ect HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 879 of 1139

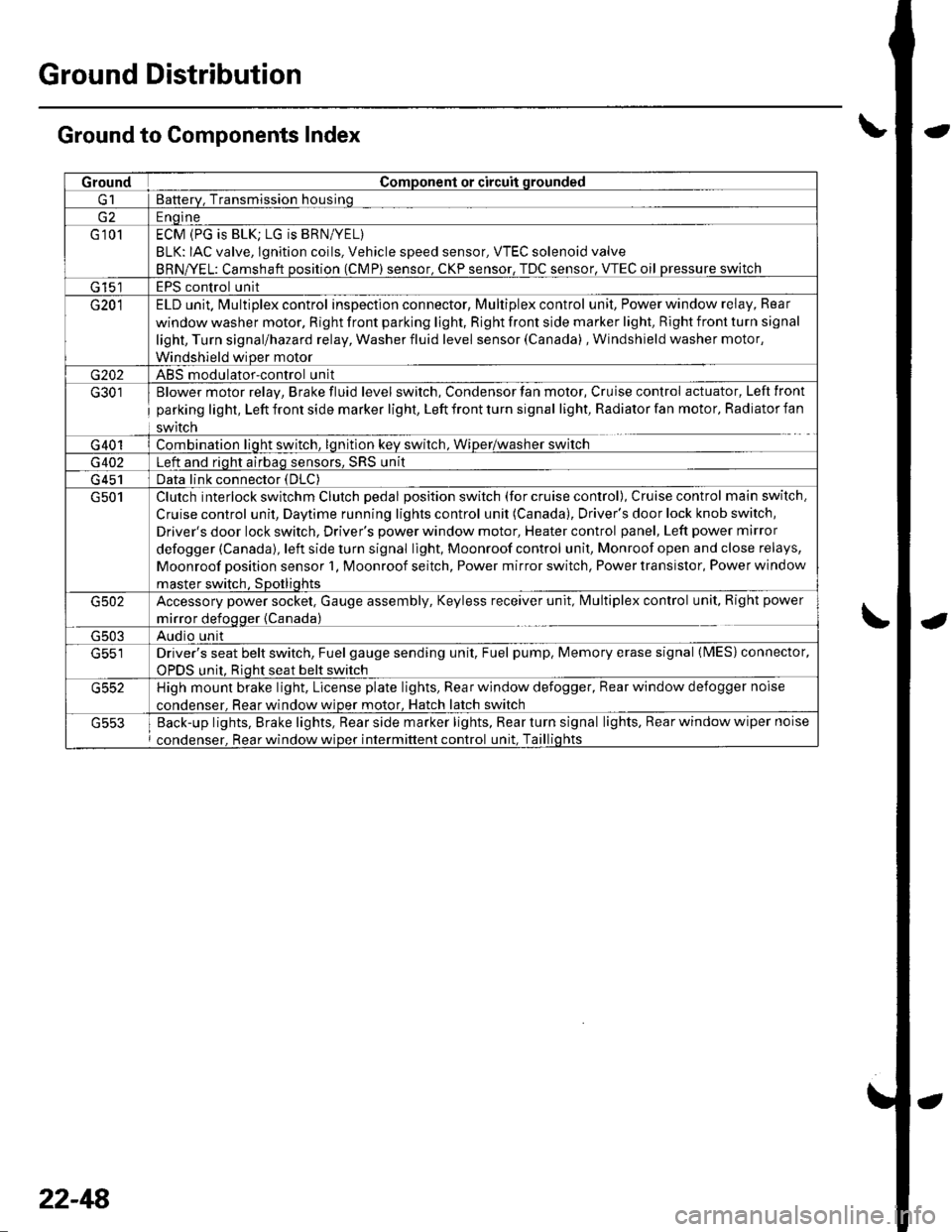

Ground Distribution

Ground to Components Index

GroundComponent or circuit qrounded

Batterv, Transmission housinq

E ngine

G 101ECM (PG is BLK; LG is BRN/YEL)

BLK: IAC valve, lgnition coils, Vehicle speed sensor, VTEC solenoid valve

BRNA/EL: Camshaft oosition (CMP) sensor. CKP sensor, TDC sensor. VTEC oil pressure switch

G 15'�]EPS control unit

G201ELD unit. Multiplex control inspection connector, Multiplex control unit, Power window relay, Rear

window washer motor, Right front parking light, Right front side marker light, Right front turn signal

light, Turn signal/hazard relay, Washer fluid level sensor (Canada) , Windshield washer motor,

Windshield wiDer motor

G202ABS modulator-control unit

G301

G401

Blower motor relay, Brake fluid level switch, Condensor fan motor, Cruise control actuator, Left front

parking light, Left front side marker light, Left front turn signal light, Radiator fan motor, Radiator fan

swrtcn

Combination liqht switch, lqnitlon kev srvitch, Wiper/wasfrer sr,virch

G402Left and riqht airbaq sensors, SRS unit

G 451Data link connector (DLC)

G501Clutch interlock switchm Clutch pedal position switch (for cruise control), Cruise control main switch,

Cruise control unit, Daytime running lights control unit (Canada), Driver's door lock knob switch,

Driver's door lock switch, Driver's power window motor, Heater control panel, Left power mirror

defogger (Canada), left side turn signal light, Moonroof control unit, Monroof open and close relays,

Moonroof position sensor '1, Moonroof seitch, Power mirror switch, Power transistor, Power window

master switch. SDotliqhts

G502Accessory power socket, Gauge assembly, Keyless receiver unit, lvlultiplex control unit, Right power

mirror defogger {Canada)

G503Audio unit

G551Driver's seat belt switch, Fuel gauge sending unit, Fuel pump, Memory erase signal (IMES) connector,

