Head bolt spec HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 903 of 1395

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber, toe, and turning angle). Follow the equipment

manufacturer's instructions,

3.

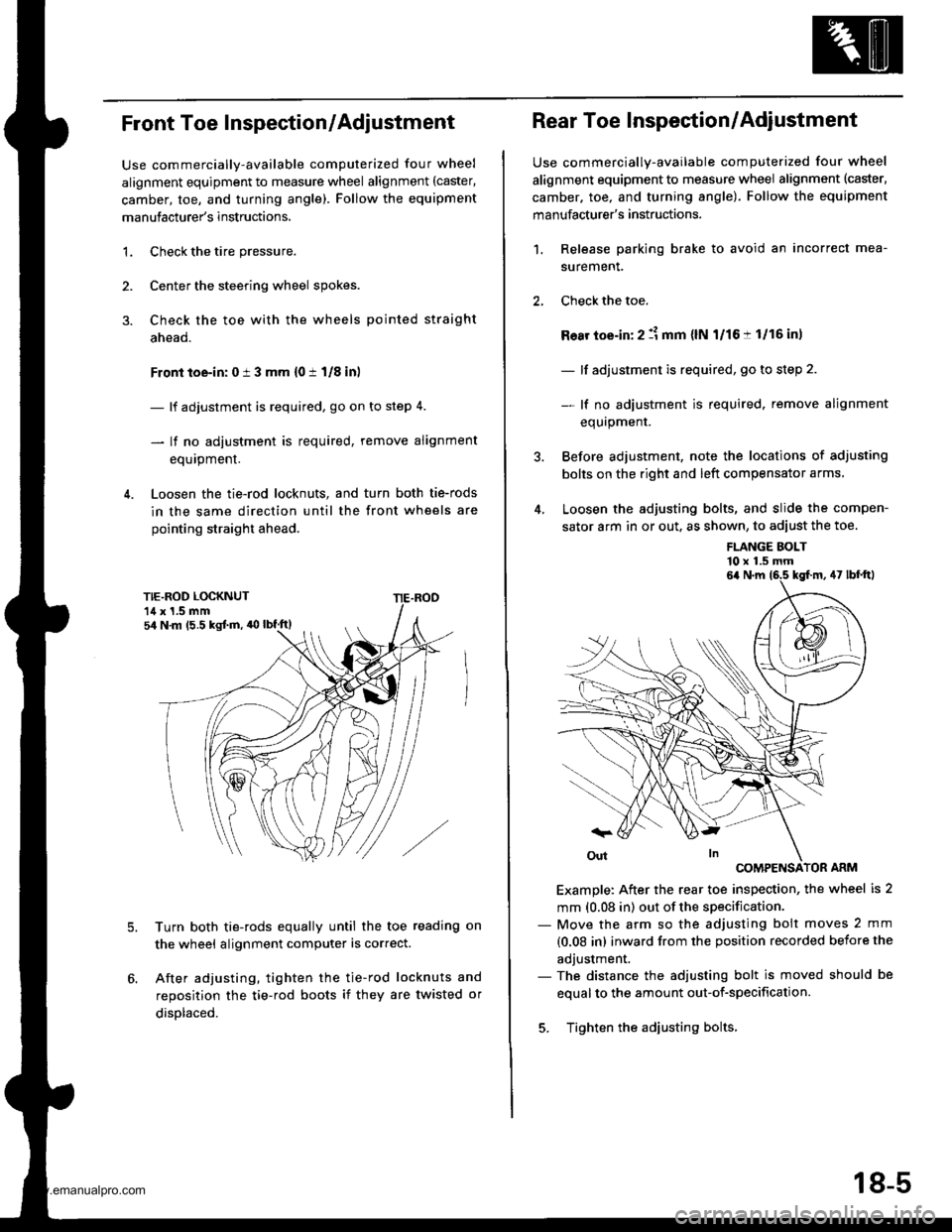

1.Check the tire pressure.

Center the steering wheel spokes.

Check the toe with the wheels pointed straight

ahead.

Front toe-in: 0 i 3 mm {0 t 1/8 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equipment.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are

pointing straight ahead.

5.Turn both tie-rods equally until the toe reading on

the wheel alignment computer is correct.

After adjusting, tighten the tie-rod locknuts and

reposition the tie-rod boots if they are twisted or

displaced.

sir N m (5.5 kgJ.m, 'O lbf.ft)

Rear Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber. toe, and turning angle). Follow the equipment

manufacturer's instructions.

