positive terminal HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 204 of 1395

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 274 of 1395

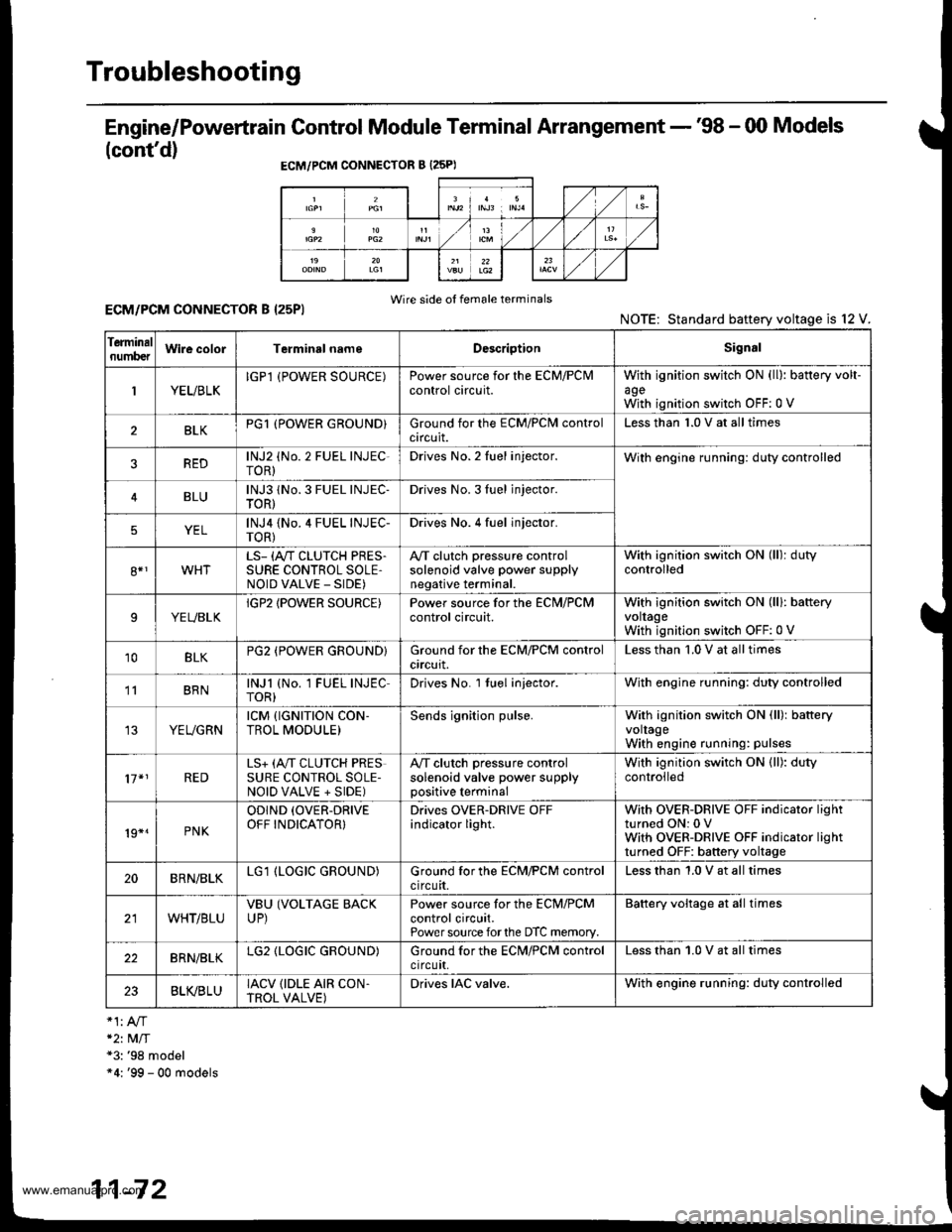

Troubleshooting

Engine/Powertrain Control Module Terminal Arrangement - '98 - 00 Models

(cont'd)

ECM/PCM CONNECTOR B {25PI

Wire side of female terminalsECM/PCM CONNECTOR B I25PI

*2t MlT*3: '98 model"4: '99 - 00 models

NOTE: Standard baftery voltage is l2

Ierminalnumb€tWire colorTerminsl nameDescriptionSignal

1YEUBLKIGPl (POWER SOURCE)Power source for the ECM/PClvlcontrol circuit.withagewith

ignition switch ON (ll): battery volt-

ignition switch OFF:0 V

BLKPG1 (POWER GROUND}Ground for the ECM/PClvl controlcircuit.Less than 1.0 V at all times

REDlNJ2 (No. 2 FUEL INJEC-roR)Drives No. 2 Iuel injector.With engine running: duty controlled

BLUlNJ3 1No. 3 FUEL INJEC-TOR)Drives No. 3Iuel jnjector.

YELlNJ4 {No.4 FUEL INJEC-TOR)Drives No. 4 fuel injector.

8*1WHTLS- (A"/T CLUTCH PRES.SURE CONTROL SOLE,NOID VALVE _ SIDE)

A,/T clutch pressure controlsolenoid valve power supplynegative terminal.

With ignition switch ON (ll): dutycontrolled

9YEUBLKIGP2 IPOWER SOURCE)Power source for the ECN,I/PCMcontrol circuit.With ignition switch ON (lll: bafteryvoltageWith ignition switch OFF:0 V

10BLKPG2 (POWER GROUND}Ground for the ECM/PCM controlcrrcurt.Less than '1.0 V at all times

' BRNlNJl (No. 1 FUEL INJECTOR)Drives No. l tuel injector.With engine running: duty controlled

YEUGRNrcM {rGNrTroN coN-TROL MODULE)Sends ignition pulse.With ignition switch ON (ll): batteryvoltageWith engine running: pulses

17*1REDLS+ (A,,IT CLUTCH PRESSURE CONTROL SOLE-NOID VALVE + SIDE)

A,/T clutch pressure controlsolenoid valve power supplypositive terminal

With ignition switch ON (ll): dutycontrolled

19*.PNK

ODIND (OVER-DRIVE

OFF INDICATOR}Drives OVER-DRIVE OFFindicator light.With OVER-DRIVE OFF indicator lightturned ON: 0 VWith OVER-DRIVE OFF indicator lightturned OFF: battery voltage

20BRN/BLKLG1 (LOGIC GROUND)Ground for the ECM/PCM controlcircuit.Less than 1.0 V at all times

WHT/BLUVBU (VOLTAGE BACKUP)Power source for the ECM/PCMcontrol circuit.Power source forthe DTC memory.

