Testing HONDA CR-V 1997 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 677 of 1395

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

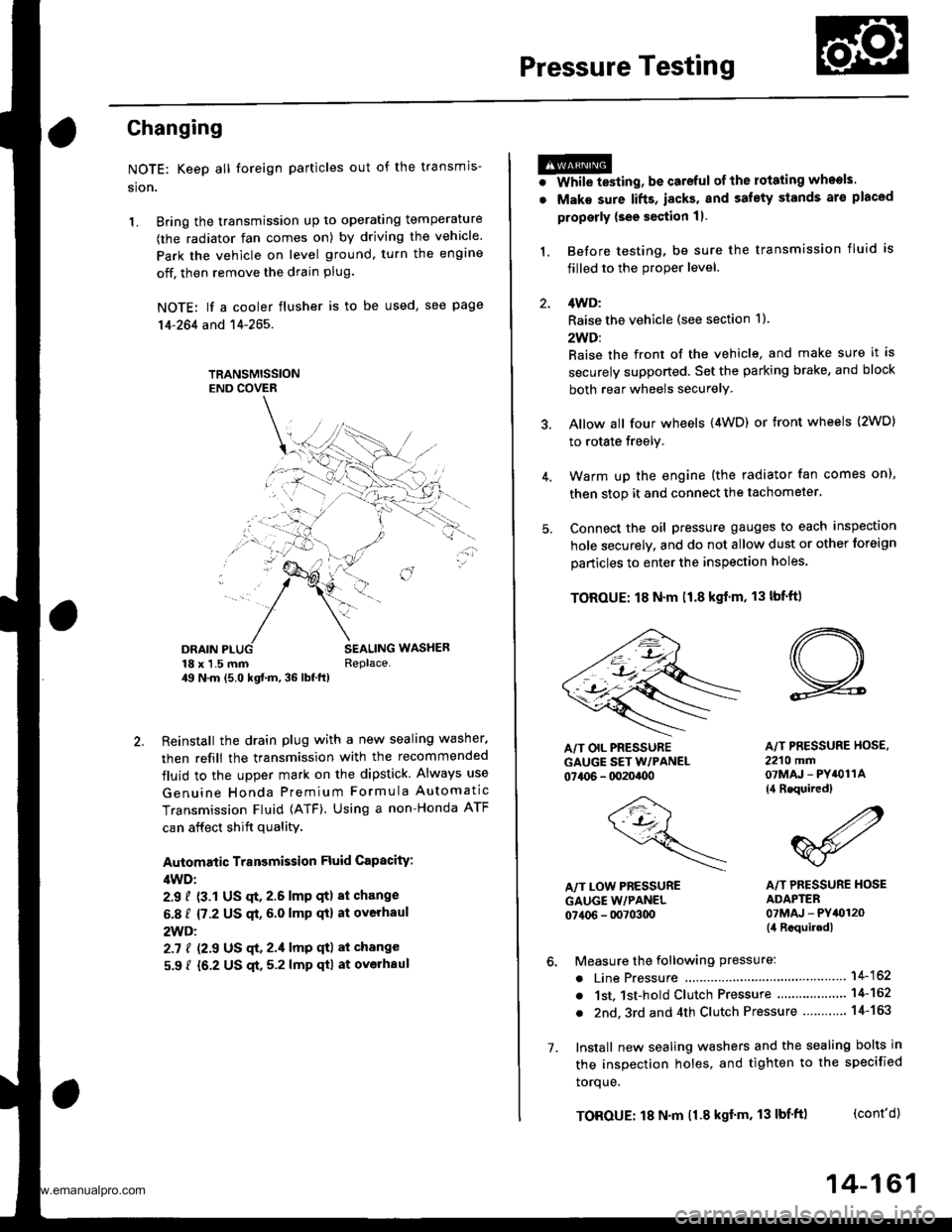

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 678 of 1395

Pressure Testing

(cont'd)

