D connector HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 661 of 1395

1?

4678

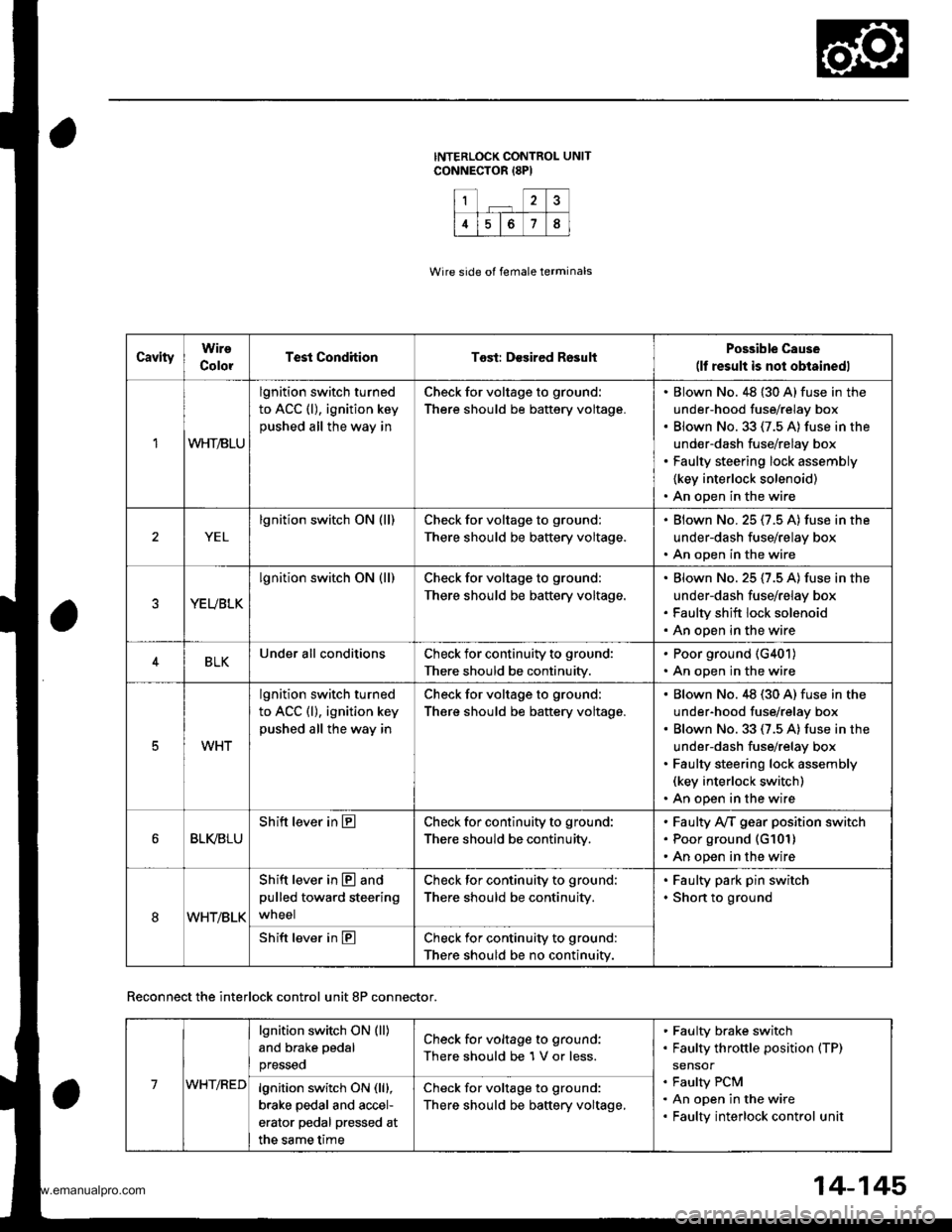

CavityWire

ColorTest CondhionTost: Desired RosultPossible Cause(lf result is not obtainedl

1WHT/BLU

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 {30 A} fuse in the

under-hood fuse/relay box

Blown No.33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly

{key interlock solenoid)

An open in the wire

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box

An open in the wire

YEUBLK

lgnition switch ON (ll)Check for voltage to ground:

There should be baftery voltage.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An open in the wire

4BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401)

. An open in the wire

5WHT

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No.48 (30 A) fuse in the

under-hood fuse/relay box

Blown No. 33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly(key interlock switch)

An open in the wire

BLI(BLU

Shift lever in ECheck for continuity to ground:

There should be continuity,

Faulty Ay'T gear position switch

Poor ground (G101)

An open in the wire

8WHT/BLK

Shift lever in @ and

pulled toward steering

wneel

Check for continuity to ground:

There should be continuity.

Faulty park pin switch

Shon to ground

Shift lever in ECheck for continuity to ground:

There should be no continuity.

Wire side of female terminals

Reconnect the interlock control unit 8P connector.

14-145

7WHT/RED

lgnition switch ON (ll)

and brake pedal

presseo

Check for voltage to ground:

There should be 1 V or less.

Faulty brake switch

Faulty throttle position (TP)

sensor

Faulty PCM

An open in the wire

Faulty interlock control unit

lgnition switch ON (lll,

brake pedal and accel-

erator pedal pressed at

the same time

Check for voltage to ground:

There should be baftery voltage,

www.emanualpro.com

Page 662 of 1395

lnterlock System

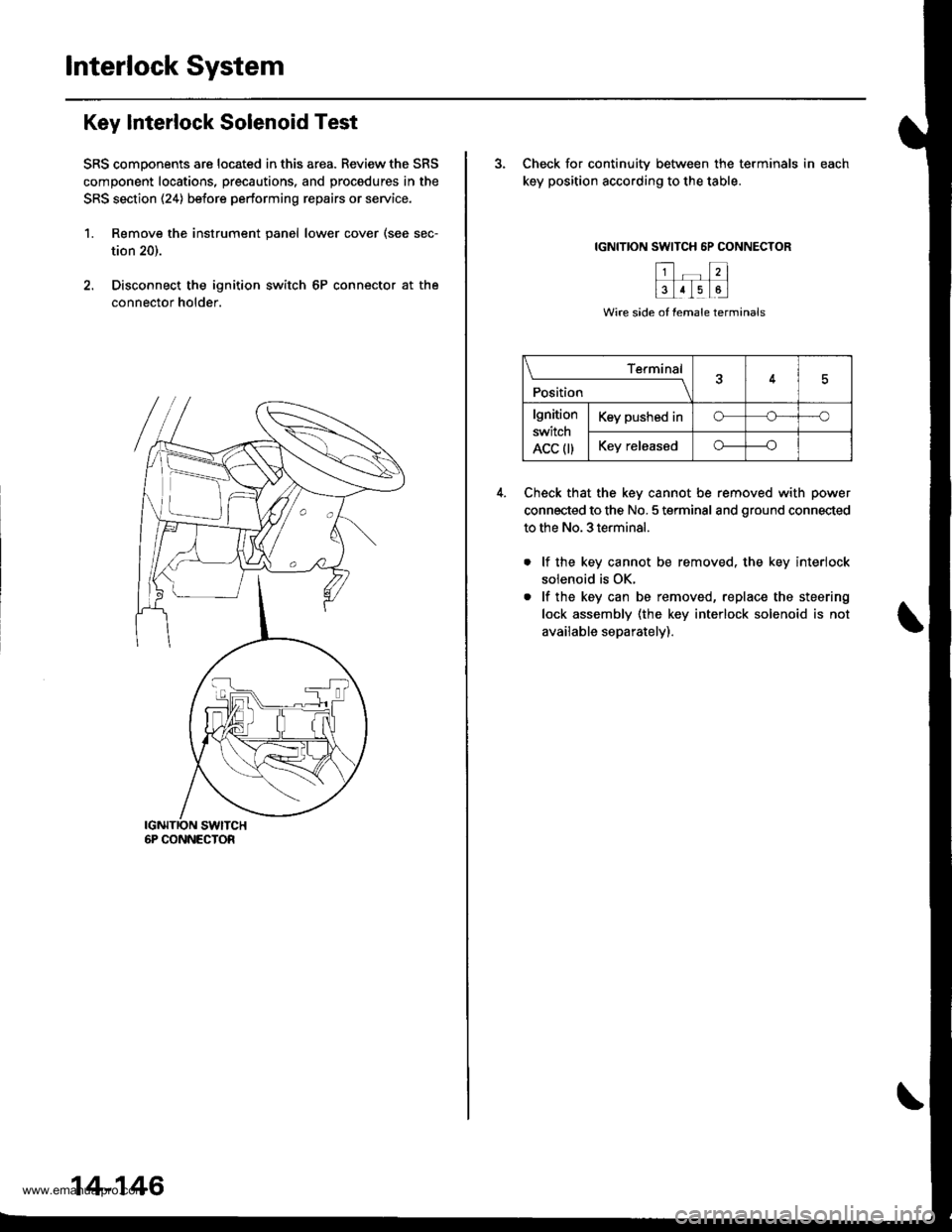

Key Interlock Solenoid Test

SRS comoonents are located in this area. Review the SRS

component locations, precautions. and procedures in the

SRS section (24) before pertorming repairs or service.

1. Remove the instrument panel lower cover (see sec-

tion 20).

2. Disconnect the ignition switch 6P connector at the

connector holder.

6P CONNECTOR

14-146

3. Check for continuitv between the terminals in each

key position according to the table.

IGNITION SWITCH 6P CONNECTOR

Check that the key cannot be removed with power

connected to the No. 5 terminal and ground connected

to the No. 3 terminal.

lf the key cannot be removed. the key interiock

solenoid is OK.

lf the key can be removed, replace the steering

lock assembly (the key interlock solenoid is not

available separately).

\____________r{r4

Position

lgnition

switch

ACC 0)