Battery voltage at all times

22BRN/BLKLG2 (LOGIC GROUND)Ground for the ECN4/PCM controlctrcutt,Less than 1.0 V at all times

23BLVBLUIACV {IDLE AIR CON.TROL VALVE)Drives IAC valve.With engine running: duty controlled

11-72

www.emanualpro.com

Page 389 of 1395

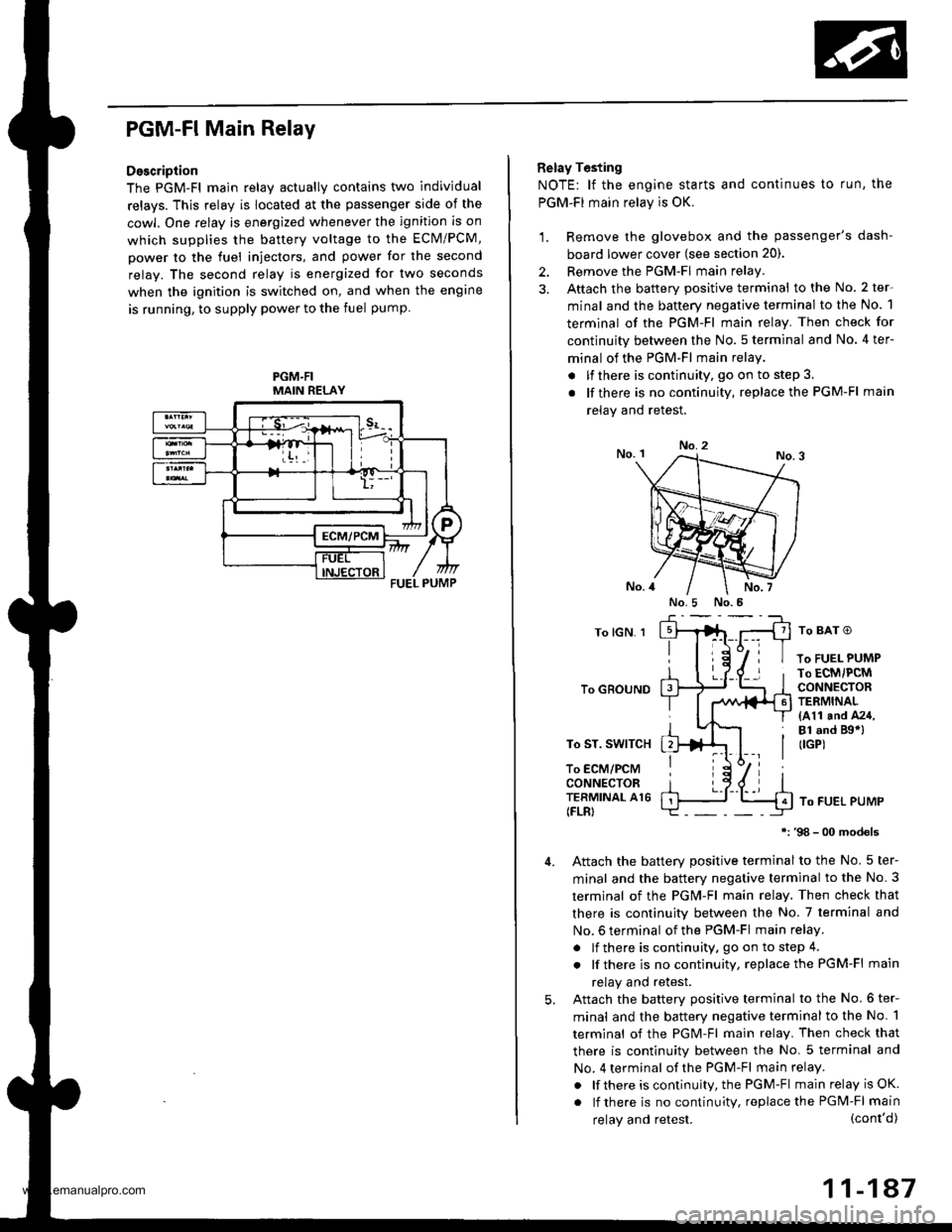

PGM-FI Main Relay

Description

The PGM-Fl main relav actuallv contains two individual

relays. This relay is located at the passenger side of the

cowl. One relay is energized whenever the ignition is on

which supplies the battery voltage to the ECM/PCM,

power to the fuel injectors, and power for the second

relay. The second relay is energized for two seconds

when the ignition is switched on, and when the engine

is running, to supply power to the fuel pump

PGM.FIMAIN RELAY

Belay Testing

NOTE: lf the engine starts and continues to run, the

PGM-FI main relay is OK.

1. Remove the glovebox and the passenger's dash-

board lower cover (see section 20).

2. Remove the PGM-FI main relay

3. Aftach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check for

continuity between the No. 5 terminal and No. 4 ter-

minal of the PGM-FI main relay

. lfthere is continuity, go on to step 3.

. lf there is nocontinuity, replacethe PGM-Fl main

relav and retest.

No.2

To lGN. 1

To GROUND

To ST. SWITCH

To ECM/PCMCONNECTORTERMINAL A16(FLR)

To BAT O

To FUEL PUMPTo ECM/PCMCONNECTORTERMINAL(411 and A24,Bl .nd Bgal(IGP)

To FUEL PUMP

98 - 00 models

Attach the batterv Dositive terminal to the No. 5 ter-

minal and the battery negative terminal to the No. 3

termjnal of the PGM-Fl main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-FI main relay.

