Brake master cylinder HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 22 of 1139

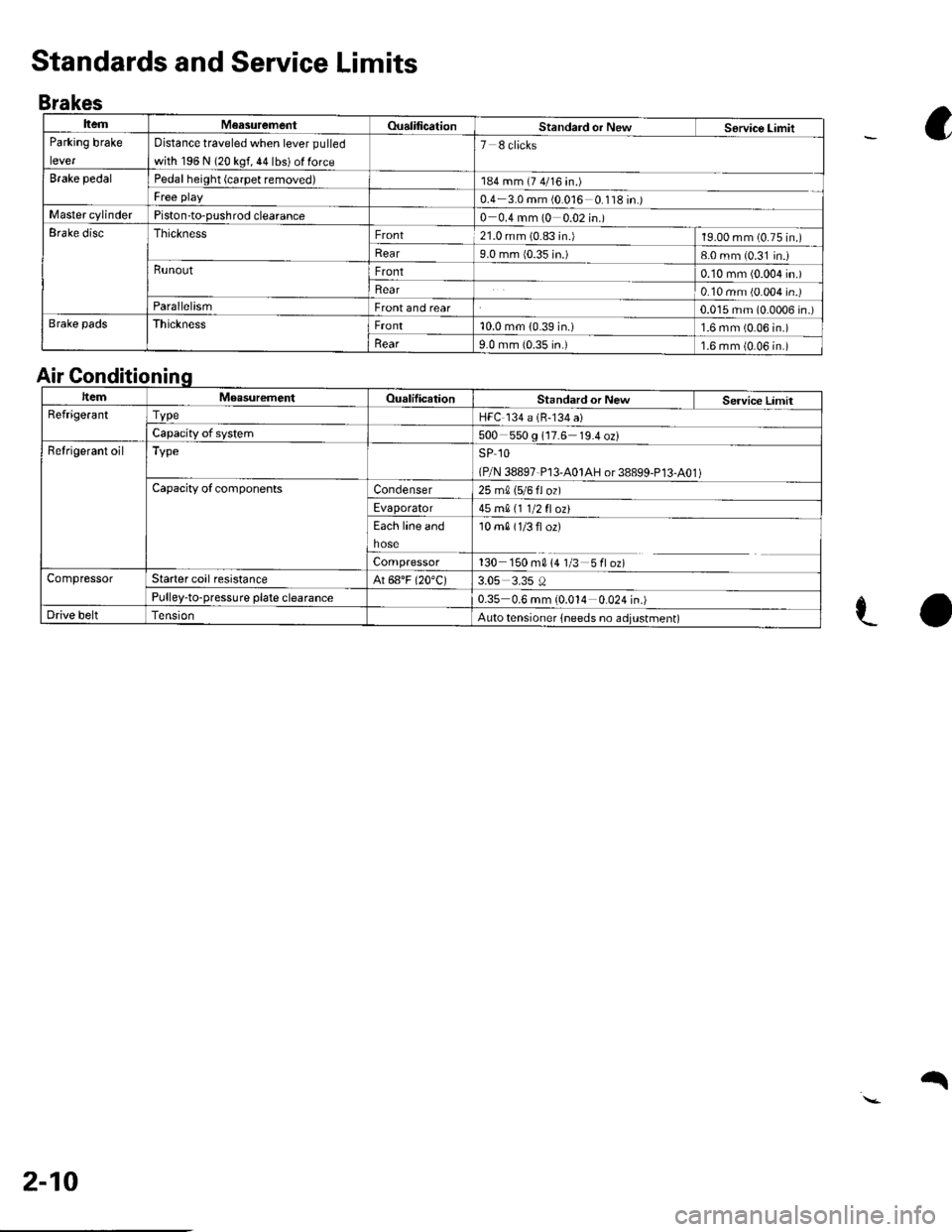

ItemM€asurementOualificationStandard or NewService LimitParking brake

lever

Distance traveled when lever pulled

with 196 N (20 kgf, 44 lbs) ol force

7 8 clicks

Brake pedalPedal height (carpet removed)184 mm (7 4/16 in.)

Free play0.4 3.0 mm (0 016 0 '118 in.)Master cylinderPiston-to-pushrod clearance0 0.4 mm (0 0.02 in.)Erake discThicknessFront21.0 mm (0.83 in.)19.00 mm (0.75 in.)

Rear9.0 mm {0.35 in.)8-0 mm (0.31 in.iRunoutFront0.10 mm (0.004 in.)

Rear0.10 mm (0.004 in.)ParallelismFront and rear0.015 mm (0.0006 in.)Brake padsThicknessFront10.0 mm (0.39 in.)1.6 mm (0.06 in.)

llear9.0 mm {0.35 in.)1.6 mm (0.06 in.)

