cylinder head HONDA CIVIC 2003 7.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 132 of 1139

Valves, Springs, and Valve Seals Installation

Special Tools Required

Valve spring compressor attachment 07VAE-00101 0A

1. Coat the valve stems with engine oil. lnstall the

valves in the valve guides.

2. Check that the valves move up and down smoothly.

Installthe spring seats on the cylinder head.

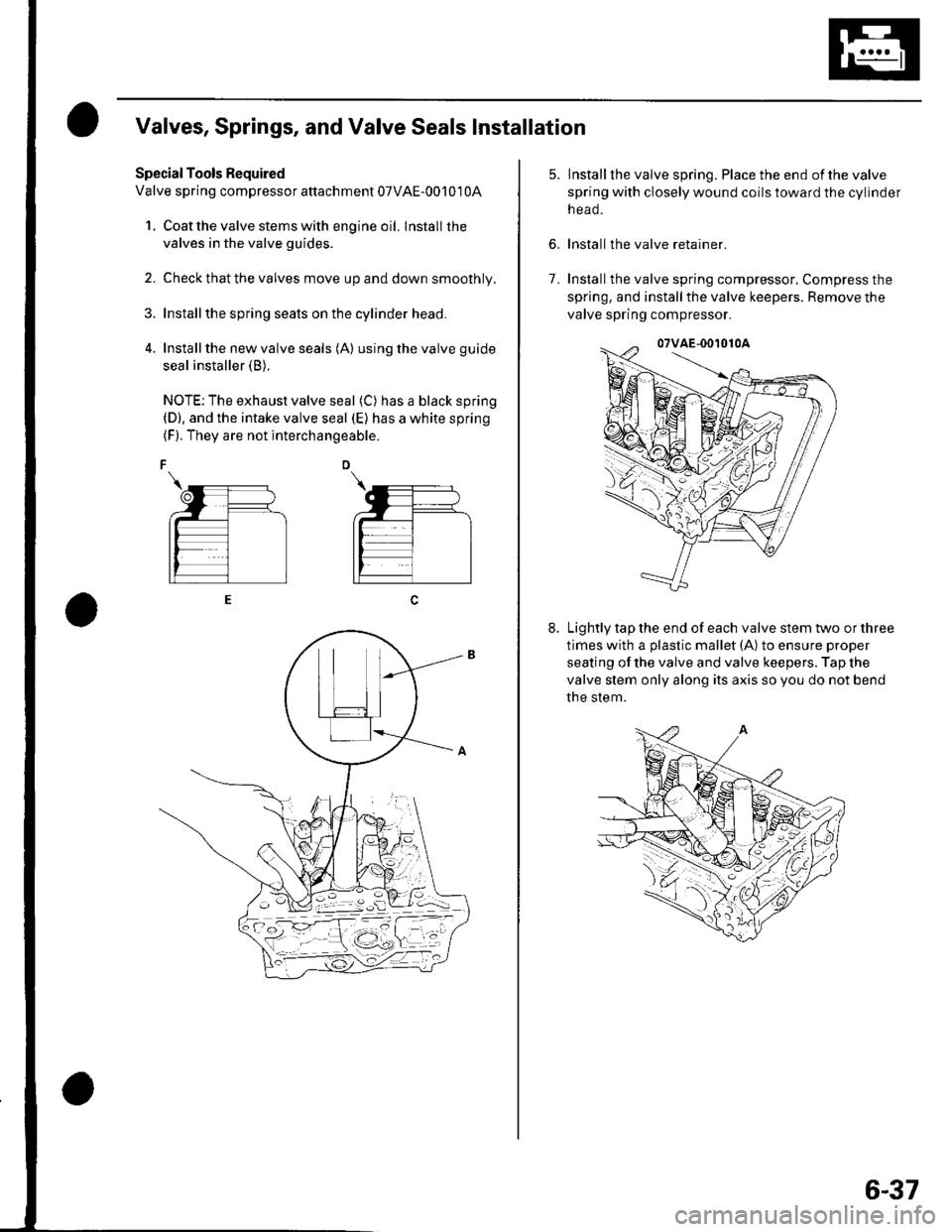

Install the new valve seals (A) using the valve guide

seal installer (B).

NOTE: The exhaust valve seal (C) has a black spring(D), and the intake valve seal (E) has a white spring(F). They are not interchangeable.

6.

lnstallthe valve spring. Place the end ofthe valve

spring with closely wound coils toward the cylinder

n eao.

Install the valve retainer.

Installthe valve spring compressor, Compress the

spring, and install the valve keepers. Remove the

valve spring compressor.

Lightly tap the end of each valve stem two or three

times with a plastic mallet (A) to ensure proper

seating of the valve and valve keepers. Tap the

valve stem only along its axis so you do not bend

the stem.

7.

6-37

Page 133 of 1139

Cylinder Head

Rocker Arm Assembly Installation

:,ean and dry the No. 5 rocker shaft holder mating

surfaces.

eeassemble the rocker arm assembly (see page 6-

21 t.