OPDS unit. Rioht seat belt switch

G552High mount brake light, License plate lights, Rear window defogger, Rear window defogger noise

condenser. Rear window wioer motor, Hatch latch switch

Back-up lights, Brake lights, Rear side marker lights, Rear turn signal lights, Rear window wiper noise

condenser, Rear window wiper intermittent control unit, Taillights

22-48

Page 880 of 1139

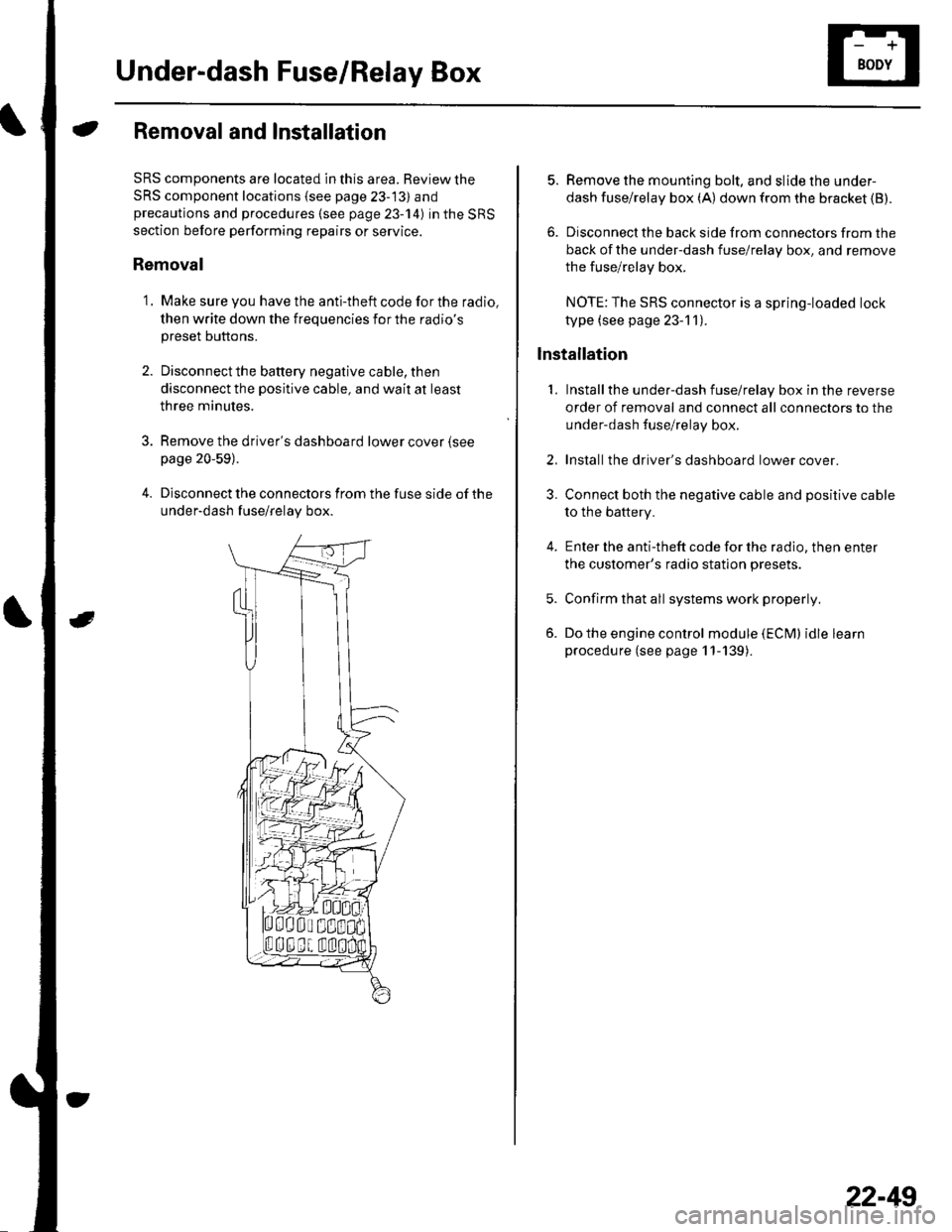

Under-dash Fuse/Relay Box

Removal and Installation

SRS components are located in this area. Review the

SRS component locations {see page 23-13) andprecautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

Removal

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's

preset buttons.

2. Disconnectthe battery negative cable, then

disconnect the positive cable, and wait at least

three minutes.

3. Remove the driver's dashboard lower cover (see

page 20-59).

4. Disconnect the connectors from the fuse side of the

under-dash fuse/relay box.

5. Remove the mounting bolt, and slide the under-

dash fuse/relay box (A) down from the bracket {B).

6. Disconnect the back side from connectors from the

back of the under-dash fuse/relay box, and remove

the fuse/relay box.

NOTE:The SRS connector is a spring-loaded lock

type (see page 23-1 1).

lnstallation

1. Installthe under-dash fuse/relay box in the reverse

order of removal and connect all connectors to the

under-dash fuse/relay box.

2. Installthe driver's dashboard lower cover.

3. Connect both the negative cable and positive cable

to the battery.

4. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

5. Confirm that all systems work properly,

6. Do the engine control module (ECM) idle learn

procedure (see page 11-139).

22-49

Page 881 of 1139

Battery

{Battery Test

Use either a JCI or Bear ARBST tester, and follow the

manufacturer's procedures. lf Vou don't have one of

these computerized testers, follow this conventional

test procedure:

1. Be sure the temperature of the electrolyte is

between 70'F (21"C) and 100'F (38'C).

2. Inspect the battery case for cracks or leaks.

. lf thecase isdamaged, replacethe battery.l. lf the case looks OK, go to step 3.

3. Check the indicator EYE.

. lf the EYE indicatesthe baftery ischarged, goto

step 4.. lf the EYE indicatesa lowcharge, gotostep7.

