Oil drain plug HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 85 of 1139

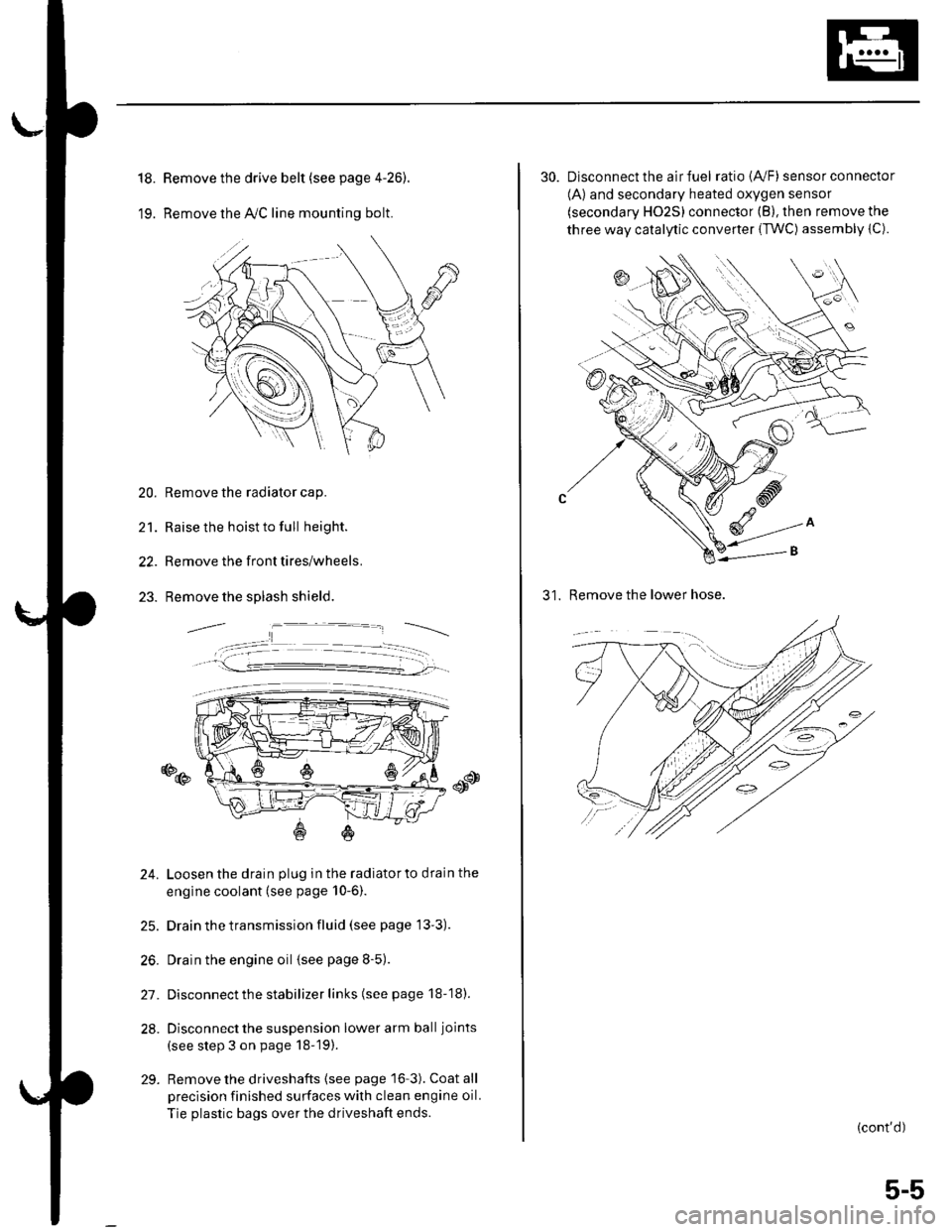

18.

19.

Remove the drive belt (see page 4-26).

Remove the lvC line mounting bolt.

