HEATER UNIT HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 710 of 1139

Interior Trim

Carpet Replacement (cont'dl

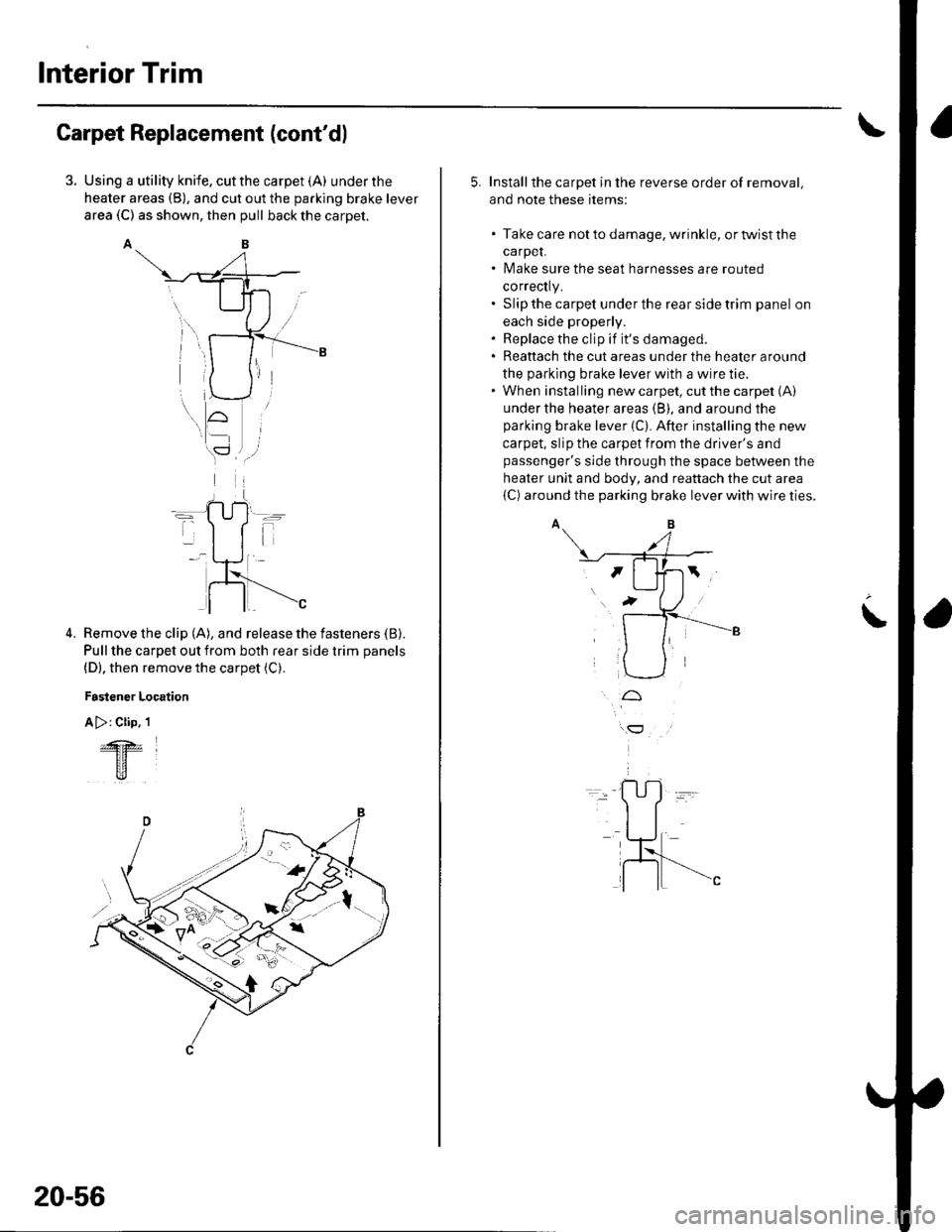

Using a utility knife, cut the carpet (A) under the

heater areas (B), and cut out the parking brake lever

area (C) as shown, then pull back the carpet.

AB

Remove the clip (A), and release the fasteners (B).

Pull the carpet out from both rear side trim panels

(D), then remove the carpet (C).

Fastener Location

A >: Clip. 1

4.

&z

tr

20-56

5. Installthe carpet in the reverse order of removal,

and note these items:

. Take care notto damage, wrinkle, ortwistthe

carpeL. Make sure the seat harnesses are routed

correctly.. Slip the carpet under the rear side trim panel on

each side properly.. Replace the clip if it's damaged.. Reattach the cut areas under the heater around

the parking brake lever with a wire tie.. When installing new carpet, cut the carpet (A)

under the heater areas (B), and around the

parking brake lever (C). After installing the new

carpet, slip the carpet from the driver's and

passenger's side through the space between the

heater unit and body, and reattach the cut area

{C) around the parking brake lever with wire ties.

