section 9 HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1152 of 1395

Compressor

Replacement

lf the compressor is marginally operable. run the

engine at idie speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

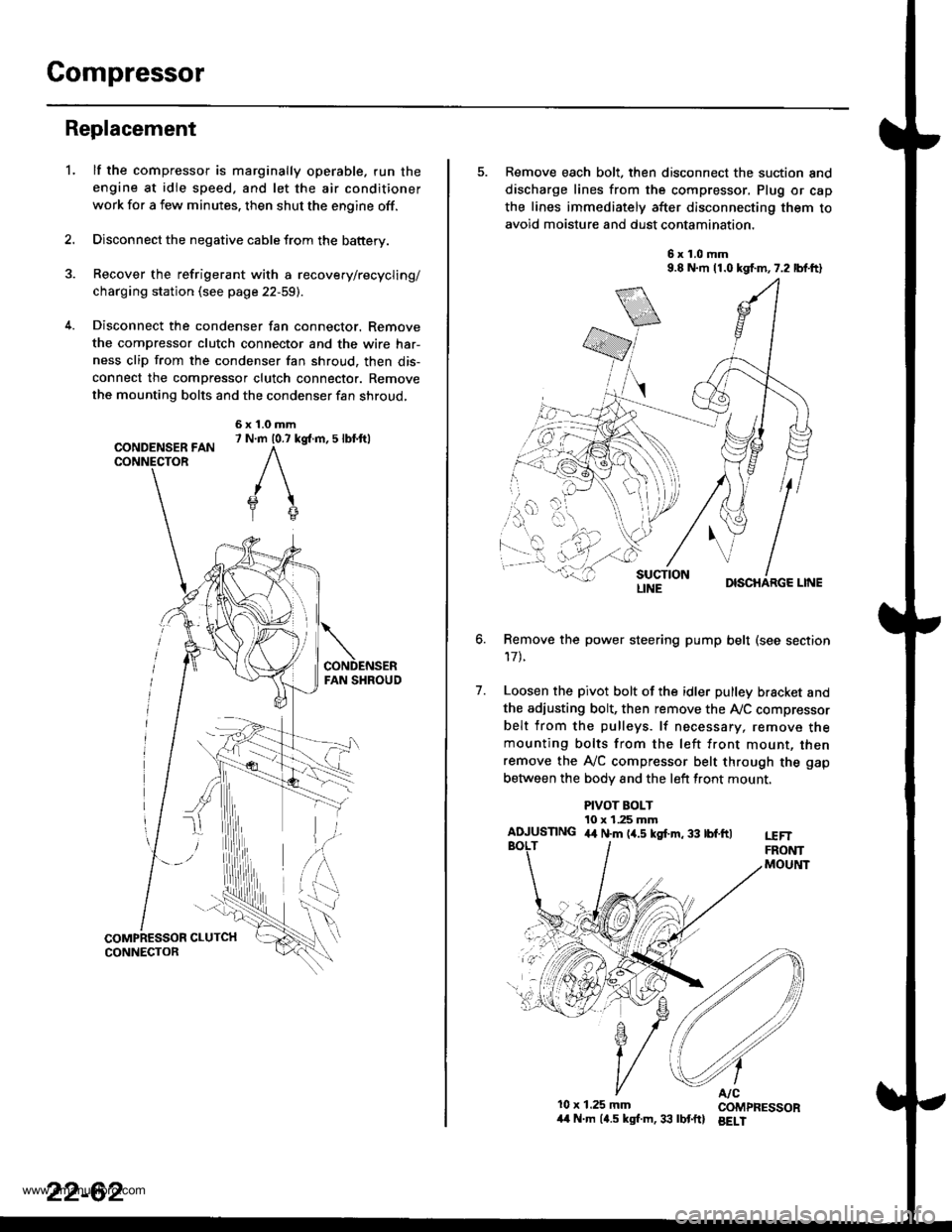

Disconnect the condenser fan connector. Remove

the compressor clutch connector and the wire har-

ness clip from the condenser fan shroud, then dis-

connect the compressor clutch connector. Remove

the mounting bolts and the condenser fan shroud,

CONDENSER FANCONNECTOR

6x1.0mm7 N.m 10.7 kg{.m, 5 lbl.ftl

'L

2.

5. Remove each bolt, then disconnect the suction and

discharge lines from the compressor. Plug or cap

the lines immediately after disconnecting them to

avoid moisture and dust contamination,

6x1.0mm9.8 N.m 11.0 kgf.m,7.2 lbf.ft)

DISCHARGE LINE

Remove the power steering pump belt (see section

17t.

