ecm HONDA CIVIC 2003 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 272 of 1139

DTC P0134: Ay'F Sensor (Sensor 1) No Activity

Detected

1. Check the attachment state of the A,/F sensor(Sensor 1).

ls it slacked f rom the exhaust pipe?

YES- Reinstall the Ay'F sensor (Seneor 1) (see page

11-113).t

NO-Go to step 2.

2. Reset the ECM (see page 1 1-4).

3. Stan the engine. Hold the engine speed at

3,000rpm with no load (in neutral) until the radiator

fan comes on, then let it idle for 2 minute.

ls DTC PO134 indicated?

YES-Replace the Ay'F sensor {Seneor 1) (see page

11-113).t

NO - Intermittent failu re, sistem is OK at this time.

Check for poor connections or loose terminals at

the Ay'F sensor (Seneor 1 ) and the ECM.I

DTC P0137: Secondary HO2S (Sensor 2)

Circuit Low Voltage

1. Reset the ECM (see page I1-4)

2. Start the engine. Hold the engine at 3,000 rpm wilh

no load (in neutral) until the radiator fan comes on.

3. Check the secondary HO2S (Sensor 2) output

voltage at 3,000 rpm with the scan tool.

ls there 0.3 V or less?

YES Go to step 4.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the secondary HO2S (Sensor 2) and at the ECM.I

Turn the ignition switch OFF.

Disconnect the secondary HO2S (Sensor 2) 4P

connector.

Turn the ignition switch ON (ll).

Check the secondary HO2S (Sensor 2) output

voltage with the scan tool.

ls there 0.3 V or less?

YES Go to step 8.

NO Replace the secondary HO2S (Sensor 2).1

Turn the ignition switch OFF.

Disconnect ECM connector E (31P).

icont'd)

4.

5.

6.

7.

8.

9.

11-65

Page 273 of 1139

PGM-FISystem

aDTC Troubleshooting (cont'dl

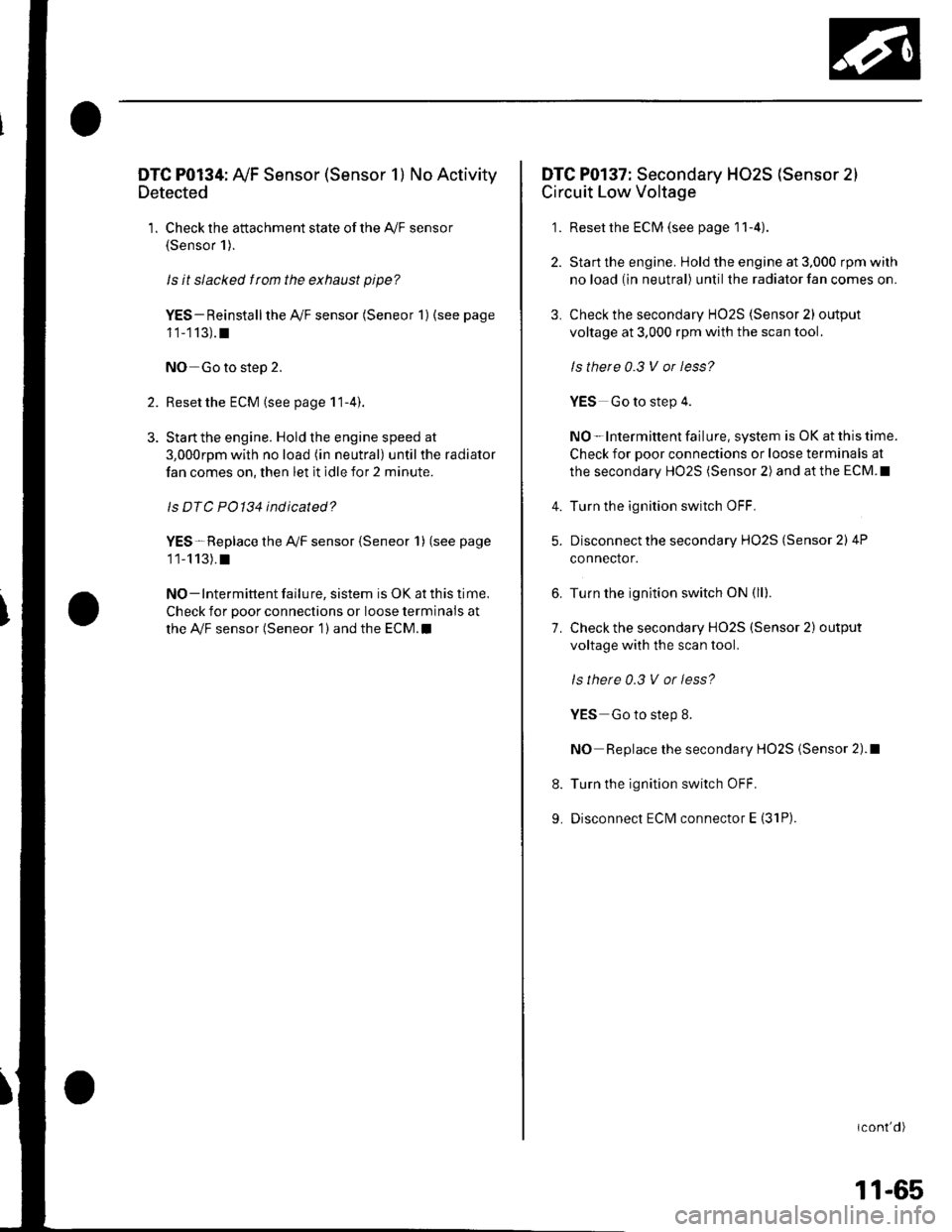

10. Check for continuity between the secondary HO2S(Sensor 2) 4P connector terminal No. 2 and bodygrou nd.

SECONDARY H02SISENSOR 2) 4P CONNECTOR

Terminal side of male terminals

ls there continuity?