Release parking brake to avoid an incorrect mea-

surement.

Check the toe.

Ro8r toe-in: 2 :1 mm {lN l/16:t 1/16 in,

- lf adjustment is required, go to step 2.

- lf no adiustment is required. remove alignment

equrpmenr.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts, and slide the compen-

sator arm in or out. as shown, to adiust the toe.

1.

FLANGE BOLT'10 x 1.5 mm

COMPENSATOR ARM

Example: After the rear toe inspection, the wheel is 2

mm (0.08 in) out of the specification.- Move the arm so the adjusting bolt moves 2 mm

{0.08 in) inward from the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

5. Tighten the adjusting bolts.

6a N.m 16.5 kgf.m, 47 lbf'ftl

18-5

www.emanualpro.com

Page 909 of 1395

12.

13.

14.

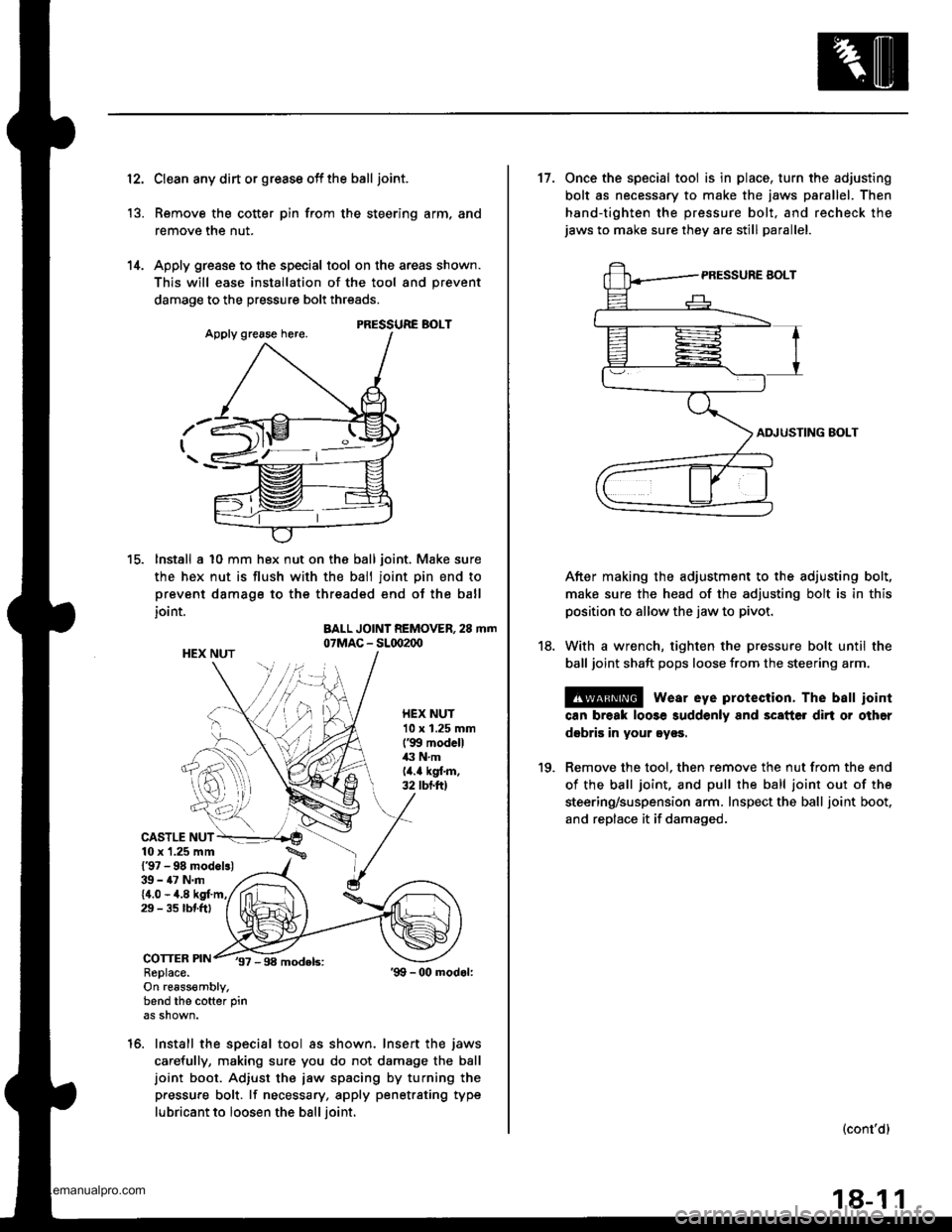

Clean any dirt or grease off the ball joint.

