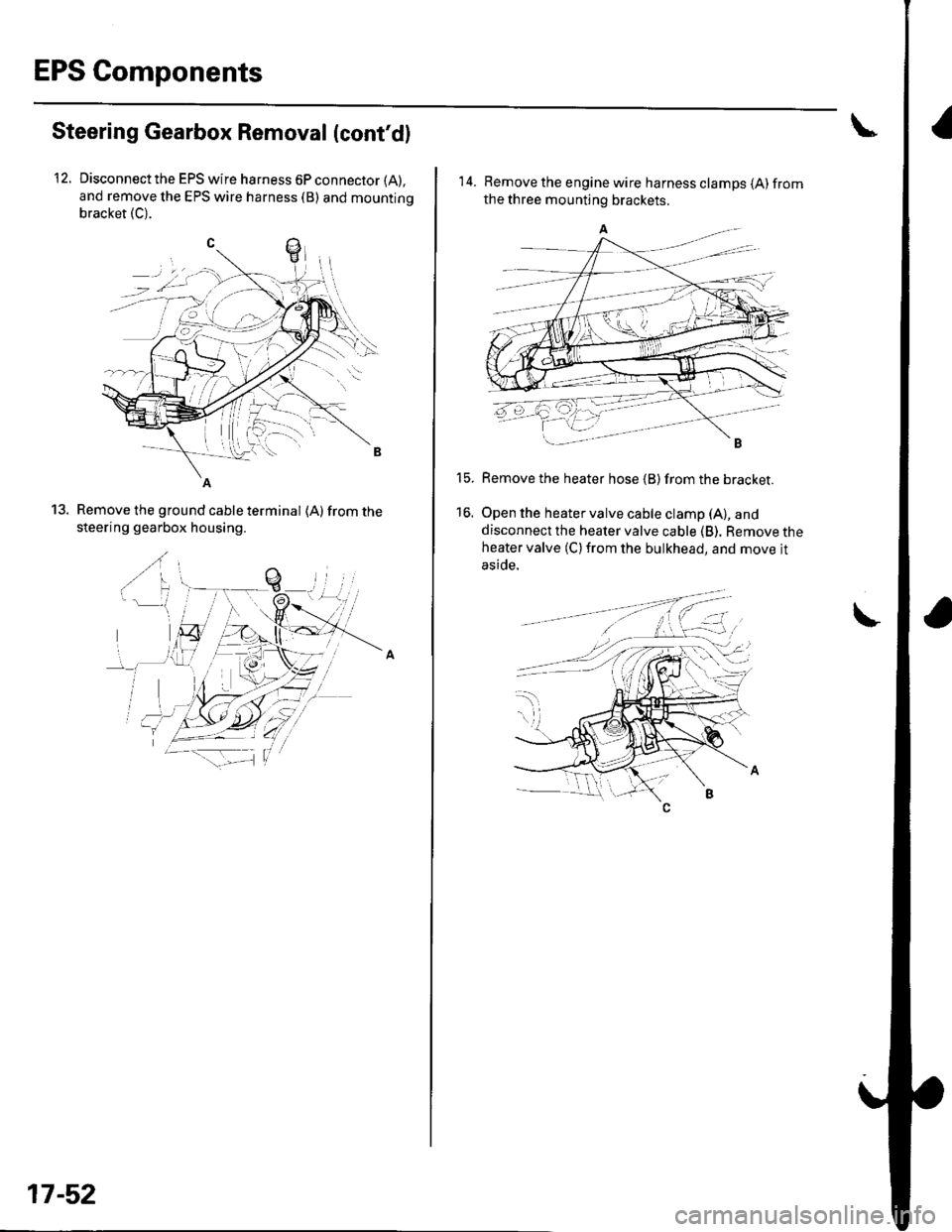

Disconnect the EPS wire harness 6P connector (A),

and remove the EPS wire harness (B) and mountino

bracket (C).

12.

Remove the ground cable terminal (A) from the

steering gearbox housing.

..(

.,/ a

b-H\

ry T,-.lt'^ \

'" \--

13.

_-1..1.-'

-a--zii F--_1

17-52

14. Remove the engine wire harness clamps {A)fromthe three mounting brackets.

Remove the heater hose {B) from the bracket.

Open the heater valve cable clamp (A), and

disconnect the heater valve cable (B). Remove theheater valve (C) from the bulkhead, and move jt

aside.

t5.

16.

I

Page 554 of 1139

Steering Gearbox Installation

2.

