Battery HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1280 of 1395

Wipers/Washers

1.

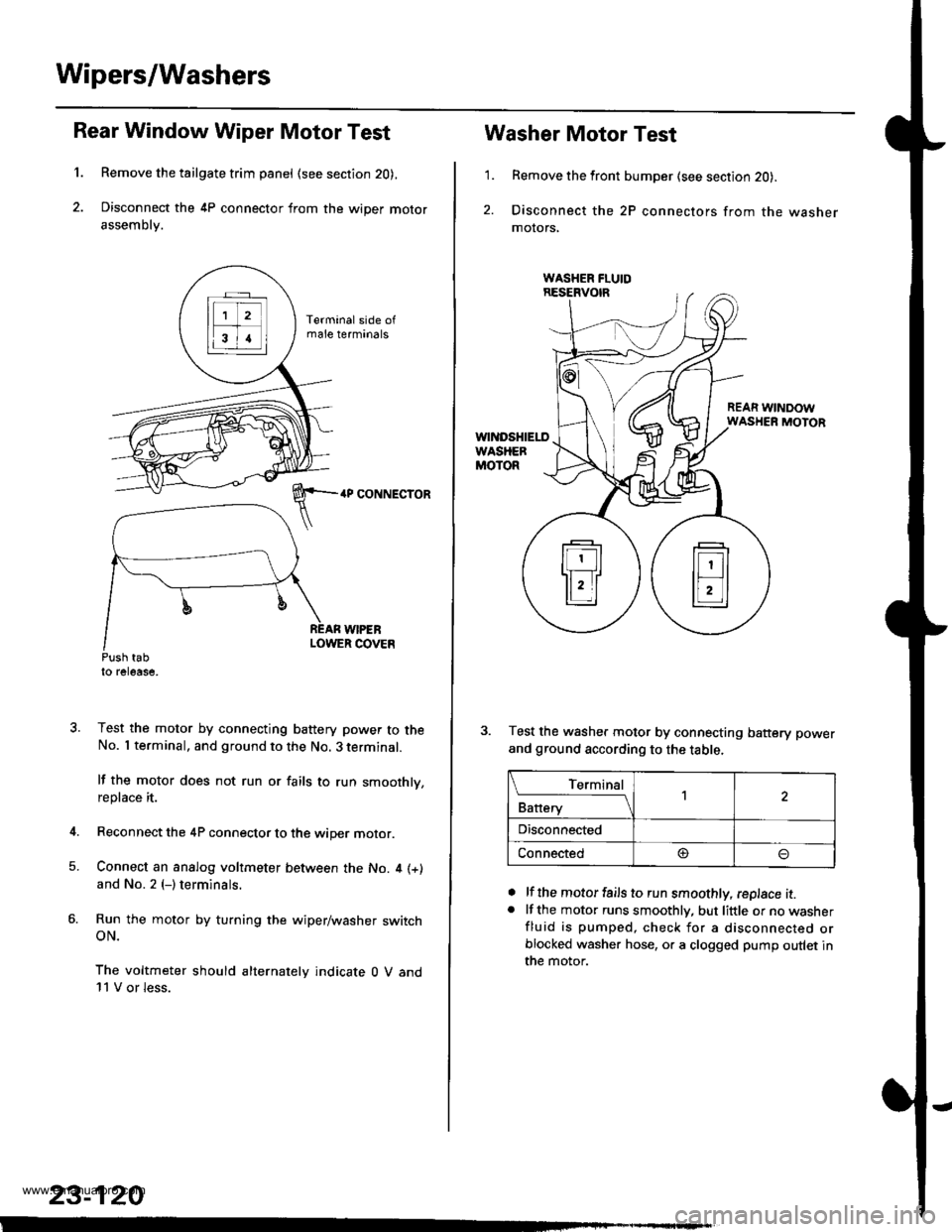

Rear Window Wiper Motor Test

Remove the tailgate trim panel (see section 20),

Disconnect the 4P connector from the wiper motor

assembly.

4P CONNECTOR

WIPEBLOWER COVEnPush tabto release,

Test the motor by connecting battery power to theNo. I terminal, and ground to the No. 3 terminal.

lf the motor does not run or fails to run smoothly,replace it.

Reconnect the 4P connector to the wiper motor.

Connect an analog voltmeter between the No. 4 (+)

and No. 2 (-) terminals.

Run the motor by turning the wiper/washer switchoN.

The voltmeter should alternately indicate 0 V and11 V or less.

4.

5.

23-120

1.

Washer Motor Test

Remove the front bumper (see section 20).

Disconnect the 2P connectors from the washermolors,

REAR WINDOWWASHER MOTOR

Test the washer motor by connecting battery power

and ground according to the table.

lf the motor fails to run smoothly, replace it.lf the motor runs smoothly, but little or no washerfluid is pumped, check for a disconnected orblocked washer hose, or a clogged pump outlet inthe motor.

