connector 3p HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 895 of 1139

Gauges

2.

3.

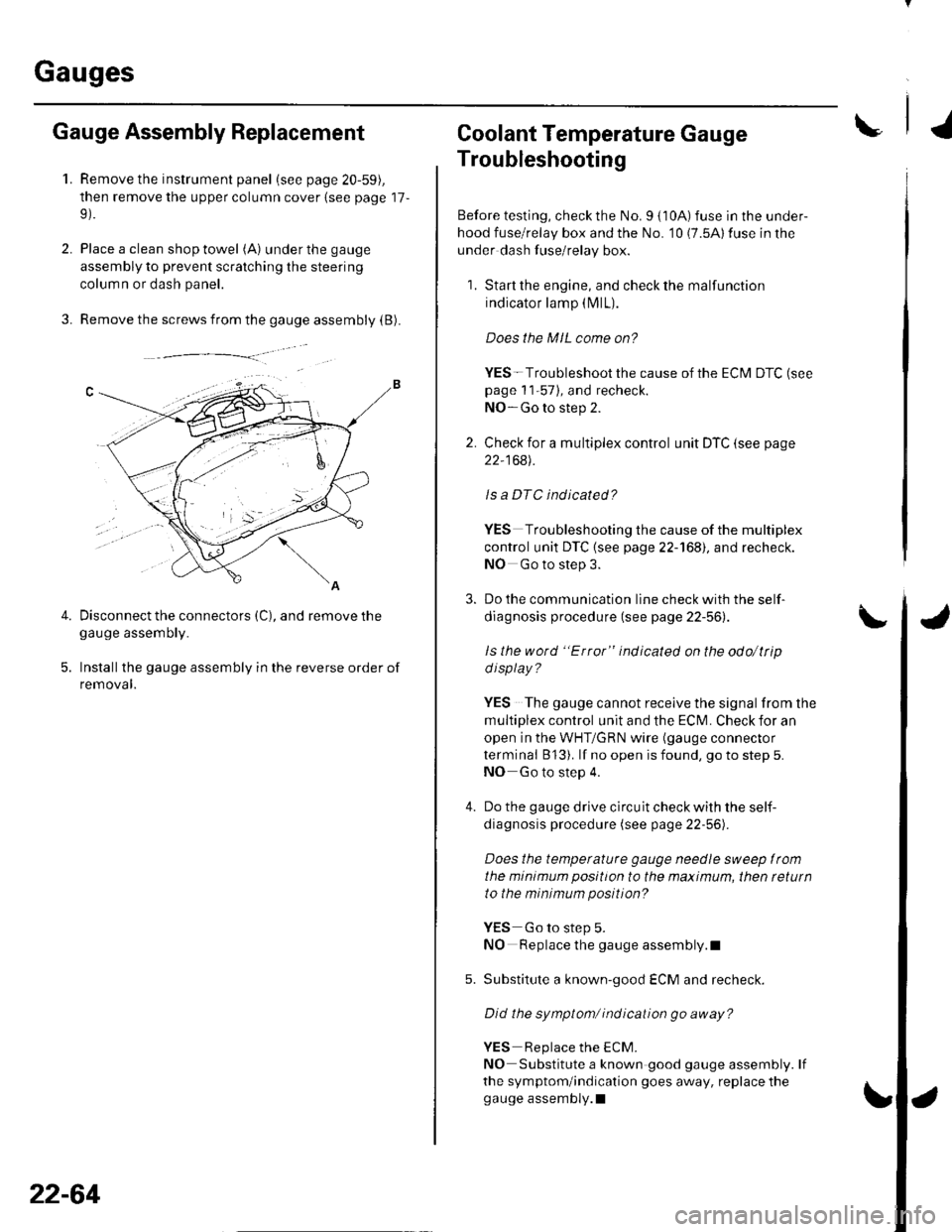

Gauge Assembly Replacement

1.Remove the instrument panel (see page 20-59),

then remove the upper column cover {see page 17-

Place a clean shop towel (A) under the gauge

assembly to prevent scratching the steering

colum n or dash panel.

Remove the screws from the gauge assembly (B).

Disconnect the connectors (C), and remove thegauge assemDry.

Installthe gauge assembly in the reverse order of

removal.

Coolant Temperature Gauge

Troubleshooting

Before testing, check the No. I { 10A) fuse in the under-

hood fuse/relay box and the No. '10 (7.5A) fuse in the

under dash fuse/relay box.

1. Start the engine, and check the malfunction

indicator lamp (MlL).

Does the MIL come on?

YES- Troubleshoot the cause of the ECM DTC (see

page 1 1-57), and recheck.

NO-Go to step 2.

2. Check for a multiplex control unit DTC (see page

22,168).

ls a DTC ind icated?

YES Troubleshooting the cause of the multiplex

control unit DTC {see page 22-168), and recheck.

NO Go to step 3.

3. Do the communication line check with the self-

diagnosis procedure (see page 22-56).

ls the word "Error" indicated on the odo/ttip

d isplay ?

YES The gauge cannot receive the signal from the

multiplex control unit and the ECI\,4. Check for an

open in the WHT/GRN wire (gauge connector

terminal B 13). lf no open is found, go to step 5.

NO Go to step 4.

4. Do the gauge drive circuit check with the self-

diagnosis procedure (see page 22-56).

Does the temperature gauge needle sweep lrom

the minimum position to the maximum, then tetutn

to the minimum position?

YES Go to step 5.

NO Replace the gauge assembly.l

5. Substitute a known-good ECM and recheck.

Did the symptom/ ind ication go away?

YES Replace the ECM.

NO Substitute a known good gauge assembly. lf

the symptom/indication goes away, replace thegauge assembly.l

4.

