clearance HONDA CR-V 1997 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 459 of 1395

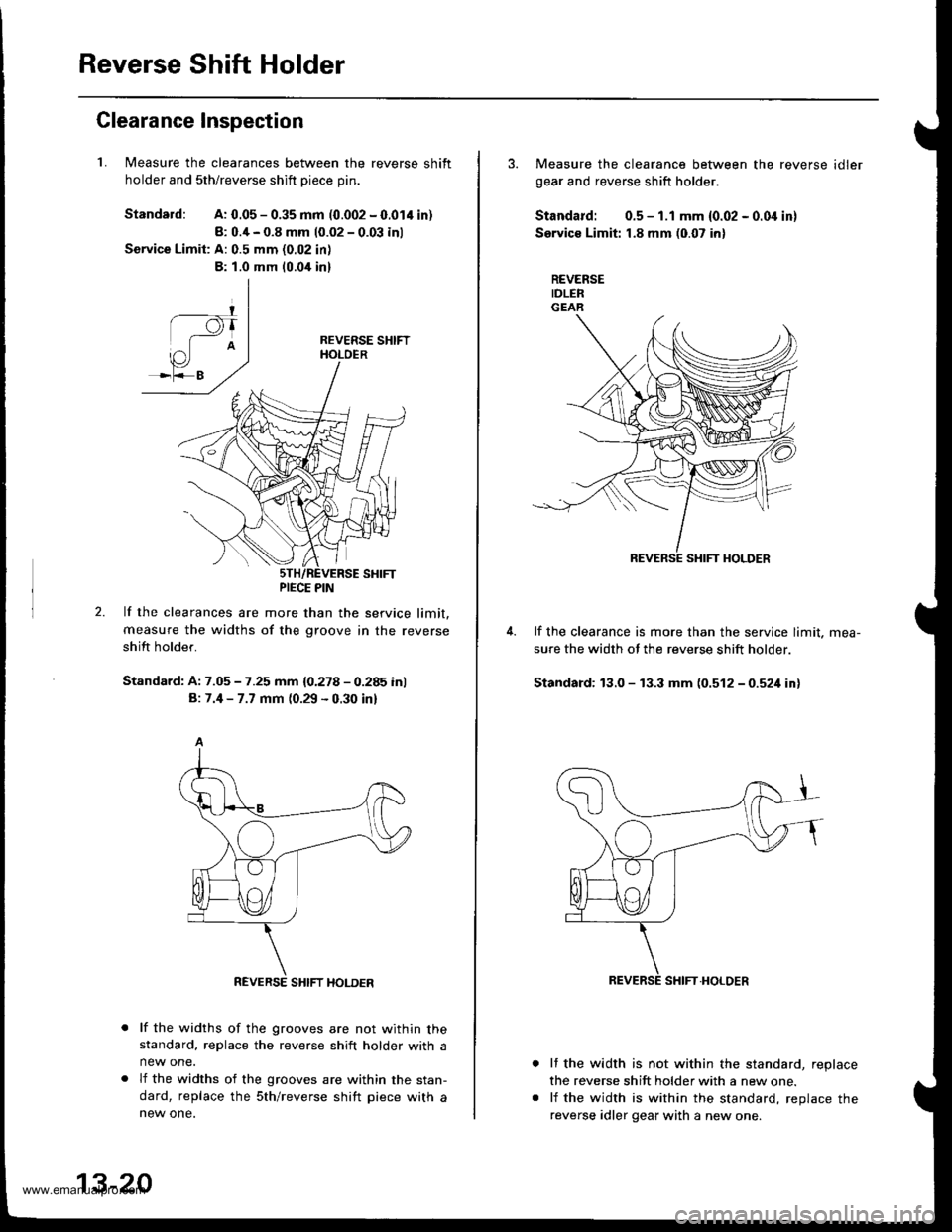

Reverse Shift Holder

Clearance Inspection

1.Measure the clearances between the reverse shift

holder and sth/reverse shift Diece Din.

Standard:A: 0.05 - 0.35 mm (0.002 - 0.014 in)

8: 0.4 - 0.8 mm 10.02 - 0.03 inl

Service Limit: A: 0.5 mm (0.02 in)

B: 1.0 mm 10.0,[ in]

2.lf the clearances are more than the service limit.

measure the widths of the groove in the reverse

shift holder.

Standard: A: 7.05 - 7.25 mm {0.278 - 0.285 inl

B: 7.4 - 7.7 mm (0.29 - 0.30 inl

lf the widths of the grooves are not within thestandard, replace the reverse shift holder with a

new one.

lf the widths of the grooves are within the stan-

dard, replace the sth/reverse shift piece with anew one.

PIECE PIN

REVERSE SHIFT HOLDER

13-20

3. Measure the clearance between the reverse idler

gear and reverse shift holder.

Standard: 0.5 - 1.1 mm {0.02 - 0.0i1 in}

Service Limit: 1.8 mm (0.07 in)

REVERSEIDLERGEAR

lf the clearance is more than the service limit. mea-

sure the width ot the reverse shift holder.

Standard: 13.0 - 13.3 mm (0.512-0521inl

It the width is not within the standard, replace

the reverse shift holder with a new one.

lf the width is within the standard, reolace the

reverse idler gear with a new one.

