k2 terminal HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 95 of 1139

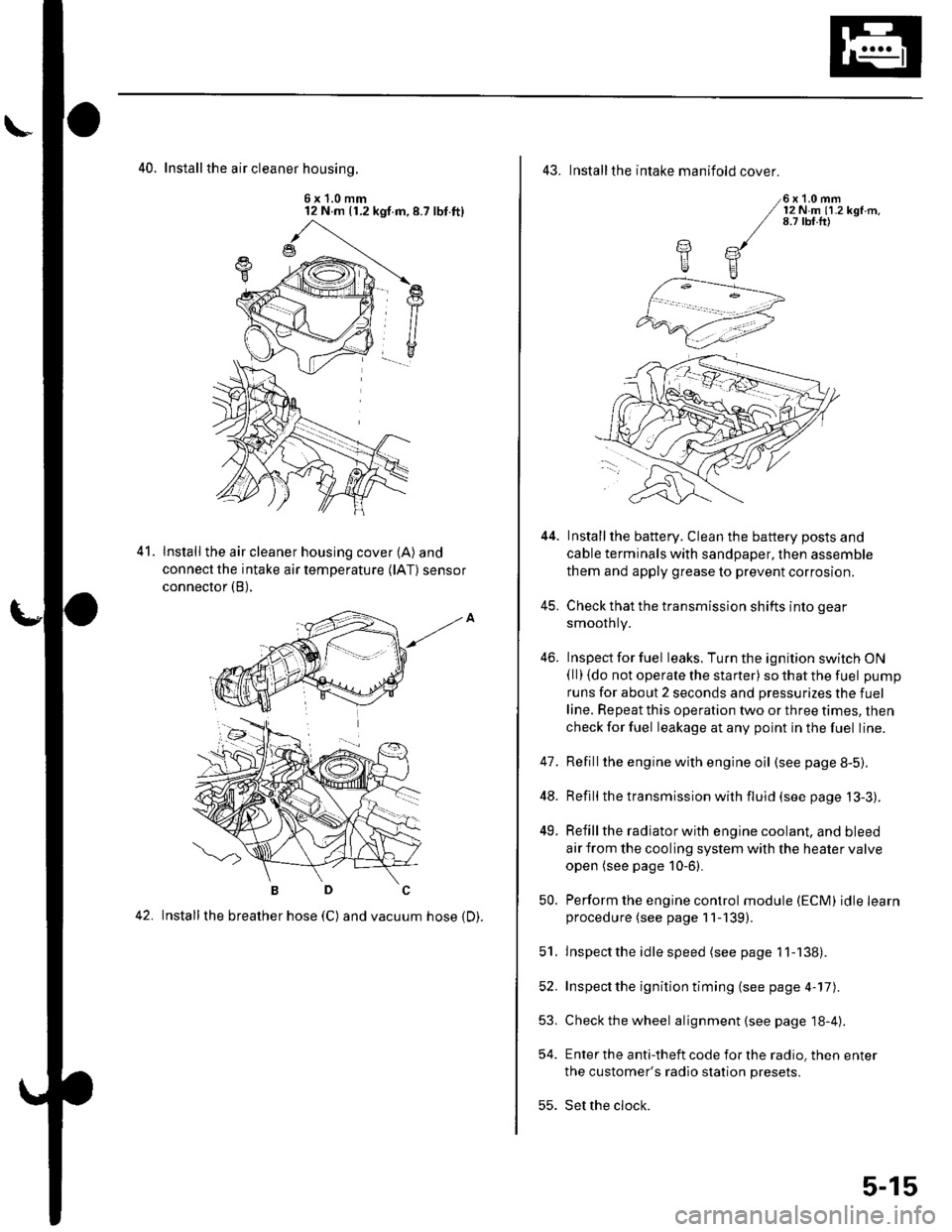

40. Install the air cleaner housinq.

6x1.0mm12 N m (1.2 kgf.m,8.7 lbt.ft)

Install the air cleaner housing cover (A) and

connect the intake air temperature (lAT) sensor

connector (B),

42. Installthe breather hose (C) and vacuum hose 1D).

41.

43. Installthe intake manifold cover.

6x1.0mm12Nm11.2kgf.m.8.7 tbf.ft)

Installthe battery. Clean the battery posts and

cable terminals with sandpaper, then assemble

them and apply grease to prevent corrosion.

Check that the transmission shifts into gear

smoothly.

Inspect for fuel leaks. Turn the ignition switch ON(ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refillthe engine with engine oil (see page 8-5).

Refill the transmission with fluid (see page 13-3).

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

Perform the engine control module (ECM) idle learnprocedure (see page 11-139).

Inspect the idle speed (see page 1 1-138).

Inspect the ignition timing (see page 4-17).

Check the wheel alignment {see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

YE

44.

41.

]tE

46.

48.

49.

52.

53.

54.

50.

51.

55.