22-64

Page 896 of 1139

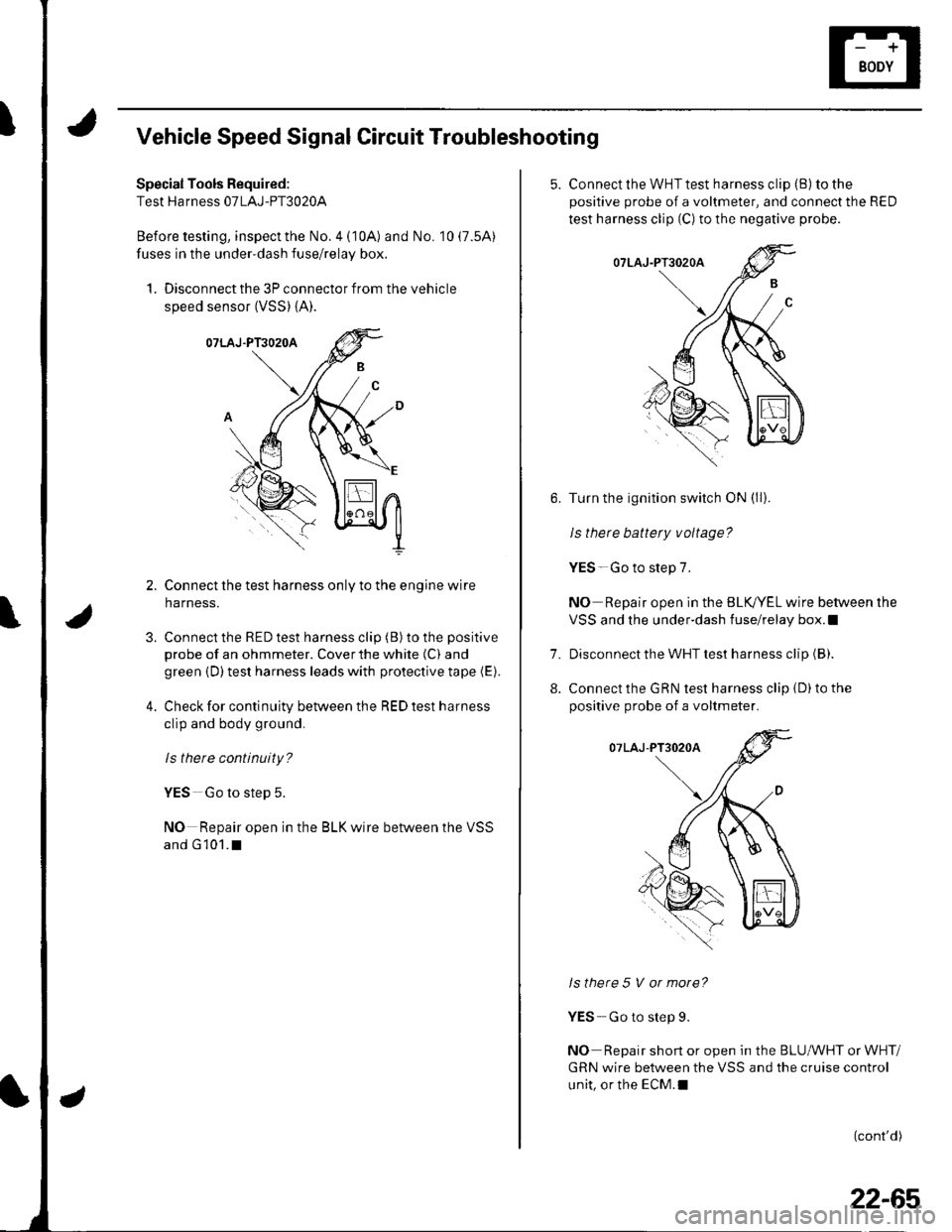

IVehicle Speed Signal Circuit Troubleshooting

Special Tools Required:

Test Harness 07LAJ-PT3020A

Before testing, inspect the No. 4 (10A) and No. 10 (7.5A)

fuses in the under-dash fuse/relay box.

1. Disconnect the 3P connector from the vehicle

speed sensor (VSS) {A).

Connect the test harness only to the engine wire

harness.

Connect the RED test harness clip (B) to the positive

probe of an ohmmeter. Cover the white (C) and

green {D) test harness leads with protective tape (E).

Check for continuity between the RED test harness

clip and body ground,

ls there continuity?

YES Go to step 5.

NO Repair open in the BLK wire between the VSS

and G 101.I

3.

4.

5. Connect the WHT test harness cliD (B) to the

positive probe of a voltmeter, and connect the RED

test harness clip (C) to the negative probe.

Turn the ignition switch ON (ll).

le thara h2ltarv v^ltada?

YES-Go to step 7.

NO Repair open in the BLK,/YEL wire between the

VSS and the under-dash fuse/relay box.l

Disconnect the WHT test harness clip (B).

Connect the GRN test harness clip {D) to the

positive probe of a voltmeter.

Is there 5 V or more?

YES- Go to step 9.

NO Repair short or open in the BLUMHT or WHT/

GRN wire between the VSS and the cruise control

unit, or the ECM.I

(cont'd)

7.

8.