www.emanualpro.com

Page 461 of 1395

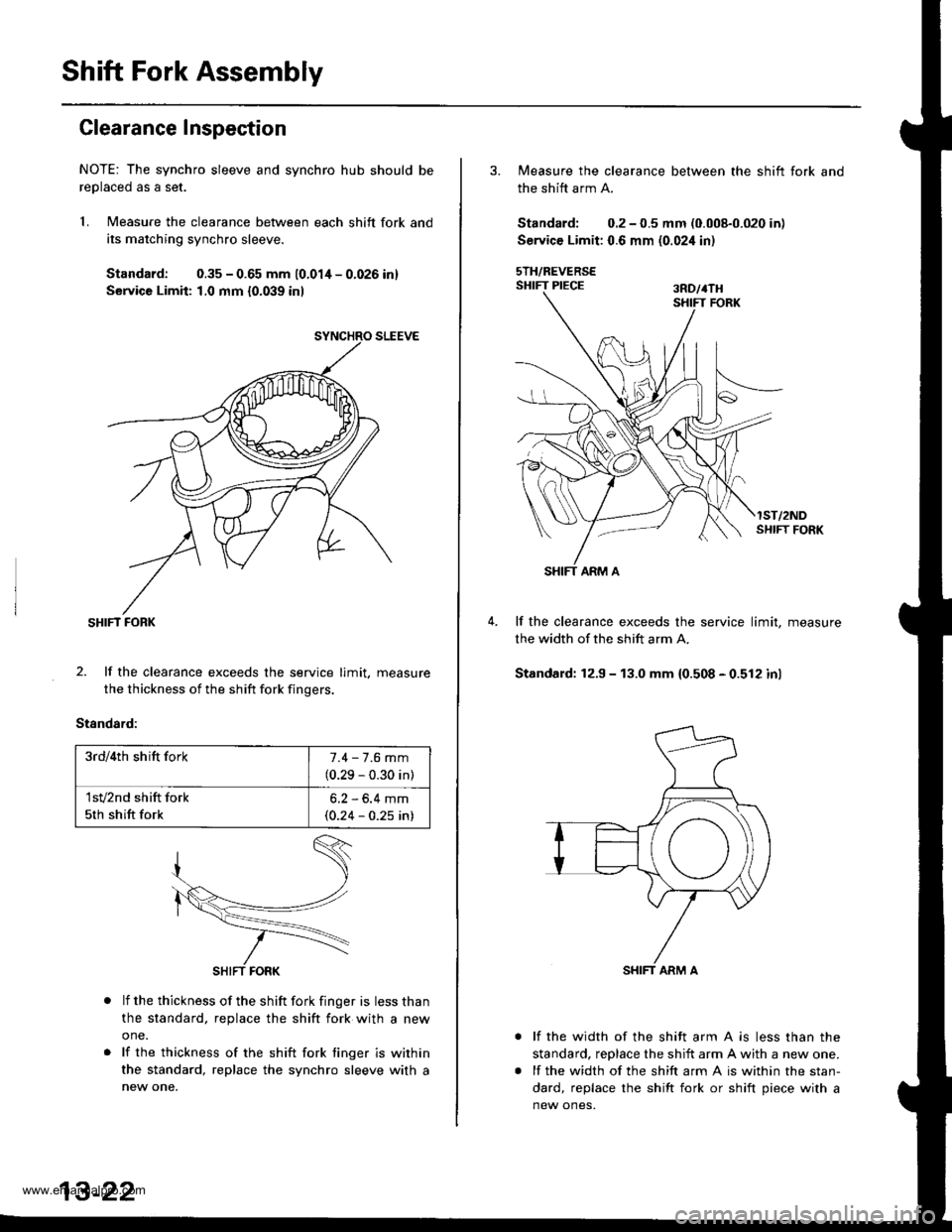

Shift Fork Assembly

Clearance Inspection

NOTE: The synchro sleeve and synchro hub should be

reolaced as a set.

1. Measure the clearance between each shift fork and

its matching synchro sleeve.

Standard: 0.35 - 0.65 mm 10.01/t - 0.026 inl

Service Limit: 1,0 mm {0.039 inl

SHIFT FORK

2. lf the clearance exceeds the service limit. measure

the thickness of the shift fork fingers.

Standard:

lf the thickness of the shift fork finger is less than

the standard, replace the shift fork with a new

one.

lf the thickness of the shift fork tinger is within

the standard, replace the synchro sleeve with a

new one.

3rd/4th shift fork7.4 - 7.6 mm

(0.29 - 0.30 in)

1sv2nd shift fork

5th shift fork

6.2 - 6.4 mm(0.24 - 0.25 in)

3. Measure the clearance between the shift fork and

the shift arm A.

Standard; 0.2 - 0.5 mm (0.008-0.020 in)

Service Limit: 0.6 mm (0.02i1 in)

sTH/REVERSESHIFT PIECE ran,rru

lST/2NDSI{IFT FORK

lf the clearance exceeds the service limit, measure

the width of the shift arm A.

Standard: 12.9 - 13.0 mm 10.508 - 0.512 inl

lf the width of the shift arm A is less than the

standard, reDlace the shift arm A with a new one.

lf the width of the shift arm A is within the stan-

dard, replace the shift fork or shift piece with a

new ones.