Standards and Service Limits

Brakes

a

e-o

Air Gonditionin

ItemMoasurementOualilicationStandard or New Service LimitRefrige.antTvpeHFC 134 a (B-134 a)

Capacity of system500 550 g 117.6 19.4 oz)Refrigerant oilTypeSP 1O

(P/N 38897-P13-A01AH or 38899-P13-A01 )Capacity ofcomponentsCondenser25 m0, 15/6 fl ozl

Evaporator45 mA 11 1/2 fl ozt

Each line and

hose

10 m0 (1/3 fl or)

Compressor130 150 m014 1/3 5floz)CompressorStarter coil resistanceAt 68"F (20"C)3.05 3.35 0Pulley-to-pressure plate clearance0.35 0.6 mm (0.014 0.024 in.)Drive beltAuto tensioner lneeds no adjustment)

2-10

q

Page 31 of 1139

Do the items in parts A, B, C, D, and E as required for mileage/time interval listed.

AReplace engine oillsee page 8-5i. Capacity without lilter change: 4.0 S (4.2 US qt, 3.5 lmp qt)Rotate tires. Follow the pattern shown in the Owner's Manual Checktire information and condition.

BReplace engine oil filter lsee page 8-6). Capacity with filter change: 4.20 (4.4 US qt, 3.7 lmp qt)Inspect front and rear brakes (see page 19 3i.. Check pads and djscs for wear (thickness), damage, and cracks.' Check calipers tor damage, leaks, and tjghtness ot mount bolts.Check parking brake adjustment. Should be Iully applied within 7 to I clicks.Inspect tie rod ends, steering gearbox, and boots {see page 17 5).. Check rack grease and steering linkage.. Check boots for damage and leaking grease. Chack fluid line {or damage and leaks.lnspect suspension components.. Chock bolts fo r tig htness.. Check condition of ball ioint boots lor deterioration and damage.Inspect driveshaft boots. Check boots for cracks and boot bands for tightness (see page 16-3).Insp€ct brake hoses and lines {including ABS). Checkthe mastercylinder, proponioning control valve, and ABS modulator{or damageand leakage.Check all fluid levels and condition ot tluids; check for leaks. lf necessary, add MTF lsee page 13'3), engioe coolant, brake fluid, and

Lwindshield washer fluid.lnspectexhaust system*. Check catalytic converter heatshield, exhaust pipe and mufflerfordamage,leaks, and tightness {soe page 9,8).lnspect {uel lines and connections*. Check for loose connections, cracks and deterioration; retighten loose connoctions and replacedamaged parts (s€e page 11 146).

InsDect and adiust drive belt.. Look for cracks and damage, and inspect auto tensioner (needs no adjustment).Replace the dust and pollen lilter (see page 21 39).. Replacethe dustand pollen filter whenever airf low lrom the heating and cooling system is lessthan normal.

Replace air cleaner element every 30,000 miles (48,000 km) (independent of time).

l

D

Ei I Replace brake fluid every 3 years (independent oI mileage).

According to state and federal regulations, failure to do the maintenance items marked with asterisk( * ) will not void customer's emissionswarranties. However, Honda recommends that all maintsnance service be done at the recommended interval to ensure long term reliability.

Y

3-5

Page 33 of 1139

L

A

I

Do the items in parts A, B, C, D, E, F, and G as required for mileage/time interval listed.

Feplace engine oil(see pageS 5). Capacity withoutlilter change:4.0 q (4.2 US qt,3.5lmp qt)

Replace engjne oil filter (see page I 6). Capacity with filter change: 4.2 0 14.4 US qt, 3.7 lmp qt)Insoect front and rear brakes,. Check pads and discsforwearlthickness), damage, andcracks.. Check calipers for damage, leaks, and tightness of mount bolts.Lubricate door locks, latches and hinges with Honda white lithium grease.Rotate tires, if the vehicle has been driven the distance listed. Follow the pattern shown in the Owner's Manual-Check tire inflaron aoocondition,Inspecttie rod ends, steering gearbox, and boots (see page 17,5).. Check rack grease and steering linkage.. Check boots for damage and leaking grease.. Checklluid linefordamage and leaks.Inspect suspensron components. Check bolts for tightness.. Check condition of ball joint boots for deterioration and damage.Inspect driveshaft boots. Check boots for cracks and boot bands for tightness (see page 16-3).

Check parking brake adjustment. Should be fully applied within 7 to 9 clicks.Insp€ct brake hoses and lioes. (including ABS). Check the master cylinder, proportioning control valve, and ABS modulator for damageand leakage (see page 19-24).Check all fluid levels and condition ot lluids; check for leaks. lf necessary, add MTF (see page 13 3), engine coolant, brake fluid, andwindshield washer f luid.Inspect exhaust system*. Check catalytic converter heat shield, exhaust pipe and muffler for damage, leaks, and tightness (see page 9 8).Inspect fuel lines and connections*. Check for loose connections, cracks and deterioration; retighten loose connections and replacedamaged pans (seo page 11'146).Check alllights. Checkfunction otallinterior and exterior lights, andthe position ofthe headlights (see page 22-68).Inspect the v€hicle underbody. Check the paint for damage, scratches, stone chippin0, and dents.