22-65

Page 897 of 1139

Gauges

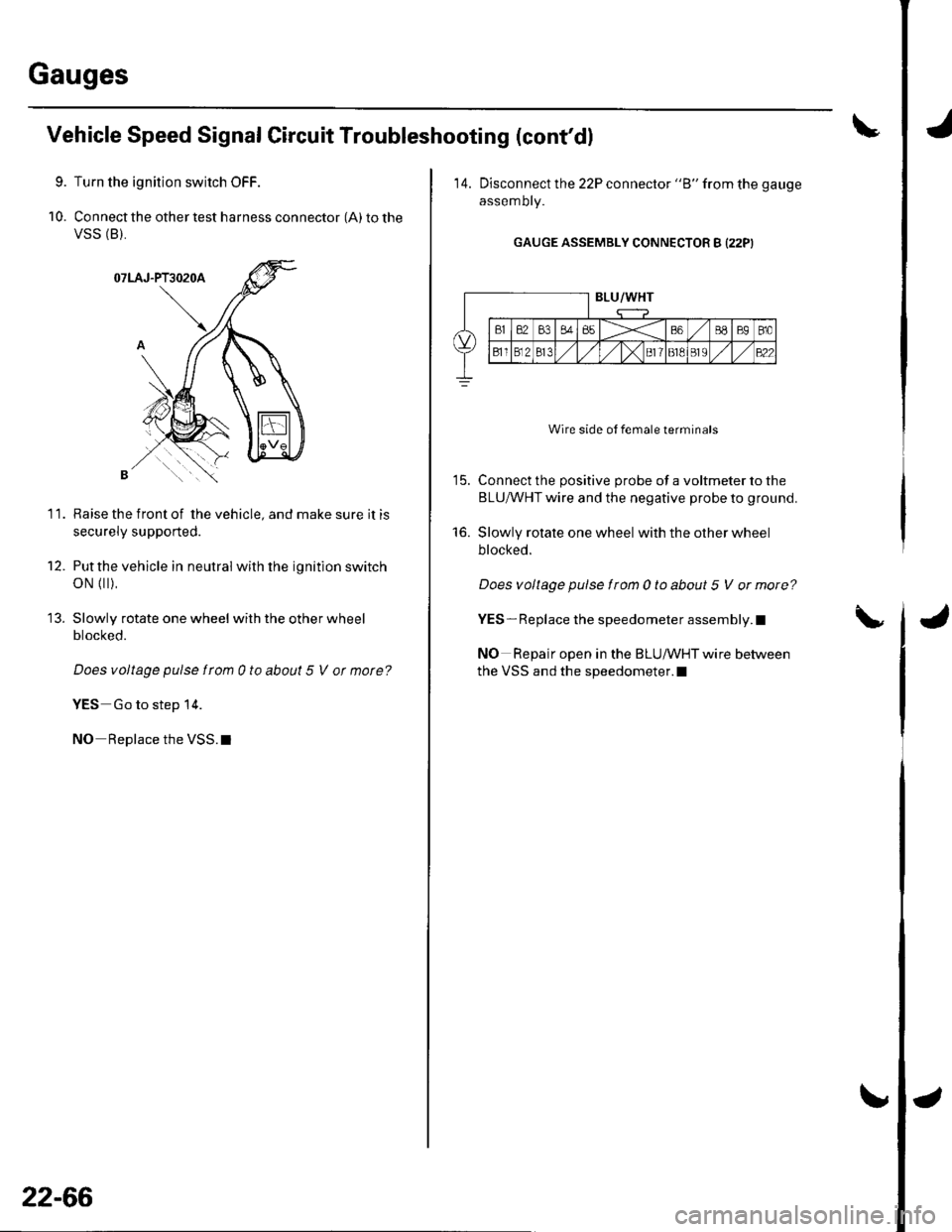

9.

10.

Vehicle Speed Signal Circuit Troubleshooting (cont'dl

Turn the ignition switch OFF.

Connect the other test harness connector (A) to the

VSS (B),

11.Raise the front of the vehicle, and make sure it is

securely supported.

Put the vehicle in neutral with the ignition switch

oN {|| ),

Slowly rotate one wheel with the other wheel

blocked.

Does voltage pulse ttom 0 to about 5 V ot morc?

YES Go to step 14.

NO Replace the VSS.I

't2.

t5.

22-66

14. Disconnect the 22P connector "8" from the gauge

assemDry.

GAUGE ASSEMBLY CONNECTOR B (22P)

Wire side ot female terminals

'15. Connect the positive probe of a voltmeter to the

BLU/WHT wire and the negative probe to ground.

'16. Slowly rotate one wheel with the other wheel

blocked.

Does voltage pulse f rom 0 to about 5 V or more?