Key pushed ino---'o

Key releasedo----o

www.emanualpro.com

Page 663 of 1395

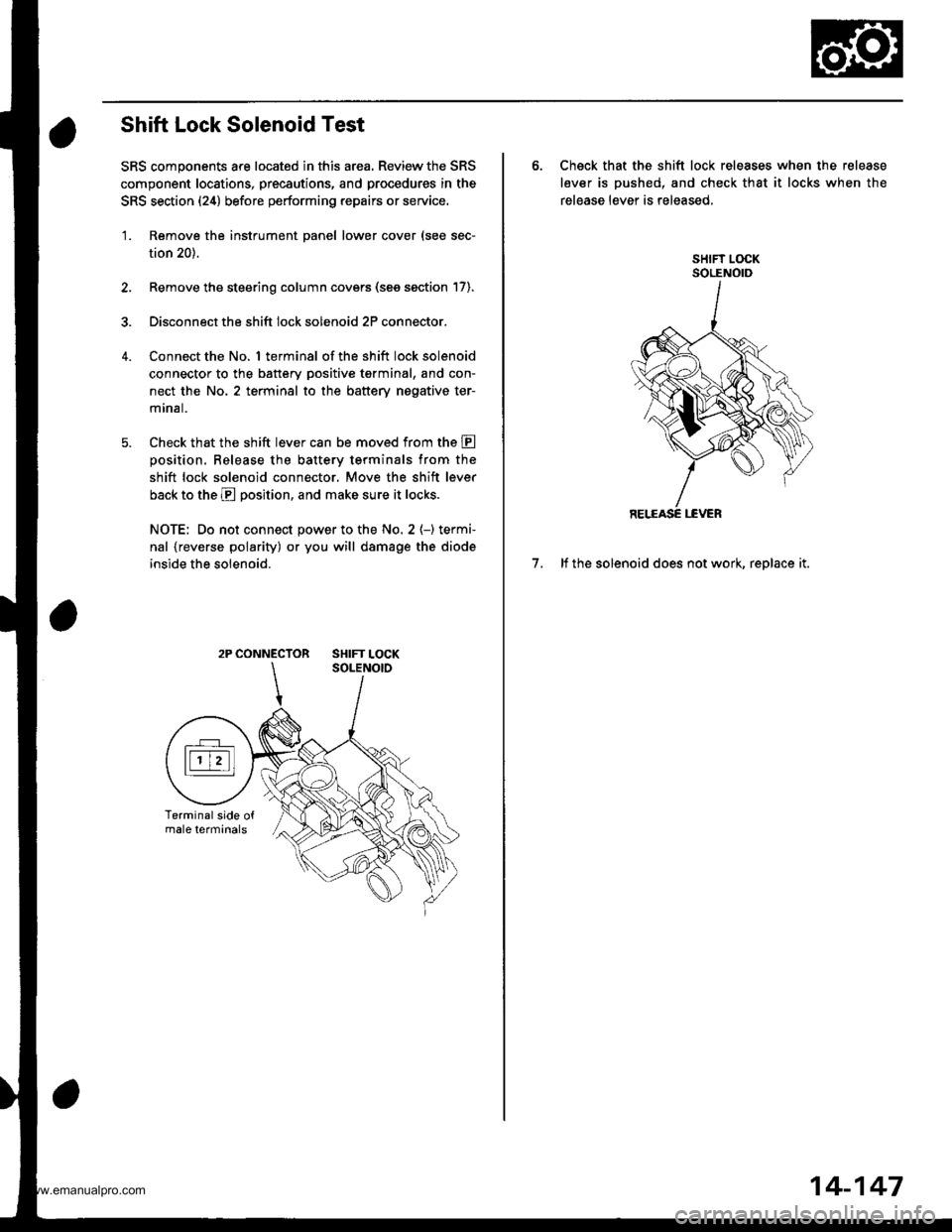

Shift Lock Solenoid Test

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service,

'1. Remove the instrument panel lower cover (see sec-

tion 20).

2. Remove the steering column covers (see section 17).

3. Disconnect the shift lock solenoid 2P connector.

Connect the No. 1 terminal of the shift lock solenoid

connector to the battery positive tgrminal, and con-

nect the No. 2 terminal to the battery nogative ter-

mrnal.

Check that the shift lever can be moved from the E

oosition. Release the batterv terminals from the

shift lock solenoid connector. Move the shift lever

back to the E position, and make sure it locks.

NOTE: Do not connect power to the No. 2 (-) termi-

nal {reverse polarity) or you will damage the diode

inside the solenoid.

2P CONNECTOR SHIFT LOCK

6. Check that the shift lock releases when the release

lever is pushed, and check that it locks when the

release lever is released,

7. lf the solenoid does not work, replace it.

14-147

www.emanualpro.com

Page 664 of 1395

Interlock System

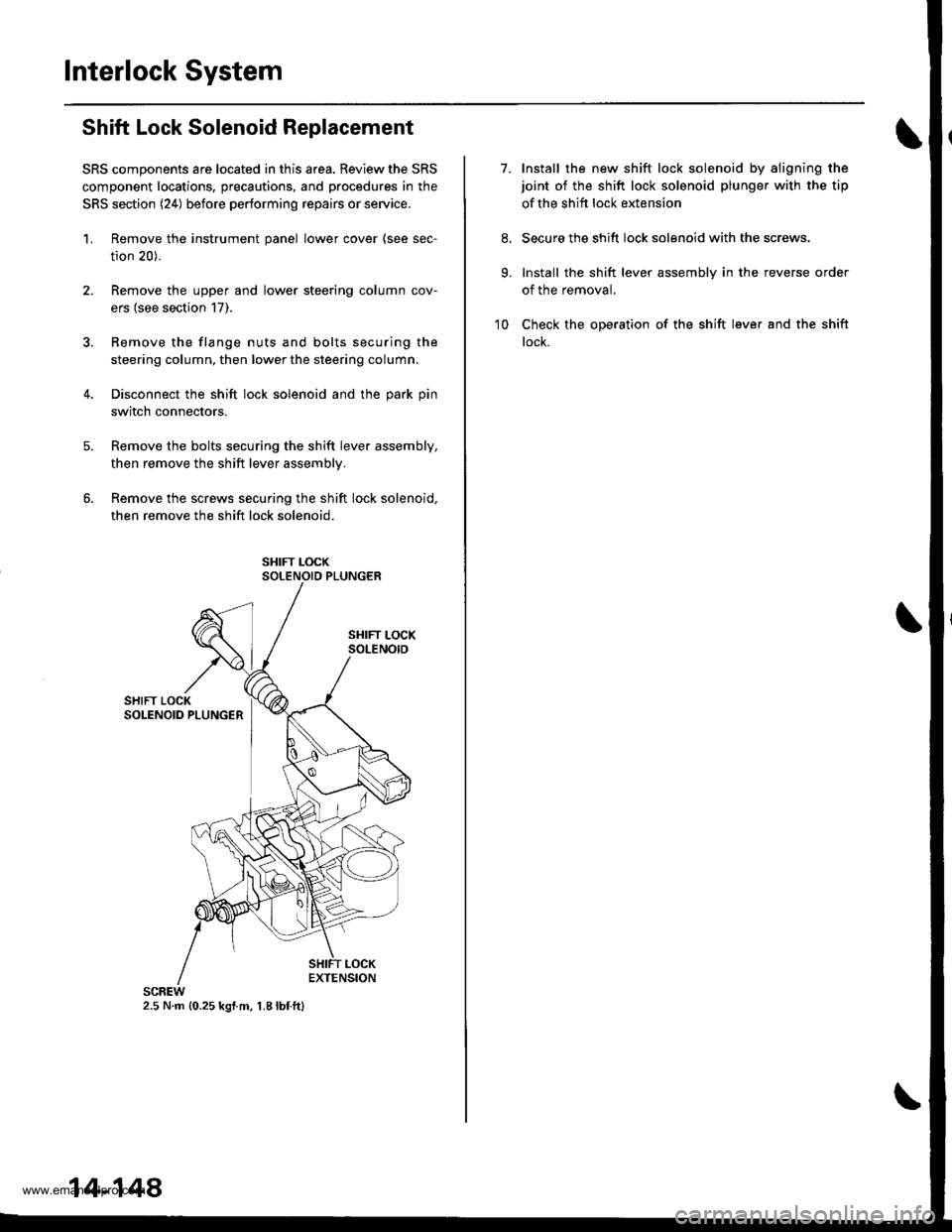

Shift Lock Solenoid Replacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (24) before performing repairs or service.

'L Remove the instrument panel lower cover (see sec-

tion 20).

2. Remove the upper and lower steering column cov-

ers (see section 17).

3. Bemove the flange nuts and bolts securing the

steering column, then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin

switch connectors.

Remove the bolts securing the shift lever assembly,

then remove the shift lever assemblv.

Remove the screws securing the shift lock solenoid,

then remove the shift lock solenoid.