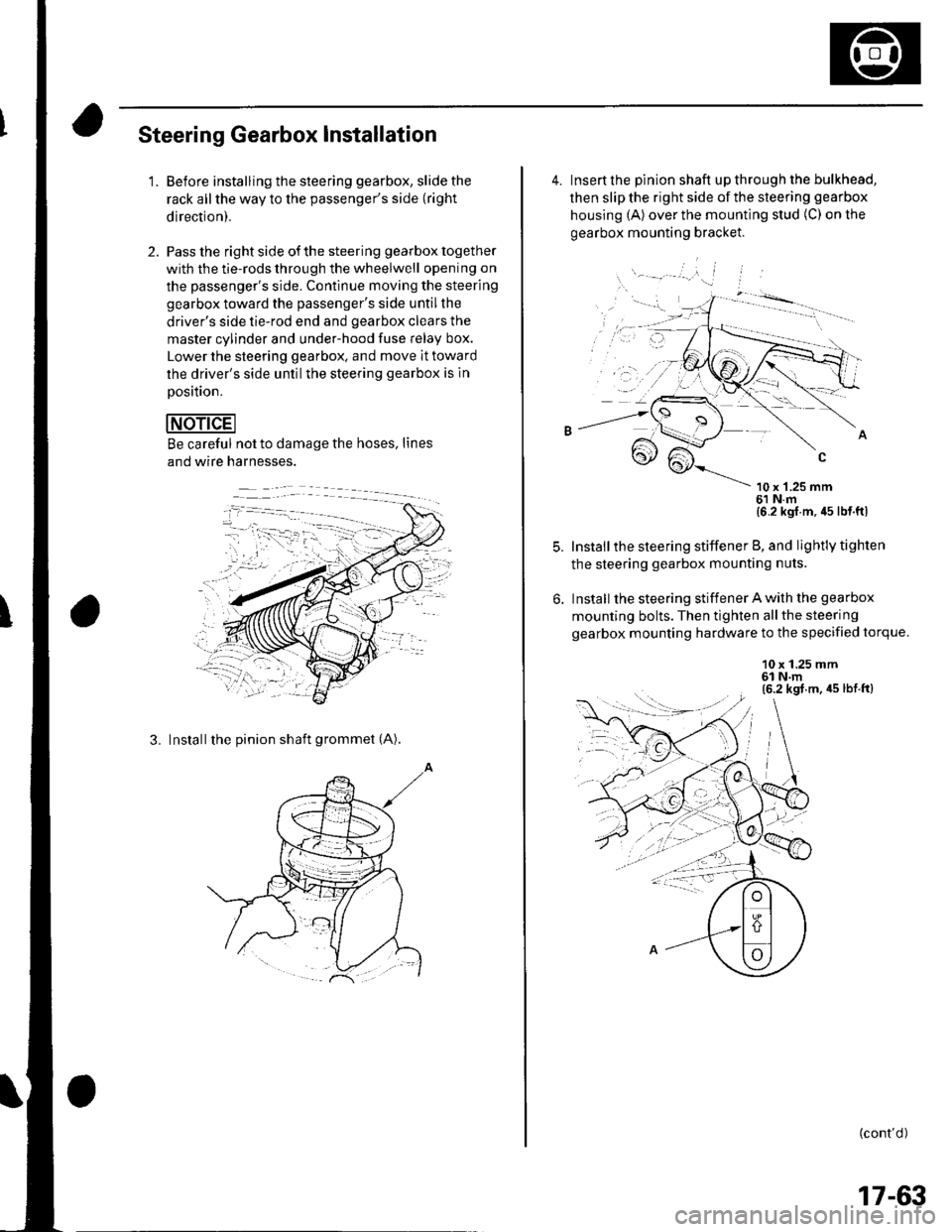

'1.Before installing the steering gearbox, slide the

rack all the way to the passenger's side (right

direction).

Pass the right side of the steering gearbox together

with the tie-rods through the wheelwell opening on

the passenger's side. Continue moving the steering

gearbox toward the passenger's side untilthe

driver's side tie-rod end and gearbox clears the

master cylinder and under-hood fuse Ielay box.

Lower the steering gearbox. and move it toward

the driver's side untilthe steering gearbox is ln

Dosition.

Be careful not to damage the hoses, lines

and wire harnesses.

3. Installthe pinion shaft grommet (A).

4. Insert the pinion shaft up through the bulkhead,

then slip the right side of the steering gearbox

housing (A) over the mounting stud (C) on the

gearbox mounting bracket.

\- --' '.'', i

10 x '1.25 mm61 N.m{6 2 kgl m, 45 lb{ ftl

Install the steering stiffener B, and lightly tighten

the steering gearbox mounting nuts.

Install the steering stiffener A with the gearbox

mounting bolts. Then tighten allthe steering

gearbox mounting hardware to the specified torque.

10 x 1.25 mm6l N.m(6.2 kgt.m, 45 lbt.ft)

: --.-{..

(cont'd )

:-1....

17-63

Page 555 of 1139

EPS Components

Steering Gearbox Installation (cont'd)

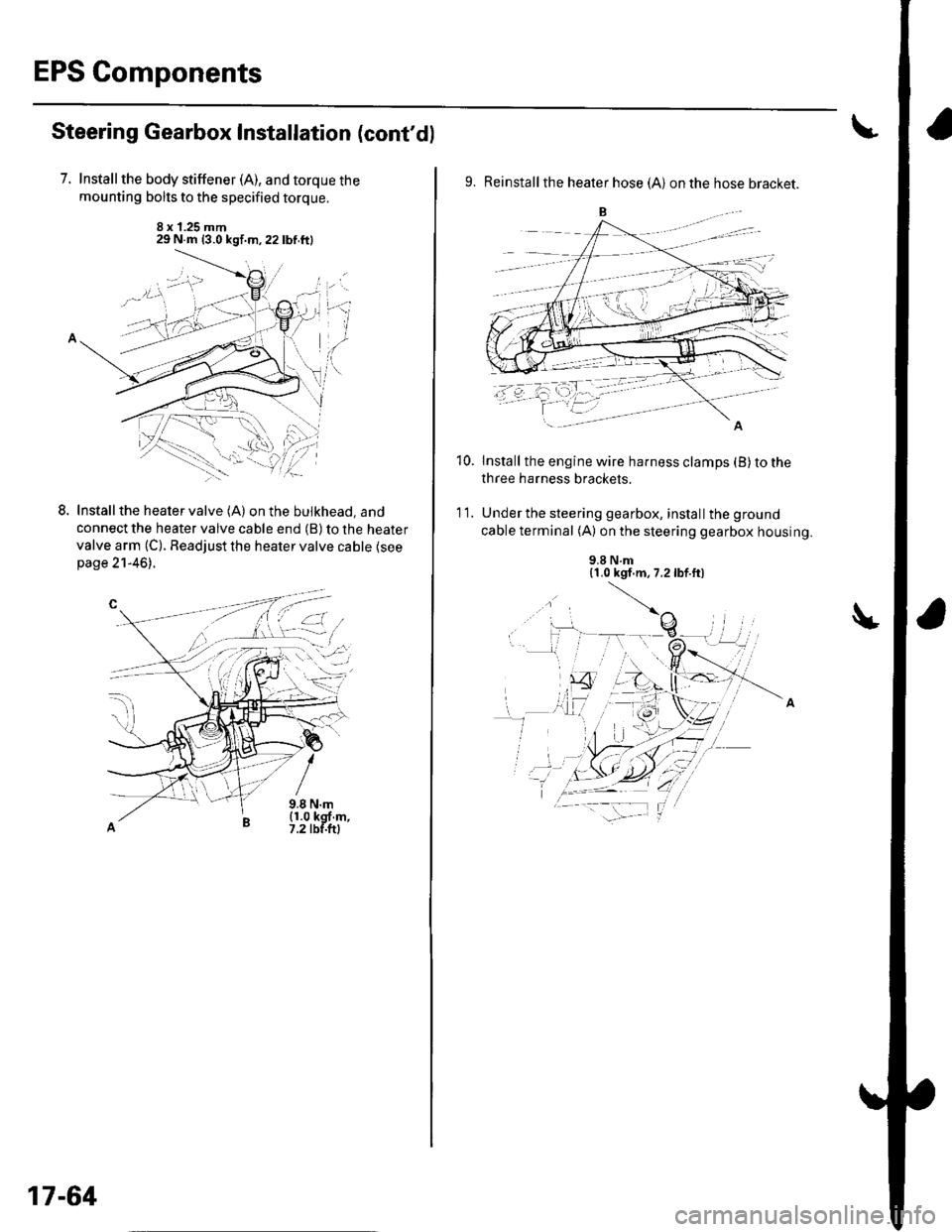

7. Installthe body stiffener (A), and torque the

mounting bolts to the specified torque.