20. Remove the radiator cap.

21. Raise the hoist to full height.

22. Remove the front tires/wheels.

23. Remove the splash shield.

o@

24. Loosen the drain plug in the radiatorto drain the

engine coolant (see page 10-6).

25. Drain the transmission fluid (see page 13'3).

26. Drain the engine oil {see page 8-5).

27. Disconnect the stabilizer links (see page 18-18).

28. Disconnect the suspension lower arm ball joints

(see step 3 on page 18-19).

29. Remove the driveshafts {see page 16-3). Coat all

precision finished surfaces with clean engine oil.

Tie plastic bags over the driveshaft ends.

30. Disconnect the air fuel ratio {4,/F) sensor connector

(A) and secondary heated oxygen sensor

(secondary HO2S) connector (B), then remove the

three way catalytic converter {TWC) assembly {C).

31. Remove the lower hose.

(cont'd)

5-5

Page 413 of 1139

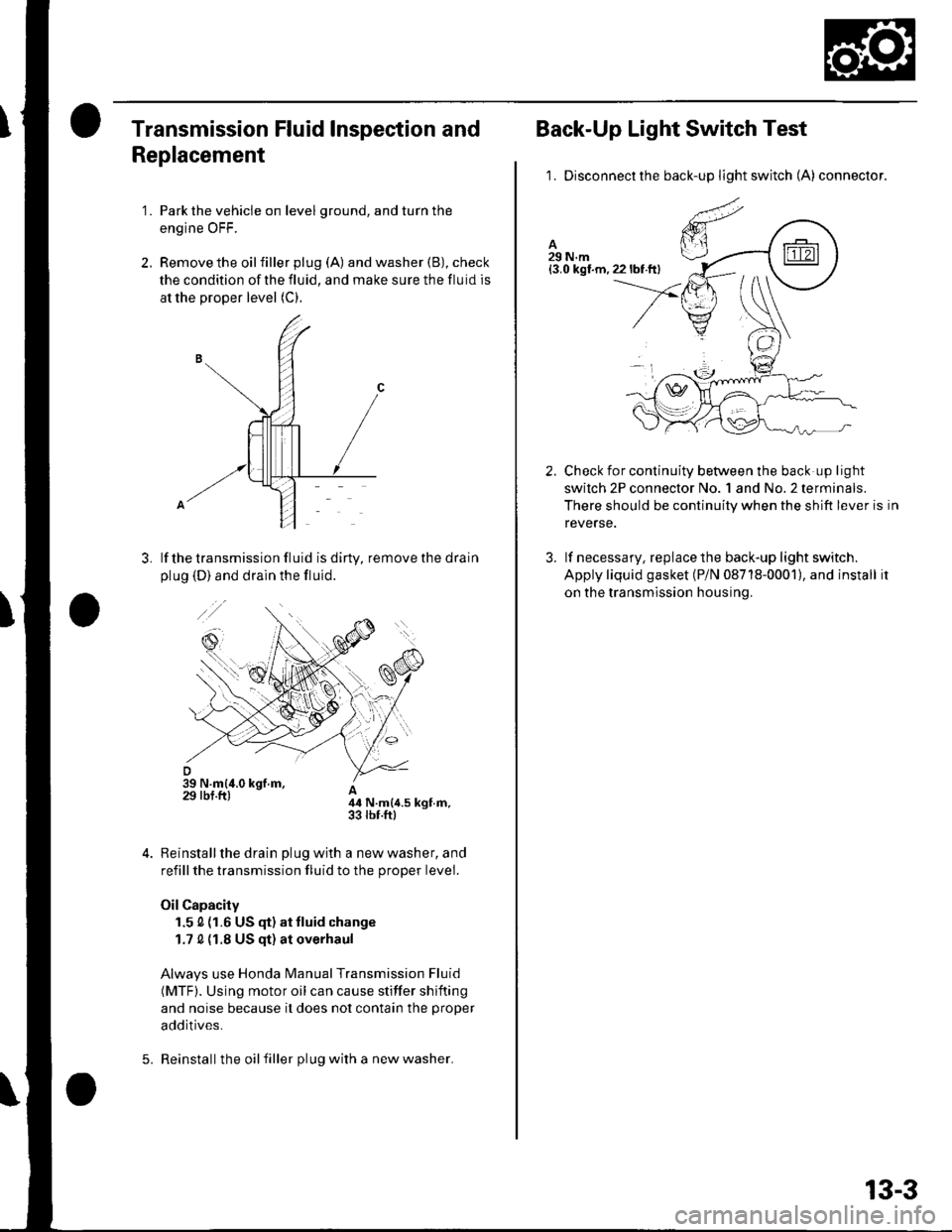

Transmission Fluid Inspection and

Replacement

'1. Park the vehicle on level ground, and turn the

engine OFF.

2. Remove the oilfiller plug (A) and washer (B), check

the condition of the fluid, and make sure the fluid is

at the proper level (C).

lf the transmission fluid is diny, remove the drain

plug (D) and drain the fluid.

A44 N.m{4.5 kgt.m,33 rbr.ftl

Reinstall the drain plug with a new washer, and

refill the transmission fluid to the proper level.

Oil Capacity

1.5 0 (1.6 US (F) at tluid change

1.7 0 {1.8 US qt) at overhaul

Always use Honda Manual Transmission Fluid

(MTF). Using motor oil can cause stiffer shifting

and noise because it does not contain the proper

additives.

Reinstall the oil filler plug with a new washer.5.

13-3

Back-Up Light Switch Test

1. Disconnectthe back-up light switch (A) connector.

Check for continuity between the back up light

swilch 2P connector No. 1 and No.2 terminals.

There should be continuity when the shift lever is in

reverse.

lf necessary, replace the back-up light switch.

Apply liquid gasket (P/N 08718-0001), and install it

on the transmission housing.

2.

3.

Page 425 of 1139

o,. @\

'\b

e

P\B

z-W

-

€:

iq { "