5-15

Page 136 of 1139

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

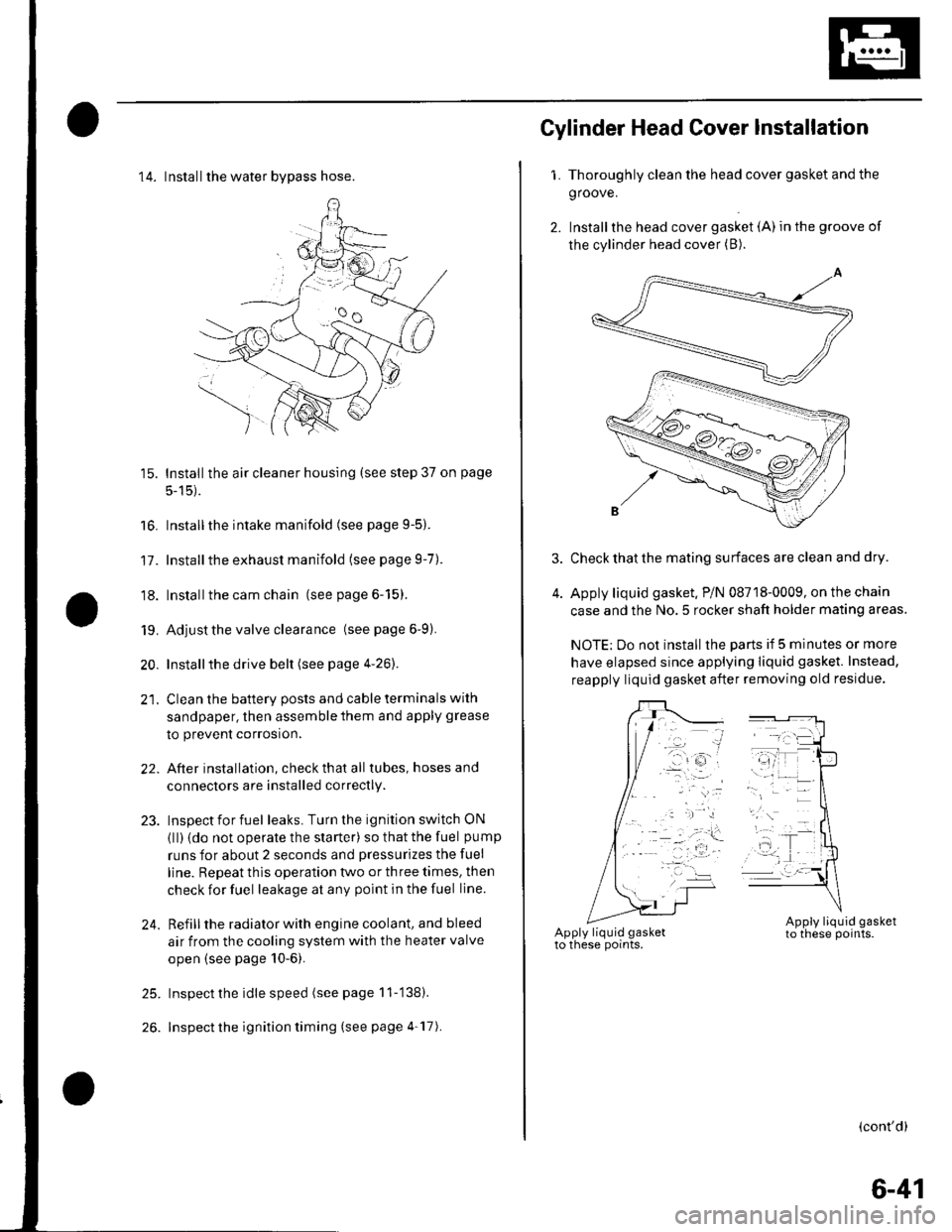

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 170 of 1139

Engine Lubrication

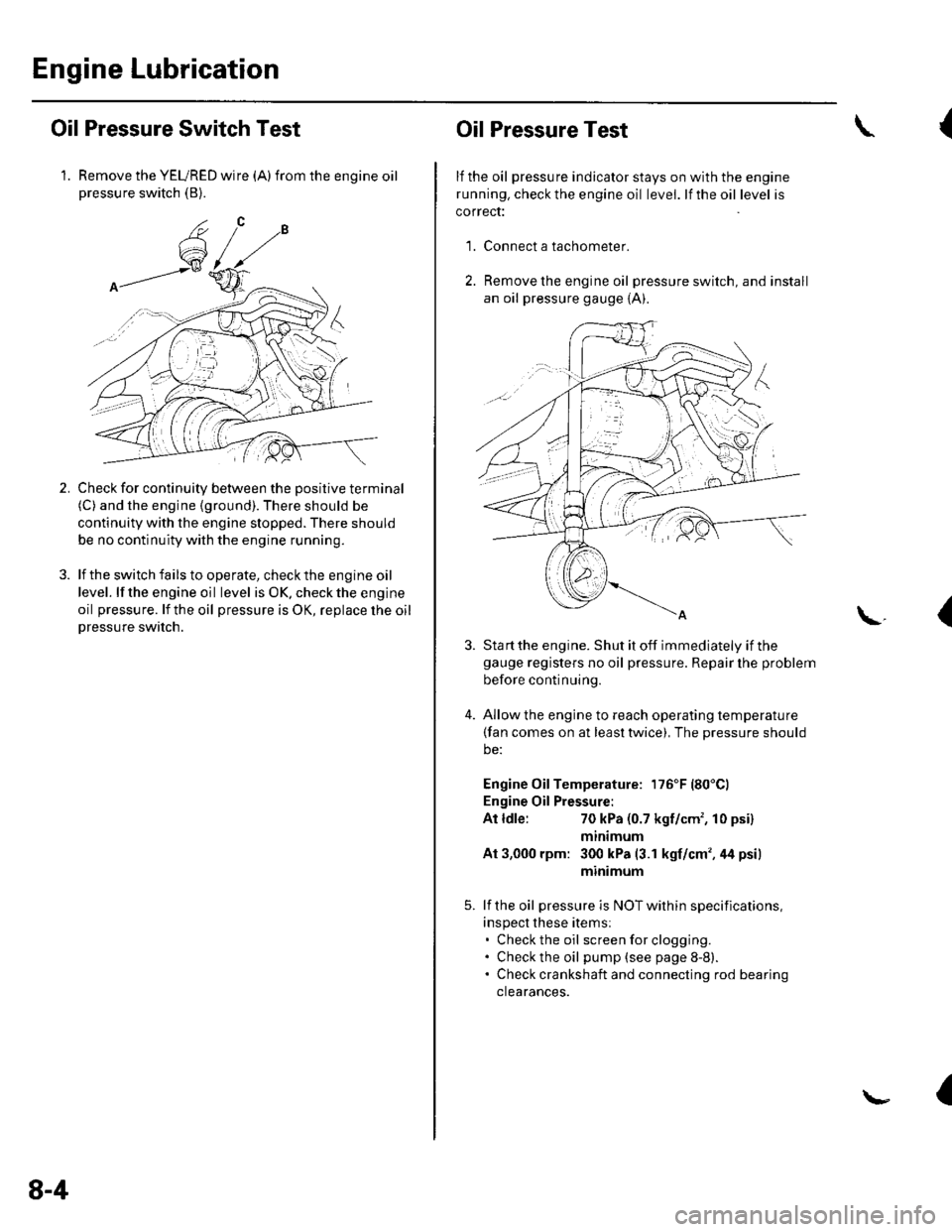

Oil Pressure Switch Test

1. Remove the YEURED wire (A)from the engine oilpressure switch (B).

Check for continuity between the positive terminal(C) and the engine (ground). There should be

continuity with the engine stopped. There should

be no continuity with the engine running.

lf the switch fails to operate, check the engine oil

level. lf the engine oil level is OK. check the engine

oil pressure. lf the oil pressure is OK, replace lhe oil

Dressure switch.