YES-Repair shon in the wire between the ECM(E2) and the secondary HO2S (Sensor 2). t

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I|

11-66

DTC P0138: Secondary HO2S (Sensor 2)

Circuit High Voltage

1. Resetthe ECM {see page'11-4).

2. Startthe engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

3. Check the secondary HO2S (Sensor 2) output

voltage at 3,000 rpm with the scan tool.

ls thete 1.0 V or morc?

YES Go to step 4.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the secondary HO2S (Sensor 2) and at the ECM.I

4. Turn the ignition switch OFF.

5. Disconnect the secondary HO2S (Sensor 2) 4P

connector.

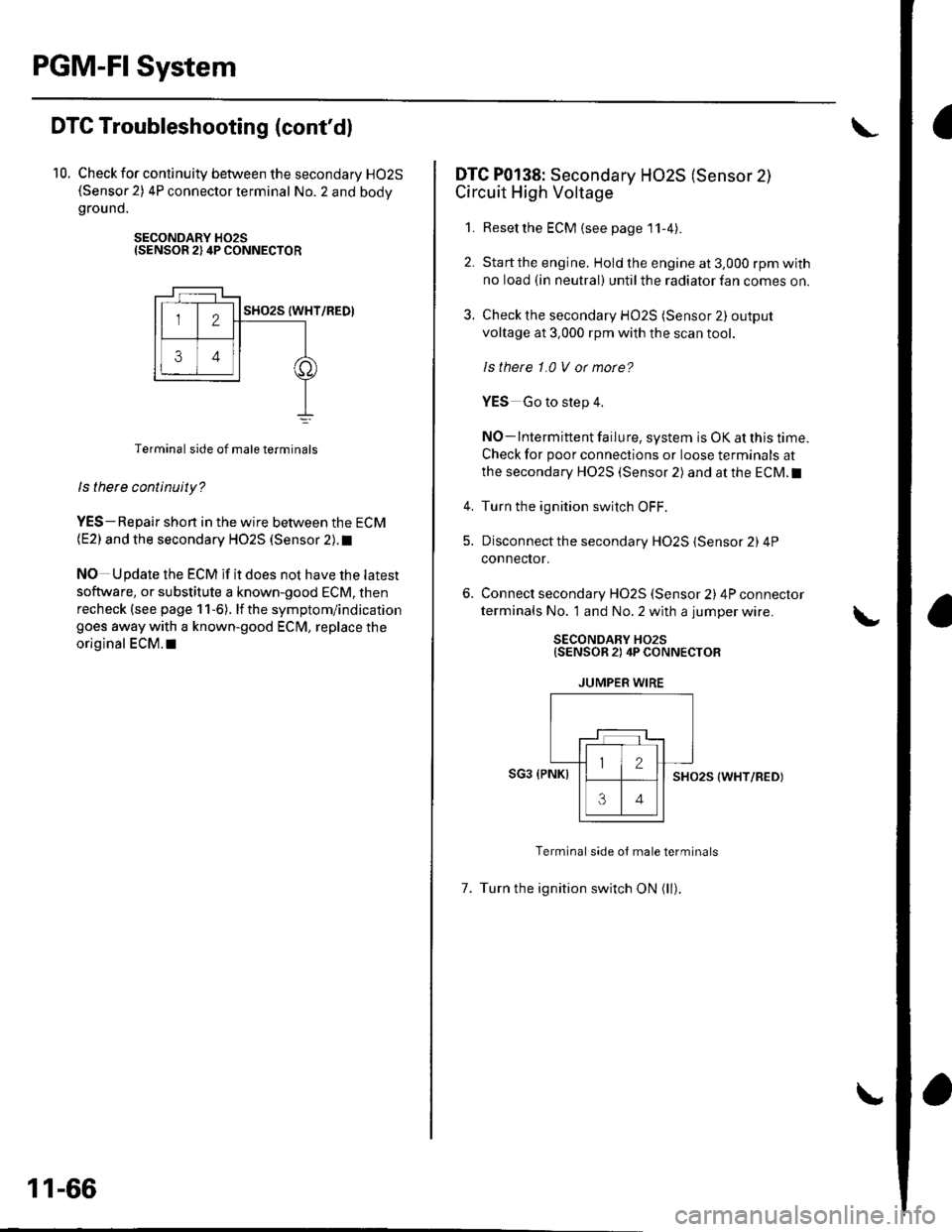

Connect secondary H02S (Sensor 2) 4P connector

terminals No. 1 and No. 2 with a jumper wire.

SECONDARY HO2S{SENSOR 2) 4P CONNECTOR

JUMPER WIRE

SG3 (PNKISHO25 (WHT/RED)

Terminal side oJ male terminals

7. Turn the ignition switch ON (ll).

Page 274 of 1139

8.Check the secondary H02S (Sensor 2) output

voltage with the scan tool,

ls there 1.0 V ot mote?

YES-Go to step 9.