8 x 1.25 mm29 N.m {3.0 kgf.m,22lbf.ftl

LInstall the heater valve (A) on the bulkhead, and

connect the heater valve cable end (B) to the heater

valve arm (C). Readjust the heater valve cable {seepage 21-46).

9.8 N.m(1.0 kgf m,7.2 tbf.ftl

L-t ,:.i.t'

17-64

9. Reinstall the heater hose (A) on the hose bracket.

Install the engine wire harness clamps (B) to the

three harness brackets.

Under the steering gearbox, install the ground

cable terminal (A) on the steering gearbox housing.

10.

'I t.

9.8 N.m{1.0 kgf.m, 7.2lbf.ft)

Page 556 of 1139

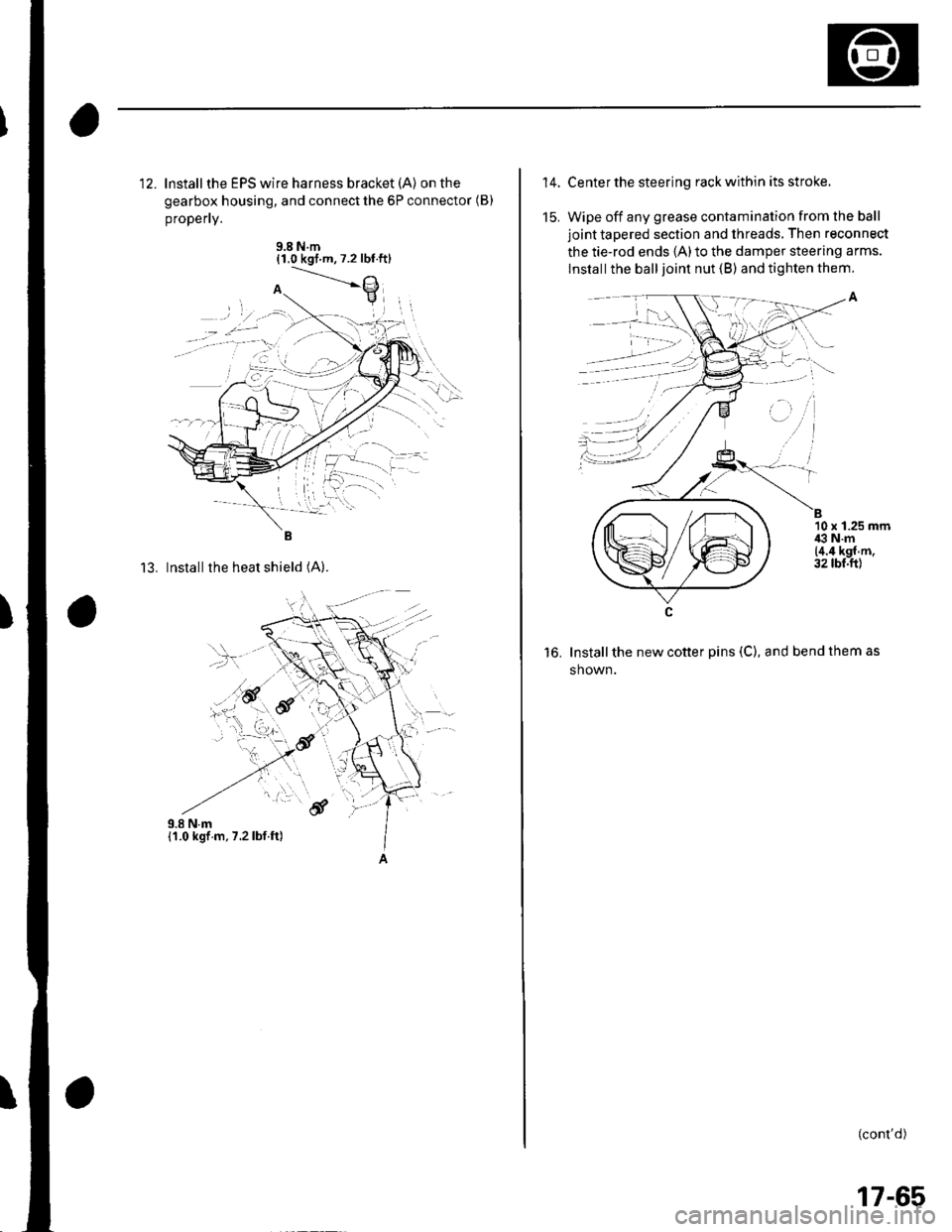

12. lnstallthe EPS wire harness bracket (A) on the

gearbox housing, and connect the 6P connector (B)

propefly.

9.8 N.m{1.0 kgt m,7.2 lbt.ftl

13. Installthe heat shield (A).

,.!,..''6f

14.

15.

Center the steering rack within its stroke.

Wipe off any grease contamination from lhe ball

joint tapered section and threads. Then reconnect

the tie-rod ends 1A)to the damper steering arms.

lnstall the ball joint nut (B) and tighten them.

Install the new cotter pins (C), and bend them as

shown.

(cont'd)

B10 x 1.25 mmi€ N.m{4.4 kgf.m.32 tbt.ftl

to.