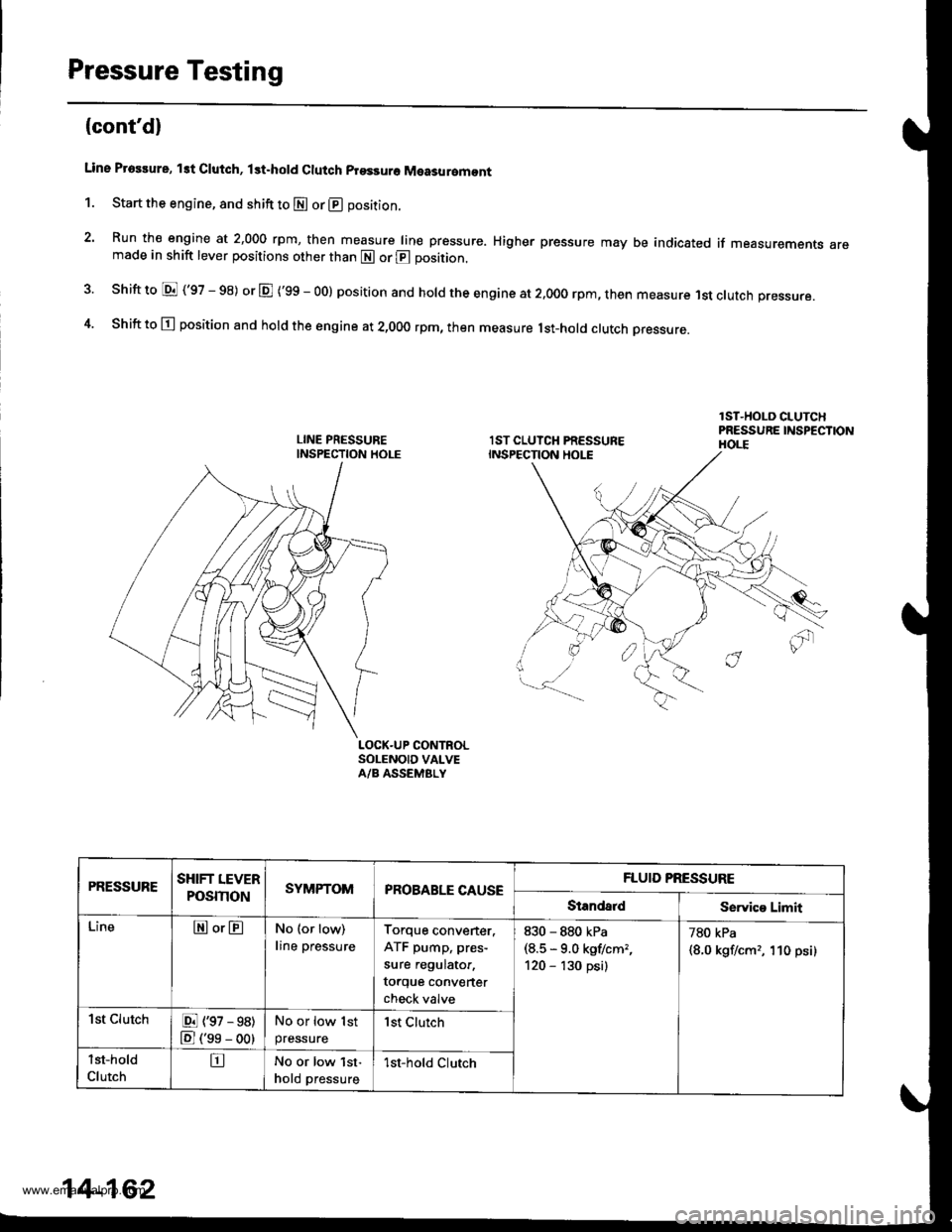

Line Proslure, lst Clutch, lst.hold Clutch prsssuro Measuromont

1. Start the engine, and shift to E or @ position.

2. Run the engine at 2,000 rpm, then measure line pressure. Higher pressure may be indicated if measurements aremade in shift lever positions other than E or @ position.

shift to E ('97 - 98) or E ('99 - oo) position and hold the engine at 2.ooo rpm, then measure 1st clutch pressure.