NO Replace the secondary HO2S (Sensor 2).1

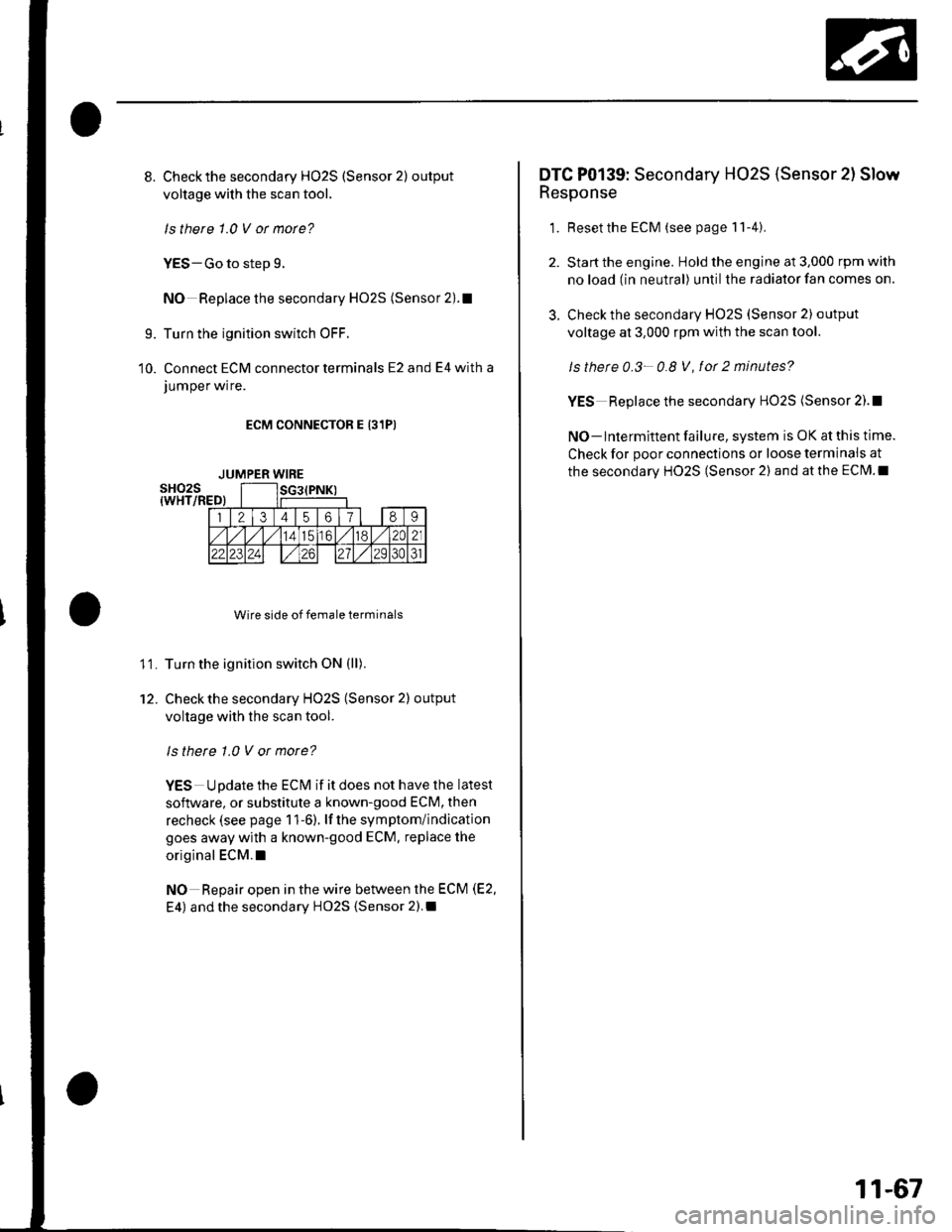

Turn the ignition switch OFF.

Connect ECM connector terminals E2 and E4 with a

JUmper wrre.

ECM CONNECTOR E 131PI

Wire side of female terminals

Turn the ignition switch ON (ll).

Check the secondary HO2S (Sensor 2) output

voltage with the scan tool.

ls there 1.0 V or more?

YES Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM. replace the

original ECM.I

NO Repair open in the wire between the ECM (E2,

E4) and the secondary HO2S {Sensor 2).I

9.

10.

11.

12.

JUMPER WIRE

3.

DTC P0139: Secondary HO2S (Sensor 2l Slow

Response

1. Resetthe ECM (see page 11-4).

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

Check the secondary HO2S (Sensor 2) output

voltage at 3,000 rpm with the scan tool.

ls thete 0.3- 0.8 V, fot 2 minutes?

YES Replace the secondary HO2S (Sensor 2).!

NO- lntermittent failure, system is OK at this time.

Check for poor connections or loose terminais at

the secondary HO2S (Sensor 2) and at the ECM.I

11-67

Page 275 of 1139

PGM-FISystem

3.

DTC Troubleshooting (cont'dl

DTC P0141: Secondary HO2S (Sensor 2l

Heater Circuit Malfunction

1. Reset the ECM (see page 1 l-4)

2. Start the engine.

ls DTC P0141 indicated?

YES-Go to step 3.

NO-lntermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the secondary HO2S (Sensor 2) and at the ECM.I

Turn the ignition switch OFF.

Disconnect the secondary H02S (Sensor 2) 4P

connecror.