4. Apply a 300 amp load for 15 seconds to remove the

surface charge.

5, Wait 15 seconds, then apply a test load of 280 amps

for 15 seconds.

6. Record battery voltage.

. lf voltage is above9.6volts,the battery isOK.l. lf voltage is below9.6volts, gotostepT.

7. Charge the battery on High (40 amps) until theEYE

shows the battery is charged, plus an additional 30

minutes. lf the battery charge is very low, it may be

necessary to bypass the charger's polarity

protection circuitry.

. lf the EYE indicatesthe battery is chargedwithin

3 hours, the battery is OK.l. lf the EYE indicatesthe battery is notcharged

within 3 hours, replace the battery.l

A battery can explode if you do not follow the

proper procedure, causing serious injury to anyone

nearby. Follow all procedures carefully and keep

sparks and open flames away from the battery.

22-50

Page 882 of 1139

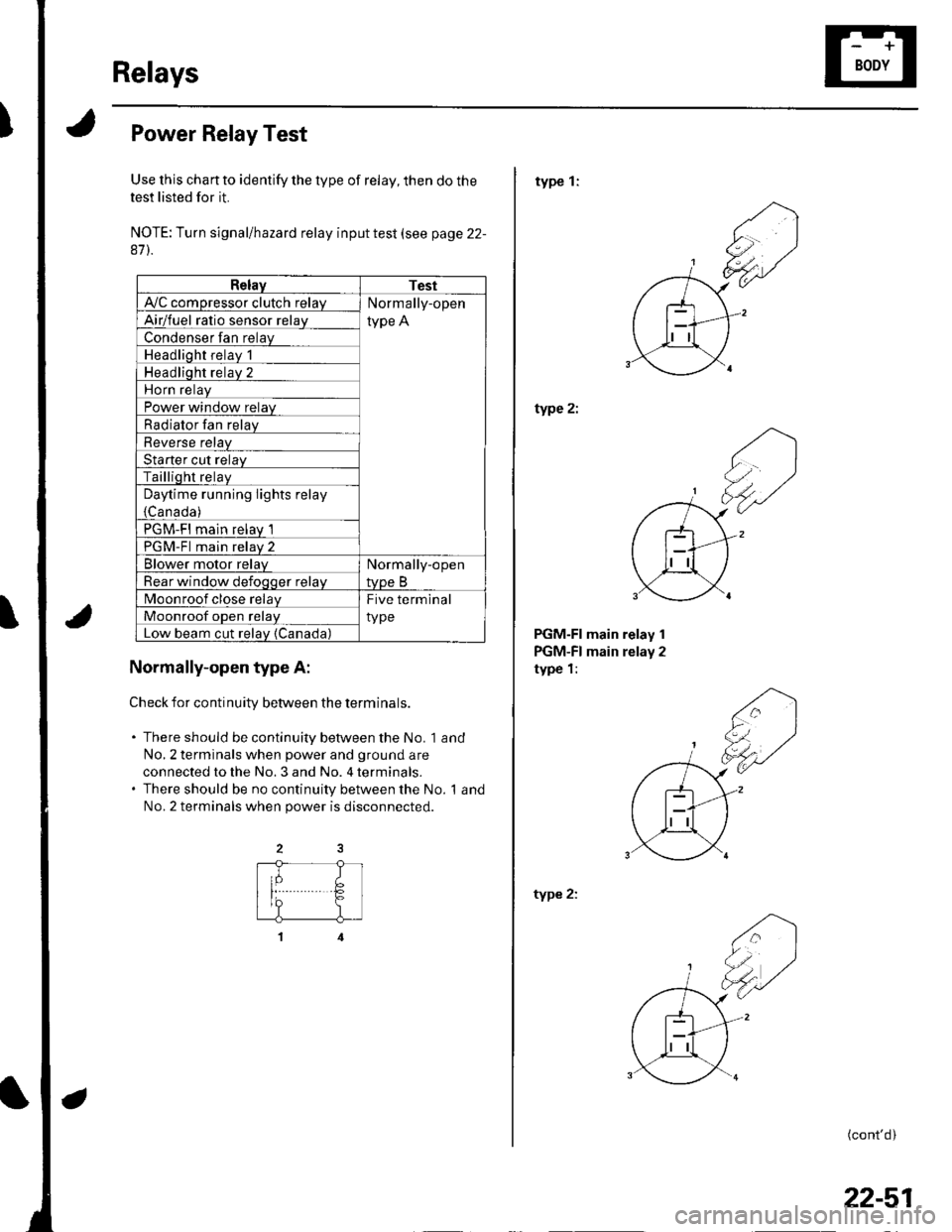

Relays

Power Relay Test

Use this chan to identify the type of relay, then do the

test listed for it.

NOTE: Turn signal/hazard relay input test (see page 22-

87).

RelayTest

A'lC comoressor clutch relavNormally-open

type AAirlfuel ratio sensor relav

Condenser fan relay

Headlioht relav 1

Headliqht relav 2

Horn relav

Power window relay

Radiator Ian relay

Reverse relav

Starter cut relav

Tailliqht relaV

Daytime running lights relay

{Canada )

PGM-FI main relav 1

PGM-Fl main relav 2

Blower motor relavNormally-open

tvpe BRear window defoqoer relav

Moonroof close relayFive terminal

typeMoonroof oDen relav

Low beam cut relav {Canada)

Normally-open type A:

Check for continuitv between the terminals.