Shift to E position and hold the engine at 2,000 rpm, then measure lst-hotd ctutch Dressure.

LOCK.UP CONTROLSOLENOID VALVEA/B ASSEMBLY

4.

PRESSURESHIFT LEVER

POSmONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandaldService Limit

LineEor@No (or low)

line pressure

Torque converter.

ATF pump, pres-

sure regulator,

torque converter

check valve

830 - 880 kPa(8.5 * 9.0 kgflcm,,

120 - '130 psi)

780 kPa

{8.0 kgf/cm,, 'l10 psi)

1st ClutchE (97 - 98)

E ('se - oo)

No or low 1st

pressurelst Clurch

lst-hold

ClutchtrNo or low lst-

hold pressure1st-hold Clutch

14-162

www.emanualpro.com

Page 1100 of 1395

Troubleshooting

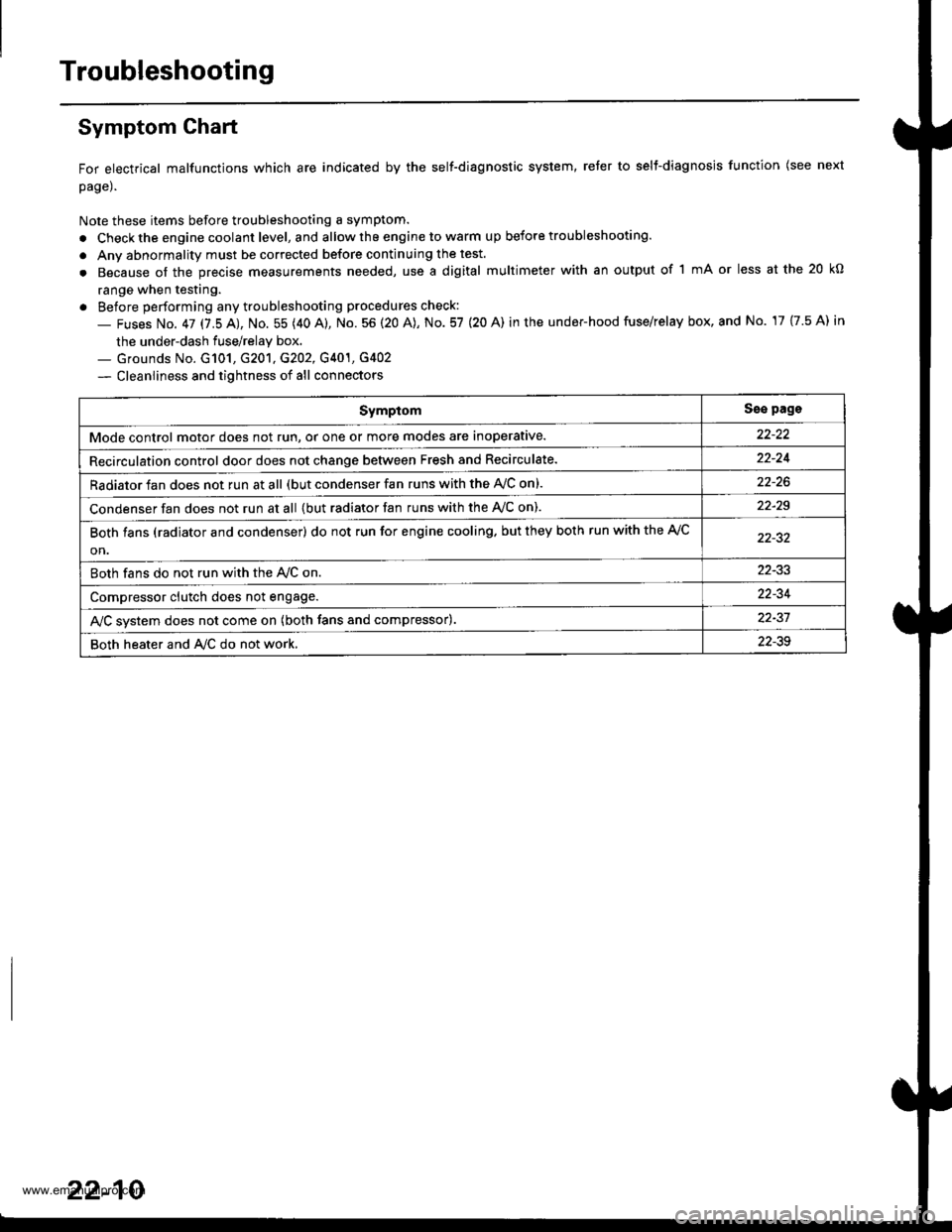

Symptom Ghart

For electrical malfunctions which are indicated by the self-diagnostic system, reter to selt-diagnosjs function (see next

page).

Note these items before troubleshooting a symptom.

. Check the engine coolant level, and allow the engine to warm up before troubleshooting.

. Anv abnormality must be corrected before continuing the test.

. Because of the precise measurements needed, use a digital multimeter with an output of 1 mA or less at the 20 kO

range when testing.

. Before performing any troubleshooting procedures check:

- Fuses No. 47 17.5 AJ, No. 55 (40 A), No. 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in

the under-dash fuse/relay box.._ Grounds No. G101, G201, G202, G401, G4O2

- Cleanliness and tightness of all connectors

SymptomSse pags

Mode control motor does not run, or one or more modes are inoperative.

Recirculation control door does not change between Fresh and Recirculate.22-24

Radiator fan does not run at all (but condenser fan runs with the AVC on).

Condenser fan does not run at all {but radiator fan runs with the Ay'C on).22-29

Both fans (radiator and condenser) do not run for engine cooling. but they both run with the A,/C

on.

Both fans do not run with the Ay'C on22-33

Compressor clutch does not engage.22-34

AJC svstem does not come on (both fans and compressor).22-37

Both heater and A/C do not work,22-39

22-10

www.emanualpro.com

Page 1165 of 1395

Five-step Troubleshooting

1.

3.

Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. lf several

circuits fail at the same time, the fuse or ground is a

likely cause,

Based on the symptoms and your understanding of

the circuit operation, identify one or more possible

causes of the problem.

lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep jn mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible,

Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. lf the problem was a blown fuse, be sure to

test all of the circuits on the fuse. lvlake sure no new

problems turn up and the original problem does nol

recur.

4.