t

Page 716 of 1139

Dashboard

Dashboard Center Panel Removal/lnstallation

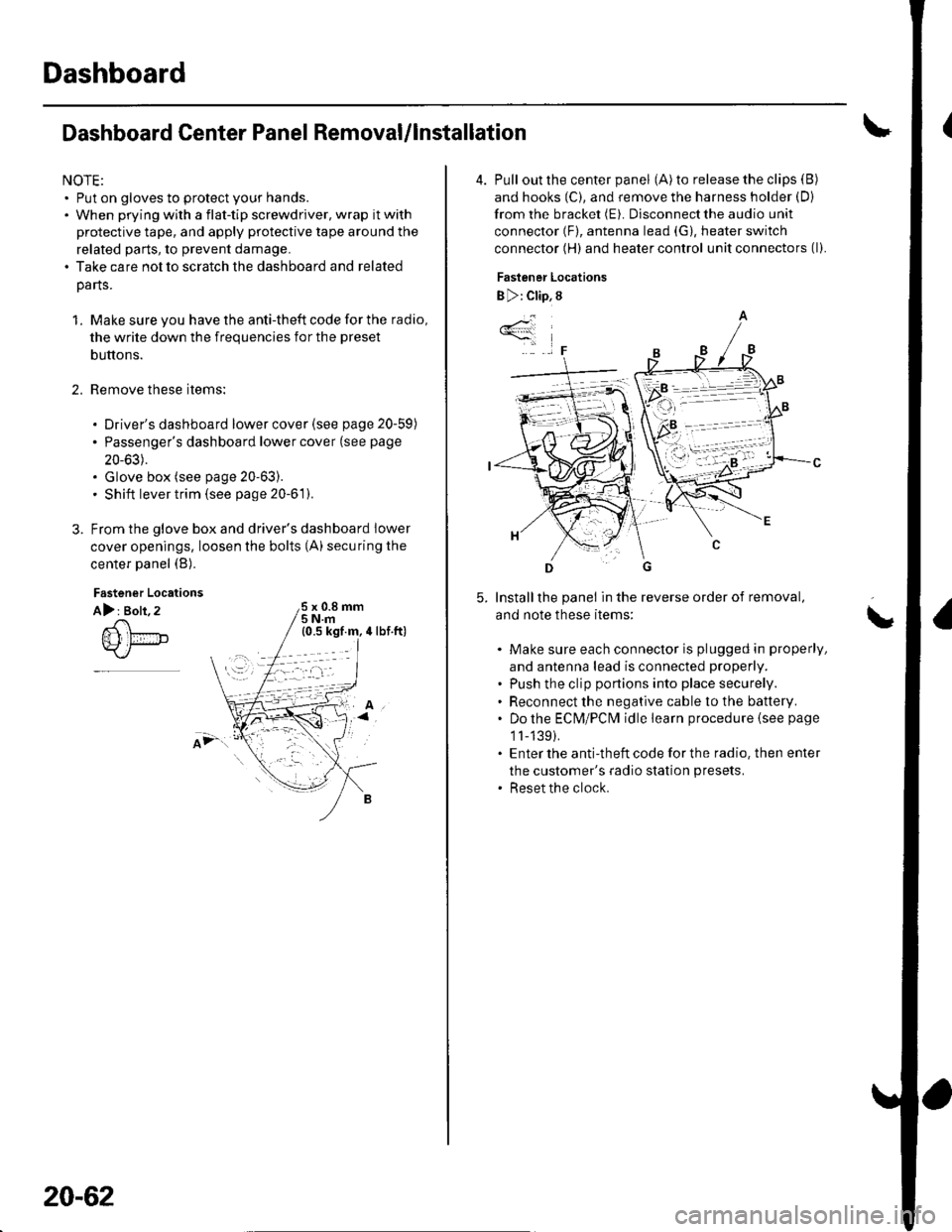

NOTE:. Put on gloves to protect your hands.. When prying with a flat-tip screwdriver, wrap it with

protective tape, and apply protective tape around the

related parts, to prevent damage.. Take care not to scratch the dashboard and related

parts.

1. Make sure you have the anti-theft code for the radio,

the write down the frequencies for the preset

buttons.

Remove these items:

. Driver's dashboard lower cover (see page 20-59)

. Passenger's dashboard lower cover (see page

20-63).. Glove box (see page 20-63).. Shift lever trim {see page 20-61).

From the glove box and driver's dashboard Iower

cover openings, loosen the bolts (A) securing the

center panel (B).

2.

Fastener Locations

A): Bolt, 2x 0.8 mm5Nm

;.'

20-62

4. Pull out the center panel (A) to release the clips (B)

and hooks (C), and remove the harness holder (D)

from the bracket (E). Disconnect the audio unit

connector (F), antenna lead (G), heater switch

connector (H) and heater control unit connectors (l).

Fastener Locations

B ): Clip, 8

Installthe panel in the reverse order of removal,

and note these items:

Make sure each connector is plugged in properly,

and antenna lead is connected properly.

Push the clip portions into place securely.

Reconnect the negative cable to the battery.

Do the ECN4/PCt\4 idle learn procedure {see page

1l-139).

Enter the anti-theft code for the radio. then enter

the customer's radio station presets.

Reset the clock.

*4

,F

\

Page 773 of 1139

21-2

z t-'5

z t-o

z t-o

21-8

21-9

21-10

21-11

21-14

z t- to

HVAC (Heating, Ventilation, and Air Gonditioningl

Heating and Air Conditioning

SpecialTools

Comoonent Location lndex ........

A/C Service Tios and

Precautions

A,/C Refrigerant Oil

ReDlacement

General Troubleshooting

lnformation

DTC Troubleshooting Index .......

Symptom Troubleshooting

1ndex..............

System Description .....................

Circuit Diagram

DTC Troubleshooting ..................