www.emanualpro.com

Page 463 of 1395

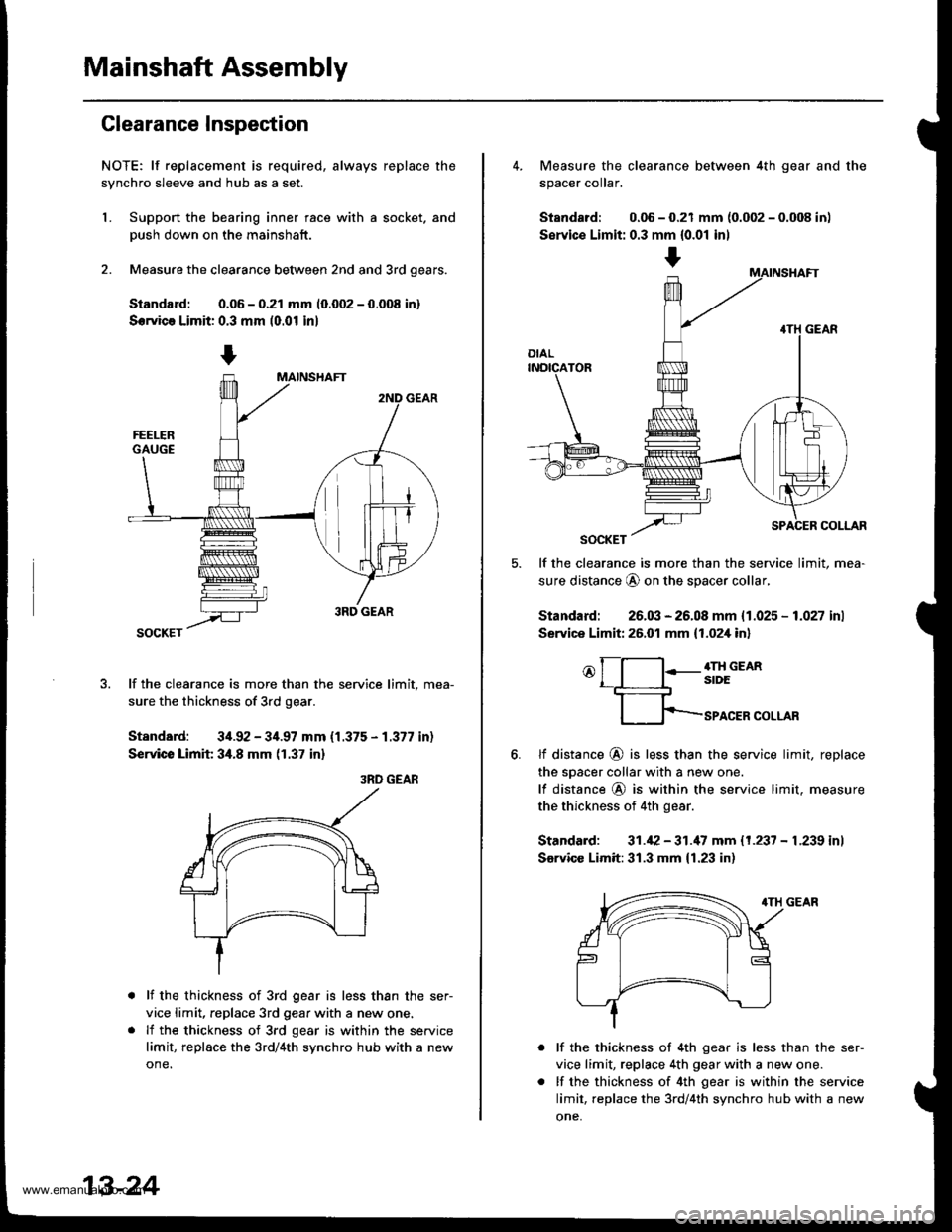

Mainshaft Assembly

Clearance Inspection

NOTE; lf replacement is required, always replace the

synchro sleeve and hub as a set.

L Support the bearing inner race with a socket. and

Dush down on the mainshaft.

2. Measure the clearance between 2nd and 3rd oears.

Siandard: 0.06 - 0.21 mm 10.002 - 0.008 in)

Servica Limit: 0.3 mm (0.01 in)

lf the clearance is more than the service limit, mea-

sure the thickness of 3rd gear.

Standard: 34.92 - 34.97 mm {1.375 - 1.377 in)

Service Limit 34.8 mm (1.37 in)

3RD GEAR

lf the thickness of 3rd gear is less than the ser-

vice limit, replace 3rd gear with a new one.

lf the thickness of 3rd gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one.

13-24

+

4. Measure the clearance between 4th gear and the

spacer coIar,

Standard: 0.06 - 0.21 mm {0.002 - 0.008 in)

Servic€ Limit: 0.3 mm {0.01 inl

lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar,

Standard: 26.03 - 26.08 mm {1.025 - 1.027 inl

Service Limit: 26.01 mm {1.02,[ in]

o[-l:-g;;em

fp-rro.ERcoLLAR

6.tf distance @ is less than the service limit, replace

the sDacer collar with a new one.

lf distance @ is within the service limit. measure

the thickness of 4th gear.

Standard: 31.42 - 31.'17 mm 11.237 - L239 inl

Sarvicc Limit:31.3 mm {1.23 in)

lf the thickness of 4th gear is less than the ser-

vice limit, replace 4th gear with a new one.

lf the thickness of 4th gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one,

www.emanualpro.com

Page 464 of 1395

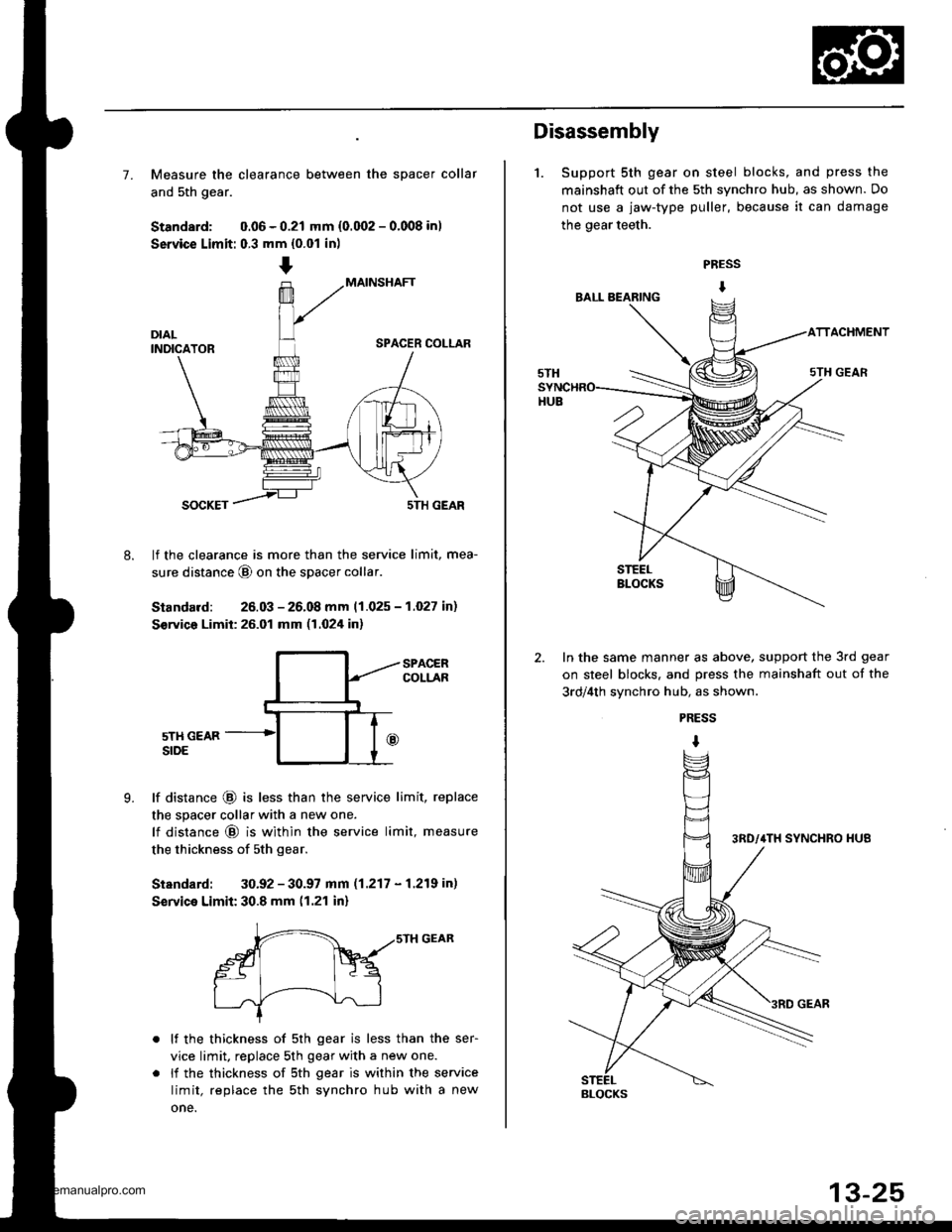

7. Measure the clearance between the spacer collar

and 5th gear.

Standard: 0.06 - 0.21 mm {0.002 - 0.008 in)

Service Limit: 0.3 mm {0.01 in)

MAINSHAFT

SPACER COLLAR

8.

SOCKET5TH GEAR

lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar

Standard: 26.03 - 26.08 mm 11.025 - 1.027 in)

S€rvico Limit: 26.01 mm (1.024 in)

9.