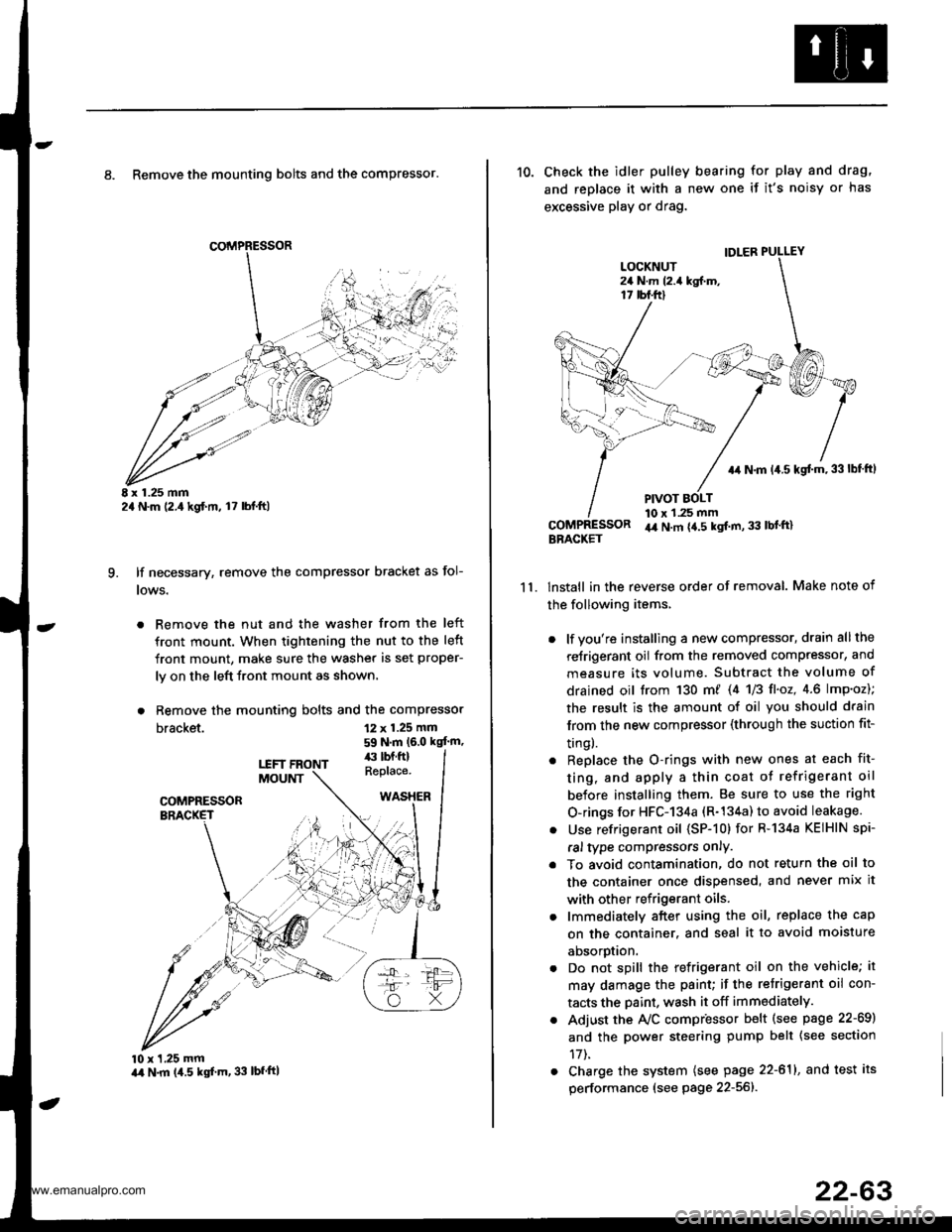

Loosen the pivot bolt of the idler pulley bracket and

the adiusting bolt, then remove the Ay'C compressor

belt from the pulleys. lf necessary, remove themounting bolts from the left front mount, thenremove the A,/C compressor belt through the gap

between the bodv and the left front mount.

6.

7.

PIVOT BOLT10 x 1.25 mmAIUUSTING 4,t N.m (4.5 kgf.m, 33 tbf.ftlt€FTFRONTMOUltlT

10x 1.25 mm COMPRESSOR/t4 N.m (4.5 kgl.m,33 lbtftl BELI

LINE

www.emanualpro.com

Page 1153 of 1395

8. Remove the mounting bolts and the compressor.

E x 1.25 mm2a N.m (2.,1kgf.m, l7 lbl.ft)

lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer from the left

front mount. When tightening the nut to the left

front mount, make sure the washer is set proper-

ly on the left front mount as shown.

. Remove the mounting bolts and the compressor

bracket.

q

12 x 1.25 mm

59 N.m (6.0 kgt'm,

10 x 1,25 mmart N.m (4.5 kgf'm, 33 lbfftl

11.

10. Check the idler pulley bearing for play and drag,

and replace it with a new one if it's noisy or has

excessive play or drag.

lnstall in the reverse order of removal. Make note of

the following items,

. lf you're installing a new compressor, drain all the

reJrigerant oil from the removed compressor, and

measure its volume. Subtract the volume of

drained oil trom 130 m/ 14 U3 fl'o2,4.6 lmp'oz);

the result is the amount of oil you should drain

lrom the new compressor (through the suction fit-

trngl.

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat o{ refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Use refrigerant oil (SP-10) for R-134a KEIHIN spi-

ral type compressors only.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container. and seal it to avoid moisture

aDsorprlon.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the retrigerant oil con-

tacts the Daint, wash it off immediately.

. Adjust the Ay'C compr'essor b€lt (see psge 22-69)

and the power steering pump belt {see section

17t.

. Charge the system (see page 22-611, and test its

performance (see page 22-56]-.

IDLER PULLEY

+r N.m 14.5 kgt m,33lbf ftl

PIVOT BOLT10 x 1.25 mmir4 N.m {4.5 kgt m, 33 lbl'ft}BBACKET

www.emanualpro.com

Page 1160 of 1395

Gondenser

't.

Replacement

Recover the refrigerant with a recovery/recycling/

charging ststion (see page 22-59)

Remove the front grille (see section 20).

Remove the coolant reservoii, but do not discon-

nect the reservoir hose Jrom the coolant reservoir

and the radiator.