2.

8-4

Oil Pressure Test

lf the oil pressure indicator stays on with the engine

running. check the engine oil level. lf the oil level is

correct:

Connect a tachometer.

Remove the engine oil pressure switch, and install

an oil pressure gauge {A).

{

'1.

\.(

4.

Sta rt the engine. Shut it off immediately if thegauge registers no oil pressure. Repair lhe problem

before continuing.

Allow the engine to reach operating temperature(fan comes on at least twice), The pressure should

be:

Engine Oil Temperature: 176'F (80'Cl

Engine Oil Pressure:

At ldle:70 kPa (0.7 kgf/cm', 10 psi)

mtntmum

At 3,000 rpm: 300 kPa (3.1 kgf/cm',44 psi)

minimum

lf the oil pressure is NOT within specifications,

inspect these items:. Check the oil screenforclogging.. Check the oil pump (see page 8-8).. Check crankshaft and connecting rod bearing

clearances.

I

Page 194 of 1139

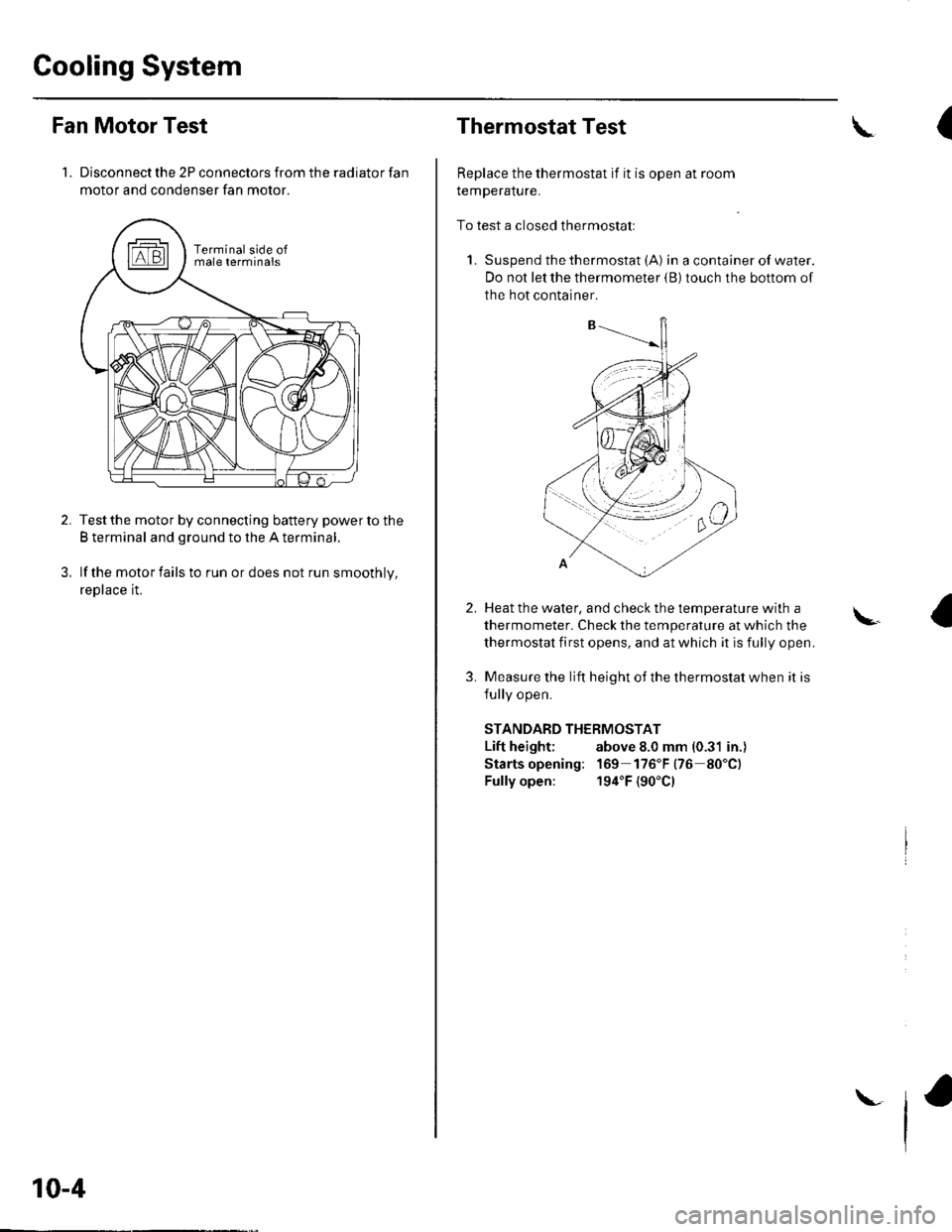

Cooling System

Fan Motor Test

1. Disconnect the 2P connectors from the radiator fan

motor and condenser fan motor.

Test the motor by connecting battery power to the

B terminal and ground to the A terminal.

lf the motor fails to run or does not run smoothly,

reptace rL

10-4

\

Thermostat Test

Replace the thermostat if it is open at room

remperalure.

To test a closed thermostatl

1. Suspend the thermostat (A) in a container of water.

Do not let the thermometer {B) touch the bottom of

the hot container.

(\

2.

3.

Heat the water, and check the temDerature with a

thermometer. Check the temperature at which the

thermostat first opens, and at which it is fully open.

Measure the lift height of the thermostat when it is

fullv ooen.

STANDARD THERMOSTAT

Lift height; above 8.0 mm (0.31 in.)

Starts opening: 169 176"F(76 80"C)

Fully open: 194"F {90'Cl

\.

Page 204 of 1139

Fan Gontrols

Radiator Fan Circuit Troubleshooting

1. Check the No. 4 (20A) fuse in the under-hood

fuse/relay box, and the No. 14 (10A) fuse in the

under-dash fuse/relay box.

ls the tuse (s) OK?

YES-Go to step 2.

NO- Replace the fuse (s) and recheck.l

2. Remove the radiator fan relay from the under-hood

fuse/relay box, and test it (see page 22-51).

ls the relay OK?

