wheel torque HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 591 of 1139

3.

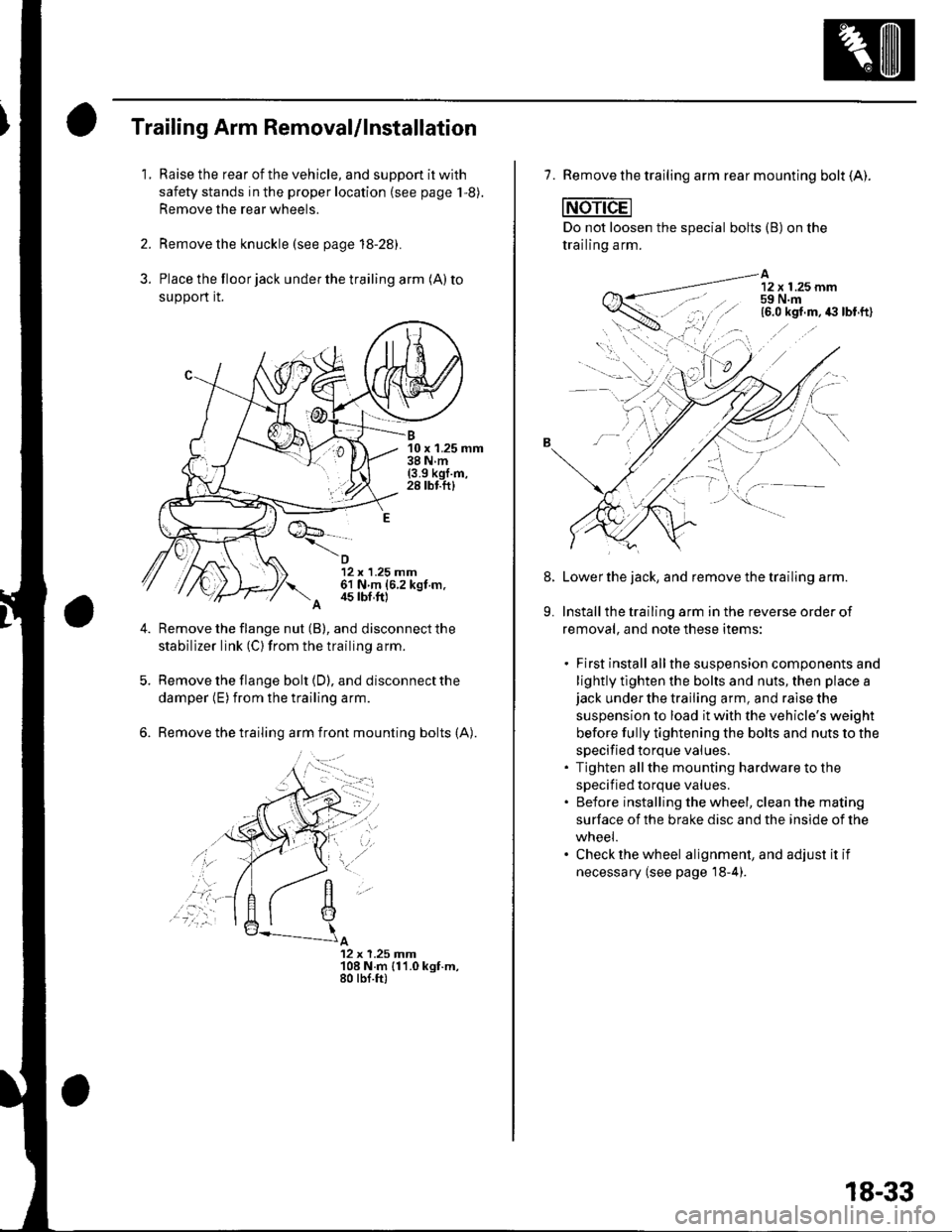

Trailing Arm Removal/lnstallation

1.Raise the rear of the vehicle, and suppon it with

safety stands in the proper location (see page 1,8).

Remove the rear wheels.

Remove the knuckle (see page 18-28).

Place the floor jack under the trailing arm (A) to

support it.

B10 x 1.25 mm38Nm(3.9 kgl.m,28 tbf.ftl

12 x 1.25 mm61 N m (6.2 kgt m.