, -', ''l

:1)

17-65

Page 610 of 1139

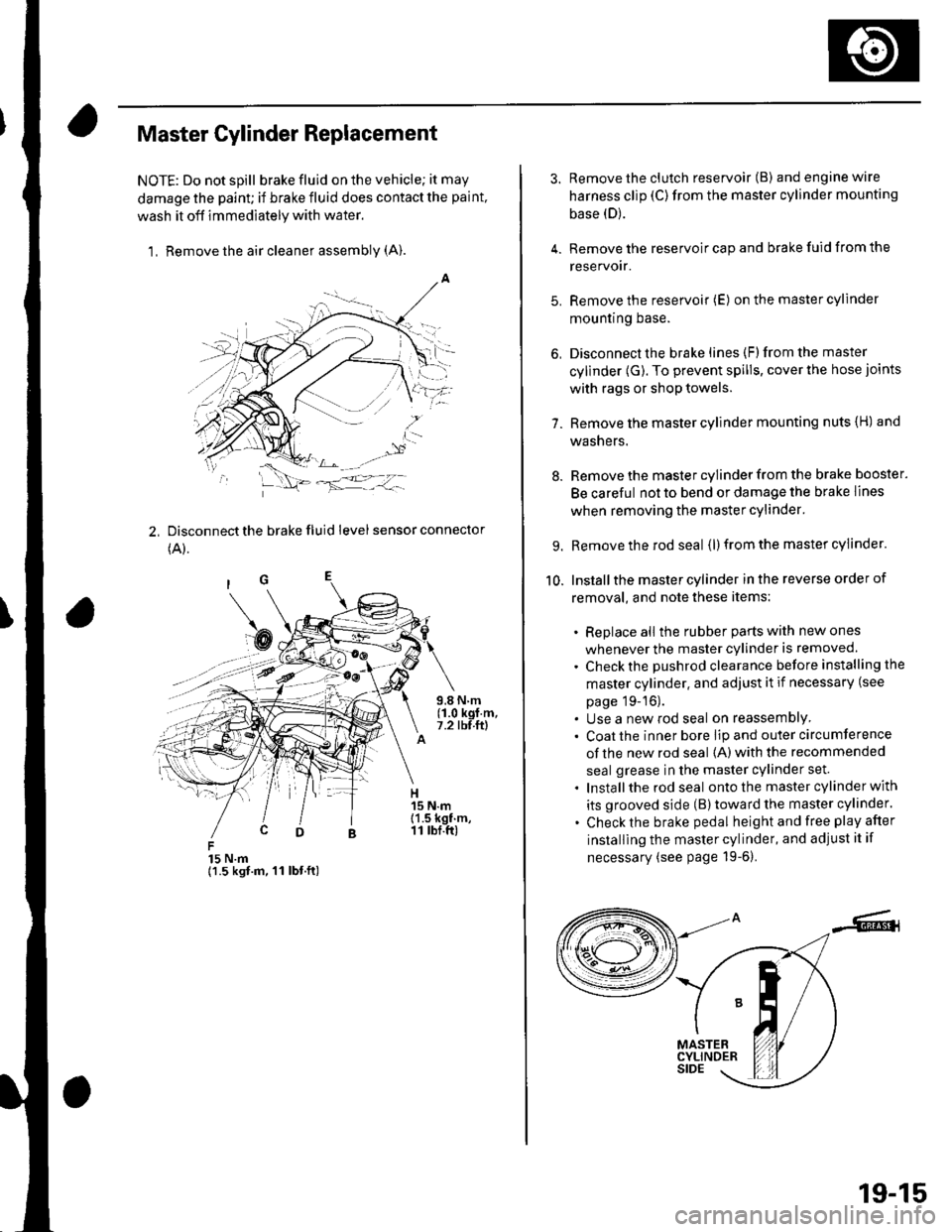

Master Cylinder Replacement

NOTE: Do not spill brake fluid on the vehicle; it may

damage the paint; if brake fluid does contact the paint,

wash it off immediately with water,

1, Remove the air cleaner assembly (A).

2, Disconnect the brake fluid level sensor connector

(A).

15 N.m{1.5 kgt.m, 11 lbt.ft)

3. Remove the clutch reservoir (B) andenginewire

harness clip (C)from the master cylinder mounting

base (D).

4. Remove the reservoir cap and brake fuid from the

reservoir.

5. Remove the reservoir (E) on the master cylinder

mountrng Dase.

6, Disconnect the brake lines (F)from the master

cylinder (G). To prevent spills, cover the hose joints

with rags or shop towels.

7. Remove the master cylinder mounting nuts {H) and

washers.

8. Remove the master cylinder from the brake booster.

Be careful not to bend or damage the brake lines

when removing the master cylinder.

9. Remove the rod seal (l) from the master cylinder.

10. Installthe master cylinder in the reverse order of

removal, and note these items:

. Replace all the rubber parts with new ones

whenever the master cylinder is removed.

. Check the pushrod clearance before installing the

master cylinder. and adjust it if necessary (see

page 19-16).. Use a new rod seal on reassemblY. Coat the inner bore lip and outer circumference

of the new rod seal {A) with the recommended

seal grease in the master cylinder set.

. Installthe rod seal ontothe master cylinder with

its grooved side (B)toward the master cylinder.

. Check the brake pedal height and free play after

installing the master cylinder, and adjust it if

necessary (see page 19-6).