Recirculation Control Motor

CircuitTroubleshooting .......... 21-25

Heater Control Power and Ground

Circuits Troubleshooting ........ 21-27

Condenser Fan Circuit

Troubleshooting ...................... 21-28

Radiator and Condenser Fans

Common Circuit

Troubfeshooting ...................... 21-29

Compressor Clutch Circuit

Troubleshooting ...................... 21-30

A,/C Pressure Switch Circuit

Troubleshooting ...................... 21-32

Air Mix Control Motor

Test and Reolacement ............. 21-34

Mode Control Motor

Test and Replacement ............. 21-35

Recirculation Control Motor

Test and Reolacement ............. 21-36

Evaporator Temperature Sensor

Reolacement and Test ............. 21-31

Power Transistor Test ................. 21 -38

Heater Control Panel and

Push Switch Assemblv

Removal and Installation ........ 21-38

Dust and Pollen Filter

Reolacement ..21-39

Blower Unit Removal and

lnstallation ...... 21-39

Blower Unit Comoonents

ReDlacement ............................ 21-41

Evaporator Core

Reolacement ..21-42*Heater Unit/Core

ReDlacement ..21-43

Heater Valve Cable

Adjustment .....21-46

CompressorReplacement .......... 21-47

Comoressor Clutch Check .......... 21-48

Comoressor Clutch Overhaul ..... 21-49

Compressor Thermal Protector

Reo1acement ............................ 21-51

Comoressor Relief Valve

Reolacement ............................ 21-51

Condenser Reolacement ............ 21-52

Refrigerant Recovery .................. 21-53

System Evacuation ...................... 21-54

System CharginS ......................... 21-55

Refrigerant LeakTest .................. 21-56

A,/C Svstem Tests ........................ 21-57

Page 775 of 1139

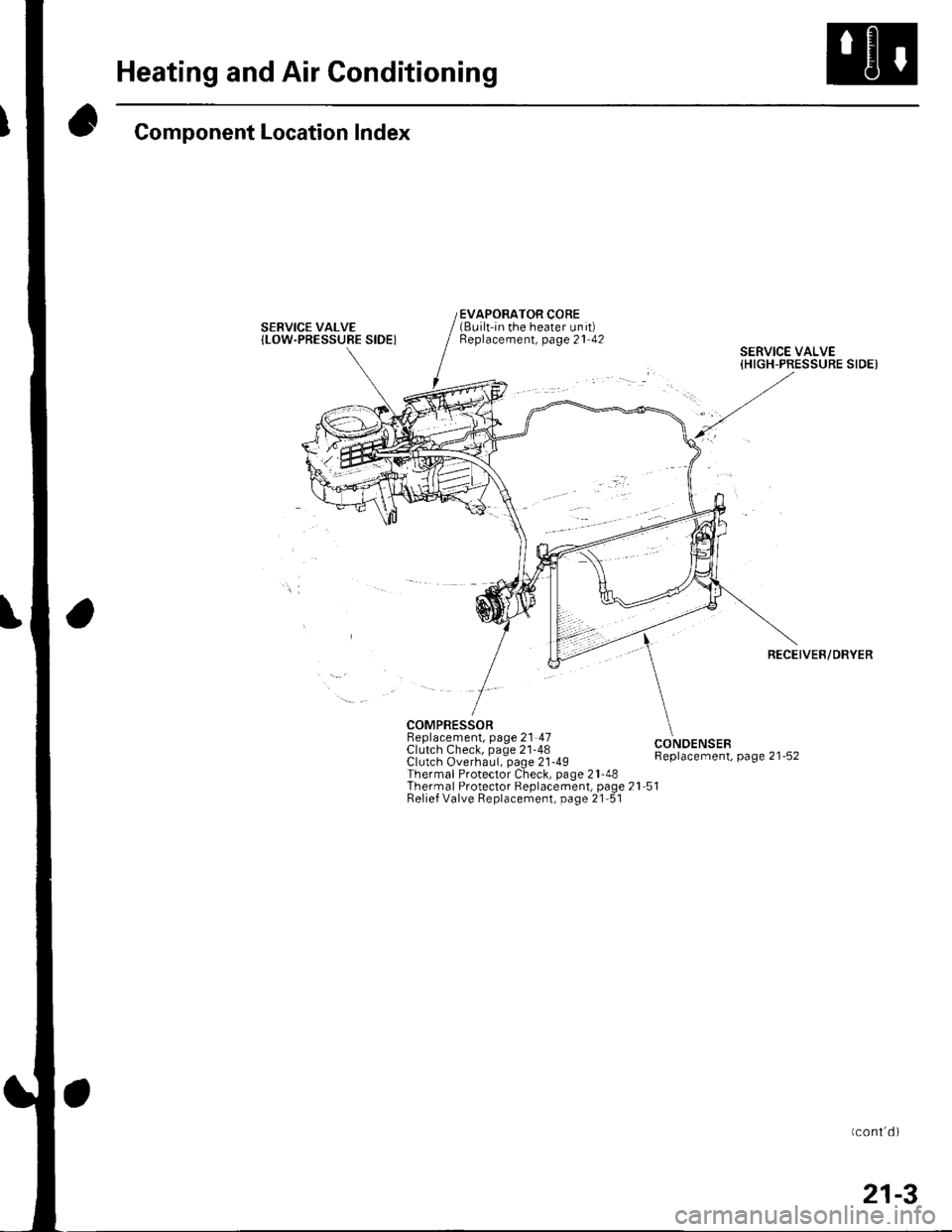

Heating and Air Gonditioning

Component Location Index

SERVICE VALVE{LOW.PRESSUBE SIDEI

EVAPORATOR CORE(Built-in the heater unit)Beplacement, page 21 42

COMPRESSORBeplacement, page 21 47Clutch Check, page 21-48Clutch Overhaul, page 21-49Thermal Protector Check, page 21-48Thermal Protector Replacement, page 21 51Relief Valve Replacement, page 21 51