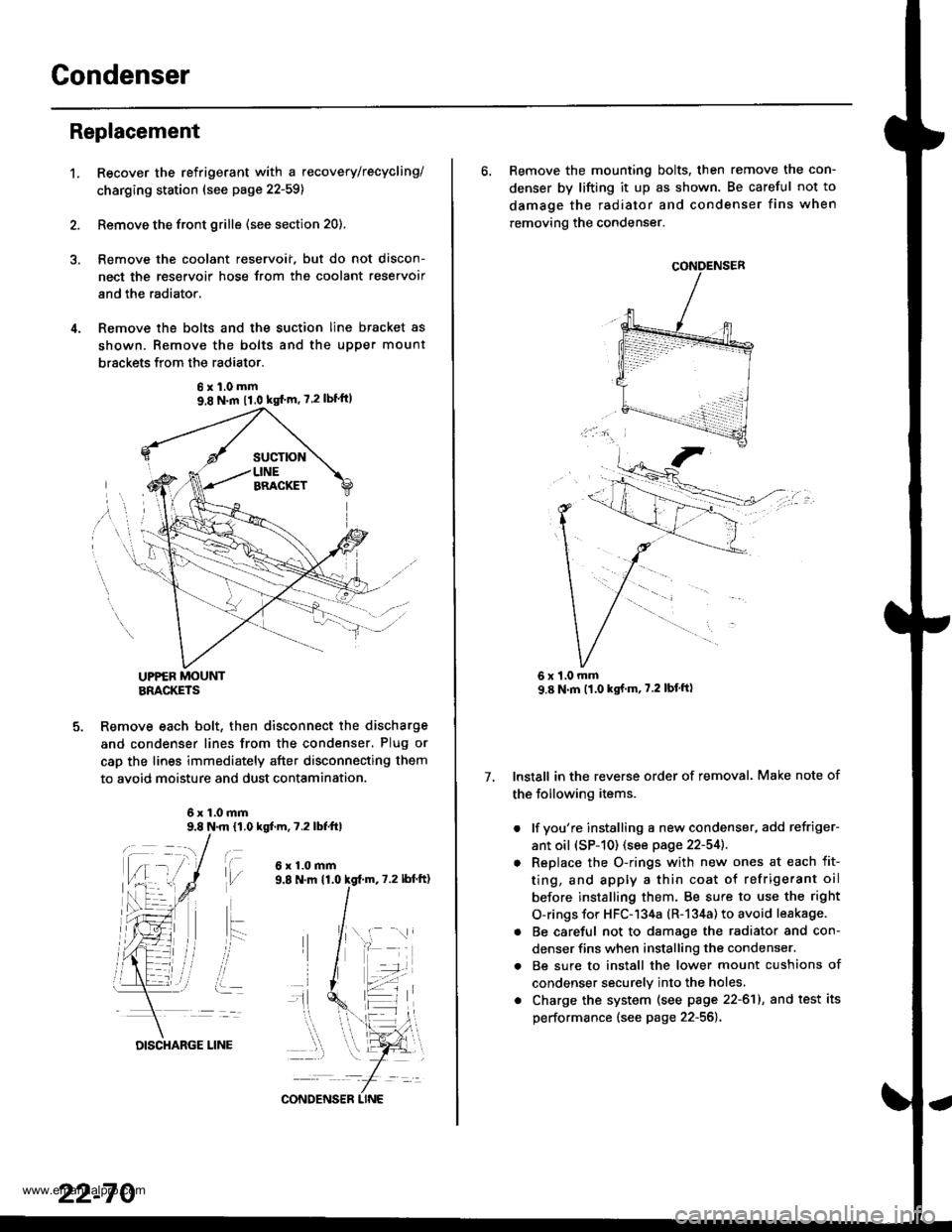

Remove the bolts and the suction line bracket as

shown. Remove the bolts and the upper mount

brsckets from the radiator.

UPPER MOUNTBRACKETS

Remove each bolt, then disconnect the discharge

and condenser lines from the condenser, Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contamination.

6x1.0mm9.8 N.m 11,0 kgf.m, 7.2 lbfttl

t\,l/

ait- -:

i..

6x1.0mm

6xl.0mm9,8 N.m 11.0 kgf'm' 7.2lbf'ft)

22-70

DISCHARGE LINE

CONDENS€R LINE

6. Remove the mounting bolts, then remove the con-

denser by lifting it up as shown. Be careful not to

damage the radiator and condenser fins when

removing the condenser.

Install in the reverse order of removal. Make note of

the following items.

. lf you're installing a new condenser, add refriger-

ant oil (sP-10) (see page 22-54]..

o Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Be careful not to damage the radiator and con-

denser fins when installing the condenser.

. Be sure to install the lower mount cushions of

condenser securely into the holes,

. Charge the system (see page 22-61), and test its

performance (see page 22-56).

7.

1,0 mm

www.emanualpro.com

Page 1161 of 1395

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1209 of 1395

Under-dash Fuse/Relay Box

I

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (241 before performing repairs or ser-

vice.