. lf there is continuity, go on to step 4.

. lf there is nocontinuity, replacethe PGM-Fl main

relay and retest.

Attach the batterv oositive terminal to the No.6 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check that

there is continuitv between the No. 5 terminal and

No. 4 terminal of the PGM-Fl main relay.

. lf there is continuity, the PGM-Fl main relay is OK.

. lf there is nocontinuity, replacethe PGM-FI main

5.

(cont'd)

11-147

No.5 No.5

relay and retest.

www.emanualpro.com

Page 564 of 1395

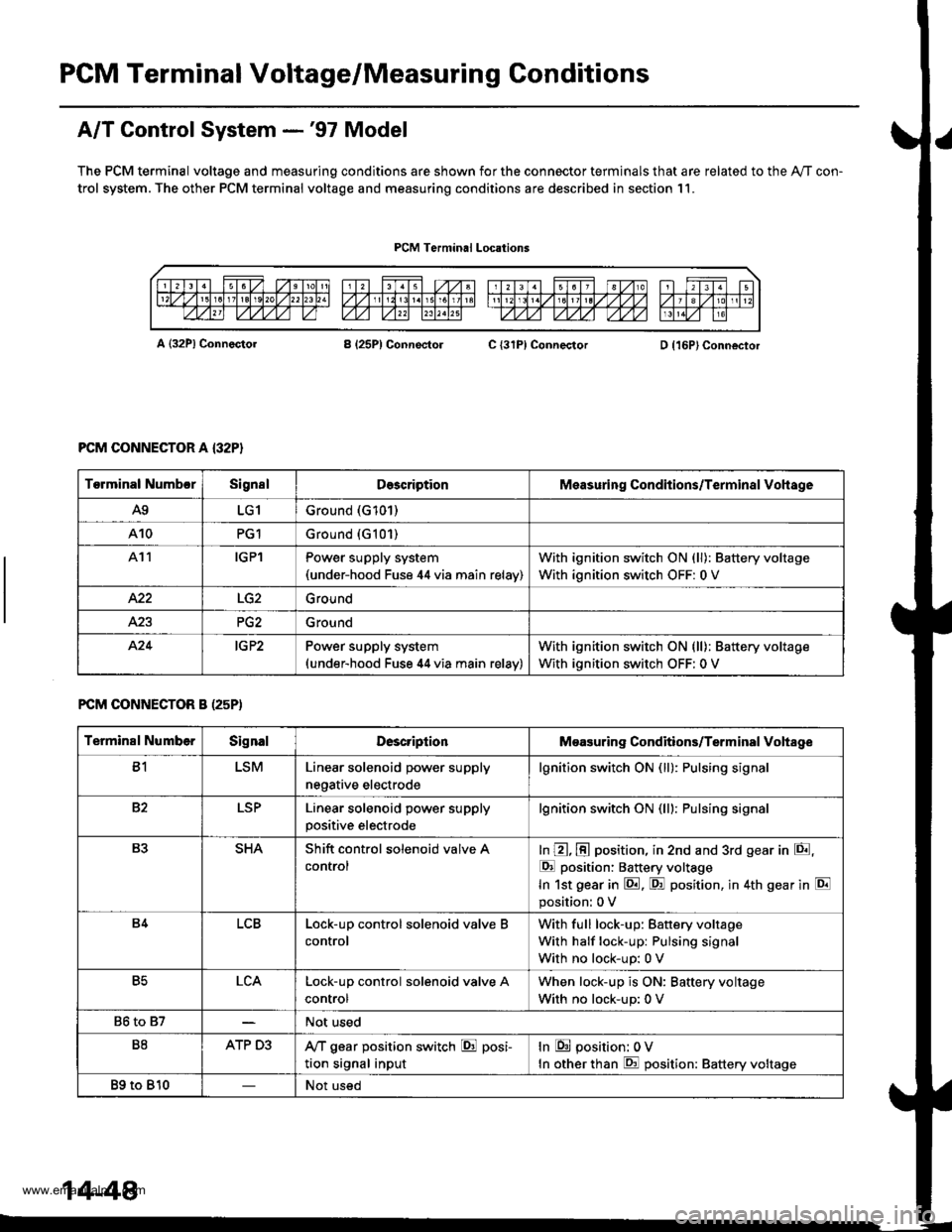

PGM Terminal Voltage/Measuring Conditions

A/T Control System -'97 Model

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the Ay'T con-

trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

PCM Terminal Locations

A {32P} ConnectorB (25P1 ConnectolC {31PI ConnectorD {16P}Connector

PCM CONNECTOR A {32P}

FCM CONNECTOR B (25P)

Torminal NumbcrSignslDescriptionMeasuring Conditions/Terminal Vohage

A9LG1Ground (G101)

A10PG1Ground {G101)

At1IGPlPower supply system(under-hood Fuse 44 via main relav)

With ignition switch ON (ll): Battery voltage

With ignition switch OFF: 0 V

422Ground

Ground

424IG P2Power supply system(under-hood Fuse 44 via main relav)