SERVICE VALVE{HIGH-PRESSURE SIDEI

RECEIVER/DRYER

CONOENSEBReplacement, page 21-52

Page 777 of 1139

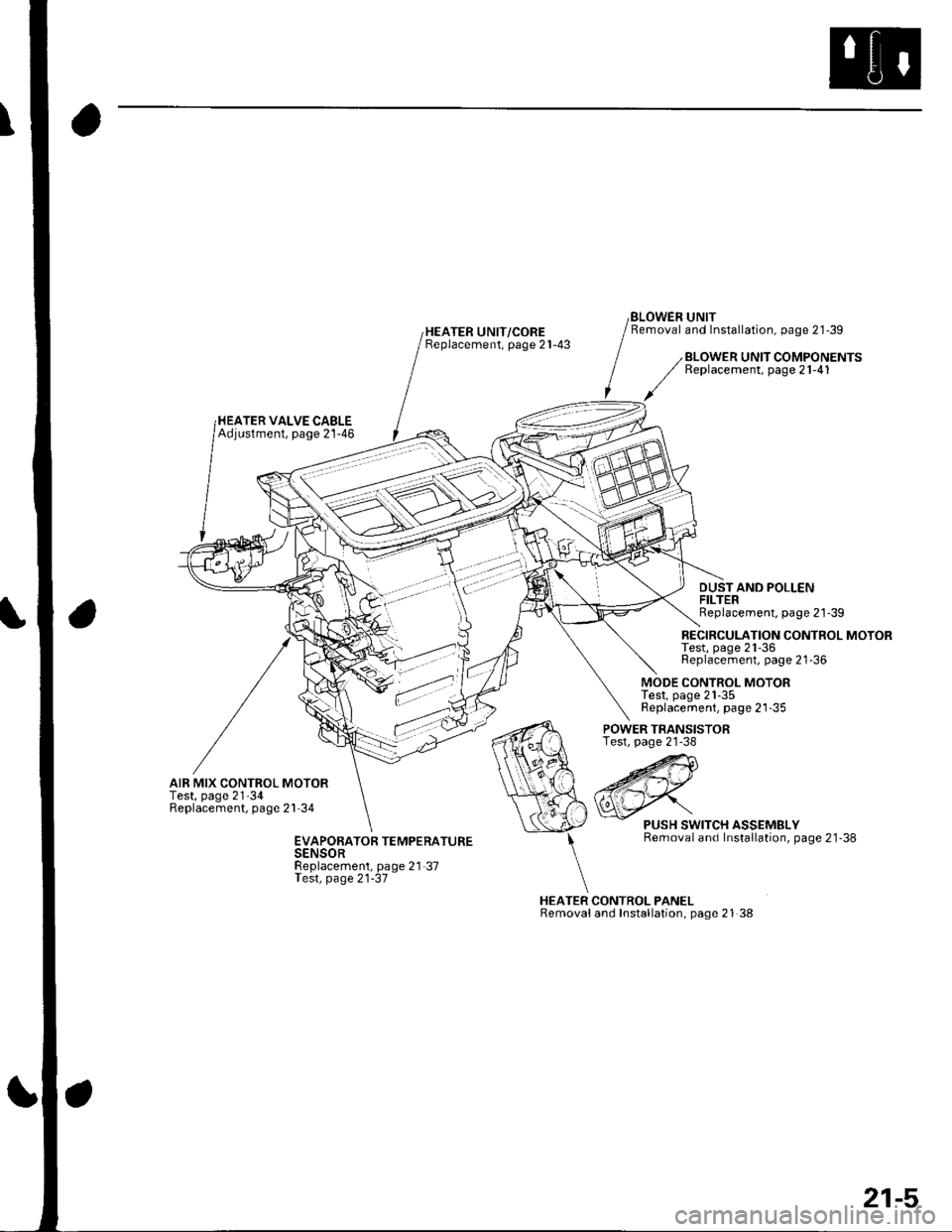

HEATER UNIT/COREBeplacement, page 21-43

BLOWEN UNITRemoval and Installation, page 21-39

HEATER VALVE CABLEAdjustment, page 21-46

BLOWER UNIT COMPONENTSReplacement, page 21-41

DUSTAND POLLENFILTERReplacement, page 21'39

RECIRCULATION CONTROL MOTORTest, page 21-36Replacement, page 21-36

MODE CONTROL MOTORTest, page 21-35Replacement, page 21-35

AIR MIX CONTROL MOTORTest, page 21'34Replacement, page 21'34

POWER TRANSISTORTest, page 21-38

HEATER CONTROL PANELRemovaland Installation, page 21 38

PUSH SWITCH ASSEMBLYRemoval and Installation, page 21'38EVAPORATOR TEMPERATURESENSORReplacement, page 21-37Test, page 21-37