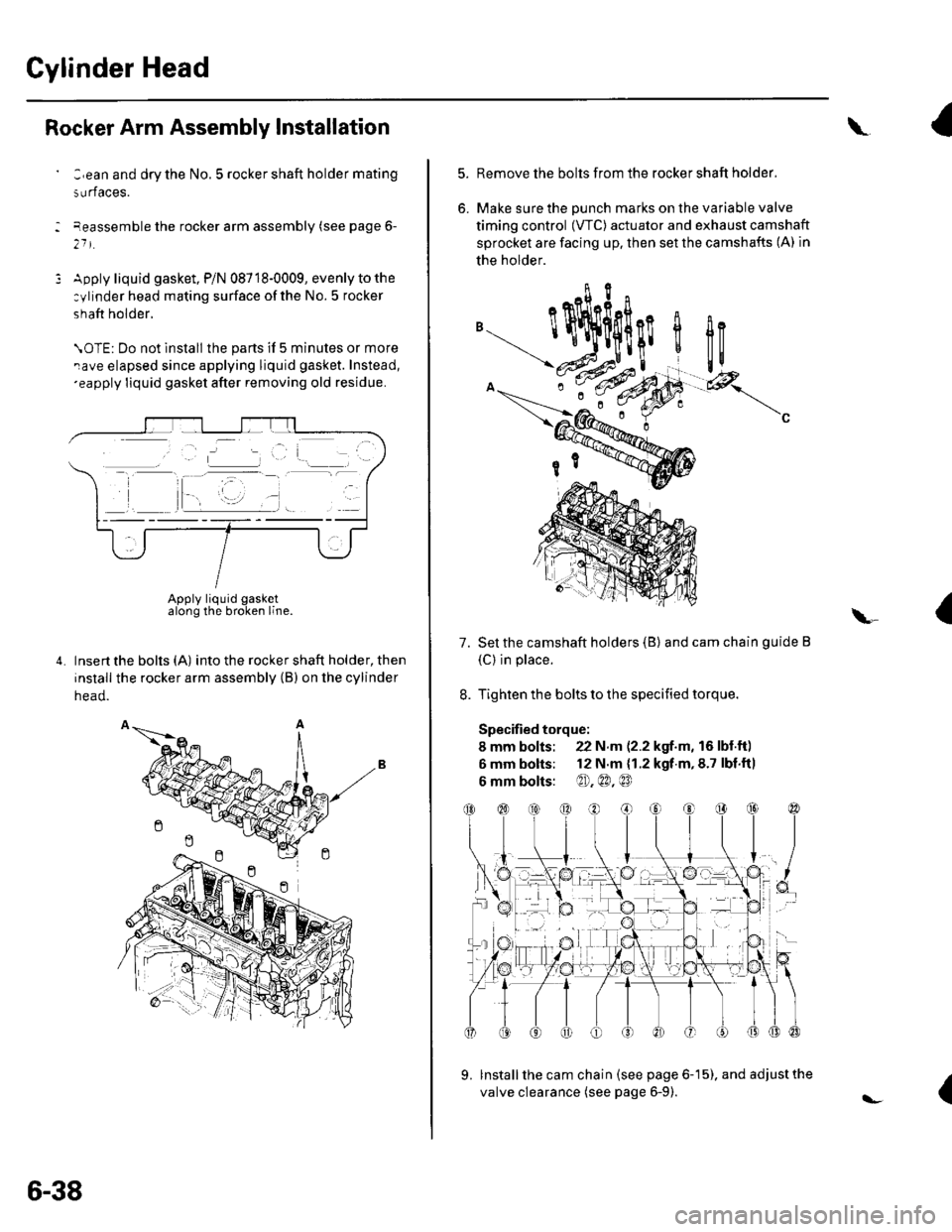

Apply liquid gasket, P/N 08718-0009, evenly to the

:ylinder head mating surface ofthe No. 5 rocker

shaft holder.

\OTE: Do not lnstall the parts if 5 minutes or more

rave elapsed since applying liquid gasket. Instead,'eapply liquid gasket after removing old residue.

Insert the bolts (A) into the rocker shaft holder, then

install the rocker arm assembly (B) on the cylinder

head.

Apply liquid gasketalong the broken line.

6-38

l-

\

5.

6.

Remove the bolts from the rocker shaft holder.

Make sure the DUnch marks on the variable valve

timing control (VTC) actuator and exhaust camshaft

sprocket are facing up. then set the camshafts (A) in

the holder.

Set the camshaft holders (B) and cam chain guide B

(C) in place.

Tighten the bolts to the specified torque.

Specified torque:

8 mm bolts: 22 N.m (2.2 kgf.m, 16 lbl.ft)

6 mm bolts: 12 N.m {1.2 kgf.m,8.7 lbf.fil

6 mm bolts: @),@.@

lnstall the cam chain (see page 6-15). and adjust the

valve clearance (see page 6-9).

I

flc

a\-

7.