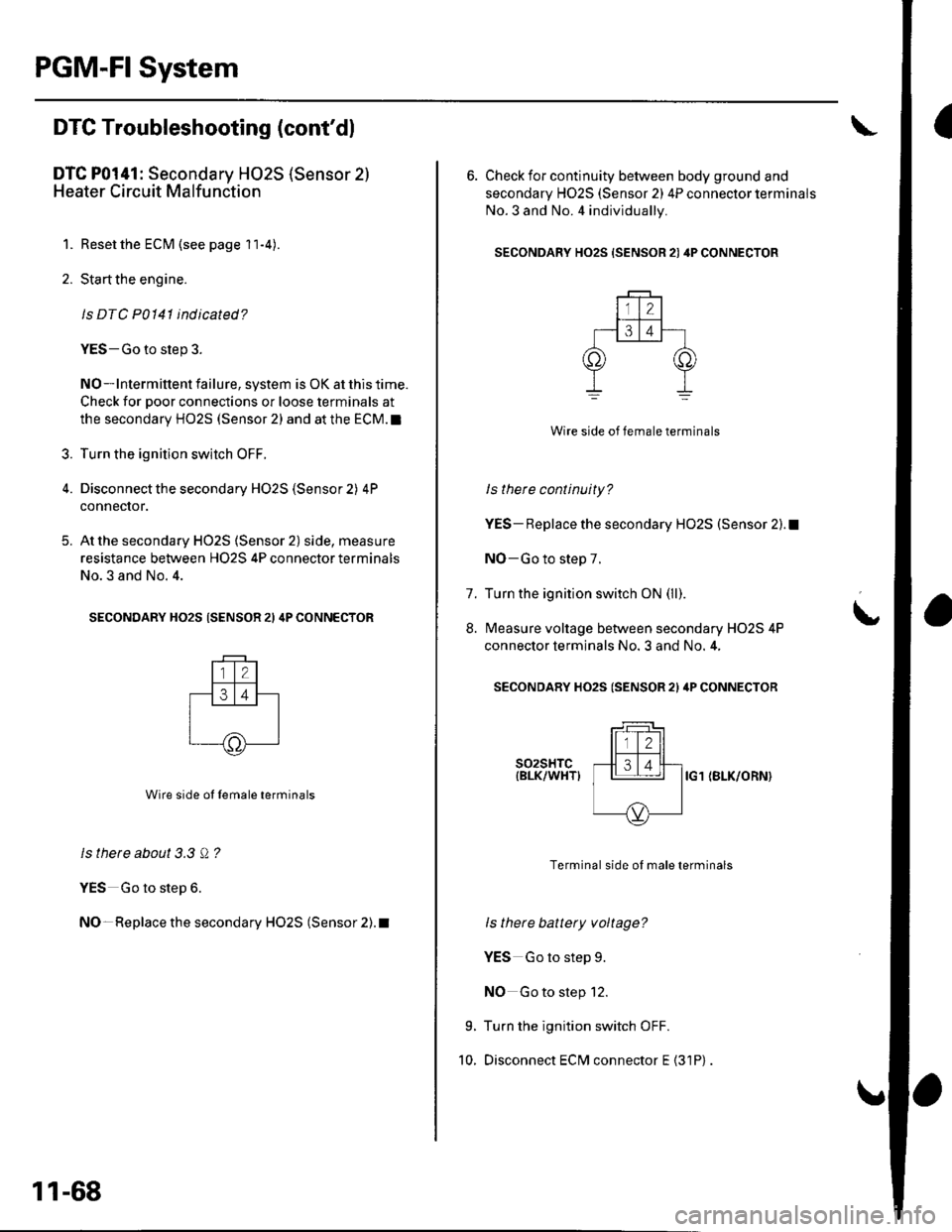

At the secondary HO2S (Sensor 2) side, measure

resistance between H02S 4P connector terminals

No.3 and No. 4.

SECONDARY HO2S (SENSOR 21 4P CONNECTOR

Wire side ol lemale terminals

ls there about 3.3 Q ?

YES Go to step 6.

NO- Replace the secondary HO2S (Sensor 2). t

5.

11-68

6. Check for continuity between body ground and

secondary H02S (Sensor 2) 4P connector terminals

No.3 and No. 4 individually.

SECONDARY HO2S {SENSOR 21 4P CONNECTOR

Wire side of female terminals

ls there continuity?

YES- Replace the secondary HO2S (Sensor 2).1

NO-Go to step 7.

Turn the ignition switch ON (ll).

Measure voltage between secondary H02S 4P

connector terminals No. 3 and No. 4,

SECONDARY HO2S (SENSOR 2l ilP CONNECTOR

t

7.

8.

9.

10.

s02sHTc{BLK/WHTIIG1 (BLK/ORN}

Terminal side of male terminals

ls there battery voltage?

YES Go to step 9.

NO Go to step 12.

Turn the ignition switch OFF.

Disconnect ECM connector E {31P)