With ignition switch ON (ll): Battery voltage

With ignition switch OFF: 0 V

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Vohage

B1LSMLinear solenoid power supply

negative electrode

lgnition switch ON (ll): Pulsing signa

82LSPLinear solenoid power supply

positive electrode

lgnition switch ON (lll: Pulsing signa

B3SHAShift control solenoid valve A

control

In @, @ position, in 2nd and 3rd gear in E,

E position: Battery voltage

In 1st gear in E. F! position, in 4th gear in E

position: 0 V

B4LCBLock-up control solenoid valve B

control

With full lock-up: Battery voltage

With half lock-up: Pulsing signal

With no lock-up: 0 V

B5LCALock-up control solenoid valve A

control

When lock-up is ON: Baftery voltage

With no lock-up: 0 V

86 to 87Not used

B8ATP D3,VT gear position switch E posi-

tion signal input

In E position: 0V

In other than E position: Battery voltage

89 to 810Not used

14-48

www.emanualpro.com

Page 570 of 1395

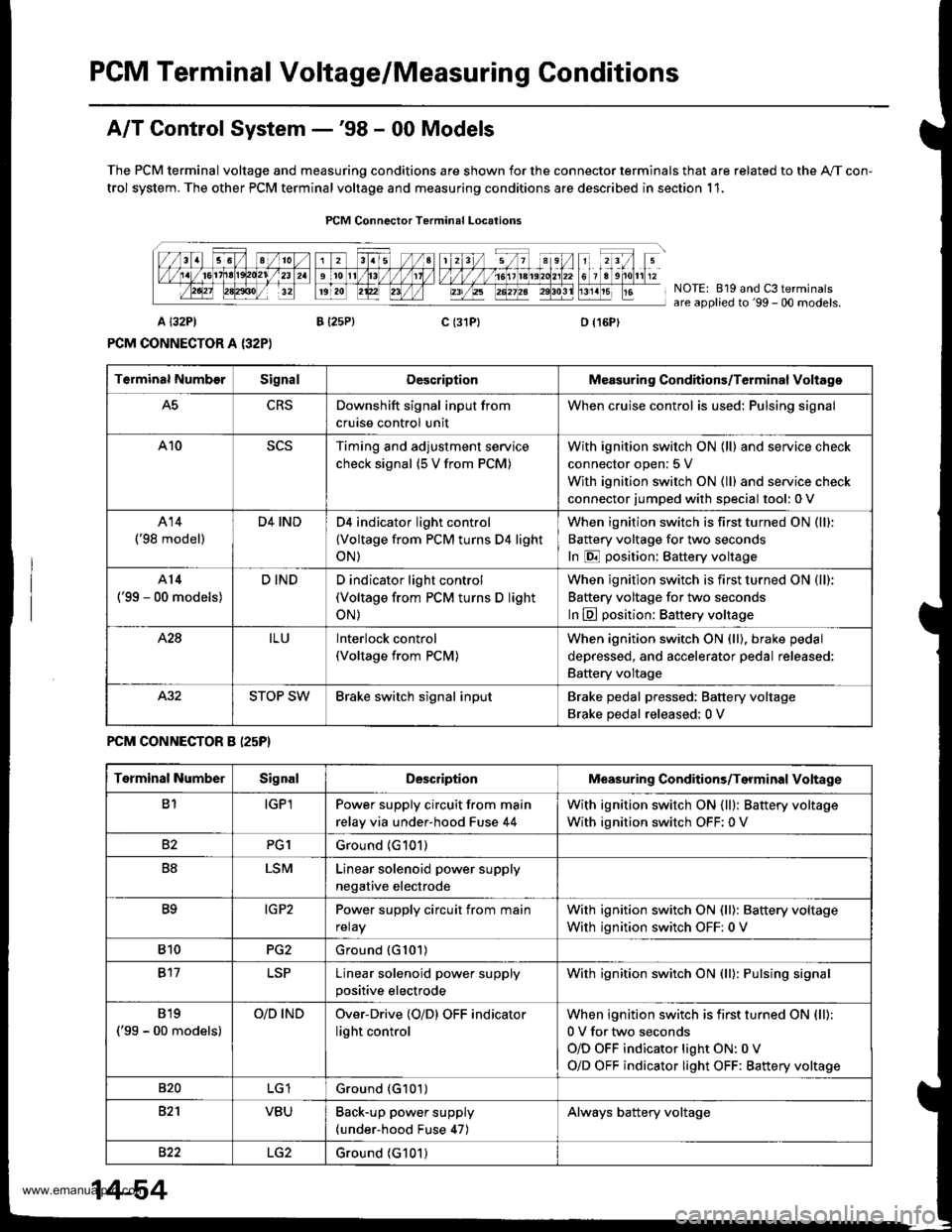

PCM Terminal Voltage/Measuring Conditions

A/T Control System -'98 - 00 Models

The PCM terminal voltage and measuring conditions are shown for the connector terminals that are related to the A"/T con-

trol system. The other PCM terminal voltage and measuring conditions are described in section 11.

FCM Connector Terminal Localions

NOTE: 819 and C3 terminalsare applied to'99 - 00 models.

o (16Pt

T6rminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

A5CRSDownshift signal input from

cruise control unit

When cruise control is used; Pulsing signal

A10scsTiming and adjustment service

check signal (5 V from PCM)

With ignition switch ON (ll) and service check

connector open:5 V

With ignition switch ON (ll) and service check

connector jumped with special tool: 0 V

A14('98 model)

D4 INDD4 indicator light control

{Voltage from PCM turns D4 light

oN)

When ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltage

A14

('99 - 00 models)

D INDD indicator light control(Voltage from PCM turns D light

oN)

When ignition switch is first turned ON (ll):

Baftery voltage for two seconds

ln E position: Battery voltage

428ILUInterlock control(Voltage from PCM)

When ignition switch ON {ll), brake pedal

depressed, and accelerator pedal released:

Battery voltage

A.32STOP SWBrake switch signal inputBrake pedal pressed; Battery voltage

Brake pedal released: 0 V

FCM CONNECTOR B I25P}

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

B1IGPlPower supply circuit from main

relay via under-hood Fuse 44

With ignition switch ON {ll): Battery voltage

With ignition switch OFF: 0 V

82PG1Ground (G101)

B8LSMLinear solenoid power supply

negative electrode

IG P2Power supply circuit from main

relay

With ignition switch ON (ll): Baftery voltage

With ignition switch OFF: 0 V

810PG2Ground (G101)

B17Linear solenoid power supply

positive electrode

With ignition switch ON (ll): Pulsing signal

819

('99 - 00 models)