YES Go to step 3.

NO Replace the radiator fan relay. t

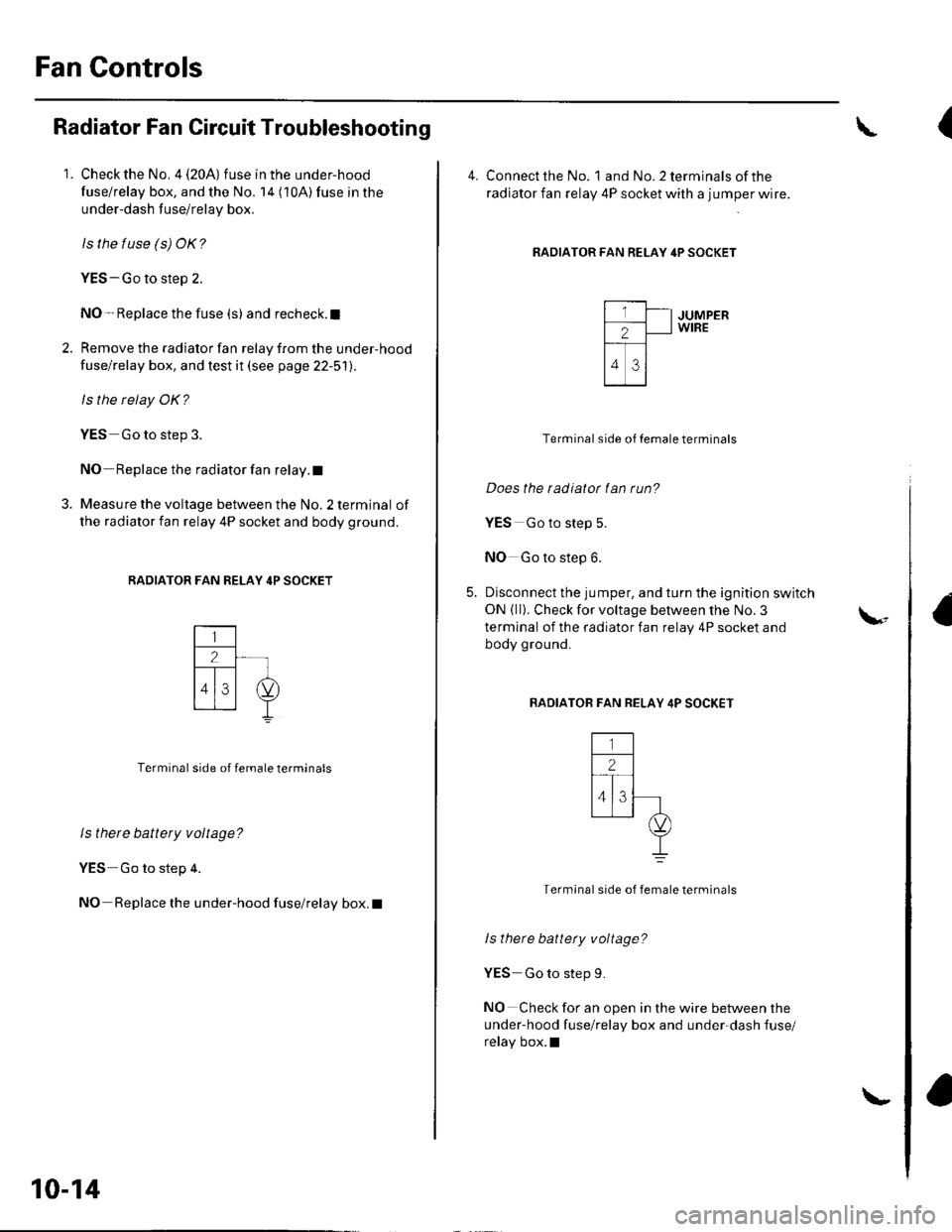

3. Measure the voltage between the No. 2 terminal of

the radiator fan relay 4P socket and body ground.

RADIATOR FAN RELAY 4P SOCKET

Terminal side of female terminals

ls there battery voltage?

YES Go to step 4.