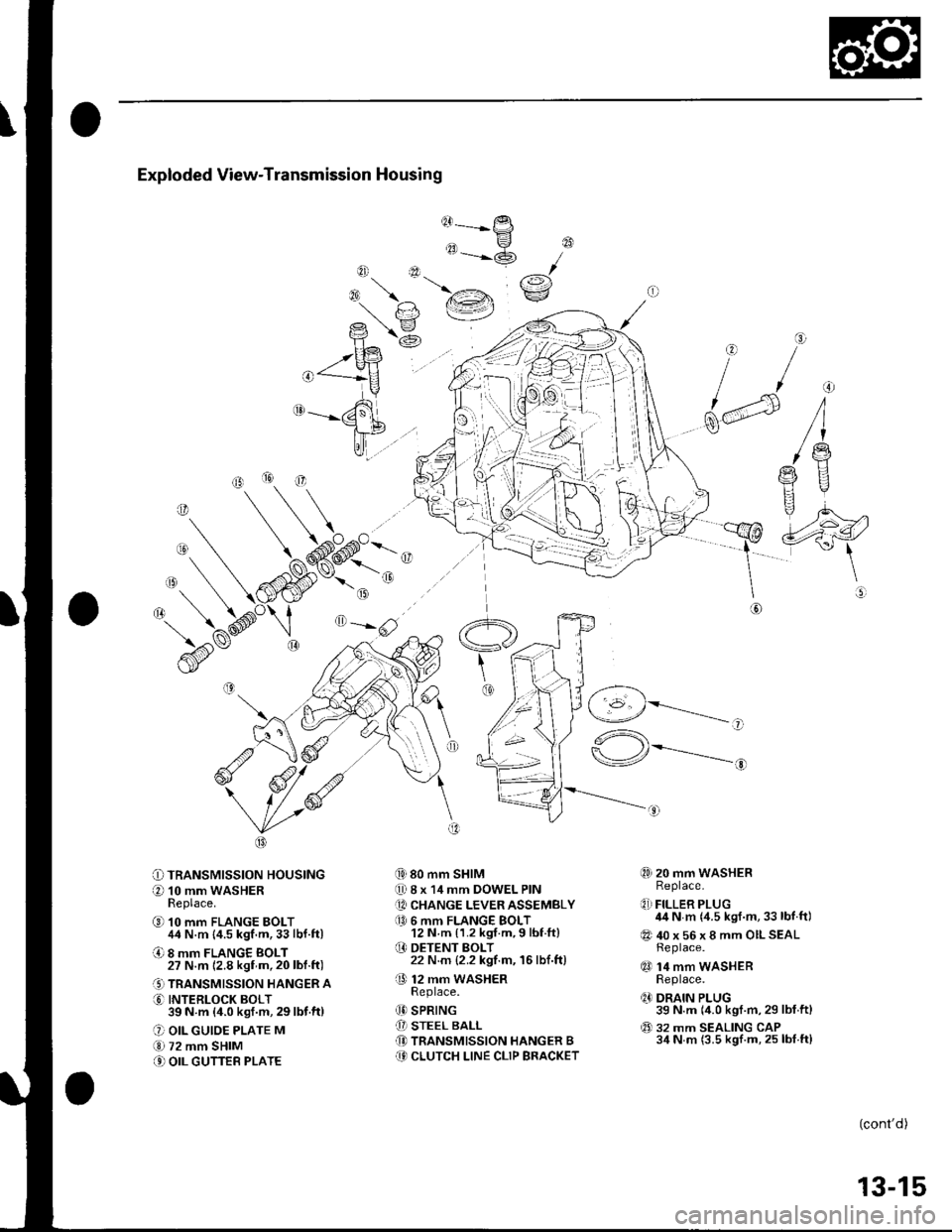

Exploded View-Transmission Housing

@------

tt-P

"=-@

{i) 80 mm SHIM

0 8 x 14 mm DOWEL PIN

[A CHANGE LEVER ASSEMBLY

a0 6 mm FLANGE BOLT12 N m {1.2 kgf.m,9 lbf ft}

O DETENT BOLT22 N.m {2.2 kgf.m, 16lbf.ft)

O 12 mm waSHERReDlace.

(D SPRING

[I STEEL BALL(D TRANSMISSION HANGER B(9 CLUTCH LINE CLIP BRACKET

@

rai\€:/

o

f/

dd

\@

O=-rlF,z

O TRANSMISSION HOUSING

O 10 mm WASHERReplace.

@ 10 mm FLANGE BOLT44 N.m {4.5 kgf.m,33lbf.ft)

O 8 mm FLANGE BOLT27 N.m 12.8 kgf m,20lbl.ft)

.' TRANSMISSION HANGER A

O INTERLOCK BOLT39N m (4.0ksf.m,29lbf.ft)

O OIL GUIOE PLATE M

€.1 72 mm SHIM

.' OIL GUTTEB PLATE

,-1 _\(g/----------__-

"^\

\-/r*---------..-,

@) 20 mm WASHERReplace.

q,] FILLER PLUG44 N m {4.5 kgf.m,33 lbf.ft)

@ 40 x 56 x 8 mm OILSEALReplace.

qO 14 mm WASHERReplace.

q' DRAIN PLUG39 N.m (4.0 kgf.m,29 lbf.ftl

@ 32 mm SEALING CAP34 N m (3.5 kgf.m, 25 lbf.ft)

o

(cont'd)