SPACERCOLLAR

5TH GEARSIDE

lf distance @ is less than the service limit, replace

the spacer collar with a new one.

lf distance @ is within the service limit, measure

the thickness of sth gear.

Standard: 30.92 - 30.97 mm (1.217 - 1.219 in)

Service Limit: 30.8 mm (1.21 in)

r-- ,,srH GEAR

gt Fq

I .J'-----!--\--J-l

lf the thickness of 5th gear is less than the ser-

vice limit, replace 5th gear with a new one.

li the thickness of sth gear is within the service

limit, replace the sth synchro hub with a new

one.

Disassembly

1. Support 5th gear on steel blocks, and press the

mainshaft out of the 5th synchro hub, as shown. Do

not use a jaw-type puller, because it can damage

the gear teeth.

PRESS

I

ACHMENT

In the same manner as above, support the 3rd gear

on steel blocks. and press the mainshaft out of the

3rd/4th svnchro hub, as shown.

PRESS

I

BLOCKS

www.emanualpro.com

Page 468 of 1395

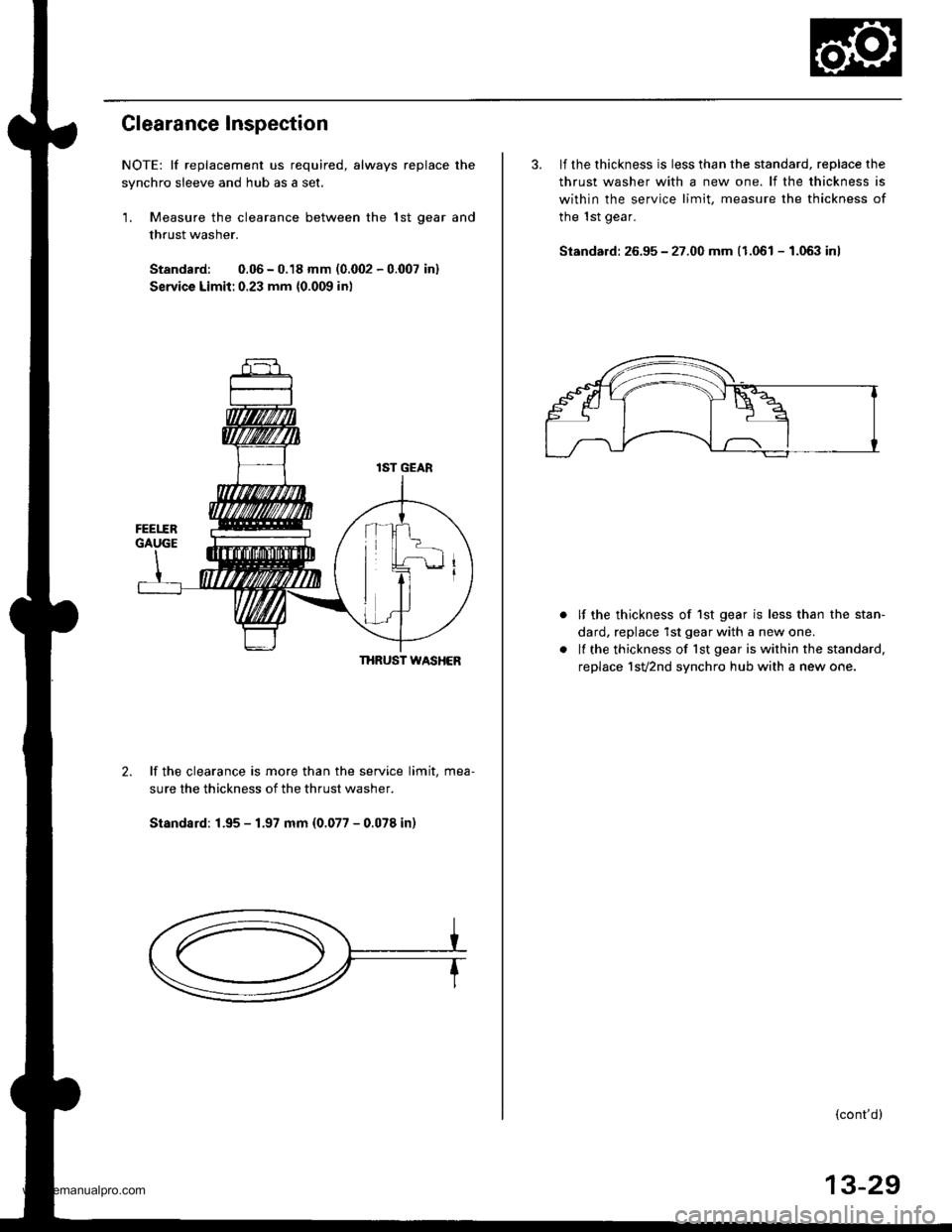

Clearance Inspection

NOTE: lf replacement us required, always replace the

synchro sleeve and hub as a set.

1. Measure the clearance between the lst oear and

thrust washer.

Standard: 0.06 - 0.18 mm (0.@2 - 0.007 in)

Servica Limit:0.23 mm {0.009 in)

THRUST WASHER

2.lf the clearance is more than the service limit, mea-

sure the thickness of the thrust washer.

Standsrd: 1.95 - 1.97 mm (0.077 - 0.078 in)

3. lf the thickness is less than the standard, reDlace the

thrust washer with a new one. lf the thickness is

within the service limit, measure the thickness of

the 1st gear.

Standard: 26.95 - 27.00 mm (1.061 - 1.063 inl

lf the thickness of 1st gear is less than the stan-

dard, replace 1st gear with a new one.

lf the thickness of lst gear is within the standard.

replace 1sv2nd synchro hub with a new one.