O/D INDOver-Drive (O/D) OFF indicator

light control

When ignition switch is first turned ON (ll):

0 V for two seconds

O/D OFF indicator light ON:0 V

O/D OFF indicator light OFF: Battery voltage

s20Ground (G101)

B�21VBUBack-up power supply(under-hood Fuse 47)

Always battery voltage

B�22LG2Ground (G101)

14-54

www.emanualpro.com

Page 606 of 1395

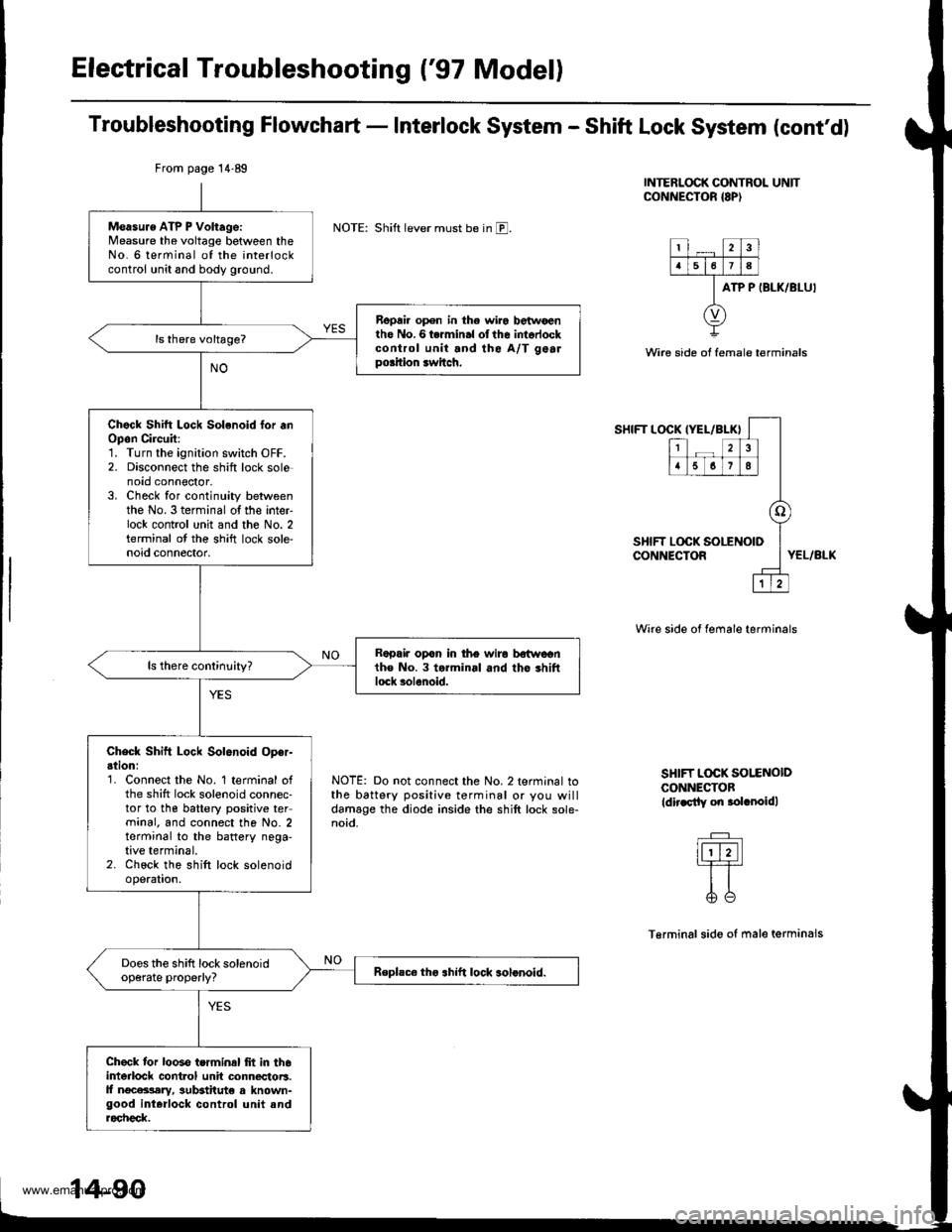

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Interlock System - Shift Lock System (cont'd)

INTERLOCK CONTROL UNITCONNECTOR {8P)

NOTE: Shift lever must be in E.

ATP P IBLK/BLU'

Wire side ot female terminals

SHIFT LOCKIYEL/BLK}

12

5678

o

LOCK SOLENOID

1

SHIFT LOCK !CONNECTORYEL/BLK

NOTE: Do not connect the No. 2 terminal tothe battery positive terminal or you willdamage the diode inside the shift lock sole-noid.

Wire side of female terminals

SHIFT L@K SOI.ENOIDCONNECTOBldir.sily on .olrnoidl

Terminalsido of male terminals

From page 14.89

Measu.e ATP P Voltage:Measure the voltage between theNo. 6 terminal of the interlockcontrol unit and body ground.

Repai. open in the wir6 betwoentho No.6 termin.l olthe intorlockcontrol unit and the A/T gealpo.ition rwitch.

Chock Shitt Lock Solenoid lor .nOpon Circuit:1. Turn the ignition switch OFF.2. Disconnect the shift lock solenoto connoctor.3. Check for continuity betweenthe No. 3 terminal of the inter-lock contrcl unit and the No. 2terminal ot the shift lock sole-noid connector.

Rapair opon in the wiro bstwcentho No. 3 torminal and tho shiftlock solenoid.

Check Shift Lock Solenoid Oper-ation:'1. Connect the No. 1 terminal ofthe shift lock solenoid connec-tor to the battery positive terminal. and connect the No. 2terminal to the battery nega-tive terminal.2. Chock the shift lock solenoidoperation.

Does the shift lock solenoidop€rate properly?Replsc€ tho .hift lock solonoid.