21-5

Page 804 of 1139

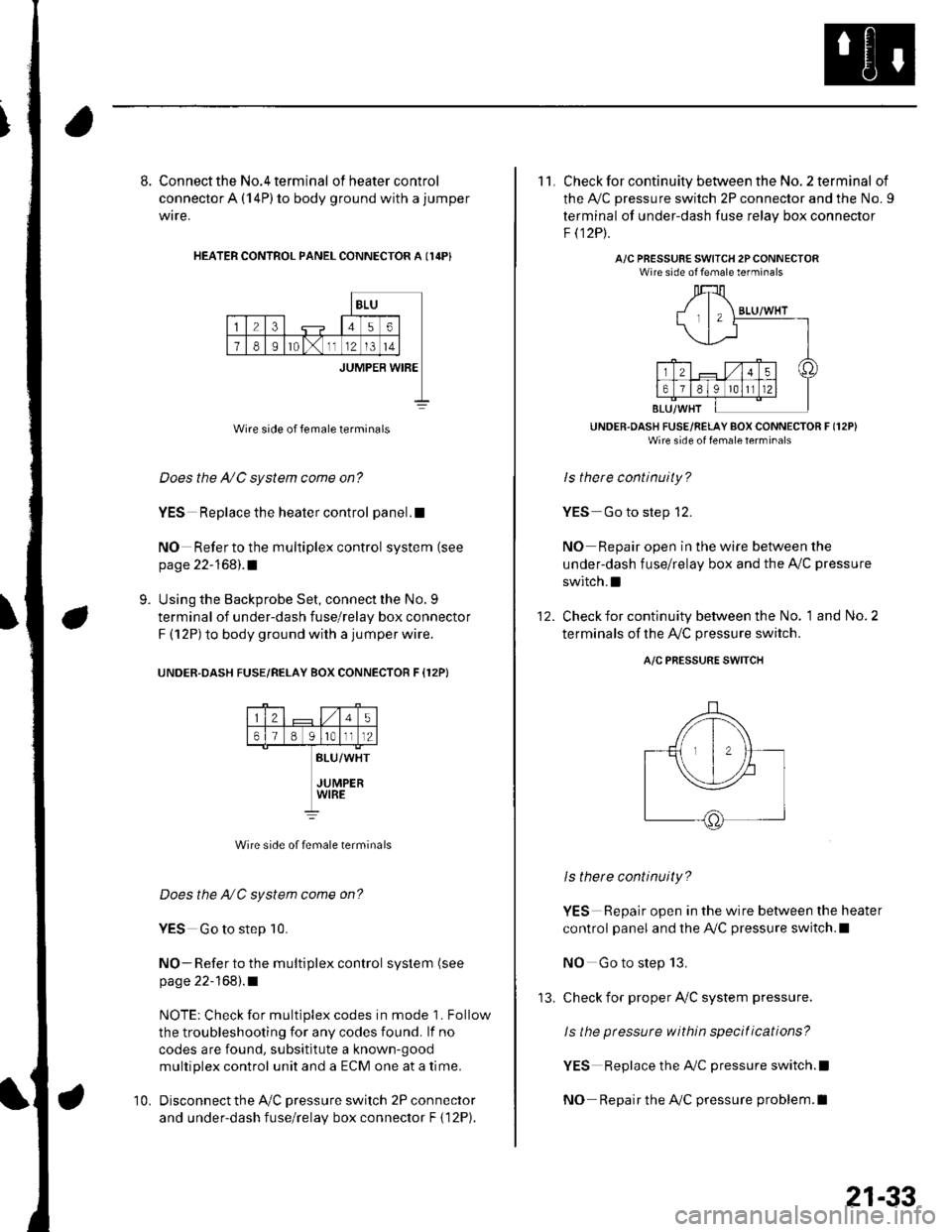

8. Connect the No.4 terminal ofheatercontrol

connector A (14P) to body ground with a jumper

wire,

HEATER CONTROL PANEL CONNECTOR A I14P}

BLU

23456

78Ir0lx1112l3t4

JUMPER WIBE

Wire side of female terminals

Does the A/C system come on?

YES Replace the heater control panel.!

NO Refer to the multiplex control system (see

page 22-168).1

Using the Backprobe Set, connect the No. 9

terminal of under-dash fuse/relay box connector

F (12P) to body ground with a jumper wire.

UNOER.DASH FUSE/RELAY BOX CONNECTOR F {12P}

9.

25

61B g lrotll2

BLU/WHT

JUMPERWIRE

Wire side of female terminals

Does the NC system come on?

YES Go to step 10.

NO- Refer to the multiplex control system (see

page 22-168).1

NOTE: Check for multiplex codes in mode '1. Follow

the troubleshooting {or any codes found. lf no

codes are found, subsititute a known-9ood

multiplex control unit and a ECM one at a time.

Disconnect the Ay'C pressure switch 2P connector

and under-dash fuse/relay box connector F { 12P).

10.

'13.

21-33

11. Check for continuity between the No. 2 terminal of

the A,/C pressure switch 2P connector and the No. 9

terminal of under-dash fuse relav box connector

F t12Pt.

A/C PRESSURE SWITCH 2PCONNECTORWire side of female terminals

UNDER.OASH FUSE/RELAY BOX CONNECTOR F (12P)

Wire side of fenale lerrrinal'

ls there continuity?

YES Go to step 12.

NO Repair open in the wire between the

under-dash fuse/relay box and the A,,/C pressure

switch.I

Check for continuity between the No. 1 and No. 2

terminals of the A,/C pressure switch.

12.

A/C PRESSURE SWITCH

ls there continuity?

YES Repair open in the wire between the heater

control panel and the A,/C pressure switch.l

NO Go to step 13.

check for proper Ay'C system pressure.

ls the pressure within specitications?