Remove the cotter pin from the steering arm, and

remove the nut.

Apply grease to the special tool on the areas shown.

This will ease installation of the tool and prevent

damage to the pressure bolt threads.

PRESSURE BOLT

lnstall a 10 mm hex nut on the ball joint. Make sure

the hex nut is flush with the ball joint pin end to

prevent damage to the threaded end of the ball

joint.

BALL JOINT REMOVER, 28 mm07MAC - SL(x)2(x)HEX NUT

HEX NUT10 x 1.25 mm('99 modcll43 N.mlit.a kgl.m.32 tbtft)

37 -98 models:

tc.

6:)

CASTLE NUT10 x '1.25 mm

l'97 - 98 modcls)39 - 47 N.m{4.0 - 4.829 - 3s rbtftt

COTTERReplace.On re6ss€mbly,bend the cofter pin

16. Install the special tool as shown. Insert the jaws

carefully, making sure you do not damage the balljoint boot. Adiust the jaw spacing by turning the

pressure bolt. lf necessary, apply penetrating type

lubricant to loosen the ball ioint.

'99 -00 modol:

18.

17. Once the special tool is in place, turn the adjusting

bolt as necessary to make the jaws parallel. Then

hand-tighten the pressure bolt, and recheck thejaws to make sure they are still parallel.

ADJUSTING BOLT

After making the adjustment to the adjusting bolt,

make sure the head of the adjusting bolt is in this

position to allow the jaw to pivot.

With a wrench, tighten the pressure bolt until the

ball joint shaft pops loose from the steering arm.

@ wear eye protection. The balt iointcan break loose suddenly and scatter dirt or other

dsbris in your ey€s.

Remove the tool, then remove the nut from the end

of the ball joint, and pull the ball joint out of the

steering/suspension arm. Inspect the ball joint boot.

and replace it if damaged.