Check tor looso terminal frt in th6interlock cont.ol unit connectoB.ll ngcara,lary, sutEtitut€ a known-good interlock control unit androcheck.

www.emanualpro.com

Page 607 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont HONDA CR-V 1997 RD1-RD3 / 1.G User Guide

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont](/img/13/5778/w960_5778-606.png)

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont'd)

lgnition key cannot be moved

Irom ACC (l) pGition to LOCK (0)

position while Pushing the igni-

tion kev with the shift lever in lllposifio;, and the shift lever but-

ton rcleased.

Check Key Interlock Solenoid

Op€ration:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-

tor to the battery Positive ter

minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole

noid operation A clicking

so!nd sho!ld be heard.

Faulty koy interlock solenoid.

Replace the ignition key cylinder/

steedng lock as36mbly

Does the key interlock

solenoid operate properly?

Check Key Interlock Switch OPer'

adon:1. Connect the No. 5 terminal of

the ignition switch connector

to the battery Positive termi

nal, and connect the No 3 ter

minal to the baftery negative

termrnal,2. Turn the ignition switch to

ACC (l), then push rt.

3. Check the key interlock sole'

noid operation. A clicking

sound should be heard whilepushing the ignition key.

Faulty key inte.lock switch

Replaco the ignition key cylindor/

stoering lock a3r.mblY.

Does the key interlocksolenoid operate ProPerlY?

To page 14 92

14-91

www.emanualpro.com

Page 644 of 1395

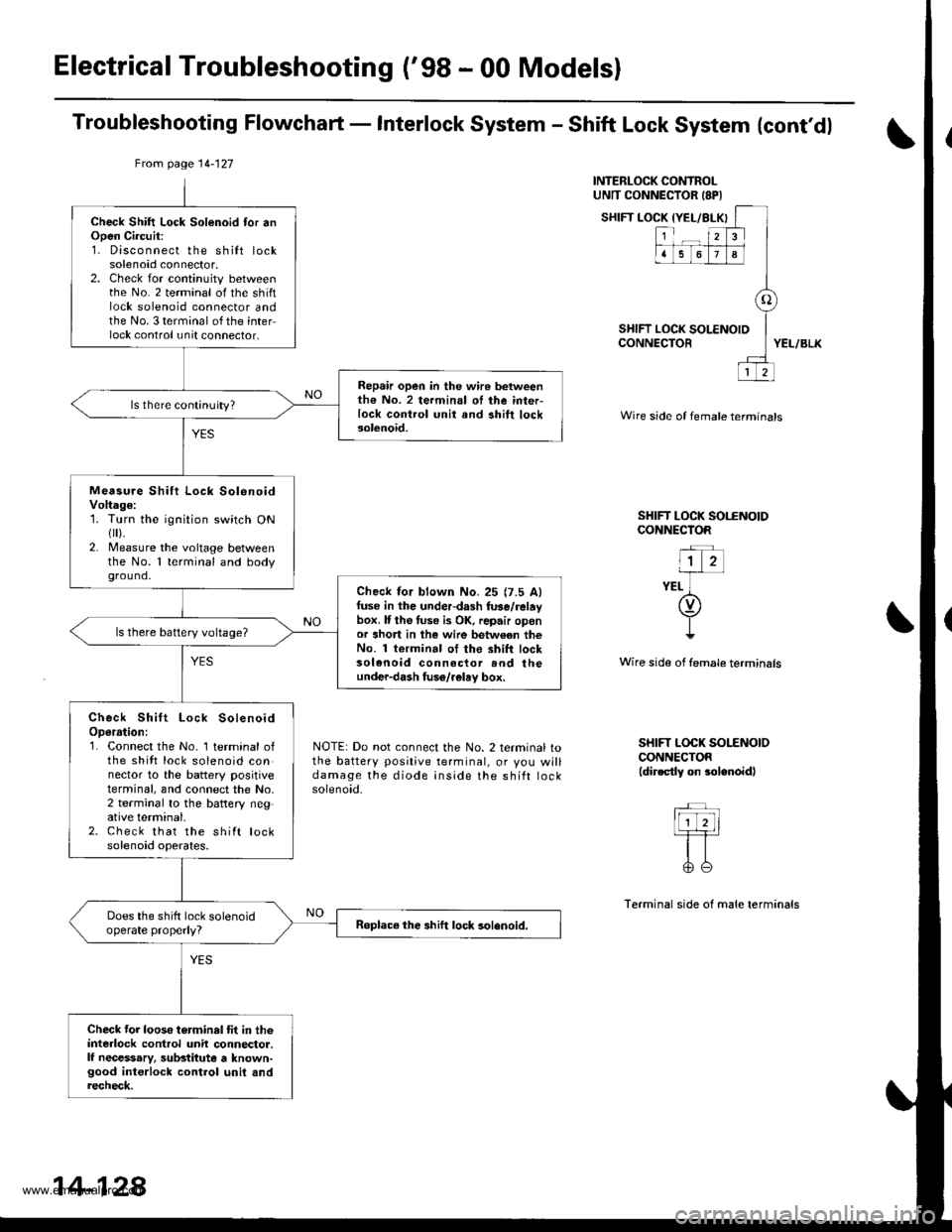

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchaft - Interlock System - Shift Lock System {cont'dl

INTERLOCK CONTROLUNTT CONNECTOR ISPI

SHIFT LOCK IYEL/BLX

SHIFT LOCK tCONNECTOR

{YEL/BLKI

123

1678

o

LOCK SOLENOID

12

YEL/BLK

Wire side of female termtnals

SHIFT LOCK SOI.ENOIDCONNECTOR

"l z-irr-

YEL ](v)

I!

Wire side of female terminsls

NOTE: Do not connect the No. 2 terminal tothe battery positive terminal, or you willdamage the diode inside the shift rocKsolenoid.