13-15

Page 459 of 1139

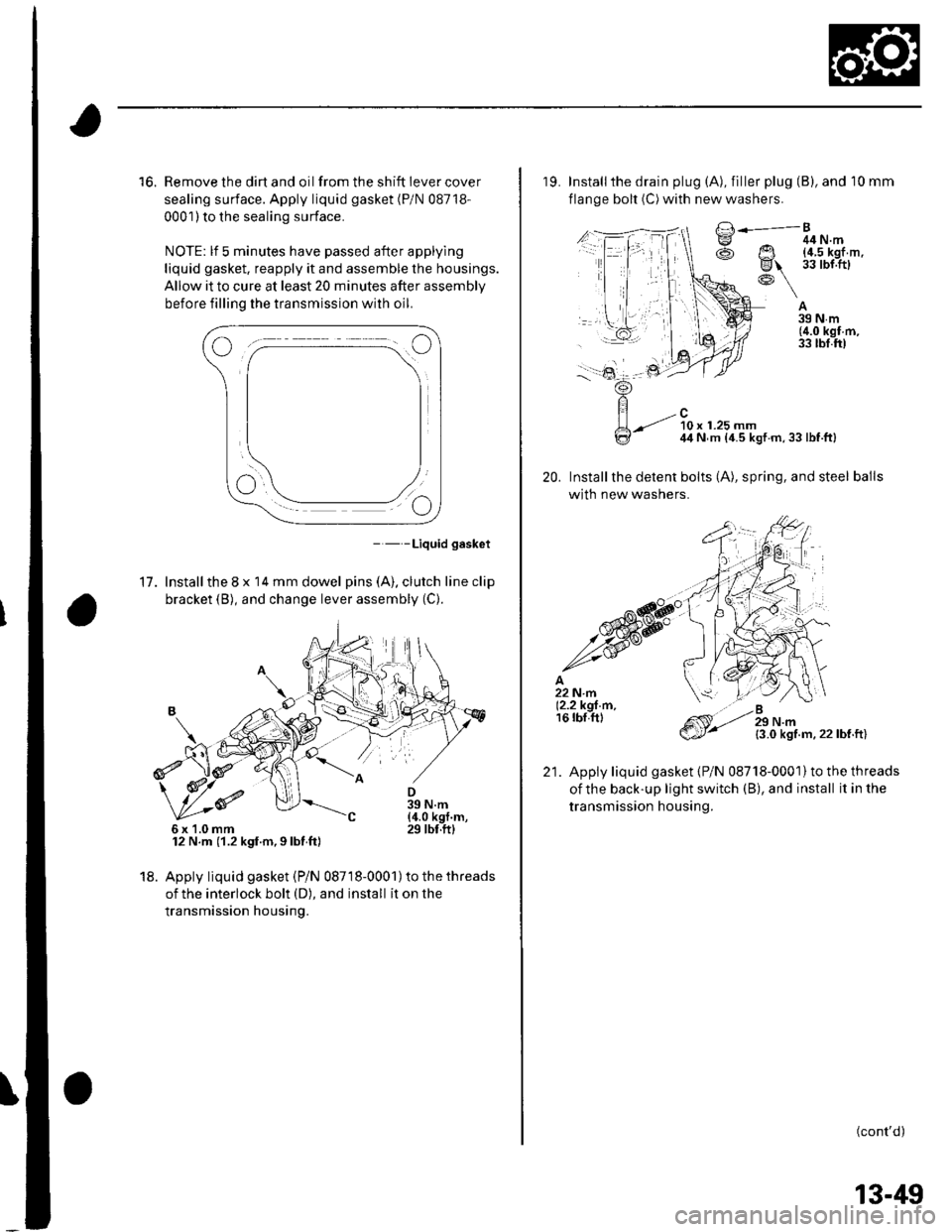

16. Remove the dirt and oil from the shift iever cover

sealing surface. Apply liquid gasket (P/N 08718-

0001) to the sealing surface.

NOTE: lf 5 minutes have passed after applylng

liquid gasket. reapply it and assemble the housings.

Allow it to cure at least 20 minutes after assembly

before filling the transmission with oil.

- - -Liquid gasket

17. Installthe 8 x 14 mm dowel pins (A). clutch line clip

bracket (B), and change lever assembly (C).

12 N.m (1.2 kgf.m,9lbt ft)

18. Apply liquid gasket (Pi N 08718-0001) to the threads

of the interlock bolt (D), and install it on the

transmission housing.

6x1.0mm

19. Installthe drain plug (A), filler plug (B), and 10 mm

flange bolt (C) with new washers.

A39Nm(4.0 kgf m,33 tbl.ft)

20.