NO Replace the under-hood fuse/relay box. I

10-14

\-

(

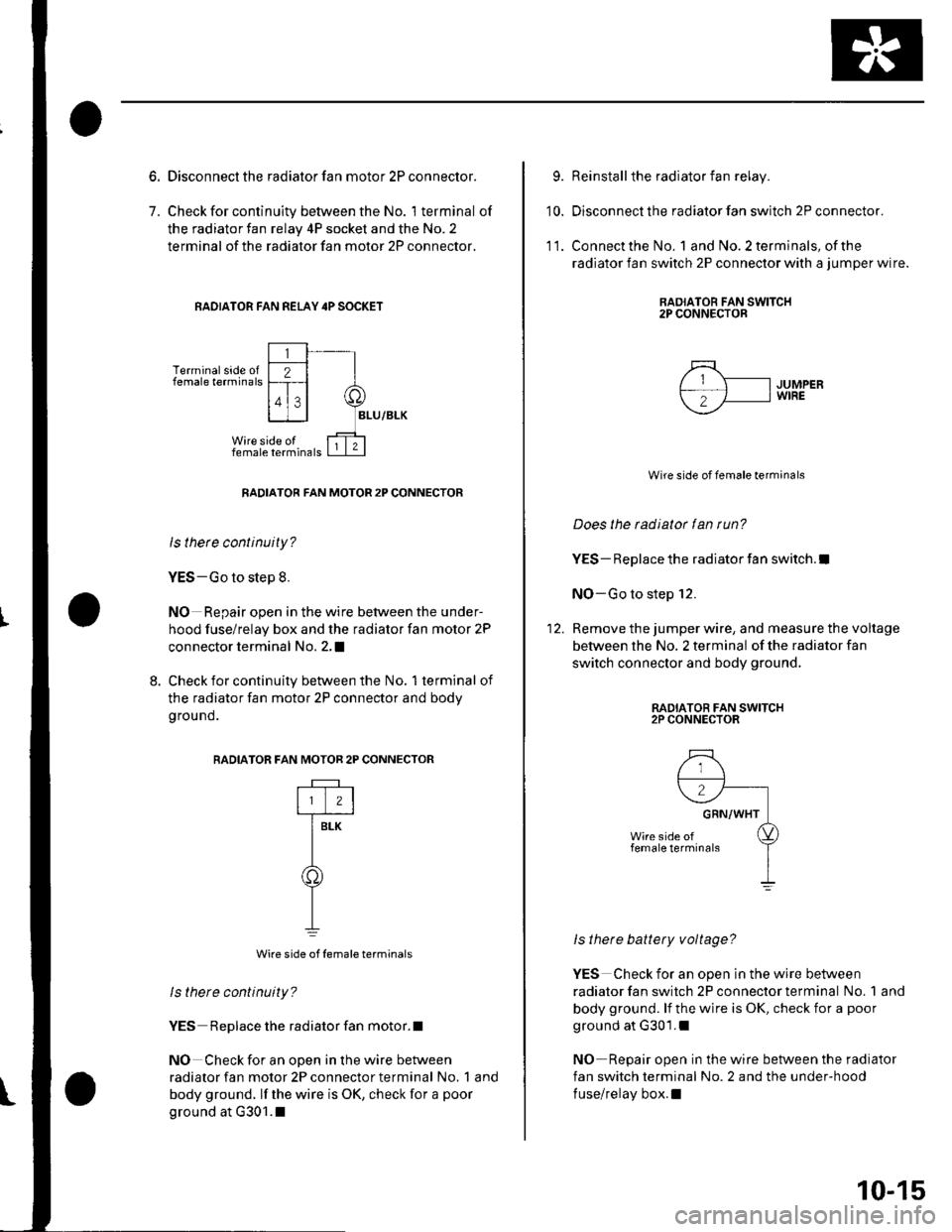

4. Connect the No. landNo.2terminalsofthe

radiator fan relay 4P socket with a jumper wire.

RADIATOR FAN RELAY 4P SOCKET

JUMPERWIRE

Terminal side of Iemale terminals

Does the radiatot fan run?

YES Go to step 5.

NO Go to step 6.

Disconnect the jumper, and turn the ignition switch

ON { ll}. Check for voltage between the No. 3

terminal of the radiator fan relay 4P socket and

body ground.

BADIATOB FAN RELAY 4P SOCKET

Termlnal side of female terminals

ls there battety voltage?

YES-Go to step 9.

NO Check for an open in the wire between the

under-hood fuse/relay box and under-dash fuse/

relay box.l

\-

Page 205 of 1139

7.

Disconnect the radiator fan motor 2P connector.

Check for continuity between the No. 1 terminal of

the radiator fan relay 4P socket and the No. 2

terminal of the radiator fan motor 2P connector.

RAOIATOR FAN REI-AY 4P SOCKET

Terminal side offemale terminals

RADIATOR FAN MOTOR 2P CONNECTOR

ls thete continuity?

YES-Go to step 8.

NO Repair open in the wire between the under-

hood fuse/relay box and the radiator fan motor 2P

connector terminal No. 2,I

8. Check for continuity between the No, 1terminal of

the radiator fan motor 2P connector and bodv

g rou nd.

RADIATOR F

Wire side of female terminals

ls there continuity?

YES Replace the radiator fan motor.l

NO Check for an open in the wire between

radiator fan motor 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

AN MOTOR 2P CONNECTOR

rftr

T-

Y

9.

10.

Reinstall the radiator fan relay.

Disconnect the radiator fan switch 2P connector.

Connect the No. 1 and No. 2 terminals, of the

radiator fan switch 2P connector with a jumper wire.

RAOIATOR FAN SWITCH2P CONNECTOR

11.

5\- IJUMPERf-; 'fl I wrRE

--

Wire side of female terminals

Does the radiator fan run?

YES- Replace the radiator fan switch.l

NO-Go to step 12.

Remove the jumper wire, and measure the voltage

between the No, 2 terminal of the radiator fan

switch connector and body ground,

RADIATOR FAN SWITCH2P CONNECTOR

ls there battery voltage?

YES Check for an open in the wire between

radiator fan switch 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

NO Repair open in the wire between the radiator

fan switch terminal No. 2 and the under-hood

fuse/relay box.l

10-15

Page 206 of 1139

Fan Controls

Radiator Fan Switch Circuit

Troubleshooting (Openl

1. Disconnect the radiator fan switch 2P connector.

2. Turn the ignition switch ON (ll).

3. Measure voltage between the No.2 terminal ofthe

radiator fan switch 2P connector and body ground.

RADIATOR FAN SWITCH 2PCONNECTOR

ls there battety voltage?

YES-Go to step 4.

NO- Repair open in the wire between the radiator

fan switch 2P connector terminal No. 2 and under-

hood fuse/relay box.l

Turn the ignition switch OFF, and check for

continuity between the No. '1 terminal of the

radiator fan switch 2P connector and body ground.

RADIATOB FAN SWITCX 2PCONNECTOR

ls there continuity?

YES Replace the radiator fan switch. t

NO Check for an open in the wire between theradiator fan switch 2P connector terminal No. 1 and

body ground. lf the wire is OK, check for a poor

ground at G301.1

10-16

\-

Radiator Fan Switch Circuit

Troubleshooting (Short)

NOTE: After troubleshooting, perform the engine

control module (ECM)idle learn procedure (see page

1 1,139).

1. Remove the radiator fan relay from the under-hood

fuse/relay box, and test it (see page 22-51).

ls the relay OK?

YES Go to step 2.

NO Replace the radiator fan relay.I

2. Remove the radiator fan switch, and test it (see

page 10-17 ).

Is the radiatot tan switch OK?

4.

YES Go to step 3.

NO Replace the radiator fan switch.I

Disconnect the battery negative cable from the

battery.

Disconnect engine control module {ECM) connector

B (24P) and the under hood fuse relay box 14P

connector.

Check for continuity between the No. 2 terminal of

the radiator fan switch 2P connector and bodygrouno.

RADIATOR FAN SWITCH2P CONNECTOR

lstnere continuity?

YES Repair short in the wire between the radiator

fan switch 2P connector terminal No. 2 and under-

hood fuse/relay box.l

NO Replace the under-hood fuse/relay box.t

\I

\

Page 207 of 1139

Radiator Fan Switch Test

NOTE: Bleed air from the cooling system after installing

the radiator fan switch (see page 10-6).

1, Remove the radiator fan switch from the radiator

(see page 10-17).