L

D

E

F

H

InsDect and adiust drive belt.. Look tor cracks and damage, and inspect auto tensioner {needs no adjustment).Reolace dust and oollen filter.

Replace air cleaner element every 15,000 miles 124,000 km) in dustv condition {independent ol timei otherwise use Normal Conditionsscredule (see page 11-162).

lReplaceaircleanerelementevery30,000miles(48,000km)(independento{timei(seepagell-162).

Replace brake fluid every 3 years (independent oJ mileagei.

Replacethe dust and pollen Iilter every 15,000 miles ifvehicle is driven mostlywhere air has high concentration olsootfrom industryanddiesel powered vehiclesj also replace the dust and pollen filter anytime aarflow is less than ussal (see pags 21-39).

According to state and federal regulations, failure to do the maintenance items marked with asterisk (*) will not void customer's emissionswarranties. However, Honda recommends that all maintenance services be done at the recommended interval to ensure long-term reliability,

3-7

Page 402 of 1139

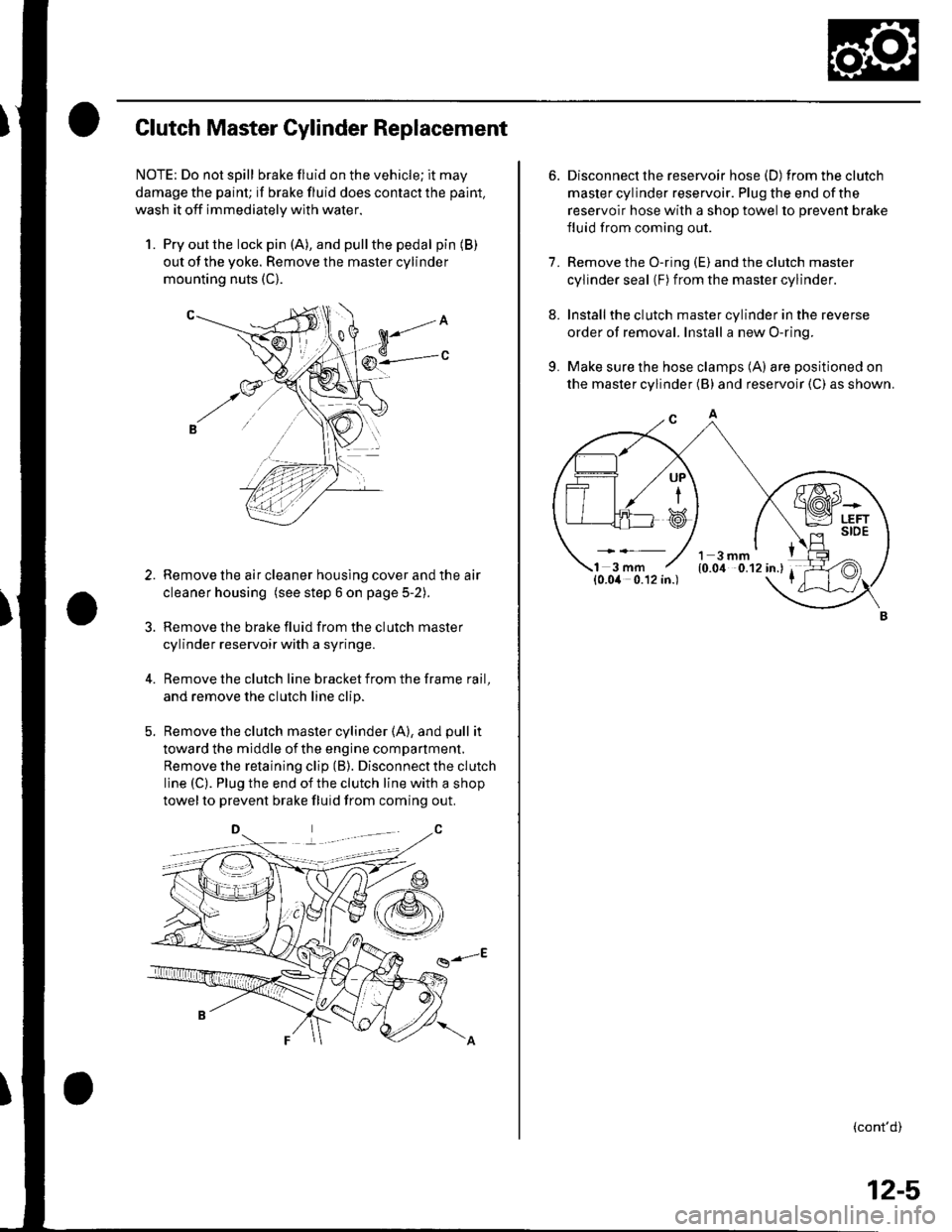

Clutch Master Cylinder Replacement

NOTE: Do not spill brake fluid on the vehicle; it may

damage the paint; if brake fluid does contact the paint,

wash it off immediatelV with water.