Page 276 of 1139

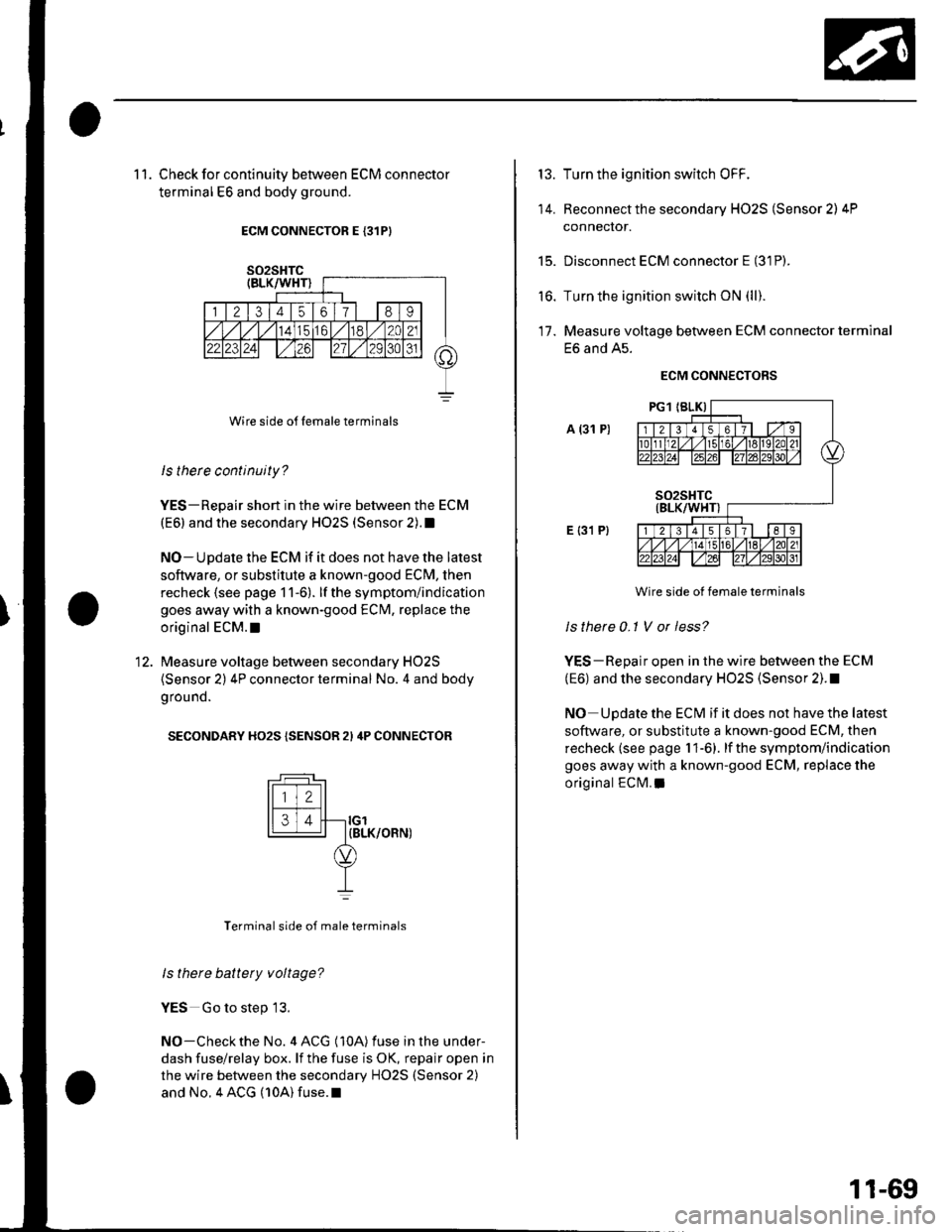

1 1. Check for continuity between ECM connector

terminal E6 and body ground.

ECM CONNECTOR E {31PI

Wire side o{f Iemale terminals

ls therc continuity?

YES-Repair short in the wire between the ECM

(E6) and the secondary HO2S (Sensor 2).1

NO-Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

Measure voltage between secondary HO2S

(Sensor 2) 4P connector terminal No. 4 and body

g rou nd.

SECONDARY HO2S {SENSOR 2I 4P CONNECTOR

tFff I

l[faJl--ro'14 | IBLK/OFN)

YI

Terminal side of male terminals

ls there battety voltage?

YES Go to step 13.

NO-Checkthe No. 4 ACG (10A) fuse in the under-

dash fuse/relay box. lf the fuse is OK, repair open in

the wire between the secondary HO2S (Sensor 2)

and No. 4 ACG (10A) fuse.l

13.

14.

t5.

to.

Turn the ignition switch OFF.

Reconnect the secondary HO2S (Sensor 2) 4P

connector.

Disconnect ECM connector E (31P).

Turn the ignition switch ON (ll).

Measure voltage between ECM connector terminal

E6 and A5.

ECM CONNECTORS

A (31 P)

E {31 P}

Wire side ot female terminals

Is there 0-1 V or less?

YES-Repair open in the wire between the ECM

(E6) and the secondary HO2S (Sensor 2). !

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM. a

17.

11-69

Page 279 of 1139

PGM-FI System

IDTC Troubleshooting (cont'dl

DTC P0301: No. 1 Cylinder Misfire

DTC P0302: No. 2 Cylinder Misfire

DTC P0303: No. 3 Cylinder Misfire

DTC P0304: No. 4 Cylinder Misfire

1. After checking and recording the freeze data, reset

the ECM (see page 1 1-4). lf there is no freeze data of

the misfire, just clear the DTC.

2. Start the engine, and listen for a clicking sound

from the injector at the problem cylinder.

Does the injector click?

YES-Go to step 3.

NO-Go to step 30.

3. Turn the ignition switch OFF.

4. Exchange the ignition coil from the problem

cylinder with one from another cylinder,

5. Test-drive the vehicle for several minutes in the

range of the freeze data or under va rious

conditions if there was no freeze data.

6. Check for a DTC or a Temporary DTC with the scan

root.

ls DTC or Tempotaty DTC P0301, P0302, P0303

or P0304 ind icated?

YES Go to step 7.

NO Intermittent misfire due to poor contact at the

ignition coil connectors {no misfire at this time).

Make sure the coil connections are secure.l

11-72

8.

9.

1.

11.

Determine which cylinder(s) had the misfire.

Does the misf ire occur in the cylinder where the

ignition coil was exchanged?

YES Replace the faulty ignition coil.!

NO-Go to step 8.

Turn the ignition switch OFF.

Exchange the spark plug from the problem cylinder

with one from another cylinder.

Test-drive the vehicle for several minutes in the

range of the freeze data or under various

conditions if there was no freeze data.

Check for a DTC or Temporary DTC with the scan

Tool.

ls DTC ot Tempotary DTC P0301, P0302, P0303

or P0304 ind icated?

YES Go to step 12.

NO Intermittent misfire due to spark plug fouling,

etc. (no misfire at this time).1

Determine which cylinder(s) had the misfire.

Does the misl ire occur in the cylinder where the

spark plug was exchanged?

YES Replace the faulty spark plug.l

NO Go to step 13.

Turn the ignition switch OFF.

Exchange the lnjector from the problem cylinder

with one from another cylinder.

Let the engine idle for 2 minutes.

10.

14.

t5.

Page 280 of 1139

16.Test-drive the vehicle for several minutes in the

range of the freeze data or under various

conditions if there was no freeze data.

Check for a DTC or a Temporary DTC with the scan

Tool.

ls DTC or Temporary DTC P0301, P0302, P0303

or P0304 indicated?

YES Go to step 18.

NO lntermittent misfire due to bad contact at the

injector connector (no misfire at this time). Make

sure the injector connection is secure. Check for

poor connections or loose terminals at the

injector.l

Determine which cylinder(s) had the misfire.

Does the misf ire occur in the cylinder where the

i njector w as exchanged ?

YES- Replace the faulty injector.I

NO-Go to step 19.

Turn the ignition switch OFF.

Disconnect the ignition coil 3P connector from the

problem cylinder.

Turn the ignition switch ON (ll).

't7 .

18.

19.

20.