{cont'd}

13-29

www.emanualpro.com

Page 469 of 1395

Countershaft Assembly

Clearance Inspection (cont'dl

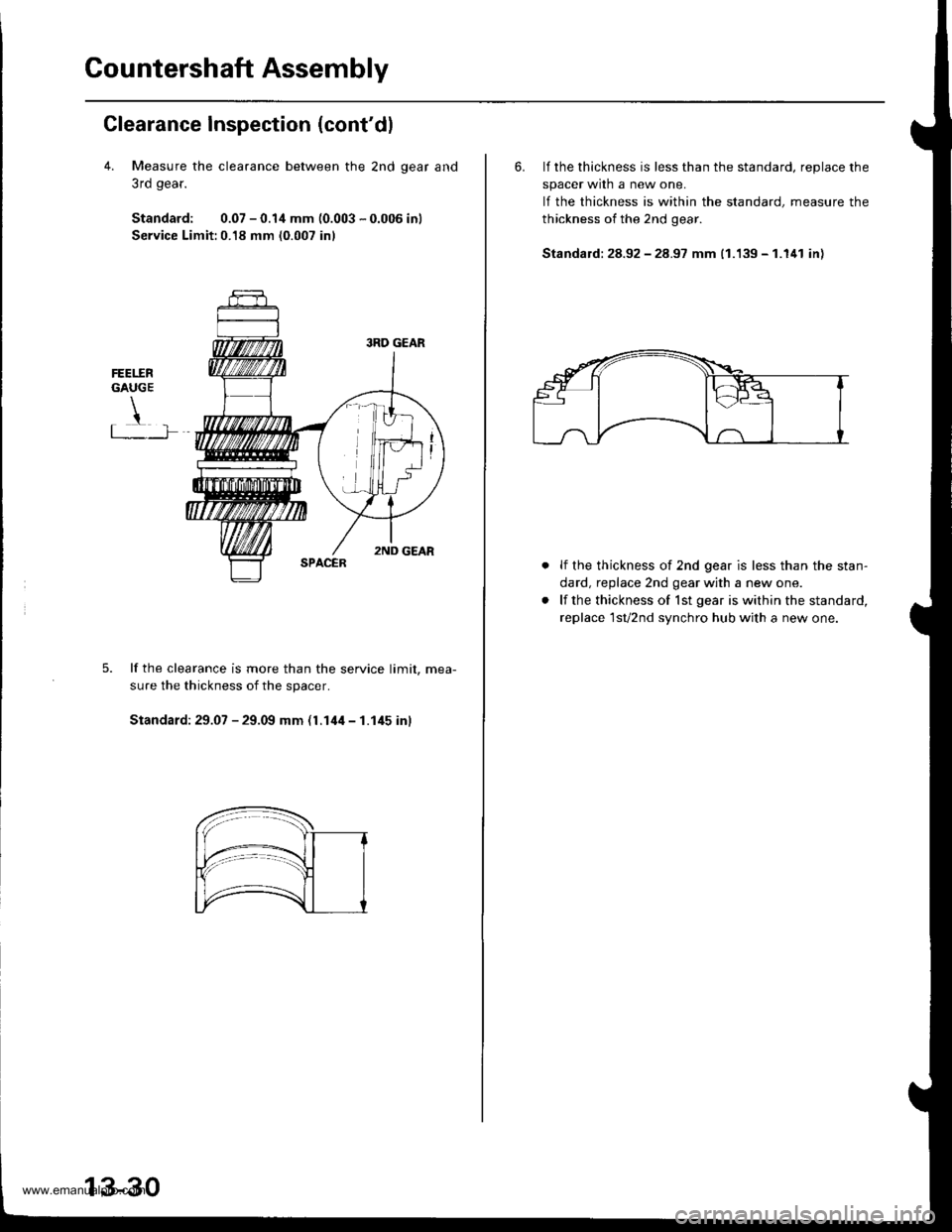

4. Measure the clearance between the 2nd qear and

3rd gear.

Standard: 0.07 - 0.1,1 mm (0.003 - 0.006 inl

Service Limit:0.18 mm (0.007 inl

FEET.ERGAUGE

!t .�-]�

lf the clearance is more than the service limit. mea-

sure the thickness of the spacer.

Standard: 29.07 - 29.09 mm (l.14il - 1.145 inl

13-30

6. lf the thickness is less than the standard, reDlace the

spacer wrln a new one.

lf the thickness is within the standard, measure the

thickness of the 2nd gear.

Standald: 28.92 - 28.97 mm (1.139 - 1.141 in)

lf the thickness of 2nd gear is less than the stan-

dard, replace 2nd gear with a new one.

lf the thickness of lst gear is within the standard,

replace 1sv2nd synchro hub with a new one.

www.emanualpro.com

Page 476 of 1395

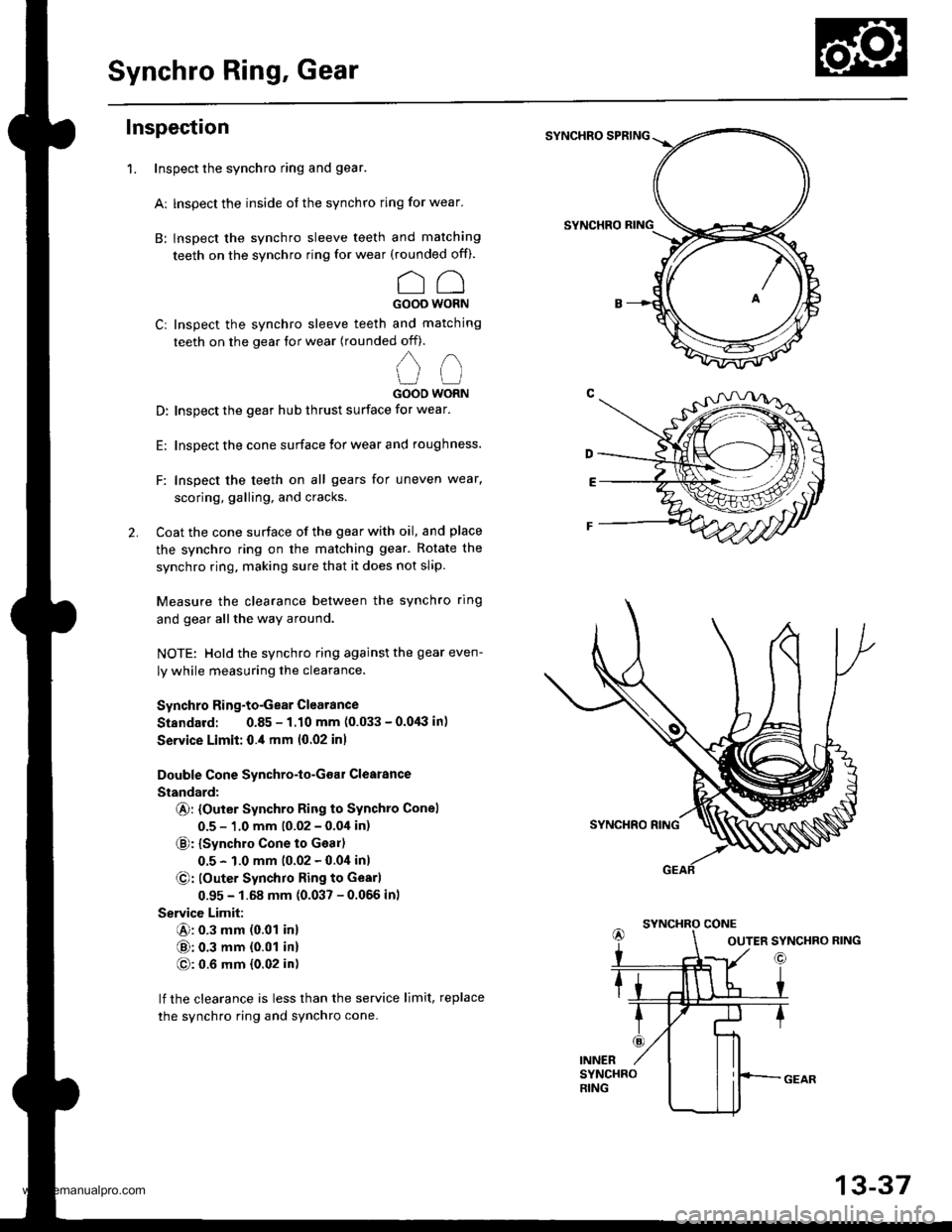

Synchro Ring, Gear

Inspection

Inspect the synchro ring and gear.