1. Pry out the lock pin (A), and pullthe pedal pin (B)

out of the yoke. Remove the master cylinder

mounting nuts (C).

Remove the air cleaner housing cover and the air

cleaner housing (see step 6 on page 5-2).

Remove the brake fluid from the clutch master

cylinder reservoir with a syringe.

Remove the clutch line bracket from the frame rail,

and remove the clutch line clip.

Remove the clutch master cylinder (A), and pull it

toward the middle of the engine compartment.

Remove the retaining clip (B). Disconnect the clutch

line (C). Plug the end of the clutch line with a shop

towelto prevent brake fluid from coming out.

g-E

3.

6. Disconnect the reservoir hose (D) fromtheclutch

master cylinder reservoir. Plug the end of the

reservoir hose with a shop towel to prevent brake

fluid from coming out.

7. Remove the O-ring (E) and the clutch master

cylinder seal (F) from the master cylinder.

8. Installthe clutch master cylinder in the reverse

order of removal. Install a new O-ring.

9. Make sure the hose clamps (A) are positioned on

the master cylinder (B) and reservoir (C) as shown.

(cont'd)

UP

i

12-5

Page 405 of 1139

Clutch

Slave Cylinder Replacement (cont'd)

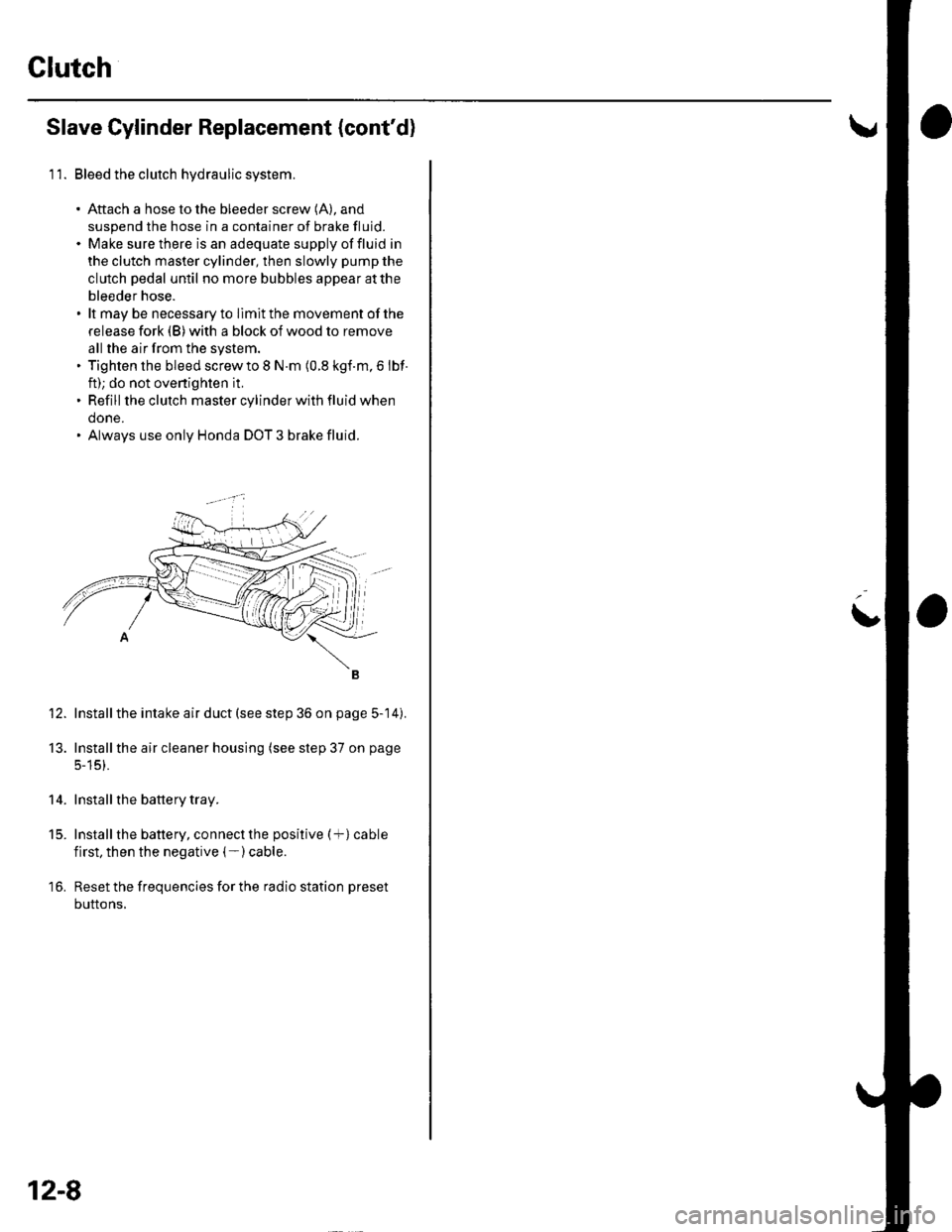

11. Bleed the clutch hydraulic system.

. Aftach a hose to the bleeder screw (A), and

suspend the hose in a container of brake fluid.. Make sure there is an adequate supply offluid in