a

a

L_Iq'.r91

Battery

,l

Disconnected

Connected@

www.emanualpro.com

Page 1287 of 1395

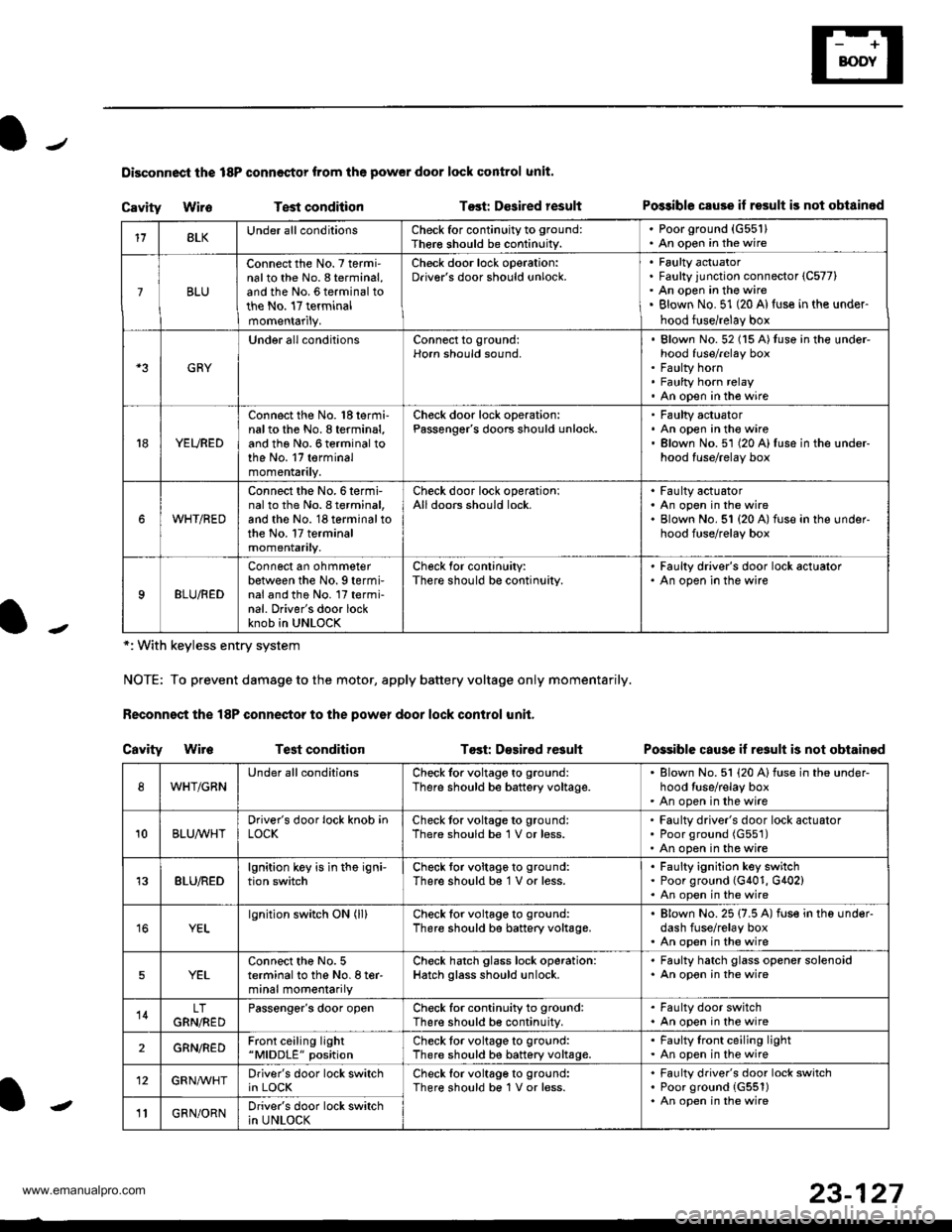

Disconnoci the 18P connestor from the pow€r door lock control unit.

Cavity WireTest conditionTost: Dcsired resultPo$ible csuse il result is not obtainod

Possible cause if result is not obtain€d

*: With keyless entry system

NOTE: To prevent damage to the motor, apply battery voltage only momentarily.

Feconnoct the 18P conneqtor to the power door lock control unit,

Cavity Wir6Test conditionTost: D€sirod result

118LKUnder all conditionsCheck for continuity to ground:

Ther€ should be continuity.

. Poorground (G55'l). An open in the wire

7BLU

Connect the No. 7 termi'nalto the No. 8 terminal,and the No. 6 terminal tothe No. 17 terminalmomentarily.

Check door lock operation:Driver's door should unlock.Faulty actuatorFaulty junction connector (C577)

An open in the wireBlown No. 51 (20 Al{use in the under-

hood fuse/relay box

GRY

Under all conditionsConnect to ground:Horn should sound,Blown No. 52 (15 A)tuso in the under-hood fuse/relay boxFaulty hornFaulty horn relayAn open in tho wire

YEURED

Connect the No. 'l8 termi-nalto the No. 8 terminal,and the No. 6 terminal tothe No. 17 terminalmomentarily.

Check door lock operation:Passenger's doors should unlock.Faulty actuatorAn open in the wireBlown No.51 (20 A)fuse in the under-hood fuse/relay box

WHT/RED

Connect the No.6termi-nal to th6 No. I terminal,and the No. 18 terminal tothe No. 17 terminalmomentarily.

Check door lock operationlAll doors should lock.Faulty actuatorAn open in the wireBlown No. 51 {20 A) fuse in ihe under-hood fuse/relay box

9BLU/RED

Connect an ohmmeterbetween the No. 9 termi-nal and the No. l7 termi-nal. Driver's door lockknob in UNLOCK

Check for conlinuity:There should be continuity.

' Faulty driver's door lock actualor. An open in the wire

WHT/GRNUnder all conditionsCheck for voltage to ground:

There should be battery voltage.Blown No. 51 (20 Alfuse in the under-hood tuse/relay boxAn open in the wire

10BLUAVHTDriver's door lock knob inLOCKCheck tor voltage to ground:There should be 1 V or less.Faulty driver's door lock actuatorPoor ground (G551)

An open in the wire

13BLU/REDlgnition key is in the igni-tion switchCheck tor voltage to ground:

There should b€ 1 V or less.Faulty ignition key switchPoor ground (G401, G402)An open in the wire

YELlgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.Blown No. 25 (7.5 A) fuse in the under-dash fuse/relay boxAn open in the wire

5YELConnect the No. 5terminal to the No. I ter-minal momentarily

Check hatch glass lock operation:Hatch glass should unlock.

. Faulty hatch glass opener solenoid. An opon in the wire

14LTGRN,NEDPassengor's door openCheck for continuity to ground:There should b€ continuity.

. Fa(llty door switch. An open in the wire

2GRN/R€DFront ceiling light"MlDDLE" positionCheck tor voltage to ground:There should be battery voltage.Faulty lront ceiling lightAn open in the wire

12GRNAr'VHTDriver's door lock switchin LOCKCheck lor voltage to ground:There should be 1V or less.Faulty driver's door lock switchPoor ground {G551)An open in the wire' GRN/ORNDriver's door lock switchin UNLOCK-