A 4s tbf,ft)

Remove the flange nut (B), and disconnect the

stabilizer link (C) from the trailing arm.

Remove the flange bolt {D), and disconnect the

damper (E) from the trailing arm.

Remove the trailing arm front mounting bolts (A).

A12 x 1.25 Jnm108 N.m {11.0 kgt.m,80 tbf.ft)

,'a':r -

7. Remove the trailing arm rear mounting bolt (A).

Do not loosen the special bolts (B) on the

trailing arm.

A12 x 1.25 mm59 N.m

-----\':,'.ttg

'.,--1..-r.':1

Lower the jack, and remove the trailing arm.

Install the trailing arm in the reverse order of

removal, and note these items:

. First install allthe suspension components and

lightly tlghten the bolts and nuts, then place ajack under the trailing arm, and raise the

suspension to load it with the vehicle's weight

before fully tightening the bolts and nuts to the

specified torque values.. Tighten allthe mounting hardware to the

specif ied torque values.. Before installing the wheel, clean the mating

surface of the brake disc and the inside of the

wneei.. Check the wheel alignment, and adjust it if

necessary (see page'18-4).

8.

9.

18-33

Page 595 of 1139

D

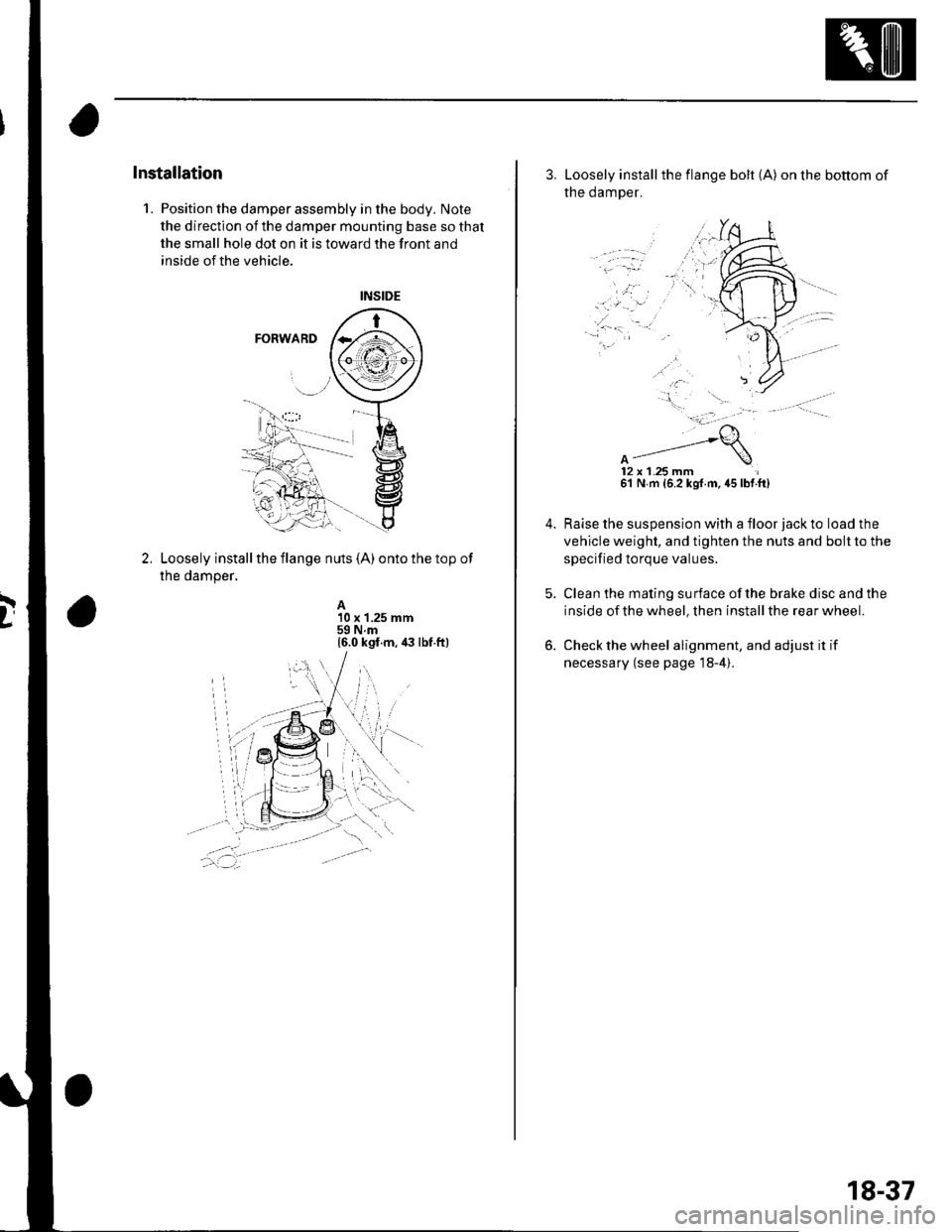

Installation

1. Position the damper assembly in the body. Note

the direction of the damper mounting base so that

the small hole dot on it is toward the front and

inside of the vehicle.

Loosely install the flange nuts (A) onto the top of

the damper,

A10 x 1.25 mm59 N.m16.0 kgt.m, ia lbt ft)

3. Loosely installthe flange bolt (A) on the bottom of

the damper.

12x 1.25 mm61 N m {6.2 kgf.m. 45 lbf.ft)

Raise the suspension with a floor jack to load the

vehicle weight, and tighten the nuts and bolt to the

specified torque values.

Clean the mating surface ofthe brake disc and the

inside of the wheel, then install the rear wheel.

Check the wheel alignment, and adjust it if

necessary (see page 18-4).