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear atthe

bleeder hose.. lt may be necessary to llmit the movement of the

release fork (B) with a block of wood to remove

all the air from the system.. Tighten the bleed screw to I N.m (0.8 kgf.m, 6 lbf

ft); do not ovenighten it,. Refill the clutch master cylinder with fluid when

done.. Always use only Honda DOT 3 brake fluid.

Install the intake air duct (see step 36 on page 5-14).

Installthe air cleaner housing (see step 37 on page

5-15).

Install the battery tray.

Install the battery, connect the positive (+) cable

first, then the negative (- ) cable.

Reset the frequencies for the radio station preset

buttons,

12.

13.

14.

t5.

16.

12-8

L

Page 596 of 1139

Brakes

Conventional Brake Components

Special Tools ... ..... ... l9-2

Component Location Index ......................................... 19-3

Brake System Inspection and

Tests ............... .......... 19-4

Brake Pedal and Brake Pedal Position Switch

Adjustment .............. 19-6

Parking Brake Check and

Adjustment .............. 19-7

Brake System Bleeding ...................... 19-8

Brake System Indicator Circuit

Diagram ................... 19-9

Parking Brake Switch Test ................. 19-10

Brake Fluid Level Switch Test ...................................... 19-10

Front Brake Pads lnsoection and

Replacement ........... 19-11

Front Brake Disc Inspection ............... 19-13

Front Brake Calioer Overhaul ...................................... 19-14

Master Cylinder Replacement ........... 19-15

Master Cylinder Inspection ................ 19-16

Brake Booster

Pushrod Clearance Adjustment ................................ 19-16

Brake BoosterTest ................... .......... 19-18

Brake Booster Reolacement .............. 19-19

Rear Brake Pads Inspection and

Reolacement ........... 19-20

Rear Brake Disc Inspection ................ 19-22

Rear Brake Caliper Overhaul ....................................... 19-23

Brake Hoses and Lines Insoection .... 19-24

Brake Hose Reolacement ................... 19-25

Parking Brake Cable Replacement .............................. 19-26

ABS (Anti-lock Brake System)