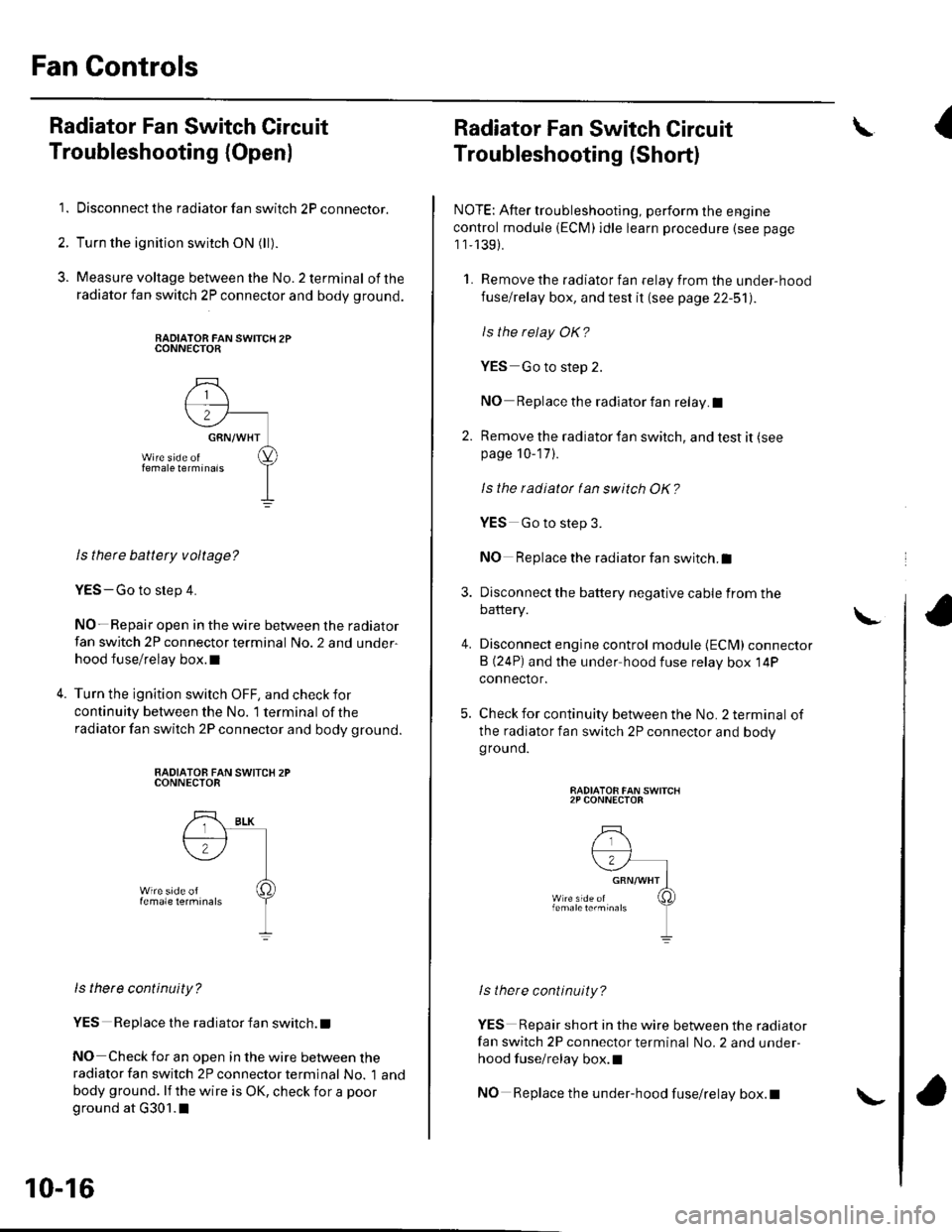

2. Suspend the radiator fan switch (A) inacontainer

of water as shown.

3. Heat the water, and check the temperature with a

thermometer. Do not let the thermometer (B) touch

the bottom of the hot conlainer.

4. Measure the continuity between terminal No. 1 and

terminal No. 2 according to the table.

Termina

Operation lTemperature1

swtTcH

ON196" 203'F(91" gs"C)