18-37

Page 608 of 1139

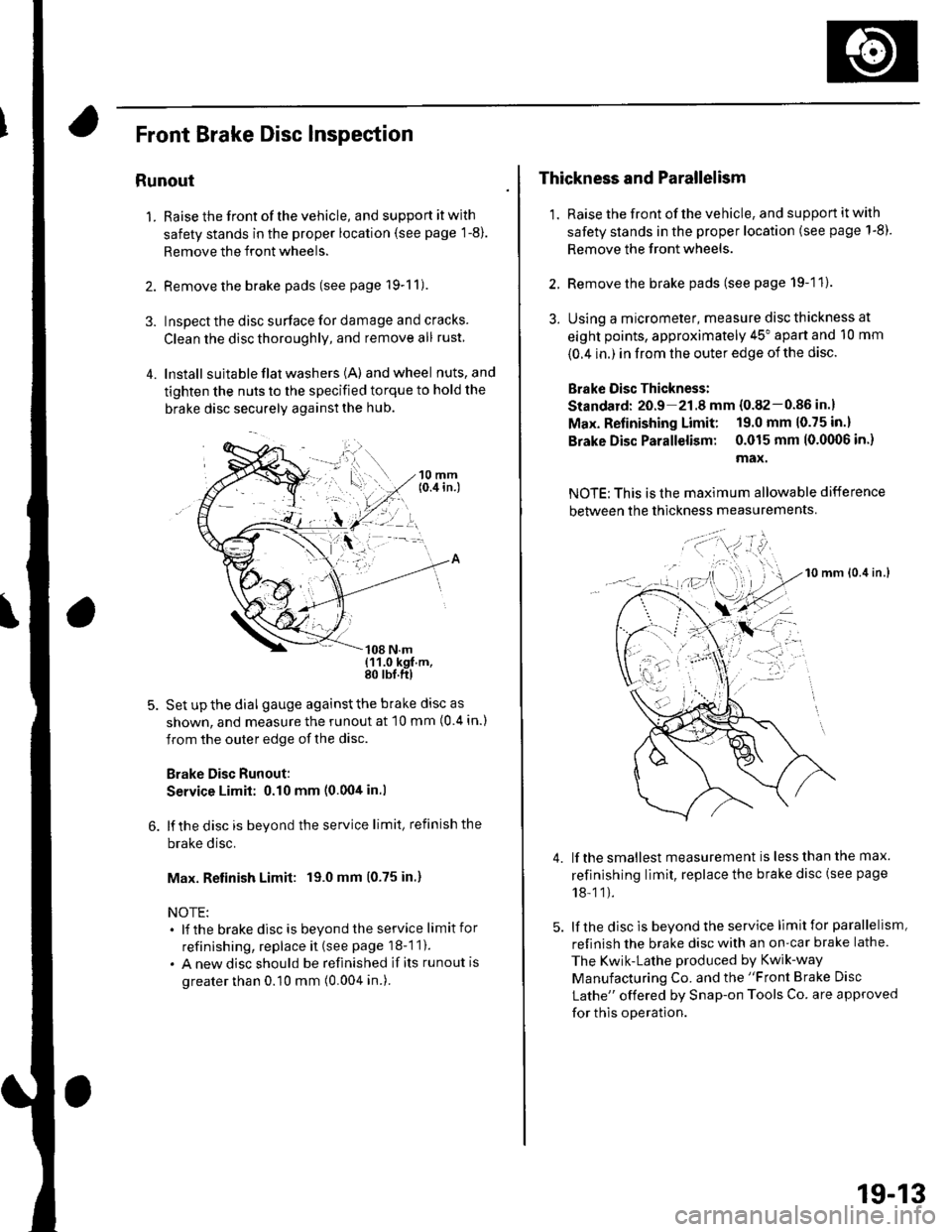

Front Brake Disc lnspection

Runout

1. Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

2. Remove the brake pads (see page 19-11).

3. Inspect the disc surface for damage and cracks.

Clean the disc thoroughly, and remove all rust

4. lnstall suita ble flat washers (A) andwheel nuts,and

tighten the nuts to the specified torque to hold the

brake disc securely against the hub.

Set up the dial gauge against the brake disc as

shown, and measure the runout at 10 mm (0 4 in.)

from the outer edge of the disc.

Brake Disc Runout:

Service Limit: 0.10 mm (0.00tt in.l

lf the disc is beyond the service limit, refinish the

brake disc.

Max. Retinish Limit: 19.0 mm (0.75 in.)

NOTE:. lf the brakedisc is beyondtheservice limitfor

refinishing, replace it (see page 18-1 1).

. A new disc should be refinished if its runout is

greater than 0.10 mm (0.004 in.).

Thickness and Parallelism

1. Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

2. Remove the brake pads (see page 19-11).

3. Using a micrometer, measure disc thickness at

eight points, approximately 45" apart and 10 mm

{0.4 in.) in from the outer edge of the disc.

Brake Oisc Thickness:

Standard: 20.9 21.8 mm {0.82-0.86 in.}

Max. Refinishing Limit: 19.0 mm 10.75 in.)

Brake Disc Parallelism: 0.015 mm 10.0(X)6 in.)

max.

NOTE: This is the maximum allowable difference

between the thickness measurements

10 mm lo.it in.l

lf the smallest measurement is less than the max.

refinishing limit, replace the brake disc (see page

18-11).

lf the disc is beyond the service limit for parallelism,

refinish the brake disc with an on-car brake lathe.

The Kwik-Lathe produced by Kwik-way

Manufacturing Co. and the "Front Brake Disc

Lathe" offered by Snap-on Tools Co. are approved

for this operation.

4.

': . --'t-'"'-

t,.