(cont'dl

1(|

18-1 1

www.emanualpro.com

Page 1080 of 1395

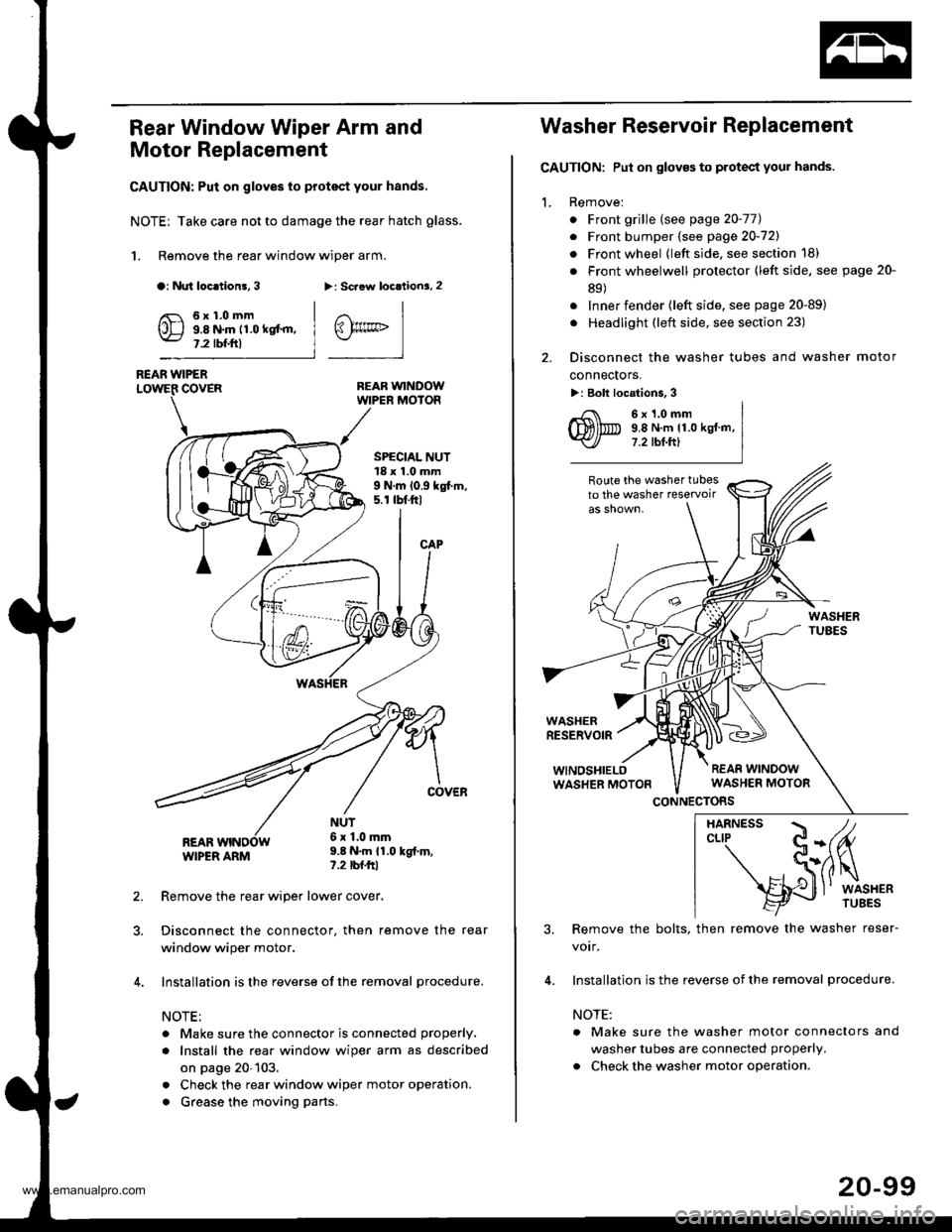

Rear Window Wiper Arm and

Motor Replacement

CAUTION: Put on gloves to protect your hands.

NOTE; Take care not to damage the rear hatch glass.

1. Remove the rear window wiper arm.

a: Nut loc.tion!, 3>: Scaow locationa, 2

REAR WINDOWWIPER MOIOR

REAR WIPERCOVER

REARWIPER ARM

6x1.0mm9.8 N.m 11.0 kgt'm,7.2 tbf.ftl

SPECIAL NUT18 x 1.0 mm9 N.m 10.9 kgt m,5. r tbt.ftl

NUT6x 1.0mm9.8 N.m {1.0 kgt.m,?.2 tbfftl

Remove the rear wiper lower cover.

Disconnect the connector, then remove the rear

window wiper motor.

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connector is connected properly.

. Install the rea. window wiper arm as described

on page 20-103.

. Check the rear window wiper motor operation.

. Grease the moving parts.

@rrc

Washer Reservoir Replacement

GAUTION: Put on gloves to protect your hands.

1. Remove:

. Front grille (see page 20-771

. Front bumper (see page 20-721

. Front wheel {left side, see section 18)

. Front wheelwell protector (left side, see page 20-

89)

. Inner fender (left side, see page 20-89)

. Headlight (left side, see section 23)

2. Disconnect the washer tubes and washer motor

connectors.

>: Bolt locations, 3

6x1.0mm9,8 N.m 11.0 kgt.m,7.2 tbt.ftl

Route the washer tubesto the washer teservoir

WASHERRESERVOIR

WINOSHIELOWASHER MOTON

CONNECTORS

3. Remove the bolts, then remove the washer reser-

votr,

4. Installation is the reverse of the removal procedure.

NOTE:

a Make sure the washer motor connectors and

washer tubes are connected properly.

. Check the washer motor operation.