OFF5' 15'F {3' 8'C) lowelthan the temoeraturewhen it goes on

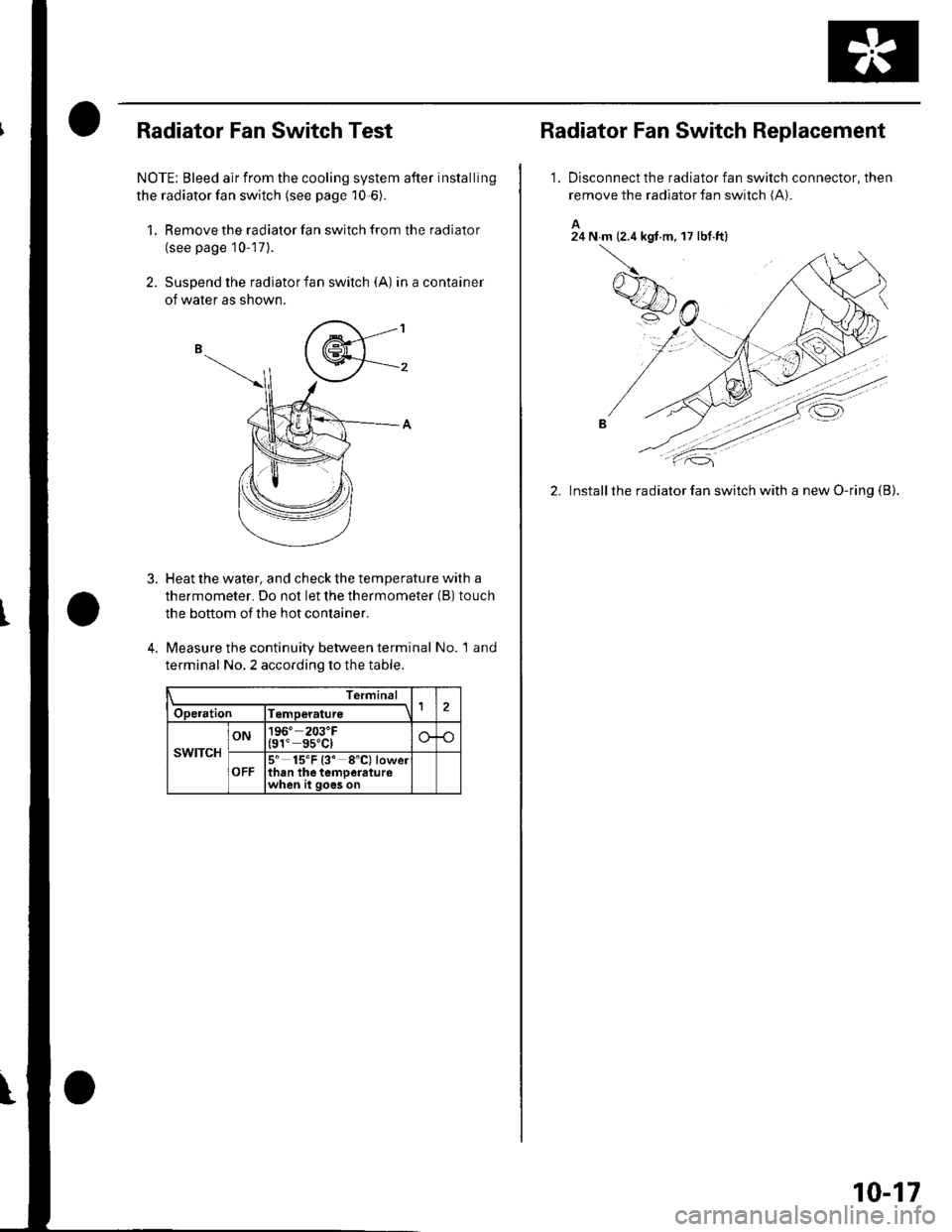

Radiator Fan Switch Replacement

1.Disconnect the radiator fan switch connector, then

remove the radiator fan switch (A).

A24 N m (2.4 kgt.m, 17 lbt.ftl

2. Installthe radiator fan switch with a new O-ring (B).

10-17

Page 210 of 1139

General Troubleshooting Information

Intermittent Failures

The term "intermittent failure" means a svstem mav

have had a failure. but it checks OK now. lf the

Malfunction Indicator Lamp (MlL) on the dash does not

come on, check for Door connections or loose terminals

at all connectors related to the circuit that Vou are

troubleshooting.

Opens and Shorts

"Ooen" and "Short" are common electrical terms. An

open is a break in a wire or at a connection. A short is

an accidental connection of a wire to ground or to

another wire. In simple electronics, this usually means

something won't work at all. With complex electronics(such as ECMs)this can sometimes mean something

works, but not the way it's supposed to.

How to Use the PGM Tester or a Scan Tool

lf the MIL {Malfunction Indicator Lamp} has come on

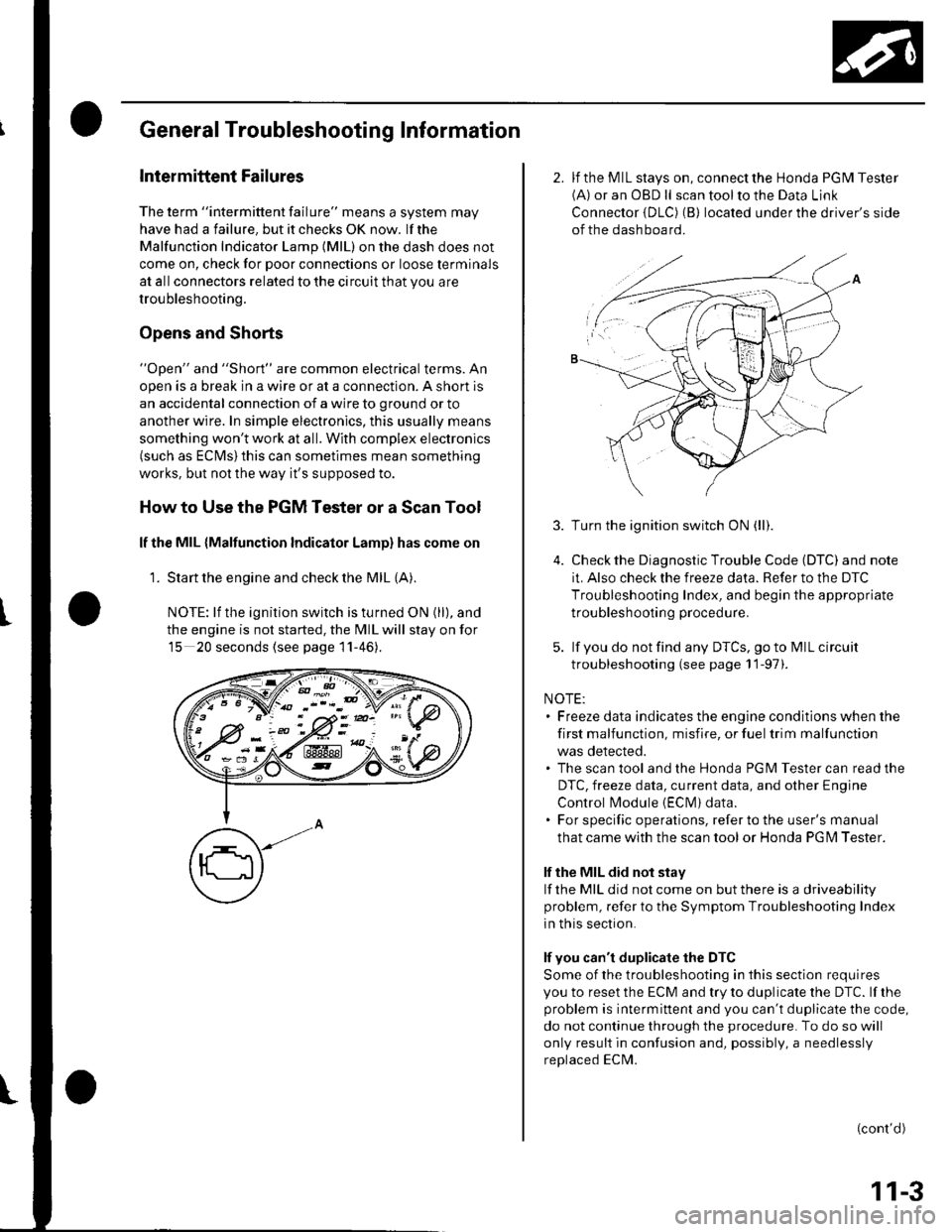

'1. Start the engine and check the MIL {A).