19-15

Page 639 of 1139

\

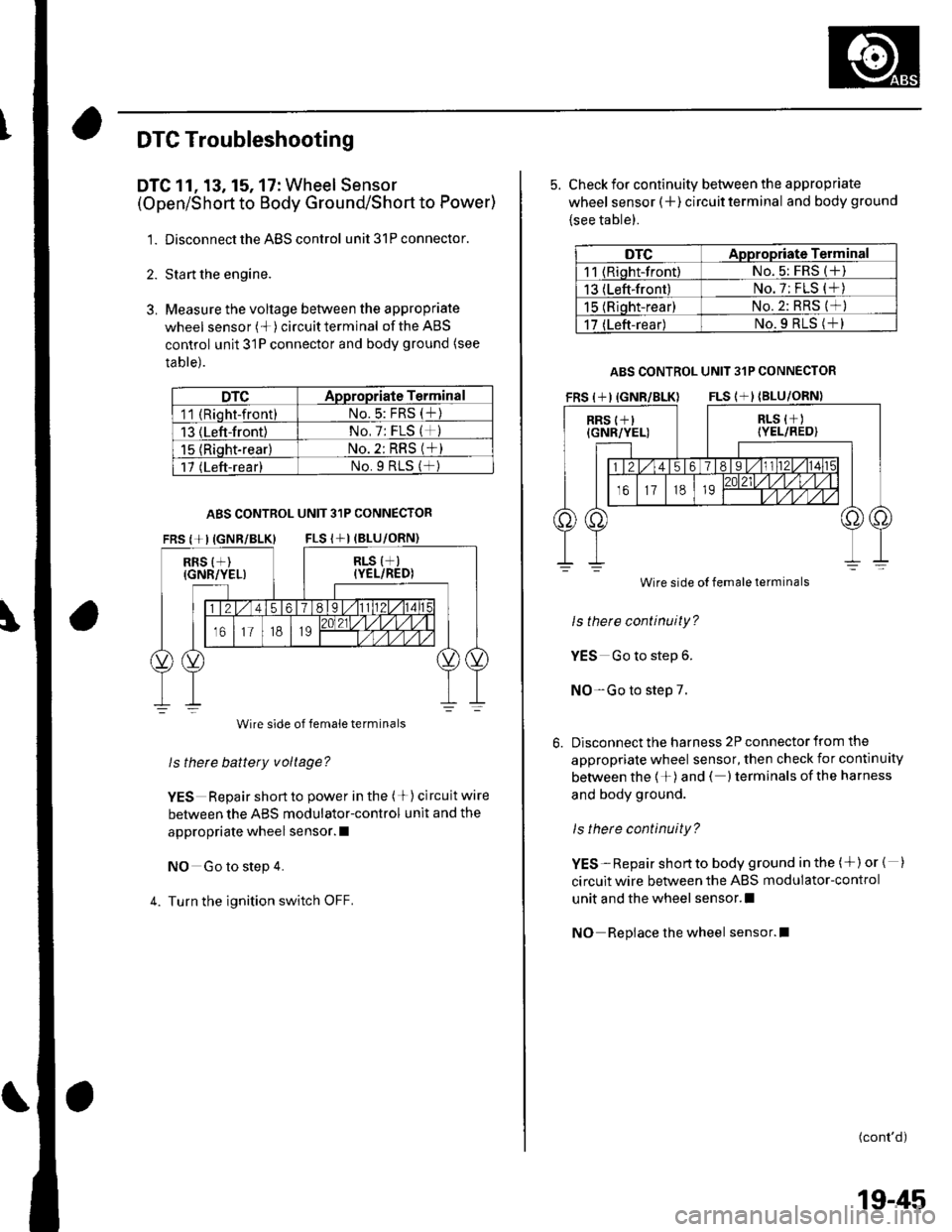

DTC Troubleshooting

DTC 11, 13, 15, 17: Wheel Sensor

(Open/Short to Body Ground/Short to Power)

1. Disconnect the ABS control unit 31P connector.

2. Sta rt the engine.

3. Measure the voltage between the appropriate

wheel sensor (*)circuitterminal of theABS

control unit 31P connector and body ground (see

table).

DTCADpropriate Terminal

11 (Rioht-front)No.5: FRS (t)

13 (Left-front)No, 7: FLS (*)

15 {Riqht-rear}No. 2: RRS (*)

17 (Left-rear)No.9 RtS (f )

ABS CONTROL UNIT 31P CONNECTOR

FRS {+IIGNR/BLK} FLS I+I (BLU

RRS {+)(GNR/YEL)

Wire side of female terminals

ls thete battery voltage?

YES Repair short to power in the (+) circuit wire

between the ABS modulator-control unit and the

appropriate wheel sensor. I

NO Go to step 4.

4. Turn the ignition switch OFF.

5. Check for continuity between the appropriate

wheel sensor (+ ) circuit terminal and body ground

{see table).

DTCAppropriate Terminal

11 (Riqht-front)No. 5: FRS (+)

13 (Left-front)No. 7: FLS (*)

15 (Rioht-rear)No.2: RRS (*)

17 (Left-rear)No.9 RLS (+l

ABS CONTROL UNIT 31P CONNECTOR

Wire side

ls there continuity?

YES Go to step 6.

NO-Go to step 7.

Disconnect the harness 2P connector from the

appropriate wheel sensor, then check for continuity

between the 1+)and ( )terminals ofthe harness

and body ground.

ls there continuity?

YES-Repair shortto body ground in the (+)or { )

circuit wire between the ABS modulator-control

unit and the wheel sensor.l

NO Repiace the wheel sensor.l

(cont'd)

