Fuel pressure valve HONDA CR-V 1997 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 381 of 1395

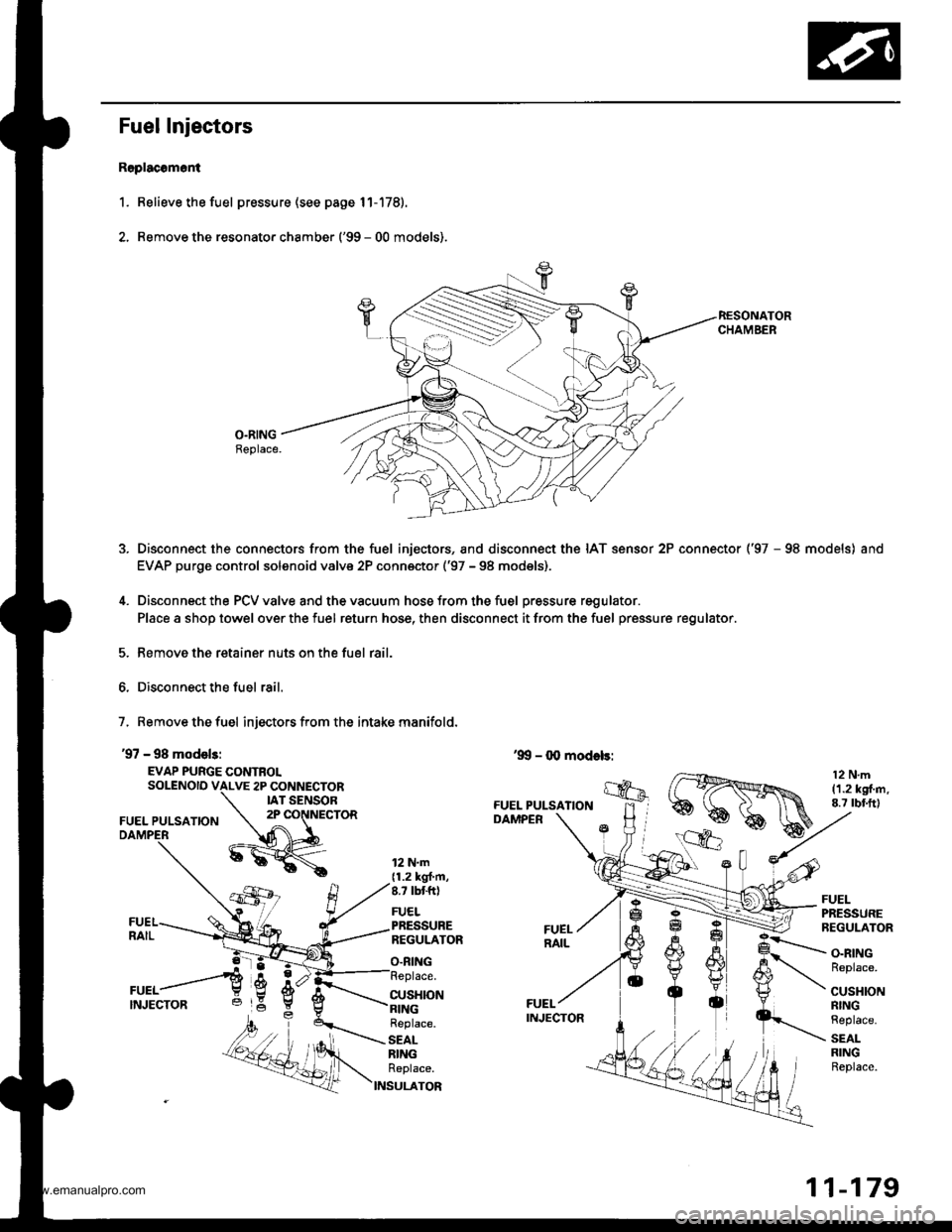

Fuel Injectors

R6placomoni

1. Relieve the fuel pressure (see page 11-178).

2. Remove the resonato. chamber ('99 - 00 models).

O.RINGBeplace.

Disconnect the connectors from the fuel injectors, and disconnect the IAT sensor 2P connector ('97 - 98 models) and

EVAP purge control solenoid valve 2P conn€ctor ('97 - 98 models),

Disconnect the PCV valve and the vacuum hose from the fuel pressure regulator.

Place a shop towel over the fuel return hose, then disconnect it from the fuel pressure regulator.

Remove the retainer nuts on the fuel rail.

Disconnect the fuel rail.

7, Remove the fuel injectors from the intake manifold.

'97 - 98 model3:

EVAP PURGE CONTROLSOLENOID VALVE 2P CONNECTORIAT SENSOR

FUEL PULSATION2P CONNECTOR

12 N.m{1.2 kgt'm,8.7 tbtft)

FUELPRESSUREREGULATOR

O.RING

FUELPRESSUREREGULATOR

CUSHION

O.RINGReplace.

CUSHIONRINGReplace.

SEALRINGReplace.

Replace.

SEALRINGReplace.