Ar lnspect the inside of the synchro ring for wear.

B: lnspect the synchro sleeve teeth and matching

teeth on the synchro ring for wear (rounded of0.

CCGOOO WORN

Cr Inspect the synchro sleeve teeth and matching

teeth on the gear tor wear (rounded off).

,,

u (-l

GOOO WORN

D: Inspect the gear hub thrust surface for wear.

E: Inspect the cone surface lor wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling, and cracks.

2. Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear. Rotate the

synchro ring, making sure that it does not slip.

Measure the clearance between the synchro ring

and gear allthe way around.

NOTE: Hold the synchro ring against the gear even-

ly while measuring the clearance.

Synchro Ring-to-Gear Clearance

Standard: 0.85 - 1.10 mm (0.033 - 0.0,lil in)

Service Limit: 0.,1 mm 10.02 inl

Double Cone Synchro-lo-Goar Clearance

Standard:

@: {Outer Synchro Ring to Synchto Conel

0.5 - 1.0 mm (0.02 - 0.04 in)

€): {synchro cone to Geal)

0.5 - 1.0 mm (0.02 - 0.0i1inl

@: louter Synchro Ring to Gearl

0.95 - 1.68 mm (0.037 - 0.056 inl

Service Limit:

@: 0.3 mm (0.01 inl

@: 0.3 mm {0.01 in}

@: 0.6 mm {0.02 in)

lf the clearance is less than the service limit, replace

the synchro ring and synchro cone.

SYNCHRO SPRING

SYNCHRO

1.

OUTER SYNCHRO RING

13-37

www.emanualpro.com

Page 479 of 1395

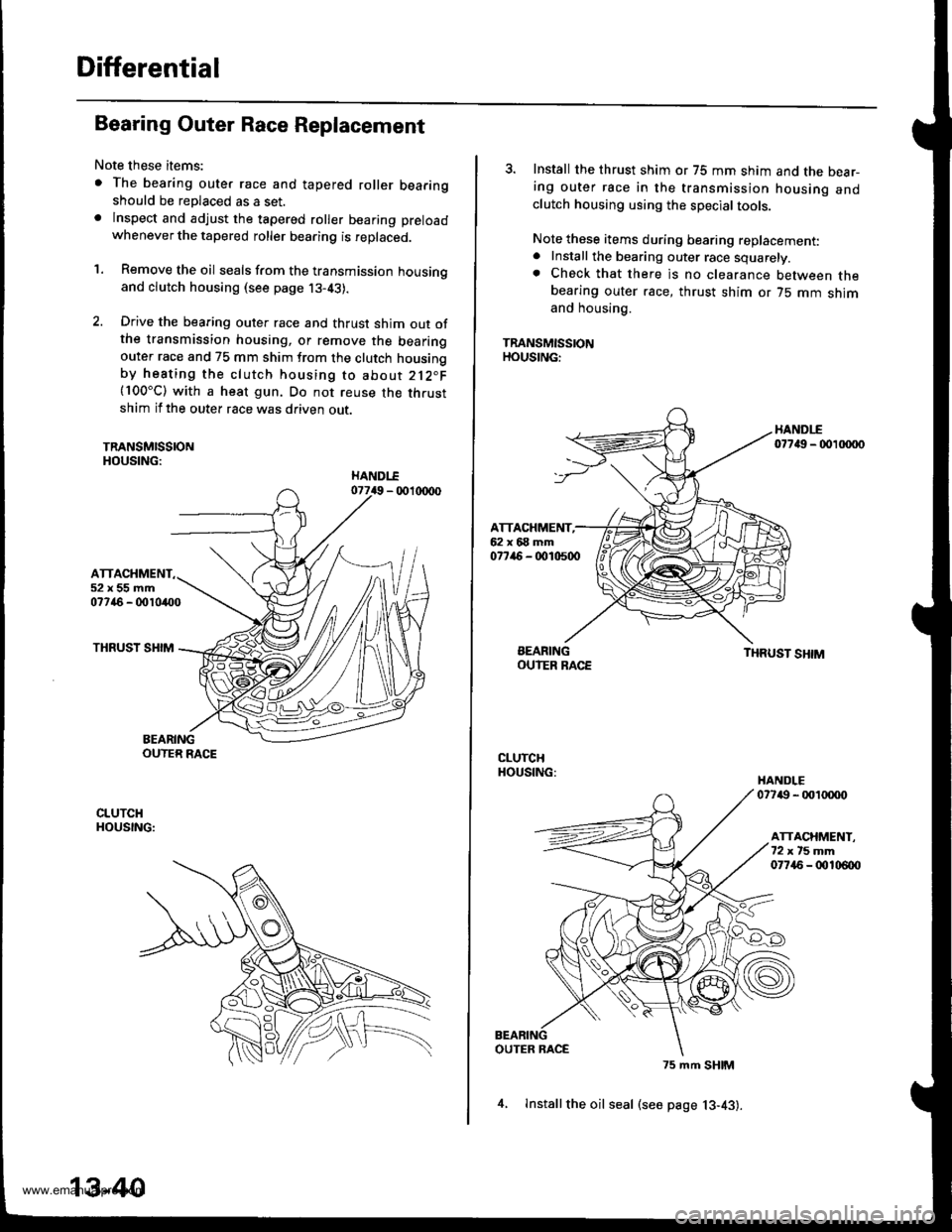

Differential

Bearing Outer Race Replacement

Note these items:

. The bearing outer race and tapered roller bearingshould be replaced as a set.. lnspect and adjust the tapered roller bearing preload

whenever the tapered roller bearing is replaced.

'1. Remove the oil seals from the transmission housingand clutch housing (see page j3-43).