SHIFT LOCK SOLENOIOCONNECTOR(dir.ctly on $lenoidl

Terminal side of male terminals

From page 14-127

Check Shift Lock Solenoid tor anOpen Ci.cuit:1. Disconnect the shilt locksolenoid connector,2. Check for continuity betweenthe No. 2 terminal of the shiftlock solenoid connector andthe No. 3 terminal of the interlock control unit connector,

Repair open in the wir6 betweenth€ No. 2 termin.l oI ihe inter-lock control unit and ahift locksolenoid.

ls there continuity?

Measu.e Shift Lock SolenoidVoltage:1. Turn the ignition switch ONflr).2. Measure the voltage betweenthe No. 1 terminal and bodyground.

Check lor blown No.25 {7.5 Alfuse in the underdash fuse/relaybox. It the tuse i3 OK, repair oponor short in lhe wire betw€en theNo. 1 terminal of tho shift locksolenoid connector rnd theunder-dash fuso/r€lay box,

ls there battery voltage?

Check Shift Lock SolenoidOperrtion:1. Connect the No. 1 terminal ofthe shitt lock solenoid connector to the battery positiveterminal, and connect the No,2 terminal to the battery neg,ative terminal.2. Check that the shift locksolenoid operates.

Does the shift lock solenoidoperate properly?Roplace the shift lock solenoid.

Check tor looso torminal tit in th6interlock control unit connector.lf necessary, substitute a known-good int€rlock control unil andrecheck.

14-128

www.emanualpro.com

Page 645 of 1395

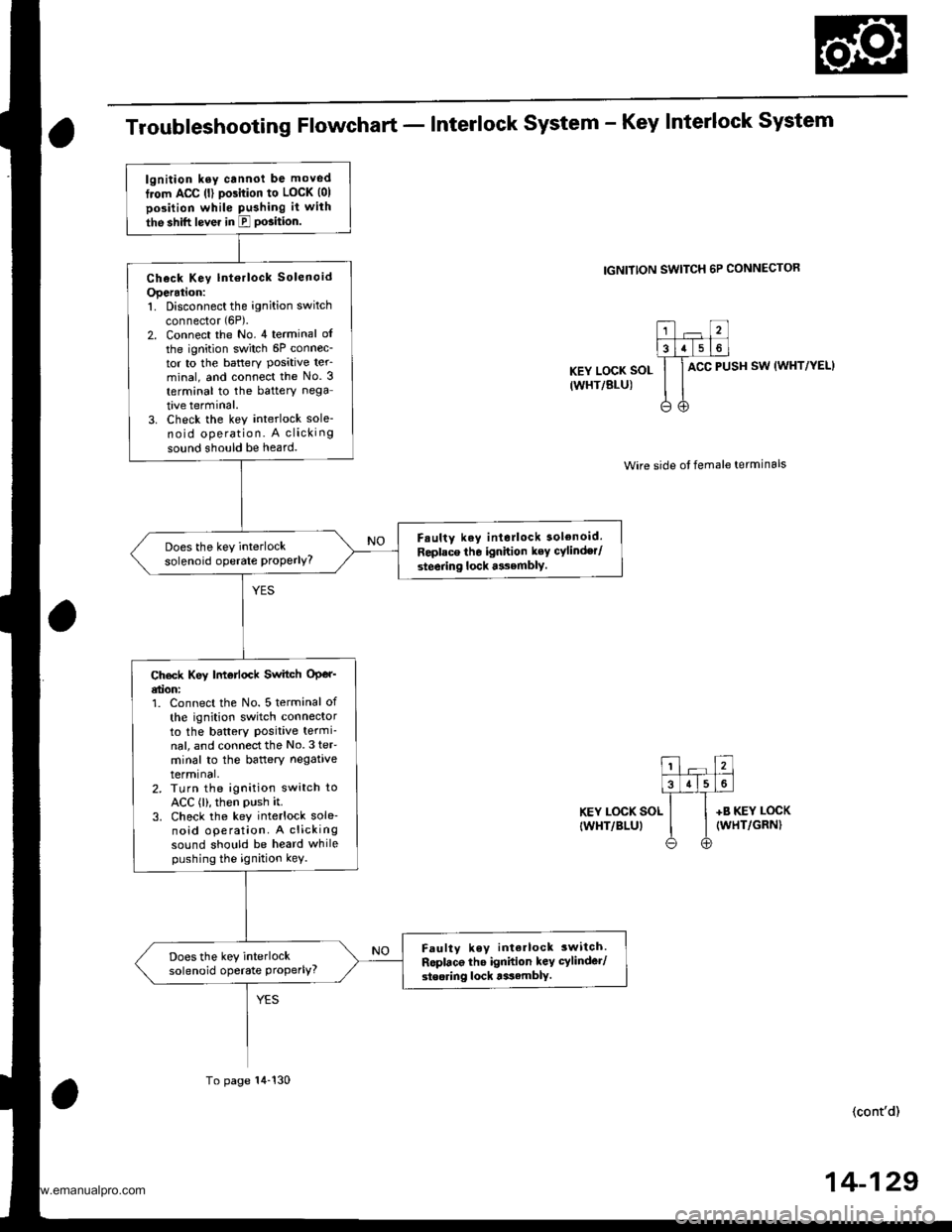

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SWITCH 6P CONNECTOR

KEY LOCK SOL

IWHT/BLU)

ACC PUSH SW (WHT/YEL}

Wire side ot female terminals

KEY LOCK SOL

IWHT/BLUI

+B KEY LOCK(WHT/GRN)

(cont'd)

lgnition ksy cannot be moved

from ACC (l) pGition to LOCK (01

position while Pushing it with

the shift lever in E PGition.

Check Key lntorlock Solenoid

Operation:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-tor to the battery Posative ter_minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole-no id operation. A clicking

sound should be heard.

F.ulty key interlock solenoid.

Replace tho ignition key cylinder/

steering lock asembly.

Does the key interlocksolenoid operate ProPerlY?