2.5 N.m {0.25 kgl.m, 1.8lbf.ft}

14-148

7.Install the new shift lock solenoid by aligning the

joint of the shift lock solenoid plunger with the tip

of the shift lock extension

Secure the shift lock solenoid with the screws,

Install the shift lever assembly in the reverse order

of the removal.

Check the operation of the shift lever and the shift

lock.

9.

10

www.emanualpro.com

Page 665 of 1395

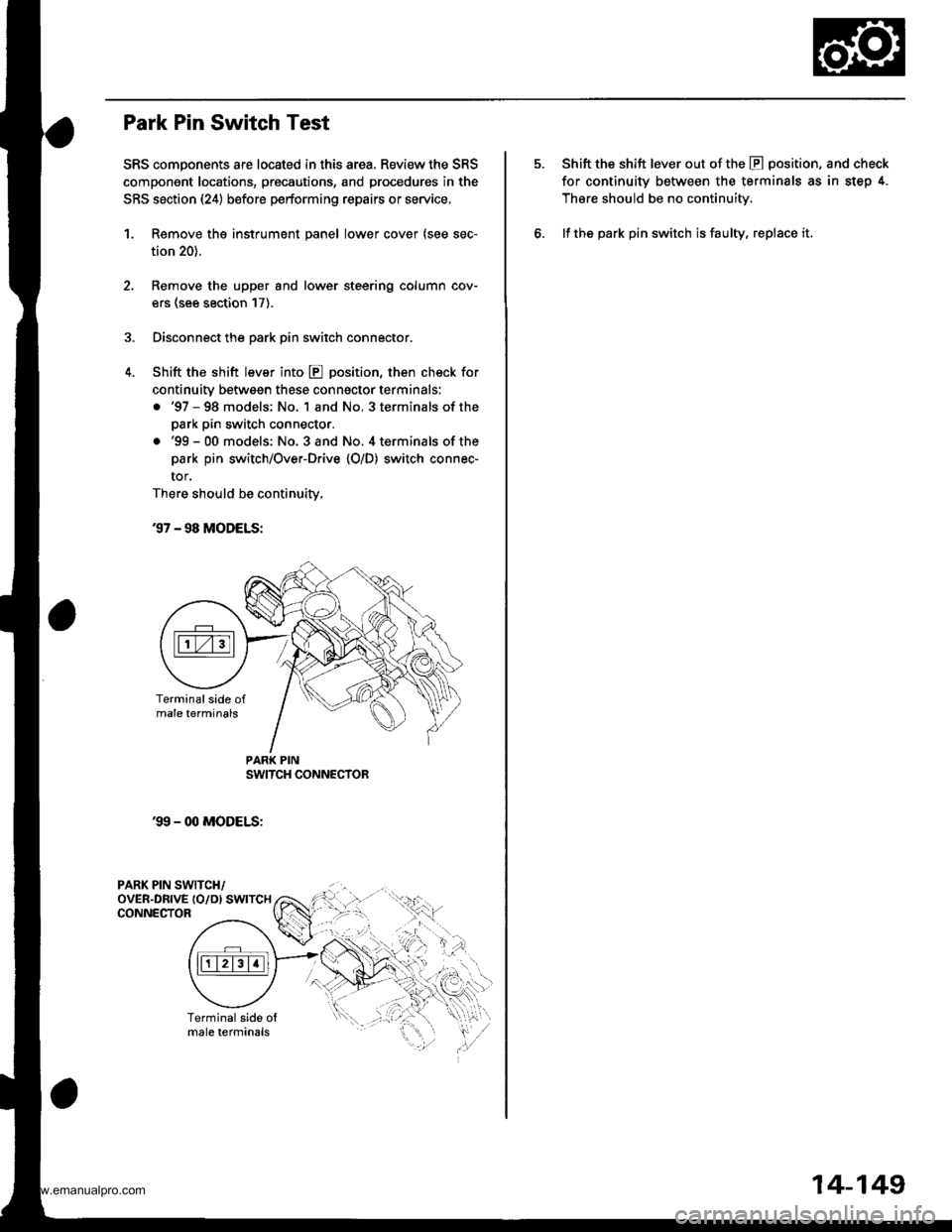

Park Pin Switch Test

SRS components are located in this area. Review the SRS

compongnt locations, precautions, and procedures in the

SRS section (24) before performing repairs or service,

1. Remove tho instrument panel lower cover (see sec-

tion 20).

Remove the upper and lower steering column cov-

ers (see section 17).

Disconnect the park pin switch connector.

Shift the shift lever into E position, then check for

continuity betwsgn these conngctor terminals:

. '97 - 98 models; No. 1 and No, 3 terminals of the

park pin switch connector.

.'99-00 models: No. 3and No. 4terminalsof the

park pin switch/Over-Drive {O/D) switch connec-

tor.

There should be continuity,

37 - 98 MODELS:

'99 - 00 MODELS:

PARK PIN SWITCH/oVER-DRTVE {O/D) SWTTCHCONNECTOR

PAR( PIN

.qI

Shift the shift lever out of the E position, and check

for continuity between the terminals as in step 4.

Thsre should be no continuity.

lf the park pin switch is faulty, replace it.