2. Drive the bearing outer race and thrust shim out ofthe transmission housing, or remove the bearingouter race and 75 mm shim from the clutch housingby heating the clutch housing to about 212"F(100"C) with a heat gun. Do not reuse the thrustshim if the outer race was driven out.

TRANSMISSIONHOUSING:

ATTACHMENT52x55mm07746 - 0010400

THRUST SHIM

BEARINGOUTER RACE

CLUTCHHOUSING:

13-40

4, lnstallthe oil seal (see page 13-43).

3. Install the thrust shim or 75 mm shim and the bear-ing outer race in the transmission housing andclutch housing using the special tools.

Note these items during bearing replacement:. Install the bearing outer race squarely.. Check that there is no clearance between thebearing outer race, thrust shim or 75 mm shimand housing.

TRANSMISSIONHOUSING:

HANDI-E07749 - 00 xxto

ATTACHMENT,62x68mm077ir6 - 0010500

BEARINGOUIER RACETHRUST SHIM

CLUTCHHOUSING:HANDLE07749 - 001tXX)o

ATTACHMENT.72xt5mm07745 - 00106{x)

OUTER RACE

75 mm SHIM

www.emanualpro.com

Page 503 of 1395

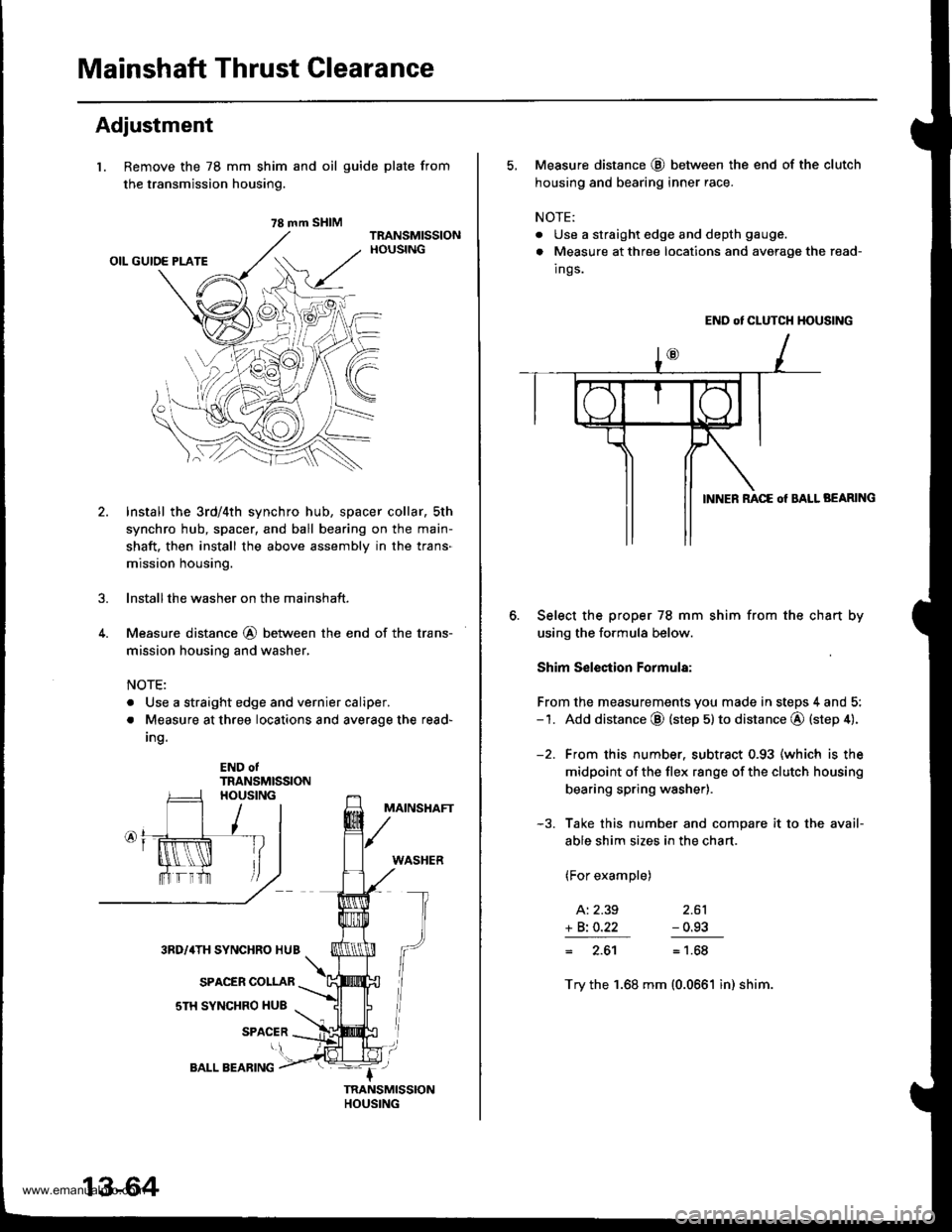

Mainshaft Thrust Clearance

Adjustment

l. Remove the 78 mm shim

the transmission housing.

4.

and oil guide plate from

Install the 3rd/4th synchro hub, spacer collar, sth

synchro hub, spacer, and ball bearing on the main-

shaft. then install the above assembly in the trans-

mission housing.

lnstallthe washer on the mainshaft.

Measure distance @ between the end of the trans-

mission housing and washer,

NOTE:

. Use a straight edge and vernier caliper.

. Measure at three locations and average the read-

Ing.

END otTRANSMISSION

MAINSHAFT

WASHER

3RD/4TH SYNCHRO HUB

SPACER COLLAR

sTH SYNCHRO HUB

SPACER

78 mm SHIM

13-64

BALL BEARING

5, Measure distance @ between the end of the clutch

housing and bearing inner race.

NOTE:

. Use a straight edge and depth gauge.

. Measure at three locations and avorage the read-

Ings.

END ot CLUTCH HOUSING

BEARING

Select the proper 78 mm shim from the chan by

using the formula below.

Shim S€lection Formula:

From the measurements you made in steps 4 and 5:-1. Add distance @ (step 5) to distance @ (step 4).

-2. From this number. subtract 0.93 (which is the

midpoint of the flex range of the clutch housing

bearing spring washer).

-3. Take this number and compare it to the avail-

able shim sizes in the chart.