23-127

www.emanualpro.com

Page 1288 of 1395

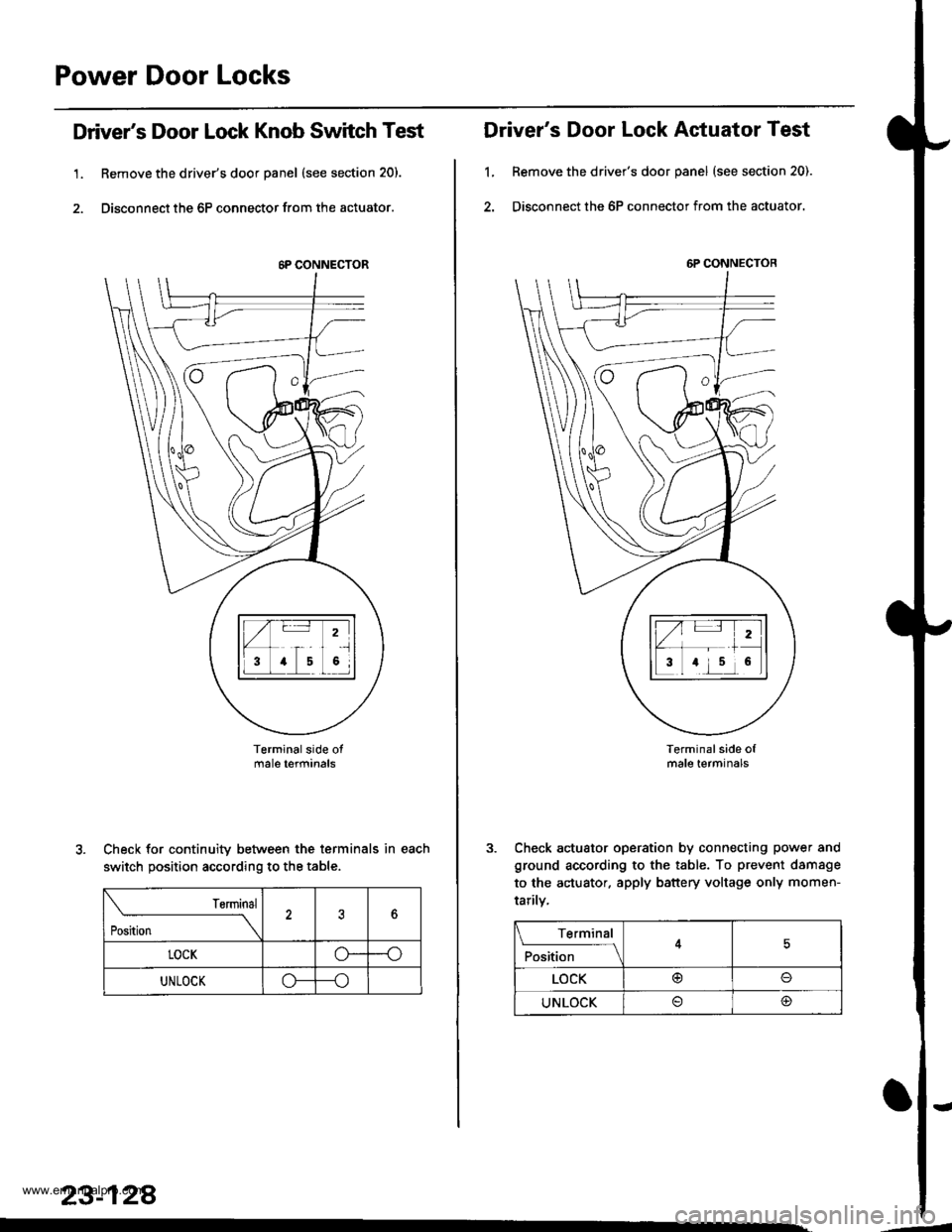

Power Door Locks

Driver's Door Lock Knob Switch Test

1. Remove the driver's door panel (see section 20).

2. Disconnect the 6P connector from the actuator.

Terminalside otmale terfiinals

Check for continuity between the terminals in each

switch position according to the table.

rsrmrnal

Position \

?6

LOCKo--o

UNLOCKo---o

23-128

.

6P CONNECTOR

Driver's Door Lock Actuator Test

1, Remove the driver's door panel (see section 20).

2. Disconnect the 6P connector from the actuator.

Terminal side ofmale terminals

Check actuator operation by connecting power and

ground according to the table. To prevent damsge

to the actuator. apply battery voltage only momen-

tarilv,

6P CONNECTOR

Terminal

F*'',1."

__l

LOCK@o

UNLOCK@

'-

www.emanualpro.com

Page 1289 of 1395

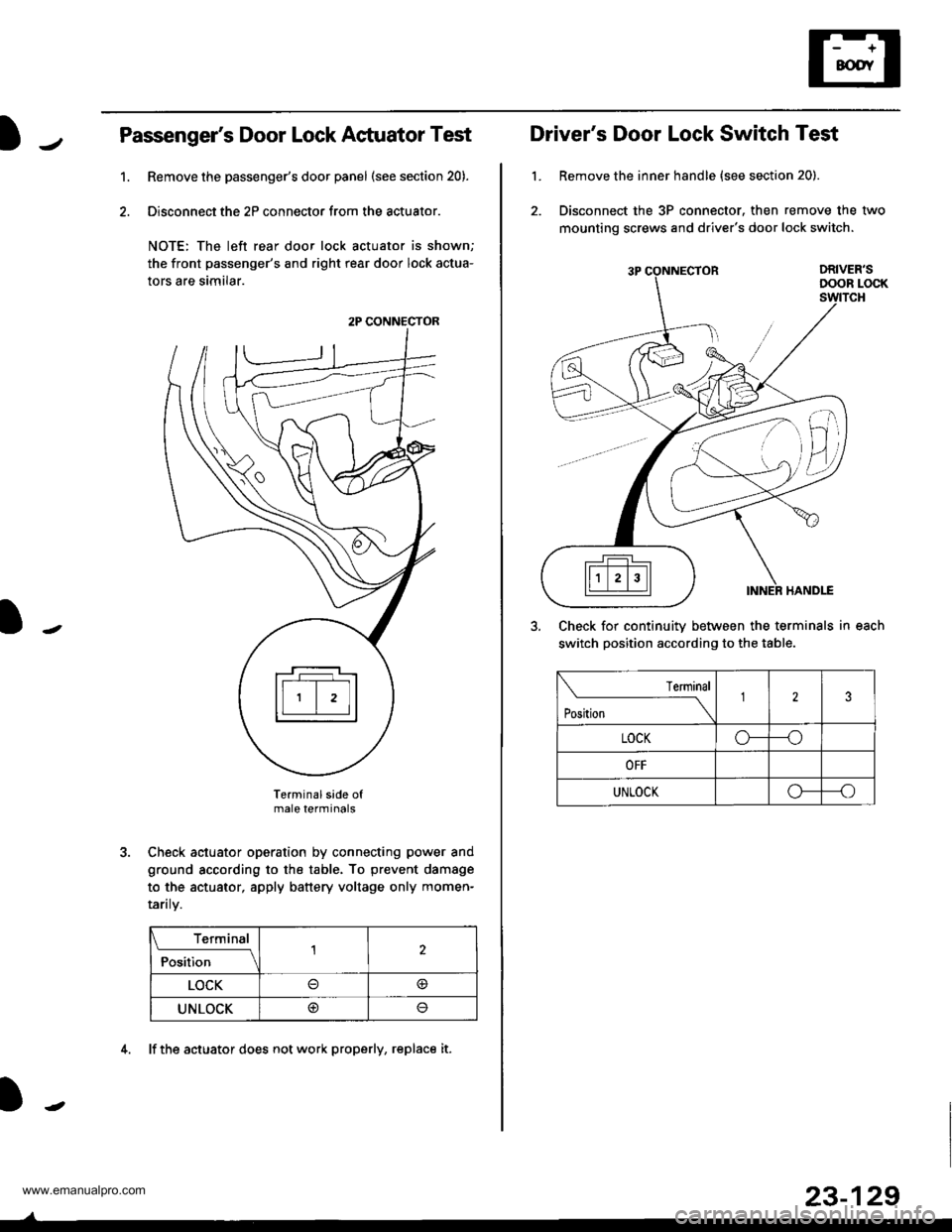

Passenger's Door Lock Actuator Test

Remove the passenger's door panel (see section 20).