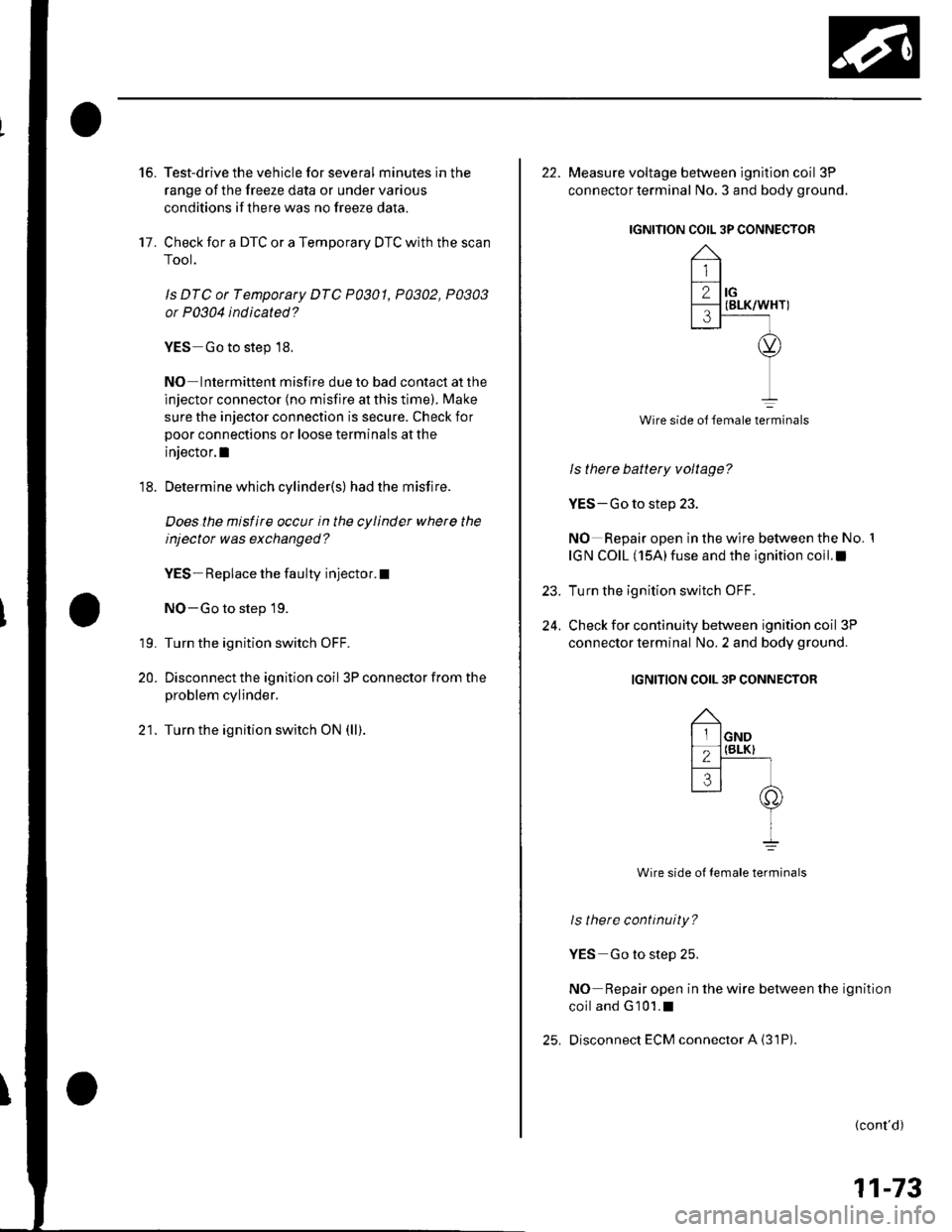

22. Measure voltage between ignition coil 3P

connector terminal No. 3 and body ground.

IGNITION COIL 3P CONNECTOR

Wire side ol female terminals

ls there battery voltage?

YES-Go to step 23.

NO Repair open in the wire between the No. 1

IGN COIL (15A)fuse and the ignition coil.I

Turn the ignition switch OFF.

Check for continuity between ignition coil 3P

connector terminal No. 2 and body ground.

IGNITION COIL 3P CONNECTOR

Wire side ot female terminals

ls there continuity?

YES Go to step 25.

NO Repair open in the wire between the ignition

coiland G101.1

Disconnect ECM connector A {31P)

23.

24.

(cont'd)