S

11-179

www.emanualpro.com

Page 382 of 1395

Fuel Supply System

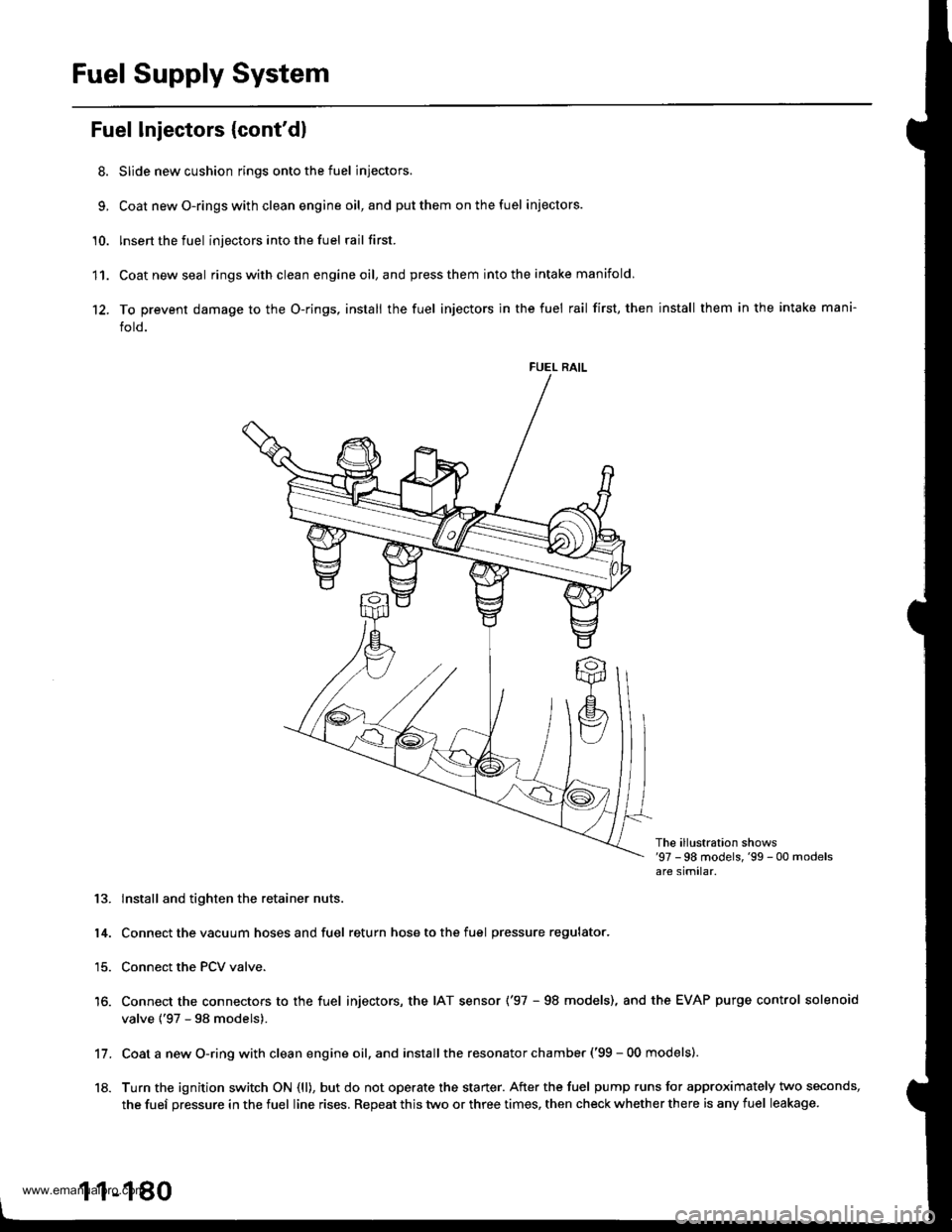

Fuel Injectors {cont'dl

8. Slide new cushion rings onto the fuel injectors.

9, Coat newO-ringswith clean engine oil,and putthem onthefuel iniectors.

'10. lnsert the fuel injectors into the fuel rail first.

11. Coatnewseal ringswithclean engineoil,and press them into the intake manifold

12. To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the intake mani-

fold.

FUEL RAIL

The ill!stration shows'97 -98 models,'99 - 00 modelsare similar.

13. lnstall and tighten the retainer nuts.

14. Connect the vacuum hoses and fuel return hose to the fuel pressure regulator.

15. Connect the PCV valve.

16. Connect the connectors to the fuel injectors, the IAT sensor ('97 - 98 models), and the EVAP purge control solenoid

valve {'97 - 98 models).

Coat a new O-ring with clean engine oil, and install the resonator chamber ('99 - 00 models).

Turn the ignition switch ON (ll), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuef pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

11.

18.