Disconnect the 2P connector from the actuator.

NOTE: The left rear door lock actuator is shown;

the front passenger's and right rear door lock actua-

tors are similar.

Terminal side ofmale terminals

Check actuator operation by connecting power and

ground according to the table. To prevent damage

to the actuator, apply battery voltage only momen-

raflry.

Terminal

;;il;--r

,l

LOCK@

UNLOCK@

1.

2P CONNECTOR

4. lf the actuator does not work properly, replace it.

23-129

L

Driver's Door Lock Switch Test

Remove the inner handle {see section 20).

Disconnect the 3P connector. then remove the two

mounting screws and driver's door lock switch.

Check for continuitv between the terminals in each

switch position according to the table.

lermlnal

Position \

123

LOCKo---o

OFF

UNLOCKo--_o

www.emanualpro.com

Page 1290 of 1395

Power Door Locks

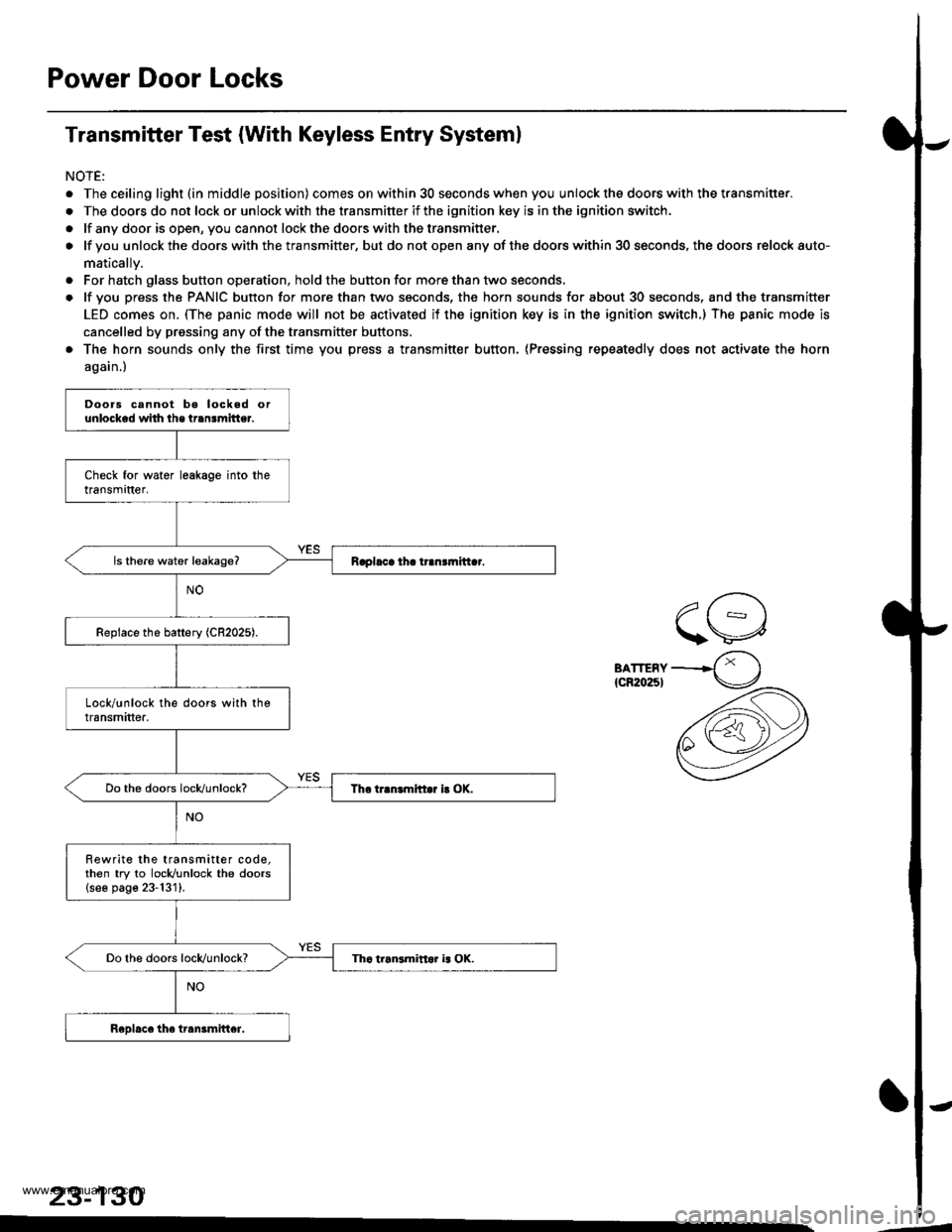

Transmitter Test (With Keyless Entry Systeml

NOTE:

. The ceiling light (in middle position) comes on within 30 seconds when you unlock the doors with the transmitter.

. The doors do not lock or unlock with the transmitter if the ignition key is in the ignition switch.

. lf any door is open, you cannot lockthe doorswith thetransmitter.

o lf you unlock the doors with the transmitter, but do not open any of the doors within 30 seconds, the doors relock auto-

matically.

. For hatch glass button operation, hold the button for more than two seconds.

. lf you press the PANIC button for more than two seconds, the horn sounds for about 30 seconds, and the transmitter

LED comes on. (The panic mode will not be activated if the ignition key is in the ignition switch.) The panic mode is

cancelled by pressing any of the transmitter buftons.

. The horn sounds only the first time you press a transmitter button, (Pressing repeatedly does not activate the horn

again.)

BATTERY{cR20251

23-130

Doors cannot bo locked orunlocked whh lhe transmitter.