14-149

www.emanualpro.com

Page 666 of 1395

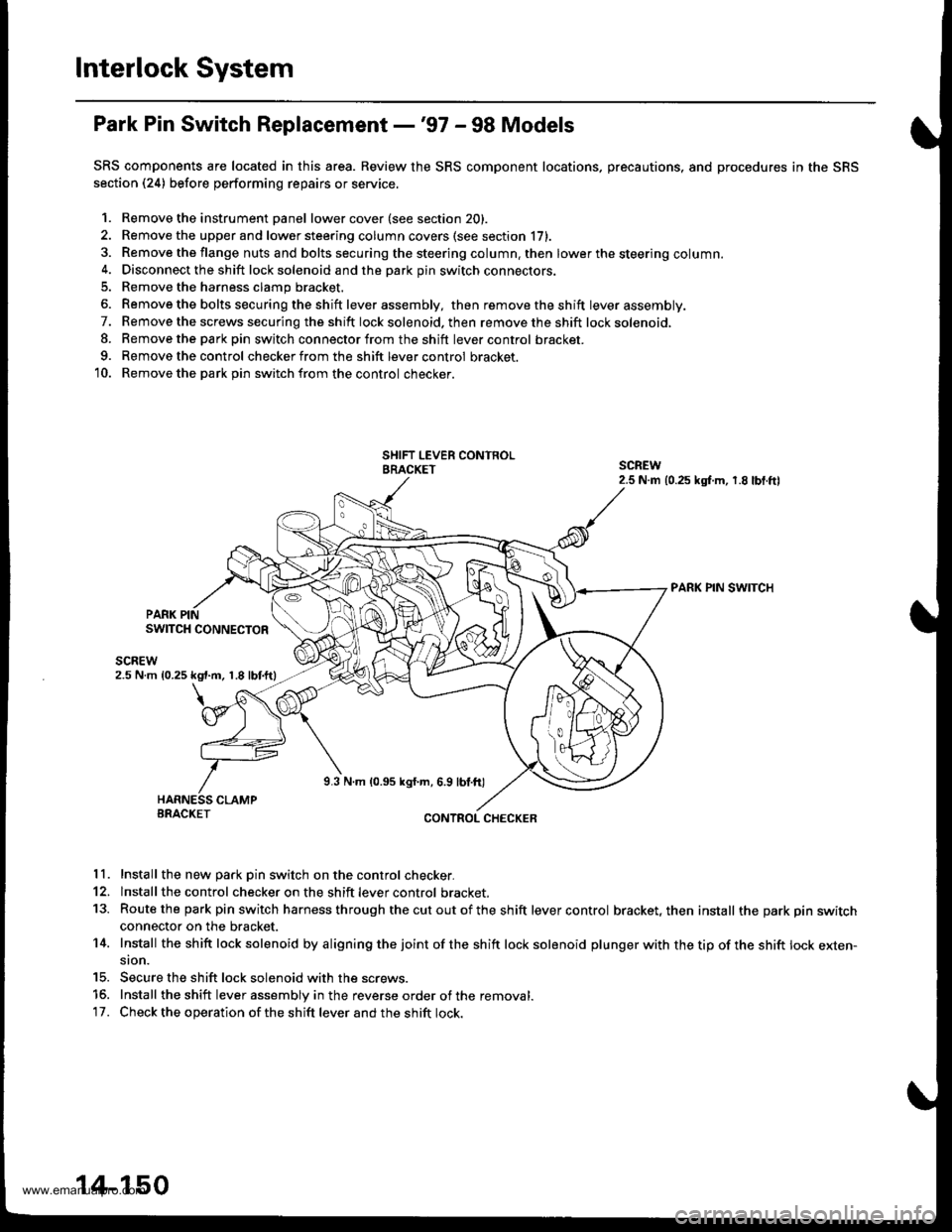

Interlock System

Park Pin Switch Replacement -'97 - 98 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

1. Remove the instrument Danel lower cover (see section 20).

2. Remove the upper and lower steering column covers (see section li,.

3. Remove the flange nuts and bolts securing the steering column. then lower the steering column.4. Disconnect the shift lock solenoid and the park pin switch connectors.

5. Remove the harness clamp bracket.

6. Remove the bolts secu ring the shift lever assembly, then removetheshift lever assembly.

7. Remove the screws securing the shift lock solenoid. then remove the shift lock solenoid,

8. Remove the parkpin switch connector from the shift lever control bracket.

9. Remove the control checker from the shift lever control bracket.

10. Remove the park Din switch from the control checker.

PARK PIN SWITCH

PARK PINSWITCH CONNECTOR

scnEw2.5 N m 10.25 kgt.m, 1.8 lbtftl

9.3 N.m 10.95 kgf.m, 6.9 lbl.ft)

BRACKETCONTROL CHECKER

11. Install the new Dark Din switch on the control checker.

12. lnstall the control checker on the shift lever control bracket.

13. Routethe park pin switch harness through thecutoutofthe shift lever control bracket, then install the park pin switchconnector on the bracket.

14. Install the sh ift lock solenoid by a ligning the joint of the sh ift lock solenoid plu nger with the tip of the shift lock exten-sion.

15. Secure the shift lock solenoid with the screws.

15. Install the shift lever assembly in the reverse order of the removal.'17. Check the operation of the shift lever and the shift lock.