1 1-180

www.emanualpro.com

Page 405 of 1395

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

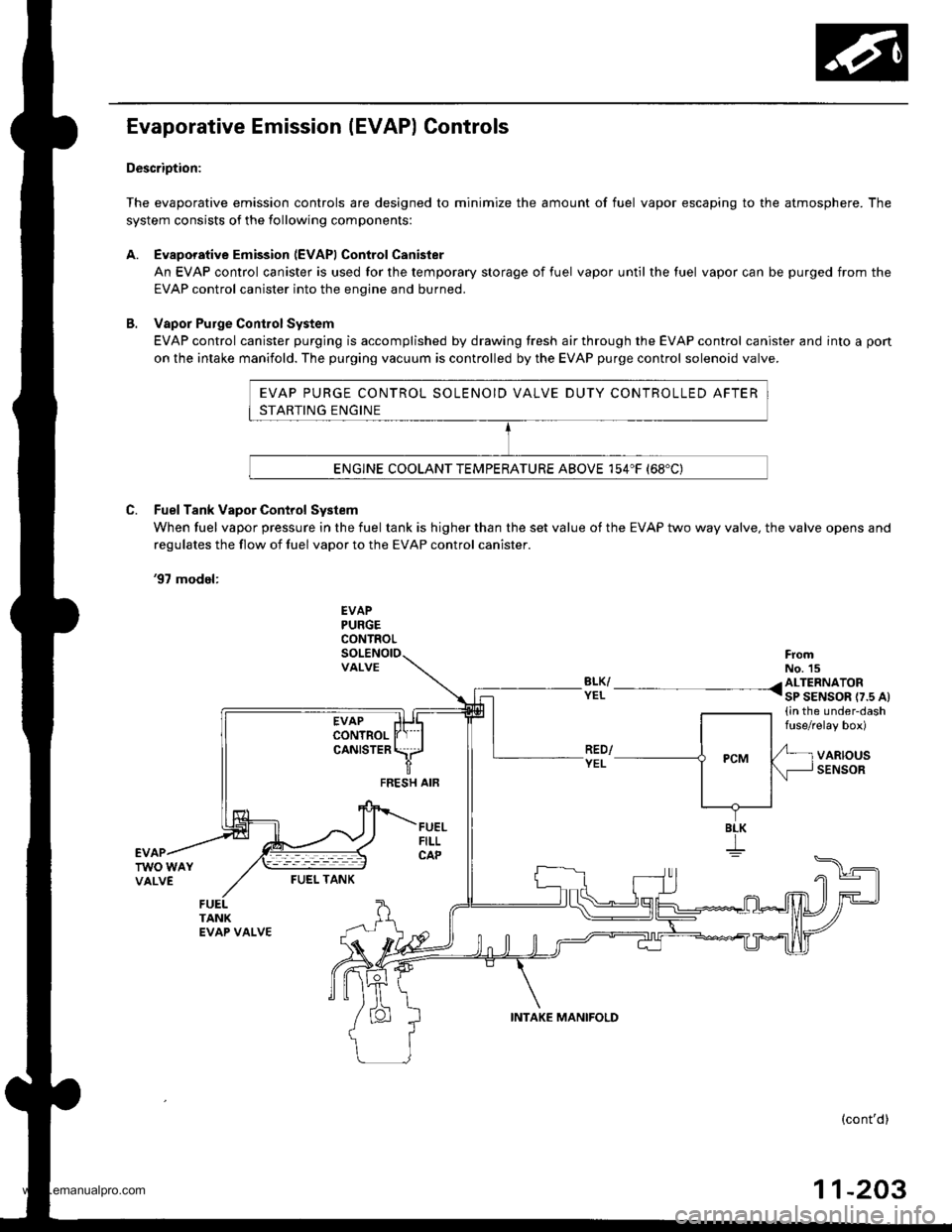

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 410 of 1395

Emission Control System

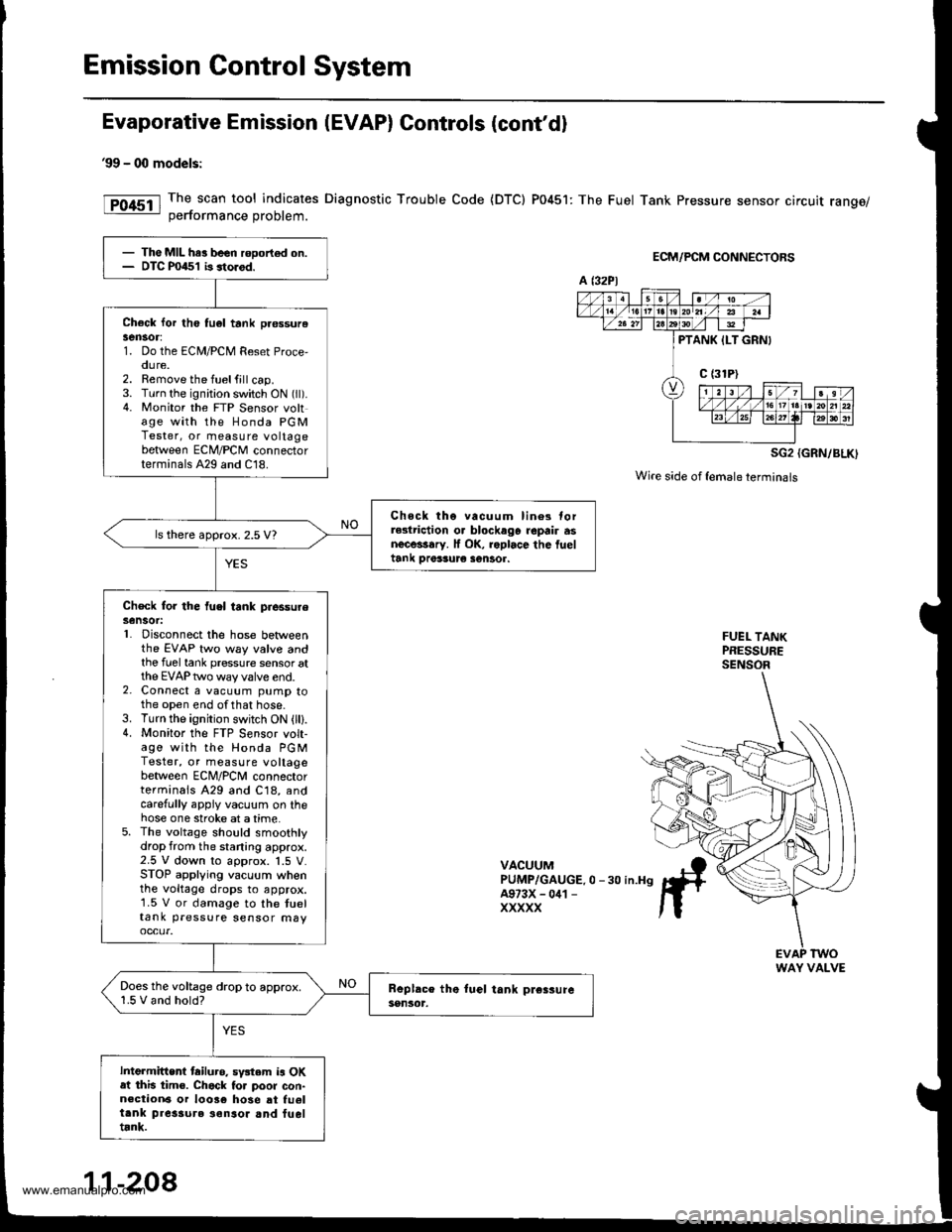

Evaporative Emission (EVAP) Controls (cont'd)

99 - 00 models:

The scan tool indicates Diagnostic Trouble Code {DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

SG2 {GRN/BLK)

Wire side of {emaleterminals

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE.0 -30 in.H9A973X - 041 -

XXXXX

- The MIL har been rooort€d on.- DTC P0451 b storod.

Check lor th6 tu6l tank pr€ssurelen30r:1. Do the ECM/PCM Reset Proce,oure.2. Remove the fuelfill cap.3. Turn the ignition switch ON (ll).4. Monitor the FTP Sensor voltage with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18.

Chock tho vacuum lin6s torrGlriction o. blockago repair asnecessary. lf OK, roplace the fueltank Drer3ur€ sentor.

ls there approx. 2.5 V?

Check for the fuel tank piessureSensot:L Disconnect the hose betweenthe EVAP two way valve andthe fuel tank pressure sensor atthe EVAP two way valve end.2. Connect a vacuum pump tothe open end ofthat hose.3. Turn the ignition switch ON (lll.4. Monitor the FTP S€nsor volt-age with the Honda PGMTester, or measure voltagebetween ECNI/PCNI connectorterminals A29 and C18, andcarefully appiy vacuum on thehose one stroke at a time.5. The voltage should smoothlydrop from the staning approx.2.5 V down to approx. 1.5 V.STOP applying vacuum whenthe voltage drops to approx.1.5 V or damage to the tueltank pressure sensor may

Does the voltage drop to approx.1.5 V and hold?