O

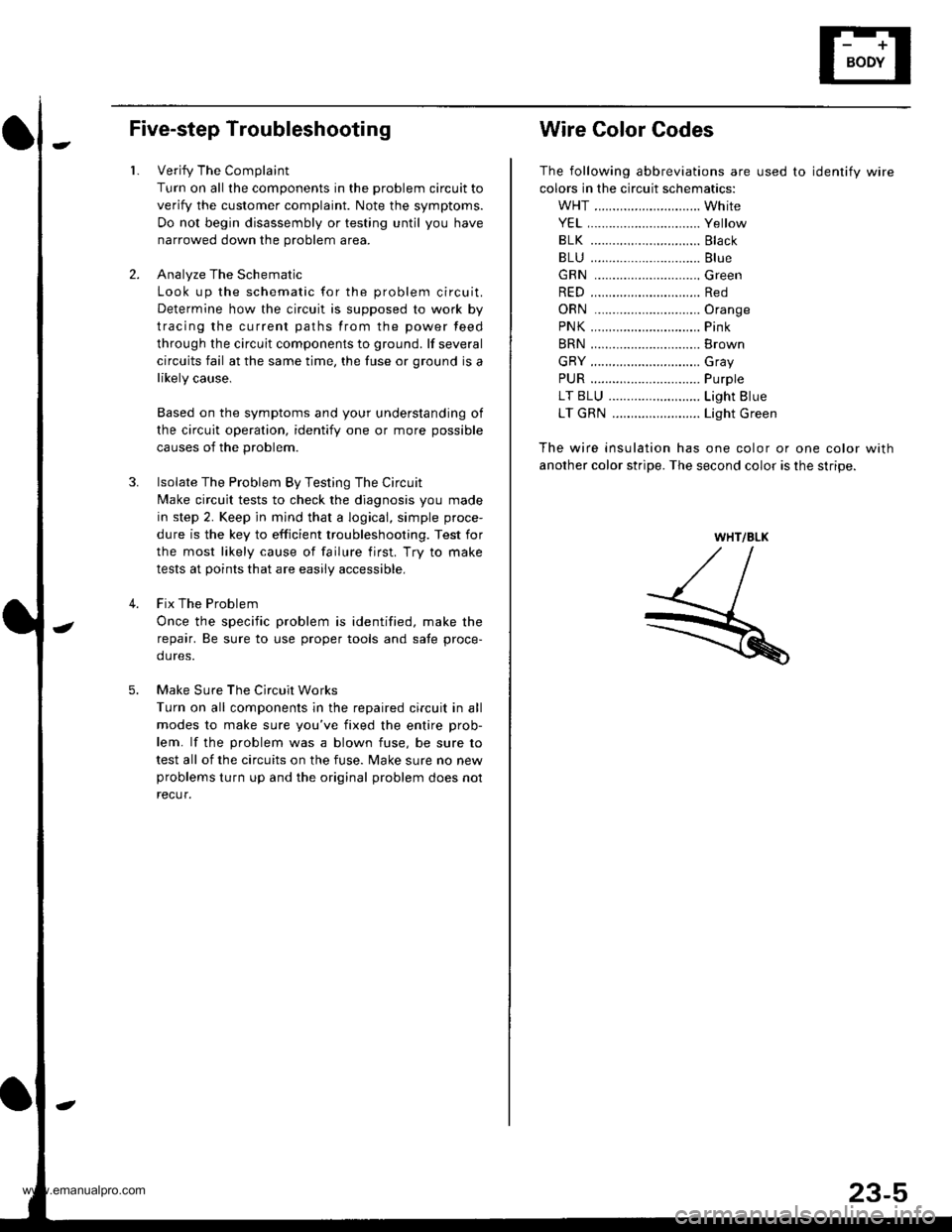

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

WHT ............................. White

YEL,.............................. Yellow

BLK ..........,................... Black

BLU .............................. Blue

GRN .............................Green

RED .............................. Red

ORN .............................Oran9e

PNK.....,........................ Pink

BRN .............................. Brown

GRY .............................. Gray

PUR .........,.................... Purple

LT BLU ..................,...... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