Rewrite the transmitter code,then try to locldunlock the doors{see page 23-131}.

www.emanualpro.com

Page 1295 of 1395

-

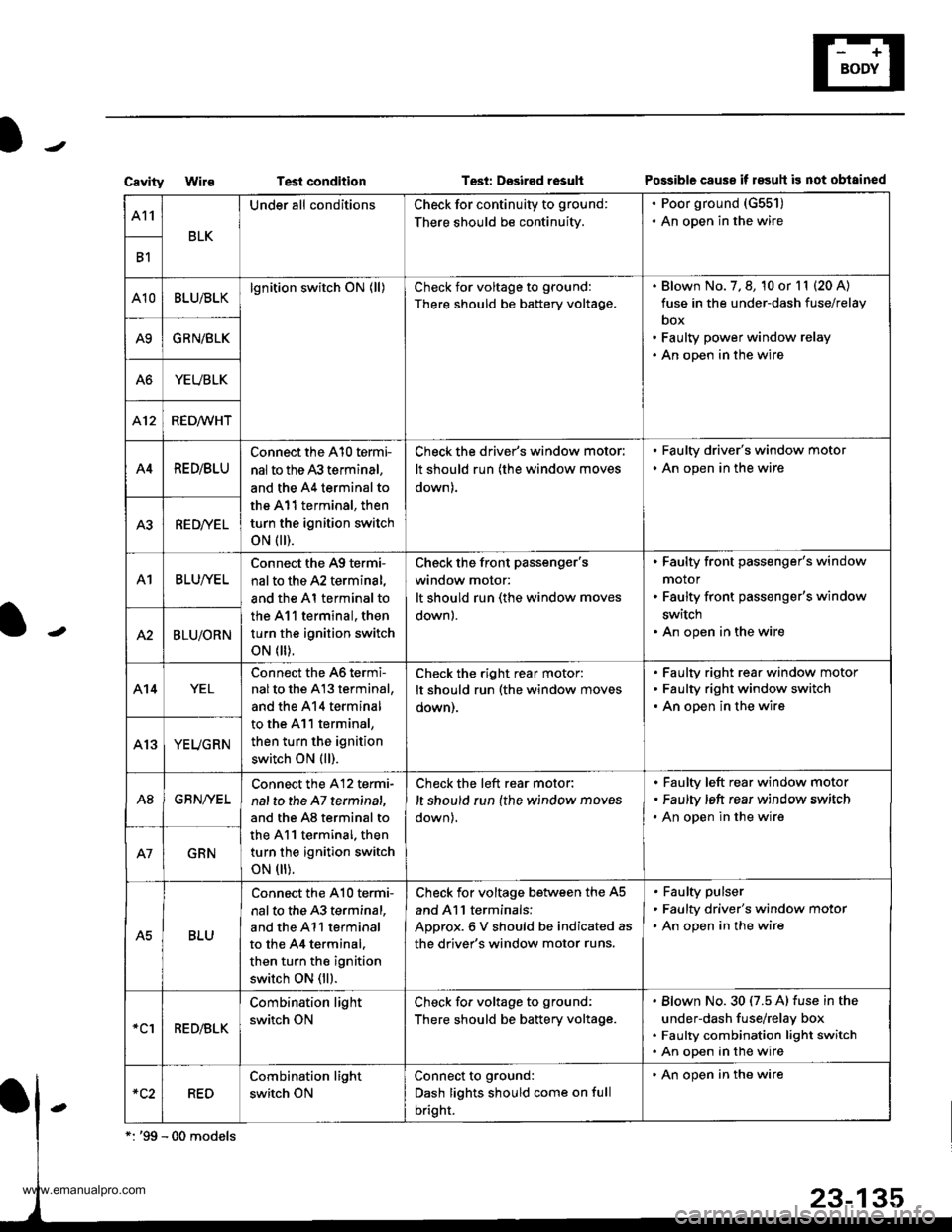

CavityWi1€Test conditionTesi: Dssired rosultPo$ible cause if 183uh is not obtained

A11

BLK

Under all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G551)

. An open in the wire

B1

A10BLU/BLKlgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No. 7, 8, 10 or l1 (20 A)

fuse in the under-dash fuse/relay

box

Faulty power window relay

An open in the wire

A9GRN/BLK

A6YEUBLK

412RED/WHT

A4RE D/BLU

Connect the A10 termi-

nal to the 43 terminal,

and the A4 terminal to

the A11 terminal, then

turn the ignition switch

oN flr).

Check the driver's window motor:

It should run (the window moves

down).

. Faulty driver's window motor

. An open in the wire

A3RED/YEL

A1BLUI/EL

Connect the A9 termi-

nal to the A2 terminal,

and the Al terminal to

the 411 terminal, then

turn the ignition switch

oN flr).

Check the front Passenger'swindow motor:

It should run (the window moves

down).

Faulty front passenger's window

motor

Faulty front passenger's window

switch

An open in the wireA2BLU/ORN

A14YEL

Connect the 46 termi-

nalto the A13 terminal,

and the 414 terminal

to the A11 terminal,

then turn the ignition

switch ON (ll).

Check the right rear motor:

It should run (the window moves

oown).

Faulty right rear window motor

Faulty right window switch

An open in the wire

YEUGRN

A8GBN/YEL

Connect the A12 termi-

nal to the A7 terminat,

and the A8 terminal to

the A11 terminal. then

turn the ignition switch

oN flr).

Check the left rear motor:

,t should run {the window moves

down),

Faulty left rear window motor

Faulty ,eft rear window srrvitch

An open in the wire

GRN

A5BLU

Connect the A10 te.mi-

nal to the 43 terminal,

and the A11 terminal

to the 44 terminal.

then turn the ignition

switch ON (ll).

Check for voltage between the A5

and Al l terminals:

ADorox.6 V should be indicated as

the driver's window motor runs.

Faulty pulser

Faulty driver's window motor

An open in the wire

*clRED/BLK

Combination light

switch ON

Check fo. voltage to ground:

There should be battery voltage.

Blown No.30 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

An open in the wire

RED

Combination light

switch ON

Connect to ground:

Dash lights should come on full

bright.