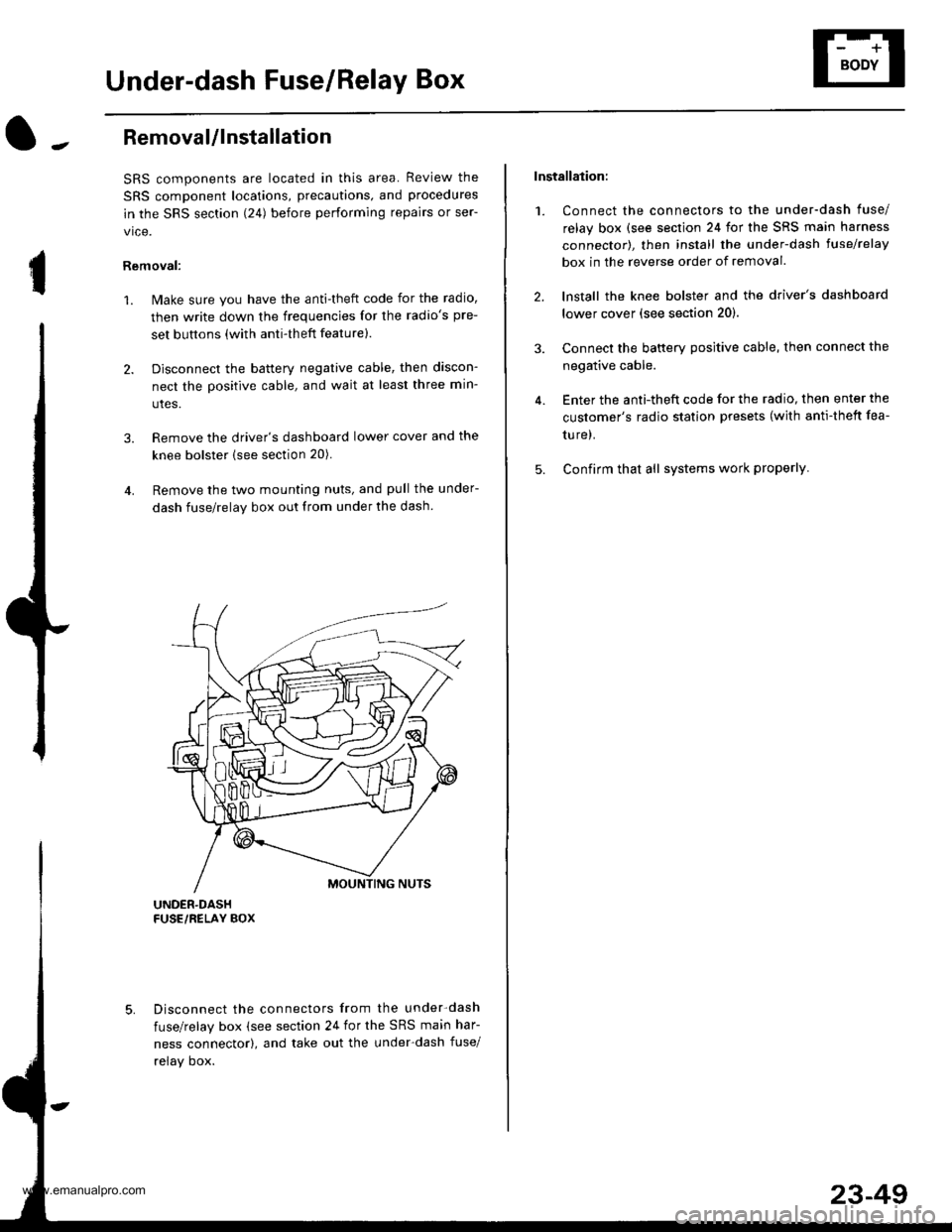

Removal:

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's pre-

set buttons (with anti-theft feature).

2. Disconnect the battery negative cable, then discon-

nect the positive cable, and wait at least three min-

utes.

3. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

4. Remove the two mounting nuts, and pull the under-

dash fuse/relay box out from under the dash

Disconnect the connectors from the under-dash

fuse/relay box (see section 24 for the SRS main har-

ness connector), and take out the under-dash fuse/

relay oox.

Installation:

1. Connect the connectors to the under-dash fuse/

relay box (see section 24 for the SRS main harness

connector), then install the under-dash lusehelay

box in the reverse order of removal.

2. lnstall the knee bolster and the driver's dashboard

lower cover (see section 20).

3. Connect the battery positive cable, then connect the

negative cable.

4. Enter the anti-theft code for the radio, then enter the

customer's radio station presets (with anti-thett fea-

ture).