Wire side of female terminals

19-45

Page 640 of 1139

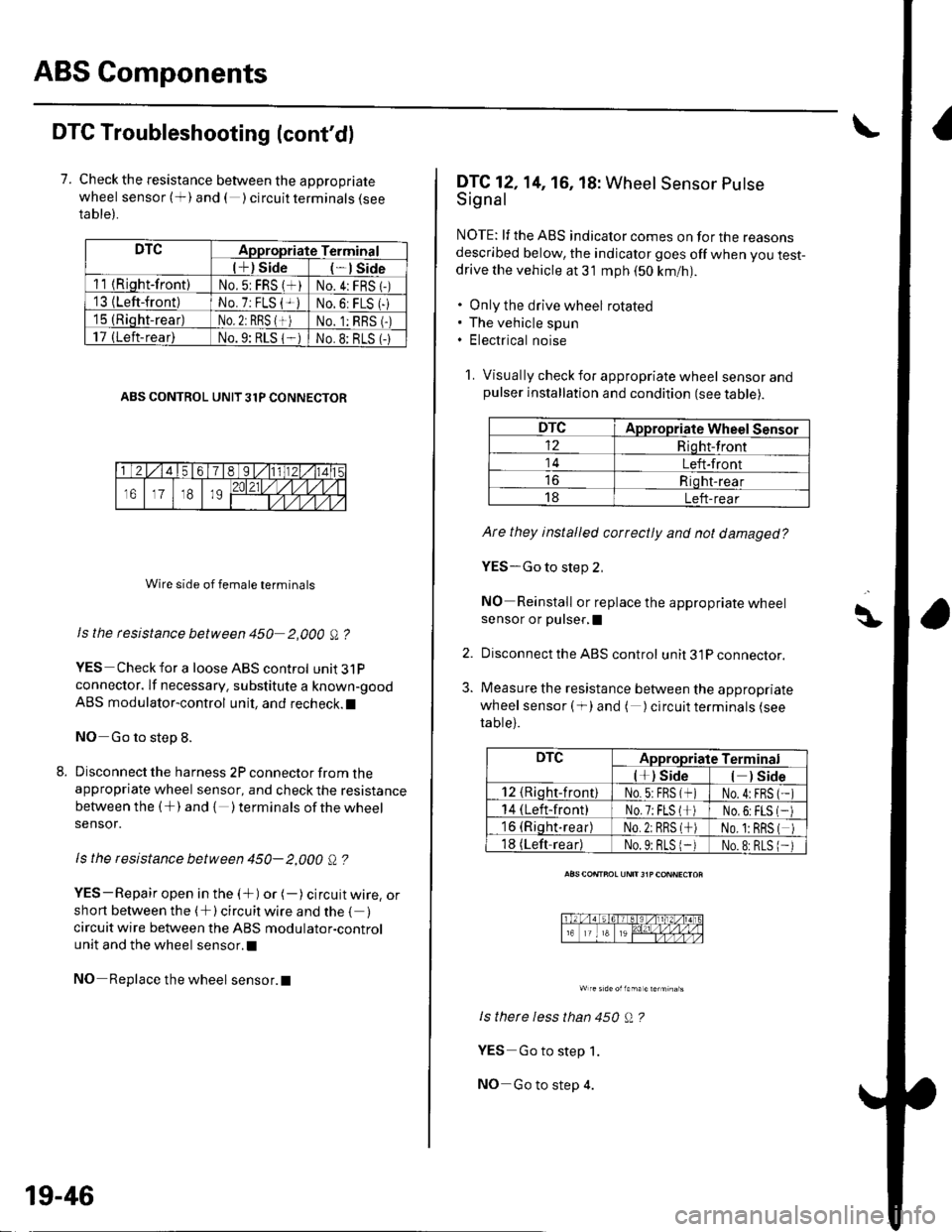

ABS Components

DTC Troubleshooting (cont'dl

7. Check the resistance between the appropriate

wheel sensor (+) and ( ) circuit terminals {seeta ble).

DTCAppropriate Terminal

l+) Side*lSide

11 {Riqht-front)No.5: FRS (*)No.4:FRS 1-)'13 {Left-front)No. 7: FLS {+iNo.6: FLS (-

15 (Rioht-rear)No. 2: RBS {+)No. 1:RBS (-)

17 (Left-rear)No.9: RLS 1-No.8: BLS (-

ABS CONTROL UNIT 31P CONNECTOR

Wire side of female terminals

Is the rcsistance between 450 2,000 A ?

YES Check for a loose ABS control unit3lP

connector. lf necessary. substitute a known-good

ABS modulator-control unit, and recheck.l

NO Go to step 8.

Disconnect the harness 2P connector from theappropriate wheel sensor, and check the resistance

between the (+) and { )terminalsof thewheel

sensor.

ls the resistance between 450- 2,000 Q ?

YES-Repair open in the (+) or (-) circuit wire, orshort between the (+) circuit wire and the { )circuit wire between the ABS modulator-control

unit and the wheel sensor.l

NO Replace the wheel sensor.l

19-46

DTC12,14, 16, 18: Wheel Sensor Putse

Signal

NOTE: lf the ABS indicator comes on for the reasonsdescribed below, the indicator goes off when you test-drive the vehicle at 31 mph (50 km/nl.

. Only the drive wheel rotated. The vehicle spun. Electrical noise

1. Visually check for appropriate wheel sensorandpulser installation and condition (see table).

DTCAppropriate Wheel Sensor

12Riqht-front

14Left-front

Riqht-rear

18Left-rear

Ate they installed correctly and not damaged?

YES-Go to step 2,

NO Reinstall or replace the appropriate wheelsensor or pulser,I

Disconnect the ABS control unit 31P connector.

Measure the resistance between the appropriate

wheel sensor ( f) and ( ) circuit terminals (see

table).

ls therc less than 450 Q ?

YES Go to step 1.

NO-Go to step 4.

\\|D

2.

3.