. There should be continuity between the No. 1 and

No,2 terminals when power and ground are

connected to the No. 3 and No. 4 terminals.. There should be no continuity between the No. 1 and

No.2 terminals when power is disconnected.

type 1:

type 2:

PGM-FI main relay 1

PGM-FI main relay 2

type 1:

type 2:

(cont'd)

22-51

Page 883 of 1139

Relays

Power Relay Test (confdl

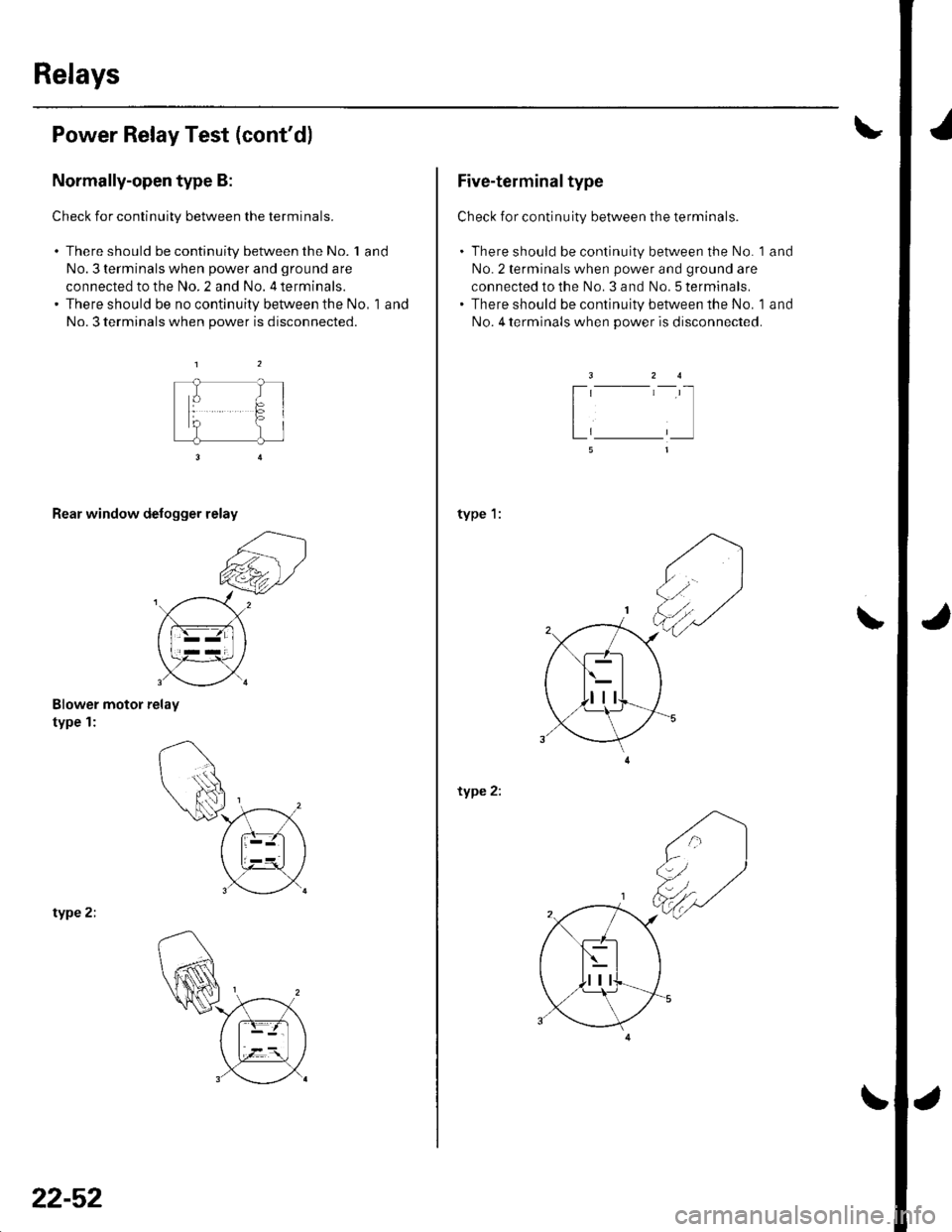

Normally-open type B:

Check for continuity between the terminals.

. There should be continuity between the No. 1 and

No. 3 terminals when power and ground are

connected to the No. 2 and No. 4 terminals.' There should be no continuity between the No, 'l and

No. 3 terminals when power is disconnected.

Blower motor relay

type 1:

type 2;

tF-gr

tJ 1l

Rear window defonn* *O,

6:)

rc*V

.r{{

n,\

(Ft)

s3.

22-52

Five-terminal type

Check for continuity between the terminals.

. There should be continuity between the No. 1 and

No.2 terminals when power and ground are

connected to the No. 3 and No. 5 terminals.. There should be continuity between the No. 1 and

No. 4 terminals when power is disconnected.

type 1:

type 2:

\

Page 884 of 1139

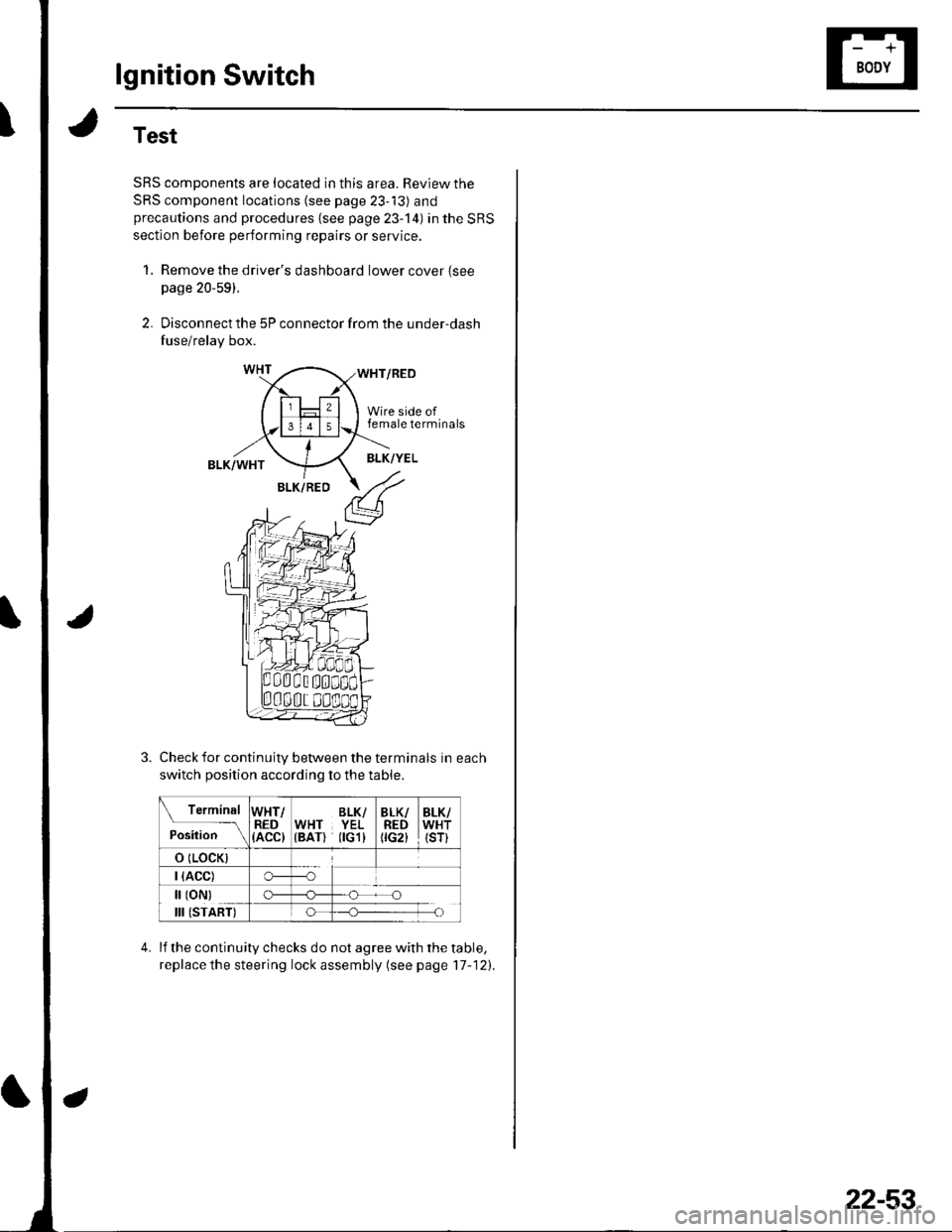

lgnition Switch

Test

SRS components are located in this area. Review the

SRS component locations (see page 23-13) andprecautions and procedures {see page 23-'l4) in the SRS

section before performing repairs or service.

1, Remove the driver's dashboard lower cover {seepage 20-59).

2. Disconnect the 5P connector from the under-dash

fuse/relay box.

WHT/RED

Wire side offemale terminals

BLK/WHTBLK/YEL

BLK/RED

Check for continuity between the terminals in each

switch position according to the table.

Terminal

p.J,i""-\

WHT/RED(ACC)

BLK/WHT YEL(BAT) flGl)

BLK/REDtrc2t

BLK/WHT(sr)

o (LocK)

| (ACC)o---o

[ (oN)

III (START)

c)-_H

o_H

lf the continuity checks do not agree with the table,

replace the steering lock assembly (see page'17-121.