NOTE: lf the ignition switch is turned ON (ll), and

the engine is not started, the MIL will stay on for

15 20 seconds (see page 11-46).

K-> ;"PN/.- -::: - -d V-: !

w:ix&K#

2. lf the MIL stays on, connect the Honda PGM Tester(A) or an OBD ll scan tool to the Data Link

Connector {DLC) (B) located under the driver's side

of the dashboard.

3.

5.

Turn the ignition switch ON (ll).

Check the Diagnostic Trouble Code (DTC) and note

it. Also check the freeze data. Refer to the DTC

Troubleshooting Index, and begin the appropriate

troubleshooting procedure.

lf you do not find any DTCS, go to MIL circuit

troubleshooting (see page 11-97).

NOTE:. Freeze data indicates the engine conditions when the

first malfunction, misfire, or fuel trim malfunction

was detected.. The scan tool and the Honda PGM Tester can read the

DTC, freeze data, current data, and other Engine

Control l\4odule {EClvl) data.. For specific operations, refer to the user's manual

that came with the scan tool or Honda PG l\4 Tester.

lf the MIL did not stay

lf the MIL did not come on but there is a driveability

problem, refer to the Symptom Troubleshooting Index

in this section.

lf you can't duplicate the DTC

Some of the troubleshooting in this section requires

you to reset the ECM and try to duplicate the DTC. lf rhe

problem is intermittent and you can't duplicate the code,

do not continue through the procedure. To do so will

only result in confusion and, possibly, a needlessly

replaced ECM.

(cont'd)

11-3

Page 212 of 1139

How to Troubleshoot Circuits at the ECM

Special Tools Required. Digital Multimeter KS-AHM-32-003 (1) or a

commercially available digital multimeter. Backprobe Set 07SAZ-0010004 (2)

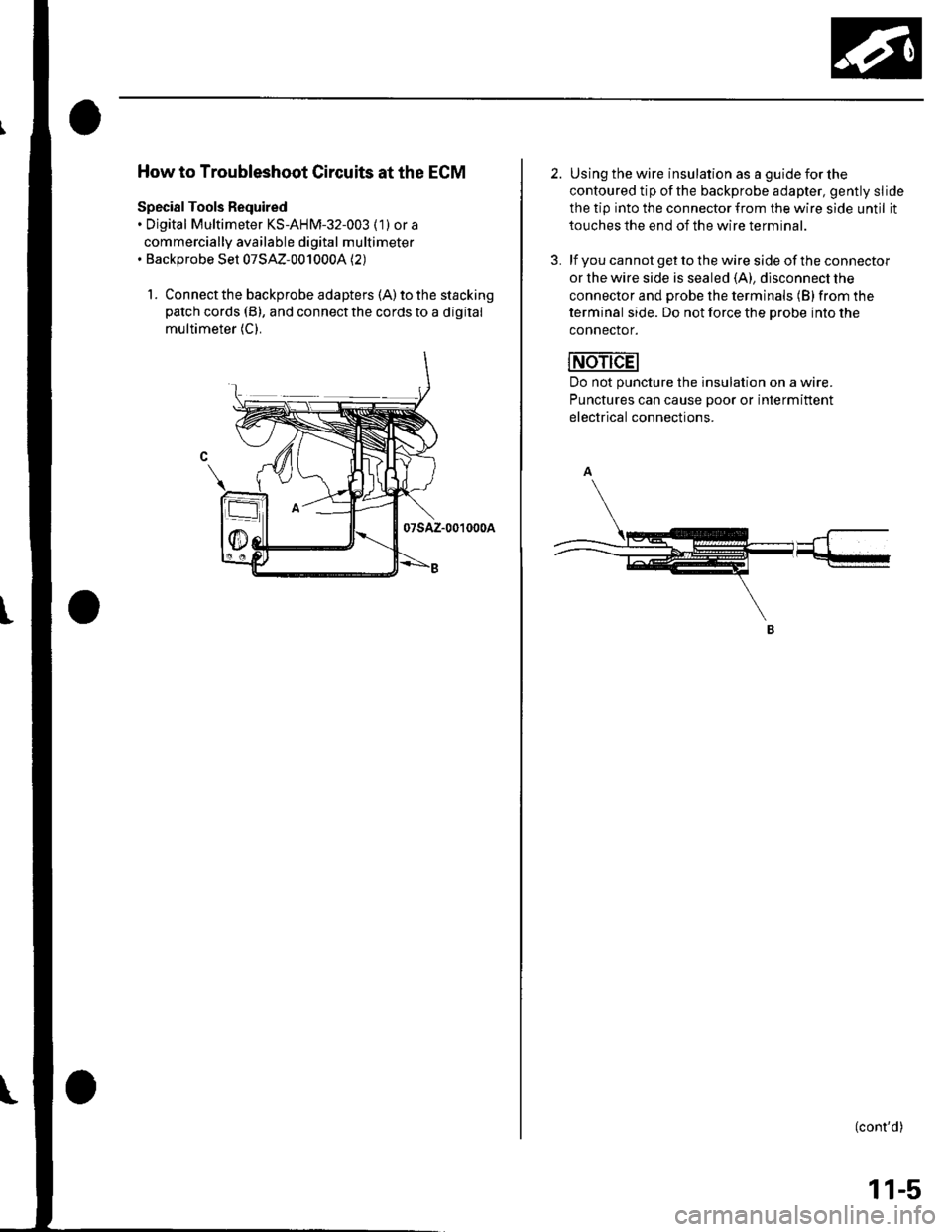

1. Connect the backprobe adapters (A) to the stacking

patch cords (B), and connect the cords to a digital

multimeter (C).

07sAz-001000A

2. Using the wire insulation as a guide for the

contoured tip ofthe backprobe adapter, gently slide

the tip into the connector from the wire side until it

touches the end of the wire terminal.

3. lf you cannot get to the wire side of the connector

or the wire side is sealed (A), disconnect the

connector and probe the terminals (B) from the

terminal side. Do not force the Drobe into the

connector.

Do not puncture the insulation on a wire.

Punctures can cause Door or intermittent

electrical connections.

(cont'd)

11-5