14-150

www.emanualpro.com

Page 667 of 1395

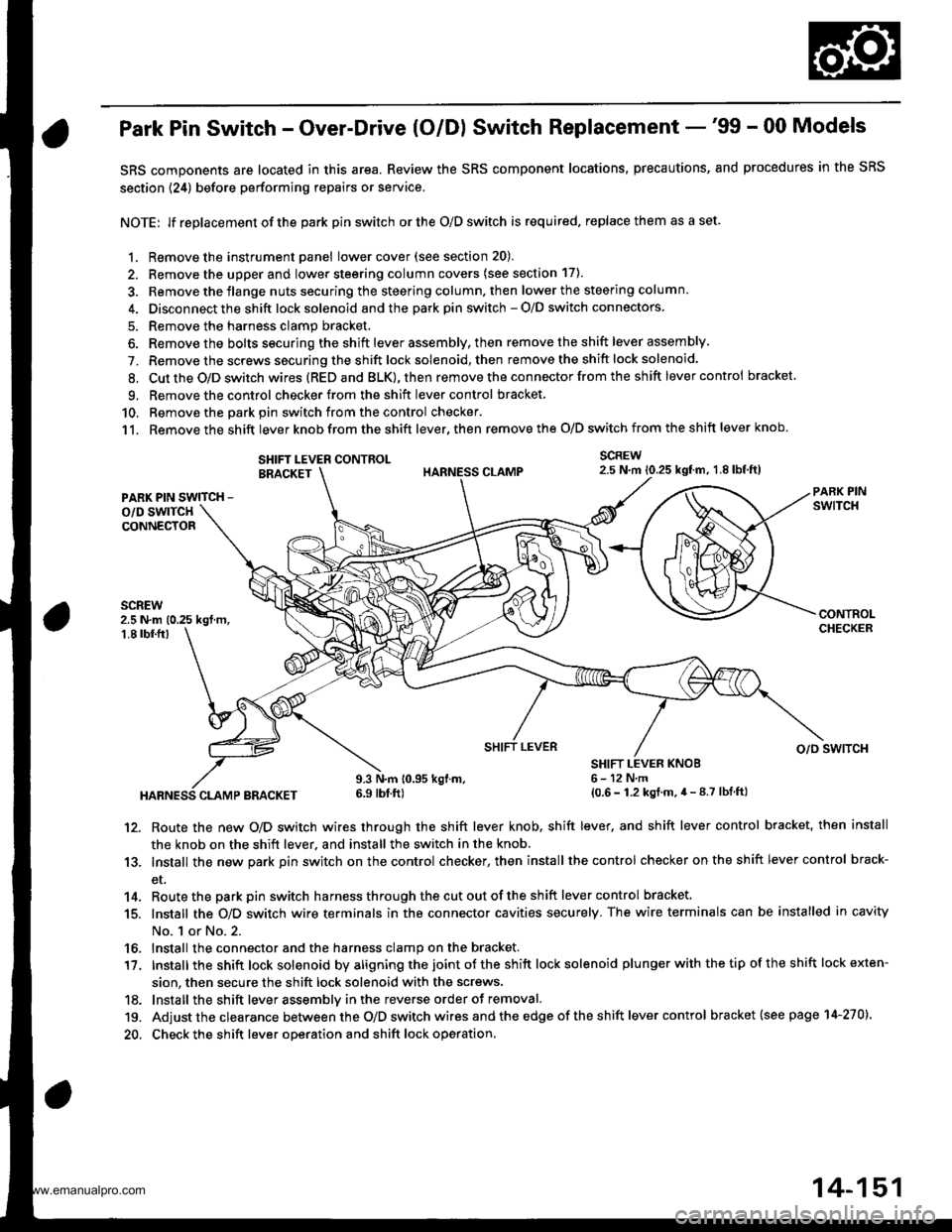

Park Pin Switch - Over-Drive (O/Dl Switch Replacement -'99 - 00 Models

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24) before performing repairs or service.

NOTE: lf replacement of the park pin switch or the O/D switch is required. replace them as a set.

1. Remove the instrument panel lowercover(see section 20).

2. Remove the upper and lower steering column covers (see section 17).

3. Remove the flange nuts securing the steering column. then lower the steering column.

4. Disconnect the shift lock solenoid and the park pin switch - O/D switch connectors

5. Remove the harness clamp bracket.

6. Remove the bolts securing the shift lever assembly, then remove the shift lever assembly.

7. Remove the screws securing the shift lock solenoid, then remove the shift lock solenoid.

8. Cut the O/D switch wires (REDand BLK),then remove the con nector from the shift lever control bracket

9. Remove the control checker from theshift lever control bracket

10. Remove the oark oin switch from the control checker.

11. Remove the shift lever knob from the shift lever, then remove the O/D switch from the shift lever knob.

SCREW2.5 N.m 10.25 kgtm, 1.8lbf,ft)SHIFT LEVER CONTROLBRACKET

PARK PIN SWITCH -

o/D swlTcHCONNECTOR

2.5 N.m (0.25 kgt m,1.8 tbf.fr)

HABNESS CLAMP BRACKET

9.3 N.m 10.95 kgl.m.6.9 tbf ft)

SHIFT LEVER KNOB6-12N,m{0.6 - 1.2 kgt.m.4 - 8.7 lbf ftl

SHIFT LEVERo/o swlTcH

12. Route the new O/D switch wires through the shift lever knob, shift lever, and shift lever control bracket, then install

the knob on the shift lever, and install the switch in the knob.

13. Install the new park pin switch on the control checker, then install the control checker on the shift lever control brack-

et.

14. Routethe parkpin switch harnessthroughthecutoutoftheshift lever control bracket.

15. Install the O/D switch wire terminals in the connector cavities securely. The wire terminals can be installed in cavity

No. 1 or No.2.

16, Install the connector and the harness clamp on the bracket.

17. tnstall the shift lock solenoid by aligning the joint ot the shift lock solenoid plu nger with the tip of the shift lock exten-

sion, then secure the shift lock solenoid with the screws,

18. lnstall the shift lever assemblv inthe reverse order of removal.

19. Adjust the clearance between the O/D switch wires and the edge of the sh ift lever control bracket (see page 14-270).