{

Page 134 of 1139

Cylinder Head Installation

Install the cylinder head in the reverse order of

removat:

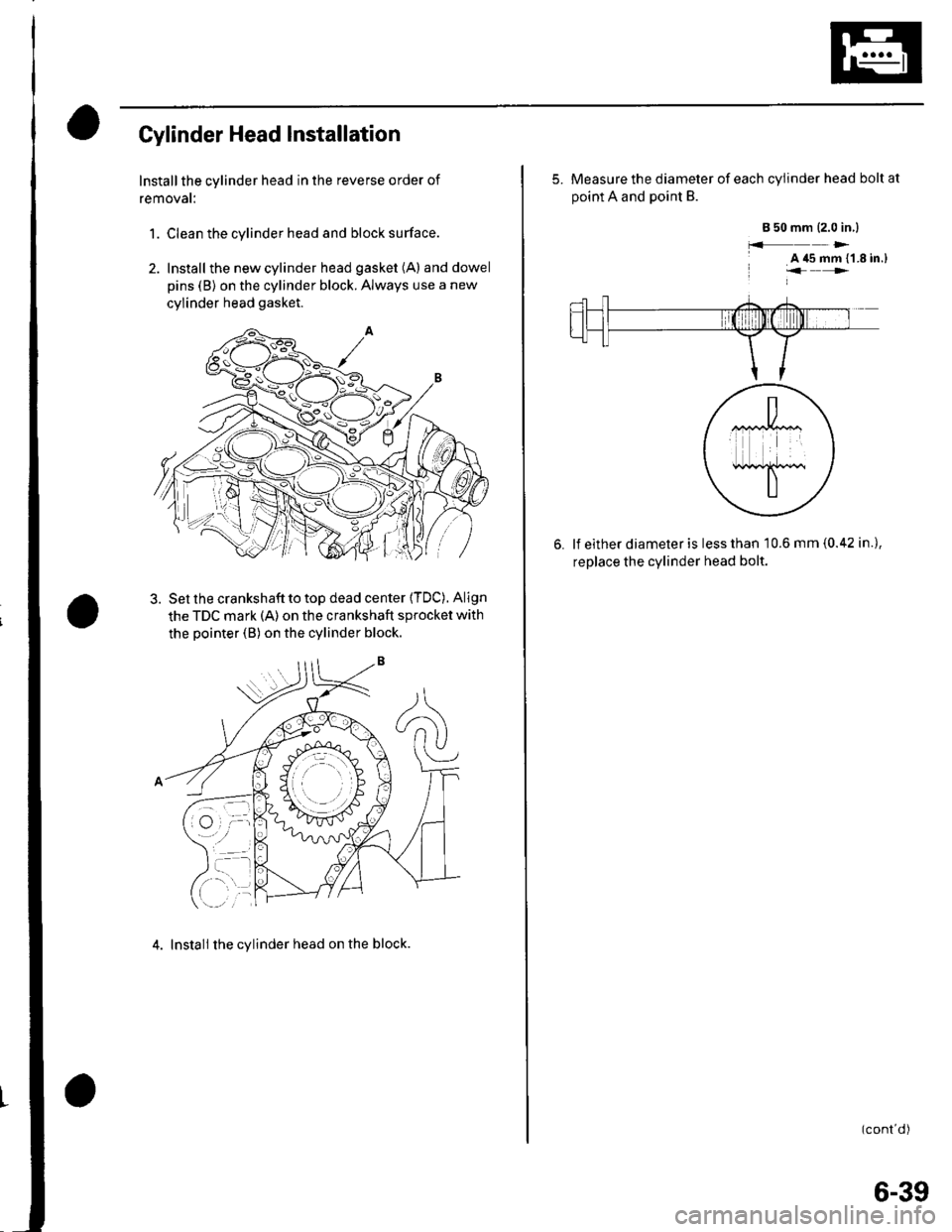

1. Clean the cylinder head and block surface.

2. Install the new cylinder head gasket (A) anddowel

pins (B) on the cylinder block. Always use a new

cylinder head gasket.

Set the crankshaft to top dead center {TDC). Align

the TDC mark (A) on the crankshaft sprocket with

the pointer (B) on the cylinder block.

4. Install the cylinder head on the block.

5. Measure the diameter of each cylinder head bolt at

ooint A and Doint B.

a 50 mm (2.0 in.l

f.f )>-

A '15 mm {'1.8 in.)"<>.

lf either diameter is less than 10.6 mm {0.42 in.),

replace the cvlinder head bolt.

(cont d)

6-39

Page 135 of 1139

Cylinder Head

8.

Cylinder Head lnstallation (cont'd)