www.emanualpro.com

Page 1222 of 1395

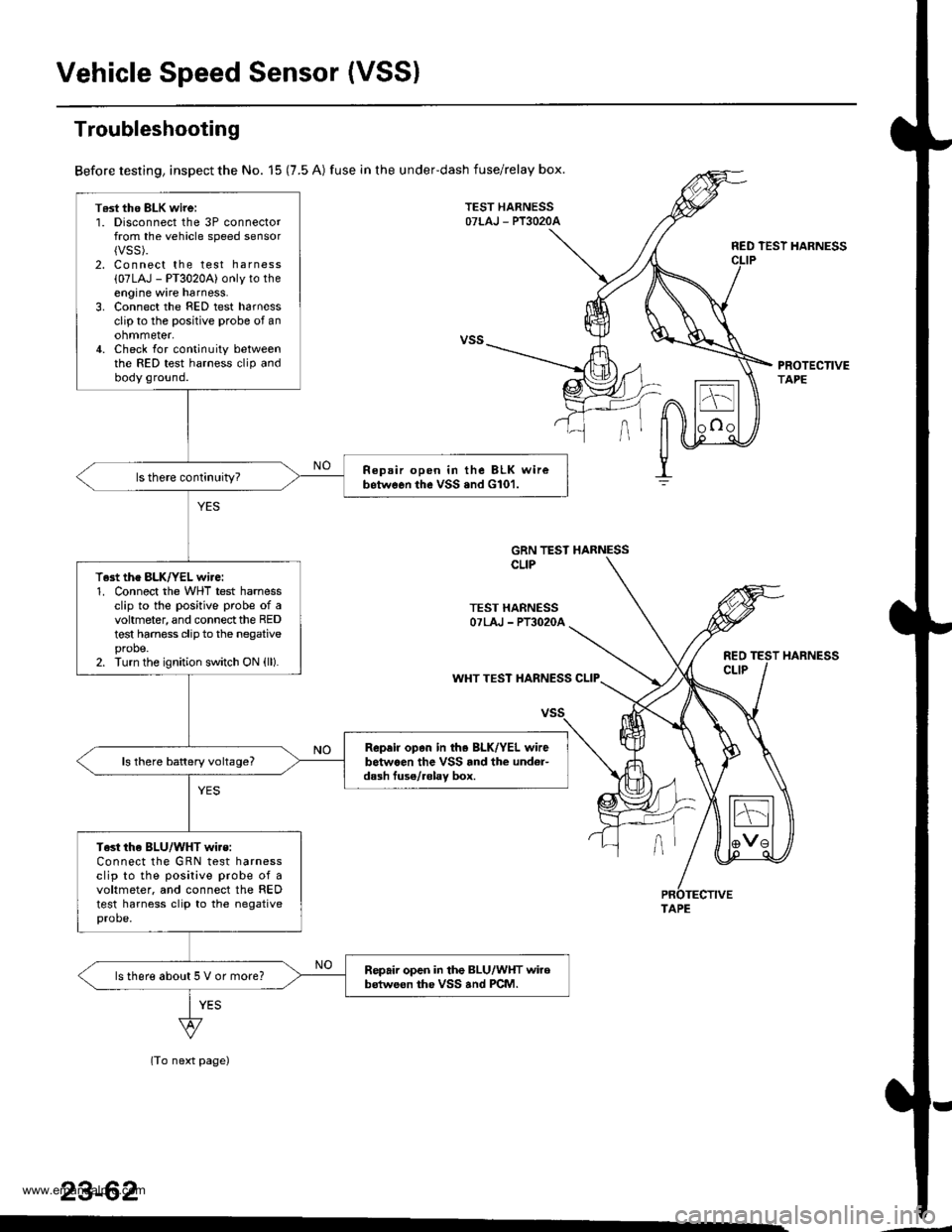

Vehicle Speed Sensor (VSSI

T6st tho BLK wirei1. Disconnect the 3P connectorfrom the vehicle speed sensor{VSS).2. Connect the test harness

{07LAJ - PT3020A) only to theengine wire harness.3. Connect the FED test harnessclip to the positive probe of anohmmeter,4. Check for continuity betweenthe RED test harness clip andbody ground.

Repair open in the BLK wirebetwGon the vSS .nd G101.

T.st the BLK/YEL wire:1. Connect the WHT test harnessclip to the positive probe of avohmeter, and connect the REDtest harness clip to the negativeprobe.2. Turn the ignition switch ON (ll).

Rep.ir op.n in th. BLK/YEL wirebetwaen the VSS rnd the und6r-dash fuse/.6lav box.ls there battery voltage?

Test the BLU/WHT wi.s:Connect the GRN test harnessclip to the posilive probe of avoltmeter. and connect the REDtest harness clip to the negativeprobe.

Repair open in the BLU/WHT wirobstweon the VSS and PCM.ls there about 5 V or more?

Troubleshooting

Before testing, inspect the No. 15 (7.5 A) fuse in the underdash fuse/relay box.

TEST HARNESSOTLAJ - PT3O2OA

RED TEST HARNESS

PROTECTIVETAPE

GRN TEST HARNESSCLIP

TEST HARNESSOTLAJ - PT3O2OA

REOCLIPWHT TEST HARNESS CLIP

(To next page)