YES Replace the AilC pressure switch.l

NO Repair the AilC pressure problem.I

Page 805 of 1139

Heating and Air Conditioning

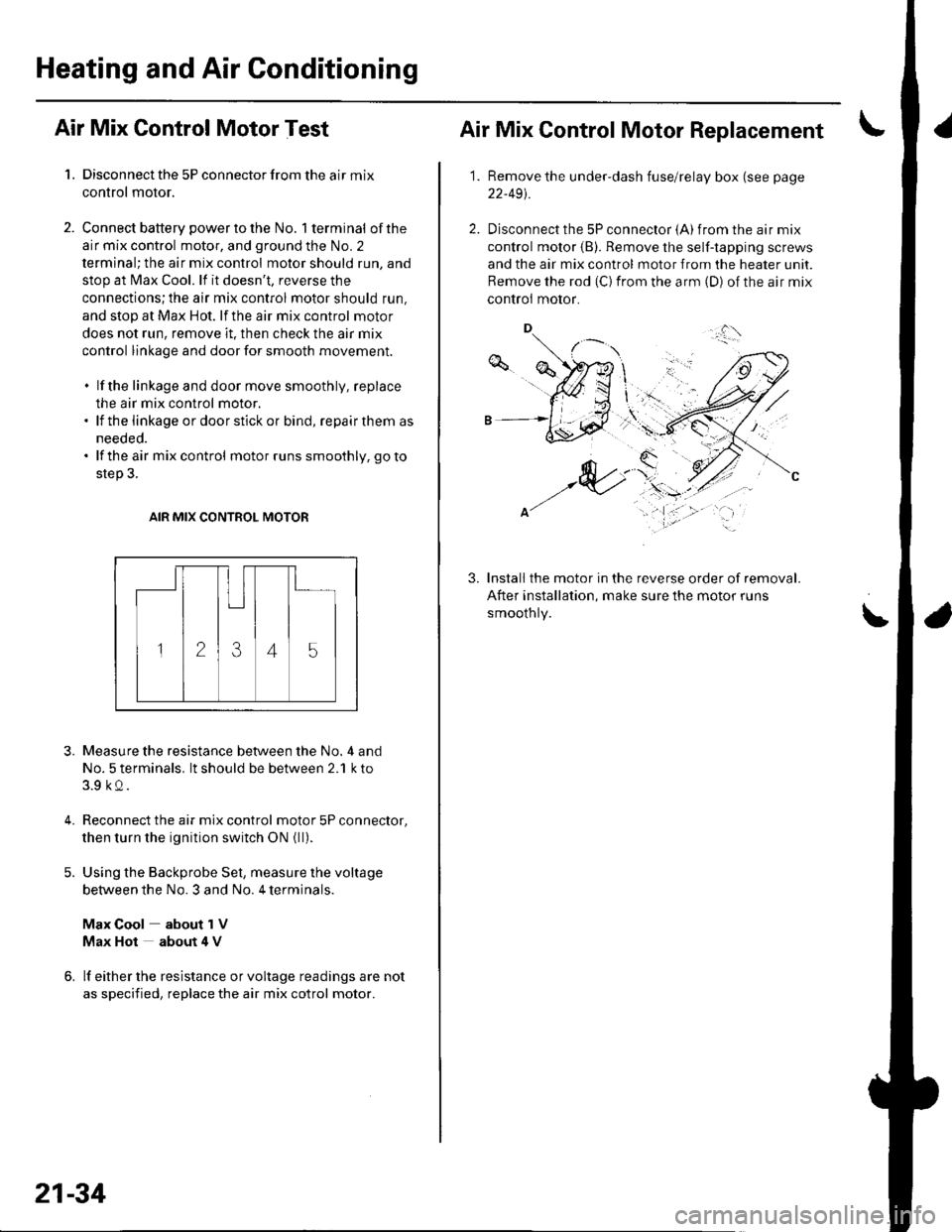

Air Mix Control Motor Test

1. Disconnect the 5P connector from the air mix

control motor.

2. Connect battery powertothe No. l terminal ofthe

air mix control motor, and ground the No. 2

terminal; the air mix control motor should run, and

stop at Max Cool. lf it doesn't, reverse the

connections;the air mix control motor should run,

and stop at Max Hot. lf the air mix control motor

does not run, remove it. then check the air mix

control linkage and door for smooth movement.

. lf the linkage and door move smoothly, replace

the air mix control motor.. lf the linkage ordoorstickor bind, repairthem as

needed.. lf the air mix control motor runs smoothly, go to

step 3.

AIR MIX CONTROL MOTOR

3.

4.

Measure the resistance between the No. 4 and

No. 5 terminals. lt should be between 2.1 k to

3.9 kQ.

Reconnect the air mix control motor 5P connector,

then turn the ignition switch ON {ll).

Using the Backprobe Set, measure the voltage

between the No. 3 and No. 4 terminals.

Max Cool about 1V

Max Hot about 4 V

lf either the resistance or voltage readings are not

as specified, replace the air mix cotrol motor.

21-34

Air Mix Control Motor Replacement

1.Remove the under-dash fuse/relay box (see page

22-491.

Disconnect the 5P connector {A) from the air mix

control motor (B). Remove the self-tapping screws

and the air mix control motor from the heater unit.

Remove the rod (C) from the arm (D) of the air mix

controi motor.

Install the motor in the reverse order of removal.

After installation, make sure the motor runs

smoothly.

3.

\'

,.,:l'

Page 806 of 1139

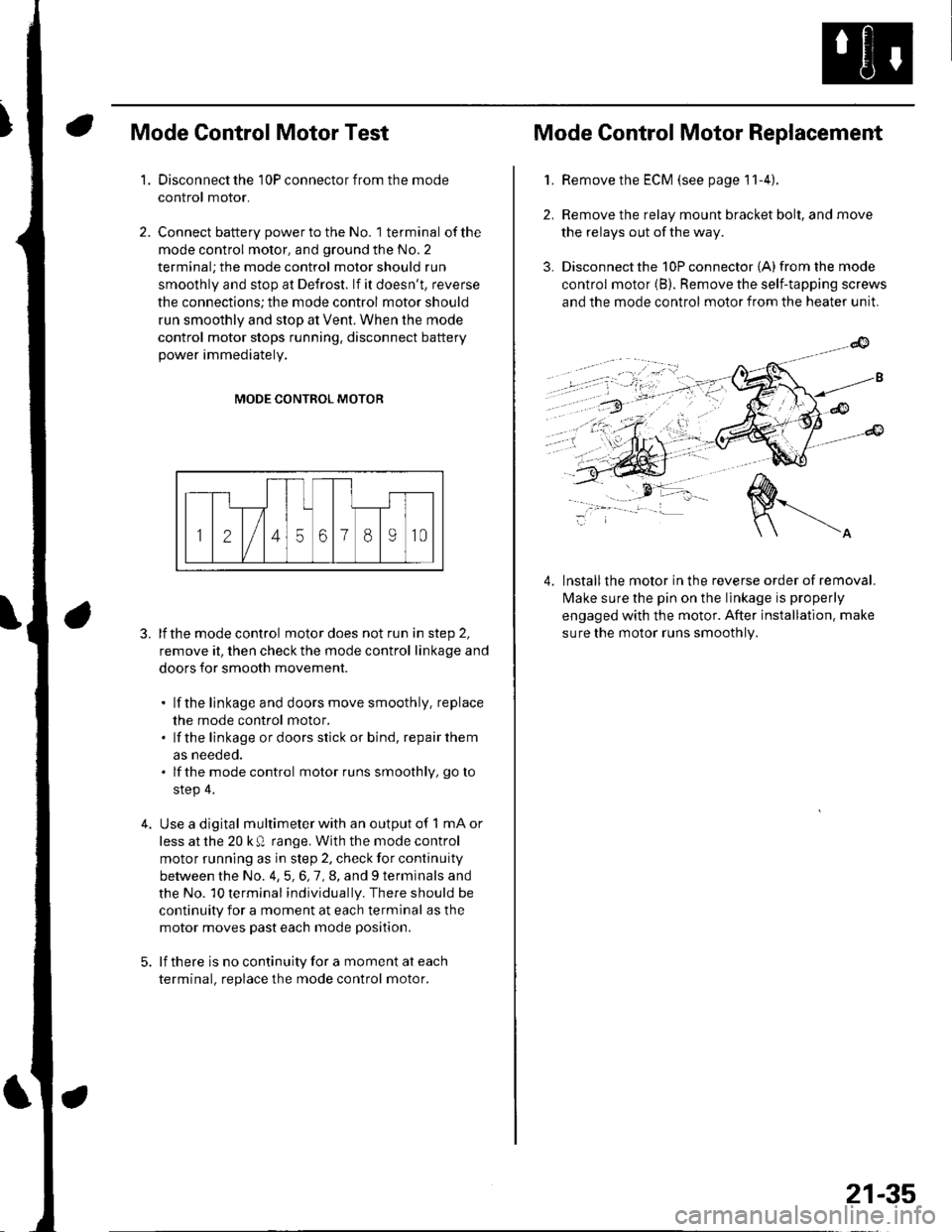

Mode Control Motor Test

Disconnect the 10P connector from the mode

control motor.