' An open in the wire

www.emanualpro.com

Page 1301 of 1395

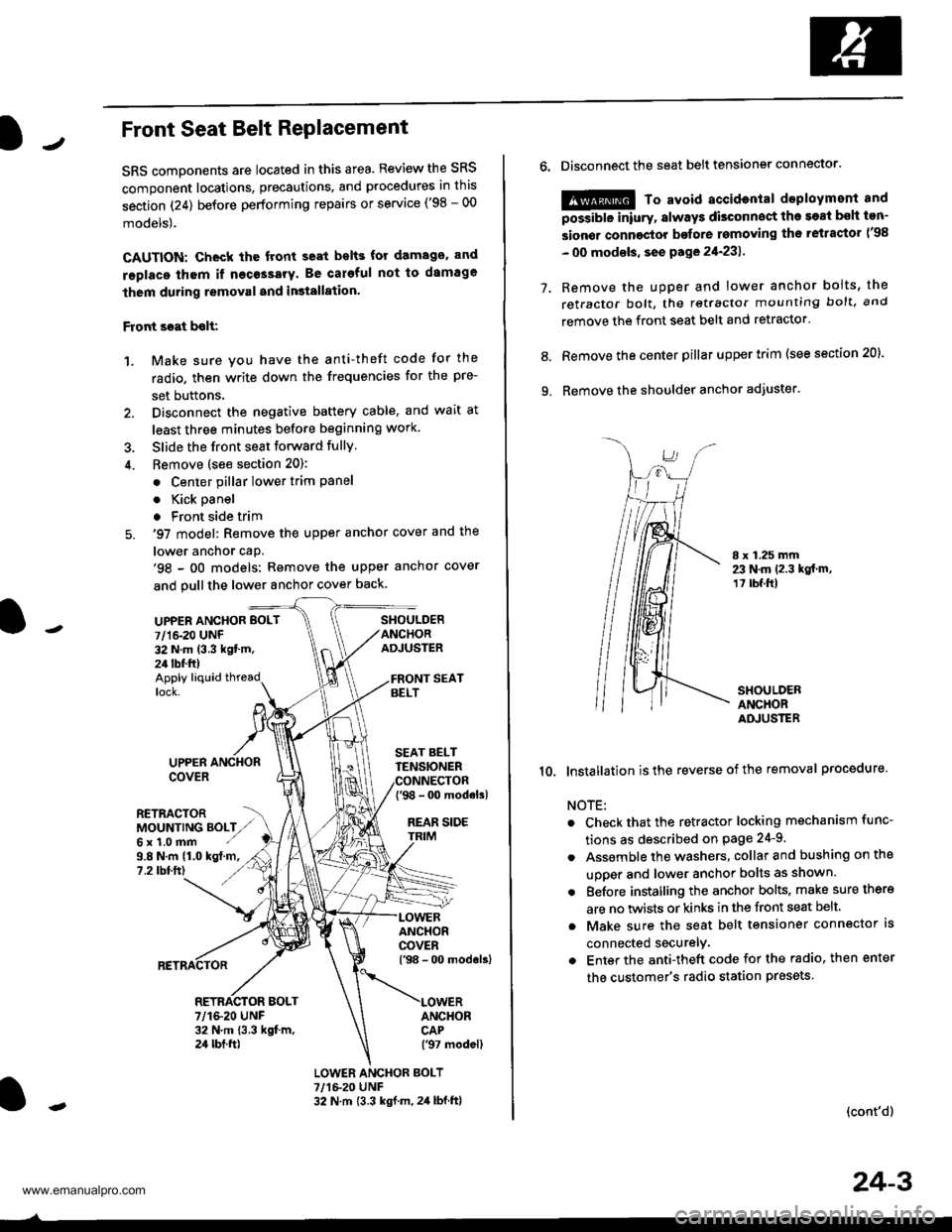

JFront Seat Belt RePlacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in this

section (24) before performing repairs or service ('98 - 00

models).

CAUTION: Check the front seat bslts for damago. and

replaco thom if necessary. Be careful not to damage

them during removal and in3tallation'

Front scat bolt:

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the pre-

set buttons.

2. Disconnect the negative battery cable, and wait at

least three minutes before beginning work.

3. Slide the front seat forward fully.

4. Bemove (see section 20):

. Center pillar lower trim Pane

. Kick oanel

. Front side trim

5. '97 model: Remove the upper anchor cover and the

lower anchor caP.'98 - oO models: Remove the upper anchor cover

and pull the lower anchor cover back.

UPPEN ANCHOR BOLT

7/1&20 UNF32 N.m (3.3 kgt'm.24 tbf.ft)

SHOULDERANCHORADJUSTER

Apply liquid threadlock.

9.8 N.m (1.0 kgt.m,?.2 tbtft)

UPPERCOVER

RETRACTORMOUNTING BOLTZ,,Gx1.0mm ./

SEAT BELTTENSIONER

{'98 - 0o modols)

REAR SIDE

ANCHORCOVERl'98 - 00 models)

ANCHORCAP('97 modell

RETRACTOR BOLT7/1&20 UNF32 N.m 13.3 kgt m,24 tbt.ft)

LOWER ANCHOR BOLT?,/1&20 UNF32 N.m {3.3 kgf.m, 2,1 lbf.ftl

o.Disconnect the seat belt tensiongr connector.

@ To avoid accidontal deployment and

possibte inlury, always disconnect the soat bsh ton-

sion€r connoctor bofore rsmoving th6 retractor l'98

- 00 modsls, se€ pa ge 21-231 .

Remove the uDDer and lower anchor boits, the

retractor bolt, the retractor mounting bolt, and

remove the front seat belt and retractor.

Remove the center pillar upper trim (see section 20).

Remove the shoulder anchor adjuster.

7.

9.

8.

I x 1.25 mm23 N.m 12.3 kgt.m,1? tbf.ft)

SHOULDERANCHORADJUSTER

10. lnstallation isthe reverse of the removal procedure.

NOTE:

Check that the retractor locking mechanism func-

tions as described on Page 24-9.

Assemble the washers, collar and bushing on the

uooer and lower anchor bolts as shown.

Eefore installing the anchor bolts, make sure there

are no twists or kinks in the front seat belt.

Make sure the seat belt tensioner connector ls

connected securelv.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets

(cont'd)