5. Confirm that all systems work properly

23-49

www.emanualpro.com

Page 1214 of 1395

lgnition Switch

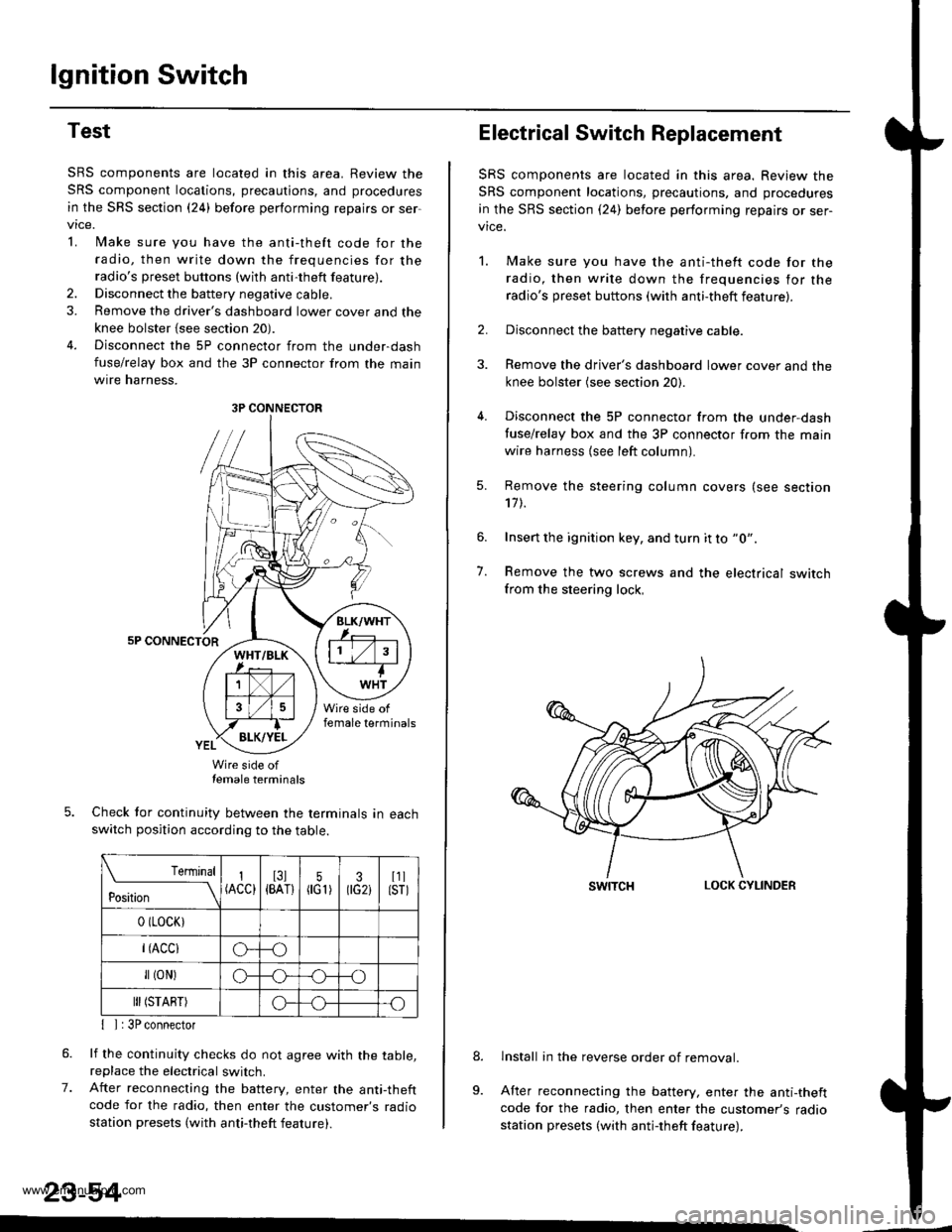

Test

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24} before performing repairs or ser

vtce.

L lMake sure you have the anti-theft code for the

radio, then write down the frequencies for theradio's preset buttons (wilh anti-theft feature).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and the

knee bolster {see section 20).

4. Disconnect the 5P connector from the under-dash

fuse/relay box and the 3P connector from the main

wtre narness,

5P CONNECTOR

Wire side oftemale terminals

Check tor continuity between the terminals in eachswitch position according to the table.

rernrnal

ros[ron \

I(ACC)I3l{BAT}5flG1)30G2iI1llsrl

0 (LocK)

r(Acclo--o

fl (oN)G_o

III (START)o--.o

7.

{ I | 3P connector

lf the continuity checks do not agree with the table,replace the electrical switch.

After reconnecting the battery, enter the anti-theftcode for the radio, then enter the customer's radio

station presets (with anti-theft feature).

23-54

3P CONNECTOR

Electrical Switch Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24) before performing repairs or ser-vice.

1. Make sure you have the anti-thett code for the

radio, then write down the frequencies for the

radio's preset buttons (with anti-theft feature).

2. Disconnect the battery negative cable.

3. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

4. Disconnect the 5P connector from the under,dash

tuse/relay box and the 3P connector f.om the main

wire harness {see left column).

7.

Remove the steering column covers (see section'17 t.

Insert the ignition key, and turn it to "0".

Remove the two screws and the electrical switchfrom the steering lock,

swrTcHLOCK CYLINDER

lnstall in the reverse order of removal.

After reconnecting the battery, enter the anti-theftcode for the radio, then enter the customer's radiostation presets (with antj-theft feature).

9.