22-53

Page 886 of 1139

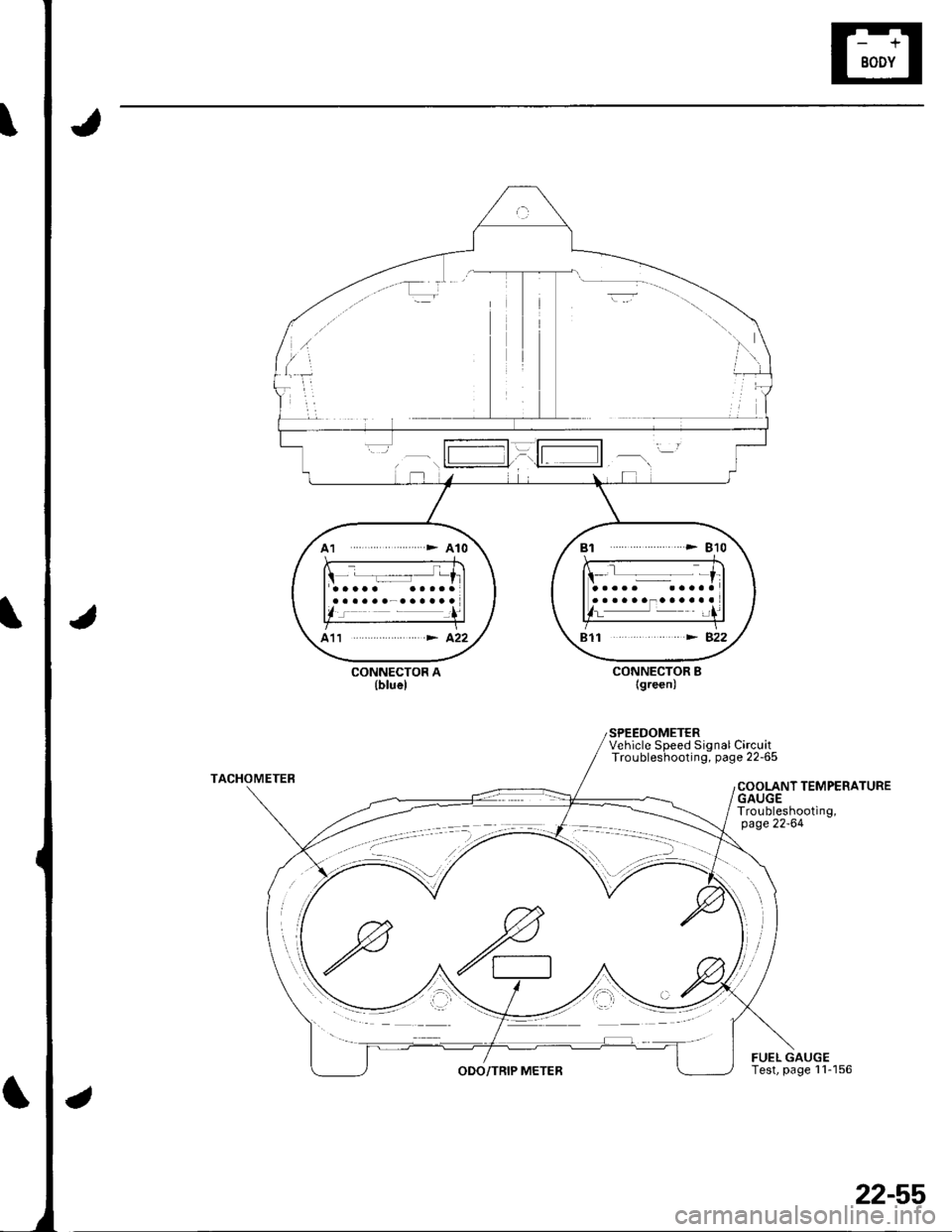

CONNECTOR A(bluelCONNECTOR BlgreenJ

SPEEDOMETERVehicle Speed Signal CircuitTroubleshooting, page 22-65

TACHOMETEB

FUEL GAUGETest, page 11-156

\7

t----/ \

i.._-

_/\

ODO/TRIP METER

22-55

Page 895 of 1139

Gauges

2.

3.

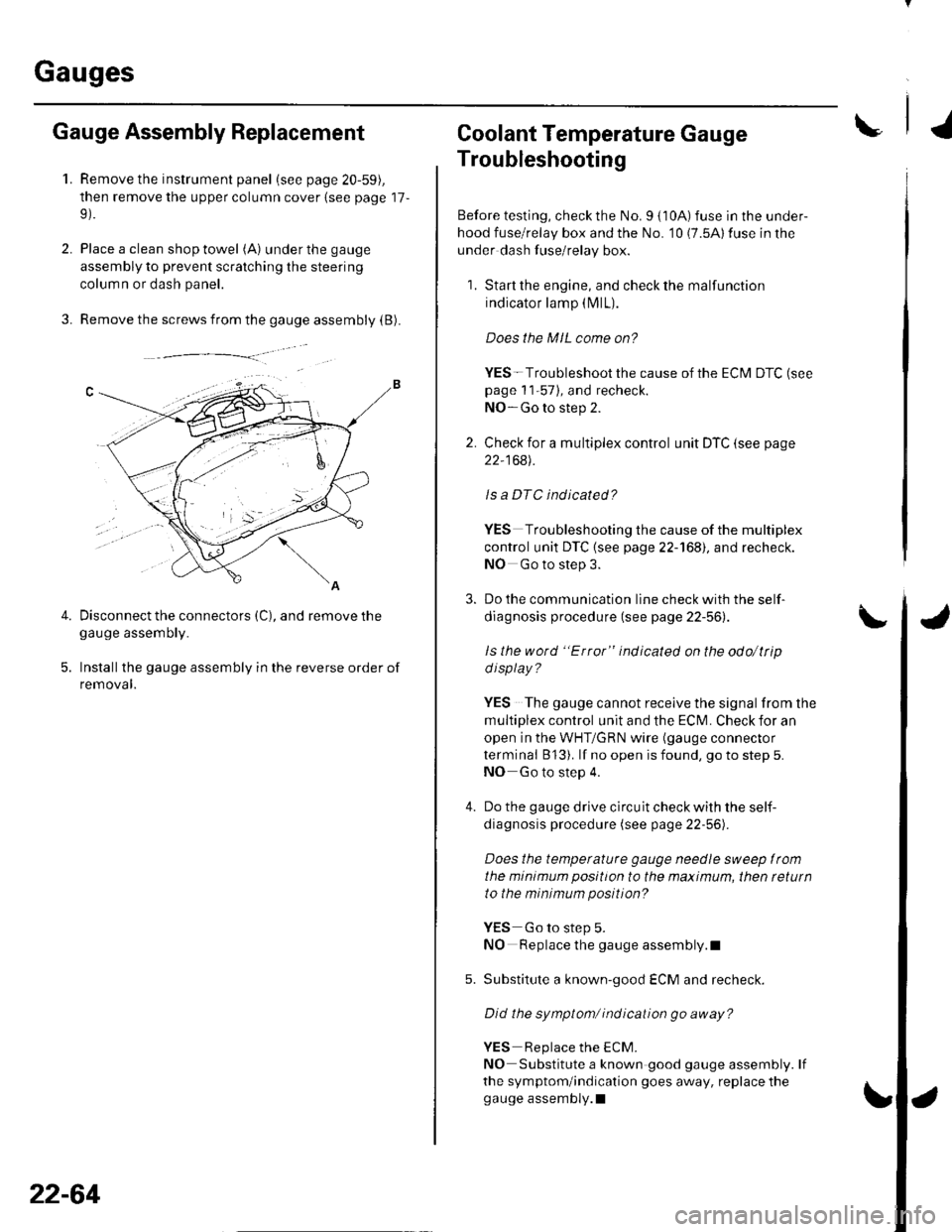

Gauge Assembly Replacement

1.Remove the instrument panel (see page 20-59),

then remove the upper column cover {see page 17-

Place a clean shop towel (A) under the gauge

assembly to prevent scratching the steering

colum n or dash panel.

Remove the screws from the gauge assembly (B).

Disconnect the connectors (C), and remove thegauge assemDry.