YES - Replace the speedometer assembly.I

NO Repair open in the BLUMHTwiTe between

the VSS and the speedometer.l

Page 898 of 1139

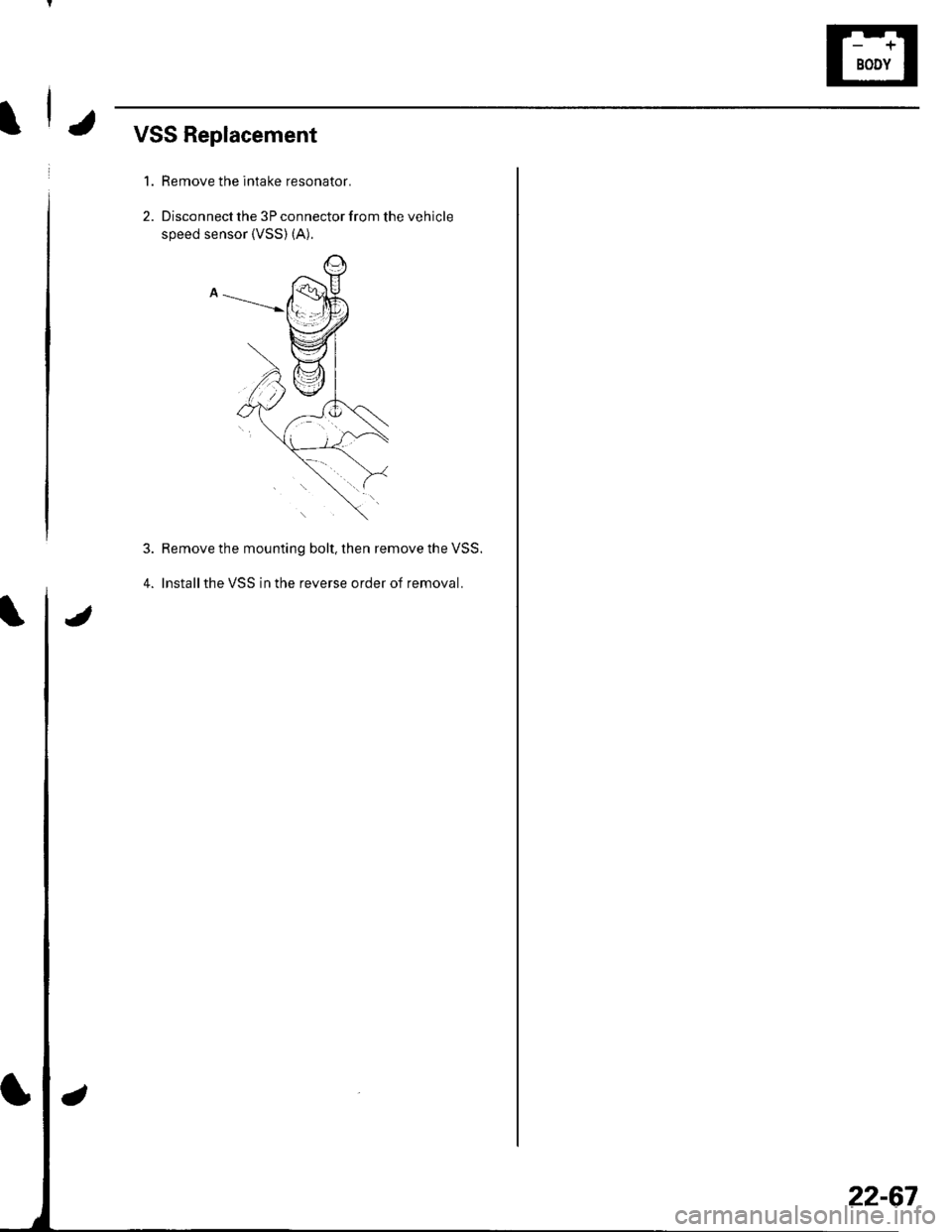

IJVSS Replacement

1. Remove the intake resonator.

2. Disconnect the 3P connector from the vehicle

speed sensor {VSS) (A).

4.

Remove the mounting bolt, then remove the VSS.

lnstallthe VSS in the reverse order of removal.

22-67

Page 907 of 1139

Exterior Lights

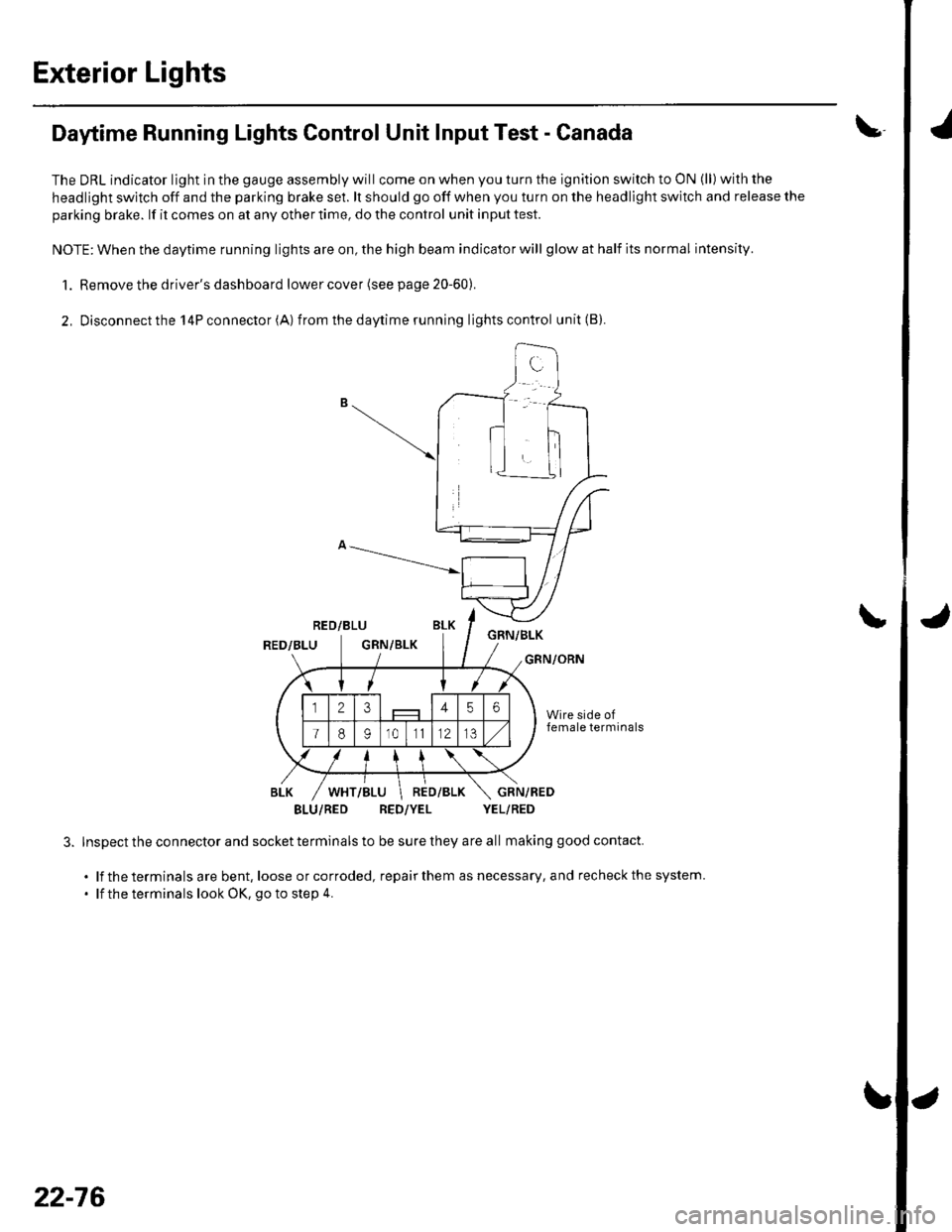

Daytime Running Lights Control Unit Input Test - Canada

The DRL indicator light in the gauge assembly will come on when you turn the ignition switch to ON (ll) with the

headlight switch off and the parking brake se1. lt should go off when you turn on the headlight switch and release the

parking brake. lf it comes on at any other time, do the control unit input test.

NOTE: When the daytime running lights are on, the high beam indicator will glow at half its normal intensity.

1. Remove the driver's dashboard lower cover (see page 20-60).

2, Disconnectthe l4Pconnector(A) from thedaytime running lightscontrol unit(B).

RED/BLUGNN/BLKRED/BLUGRN/BLKGRN/ORN

BLU/RED RED/YEL YEL/RED

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose orcorroded, repairthem as necessary, and recheckthe system.

' lf the terminals look OK, go to step 4.