www.emanualpro.com

Page 1215 of 1395

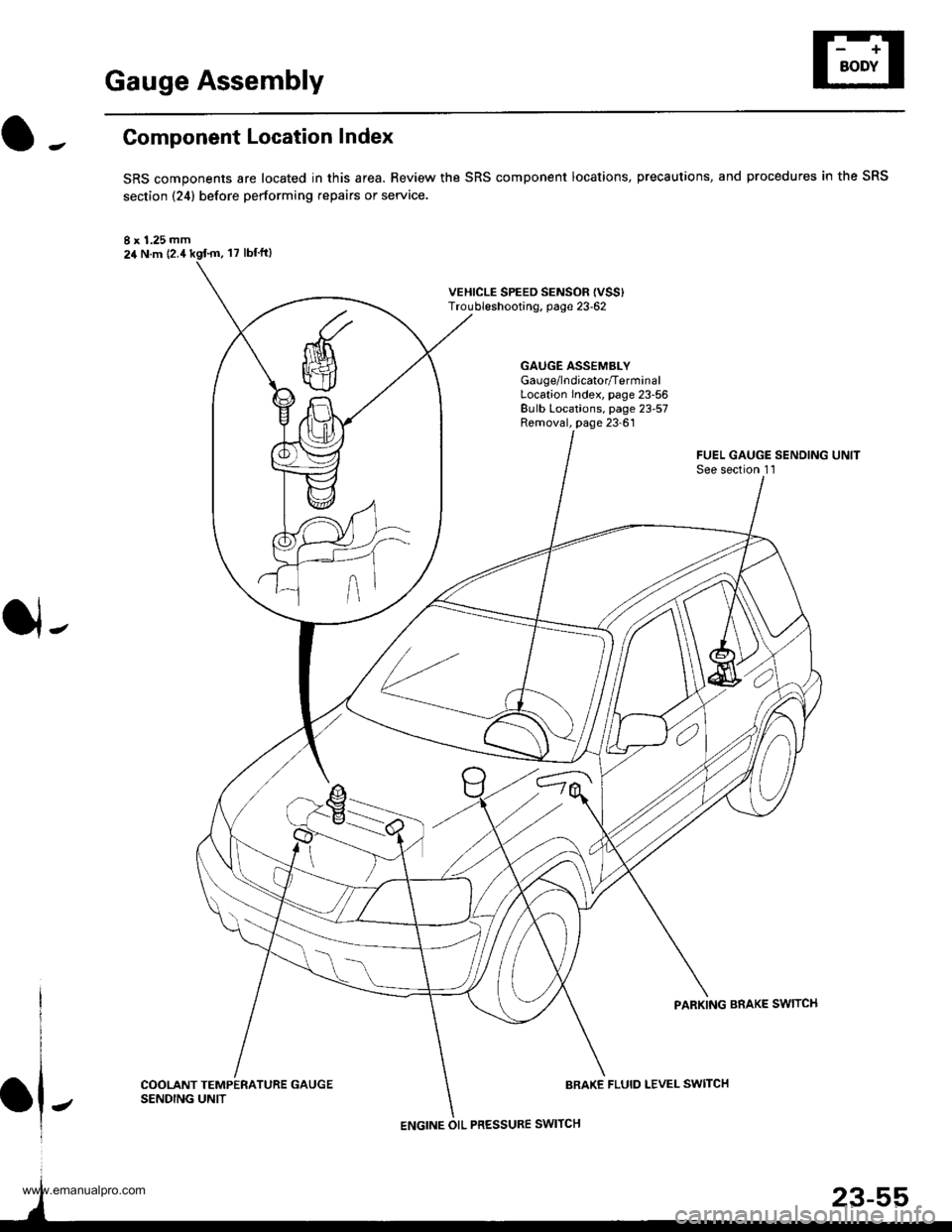

Gauge Assembly

Component Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24} before performing repairs or service.

I x 1.25 mm24 N.m {2.4

VEHICLE SPEED SENSOF {VSS'Troubleshooting, page 23-62

GAUGE ASSEMBLYGau ge/lndicator/TerminalLocation Index, page 23-56Bulb Locations, page 23-57Removal, page 23-61