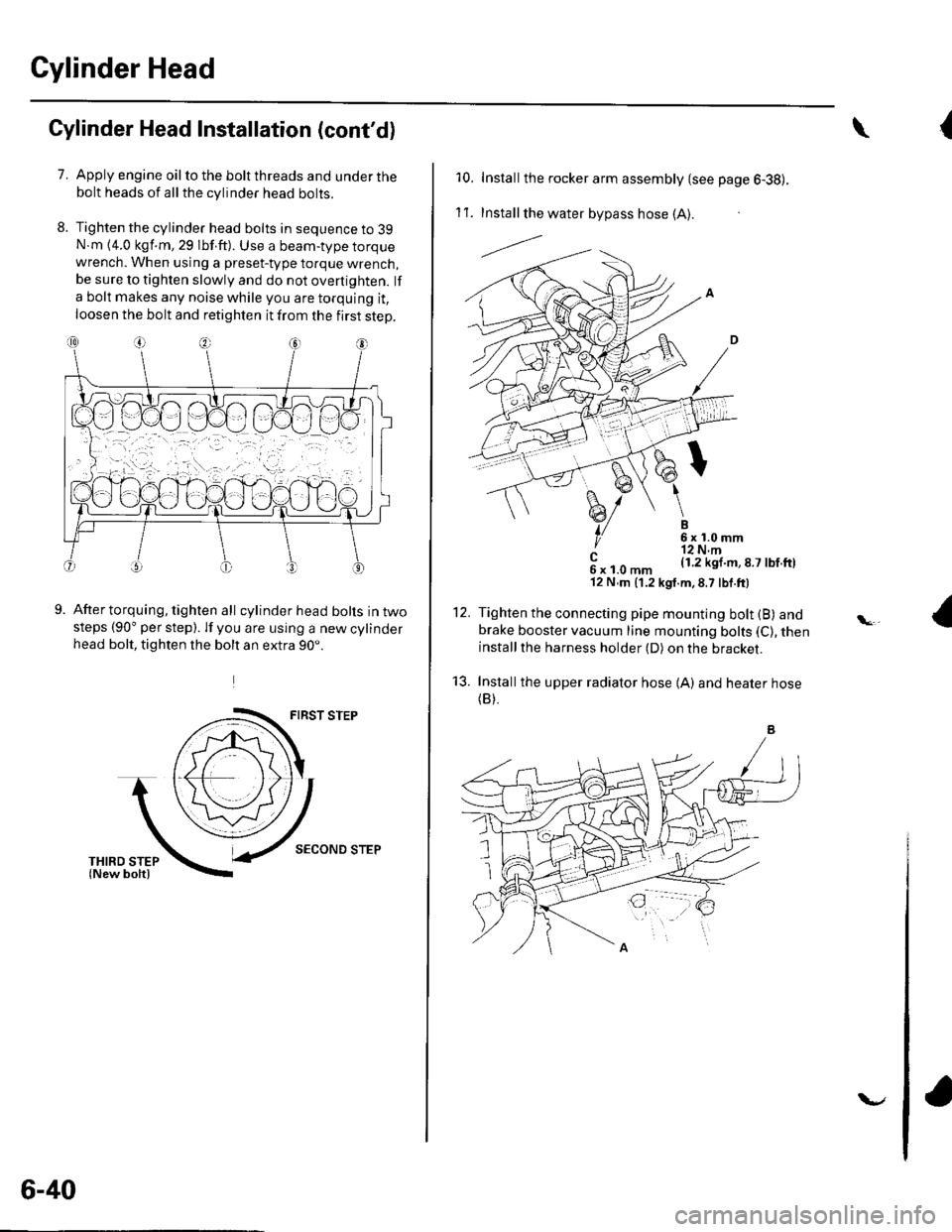

7.Apply engine oil to the bolt threads and under thebolt heads of all the cylinder head bolts.

Tighten the cylinder head bolts in sequence to 39N.m {4.0 kgf.m, 29 lbf.ft). Use a beam-type torquewrench. When using a preset-type torque wrench,be sure to tighten slowly and do not overtighten. lf

a bolt makes any noise while you are torquing it,

loosen the bolt and retighten it from the first step.

9.After torquing, tighten all cylinder head bolts in twosteps (90" per step). lf you are using a new cylinderhead bolt, tighten the bolt an extra 90..

FIRST STEP

SECOND STEP

6-40

v

{\

10. Installthe rocker arm assembly {see page 6-38).

1't .Install the water bypass hose (A).

---l.-.

B6x1.0mm'r2 N.m(1.2 kgl.m,8.7 lbf.ftl

12.

't3.

c6xl.0mm'12 N,m (1.2 kgt.m,8.7 lbf.ft)

Tighten the connecting pipe mounting bolt (B) andbrake booster vacuum line mounting bolts (C), theninstallthe harness holder (D) on the bracket.

Installthe upper radiator hose {A) and heater hose(B).