Intermittent tailuro. sv3tem is OKat this tim€. Chack to. poor con-n€ction6 or 10036 hose at fu6ltank pres3ure ionsor and fueltrnk.

a t32Pl

PTANK ILT GRNI

WAY VALVE

11-208

www.emanualpro.com

Page 415 of 1395

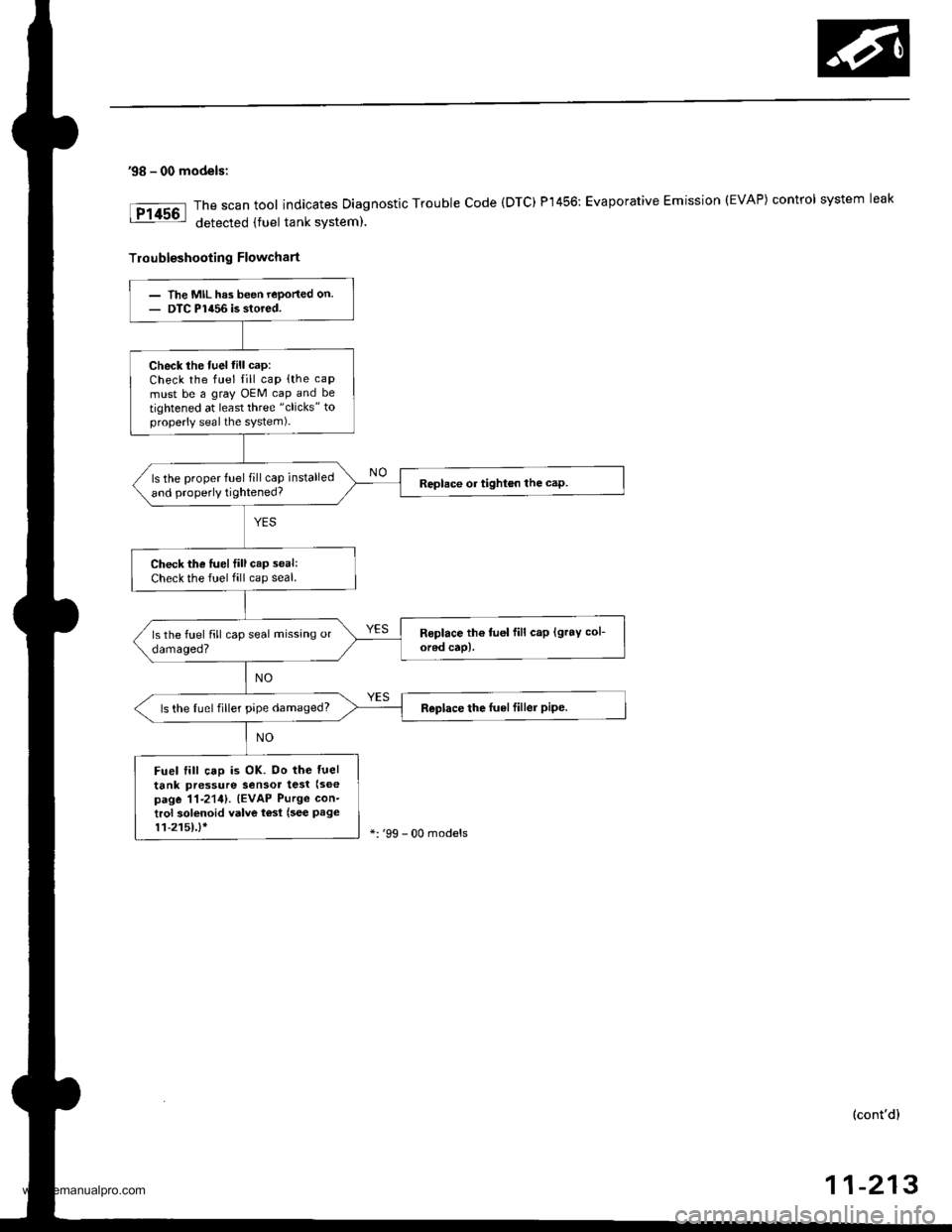

'98 - 00 models:

The scan tool indicates Diagnostic Trouble code (DTC) P1456: Evaporative Emission (EVAP) control system leak

detected {fuel tank system).

Troubleshooting Flowchart

- The MIL has been reported on.- DTC P1456 is stored.

Check the fuel fill cap:Check the fuel fill cap (the caP

must be a gray OEM cap and be

tightened at least three "clicks" toproperly seal the system)-

ls the proper fuel fill cap installed

and properly tightened?Replace or tighton the cap.

Check the lueltill cap seal:

Check the fuel fill cap seal.

Replace the luelfiller pipe.ls the tuel filler pipe damaged?

Fuel till caD is OK. Do the luel

tank pressure Sensor test (see

page 11-2111. (EVAP Purge con-

trol solenoid valve t€sl (see Page11-2151.1r':'99 - 00 models

(cont'd)