Gomponents ... 19-29

Page 598 of 1139

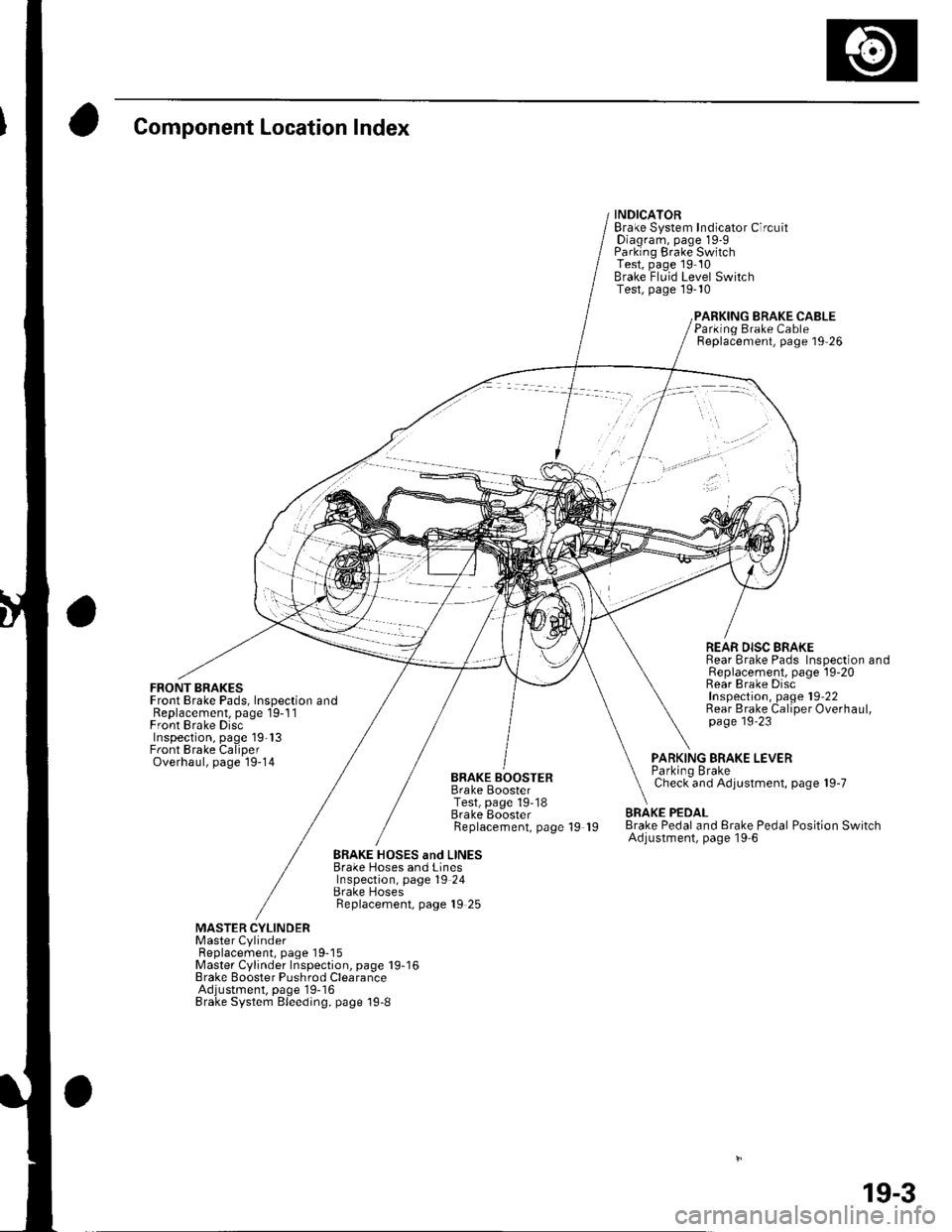

Component Location Index

FRONT BRAKESFront Brake Pads, Inspection andReplacement, page 19-1 1Front Brake DiscInspection, page 19'13Front Brake CaliperOverhaul, page 19-14

INDICATORBrake System Indicator CircuitDiagram, page 19-9Parking Brake SwitchTest, page 19 10Brake Fluid Level SwitchTest, page 19-10

BRAKE CABLE

BRAKE BOOSTERBrake BoosterTest, page 19-18Brake EoosterReplacement, page 19 19

Parking Brake CableReplacement, page 19 26

REAR DISC BRAKERear Brake Pads Inspection andReplacement, page l9-20Rear Brake DiscInspection, page 19'22Rear Brake Caliper Overhaul,page 19'23

PARKING BRAKE LEVERParkino BrakeCheck and Adjustment, page 19-7

BRAKE PEDALBrake Pedal and Erake Pedal Position SwitchAdjustment, page l9-6

BRAKE HOSES and LINESBrake Hoses and LinesInspection, page 19 24Brake HosesReplacement, page 19 25

MASTER CYLINDERMaster CylinderFl6^1.^6m6nr ^2^o 1O-18Master Cylinder Inspection, page 19-16Brake Booster Pushrod ClearanceAdjustment, page'19-16Brake System Bleeding, page 19-8