20. Check the shift lever operation and shift lock operation.

14-151

www.emanualpro.com

Page 673 of 1395

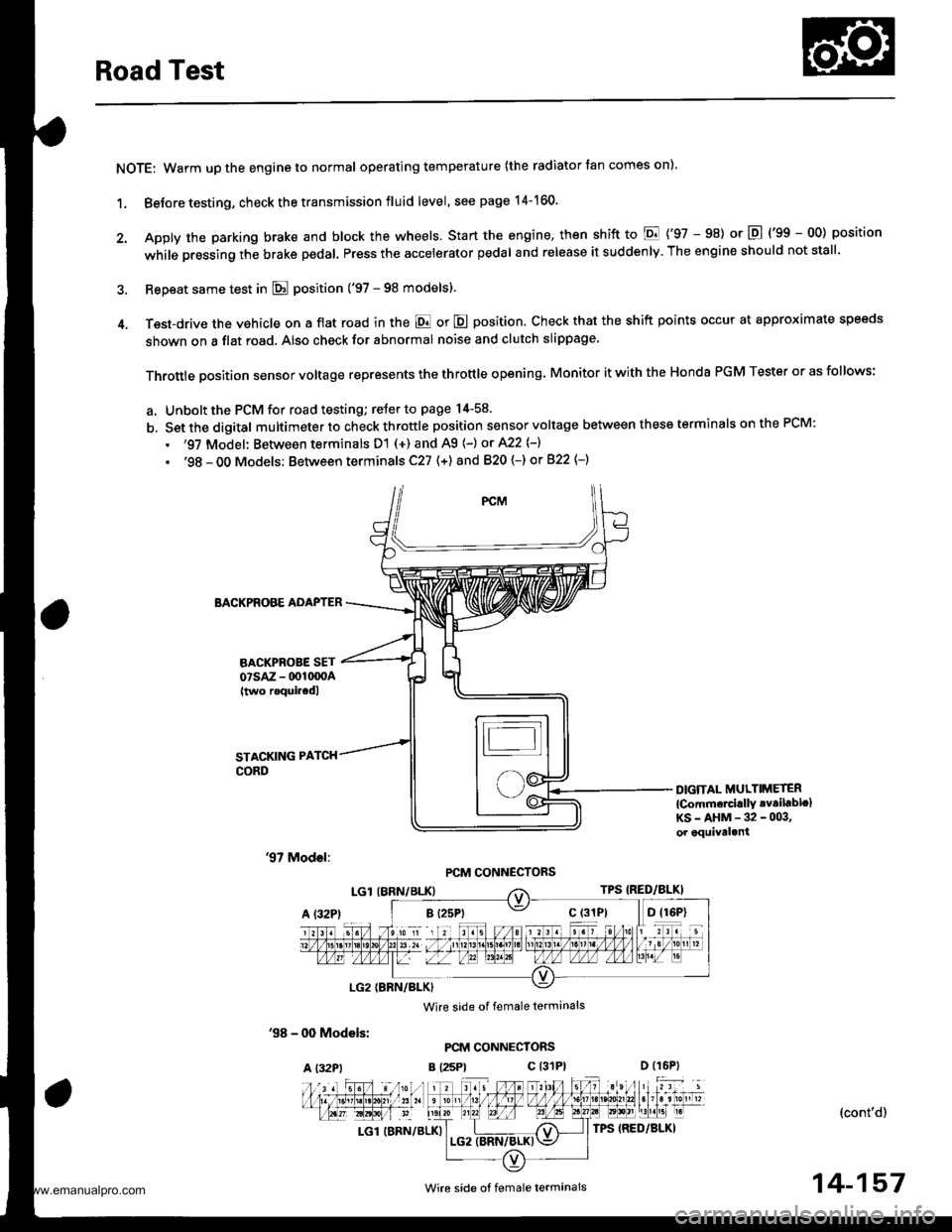

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator tan comes on).

1. Before testing, check the transmission fluid level, see page 14-160.

2. Apply the parking brake and block the wheels. start the engine, then shift to E {'97 - 98) or E {'gg - 00) position

while pressing the brake pedal. Press the accelerator pedal and release it suddenly. The engine should not stall.

3. Repeat same test in E position ('97 - 98 models).

4. Test-drive the vehicle on a flat road in the E or E position. Check that the shift points occur at approximate speeds

shown on a flat road. Also check for abnormal noise and clutch slippage.

Throttle position sensor voltage represents the throttle opening. Monitor it with the Honda PGM Tester or as follows:

a. Unbolt the PCM for road testing; reJer to page 14-58.

b. Set the digital multimeter to check throttle position sensor voltage between these terminals on the PCM:

. '97 Model: Between terminals D'! (+) and A9 (-) or A22 {-}

. '98 - OO Models; Between terminals C27 (+) and 820 (-) or 822 {-)

BACKPROBE ADAPTER

BACKPROBE SETorsAz - 001moA(two roquircdl

STACKING PATCH

CORD

DIGiTAL MULTIMETER

{Comm€rcirllY .vailablc}KS-AHM-32-003,or equival.nt

'97 Model:PCM CONNECTORS

'98 - 0O Models:

A l32Pt

Wire side of female terminals

PCM CONNECTORS

B {25Pt c l31P}

(cont'd)

LGl (BRN/BLK)

'. //B 1 l'o ti , jl. to a 2r / / 11111t1.t nait la t1 t213tr / t6t, tl / / / / 1 3 / 10n v

t-'a:IM-&E -Llfiffi-fl)\"".'E

Wire side ot female termanals14-157

www.emanualpro.com

Page 681 of 1395

Transfer Assembly

Removal

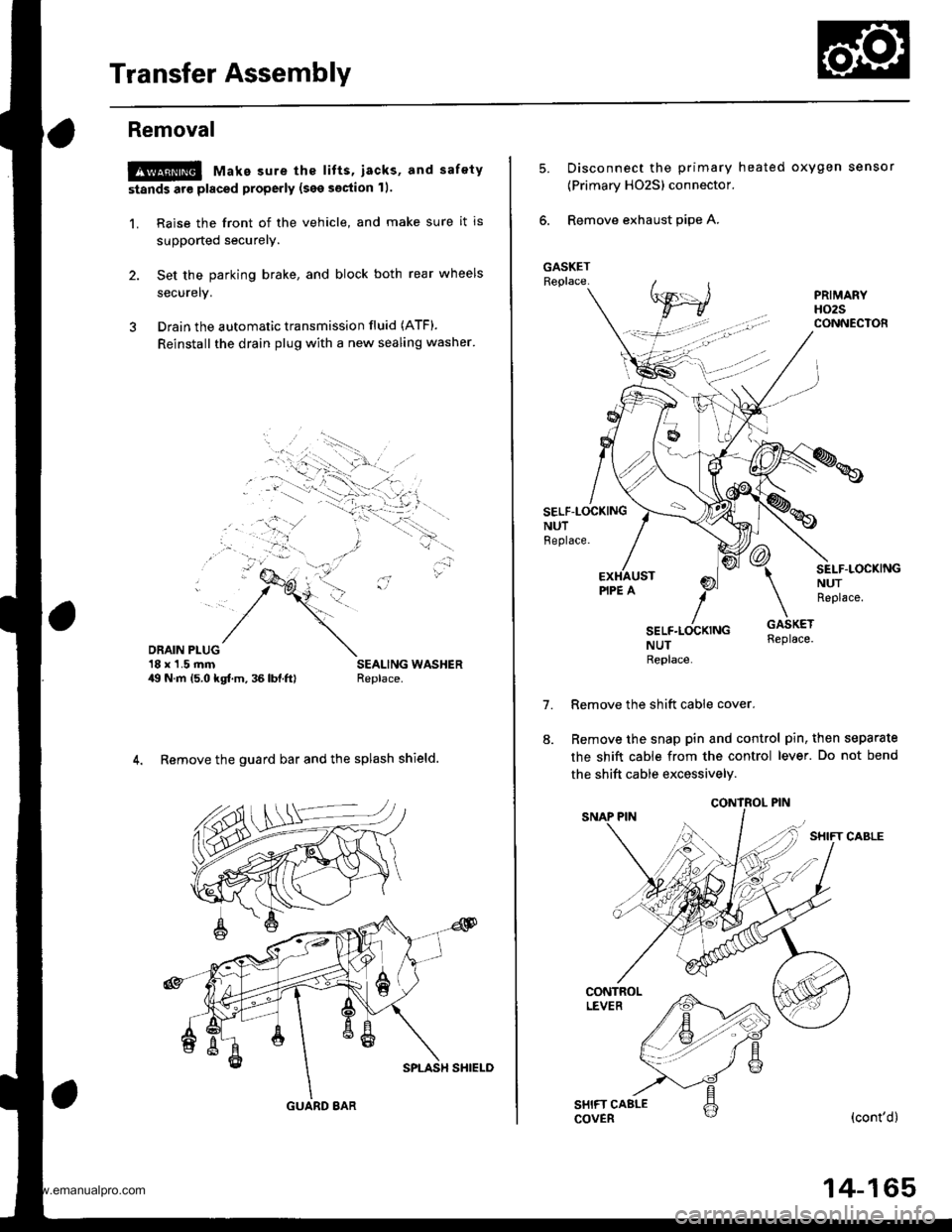

@ Make sure the lifts, iacks, and safety

stands are placed properly (see section 11.