J-

FUEL GAUGE SENDING UNITSee section 1 l

PARKING BRAKE SWITCH

COOLANT TEMPERATURE GAUGESENDING UNITBRAKE FLUID LEVEL SWITCH

ENGINE OIL PRESSURE SWITCH

www.emanualpro.com

Page 1228 of 1395

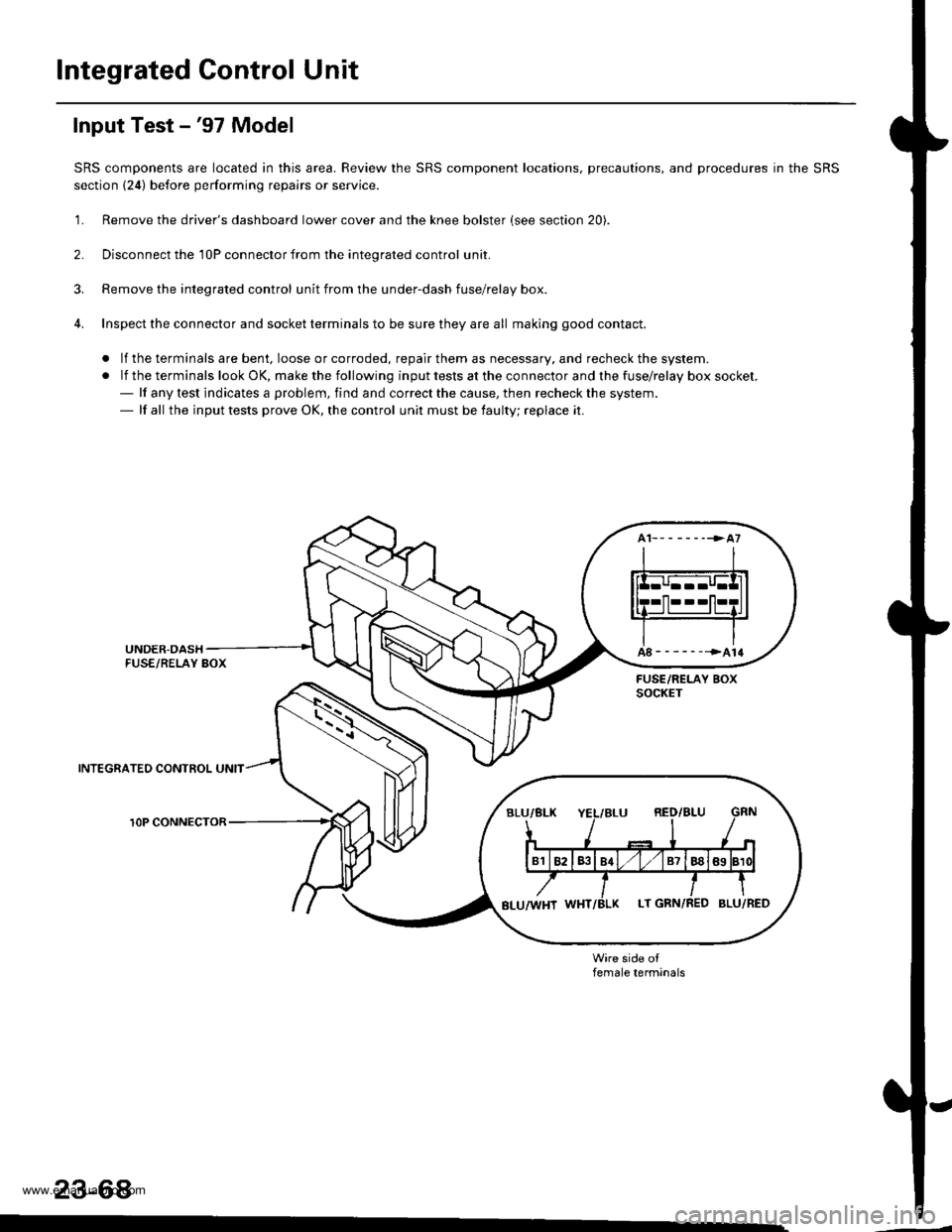

Integrated Gontrol Unit

Input Test -'97 Model

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

'1. Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Disconnect the 'l0P connector from the inteorated control unit.

3. Remove the integrated control unit from the under-dash fuse/relay box.

4. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded, repair them as necessary, and recheck the system.

.lftheterminalslookOK,makethefollowinginputtestsattheconnectorandthefuse\

/relayboxsocket.- lf any test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the control unit must be faulty; replace it.

INTEGRATEO CONTROL UNIT

rOP CONNECTOR

female terminals

23-68

www.emanualpro.com

Page 1231 of 1395

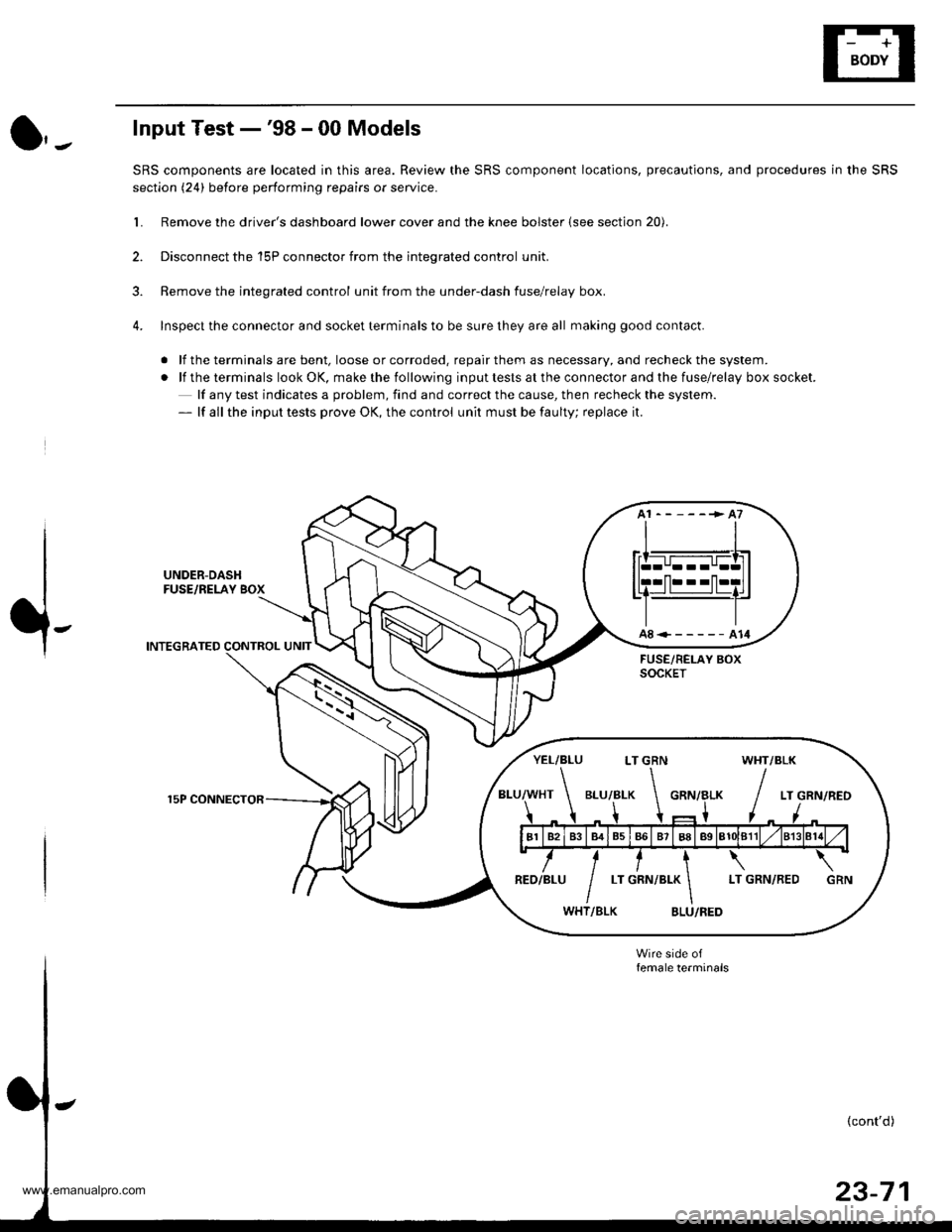

Input Test -'98 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

L Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Disconnect the 'l5P connector from the inteqrated control unit.