19-3

Page 599 of 1139

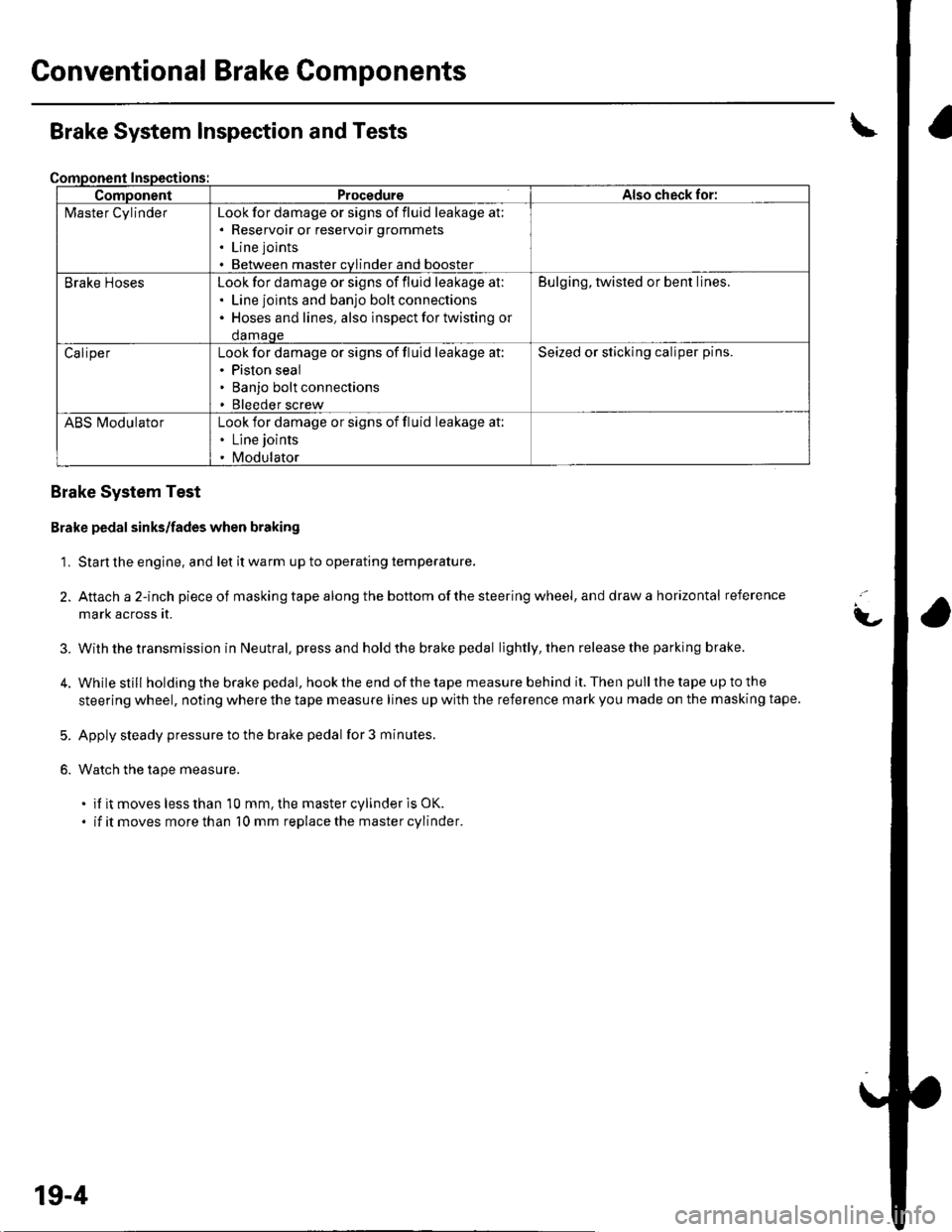

Gonventional Brake Components

ComponentProcedureAlso check for:

l\4aster CylinderLook for damage or signs of fluid leakage at;. Reservoir or reservoir grommets

. Line joints

. Between master cvlinder and booster

Brake HosesLook for damage or signs of fluid leakage at:. Line joints and banjo bolt connections. Hoses and lines. also inspect for twisting or

damaqe

Bulging, twisted or bent lines.

CaliperLook for damage or signs of fluid leakage at:. Piston seal. Banjo bolt connections. Bleeder screw

Seized or sticking caliper pins.

ABS l\ilodulatorLook for damage or signs of fluid leakage at:. Line joints

. Modulator

Brake System Inspection and Tests

Brake System Test

Brake pedal sinks/fades when braking

1. Start the engine, and let it warm up to operating temperature.

2. Attach a 2-inch pieceof masking tape along the bottom of the steering wheel, and draw a horizontal reference

mark across it.

With the transmission in Neutral, press and hold the brake pedal lightly, then release the parking brake.

While still holding the brake pedal, hook the end of the tape measure behind it. Then pull the tape up to the

steering wheel, noting where the tape measure lines up with the reference mark you made on the masking tape.

Apply steady pressure to the brake pedal for 3 minutes.

Watch the tape measure.

. if it moves less than 10 mm, the master cylinder is OK.

. if it moves more than 10 mm replace the master cylinder.

t-

3.

5.

6.

19-4

Page 600 of 1139

Rapid brake pad wear. Vehicle vibration {after a long

drivel, or High, hard brake pedal

1. Drive the vehicle until the brakes drag or untilthe

pedal is high and hard. This can take 20 or more

brake pedal applications during an extended test

drive.

2. With the engine running, raise the vehicle on a lift,

and spin all four wheels by hand.

ls there btake drag at any of the wheels?

YES Go to step 3.

NO Look for other causes of the pad wear, high

pedal, or vehicle vibration.I

3. Turn the engine off, pump the brake pedal to

deplete the vacuum in the brake booster, and then

spin the wheels again to check for brake drag.

ls therc brake dtag at any ot the wheels?

YES-Go to step 4.

NO Replace the brake booster.I

4. Without removing the brake lines, unbolt and

separate the master cylinder from the booster, then

spin the wheels lo check for brake drag.

ls there btake drag at any of the wheels?

YES Go to step 5,

NO-Check the brake pedal position switch

adjustment and pedal free play.I

5. Loosen the hydraulic lines at the master cylinder,

then spin the wheels to check for brake drag.

ls there brake drag at any of the wheels?

YES Go to step 6.

NO- Replace the master cylinder.l

6. Loosen the bleeder screws at each caliper, then

spin the wheels to check for brake drag.

Is there brake drag at any of the wheels?

YES Disassemble and repair the caliper on the

wheel(s) with brake drag.l

NO Inspect brake hose (s)/line (s).

19-5

Page 603 of 1139

Conventional Brake Components

Brake System Bleeding

NOTE:. Do not spill brake fluid on the vehicle; it may damage

the painU if brake fluid does contact the paint. wash it

off immediately with water.. The reservoir on the master cylinder must be at the

MAX (upper) level mark at the start of the bleeding

procedure and checked after bleeding each brake

caliper. Add fluid as required.. Do not reuse the drained fluid.. Always use Honda DOT 3 brake fluid. Non-Honda

brake fluid can cause corrosion and shorten the life of

the system.. Make sure no din or other foreign matter is allowed

to contaminate the brake fluid.