\

22-76

Page 908 of 1139

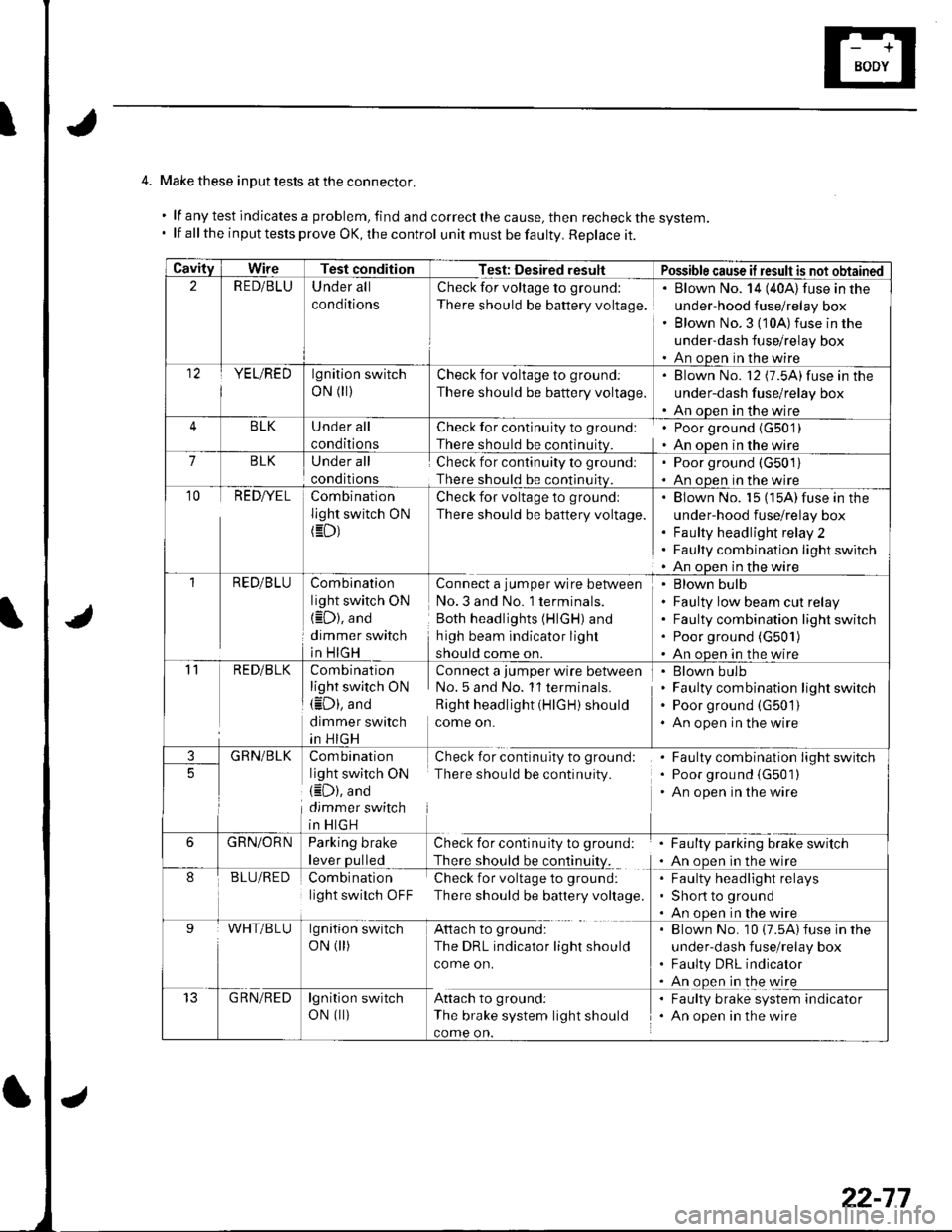

4. Make these input tests at the connector,

.lfanytestindicatesaproblem,findandcorrectthecause,thenrecheckthesystem.

. lf all the input tests prove OK, the control unit must be faulty. Replace it.

CavityWireTest conditionTest: Desired resultPossible cause if result is not obtained2R E D/BLUUnder all

conditions

Check for voltage to ground:

There should be battery voltage.

Blown No. 14 (40A) fuse in the

under-hood fuse/relay box

Blown No. 3 {10A)fuse in the

under-dash fuse/relay box

An open in the wire12YE L/RE Dlgnition switch

oN (r)Check for voltage to ground:

There should be battery voltage.

Blown No. l2 (7.5A)fuse in the

under-dash fuse/relay box

An open in the wire

BLKUnder all

conditions

Check for continuity to ground:

There should be continuitv.

. Poor ground {G50'1). An oDen in the wire7BLKUnder all

conditions

Check for continuity to ground:

There should be continuitv.

. Poor ground (G501)

' An open in the wire

10REDI/ELCombination

light switch ON/ =f\

Check for voltage to ground:

There should be battery voltage.

Blown No. 15 (15A) fuse in the

under-hood fuse/relay box

Faulty headlight relay 2

Faulty combination light switch

An open in the wire

1RED/B LUCombination

light switch ON

{iD), and

dimmer switch

in HIGH

Connect a jumper wire between

No.3 and No. 1 terminals.

Both headlights (HIGH) and

h igh beam indicator light

should come on.

Blown bulb

Faulty low beam cut relay

Faulty combination light switch

Poor ground (G50'l )

An open in the wire'11

3

RED/BLK

GRN/BLK

Combination

light switch ON(iD), and

dimmer switch

in HIGH

Com bination

light switch ON(iD), and

dimmer switch

in HIGH

Connect a jumper wire between

No. 5 and No. 11 terminals.

Right headlight (HIGH) should

come on.

Check for continulty to ground

There should be continuity.

. Blown bulb. Faulty combination light switch. Poor ground (G 50'1 ). An open in the wire

. Faulty combination light switch. Poor grou nd {G501). An open in the wire

5

6GRN/ORNParking brake

lever oulled

Check for continuity to ground:

There should be continuitv.

Faulty parking brake switch

An open in the wire

8BLU/REDCombination

light switch OFF

Check for voltage to ground:

There should be battery voltage.

Faulty headlight relays

Short to ground

An ooen in the wire

WHT/BLUlgnition switch

oN 0r)

Attach to ground:

The DRL indicator light should

come on.