19-13

Page 617 of 1139

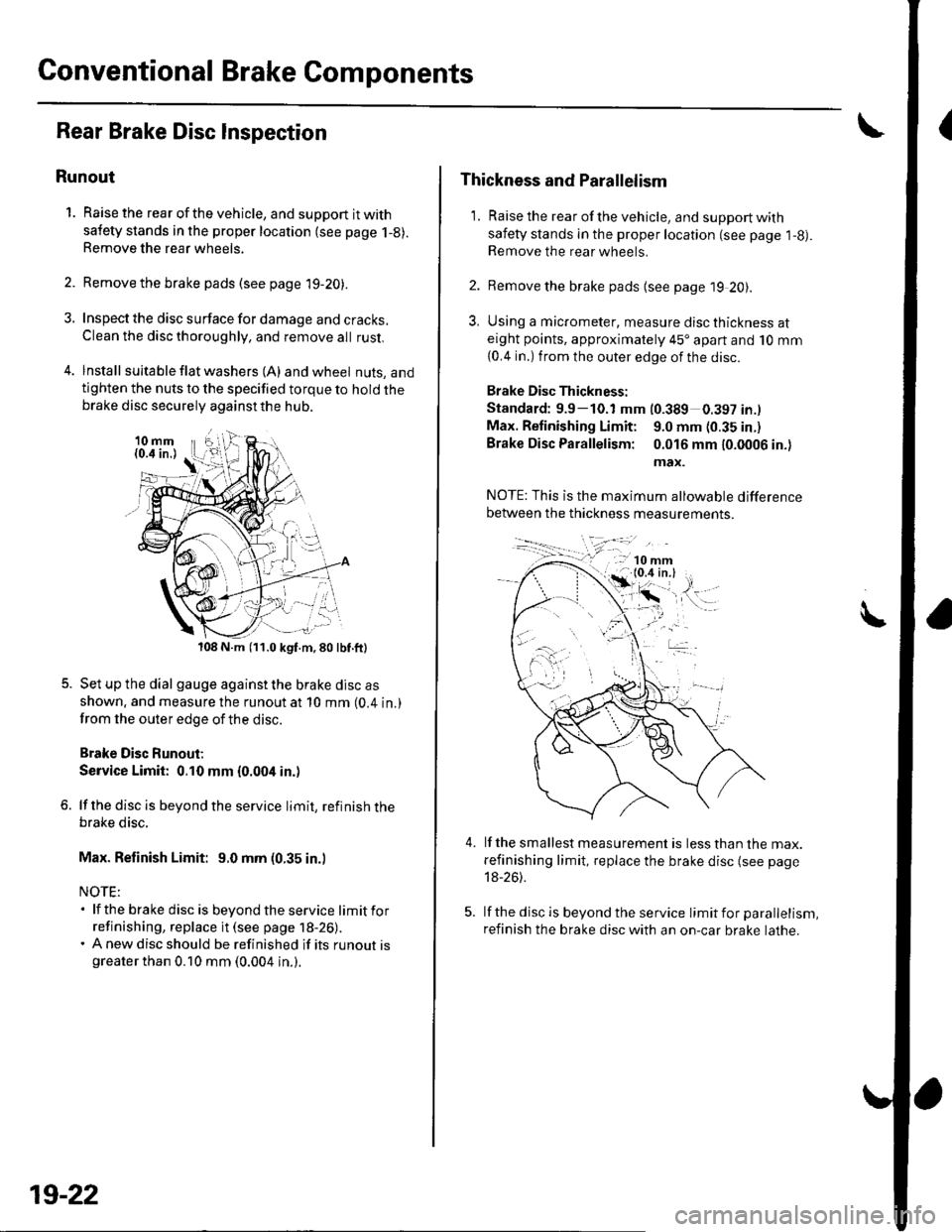

Conventional Brake Components

Rear Brake Disc Inspection

Runout

1. Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).Remove the rear wheels,

2. Remove the brake pads (see page 19-20).

3. Inspect the disc surface for damage and cracks.

Clean the disc thoroughly, and remove all rust,

4. lnstall suita ble f lat washers (A) and wheel nuts, andtighten the nuts to the specified torque to hold thebrake disc securely against the hub.

108 N.m (11.0 kgf.m,80lbf.ft)

Set up the dial gauge against the brake disc as

shown. and measure the runout at 10 mm (0.4 in.)

from the outer edge of the disc.

Brake Disc Runout;

Service Limit: 0.10 mm {0.004 in.)

lf the disc is beyond the service limit, refinish thebrake disc.

Max. Refinish Limit: 9.0 mm (0.35 in.)

NOTE:. lf the brake disc is beyondtheservice limitfor

refinishing, replace it (see page 18-26).. A new disc should be refinished if its runout isgreater than 0.10 mm (0.004 in.).

19-22

Thickness and Parallelism

1. Raise the rear of the vehicle, and support with

safety stands in the proper location (see page l-g).Remove the rear wheels.

2. Remove the brake pads {see page 19 20).

3, Using a micrometer, measure disc thickness ateight points, approximately 45'apart and 10 mm

{0.4 in.) from the outer edge of the disc.

Brake Disc Thickness:

Standard: 9.9-10.1 mm (0.389 0.397 in.l

Max. Retinishing Limit: 9.0 mm (0.35 in.)

Brake Disc Parallelism: 0.016 mm 10.0006 in.)

max.

4.lf the smallest measurement is less than the max.

refinishing limit, replace the brake disc (see page

18-26).

lf the disc is beyond the service limit for parallelism,

refinish the brake disc with an on-car brake lathe.