24-3

www.emanualpro.com

Page 1314 of 1395

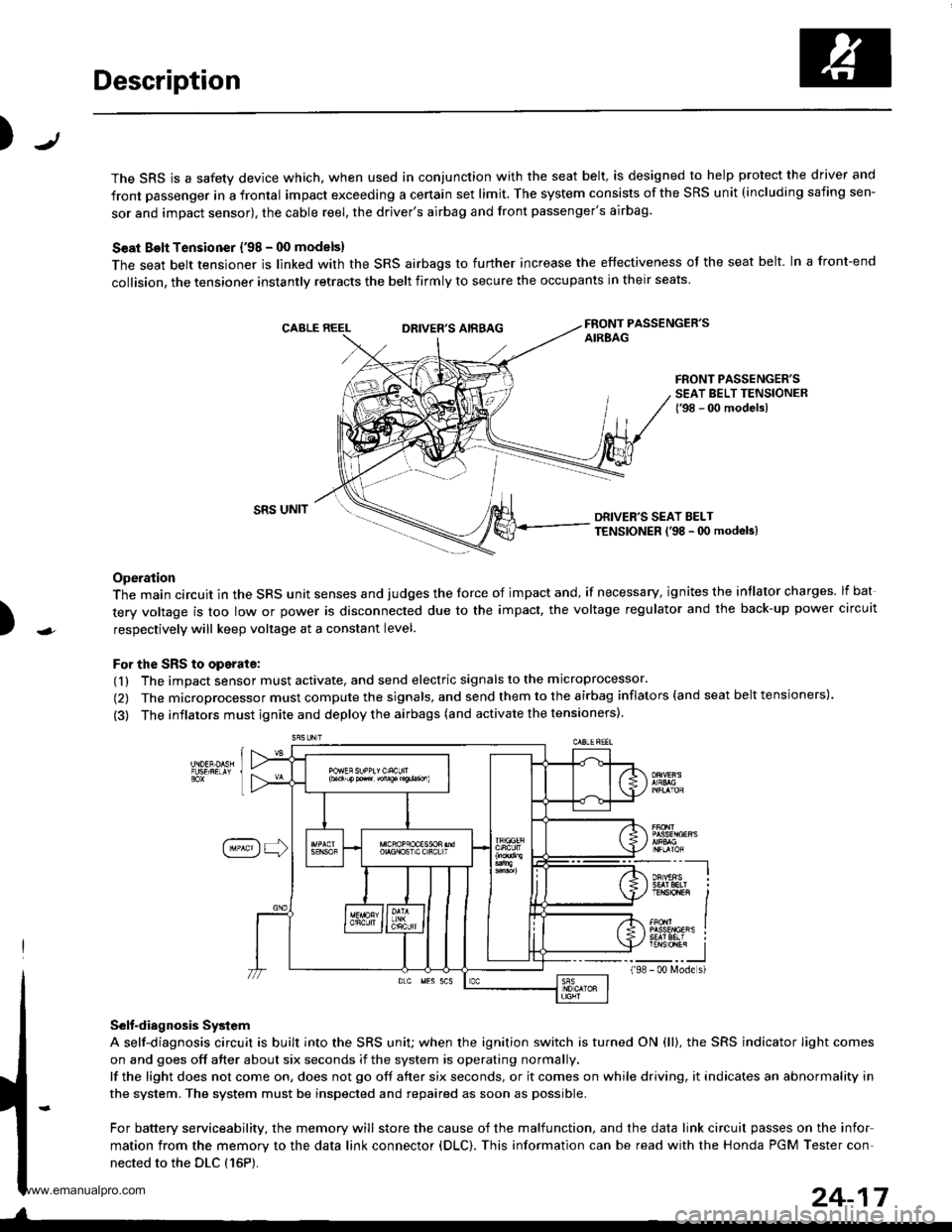

Description

J)

The SRS is a safety device which, when used in conjunction with the seat belt, is designed to help protect the driver and

front passenger in a frontal impact exceeding a certain set limit. The system consists of the SRS unit (including safing sen-

sor and impact sensor), the cable reel, the driver's airbag and front passenger's airbag.

Seat Bolt Tensioner {'98 - 00 models}

The seat belt tensioner is linked with the SRS airbags to further increase the effectiveness of the seat belt. In a front-end

collision, the tensioner instantly retracts the belt firmly to secure the occupants in their seats

FRONT PASSENGER'SAIREAGDRIVER'S AIRBAG

FRONT PASSENGER'SSEAT BELT TENSIONER{'98 - 00 modelsl

)

SRS UNITDRIVER'S SEAT BELTTENSIONER l'98 - 0O modeb)

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the intlator charges. lf bat

tery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power circuit

respectively will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate, and send electric signals to the microprocessor.

(2) The microprocessor must compute the signals, and send them to the airbag inflators (and seat belt tensioners).

(3) The inflators must ignite and deploy the airbags (and activate the tensioners).

Selt-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator Iight comes

on and goes off after about six seconds if the system is operating normally.

lf the light does not come on, does not go off after six seconds, or it comes on while driving, it indicates an abnormality in

the system. The system must be inspected and repaired as soon as possible.

For battery serviceability, the memory will store the cause of the malfunction, and the data link circuit passes on the infor

mation from the memory to the data link connector (DLC). This information can be read with the Honda PGM Tester con-

nected to the DLC {16P).

198

---__-l

TENSTO1En II

_-___J- 00 N4ode s)