. Blown No. 10 (7.5A) fuse in the

under-dash fuse/relay box. Faulty DRL indicator. An ooen in the wire

t5G RN/REDlgnition switch

oN (||)Attach to ground:

The brake system light should

come on.

Faulty brake system indicator

An open in the wire

22-77

Page 910 of 1139

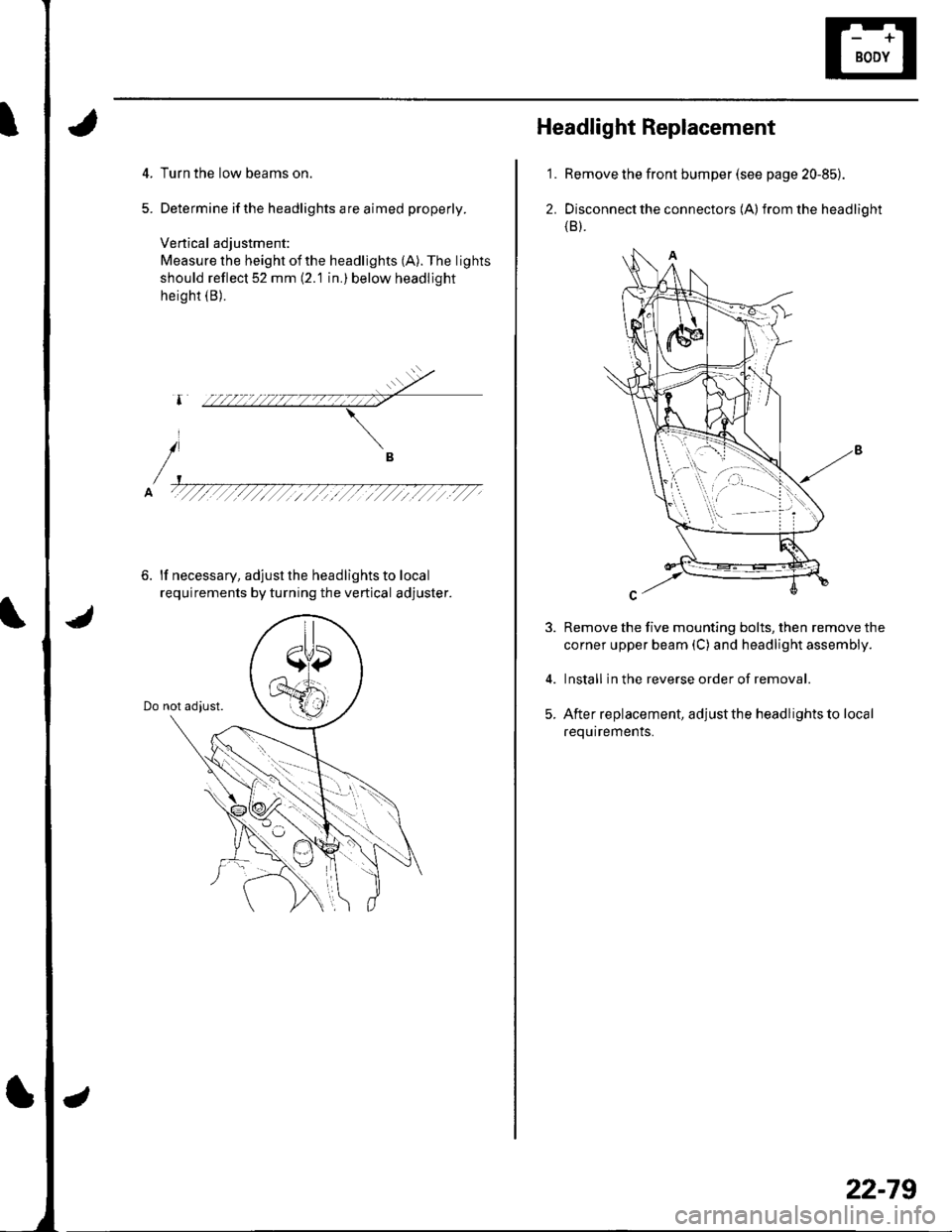

5

Turn the low beams on.

Determine ifthe headlights are aimed properly.

Vertical adjustment:

Measure the height ofthe headlights (A). The lights

should reflect 52 mm (2.'1 in.) below headljght

height (B).

6. lf necessary, adjust the headlights to local

requirements by turning the vertical adjuster.

i

Headlight Replacement

Remove the front bumper (see page 20-85).

Disconnect the connectors (A) from the headlight(B).

Remove the five mounting bolts, then remove the

corner upper beam (C) and headlight assembly.

Install in the reverse order of removal.

After replacement, adjust the headlights to local

requirements.

'1.

2.

5.

22-79

Page 911 of 1139

Exterior Lights

4.

5.