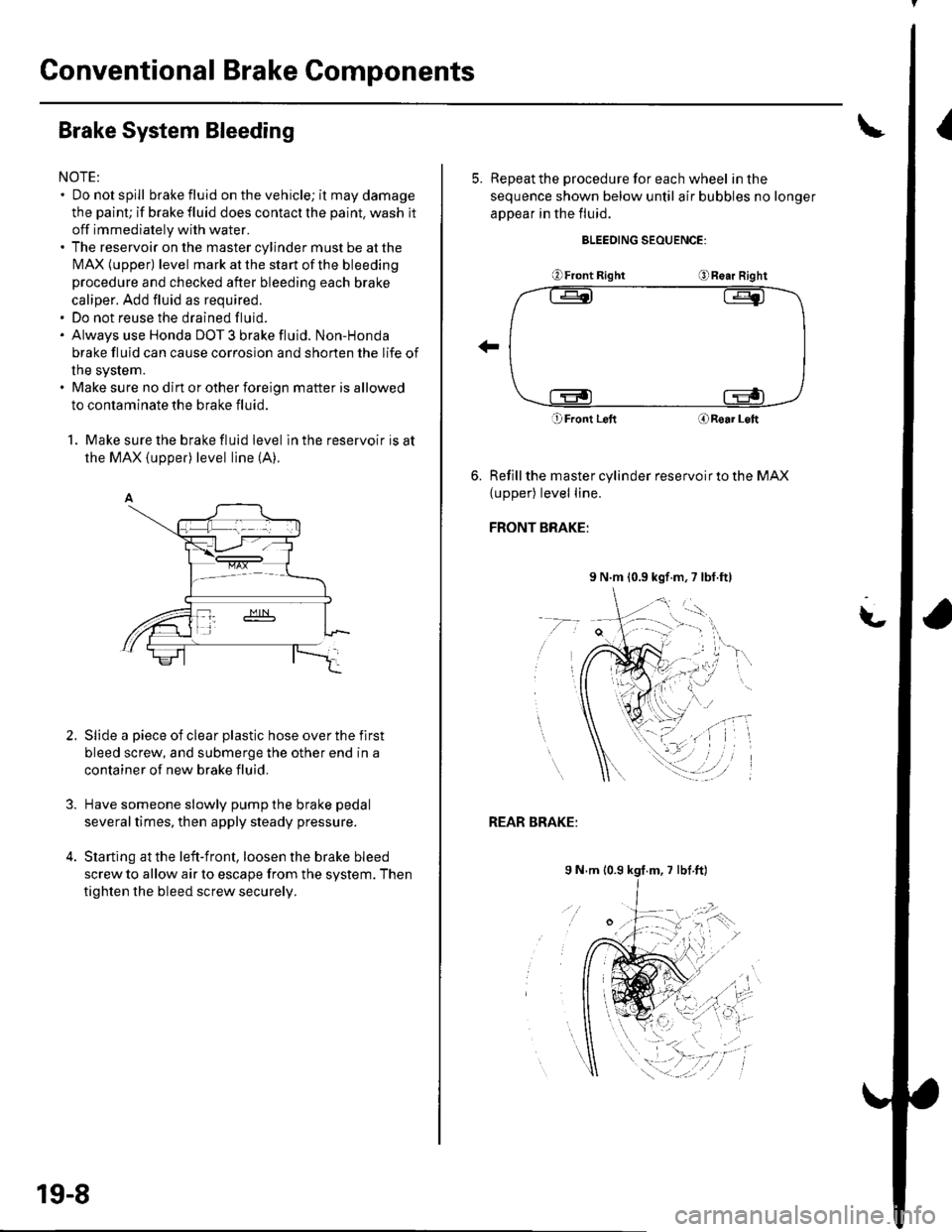

1. Make sure the brake fluid level in the reservoir is at

the MAX (upper) level line (A).

Slide a piece of clear plastic hose over the flrst

bleed screw, and submerge the other end in a

container of new brake fluid.

Have someone slowly pump the brake pedal

severaltimes, then apply steady pressure.

Starting at the left-front, loosen the brake bleed

screw to allow air to escape from the system. Then

tighten the bleed screw securely.

2.

19-8

5. ReDeatthe procedure for each wheel in the

sequence shown below until air bubbles no longer

appear in the fluid.

BLEEDING SEOUENCE:

OFront RightORe.r Right

O Front LeftORoar Loft

Refill the master cylinder reservoir to the MAX

{upper) level line.

FRONT BRAKE:

9 N.m 10.9 kgf.m,7 lbl.ft)

t-

REAR BRAKE:

9 N m 10.9 kgf.m, 7 lbf ft)