11-73

Page 281 of 1139

PGM-FI System

aDTC Troubleshooting (cont'dl

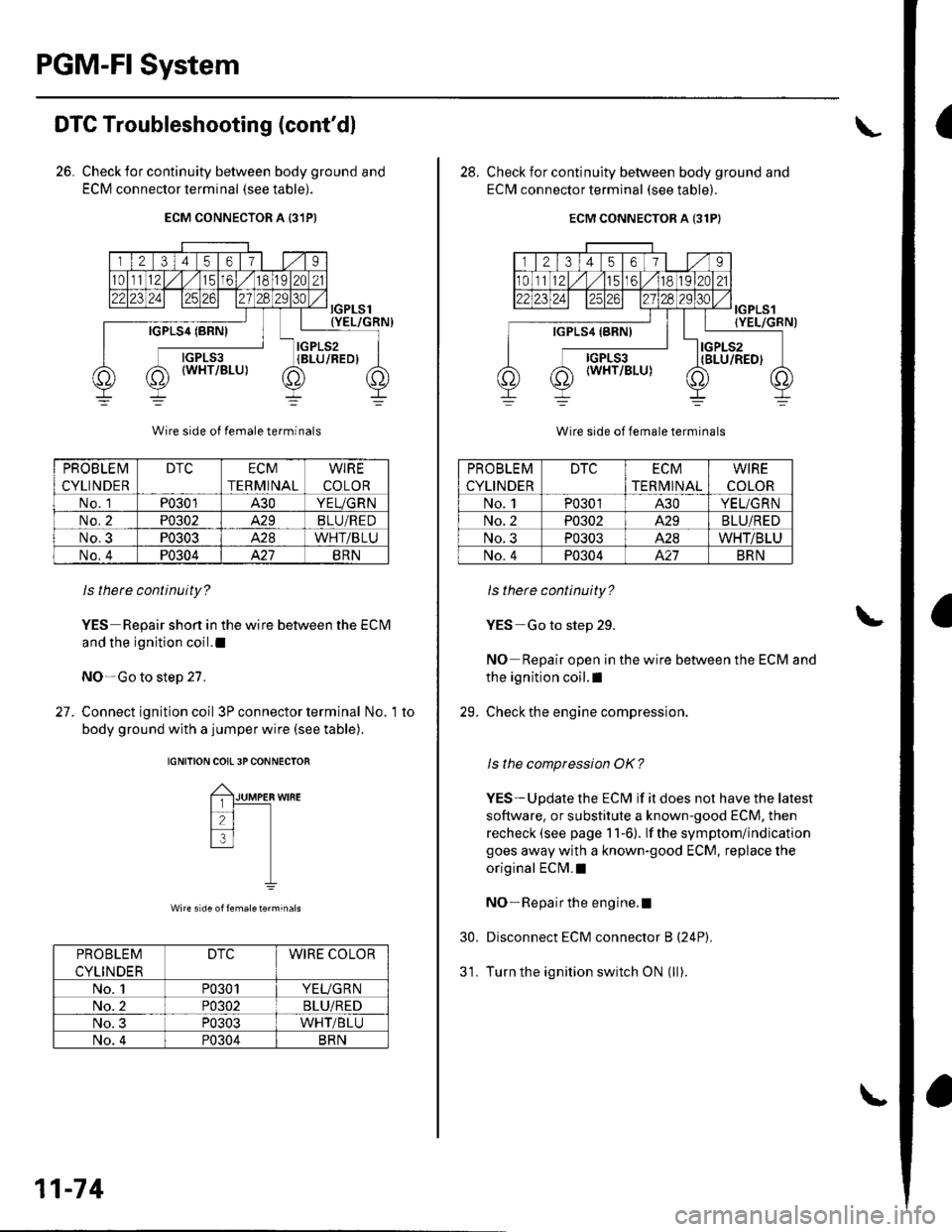

26. Check for continuity between body ground and

ECM connector terminal (see table).

ECM CONNECTOR A {31PI

PROB LE IVI

CYLINDER

DTCECM

TERMINAL

WIRE

COLOR

No. 1P0301430YEUGRN

No.2P0302A.29BLU/RED

No.3P0303428WHT/BLU

No,4P0304421BRN

ls there continuity?

YES Repair shon in the wire between the EClvl

and the ignition coil.l

NO-Go to step 27.

27. Connect ignition coil 3P con nector term inal No. 1to

body ground with a jumper wire (see table).

IGNITION COII 3PCONNECTOR

Wire s de of femaleterminals

PROBLEM

CYLINDER

DTCWIRE COLOR

No. 1P0301YEUGR N

No. 2P0302BLU/RED

No. 3P0303WHT/BLU

No. 4P0304BRN

11-74

28. Check for continuity between body ground and

ECM connector terminal (see table).

ECM CONNECTOR A {31P}

PROBLEM

CYLINDER

DTCECM

TERI\4INAL

WIRE

COLOR

No. 1P0301A30YEL/GRN

No. 2P0302429BLU/RED

No. 3P0303A.28WHT/BLU

No. 4P0304A.21BRN

ls there continuity?

YES-Go to step 29.

NO Repair open in the wire between the ECM and

the ignition coil.l

29. Check the engine compression

ls the compression OK?

YES-Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECI\4.I

NO- Repair the engine.l

Disconnect ECM connector B (24P).

Turn the ignition switch ON (ll).

30.