Page 136 of 1139

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

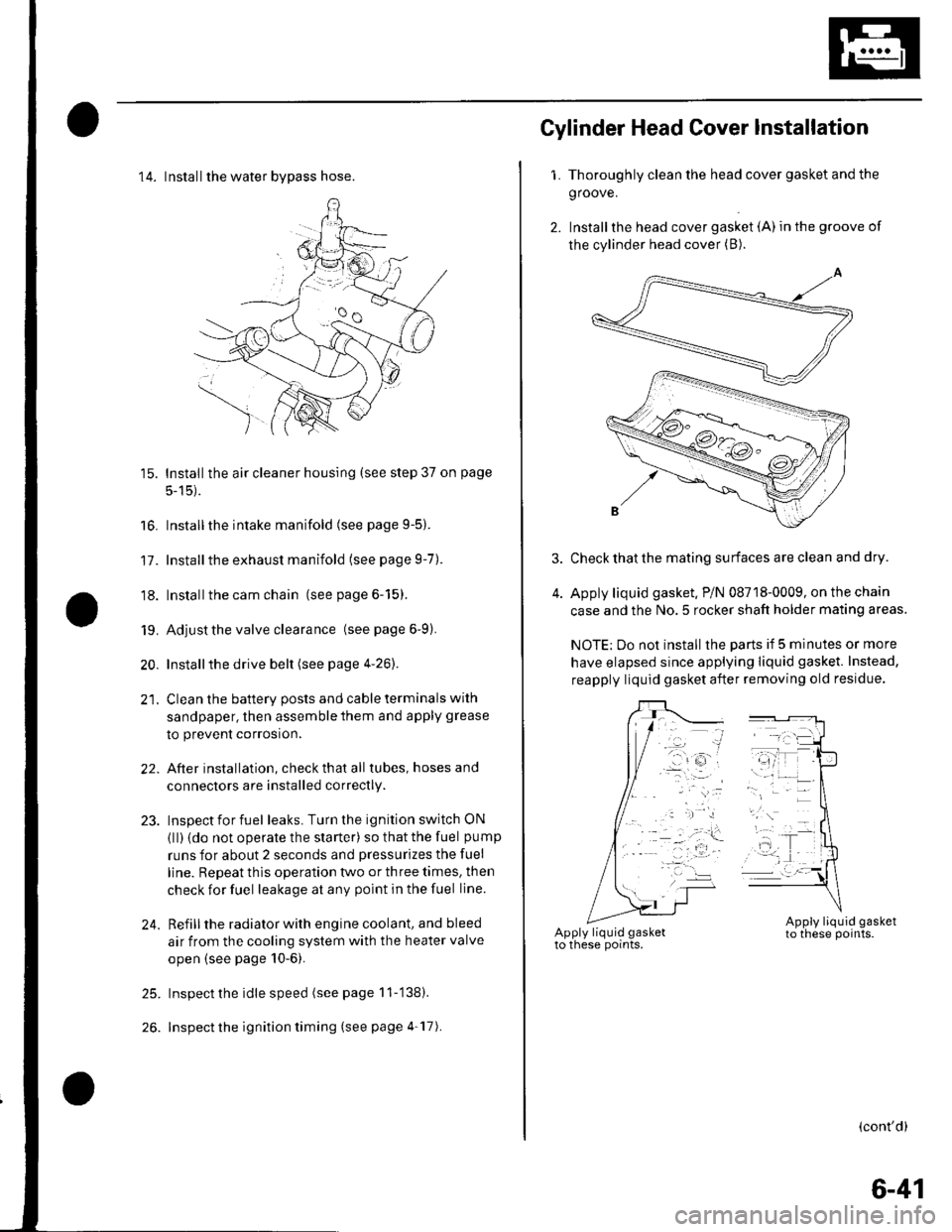

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 137 of 1139

Gylinder Head

Cylinder Head Gover Installation (cont'd)

Set the spark plug seals (A) on the spark plug tubes.

Once the cylinder head cover (B) is on the cylinderhead, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers (C). Replace any washer

that is damaged or deteriorated.

6-42

7. Tighten the bolts in two or three steps. In the final

step, tighten all bolts, in sequence, to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

8. Install the dipstick (A) and breather hose iB).

\

\l'