11-213

www.emanualpro.com

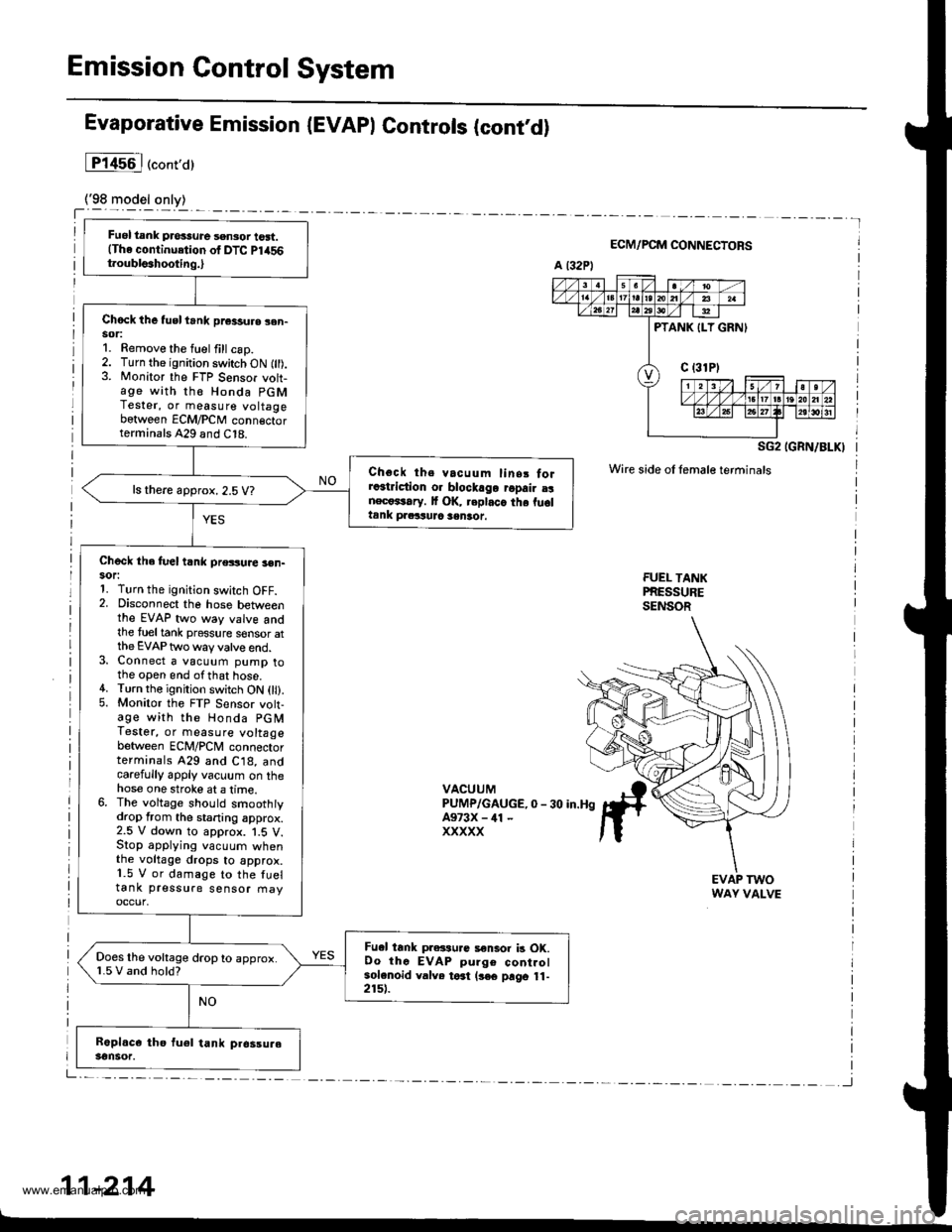

Page 416 of 1395

Emission Control System

Fuel tank pros3ure sensor tost.(The continuetion of DTC Pl456t.oubls3hooting.,

Chock the tusl trnk pr€3sure sen-sor:1. Remove the fuel fill csp.2. Turn the ignition switch ON fll).3. Monitor the FTP Sensor voh-age with th€ Honda PGMTester, or measure voltagebetween ECM/PCM conn€ctorterminals A29 and C18.

Choct ths vacuum linsr forra3triction o. blockago ropair a!nect*rary. It OK, replaca the fu6ltank praituJc sentot.

ls there approx. 2.5 V?

Check the fuel t nk pressuae 3en-sor:1. Turn the ignition switch OFF.2. Disconnect the hose betweenthe EVAP two way valve andthe tueltank pressure sensor atthe EVAP two way valve end.3. Connect a vacuum pump tothe open end ofthat hose.4. Turn the ignition switch ON 0l).5. Monitor the FTP Sensor volt-age with the Honda PGMTestet, or measure voltagebetween ECM/PCM connectorterminals 429 and C18, andcarefully apply vacuum on thehose one stroke at a lime.6. The voltage should smoothtydrop from the staning approx.2.5 V down to approx. 1.5 V.Stop applying vacuum whenthe voltage drops to approx.1.5 V or damage to the fueltank pressure sensor fiayoccur,

Fu.l tank pressu.c a€nlor b OK.Oo thc EVAP pulge controlsolenoid valve toat (3€€ prgo 11-2151.

Does the voltage drop to approx.1.5 V and hold?

Evaporative Emission (EVAPI Controls (contd)

lP14s6l("ont,a)