Connect battery power to the No. 1 terminal of the

mode control motor, and ground the No. 2

terminal; the mode control motor should run

smoothly and stop at Defrost. lf it doesn't, reverse

the connections; the mode control motor should

run smoothly and stop at Vent. When the mode

control motor stops running, disconnect battery

power immediately.

'1.

4.

MODE CONTROL MOTOR

3. lfthe mode control motor does not run in step 2,

remove it, then check the mode control linkage and

doors for smooth movement.

. lf the linkage and doors move smoothly. replace

the mode control motor.. lf the linkage ordoorsstick or bind, repairthem

as neeoeo.. lfthe mode control motor runs smoothly, go to

step 4.

Use a digital multimeter with an output of 1 mA or

less at the 20 k Q range. With the mode control

motor running as in step 2, check for continuity

between the No. 4,5,6,7,8, and 9 terminals and

the No. 10 terminal individually. There should be

continuity for a moment at each terminal as the

motor moves past each mode position.

lf there is no continuity for a moment at each

terminal. replace the mode control motor.

Mode Control Motor Replacement

2.

3.

1.Remove the ECM (see page 11-4).

Remove the relay mount bracket bolt, and move

the relays out of the way.

Disconnect the 10P connector {A) from the mode

control motor (B). Remove the self-tapping screws

and the mode control motor from the heater unit.

lnstallthe motor in the reverse order of removal.

lvlake sure the pin on the linkage is properly

engaged with the motor. After installation. make

sure the motor runs smoothly.

4.

21-35

Page 814 of 1139

Heater Unit/Core Replacement

SRS components are located in this area. Review the

SRS component locations (see page 23'13), and

precautions and procedures (see page 23-14) in the SRS

section before performing repairs or service.

1. Make sure you have the anti-theft code forthe radio,

then write down the freouencies for the radio's

Dreset buttons.

4.

Disconnect the negative cable from the battery,

Disconnect the suction and receiver lines from the

evaporator core (see page 21-42).

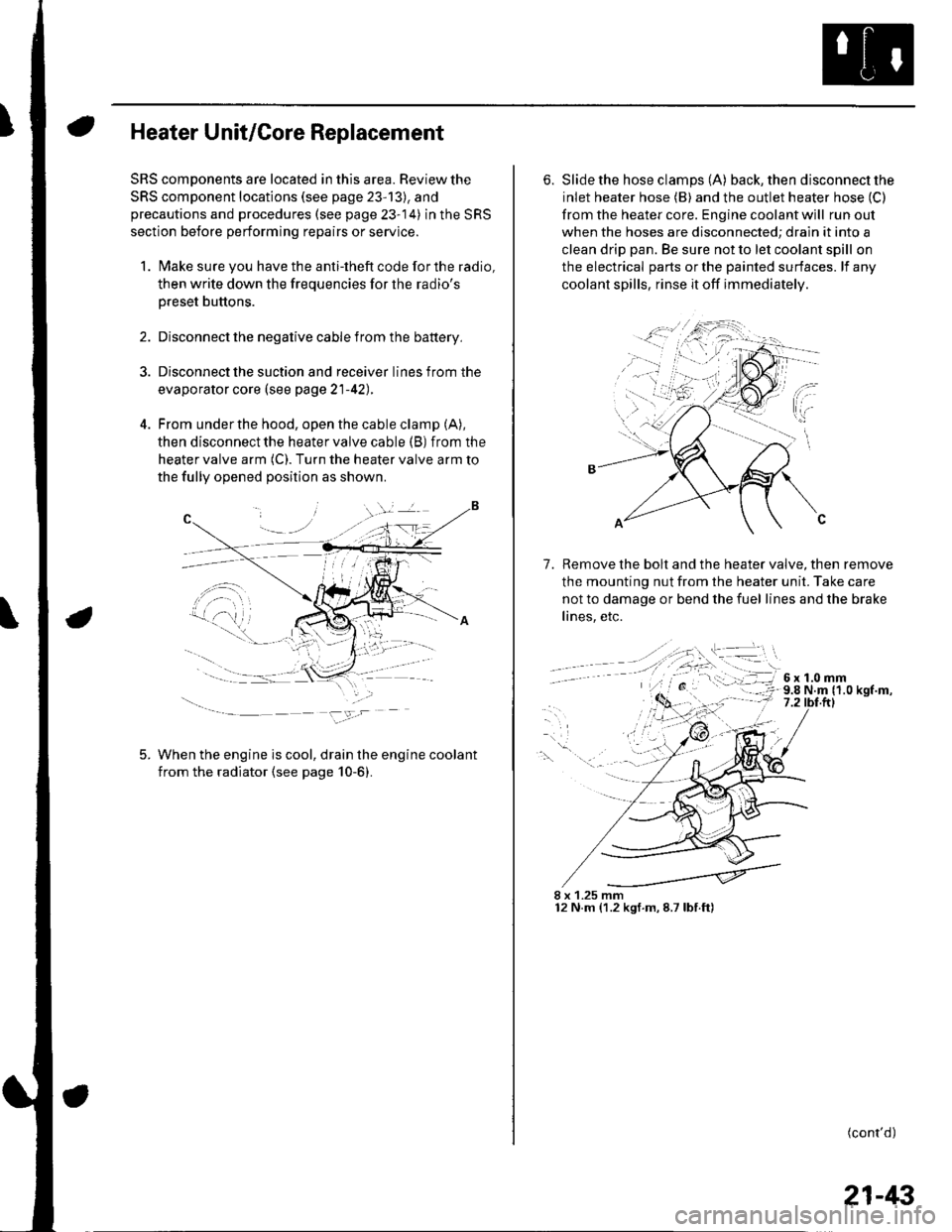

From under the hood, open the cable clamp (A),

then disconnect the heater valve cable (B) from the

heater valve arm (C). Turn the heater valve arm to

the fully opened position as shown

When the engine is cool, drain the engine coolant

from the radiator (see page 10-6).