Page 282 of 1139

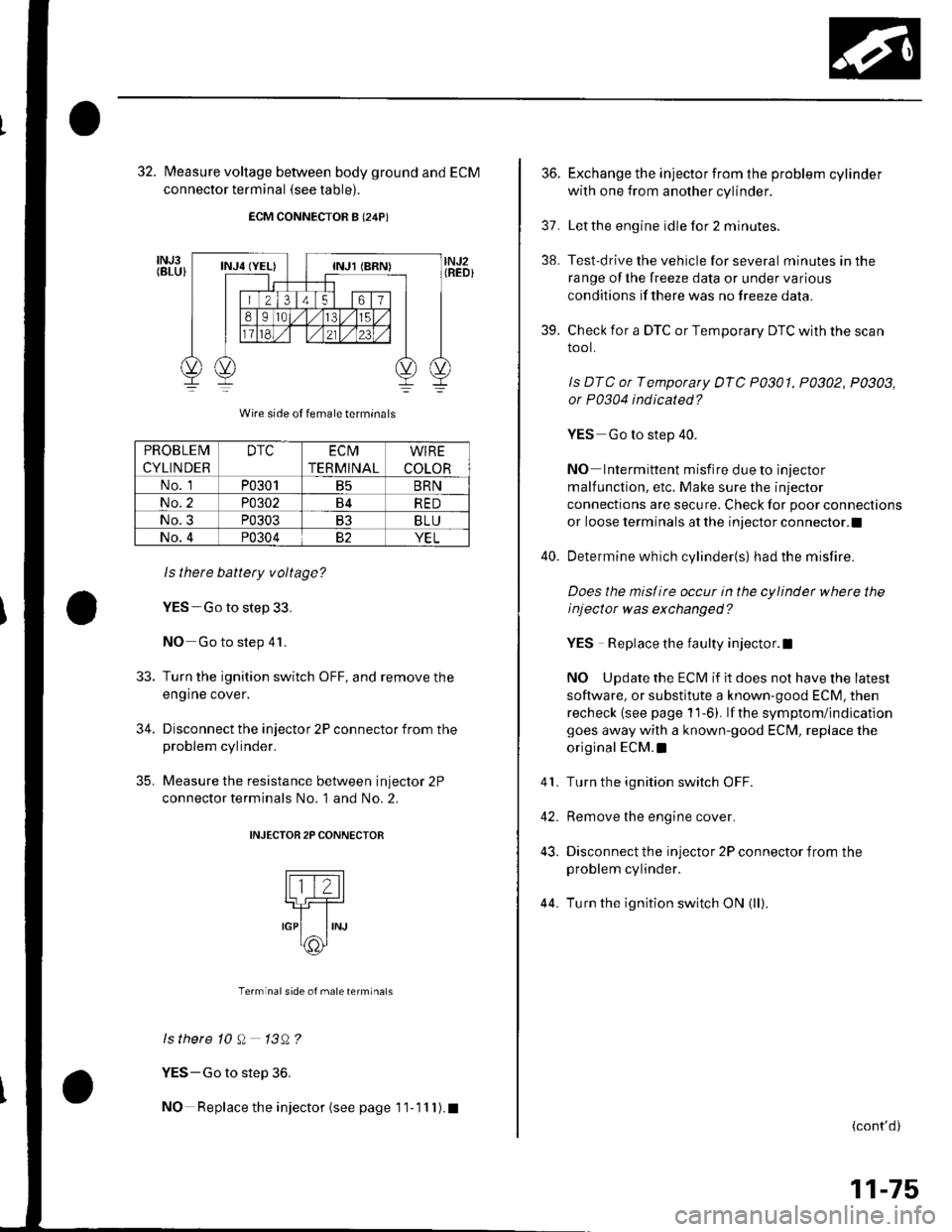

32. fvleasure voltage between body ground and ECM

connector terminal (see table).

ECM CONNECTOR B (24P)

Wire side of female termrnals

ls there battery voltage?

YES-Go to step 33,

NO Go to step 41.

Turn the ignition switch OFF, and remove the

engine cover.

Disconnect the injector 2P connector from theproblem cylinder.

Measure the resistance between injector 2P

connector terminals No. 1 and No. 2.

INJECTOB 2P CONNECTOR

Terminal side of male terminals

ls there 10 Q 13A?

YES-Go to step 36.

NO Replace the injector (see page 1 1- 11 I ). t

33.

34.

35,

PROBLEM

CYLINDER

DTCEC t\4

TERMINAL

WIRE

COLOR

No. 1P0301B5BRN

No.2P0302B4RED

No.3P0303B3BLU

No.4P0304YEL

36.Exchange the injector from the problem cylinder

with one from another cylinder.

Letthe engine idle for 2 minutes.

Test-drive the vehicle for several minutes in the

range oI the lreeze data or under various

condilions if there was no freeze data.

Check for a DTC or Temporary DTC with the scan

tool.

ls DTC or Temporary DTC P0301, P0302, P0303,

or P0304 indicated?

YES Go to step 40.

NO Intermittent misfire due to injector

malfunction, etc. Make sure the injector

connections are secure. Check for poor connections

or loose terminals at the injector connector.l

Determine which cylinder{s} had the misfire.

Does the mislirc occur in the cylinder whete the

i nj ector w as exchanged ?

YES Replace the faulty injector.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM. then

recheck (see page 1 'l-6). lf the symptom/indication

goes away with a known-good EClvl, replace the

original ECM.I

Turn the ignition switch OFF.

Remove the engine cover.

Disconnect the injector 2P connector from the

problem cylinder.

44. Turn the ignition switch ON (ll)

37.

38.

39.

41.

42.

43.

(cont'd)

11-75

Page 283 of 1139

![HONDA CIVIC 2003 7.G Repair Manual PGM-FI System

a

I

DTC Troubleshooting (contdl

45. Measure voltage between injector 2P connector

terminal No. 1 and body ground.

INJECTOR 2P CONNECTOR

tll-z]

,o, ,"=rrrr*, -lt-

oI

Wire side of female HONDA CIVIC 2003 7.G Repair Manual PGM-FI System

a

I

DTC Troubleshooting (contdl

45. Measure voltage between injector 2P connector

terminal No. 1 and body ground.

INJECTOR 2P CONNECTOR

tll-z]

,o, ,"=rrrr*, -lt-

oI

Wire side of female](/img/13/5744/w960_5744-282.png)

PGM-FI System

a

I

DTC Troubleshooting (cont'dl

45. Measure voltage between injector 2P connector

terminal No. 1 and body ground.

INJECTOR 2P CONNECTOR

tll-z]

,o, ,"=rrrr*, -lt-

oI

Wire side of female terminals

ls there battery voltage?

YES-Go to step 46.

NO-Repair open in the wire between the injector

and the PGM-Fl main relay l.l

Turn the ignition switch OFF.

Check for continuity between body ground and

ECM connector terminal (see table).

46.

47.

ECM CONNECTOR B {24P)

Wire side of female terminals

ls there continuity?

YES-Repair short in the wire between the ECM

and the ;njector.I

NO-Go to step 48.

PROBLEM

CYLINDER

DTCECM

TERMINAL

WIRE

COLOR

No. 1P030'1B5BRN

No.2P0302B4RED

No.3P0303B3BLU

No. 4P030482YEL

11-76

48. Connect injector 2P co nnector term inal No.2 to

body ground with a jumper wire {see table).

INJECTOR 2P CONNECTOR

Wire side of {emale terminals

49. Check for continuity between body ground and

ECM connector terminal (see table).

ECM CONNECTOR B I24P)

Wire side oJ temale terminals

ls therc continuity?

YES Replace the injector, then recheck.l

NO Repair open in the wire between the ECM and

the injector.I

tll-Z-l-]_r-l_rNJ

IJUMPER

IwrBE

PROBLEM

CYLINDER

DTCWIRE COLOR

No. 1P0301BRN

No.2P0302RED

No. 3P0303BLU

No. 4P0304YEL

PROBLEM

CYLINDER

DTCECM

TERMINAL

WIRE

COLOR

No. 1P0301B5BRN

No. 2P0302B4RED

No. 3P0303B3BLU

No. 4P030482YEL