/..l-.=,'-Bg ^ 44N.m

@ Ut !?iJl'.'l,''

R\-: \

-.-t ?0, ,.ru ^44 N m {4.5 kgt m,33lbf.ft}

Installthe detent bolts (A), spring, and steel balls

with new washers.

{3.0 kgf.m.22lbf.ft)

Apply liquid gasket {P/N 08718-0001}to the threads

oithe back-up light switch (B), and install it in the

transmission housing.

(cont'd)

21.

13-49

Page 778 of 1139

Heating and Air Conditioning

A/C Service Tips and Precautions

Compressed air mixed with R- 134a forms a

combustible vapor.

The vapor can burn or explode causing serious

injury.

Never use compressed air to pressure test

R-134a service equipment or vehicle air

conditioning systems.

Air conditioning refrigerant or lubricant vapor

can irritate your eyes, nose, or throat.

Be careful when connecting service equipment.

Do not breathe refrigerant or vapor.

The air conditioning system uses HFC-134a (R-134a)

ref rigerant and polyalkyleneglycol (PAG) ref rigerant oil,

which are not compatible with CFC'12 (R-12) refrigerant

and mineral oil. Do not use R-'12 refrigerant or mineral

oil in this system, and do not aftempt to use R 12

servicing equipment; damage to the air conditioning

system or your servicing equipment will result.

Use only service equipment that is U.L.-listed and is

certified to meet the requirements of SAE J2210 to

remove R-134a from the air conditioning system.

lf accidental system discharge occurs, ventilate the

work area before resuming service.

R-134a service equipment or vehicle air conditioning

systems should not be pressure tested or leak tested

with compressed air.

Additional health and safety information may be

obtained from the refrigerant and lubricant

manufacturers.

. Always disconnect the negative cable from the

battery whenever replacing air conditioning parts.

. Keep moisture and dirt out of the system. When

disconnecting any lines, plug or cap the fittings

immediately; don't remove the caps or plugs until

iust be{ore you reconnect each line.' Before connecting any hose or line, apply a few drops

of relrigerant oil to the O-ring.. When tightening or loosening a fitting, use a second

wrench to support the matching fitting.. When discharging the system, use a R-'134a

ref rigerant recovery/recycling/charging station; don't

release refrigerant into the atmosphere.

21-6

A: 130 m0 {4 l/3 tl.oz,4.6 lmp.oz)

],^

A/C Refrigerant Oll Replacement

Recommended PAG oil: KEIHIN SP 10:

. P/N 38897-P l3-A01AH: '120 m0 i4 fl oz). P/N 38899-P13'A01: 40 m0 i1 1/3 fl oz)

Add the recommended refrigerant oil in the amount

listed if you replace any of the following parts.

. To avoid contamination. do not return the oilto the

container once dispensed, and never mix it with other

refrigerant oils.. lmmediately af'ter using the oil, reinstallthe cap on

the container, and seal it to avoid moisture

aosorpron.. Donotspill the refrigerant oil on the vehicle; it may

damage the paint. lf it gets on the paint, wash it off

immediately.

Condenser ...........25 mA \516 tl.oz, 0.9 lmp.oz)

Evaporator ........... 45 m0 (1 113Il.oz, '1.4 lmp.oz)

Line or hose ......... '10 m0 {1/3 fl.oz,0.4 lmp.oz)

Receiver/Dryer .... '10 m0 ('113 fl.oz,0.4 lmp.oz)

Leakage repai r .... 25 m0, 1516 Il oz, 0.9 lmp.oz)