Page 150 of 1139

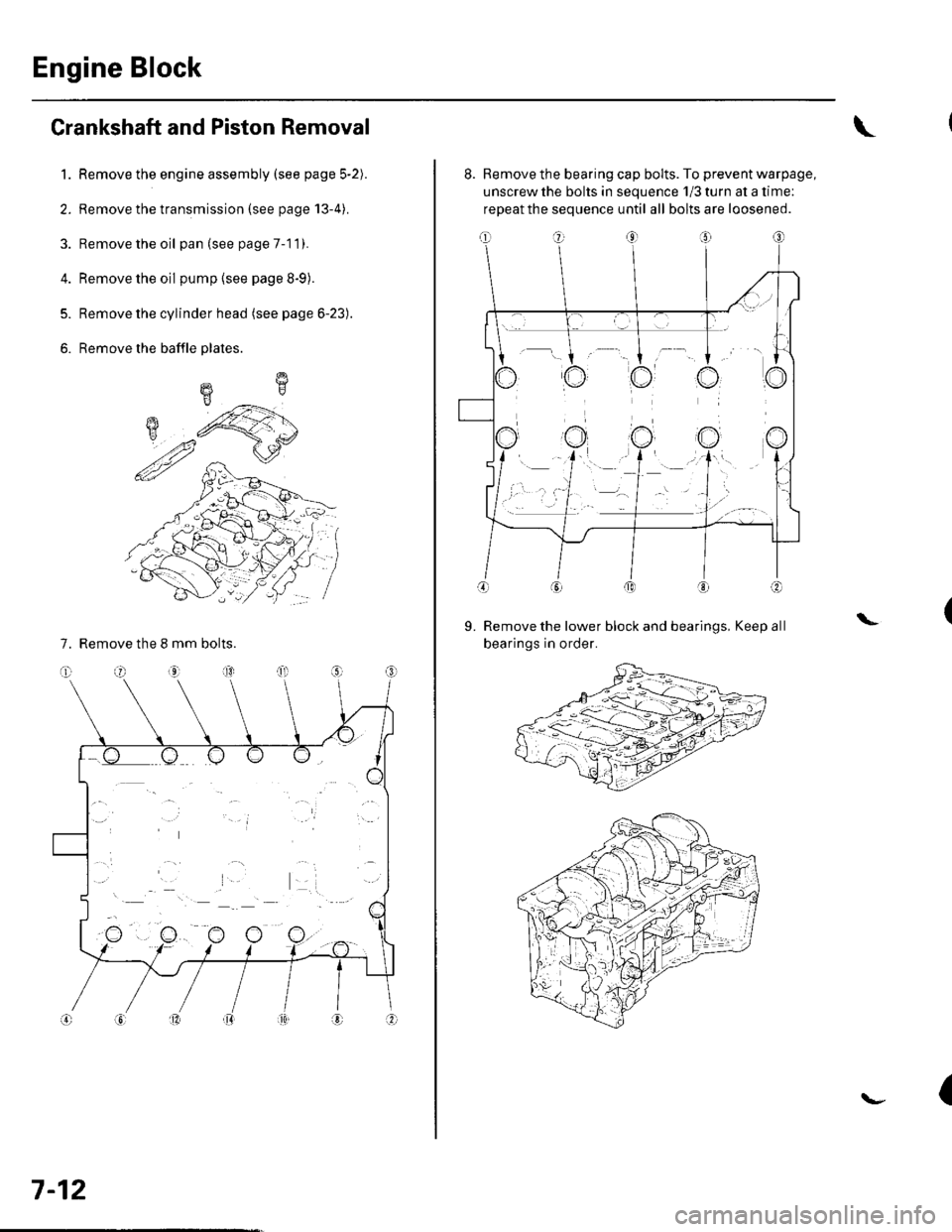

Engine Block

Crankshaft and Piston Removal

1. Remove the engine assembly (see page 5-2).

2. Remove the transmission (see page 13-4).

3. Remove the oil pan (see page 7-1 1).

4. Remove the oil pump {see page 8-9).

5. Remove the cylinder head (see page 6-23).

6. Remove the baffle plates.

7. Remove the 8 mm bolts.

E

7-12

8. Remove the bearing cap bolts. To prevent warpage,

unscrew the bolts in sequence 1/3 turn at a time:

repeat the sequence until all bolts are loosened.

Remove the lower block and bearings, Keep all

bearings in order.

\L

(

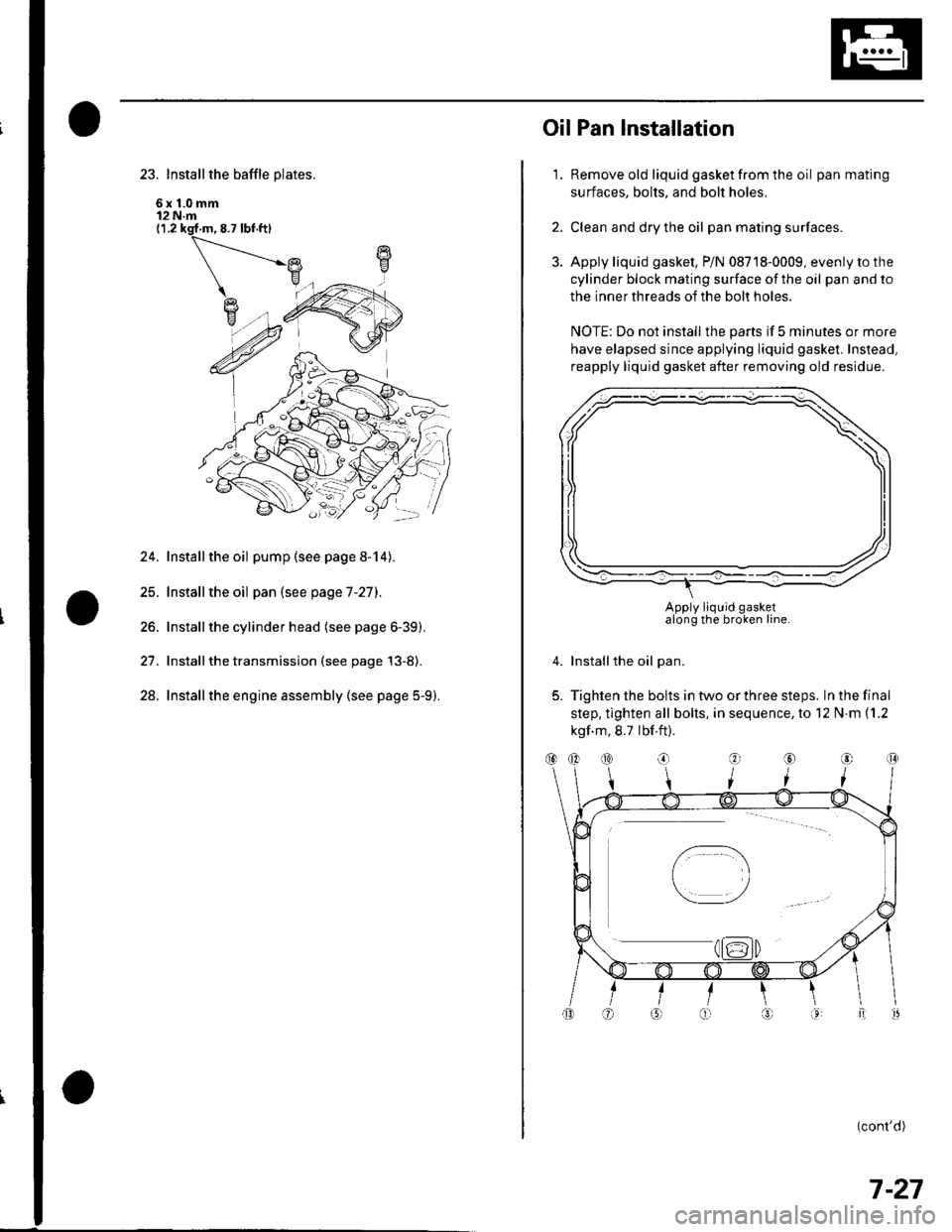

Page 165 of 1139

23. Install the baffle plates.

6x1.0mm12 N.m(1.2 ksf m, 8.7 lbf ft)