ECM/PCM CONNECTORS

SG2 IGRN/BLKI

Wire side oI female terminals

FUEI- TANKPRESSURESENSOR

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X - ill -

xxxxx

EVAP TWOWAY VALVE

11-214

www.emanualpro.com

Page 420 of 1395

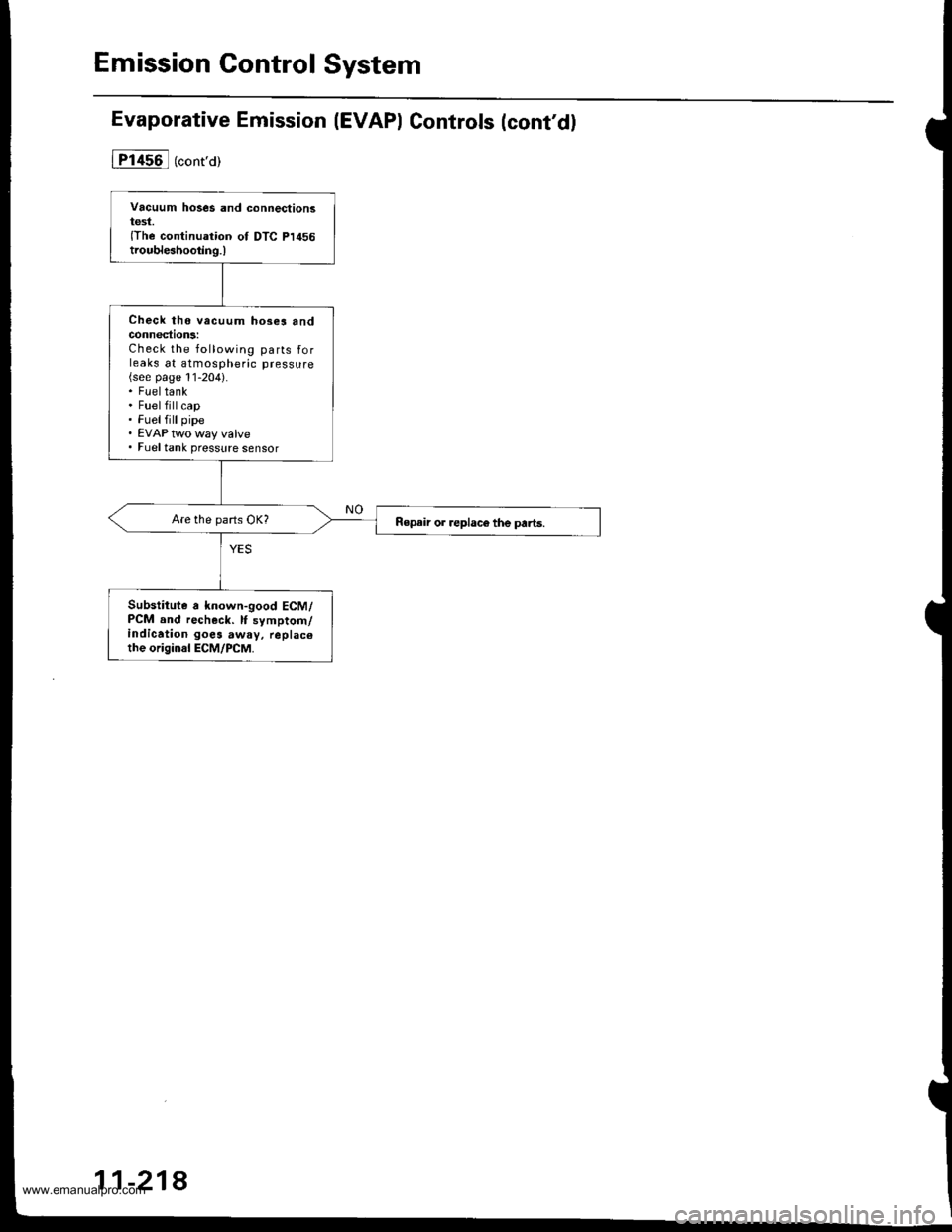

Emission Control System

Evaporative Emission IEVAPI Controls (cont'd)

lTi,t56l ("onto)

Vacuum hoses and connectionstelit.(The continuarion of DTC P1456troubleshooiing.l

Check the vacuum ho3es andconnect|ons:Check the following parts forleaks at atmospheric p ressu re{see page 11-204).. Fueltank. Fuel fill cap. Fuelfill pipe. EVAP two way valve. Fueltank pressure sensor

Repair or replaco the parts.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away, replac€the original ECM/PCM.

11-218

www.emanualpro.com

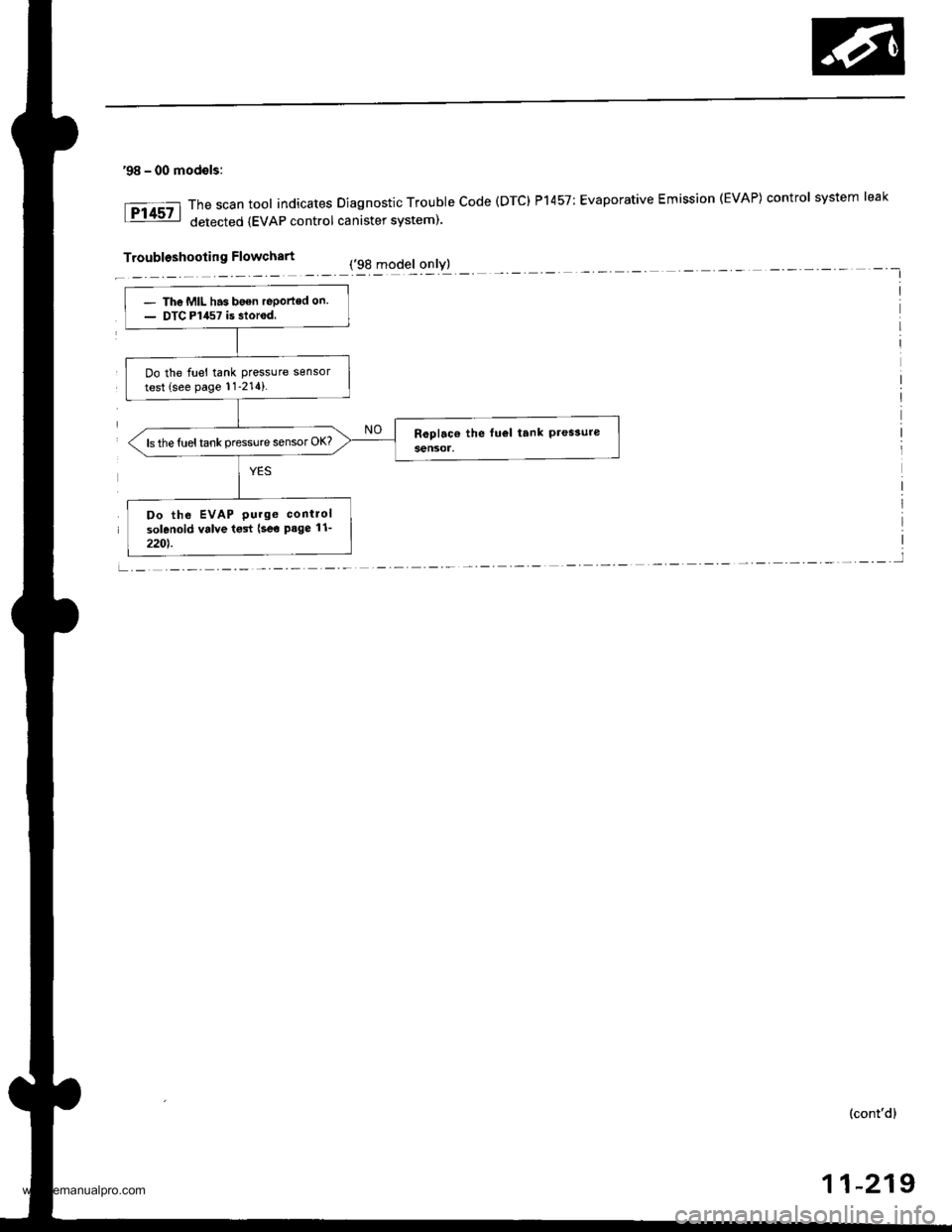

Page 421 of 1395

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble code (DTc) P1457: Evaporative Emission (EVAP) Control system leak

detected (EVAP control canister system).

Troubl6shooting Flowchart('98 model only)_]

I

- The MIL has been rePorted on.- DTC P1,157 is storod.

Do the fuel tank Pressure sensor

test {see page 11-214).

ls the {ueltank pressure sensor OK?

Do the EVAP Purge contlol

solenoid valve test lsea Page 1l_

220t.