Ch€ck Key |motlock Switch OPer'etion:1. Connect the No. 5 terminal of

th€ ignition switch connectorto the battery Positive termi-nal, and connectthe No.3 teF

minal to the baftery negativetermrnal,2. TLrrn the ignition switch toACC (l), then PUsh it.3. Check the key interlock sole-noid operation. A clickingsound should be heard whilepushing the ignition kev.

Faulty key interlock 3witch.

Roplaco the ignidon key cylinder/

steoring lock tssamblY.

Does the key interlocksolenoid operate Properly?

To page 14-130

14-129

www.emanualpro.com

Page 651 of 1395

Lock-up Control Solenoid Valve A/B Assembly

Test

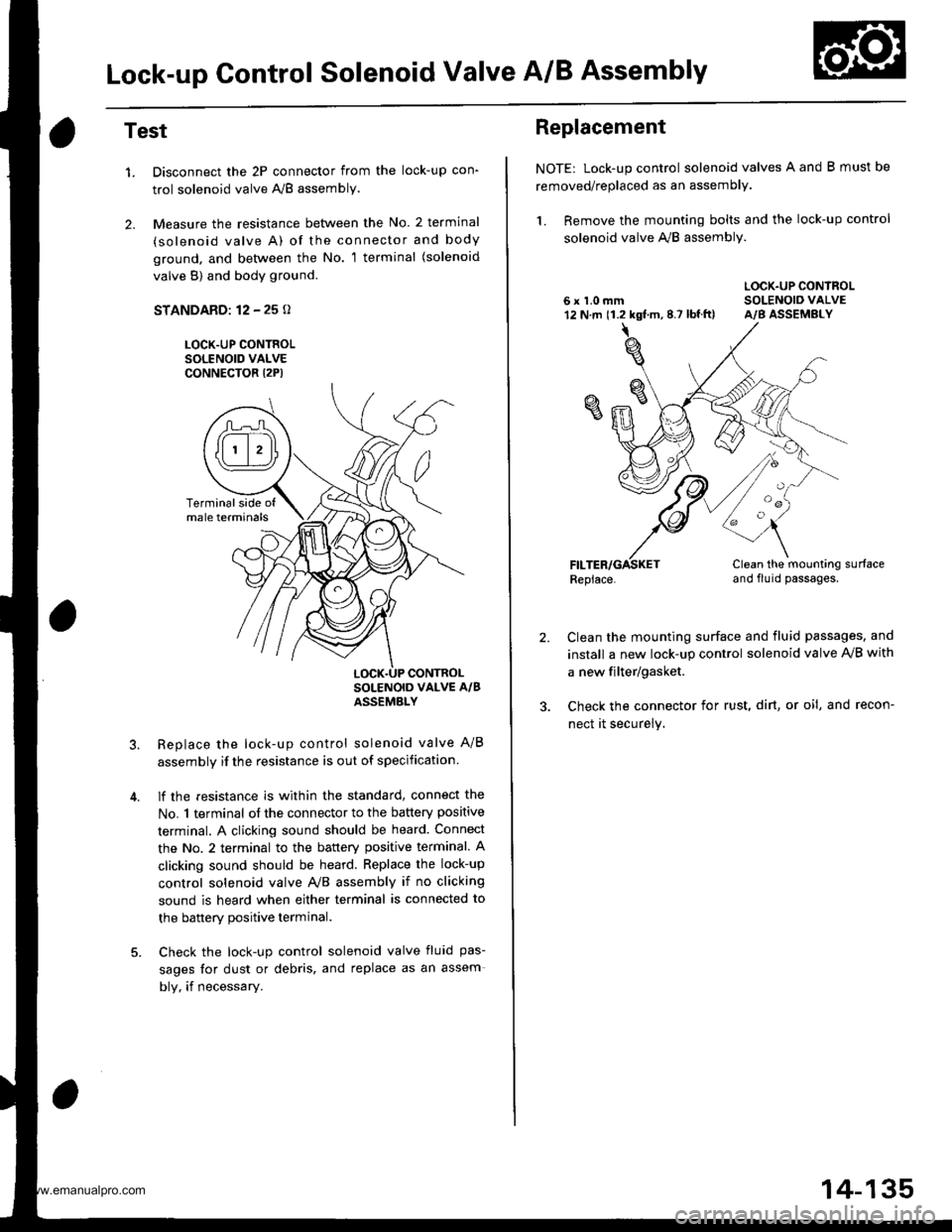

1.

2.

Disconnect the 2P connector from the lock-up con'

trol solenoid valve A'lB assembly.

Measure the resistance between the No. 2 terminal

(solenoid valve A) of the connector and body

ground. and bet\iveen the No. 1 terminal (solenoid

valve B) and body ground.

STANDARD: 12 - 25 o

LOCK-UP CONTROLSOLENOID VALVECONNECTOR I2P)

Replace the lock-up control solenoid valve A/B

assembly if the resistance is out of specification

lf the resistance is within the standard, connect the

No. 1 terminal of the connector to the battery positive

terminal. A clicking sound should be heard Connect

the No. 2 terminal to the battery positive terminal. A

clicking sound should be heard. Replace the lock-up

control solenoid valve Ay'B assembly if no clicking

sound is heard when either terminal is connected to

the banerv Dositive terminal.

Check the lock-up control solenoid valve fluid pas-

sages for dust or debris, and replace as an assem

bly, if necessary.

Terminalside ofmale terminals

LOCK.UP CONTROL

Replacement

NOTE: Lock-up control solenoid valves A and B must be

removed/replaced as an assembly.

1. Remove the mounting bolts and the lock-up control

solenoid valve A,,/B assembly.

LOCK.UP CONTROL6 x 1.0 mm SOLENOIO VALVE12 N.m 11.2 kgf.m,8.7 lbf.ft) A/B ASSEMBLY

Replace.Clean the mounting surfaceand flu id passages.

2.Clean the mounting surface and fluid passages, and

install a new lock-up control solenoid valve IVB with

a new filter/gasket.

Check the connector for rust, dirt, or oi!, and recon-

nect it securely.

oa

14-135

www.emanualpro.com