(For example)

A: 2.39 2.61

+ Bi O.22 - 0.93

= 2.61= 1.68

Try the 1.68 mm (0.0661 in) shim.

www.emanualpro.com

Page 504 of 1395

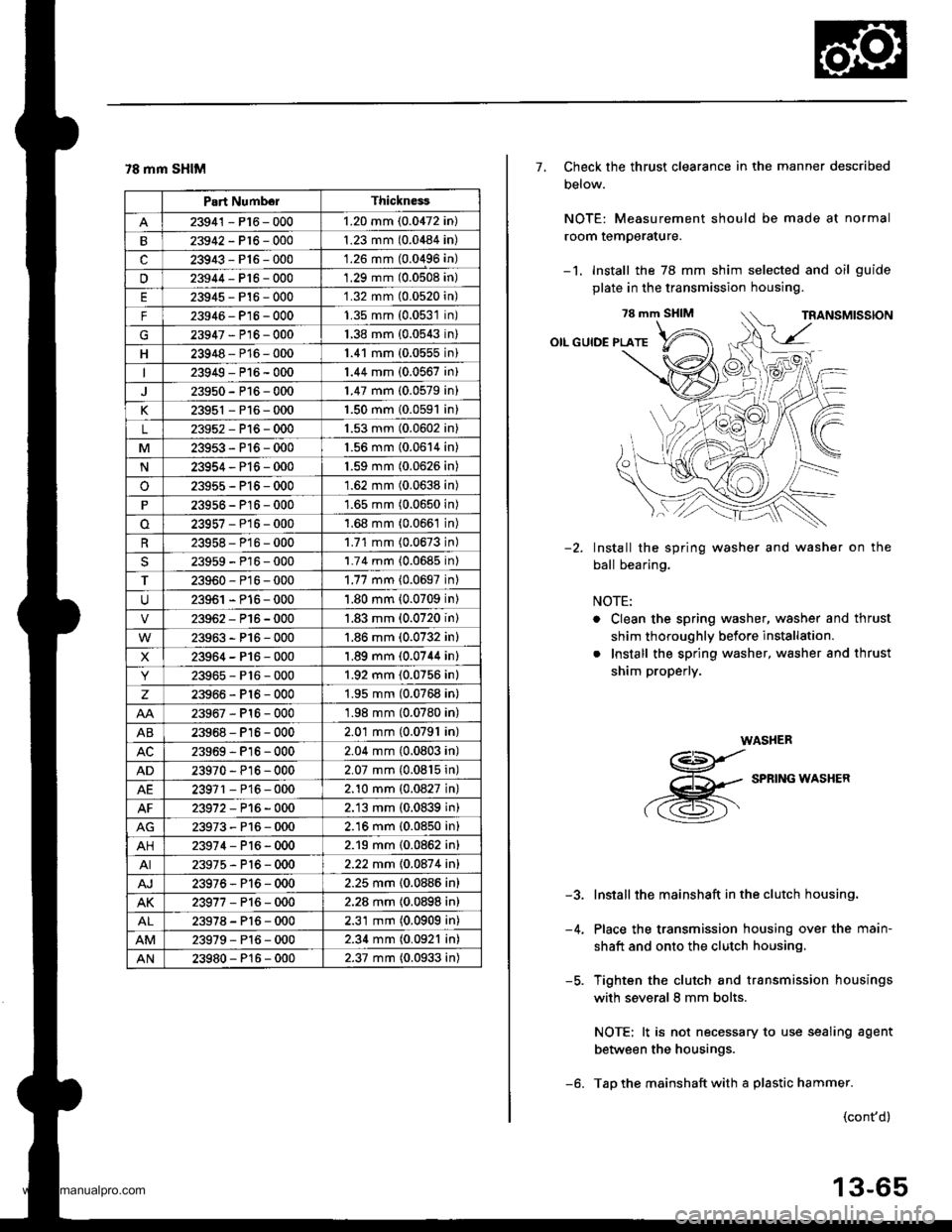

78 mm SHIM

Part NumborThickness

23941 - P16 - 0001.20 mm (0.0472 in)

23942-P16-0001.23 mm (0.0484 in)

c23943-P16-000'1.26 mm (0.0496 in)

u23944-Pt6-0001.29 mm (0.0508 in)

23945-P16-0001.32 mm (0.0520n)

F23946- P16 - 0001.35 mm (0.0531n)

G23947-P16-0001.38 mm {0.0543n)

H23948-P16-0001.41 mm (0.0555n)

23949-P16-0001.44 mm (0.0567 in)

23950-P16-0001.47 mm (0.0579 in)

K23951 - P16 - 0001.50 mm {0.0591 in}

L23952-Pl6-0001.53 mm (0.0602 in)

M23953-P16-0001.56 mm (0.0614 in)

N23954-P16-0001.59 mm (0.0626 in)

o23955-P15-0001.62 mm (0.0638 in)

23956 - P16 - 0001.65 mm (0.0650 in)

23957-P16-0001.68 mm (0.066't in)

23958- P16 - 0001.71 mm (0.0673 in)

23959-P16-0001.74 mm {0.0685 in)

T23960-P16-0001.77 mm {0.0697 inl

23961 - P16 - 0001.80 mm (0.0709 in)

23962-P16-0001.83 mm (0.0720 in)

23963-P16-000'1.86 mm (0.0732 in)

X23964-P16-0001.89 mm (0.0744 in)

23965-P16-0001.92 mm (0.0756 in)

z23966-Pl6-0001.95 mm (0.0768 in)

23967-Pl6-0001.98 mm (0.0780 in)

AB23968-P16-0002.01 mm (0.0791 in)

23969-Pl6-0002.04 mm (0.0803 in)

AD23970 - Pl6-0002.07 mm {0.0815 in)

AE23971 - P16 - 0002.10 mm {0.0827 in}

23972-P16-0002.13 mm (0.0839 in)

23973-P16-0002.16 mm (0.0850 in)

AH23974-P16-0002.19 mm (0.0862 in)

AI23975-P16-0002.22 mm 10.087 4 inl

AJ23976-Pl6-0002.25 mm {0.0886 in}

AK23977-P16-0002.28 mm {0.0898 in)

23978-Pl6-0002.31 mm (0.0909 in)

23979-Pl6-0002.34 mm (0.0921 in)

AN23980-P16-0002.37 mm (0.0933 in)

7, Check the thrust clearance in the manner described

Delow.

NOTE: Measurement should be made at normal

room temperature.

-1. Install the 78 mm shim selected and oil guide

plate in the transmission housing.

78 mm SHIM

OIL GUIDE PLATE

Install the spring washer and washer on the

ball bearing.

NOTE:

. Clean the spring washer, washer and thrust

shim thoroughly before installation.

. Install the spring washer, washer and thrust

shim properly.

WASHER

g

,-g

SPRTNG*ASHER

Install the mainshaft in the clutch housing.

Place the transmission housing over the main-

shaft and onto the clutch housing.

Tighten the clutch and transmission housings

with several 8 mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings.

Tap the mainshaft with a plastic hammer.

-2.

-5.

(cont'd)

13-65

www.emanualpro.com