Installthe gauge assembly in the reverse order of

removal.

Coolant Temperature Gauge

Troubleshooting

Before testing, check the No. I { 10A) fuse in the under-

hood fuse/relay box and the No. '10 (7.5A) fuse in the

under dash fuse/relay box.

1. Start the engine, and check the malfunction

indicator lamp (MlL).

Does the MIL come on?

YES- Troubleshoot the cause of the ECM DTC (see

page 1 1-57), and recheck.

NO-Go to step 2.

2. Check for a multiplex control unit DTC (see page

22,168).

ls a DTC ind icated?

YES Troubleshooting the cause of the multiplex

control unit DTC {see page 22-168), and recheck.

NO Go to step 3.

3. Do the communication line check with the self-

diagnosis procedure (see page 22-56).

ls the word "Error" indicated on the odo/ttip

d isplay ?

YES The gauge cannot receive the signal from the

multiplex control unit and the ECI\,4. Check for an

open in the WHT/GRN wire (gauge connector

terminal B 13). lf no open is found, go to step 5.

NO Go to step 4.

4. Do the gauge drive circuit check with the self-

diagnosis procedure (see page 22-56).

Does the temperature gauge needle sweep lrom

the minimum position to the maximum, then tetutn

to the minimum position?

YES Go to step 5.

NO Replace the gauge assembly.l

5. Substitute a known-good ECM and recheck.

Did the symptom/ ind ication go away?

YES Replace the ECM.

NO Substitute a known good gauge assembly. lf

the symptom/indication goes away, replace thegauge assembly.l

4.

22-64

Page 896 of 1139

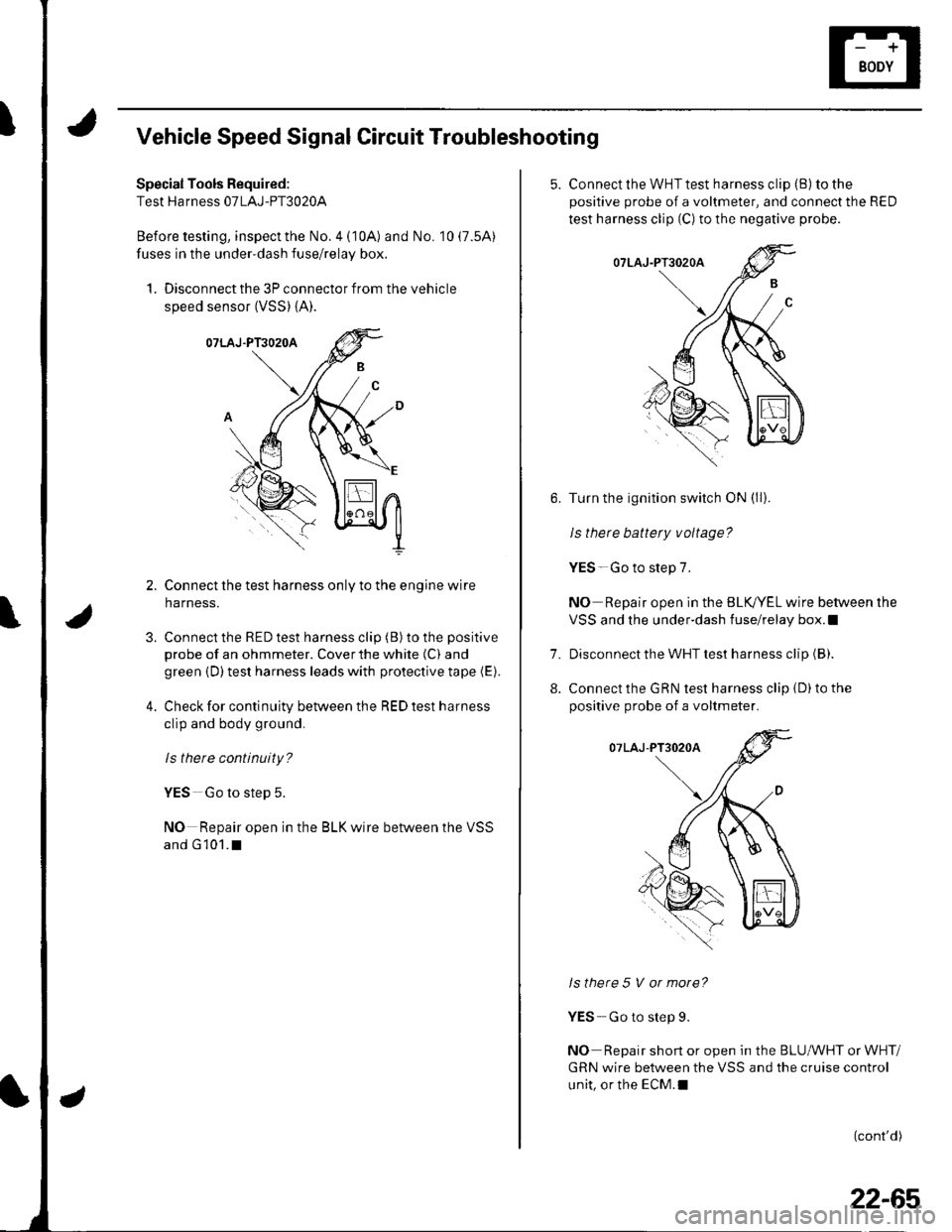

IVehicle Speed Signal Circuit Troubleshooting

Special Tools Required:

Test Harness 07LAJ-PT3020A

Before testing, inspect the No. 4 (10A) and No. 10 (7.5A)

fuses in the under-dash fuse/relay box.

1. Disconnect the 3P connector from the vehicle

speed sensor (VSS) {A).

Connect the test harness only to the engine wire

harness.