HARNESS / tcLrP C-(fu

- S(ilq

s{J

l' wrsHER

20-99

www.emanualpro.com

Page 1240 of 1395

Lighting SystemHeadlights

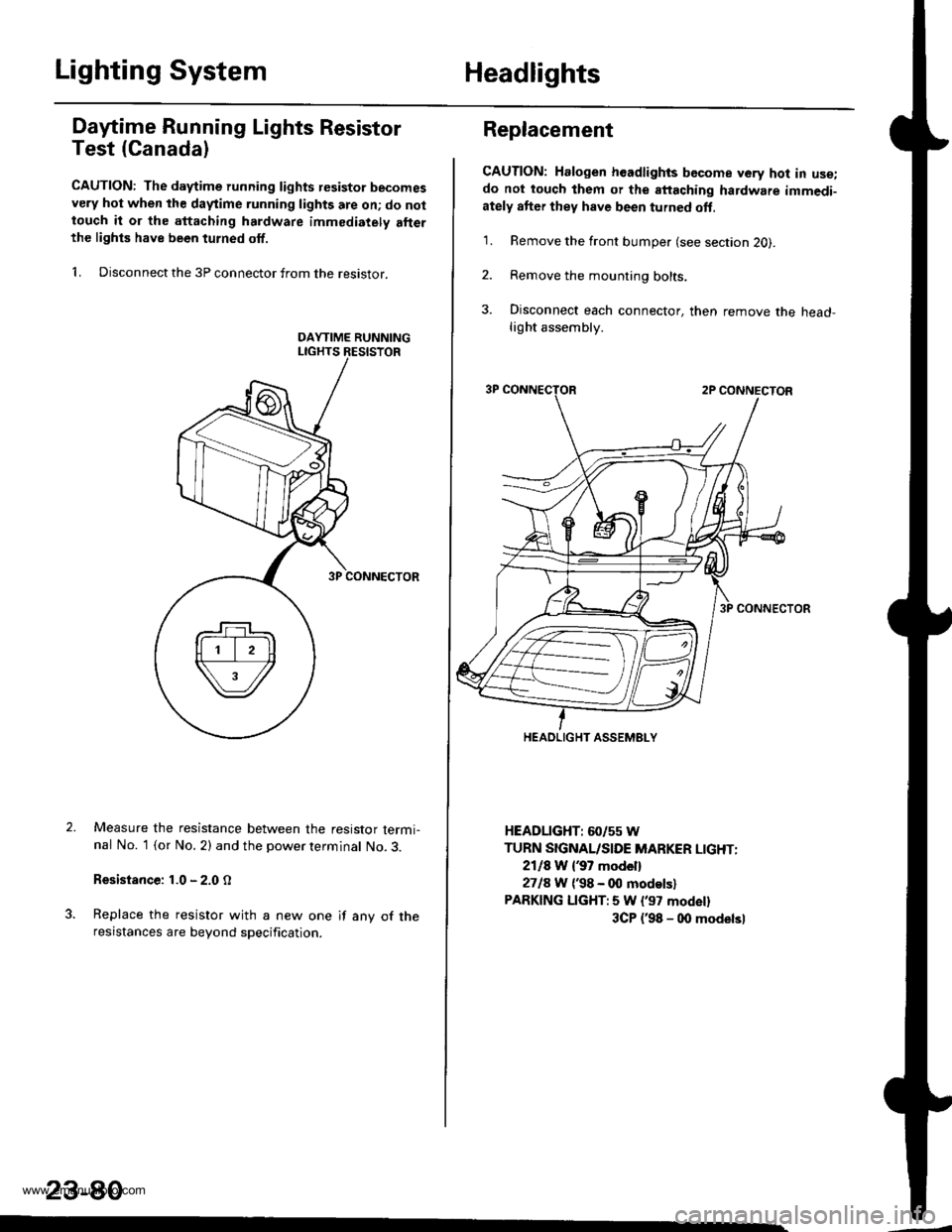

Dafime Running Lights Resistor

Test (Canada)

CAUTION: The d.ytime running lights resistor becomesvery hot when the daytime running lights are on; do nottouch it or the attaching hardware immediately allerthe lighls have been turned off.

1. Disconnect the 3P connector from the resistor.

Measure the resistance between the resistor termi-nal No. 1 (or No. 2) and the power terminal No. 3.

Resistance: 1.0 - 2.0 O

Replace the resistor with a new one if any of theresistances are beyond specification.

23-80

Replacement

CAUTION: Halogen headlights bGcome very hot in use;do not touch them or the attaching hardware immedi-ately after they have been turned oft.

1. Remove the front bumper (see section 2O).

2. Remove the mounting bolts.

3. Disconnect each connector, then remove the head-light assembly.

HEADLIGHT: 60/55 W

TURN SIGNAL/SIDE MARKER LIGHT:

2118 W {37 model}

2718 W ('98 - 00 modelsl

PARKING LIGHT:5 W l'97 modell

3CP {'98 - 00 modelsl

HEADLIGHT ASSEMELY

www.emanualpro.com

Page 1388 of 1395

Cable Reel

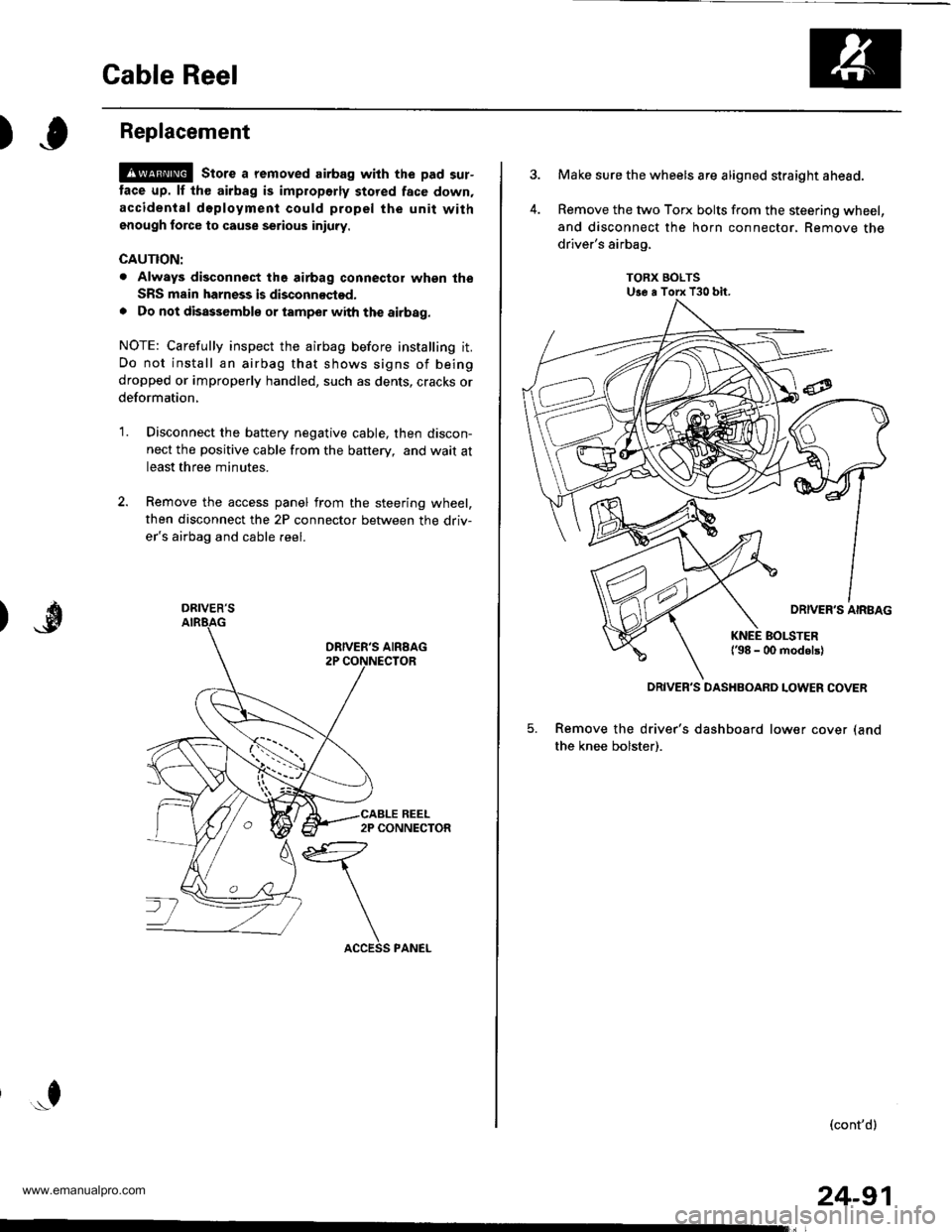

)Replacement

@ stors a removed airbag with the pad sur-

tace up. lf th€ airbag is improperly stored face down,

accidental d6ployment could propel the unit withgnough force to cause serious iniuty.

CAUTION:

. Always disconnect the airbag connector whgn the

SRS msin harness is disconnoctod.

. Do not disassemblo or tamper with the airbag.

NOTE: Carefully inspect the airbag before installing it.

Do not install an airbag that shows signs of being

dropped or improperly handled, such as dents, cracks or

deformation,

'1.Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, and wait at

least three minutes.

Remove the access panel from the steering wheel,

then disconnect the 2P connector between the driv-

er's airbag and cable reel.

*f

DRIVER'S

24-91

Make sure the wheels are aligned straight ahead.

Remove the two Torx bolts from the steering wheel,

and disconnect the horn connector, Remove the

driver's airbag,

TORX BOLTSUse a Torx T30 bit.

5. Remove the driver's dashboard lower cover (and

the knee bolster).

(cont'd)

DRIVER'S DASHBOARD LOWER COVER

www.emanualpro.com