1. Raise the front of the vehicle, and make sure it is

supported securely.

2. Set the parking brake, and block both rear wheels

securelv.

3 Drain the automatic transmission fluid (ATF).

Reinstall the drain plug with a new sealing washer'

DRAIN PLUG'18 x'1.5 rnm49 N.m 15.0 kgf.m, 36 lbl.ftl

4. Remove the guard bar and the splash shield.

GUARD 8AR

14-165

5.Disconnect the primary heated oxygen sensor

{Primary HO2S) connector.

Remove exhaust pipe A.

SELF-LOCKINGNUTBeplace.

7.

SEI-F.LOCKINGNUTReplace.

NUTReplace

Remove the shift cable cover.

Remove the snap pin and control pin, then separate

the shift cable from the control lever. Do not bend

the shift cable excessively.

(cont'd)

www.emanualpro.com

Page 684 of 1395

Transfer Assembly

Installation (cont'dl

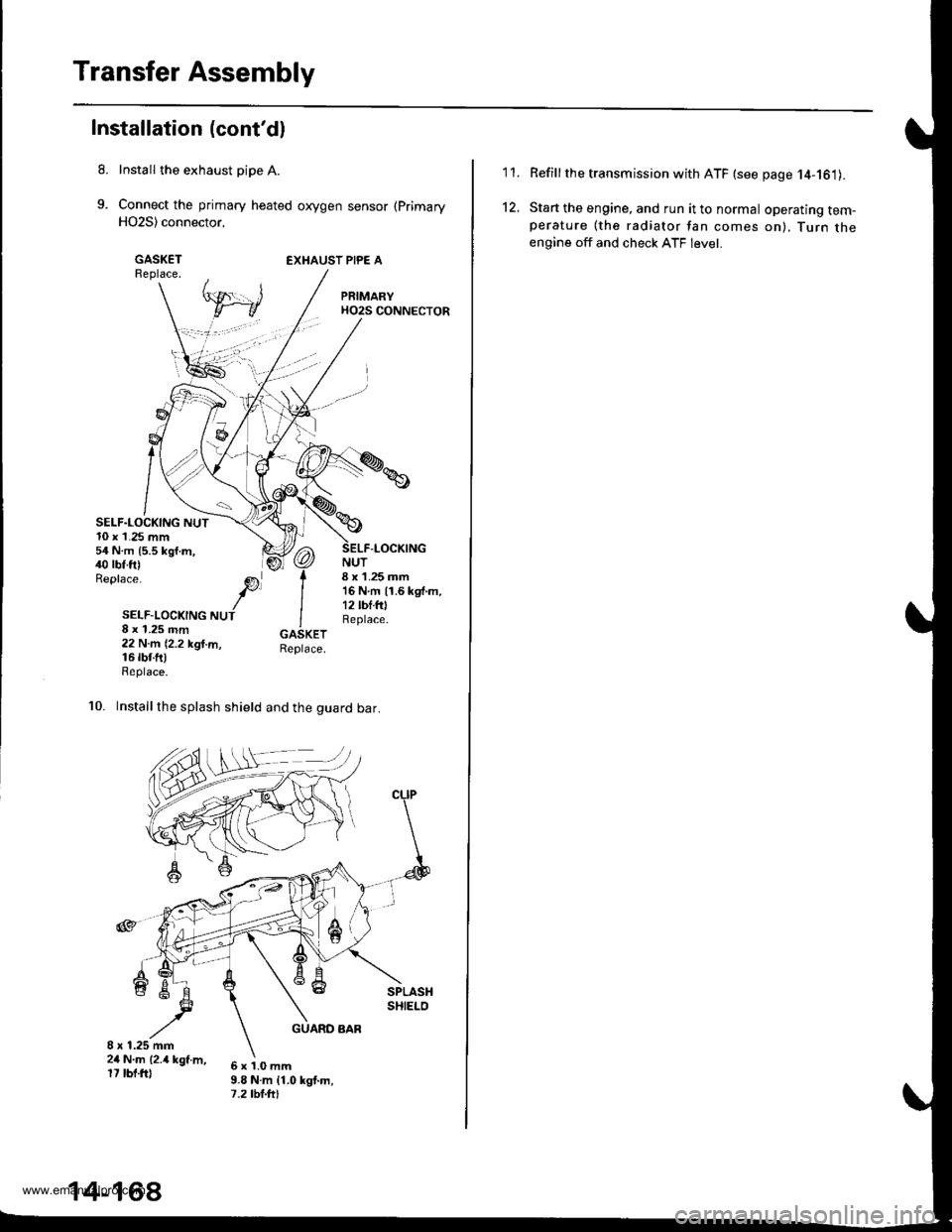

Install the exhaust pipe A.

Connect the primary heated oxygen sensor (Primary

H02S) connector,

GASKETReplace.EXHAUST PIPE A

SELF.LOCKING NUT10 x 1.25 mm54 N.m {5.5 kgf.m,40 rbf.ft)Replace.

NUT8 x 1.25 mm16Nm11.6kgf.m,12 lbf.fOReplace.

-LOCKING

SELF-LOCKING NUT8 x 1.25 mm22 N.m (2.2 kgl.m,16 rbr.fttReplace.

10. Installthe splash shield and the guard bar.

6x1.0mm9.8 N.m {1.0 kgt.m,7.2 tbt.ftt

14-168

'I '�I.

12.

Refillthe transmission with ATF (see page 14-161).

Start the engine, and run it to normal operating tem-perature (the radiator fan comes on), Turn theengine off and check ATF level.

www.emanualpro.com