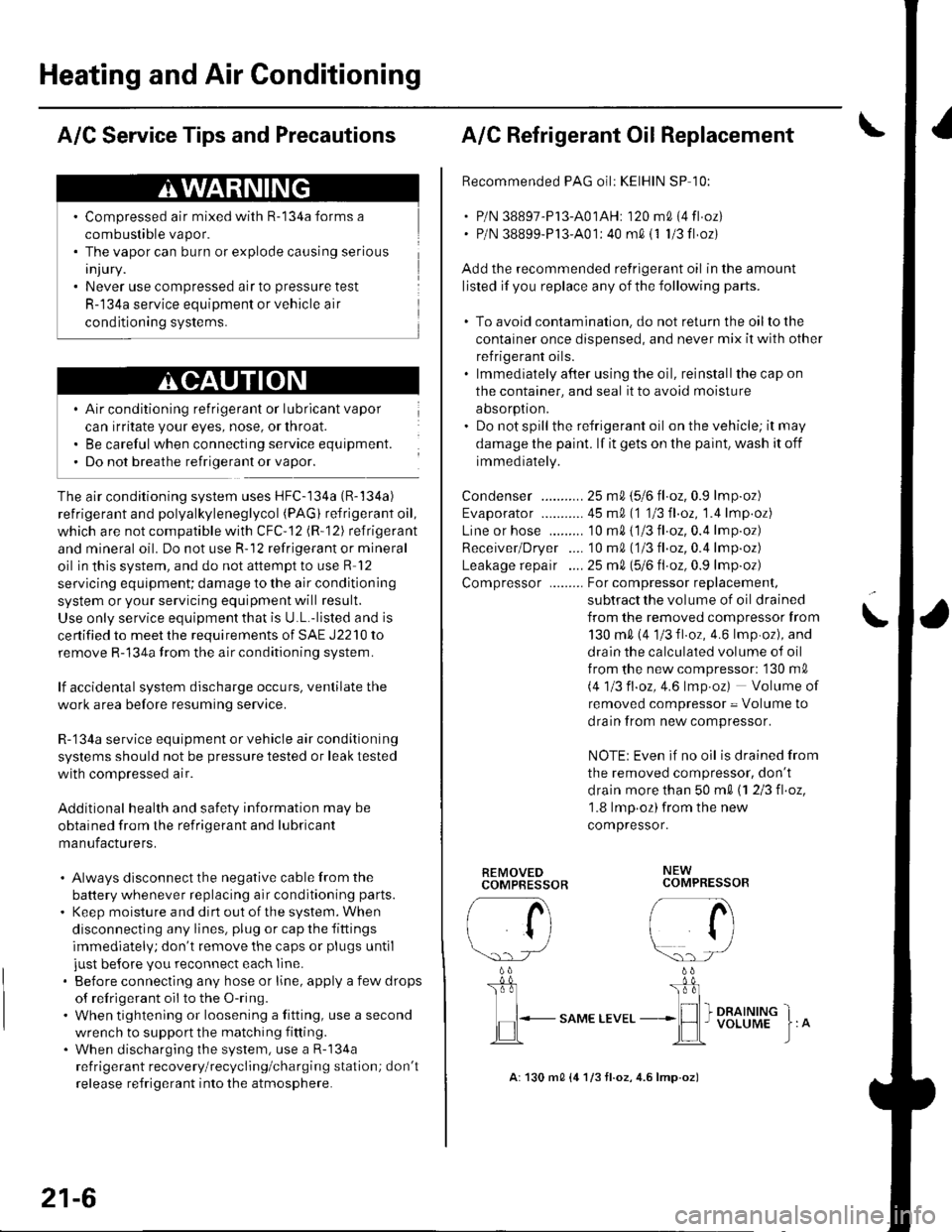

Compressor ......... For compressor replacemenl,

subtract the volume of oil drained

from the removed compressor from

130 m0 (4 1/3fl.oz, 4.6lmp.oz), and

drain the calculated volume of oil

f rom the new compressor: '130 m0

i.4113 fl.oz,4.6 lmp.oz) Volume of

removed compressor = Volume to

drain from new compressor.

NOTE: Even if no oil is drained from

the removed compressor, don't

d rain more than 50 m0 \1 2/3 fl.oz,'1.8 lmp oz)from the new

compressor.

\

REMOVEDCOMPBESSOR

rA

li

\.. rJ

b

I

,lEL.-

"o*t ttu"

NEWCOMPRESSOR

/- a\i tl

r/

\:)-) -/

_ 0L'r:l_

I I I DRAINING_*lH I voLUME