24. Installthe oil pump (see page 8-14).

25. Installthe oil pan (see page 7-27).

26. Installthe cylinder head (see page 6-39).

27. Installthe transmission (see page 13-8).

28. Installthe engine assembly (see page 5-9).

1.

OilPan lnstallation

Remove old liquid gasket from the oil pan mating

surfaces, bolts, and bolt holes.

Clean and dry the oil pan mating surfaces.

Apply liquid gasket, P/N 08718-0009, evenly to the

cylinder block mating surface of the oil pan and to

the inner threads of the bolt holes.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

Installthe oil pan.

Tighten the bolts in two or three steps. In the final

step, tighten all bolts, in sequence, to 12 N.m (1.2

kgf m, 8.7 lbf.ft).

(cont'd)

2.

3.

4.

5.

Apply liquid gasketalong the broken line.

(}@

7-27

Page 240 of 1139

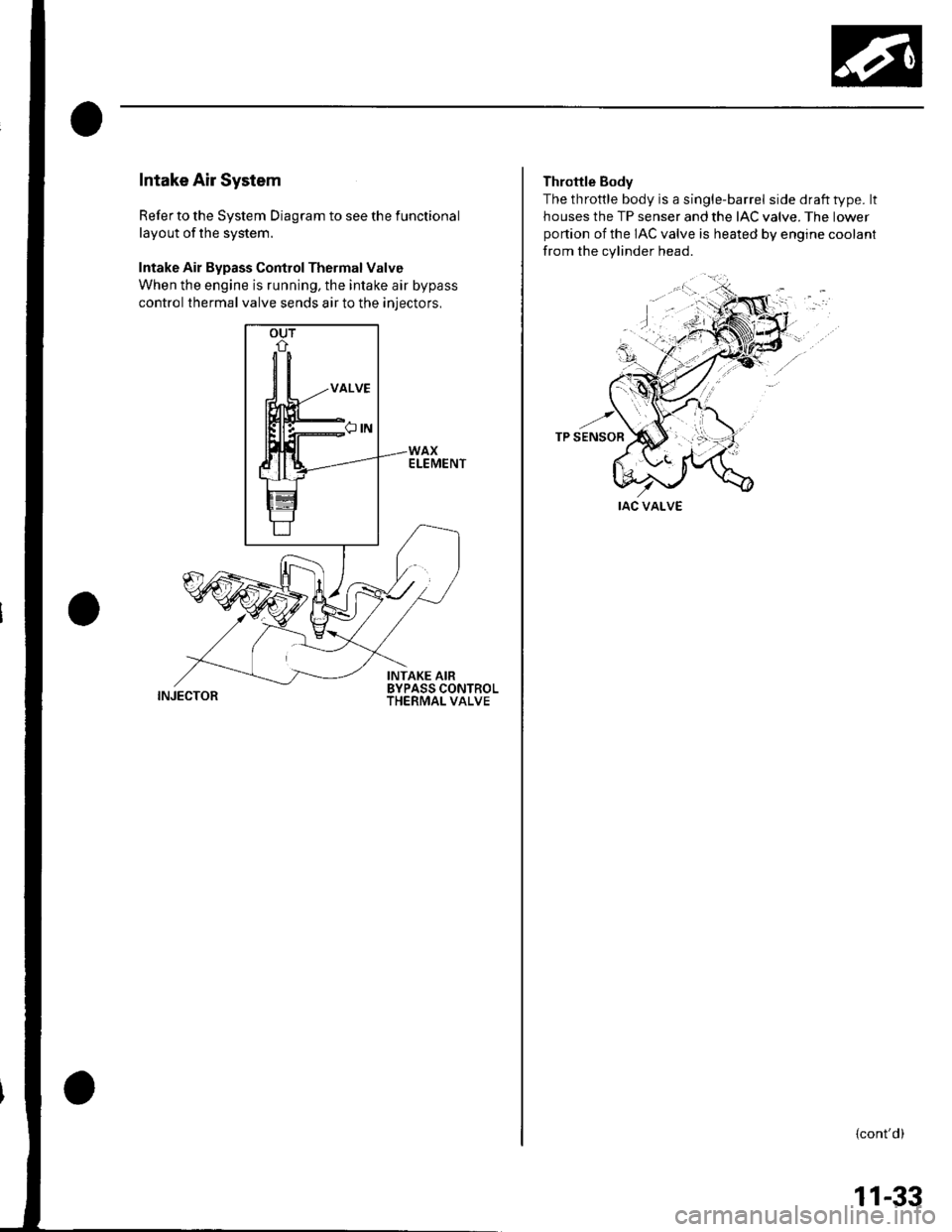

Intake Air System

Refer to the System Diagram to see the functional

layout of the system.