DTCAppropriate Terminal

l*) Side) Side

12 {Rioht-front)No.5:FBS (*No.4:FBS

14 (Left-front)No.7;FLS l*No,6:FLS

16 (Riqht.rear)No.2: RRS (*No. 1:BRS

18 (Left-readNo.9: BLS 1-No.8:RLS

Page 641 of 1139

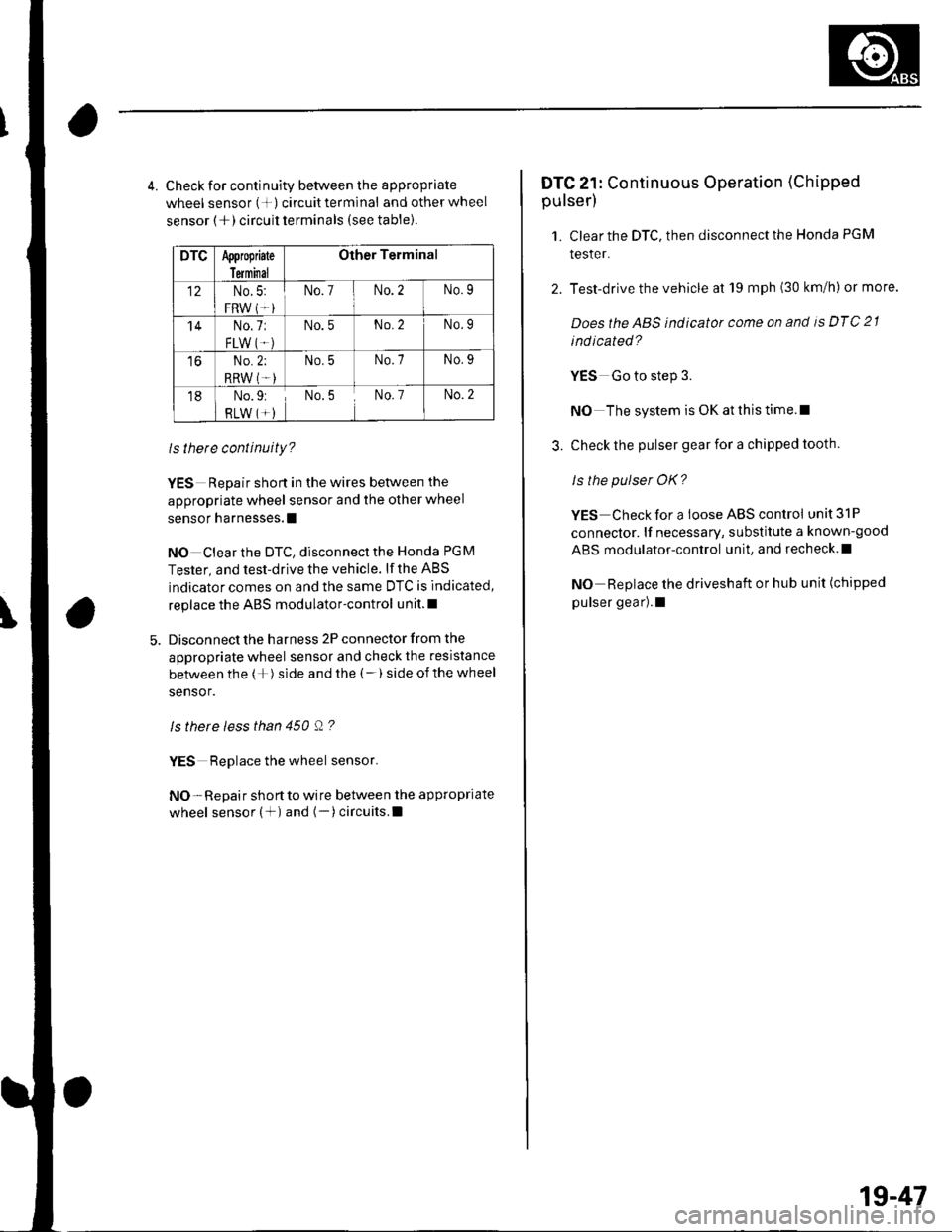

4. Check for continuity between the appropriate

wheel sensor (+) circuittermlnal and otherwheel

sensor (+) circuit terminals (see table).

DTCAppropiate

Terminal

Other Terminal

12No.5:

FRW (*i

No.7No.2No.9

'14No.7:

FLW IT.)

No.5No.2No.9

toNo.2;

RRW (T-)

No.5No.7No.9

18No.9:

RLW (*)No.5No. 7No.2

ls there continuity?

YES Repair short in the wires between the

appropriate wheel sensor and the other wheel

sensor harnesses.l

NO Clear the DTC, disconnect the Honda PGM

Tester, and test-drive the vehicle. lf the ABS

indicator comes on and the same DTC is indicated,

replace the ABS modulator-control unit.l

Disconnect the harness 2P connector from the

appropriate wheel sensor and check the resistance

between the (+) side and the (-) side ofthe wheel

sensor.

ls there less than 450 Q ?

YES Replace the wheel sensor.

NO- Repair short to wire between the appropriate

wheel sensor (+) and (-)circuits.l

DTC 21: Continuous Operation (Chipped

pulser)

1. Clear the DTC, then disconnect the Honda PGM

tesler.

2. Test-drive the vehicle at 19 mph (30 km/h) or more.

Doesthe ABS indicator come on and is DTC 21

ind icated?

YES Go to step 3.

NO The system is OK at this time.l

3. Check the pulser gear for a chipped tooth.

ls the pulser OK?

YES Check for a loose ABS control unit 31P

connector. lf necessary, substitute a known-good

ABS modulator-control unit, and recheck.l

NO Replace the driveshaft or hub unit (chipped

pulser gear).1

1g-47

Page 669 of 1139

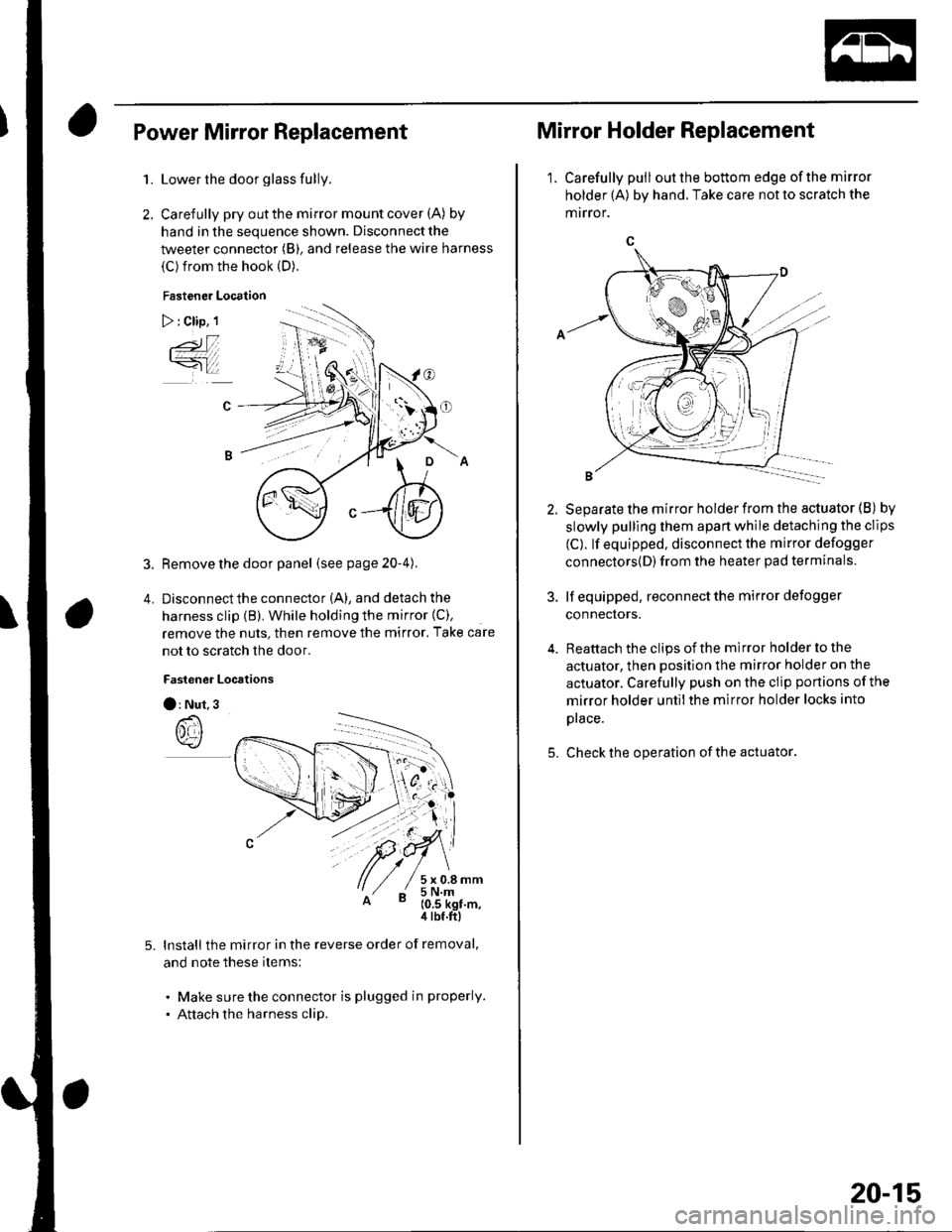

Power Mirror Replacement

1.