(cont'dl

11-219

www.emanualpro.com

Page 425 of 1395

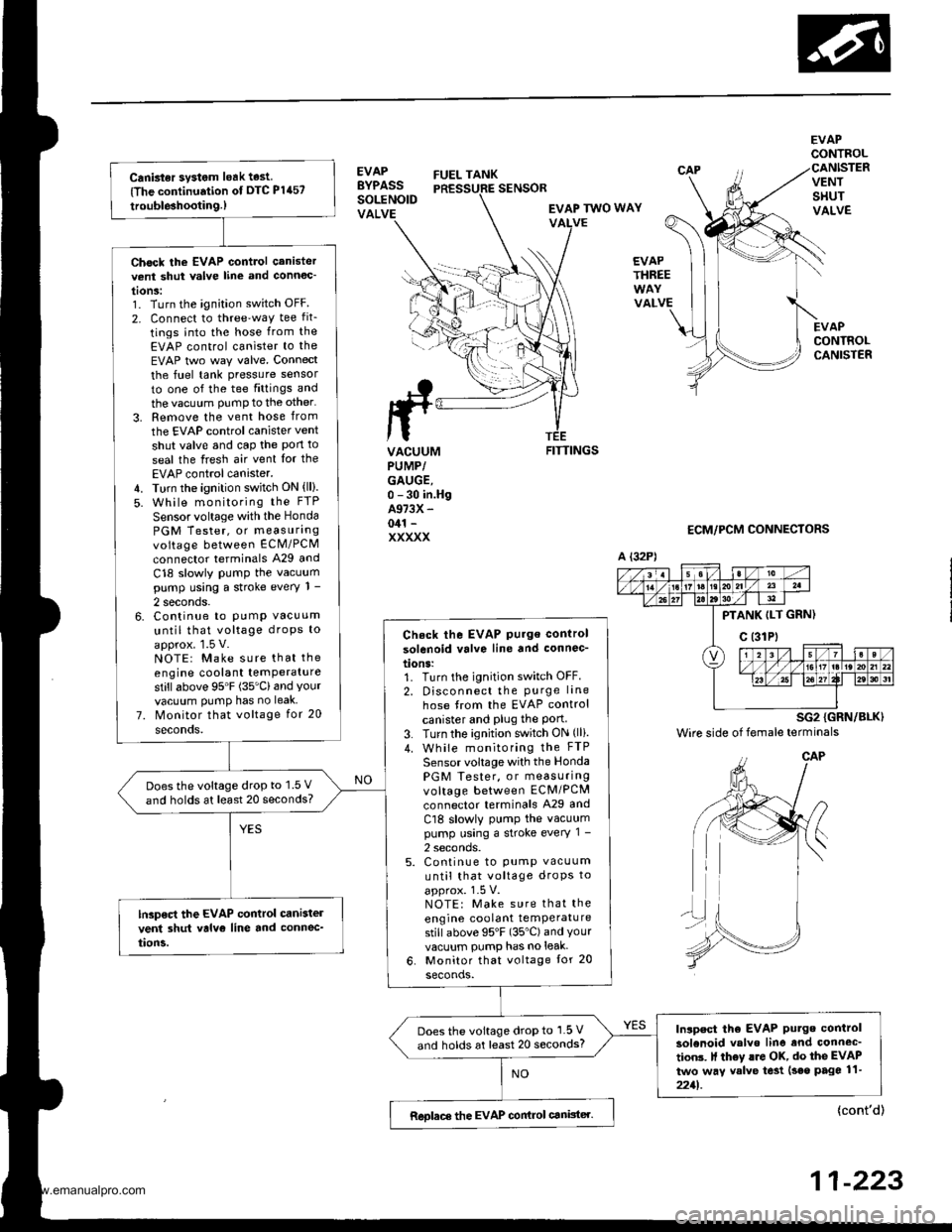

Canbter system leak test

{The continuation of DTC P1457

trouble3hootin9.)

Chock the EVAP control canistervent shut valve line and connoc'

tonS:1. Turn the ignition switch OFF

2. Connect to three'way tee fit_

tings into the hose from the

EVAP control canister to the

EVAP two way valve. Connect

the fuel tank pressure sensor

to one of the tee fittings and

the vacuum PumP to the other'

3. Remove the vent hose from

the EVAP control canister vent

shut valve and cap the Pon to

seal the fresh air vent Ior the

EVAP control canister.4. Turn the ignition switch ON (ll).

5. While monitoring the FTP

Sensor voltage with the Honda

PGM Tester, or measurangvoltage between ECM/PCM

connector terminals A29 and

C18 slowly PumP the vacuumpump using a stroke every 1 -

2 seconds.6. Continue to PumP vacuum

until that voltage droPs to

approx. 1.5 V.NOTE: Make sure that the

engine coolant temPeraturestillabove 95'F (35'Cland Yourvacuum PumP has no leak

7. Monitor that voltage for 20

seconds.

Check the EVAP Pu.ge control

solenoid valve line and connec-

tions:1. Turn the ignition switch OFF.

2. Disconnect the Purge lane

hose from the EVAP control

canister and Plug the Port3. Turn the ignition switch ON (lli.

4. While monitoring the FTP

Sensor voltage with the Honda

PGM Tester, or measuringvoltage between ECM/PCM

connector terminals A29 and

Cl8 slowly PumP the vacuumpump using a stroke every 1 -

2 seconds.5. Continue to pump vacuum

until that voltage droPs to

approx. 1-5 V.NOTE: Make sure that the

engine coolant temPeraturestill above 95'F (35"C) and Yourvacuum pump has no leak-

6. Monitor that voltage tor 20

seconds.

Doesthe voltage drop to 1.5 V

and holds at least 20 seconds?

lGp€ct the EVAP control cani3tel

vent 3hut valvo line and connec_

tion5.

Inlpect tho EVAP Putge control

solenoid valvo line and connec'

tion3. It th6y lro OK, do the EVAP

two way valve te3t (seo page 11-

2211.

Does the voltage drop to 1.5 V

and holds at least 20 seconds?

Reolace the EVAP conirol canister.

EVAPBYPASSSOLENOIDVALVE

FUEL TANK

EVAPCONTROL

VENTSHUTVALVE

EVAPCONTROLCANISTER

SENSOR

EVAP TWO WAYVALVE

EVAPTHREE

VALVE

ttrrL

ta

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X -

041 -

XXXXX

FITTINGS

ECM/PCM CONNECTORS

A {32P)

PTANK ILT GRN)

c (31Pt

SG2 {GRN/BLK)

Wire side of female terminals

{cont'd)