24-17

www.emanualpro.com

Page 1316 of 1395

Precautions/Procedures

)General Precautions

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

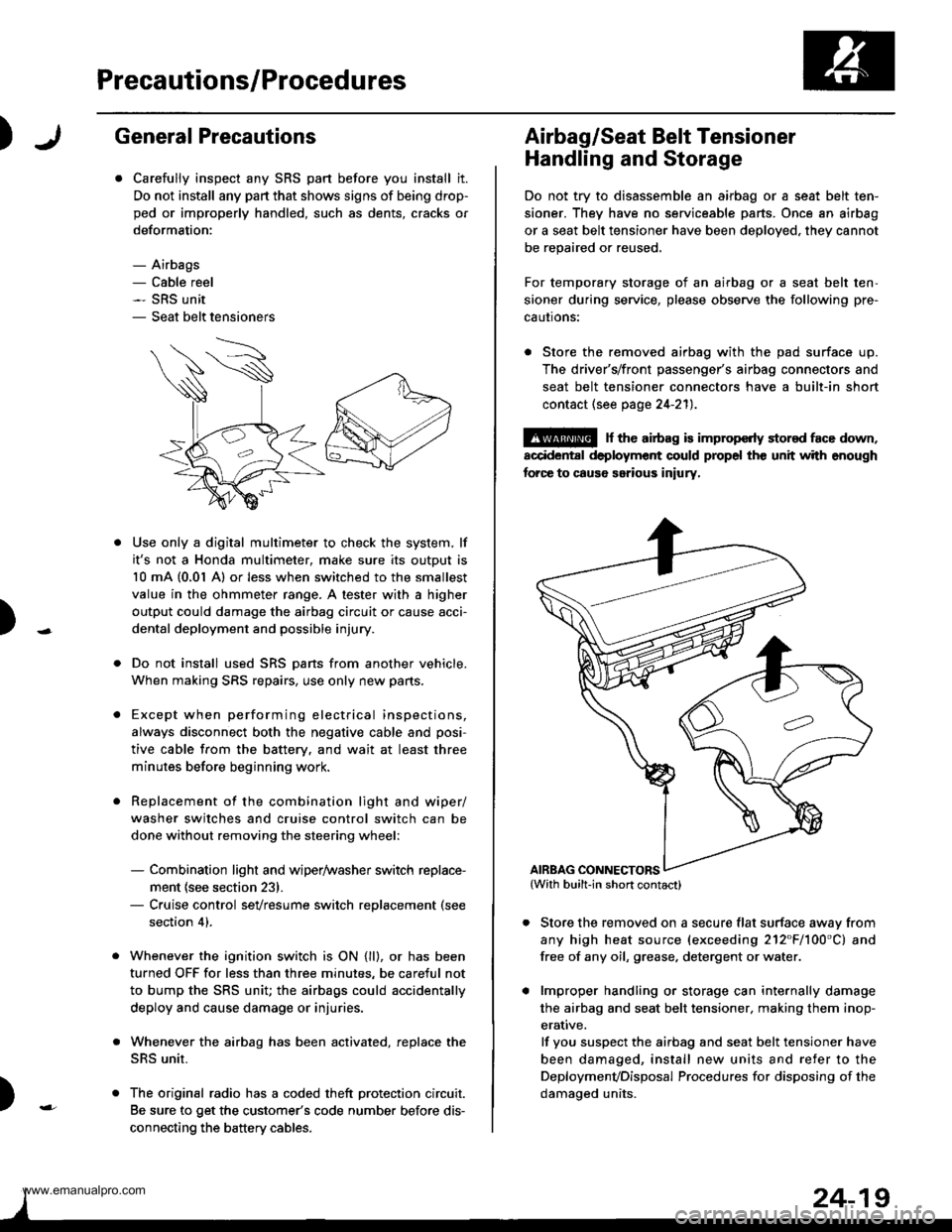

Airbag/Seat Belt Tensioner

Handling and Storage

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1320 of 1395

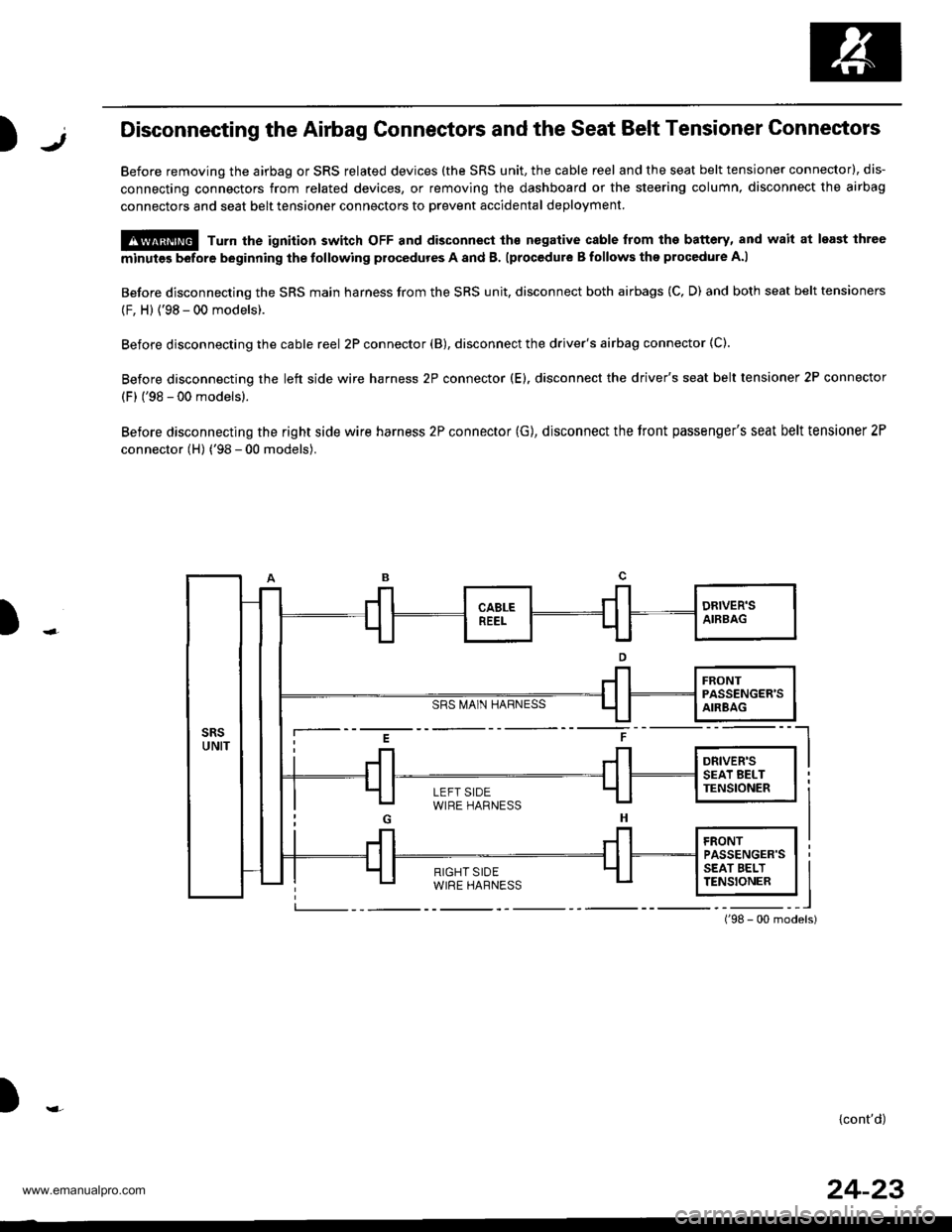

)1,Disconnecting the Airbag Gonnectors and the Seat Belt Tensioner Connectors

Before removing the airbag or SRS related devices (the SRS unit, the cable reel and the seat belt tensioner connector), dis-

connecting connectors from related devices, or removing the dashboard or the steering column, disconnect the airbag

connectors and seat belt tensioner connectors to Drevent accidental deployment

@ Turn the ignition switch oFF and disconnect ths nogative cable from the battery, and wait at least ihree

minutes before beginning the tollowing procedures A and B. lprocedure B follows the procedure A.l

Before disconnecting the SRS main harness from the SRS unit, disconnect both airbags (C, D) and both seat belt tensioners

(F, H) {'98 - 00 models).

Before disconnecting the cable reel 2P connector (B), disconnect the driver's airbag connector (C).

Before disconnecting the left side wire harness 2P connector (E). disconnect the driver's seat belt tensioner 2P connector

(F) ('98 - 00 models).

Before disconnecting the right side wire harness 2P connector (G), disconnect the tront passenger's seat belt tensioner 2P

connector (H) ('98 - 00 models).

SRS MA1N HARNESS

)

i--- E t ----l

i Jl Jl l*",r* I I

LEFT SIDEWIRE HARNESS

){cont'd)

24-23

www.emanualpro.com