Intake Air Bypass Control Thermal Valve

When the engine is running, the intake air bypass

control thermal valve sends air to the iniectors,

INJECTOR

Throttle Body

The throttle body is a single-barrel side draft type. lt

houses the TP senser and the IAC valve. The lower

portion of the IAC valve is heated by engine coolant

from the cylinder head.

IAC VALVE

{cont'd)

11-33

Page 334 of 1139

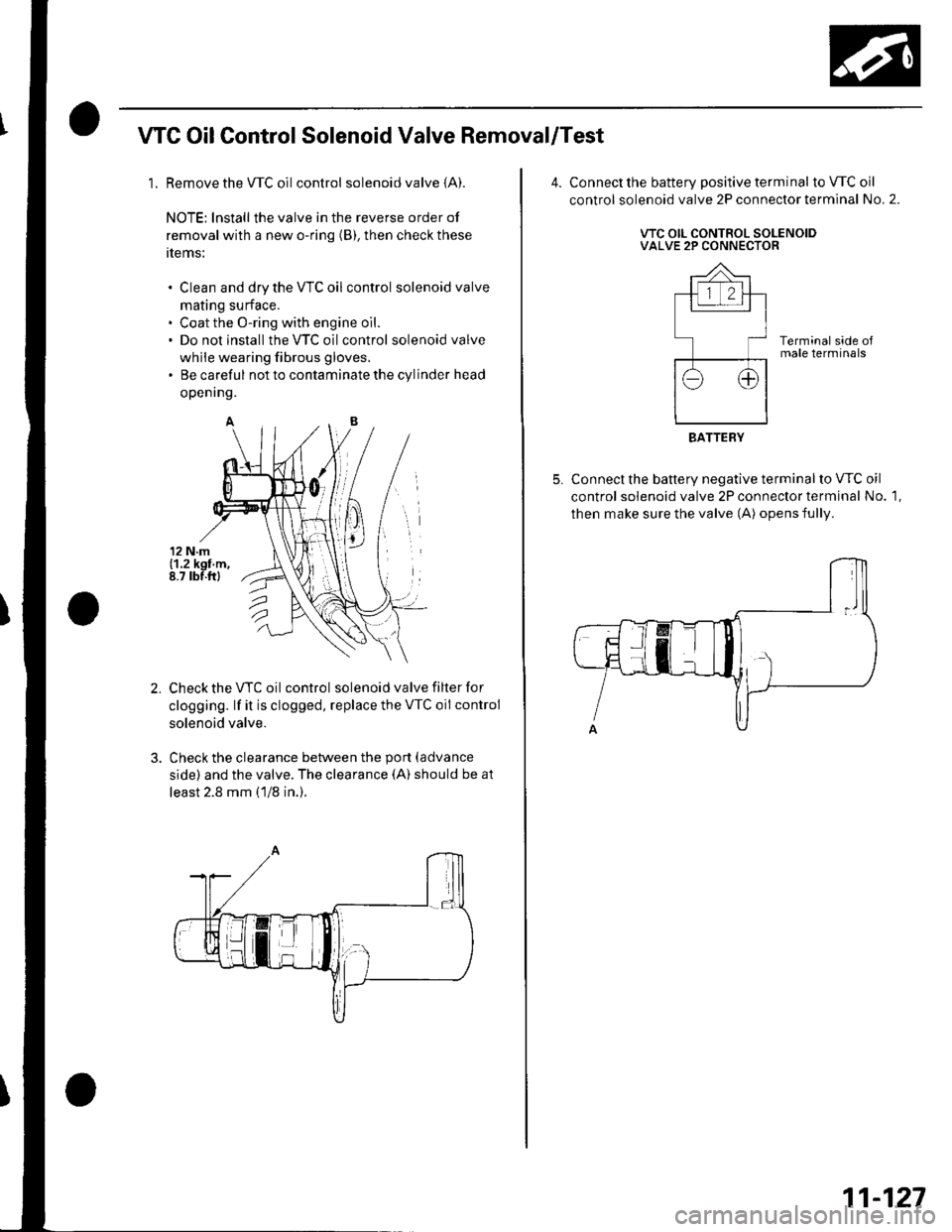

WC OilControl Solenoid Valve Removal/Test

1. Remove the WC oilcontrol solenoid valve (A).

NOTE: lnstall the valve in the reverse order of

removal with a new o-ring (B), then check these

tlems:

Clean and dry the VTC oil control solenoid valve

mating surface.

Coat the O-ring with engine oil.

Do not install the VTC oilcontrol solenoid valve

while wearing fibrous gloves,

Be careful not to contaminate the cylinder head

openrng.

Check the VTC oil control solenoid valve filter for

clogging. lf it is clogged, replace the VTC oil control

solenoid valve.

Check the clearance between the port (advance

side) and the valve. The clearance (A) should be at

least 2.8 mm (1/8 in.).

Connect the battery positive terminal to VTC oil

control solenoid valve 2P connector terminal No. 2.

VTC OIL CONTROL SOLENOIDVALVE 2P CONNECTOR

Terminal side oJmale terminals

Connect the battery negative terminal to VTC oil

control solenoid valve 2P connector terminal No. 1,

then make sure the valve (A) opens fully.

BATTERY

11-127