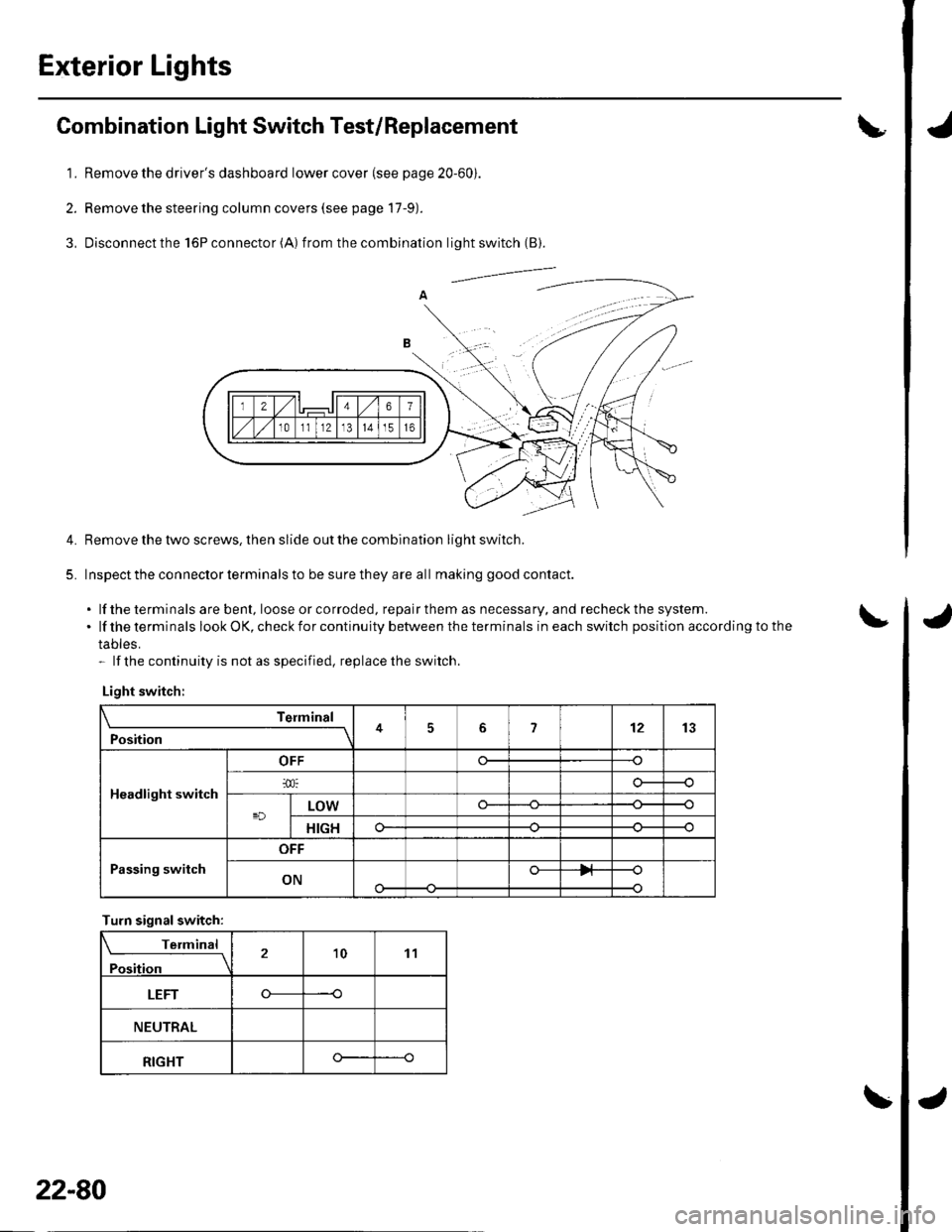

Combination Light Switch Test/Replacement

1. Remove the driver's dashboard lower cover (see page 20-60).

2. Remove the steering column covers (see page 17-9).

3, Disconnectthe l6Pconnector(A) f rom the combination light switch (B).

Remove the tlvo screws, then slide out the combination light switch.

Inspect the connector terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or co rroded, repa ir them as necessa ry, a nd recheck the system..lftheterminalslookOK,checkforcontinuitybetweentheterminalsineachswitchpositionaccordingtothe

tables.- lf the continuity is not as specified, replace the switch.

Light switch:

Telmint

Position451213

Headlight switch

OFF

LOWo--

HIGHo--

Passing switch

OFF

ONo-

Turn signalswitch:

Terminal

Position21011

LEFT----o

NEUTRAL

RIGHTo--

22-80

Page 912 of 1139

Bulb Replacement

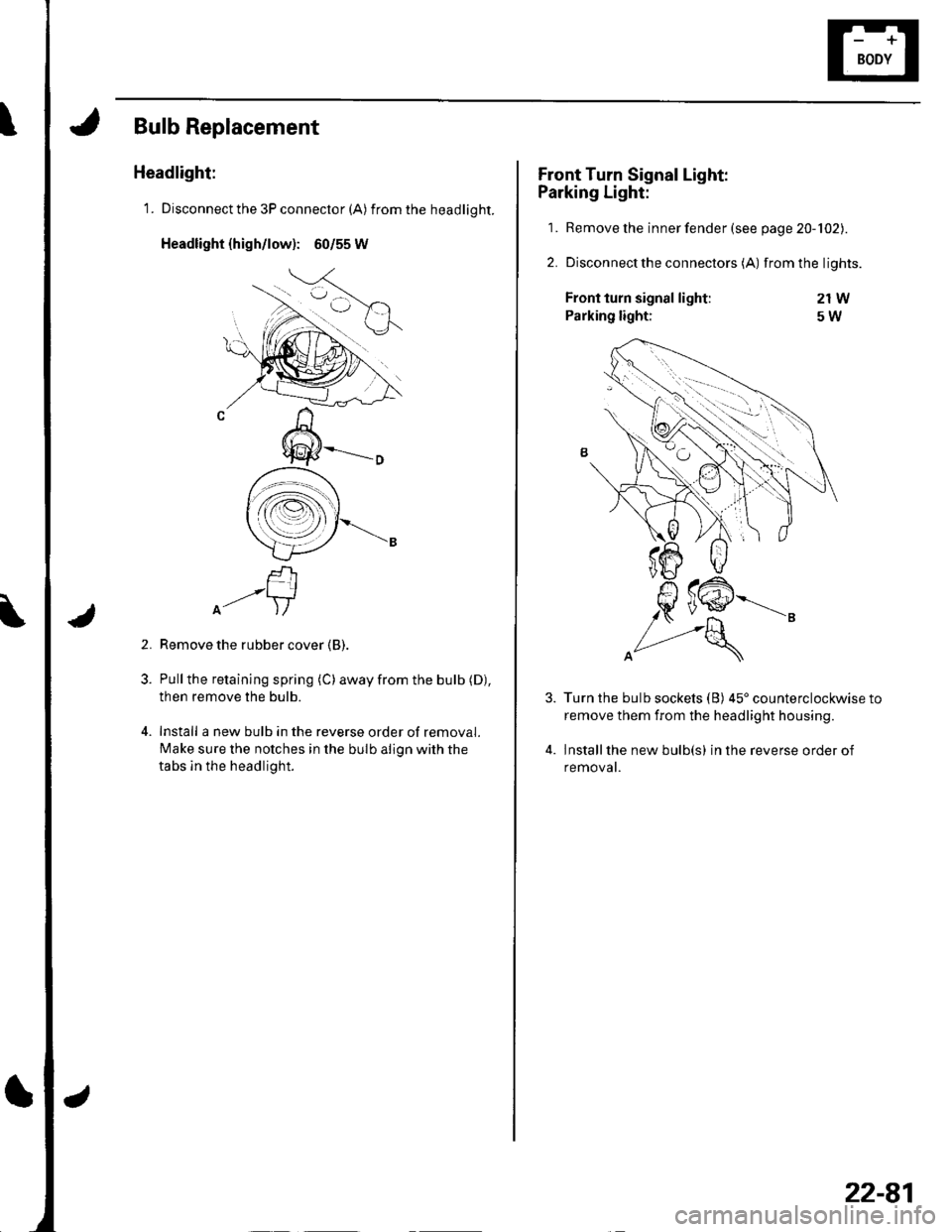

Headlight:

1. Disconnect the 3P connector (A) from the headlight.

Headlight {high/low): 60/55 W

f-rI-'-+lA- )/

Remove the rubber cover (B).