Connect the RED test harness clip (B) to the positive

probe of an ohmmeter. Cover the white (C) and

green {D) test harness leads with protective tape (E).

Check for continuity between the RED test harness

clip and body ground,

ls there continuity?

YES Go to step 5.

NO Repair open in the BLK wire between the VSS

and G 101.I

3.

4.

5. Connect the WHT test harness cliD (B) to the

positive probe of a voltmeter, and connect the RED

test harness clip (C) to the negative probe.

Turn the ignition switch ON (ll).

le thara h2ltarv v^ltada?

YES-Go to step 7.

NO Repair open in the BLK,/YEL wire between the

VSS and the under-dash fuse/relay box.l

Disconnect the WHT test harness clip (B).

Connect the GRN test harness clip {D) to the

positive probe of a voltmeter.

Is there 5 V or more?

YES- Go to step 9.

NO Repair short or open in the BLUMHT or WHT/

GRN wire between the VSS and the cruise control

unit, or the ECM.I

(cont'd)

7.

8.

22-65

Page 897 of 1139

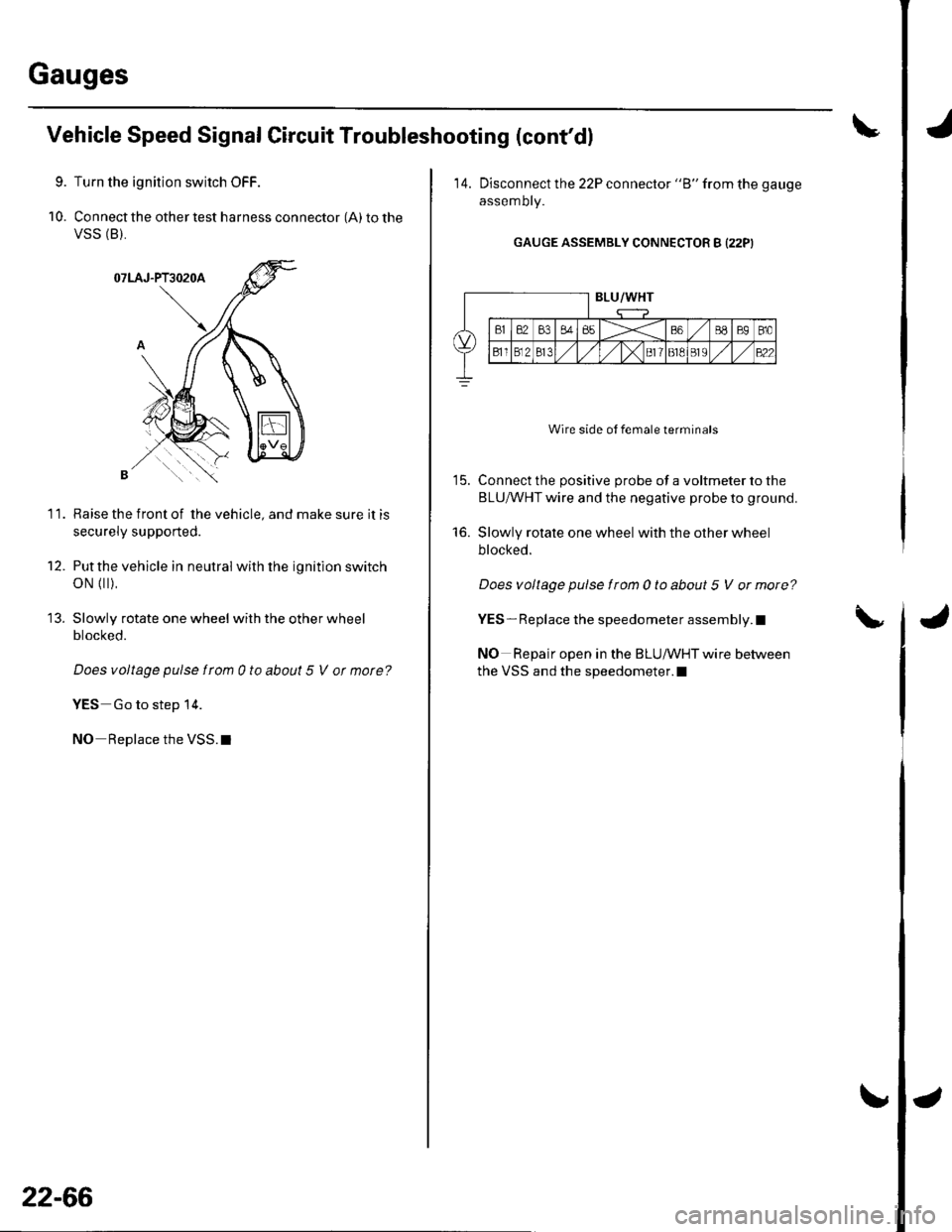

Gauges

9.

10.

Vehicle Speed Signal Circuit Troubleshooting (cont'dl

Turn the ignition switch OFF.

Connect the other test harness connector (A) to the

VSS (B),

11.Raise the front of the vehicle, and make sure it is

securely supported.

Put the vehicle in neutral with the ignition switch

oN {|| ),

Slowly rotate one wheel with the other wheel

blocked.

Does voltage pulse ttom 0 to about 5 V ot morc?

YES Go to step 14.

NO Replace the VSS.I

't2.

t5.

22-66

14. Disconnect the 22P connector "8" from the gauge

assemDry.

GAUGE ASSEMBLY CONNECTOR B (22P)

Wire side ot female terminals

'15. Connect the positive probe of a voltmeter to the

BLU/WHT wire and the negative probe to ground.

'16. Slowly rotate one wheel with the other wheel

blocked.

Does voltage pulse f rom 0 to about 5 V or more?

YES - Replace the speedometer assembly.I

NO Repair open in the BLUMHTwiTe between

the VSS and the speedometer.l