11-223

www.emanualpro.com

Page 426 of 1395

Emission Control System

Evaporative Emission (EVAP) Controls (cont,dl

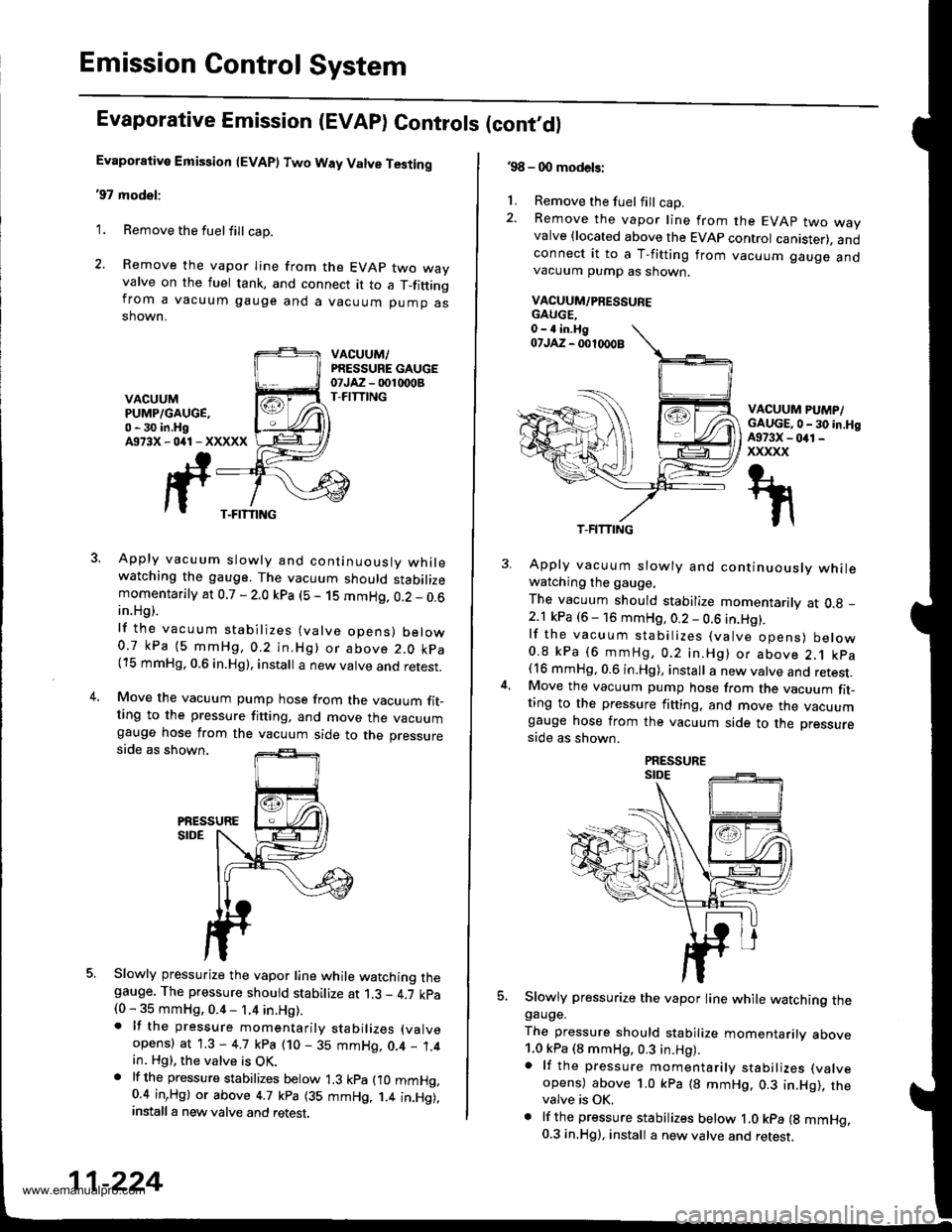

Evaporative Emission (EVAP) Two Way Valve Testing

'97 model:

1. Remove the fuelfill cap.

2. Remove the vapor Iine from the EVAP two wayvalve on the fuel tank, and connect it to a T_fittingfrom a vacuum gauge and a vacuum pump asshown.

VACUUM,/PRESSURE GAUGEotJAz - 001 rDoBT-FITTINGVACUUMPUMP/GAUGE,0 - 30 in.HgA973X-041-XXXXX

3. Apply vacuum slowly and continuouslv whilewatching the gauge. The vacuum should stabilizemomentarily at 0.7 - 2.0 kpa (5 - 1S mmHg, 0.2 _ 0.6in.Hg).

lf the vacuum stabilizes (valve opens) below0.7 kPa (5 mmHg,0.2 in,Hg) or above 2.0 kpa(15 mmHg, 0.6 in.Hg), install a new valve and retest.

4.Move the vacuum pump hose from the vacuum fit_ting to the pressure fitting, and move the vacuumgauge hose from the vacuum side to the pressureside as shown.

PiESSURESIDE

5. Slowly pressurize the vapor line while watching thegauge. The pressure should stabilize at 1.3 - 4.7 kpa(0 - 35 mmHg, 0.4 - 1.4 in.Hg).. lf the pressure momentarily stabilizes (valve

opens) at 1.3 - 4.7 kpa (10 - 35 mmHg, 0.4 _ 1.4in. Hg), the valve is OK.. lf th6 pressure stabilizes below 1.3 kpa fio mmHg,0.4 inrHg) or above 4.7 kpa (35 mmHg, 1.4 in.Hg),install a new valve and retest.

T-FITTING

11-224

.98 - 0O models:

1. Remove the fuel fill cap.2. Remove the vapor line from the EVAP two wayvalve {located above the EVAP control canister). andconnect it to a T-fitting from vacuum gauge andvacuum pump as shown.

VACUUM/PRESSUFE

VACUUM PUMP/GAUGE,0 - 30 in.HgA973X - 041 -

xxxxx

5.

Apply vacuum slowly and continuously whilewatching the gauge.

The vacuum should stabilize momentarily at O.g _

2.1 kPa (6 - 16 mmHg, 0.2 - 0.6 in.Hg).lf the vacuum stabilizes (valve opens) below0.8 kPa (6 mmHg, 0.2 in.Hg) or above 2.1 kpa(16 mmHg, 0.6 in.Hg), install a new valve and retest.Move the vacuum pump hose from the vacuum fit-ting to the pressure fitting. and move the vacuumgauge hose from the vacuum side to the pressure

side as shown.

Slowly pressurize the vapor line while watching thegauge.

The pressure should stabilize momentarilv above1.0 kPa (8 mmHg, 0.3 in.Hg).a lf the pressure momentarily stabilizes (valve

opens) above 1.0 kPa (8 mmHg. 0.3 in.Hg), thevalve is OK.. lf the pressure stabilizes below ,|.0 kpa {g mmHg.0.3 in.Hg), install a new valve and retest.

T-FITTING

www.emanualpro.com