6. Slide the hose clamps (A) back, the n d isconnect the

inlet heater hose (B) and the outlet heater hose (C)

from the heater core. Engine coolant will run out

when the hoses are disconnected; drain it into a

clean drip pan. Be sure not to let coolant spill on

the electrical parts or the painted surfaces. lf any

coolant spills, rinse it off immediately.

Remove the bolt and the heater valve, then remove

the mounting nut from the heater unit. Take care

not to damage or bend the fuel lines and the brake

lines, etc.

7.

8 x 1.25 mm12 N.m (1.2 kgf.m,8.7lbf.ft)

(cont'd)

21-43

Page 815 of 1139

Heating and Air Conditioning

Heater Unit/Core Replacement (cont'd)

8. Remove the dashboard {see page 20-66).

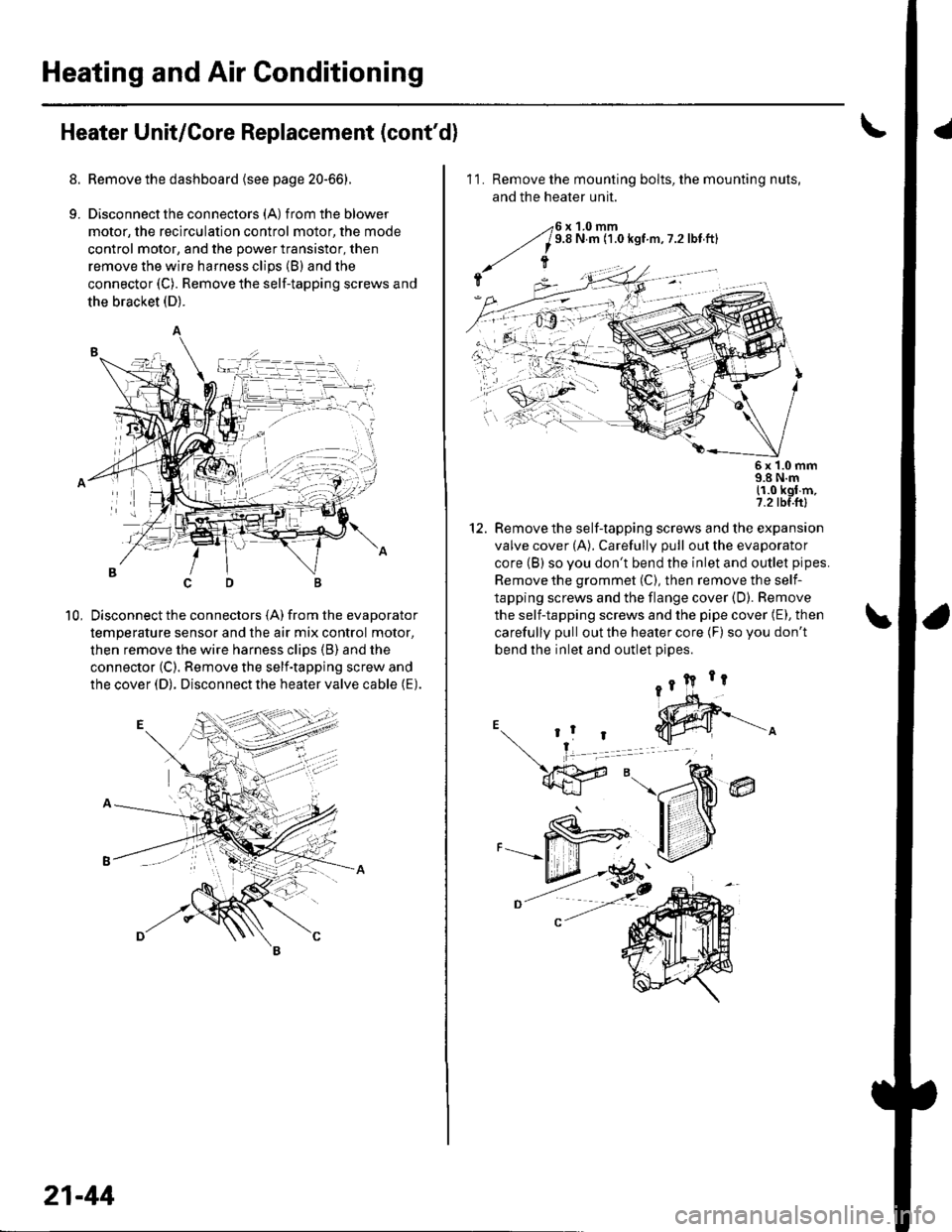

9. Disconnectthe connectors (A) from the blower

motor, the recirculation control motor, the mode

control motor, and the power transistor, then

remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screws and

the bracket (D).

Disconnect the connectors (A) from the evaporator

temperature sensor and the air mix control motor,

then remove the wire harness clips (B) and the

connector (C). Remove the self-tapping screw and

the cover (D). Disconnect the heater valve cable (E).

10,

7t,

21-44

11. Remove the mounting bolts, the mounting nuts,

and the heater unit.

Remove the self-tapping screws and the expansion

valve cover (A). Carefully pull out the evaporator

core (B) so you don't bend the inlet and outlet pipes.

Remove the grommet (C), then remove the self-

tapping screws and the flange cover (D). Bemove

the self-tapping screws and the pipe cover (E), then

carefully pull out the heater core (F) so you don't

bend the inlet and outlet oioes.

@

5x 1.0 mm9.8 N.m11.0 kgl m,7.2 tbf.ftl

12.