23-62

HARNESS

TAPE

www.emanualpro.com

Page 1273 of 1395

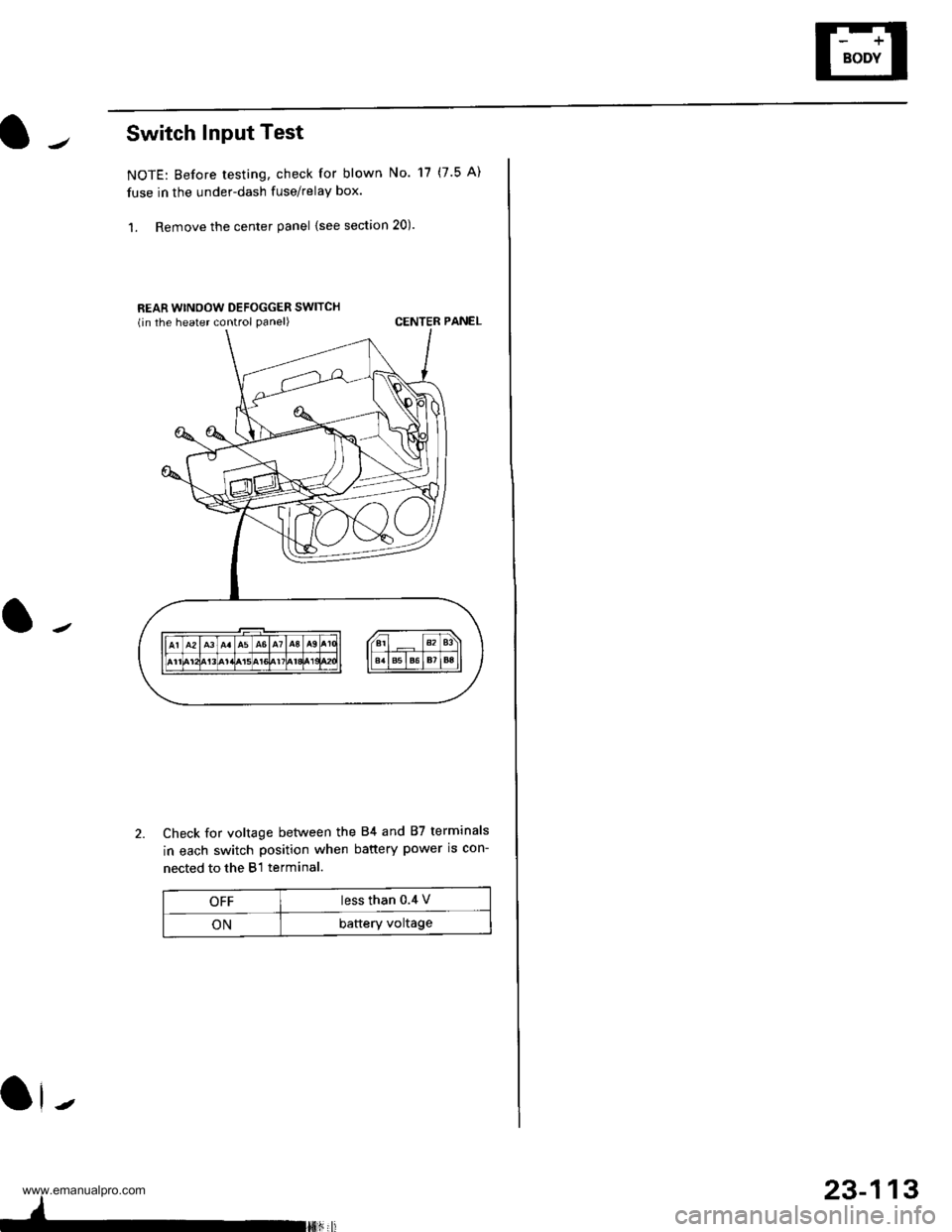

Switch Input Test

NOTE: Before testing, check for blown No. 17 (7.5 A)

fuse in the under-dash fuse/relay box.

1. Remove the center panel {see section 20).

REAR WINOOW DEFOGGER SWITCHlin the heater control oanel)CENTER PANEL

Check for voltage between the 84 and 87 terminals

in each switch position when battery power is con-

nected to the B l terminal.

OFFless than 0.4 V

ONbaftery voltage

Ol-

I

-

23-113

www.emanualpro.com