2.

5.

Lower the door glass fully.

Carefully pry out the mirror mount cover (A) by

hand in the sequence shown. Disconnect the

tweeter connector (B), and release the wire harness

(C) from the hook (D).

Fastener Location

) : Clip, 1

3. Remove the door panel (seepage20-4).

4. Disconnectthe connector (A), and detach the

harness clip (B). While holding the mirror {C),

remove the nuts, then remove the mirror. Take care

not to scratch the door.

Fastener Locrtions

O: Nut.3

lnstall the mirror in the reverse order of removal,

and note these items:

. Make sure the connector is plugged in properly.

. Attach the harness clip.

Mirror Holder Replacement

1. Carefully pulloutthe bottom edge ofthe mirror

holder (A) by hand. Take care not to scratch the

mrrror.

5.

Separate the mirror holder from the actuator (B) by

slowly pulling them apart while detaching the clips

(C). lf equipped, disconnect the mirror defogger

connectors{D) from the heater pad terminals.

lf equipped, reconnect the mirror defogger

connectors.

Reattach the clips of the mirror holder to the

actuator, then position the mirror holder on the

actuator. Carefully push on the clip portions of the

mirror holder untilthe mirror holder locks into

prace.

Check the operation of the actuator

20-15

Page 710 of 1139

Interior Trim

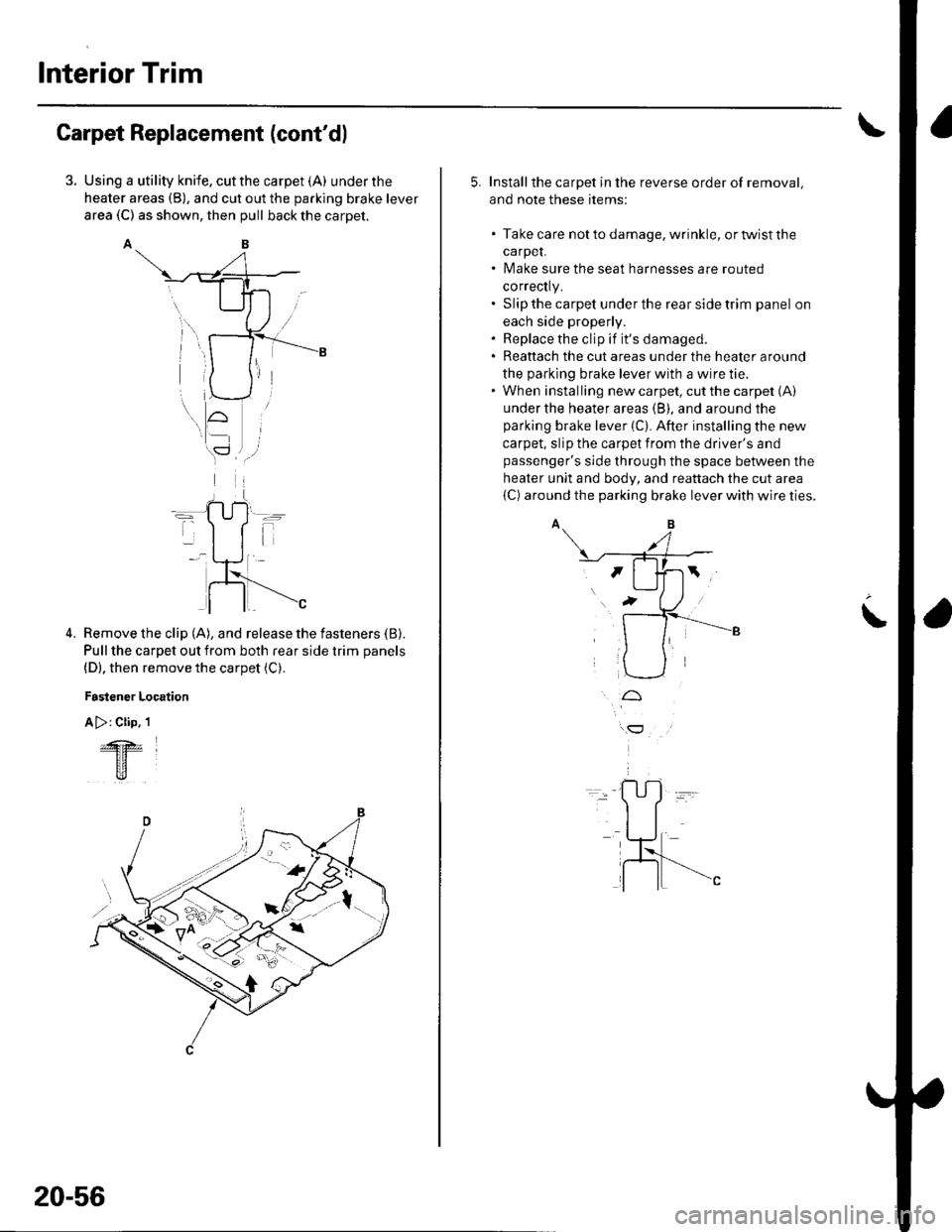

Carpet Replacement (cont'dl

Using a utility knife, cut the carpet (A) under the

heater areas (B), and cut out the parking brake lever

area (C) as shown, then pull back the carpet.

AB

Remove the clip (A), and release the fasteners (B).

Pull the carpet out from both rear side trim panels

(D), then remove the carpet (C).

Fastener Location

A >: Clip. 1

4.

&z

tr

20-56

5. Installthe carpet in the reverse order of removal,

and note these items:

. Take care notto damage, wrinkle, ortwistthe

carpeL. Make sure the seat harnesses are routed

correctly.. Slip the carpet under the rear side trim panel on

each side properly.. Replace the clip if it's damaged.. Reattach the cut areas under the heater around

the parking brake lever with a wire tie.. When installing new carpet, cut the carpet (A)

under the heater areas (B), and around the

parking brake lever (C). After installing the new

carpet, slip the carpet from the driver's and

passenger's side through the space between the

heater unit and body, and reattach the cut area

{C) around the parking brake lever with wire ties.

t