Pull the retaining spring (C) away from the bulb (D),

then remove the bulb.

Install a new bulb in the reverse order of removal.

Make sure the notches in the bulb align with the

tabs ln the headlight.

2.

Front Turn Signal Light:

Parking Light:

1. Remove the inner fender (see page 20-102).

2. Disconnectthe connectors (A) from the lights.

21W

5W

4.

Front turn signal light:

Parking light:

Turn the bulb sockets (B) 45'counterclockwise to

remove them from the headlight housing.

Installthe new bulb(s) in the reverse order of

removat.

22-81

Page 913 of 1139

Exterior Lights

1.

2.

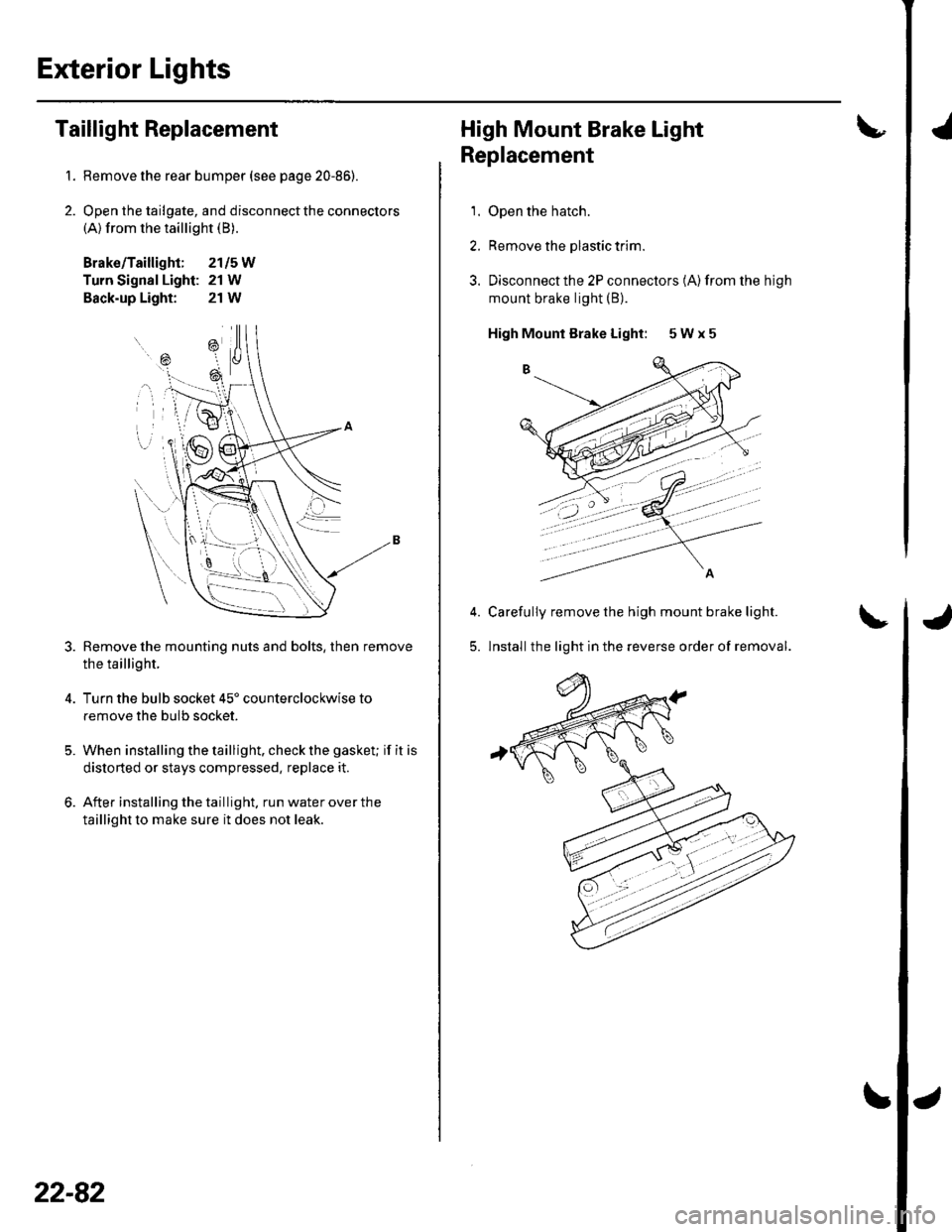

Taillight Replacement

Remove the rear bumper (see page 20-86).

Open the tailgate, and disconnect the connectors(A) from the taillight (B).

Brako/Taillight; 2115W

Turn Signal Light: 21 W

Back-up Light: 21W

Remove the mounting nuts and bolts, then remove

the taillight.

Turn the bulb socket 45' counterclockwise to

remove the bulb socket.

When installing the taillight. check the gasket; if it is

distorted or stays compressed, replace it.

After installing the taillight. run water over the

taillight to make sure it does not leak.

=\

ili--- _ \

rB , \.

---'a t

\

22-82

High Mount Brake Light

Replacement

1. Open the hatch.

2. Remove the plastic trim.

3. Disconnectthe 2P connectors (A)from the high

mount brake light (B).

High Mounl Brake Light: 5 W x 5

Carefully remove the high mount brake light.

lnstall the light in the reverse order of removal.5.

'