3. Remove the integrated control unit from the under-dash fuse/relay box.

4. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded. repair them as necessary, and recheck the system.

.lftheterminalslookOK,makethefollowinginputtestsattheconnectorandthefuse\

/relayboxsocket.

lf any test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the control unit must be faulty; replace it.

UNDER-DASHFUSE/RELAY BOX

INTEGRATED CONTROL UNIT

15P CONNECTOR

A8<------A14

YEL/BLU LT GRN WHT/BLK

www.emanualpro.com

Page 1238 of 1395

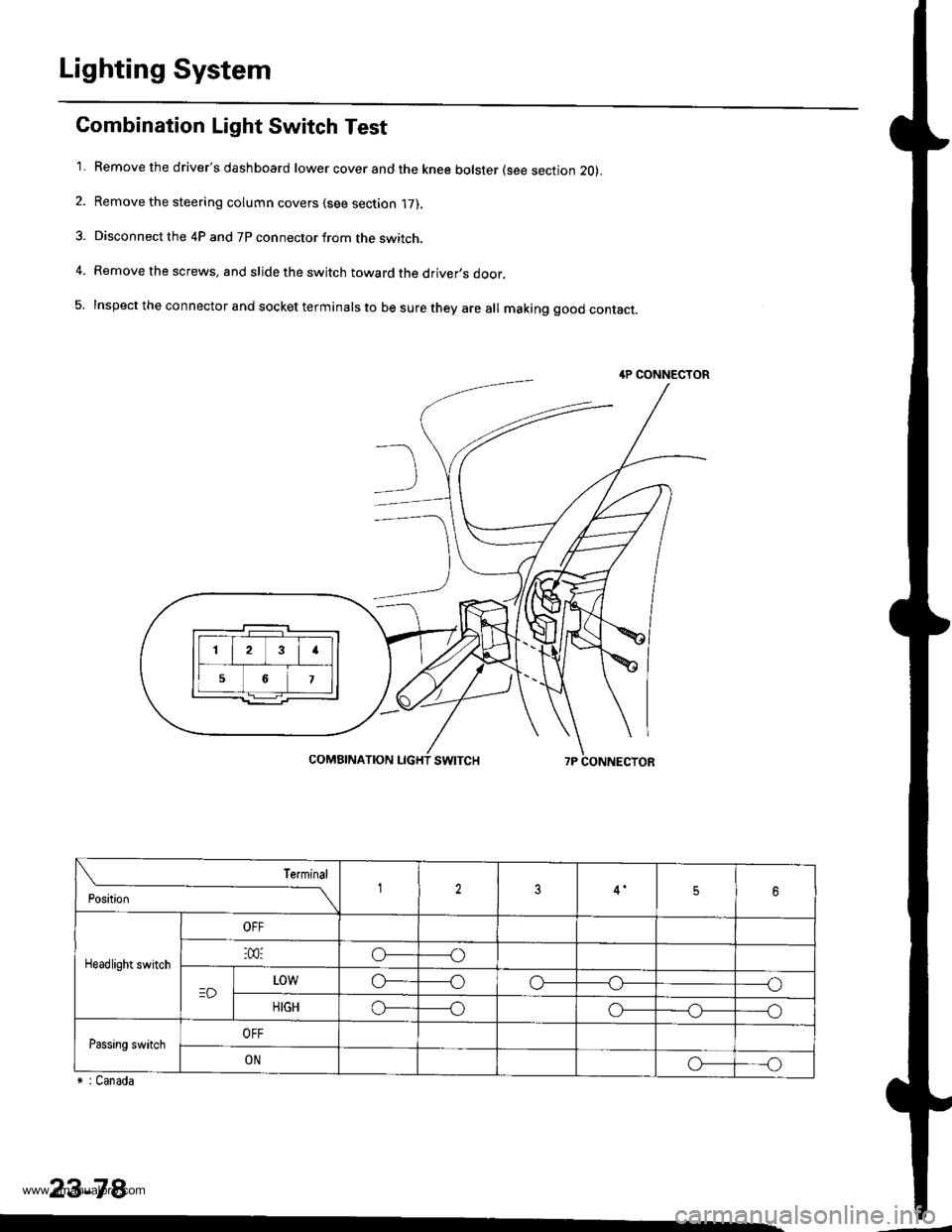

Lighting System

Combination Light Switch Test

'1. Remove the driver's dashboard lower cover and the knee bolster (see section 20).

2. Remove the steering column covers (see section '17).

3. Disconnect the 4P and 7P connector from the switch.

4. Remove the screws, and slide the switch toward the driver,s door,

5. Inspect the connector and socket terminals to be sure they are all making good contact.

r : Canada

23-78

4P CONNECTOR

23I

56

Position

Terminal12356

Headlight switch

OFF

:m:o_----o

=DL0wo------oo-----o

HIGHo_----oo-_--_o_----o

Passing switchOFF

ONo_---o

www.emanualpro.com